REGIONAL REPORT: NORTH AMERICA

16 C.C.U.S.A.

Dr. Elizabeth Moore, a research scientist at MIT’s Concrete Sustainability Hub, sat down for an interview with Rick Bohan, the Portland Cement Association’s Sr. Vice President of Cement, to discuss her work and the ongoing drive for decarbonisation in the US cement industry.

COVER STORY

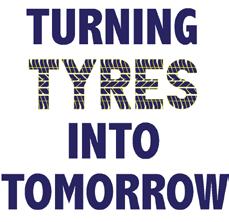

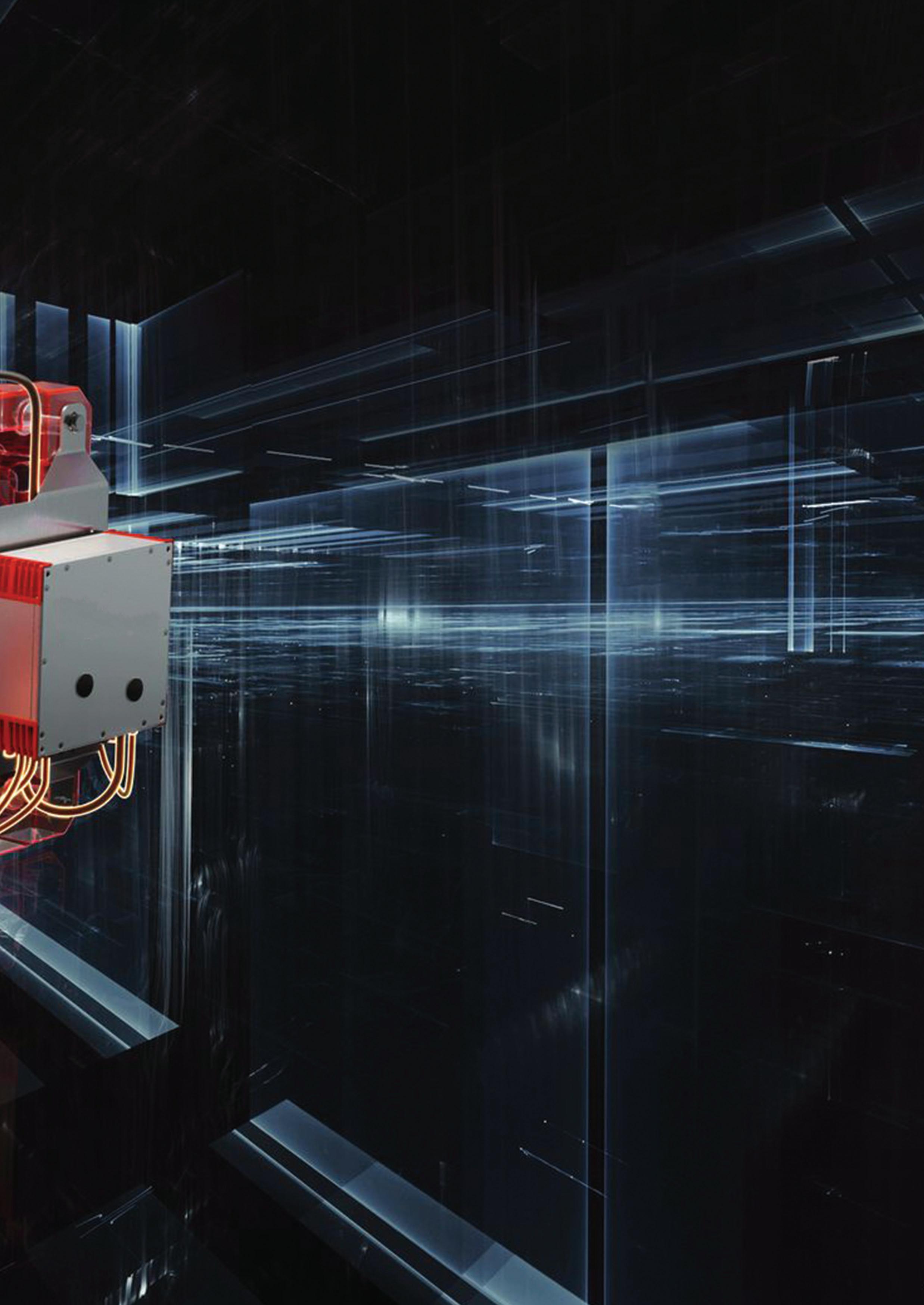

22 Industry 4.0 – Are We There Yet?

Anders Noe Dam, FLSmidth Cement, explores why the cement sector lags in embracing Industry 4.0 technologies and highlights key opportunities to accelerate the digital transformation of cement plants.

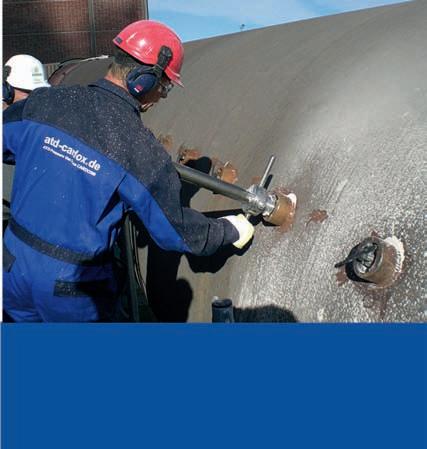

AIR CANNONS & SILO CLEAN-OUT

30 The Costly Air Cannon Conundrum

Jeff Shelton, Dracyon, outlines a three-step strategy to tackle leaking air cannons and eliminate the ‘million-dollar problem’ of air leaks.

36 Can You Handle Alternatives?

Alan Highton, Martin Engineering, examines challenges and raises solutions for handling alternative feedstocks in cement plants.

44 Successful Silo Solutions

Kearsten Huffman, Mole•Master Services Corporation, highlights the importance of proactive cement silo cleanout and inspection to prevent costly downtime, improve storage capacity, and ensure operational safety.

RAW MATERIAL PROCESSING

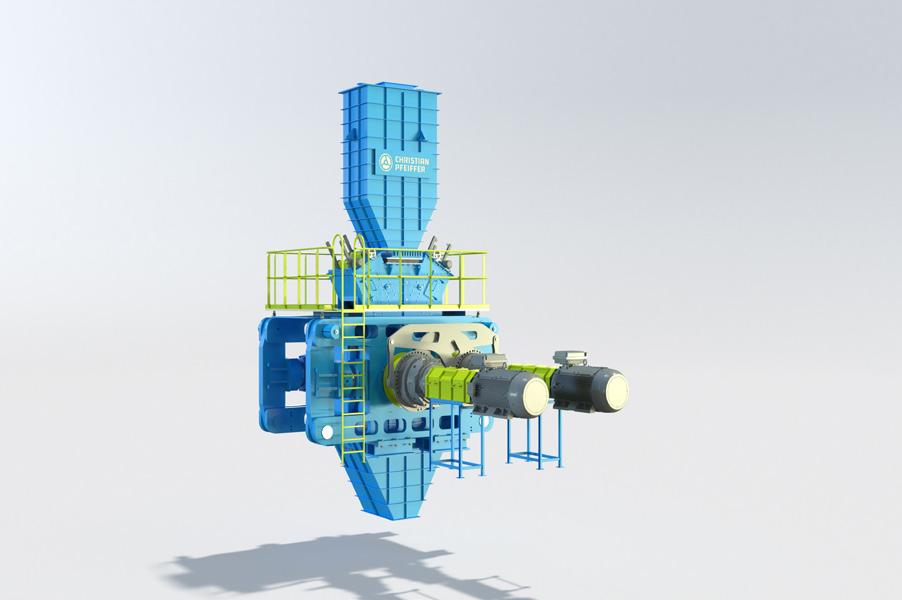

49 Crushing The Limits

Manuel Mühlbacher, Christian Pfeiffer, highlights innovations in roller press technology, focusing on enhanced reliability, simplified maintenance, and greater efficiency for raw material processing.

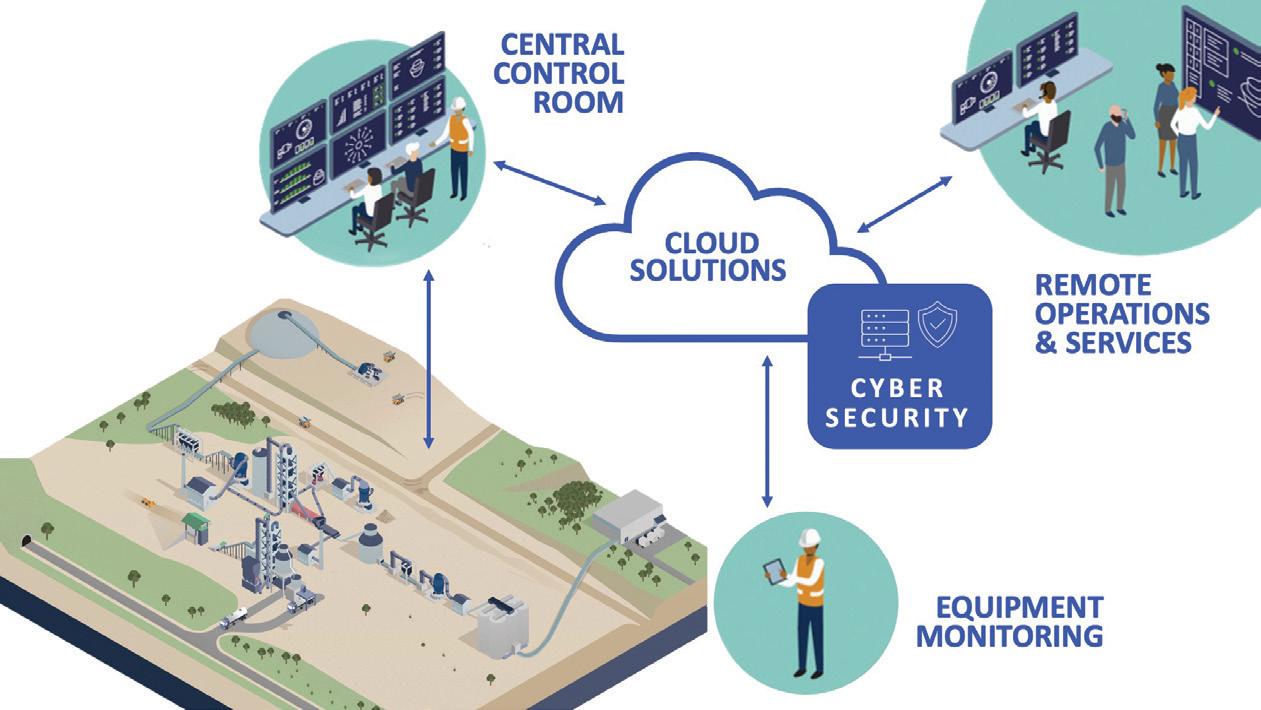

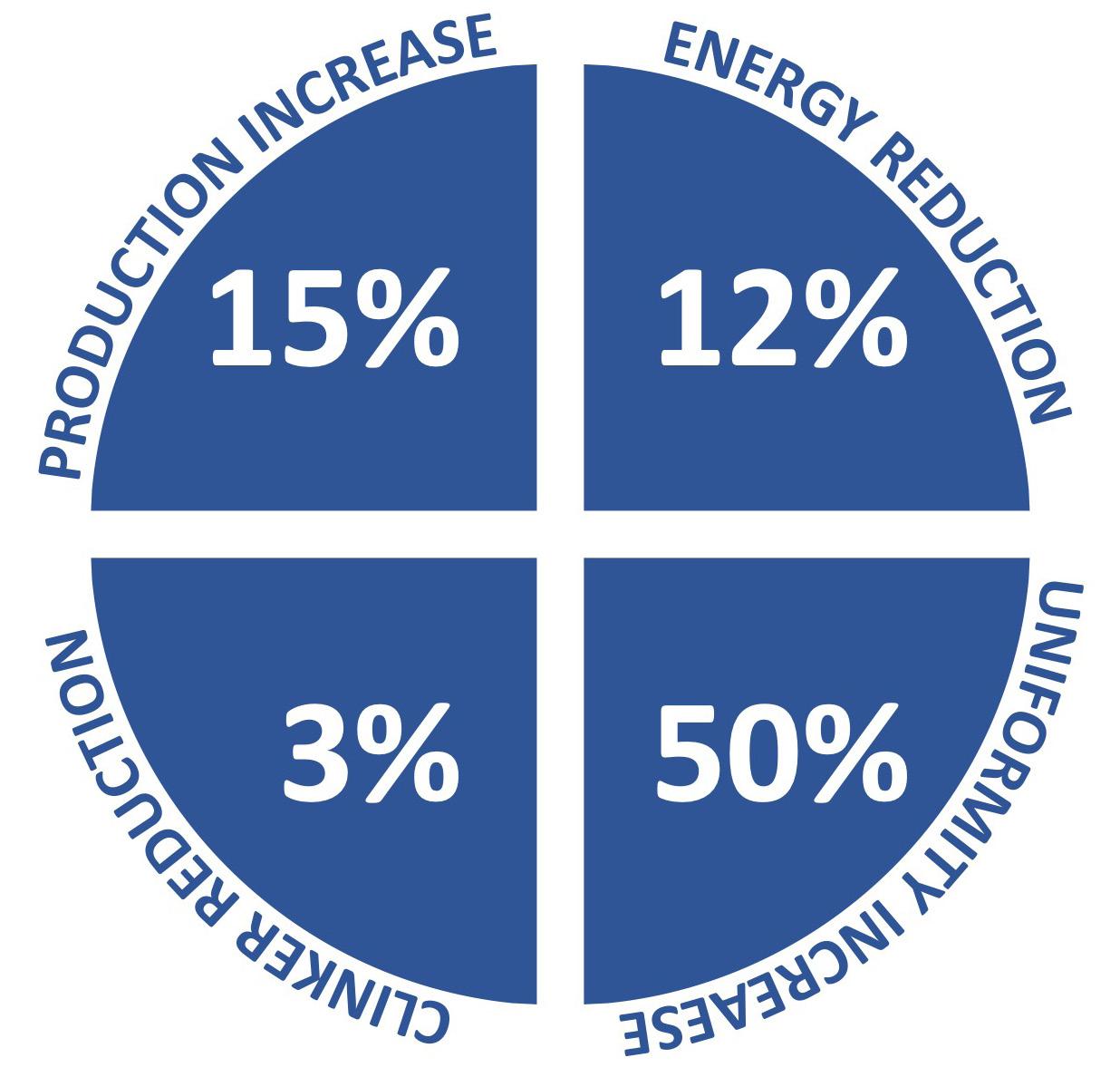

FLSmidth Cement is a technology and service supplier with a passion to help our customers produce cement efficiently. With over 140+ years of pioneering new innovations including over 50 years of developing and delivering advanced process control systems, we have been at the forefront of helping our industry benefit from digital technologies. Industry 4.0 promises a step change in efficiency, reduced waste, improved quality and cost savings. However, we are seeing many producers struggle to implement these technologies at scale. Our Cover Story, ‘Industry 4.0 – are we there yet?’ (pg 22), explores why the cement industry seems to be struggling to implement the latest digital technologies at speed and what can be done about it.

ADDITIVES & GRINDING AIDS

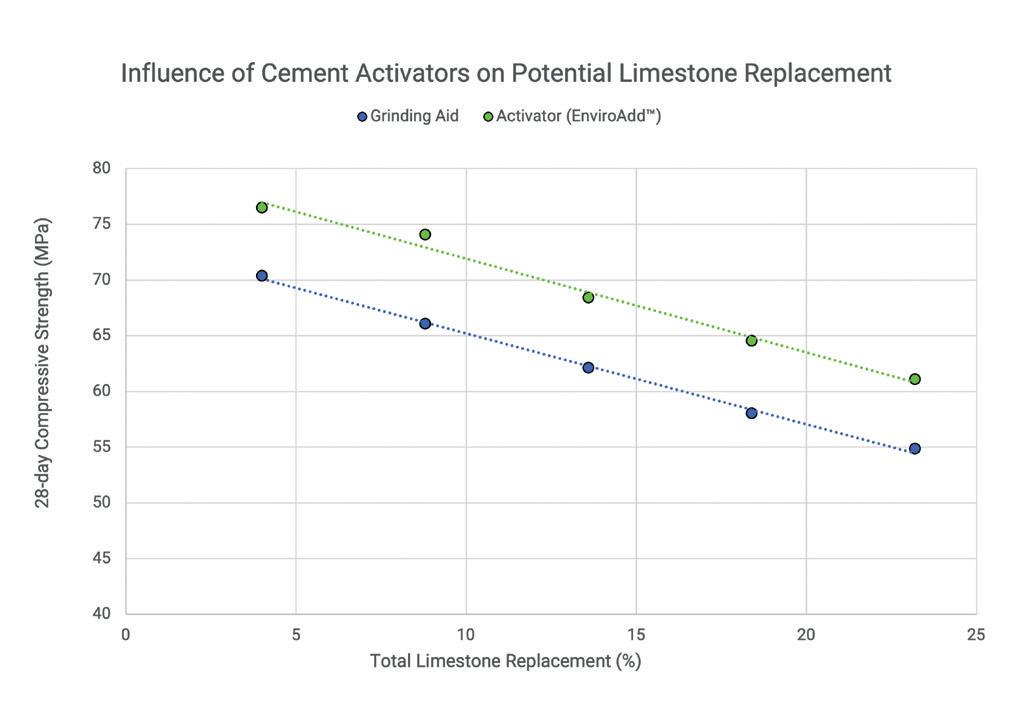

52 Stronger Blends, Greener Ends

Mike Stanzel & Oliver Sohn, Chryso North America, present a multilayered approach to maximising blended cement performance for use in concrete.

61 Great Gains With Grinding Aids

Gopala Rao Dhoopadahalli and Sheo Pujan Pandey, UNISOL CHEMTECH LIMITED, examine the role of grinding aids in enhancing the productivity, efficiency, and sustainability of cement production.

PYROPROCESS OPTIMISATION

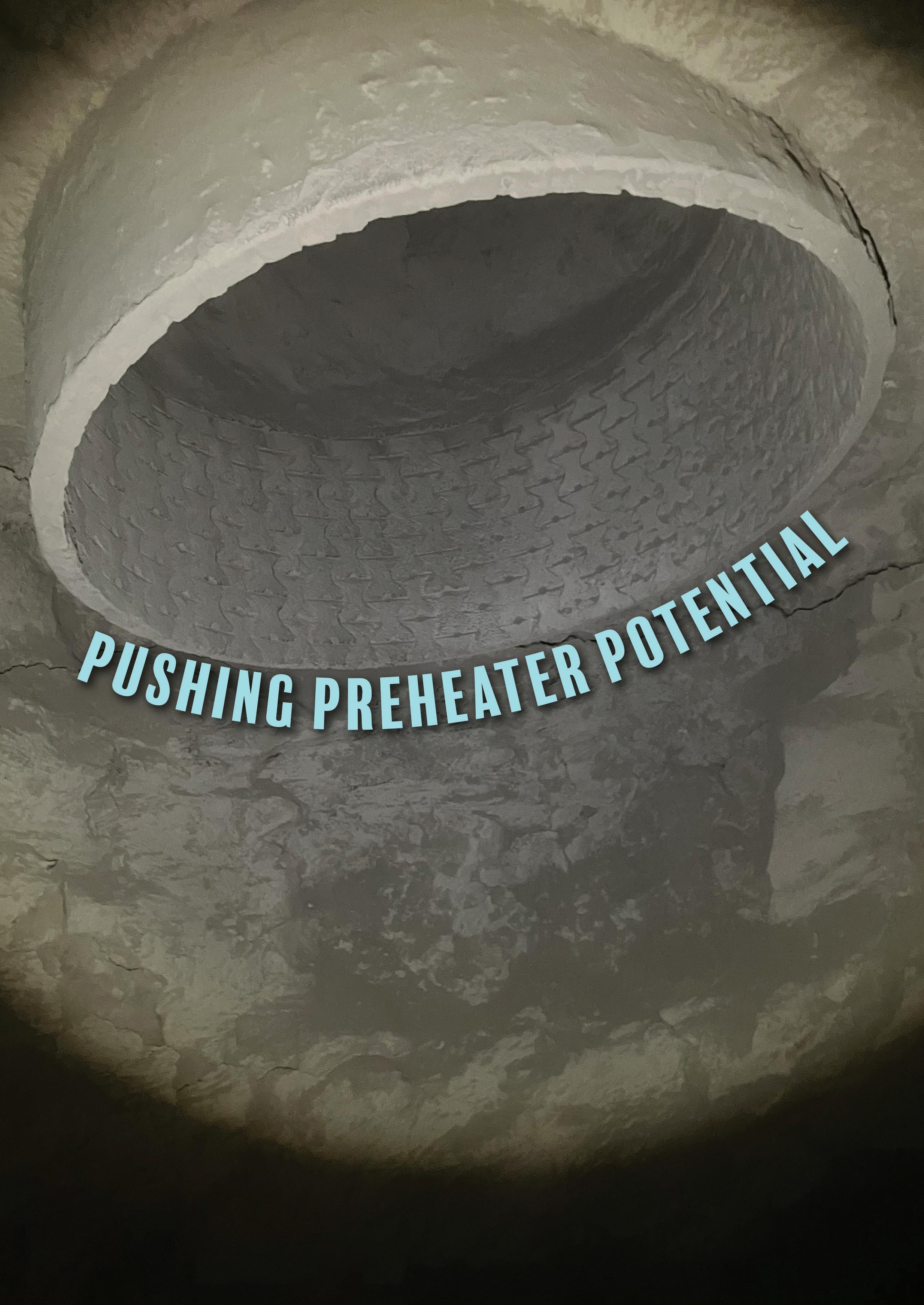

71 Pushing Preheater Potential

Lars Andersen, HASLE Refractories, explores the critical role of dip tubes in preheater cyclones and highlights how the latest generation of vortex finders is delivering extended lifetimes and improved process stability.

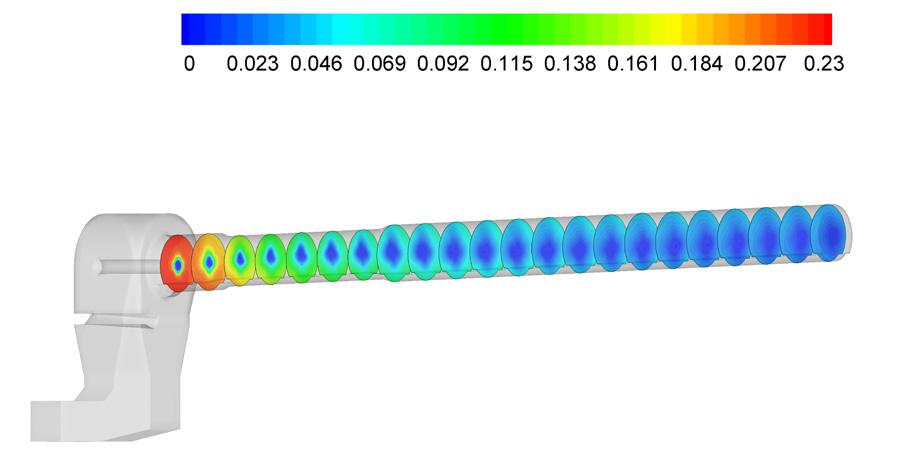

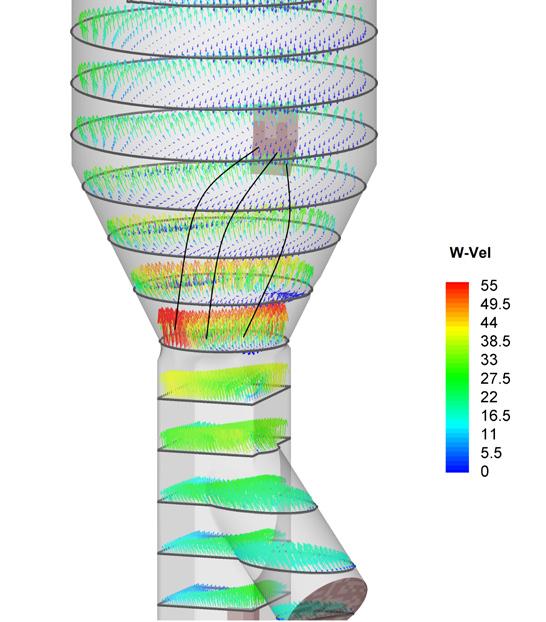

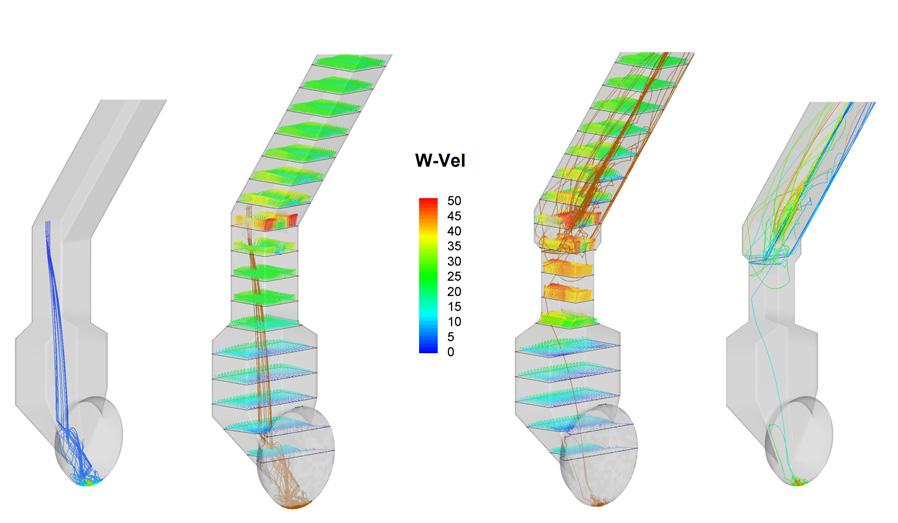

79 Marvels of MI-CFD Mechanics

M. Akritopoulos and T. Abbas, Cinar, explore the advantages of mineral interactive computational fluid dynamics (MI-CFD) in enhancing combustion efficiency, optimising alternative fuel use, and addressing challenges in the cement industry.

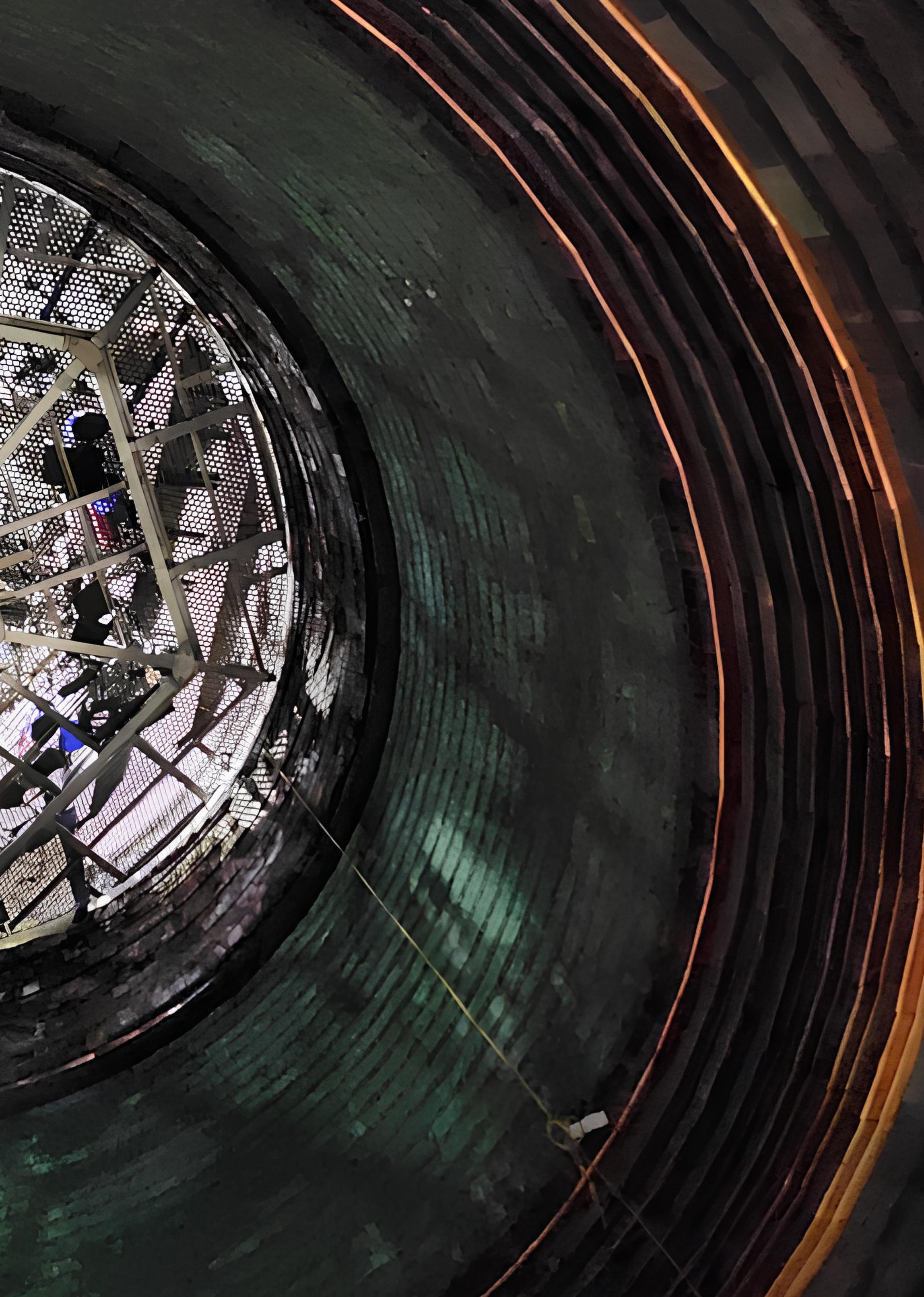

86 A Once In A Decade Chance

Katie Grube, a writer for the refractory, cement, packing, and lime industry, explains how a custom-engineered suspended platform revolutionised furnace refractory reinstallation, improving safety and efficiency during a shutdown project.

AIR POLLUTION CONTROL

92 24 Hour Baghouse Boost

Steve Klein, IAC, outlines how targeted interventions can optimise baghouse performance in just 24 labour hours.

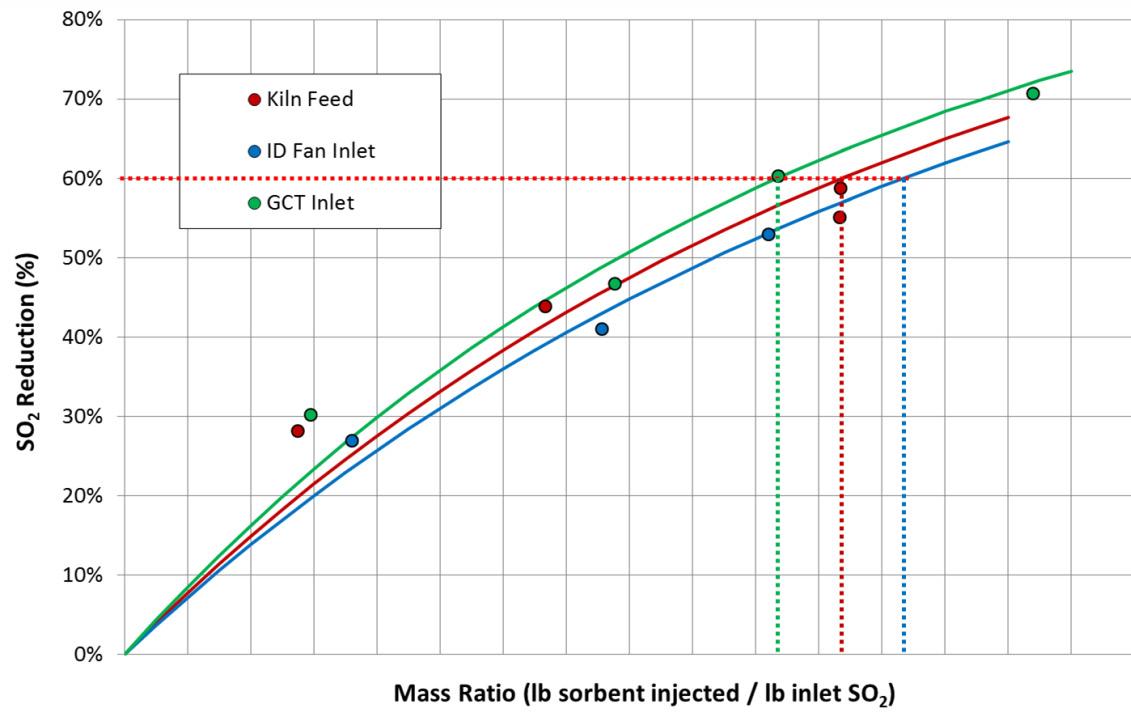

101 Optimising HCL and SO2 Abatement

Ian Saratovsky, Gerald Hunt, and Travis Reynolds, Lhoist North America, explore key strategies for optimising HCl and SO2 abatement in cement production.

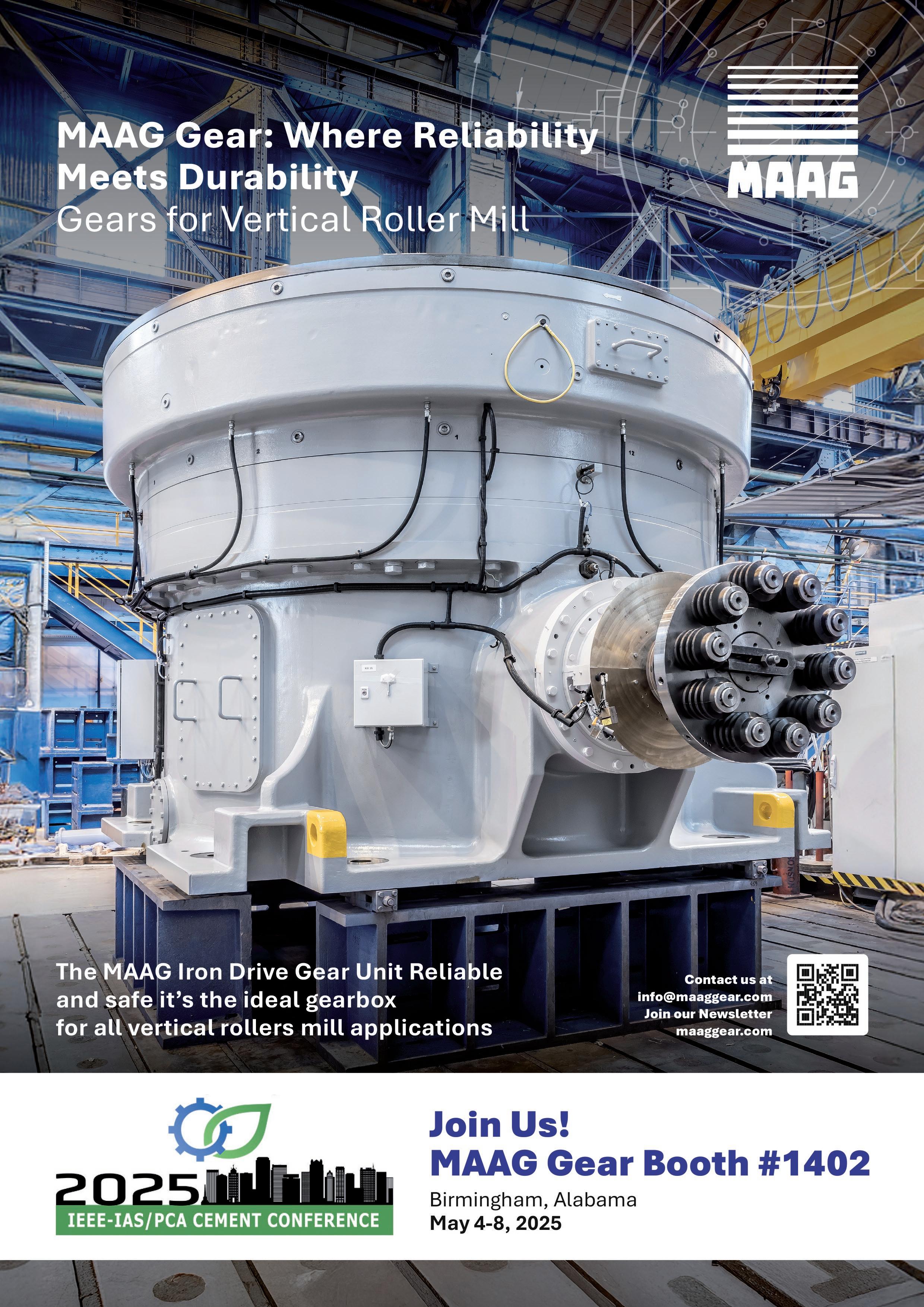

GEARS, DRIVES & MOTORS

111 Gear Up For Success

Mohamed Rezk, MAAG Gear Middle East and Sub-Sahara Africa, highlights a gearbox replacement project in Iraq that increased production and reduced energy consumption.

Powering Production With Predictive Maintenance

Andy Turner, SEW-EURODRIVE UK, discusses the benefits of using predictive maintenance software to reduce downtime in the cement industry.

DECARBONISATION

120 Turning Tyres Into Tomorrow Molins demonstrates how an end-of-life tyre recycling project is advancing decarbonisation efforts in the cement industry.

DIGITALISATION

124 Digitalising Cement Manufacturing Ighnatios Maatouk, ES Processing, explains how AI and machine learning are driving the digital transformation of cement manufacturing processes.

129 The Future Is Digital Ashutosh Dave, Schneider Electric, explores how digitalisation is key to tackling the challenges facing the cement industry, from improving competitiveness to addressing sustainability goals.

PLANT DESIGN

132 Tailored Foundations thyssenkrupp Polysius reveal why prioritising proven equipment and adaptive workflows is key to rapid plant ramp-up and sustained profitability.

An industry-leading performance spectrum coupled with exceptionally low energy consumption and other technological advantages ensure that Pfeiffer mills and machines keep your CO2 footprint smaller than that of others. Ask us about it!

Sustainability going forward – Getting it done!

ALFIE LLOYD-PERKS, EDITORIAL ASSISTANT

Erod.hardy@palladianpublications.com

Sales Manager: Ian Lewis ian.lewis@palladianpublications.com

Sales Executive: Sophie Birss sophie.birss@palladianpublications.com

Head of Events: Louise Cameron louise.cameron@palladianpublications.com

Event Coordinator: Chloe Lelliott chloe.lelliott@palladianpublications.com

Digital Events Coordinator: Merili Jurivete merili.jurivete@palladianpublications.com

Digital Content Coordinator: Kristian Ilasko kristian.ilasko@palladianpublications.com

Junior Video Assistant: Amélie Meury-Cashman amelie.meury-cashman@palladianpublications.com

Digital Administrator: Nicole Harman-Smith nicole.harman-smith@palladianpublications.com

Administration Manager: Laura White laura.white@palladianpublications.com

Reprints reprints@worldcement.com

xactly one year ago, this column showcased the US cement industry’s unprecedented leap toward decarbonisation, propelled by US$1.2 billion in federal funding under the Bipartisan Infrastructure Law and Inflation Reduction Act. For an industry long seen as a climate laggard, it was a moment of reinvention – proof that cutting emissions could align with economic ambition. Today, that progress is undeniably caught in the crossfire of shifting trade dynamics. The Trump Administration’s proposed 25% tariffs on cement imports from Canada and Mexico – suppliers of nearly a third of US cement demand – have thrust the sector into a paradox: can domestic manufacturing ambitions coexist with the global supply chains underpinning America’s infrastructure and clean energy boom?

Mike Ireland, PCA President and CEO, framed the dilemma starkly: “the industry believes 25% tariffs on cement imported from Canada and Mexico could adversely affect energy and national security while delaying infrastructure projects and raising their costs.”His warning cuts to the heart of the industry’s dual mandate – accelerating decarbonisation while navigating protectionist headwinds. Yet even as these tensions persist, the cement industry is responding with solutions that bridge competing priorities. Beyond tariffs and trade debates, the sector is forging partnerships that sidestep polarisation, as seen in three ground breaking projects.

CBP019982

Annual subscription (published monthly): £160 UK including postage/£175 (€245) overseas (postage airmail)/US$280 USA/Canada (postage airmail). Two year subscription (published monthly): £256 UK including postage/£280 (€392) overseas (postage airmail)/US$448 USA/Canada (postage airmail). Claims for non receipt of issues must be made within 4 months of publication of the issue or they will not be honoured without charge.

Applicable only to USA and Canada: WORLD CEMENT (ISSN No: 0263-6050, USPS No: 020-996) is published monthly by Palladian Publications, GBR and is distributed in the USA by Asendia USA, 17B S Middlesex Ave, Monroe NJ 08831.

Periodicals postage paid at Philadelphia, PA and additional mailing offices. POSTMASTER: send address changes to World Cement, 701C Ashland Ave, Folcroft PA 19032

Copyright © Palladian Publications Ltd 2025. All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any means, electronic, mechanical, photocopying, recording or otherwise, without the prior permission of the copyright owner. All views expressed in this journal are those of the respective contributors and are not necessarily the opinions of the publisher, neither do the publishers endorse any of the claims made in the articles or the advertisements. Uncaptioned images courtesy of Adobe Stock. Printed in the UK.

Palladian Publications Ltd

15 South Street, Farnham, Surrey GU9 7QU, UK

Tel +44 (0)1252 718999

Email: mail@worldcement.com Website: www.worldcement.com

Consider National Cement’s ‘Lebec Net Zero’ project in California. Funded by a US$500 million DOE grant and developed with Carbon TerraVault, this initiative blends carbon capture, biomass fuels, and limestone calcined clay cement (LC3) to eliminate 1 million tpy of CO2 by 2031. CEO Eric Holard sees it as a blueprint for reindustrialisation: “We are making a significant investment because we believe in creating a cleaner future and bringing innovation to domestic manufacturing.” The project’s reliance on locally sourced biomass and agricultural partnerships reduces the reliance on volatile supply chains by anchoring production within regional ecosystems.

Meanwhile, Terra CO2’s OPUS technology – a low-carbon cement substitute – offers a masterclass in pragmatic innovation. Backed by a US$52.6 million DOE grant and investors including JustClimate, its new Texas plant produces carbon-cutting cement without retrofitting existing infrastructure. In an era of trade volatility, such adaptable solutions buffer the industry against supply chain shocks.

Cemex’s Knoxville Test Center, supported by a US$101 million DOE initiative, exemplifies academia-industry collaboration. Partnering with the University of Illinois, the facility trials next-generation carbon capture technologies under real-world conditions. “Through collaboration and continuous innovation with the University of Illinois and industry peers, Cemex is committed to advancing decarbonisation solutions,” says Cemex US President Jaime Muguiro.

These projects share a common thread: they leverage collaboration to turn political and economic pressures into catalysts for innovation. This ethos reached its zenith at March’s EnviroTech 2025 conference in Athens, where 300+ industry leaders transformed ancient Greece into a modern agora of climate solutions. Against debates over tariffs and trade, the event served as a potent reminder – decarbonisation thrives not in isolation, but through alliances that transcend borders and boardrooms. Don’t forget to mark your calendars: EnviroTech returns in 2026 to explore the next frontier of industrial sustainability.

future,” said Ireneusz Kulka, Country Lead of EDP in Poland.

Cemex has signed an agreement with EDP Energia Poland to build solar installations at several Cemex plants in Poland, with a total capacity of over 14 MWp. This investment is part of Cemex’s global ‘Future in Action’ strategy to combat climate change.

Currently, Cemex has one solar farm at its ready-mix concrete plant in Pruszków. New solar installations will be added to cement plants in Chelm, Rudniki, and Gdynia, as well as concrete plants in Myslowice, Warsaw Annopol, Lublin, Szczecin, and Gdansk. These installations will start operating in the second quarter of 2025 for the concrete plants. For the cement plants, the schedule assumes PV generation will begin in the first quarter of 2026

The project will be carried out in collaboration with EDP Energia Polska, under a 15-year agreement where EDP will install and manage the solar installations, providing clean energy to Cemex facilities.

“Cemex sets ambitious decarbonisation goals, and investing in renewable energy is an important step towards reducing emissions. The concluded agreement is important in this context because it will guarantee us access to green energy in the long term. Additionally, the mentioned contract will enable the diversification of energy sources powering our plants,” said Michal Weglorz, Regional Energy Negotiator at Cemex Poland.

“We are glad that Cemex Poland, as a leader in its industry, has chosen photovoltaic solutions from EDP to implement its ambitious decarbonisation goals. This cooperation is part of our mission to support the energy transition and provide clean energy for every type of industry. We are convinced that Cemex’s investments in renewable energy will contribute to building a sustainable future and will become an inspiration for other companies from the energy-intensive sector. At EDP, we make every effort to be a reliable partner for our clients and, together with them, implement projects that have a real impact on reducing emissions and protecting the climate. In Poland, we have installed nearly 270 MWp of power in various facilities, thus supporting businesses in building a sustainable

Carbon TerraVault and National Cement sign MOU for California’s first net zero cement facility

California Resources Corporation and its carbon management business, Carbon TerraVault (CTV), announced the signing of a Memorandum of Understanding (MOU) with National Cement Company of California Inc. (National Cement) to provide carbon management services for the ‘Lebec Net Zero’ – a first-of-its-kind initiative to produce carbon-neutral cement at National Cement’s facility in California.

CTV plans to develop transportation and sequestration solutions for up to 1 million metric tpy of CO2 emissions captured from National Cement’s plant in Lebec, Kern County, California.

Captured CO2 is expected to be safely transported and securely stored in CTV’s underground storage reservoirs, contributing to California’s industrial decarbonisation efforts.

The project is expected to be California’s first net-zero cement facility, integrating carbon capture technology, utilising locally sourced biomass fuel from agricultural byproducts, and producing limestone calcined clay cement (LC3).

This effort aligns with Kern County’s Carbon Management vision, promoting economic growth, job creation, and tax benefits for local communities.

The project was one of 33 selected by the US Department of Energy (DOE) for funding under the Industrial Demonstrations Programme as a public-private partnership, with the DOE committing up to US$500 million in matching funds to accelerate its development.

Pending customary approvals, operations are expected to start in 2031.

Francisco Leon, President and Chief Executive Officer of CRC, emphasised the significance of this partnership: “This MOU with National Cement underscores the increasing demand for innovative decarbonisation solutions within California’s industrial sector. Achieving carbon neutrality in the cement industry requires bold action, and this partnership is a critical step in developing the state’s first carbon capture, transport, and storage project for this essential sector. We have a proven

bauma 2025

07 - 13 April, 2025

Munich, Germany bauma.de/en/trade-fair

IEEE-IAS/PCA Cement Conference

04 – 08 May, 2025 Birmingham, AL., USA www.cementconference.org

CEMENTTECH 2025

15 – 17 May, 2025

Hefei, China www.cementtech.org

FICEM TECHNICAL CONGRESS

08 – 11 September, 2025

Peru www.ficem.org

POWTECH

23 – 25 September, 2025 Nürnberg, Germany www.powtechtechnopharm.com

AUCBM AICCE28

11 – 13 November, 2025 Dubai, UAE www.aucbm.net

carbon management expertise and strategically located CO2 storage assets, allowing us to deliver innovative, reliable, and economically viable energy transition solutions.”

Eric Holard, Chief Executive Officer of National Cement, commented: “This is an exciting and transformative project for the cement industry. We are making a significant investment because we believe in creating a cleaner future and bringing innovation to domestic manufacturing. CTV’s leadership in safe and responsible carbon management, combined with our strategic and operational alignment, provides a clear pathway for this project being successful.”

Including this MOU with National Cement, CTV’s total carbon capture and sequestration (CCS) projects under consideration now stand at nearly 9 million tpy of CO2 emissions, reinforcing its domestic leadership in industrial decarbonisation and carbon storage solutions.

Hoffmann Green strengthens its partnership with Trecobat

Hoffmann Green Cement Technologies have announced the extension of its partnership with Groupe Trecobat, France’s 3rd largest builder of single-family homes. From March 2025, Hoffmann Green 0% clinker cements will be widely deployed on more than 100 Trecobat homes in the west of France. Founded in 1972, the Trecobat Group is a leading player in the construction of single-family homes, with sales of €203 million in 2023 and a strong territorial presence covering all the Grand Ouest region. Since January 2024, the partnership with Hoffmann Green has enabled Trecobat to accelerate its transition to sustainable construction by using 0% clinker cements for its Trecobat Green and Trecobois homes, which combine comfort and environmental performance.

After a successful first phase of trials and tests in 2024, Trecobat was convinced by the quality of Hoffmann Green’s decarbonised cements.

From March 2025, Trecobat confirms its commitment by deploying these solutions on more than 100 Trecobat Green and Trecobois homes in the West of France. This milestone represents a key step in the industrialisation of low-carbon cements for residential construction.

This deployment is based on a technical synergy between Hoffmann Green’s H-UKR cement and prefabricated floor systems from Fimurex Planchers, a specialist in the conception of reinforced concrete elements for single-family homes. This innovation enables decarbonated floors to be integrated into Trecobat Green and Trecobois wood-frame houses.

Thanks to the combination of the three partners’ cutting-edge technologies, the requirements of the 2031 threshold of the RE2020 environmental regulation are already anticipated, demonstrating their determination to accelerate the ecological transition and reduce the carbon impact of the building sector. The ATEx obtained in November 2024 for this application validates the relevance of this approach and paves the way for its wider implementation.

• BELT CLEANERS

• IDLERS

• IMPACT BEDS & LOAD ZONES

SUPPORT SYSTEMS

• POINT CLOUD SCANNING

• PULLEY LAGGING

• SAFETY EQUIPMENT & GUARDING

• SKIRTBOARD & SKIRTING SYSTEMS

• CONVEYOR TRANSFER CHUTES (DESIGN & FABRICATION)

• VULCANIZING EQUIPMENT & MECHANICAL FASTERNERS

• WEAR LINERS

• CUSTOM URETHANE PRODUCTS

Hoffmann Green relies on a vast network of partners with ready-mix concrete plants to deliver its products to Trecobat construction sites in Western France. This optimised territorial network guarantees an efficient supply of Hoffmann Green’s decarbonised concrete to all single-family home building sites.

The intensification of this partnership with volume commitments enables Hoffmann Green to pursue its diversification strategy and accelerate its sales momentum on the French market. This strategic step testifies to the growing acceptance of decarbonised solutions by key players in the construction industry, consolidating Hoffmann Green’s position as an innovation leader in the sustainable construction sector.

Julien Blanchard and David Hoffmann, Co-founders of Hoffmann Green Cement Technologies, say: “We are delighted to be taking this new step with Groupe Trecobat to build more than 100 single-family homes from March 2025 in Western France. This new development will enable us to consolidate our presence in the single-family home market and reinforce our impact in eco-responsible construction.”

Breedon Group’s Hope Cement Works is located near to the village of Hope in Derbyshire, England. It is recognised as the UK’s largest cement plant and is integral to Breedon’s cement manufacturing capabilities. In order to sustain the processing of quarried limestone required for cement manufacturing, Breedon recently executed a major project to replace its 1940’s Fuller Traylor primary gyratory crusher with a new 1250 tph primary gyratory crusher, supplied by FLSmidth. Quarry Manufacturing and Supplies Ltd (QMS) were the lead partner in the installation, with the overall project being managed by the Projects Team at Hope, alongside a team of trusted contract partners.

Hope’s cement manufacturing process starts in its quarries, which at Hope comprises of two sources of limestone: high silica limestone and low silica limestone. The quarry’s upper beds have more of the high silica limestone due to their high chert content. Further down in the quarry is where the

lower silica limestone is located. There are currently 13 operational benches in total in the limestone quarry. In addition to the limestone material, shale is also used from an adjacent quarry on site, both the limestone and shale quarrying operations are integral to the cement manufacturing plant.

More than half the cement that is made at Hope Works is transported in bulk via rail to depots in the Southeast (Dagenham and Theale), West Midlands (Walsall) and North of England (Dewsbury), ensuring the final product is delivered as sustainably as possible. Additionally, Breedon has import terminals to supply its customers in Northern England (Blyth and Runcorn), and in Scotland (Leith).

In order to sustain operations, Breedon installed a new gyratory primary crusher in September 2024. The site had operated and maintained the previous Fuller Traylor crusher since its installation in 1952, with the body of the machine being completely original since its installation. Due to advancements in primary crusher technology, and a desire by the business to improve the maintainability of the crusher, plans for the replacement of the original crusher were put in place in 2022.

The project involved the installation of a single, new primary crusher and associated equipment which was installed on the limestone crushing line. The limestone crushing line further consists of a twin line secondary and tertiary crushing stage, comprising of state-of-the-art QMS B6 cone crushers. The task of pre-assembling the new FLSmidth crusher, demolishing and removing the old Traylor crusher, and finally installing the new FLSmidth crusher, was given to QMS who worked in close partnership with the Breedon team at Hope, their contract partners and equipment suppliers FLSmidth.

George Close, UK sales director at QMS, explains: “Working closely with FLSmidth, we had to first build up the new gyratory crusher. This was a time consuming and exacting process, as we were working to tight deadlines and the crusher had to be assembled on site. This site assembly was the first time all the crusher parts had been together, as the components were delivered by FLSmidth from all over the world. This took approximately five weeks. The second stage was to remove the old primary Traylor gyratory crusher; this utilised QMS’ expertise and experience gained on working

with gyratory crushers throughout the world. This took two weeks, working 24/7, and was finally completed in mid-August (2024).

“The third and final stage of the project was the actual installation of the new crusher, this again further necessitated working round the clock, night and day, taking over five weeks to complete. In addition, the new crusher has a QMS manufactured, bespoke stainless steel lubrication system which is now integral to the crusher’s operation. We further assisted through commissioning of the crusher, alongside the Breedon and FLSmidth teams, thereby ensuring that it was fully operational.”

Alcemy reaches new milestone and continues its global expansion

Alcemy GmbH reaches new milestone with global expansion and organisational changes.

Alcemy GmbH proudly announces its latest achievements in the pursuit of helping customers optimise cement and concrete quality through cutting-edge artificial intelligence software. Since its inception in 2018, Alcemy has been revolutionising the construction industry and has now reached an extraordinary milestone: its advanced AI-based software is utilised in 30 cement plants worldwide, optimising the production of over 30 million tpy of cement. This significant achievement not only underscores the effectiveness of the technology but also highlights the trust and confidence that customers – the true decarbonisation heroes – place in Alcemy’s solutions.

Alcemy’s global footprint has expanded remarkably, now present in 12 countries and working with 15 unique customers, including global cement production leaders. To further bolster its capabilities and prepare for the next phase of growth, Alcemy has

implemented strategic organisational adjustments that align with its vision for the future. Alcemy is pleased to announce that Oliver Kanders, who has been with Alcemy since 2023 and previously served as Head of Revenue, will now assume the role of General Manager for the Cement Product Line. Oliver’s extensive experience and deep understanding of the industry will be instrumental in steering the product line to new heights of success. Additionally, Alejandro Espejel, who has been with Alcemy since 2024 and formerly held the position of Business Development for the Americas, will now take on the role of Head of Global Sales. These organisational changes are designed to streamline operations and enhance Alcemy’s focus on delivering exceptional value to its customers.

Alcemy’s ‘Software as a Service’ is rapidly becoming the go-to solution for cement producers seeking tighter quality control through predictive and prescriptive analytics. These capabilities enable cement producers to improve the performance of their products, optimise costs, and reduce their environmental footprint.

Alcemy will be actively participating in all major industry conferences throughout 2025. Notably, Alcemy will be present at the IEE/PCA Conference in Birmingham this May, followed by FICEM’s Sustainability Congress in Ecuador later the same month. This presence underscores Alcemy’s commitment to staying at the forefront of industry developments and sustainability initiatives.

Aggregate Industries has rebranded to Holcim UK as part of a strategic shift to provide the construction industry with seamless access to the latest sustainable building solutions.

With over 200 sites and 4000 employees across the UK, Aggregate Industries’ 25 brands are uniting under Holcim UK to drive this growth. Building on trusted partnerships, the move is also set to provide customers with access to more seamless, enhanced services and sustainable solutions.

Holcim UK’s strategic focus centres around leading the mission to make sustainable construction a reality, focusing on decarbonisation, nature, circularity, and innovation. Its aim is

PSCL’s Raw Mix Control System combines them better than anything else out there.

Minimise variability in raw mix proportions. Reduce thermal stress on your preheater and kiln. Lower fuel consumption.

Achieve higher kiln alternative fuel substitution rates and stricter control over your emissions without jeopardising the quality of your clinker.

And as an ongoing subscription, it’s kind to your cashflow.

to achieve this through both its commitment to reducing its own impact on communities and the planet, in addition to driving positive change for the industry and customers through its expert teams and sustainable solutions.

The consolidation comes as the construction sector faces increasing pressure to deliver more homes and buildings in line with emissions reduction and environmental policy, amid predicted growth of up to 10% by 2026.

Alongside a target to accelerate green growth, Holcim UK is committed to expanding the uptake of sustainable building materials in the UK. Currently a third of its turnover comes from sustainable products and it is aiming to continue to increase this in the next five years.

Key to this will be circular product innovation through construction demolition materials (CDM), targeting an increase of CDM used in products from 2 million t to more than 5 million t by 2030.

Following 20 years as a UK-based subsidiary of Holcim Group, the new direction sees Aggregate Industries align more closely with its Swiss-based parent company, which operates across 70 countries and employs over 60 000 people worldwide. Holcim UK will leverage global insights, innovation, and expertise in sustainable solutions from Holcim Group to enhance Aggregate Industries’ existing rich UK heritage and its understanding of the local market.

This presence in the UK market has already seen the launch of product ranges such as ECOPact low carbon readymix concrete, ECOPlanet range of low carbon cement, and its ECOCycle range of products, which are made from at least 10% recycled materials.

This focus on circularity is underpinned by continued investment, including recent acquisitions of CDM specialist companies Land Recovery and Sivyer, in addition to innovations such as neustark – the technology which permanently locks carbon removed from the atmosphere into processed demolished concrete for new products.

To support customers further, Aggregate Industries will also continue its focus on knowledge sharing and best practice through its trusted partnerships. This includes initiatives such as the Holcim Sustainable Construction Academy, which offers free CPD-certified courses on low-carbon, circular and regenerative design concepts, developed with top global institutions and architecture firms.

Speaking on the direction, Lee Sleight, CEO of Holcim UK, said: “Our evolution from Aggregate Industries to Holcim UK is much more than a rebrand. It represents a commitment to leading the sector towards a more sustainable future through a commitment to innovation and collaboration.”

“By uniting under one coherent brand, we can focus on driving sustainable growth for our business and many customers and suppliers we have formed strong partnerships with over the years. With such growth, we can continue to invest in the people and solutions capable of making a positive difference to customers and communities. Key to this will be our ongoing prioritisation of people, purpose and performance to achieve our ambitious revenue and sustainability growth targets.

“Through taking on the global brand, we can leverage Holcim Group’s global presence and the innovative solutions it has brought to a variety of different markets. With our renewed strategic direction, we will not only be able to reduce our environmental impact and make positive change as a business, but be a trusted partner to our customers as they aim to do the same.”

To mark the establishment of its new brand, Holcim UK has launched two initiatives to drive awareness for sustainability in construction and its strategic direction for making it a reality.

The first is the creation of its ‘Sustaina-billboard’, an environmentally-friendly billboard containing pollinating flowers, plants and seeds to support local wildlife, and a surrounding frame made from low carbon concrete and recycled aggregate materials.

Demonstrating its commitment to nature and biodiversity, the creation is designed to feed wildlife and insects around its Greenwich site, as well as highlighting the brand’s nature strategy, which will see it creating dedicated spaces for nature across more than 200 sites by the end of the year.

Holcim UK has also identified the specific areas where the construction sector needs to focus its efforts to overcome pressing sustainability challenges in its new report Making Sustainable Construction a Reality. Exploring the areas of decarbonisation, circular economy and waste reduction, smart construction, people and communities, and nature and biodiversity, Holcim UK is aiming to provide the wider industry with a series of steps that should be taken to progress towards making sustainable construction a reality.

Dr. Elizabeth Moore, a research scientist at MIT’s Concrete Sustainability Hub, sat down for an interview with Rick Bohan, the Portland Cement Association’s Sr. Vice President of Cement, to discuss her work and the ongoing drive for decarbonisation in the US cement industry.

Dr. Elizabeth Moore, a research scientist at MIT’s Concrete Sustainability Hub, thinks there should be more huddles among scientists, industry professionals, and US policymakers, as too often, these groups ‘stay in their bubbles’, which creates gaps in valuable communications that would help accelerate them toward their common goal: decarbonising the American cement and concrete industry.

Last Autumn, Dr. Moore closed in on one of the gaps, boarding the train from Boston, MA to the nation’s capital, to connect face to face with policymakers, which made for enlightening conversation.

Rick Bohan, the Portland Cement Association’s Sr. Vice President of Cement, spoke with Dr. Moore about her work, her Capitol Hill visits, and why it was so worthwhile to head to Washington.

Rick Bohan: What is the goal of this research you’re working on for the cement and concrete industry?

Dr Moore: "Our goal was to understand the real-world deployment costs for carbon capture technologies. When we began comparing some of the results in the literature, we realised that many studies were simply not capturing all of the costs associated with integrating a carbon capture system on site at a cement plant. Our goal was to really understand what was missing from those cost estimates – where are the gaps – and how we can provide more detail

in the overall analysis. We hoped that better information would give policymakers estimates they could use to design future incentives. After reviewing some of the policies around carbon capture and sequestration (CCS) such as the 45Q tax credit, we found that they weren't enough for many industries to actually adopt carbon capture. And so, through more detailed modelling, our hope was to find and add those missing pieces so we could have a full picture of overall costs.”

Rick Bohan: So – I know you went to Capitol Hill a short time ago. Can you tell me a little about that?

Dr. Moore: “Yes. I did go to the Hill last October, with the director of the MIT Concrete Hub, Dr. Randolph Kirchain, and with Portland Cement Association’s Senior Vice President of Government Affairs, Sean O’Neill.

We met with key decision-makers and policy stakeholders working to develop impactful strategies for their communities. When we sat down with them, we explained our key research areas at the MIT Concrete Sustainability Hub, and how we think our research can inform policies and future decision making for these leaders in regions with cement plants.

For example, we talked about different technologies and strategies that could help reduce their greenhouse gas emissions at cement plants in their area. A big part of the discussion was about what it would take to make these solutions work – like the need for new infrastructure, which could mean building in people’s backyards or using more land for infrastructure such as pipelines or storage sites. But we also highlighted the benefits: cleaner air, new jobs, and ensuring the long-term sustainability and resilience of local industries.

We hoped these conversations would highlight a range of cost-effective solutions for decarbonisation, while also bringing benefits to communities, helping them to understand the portfolio of solutions available to cement plants in their regions, and how we can demonstrate with research which policy and technology tools will be most successful to help them.”

Rick Bohan: How has what you’ve seen on the policy side informed what you’re looking at for future research?

Dr. Moore: “It was my first time going to D.C., going to the Hill, and I think that’s been a big missing piece for researchers. A lot of researchers, including myself, are in our bubbles. Our modelling and lab work are largely informed by existing literature and gaps in that literature and don’t always consider real-time industry developments.

So, going to D.C. was a very eye-opening experience to meet with the policymakers who are making these decisions and making a difference for communities in the US, both in the cement industry and beyond.

To be able to sit down and chat one-on-one, to understand some of their pain points and hear about the realistic barriers they’re running up against helps us in our research. For example, understanding the barriers helps us to reevaluate our modelling approach and refine the inputs we use, ensuring our models more accurately reflect real-world conditions.

I think it’s an invaluable experience to meet the people who are using academic research to make their decisions. More researchers should have the opportunity to engage in this way.”

Rick Bohan: How do you approach it from the standpoint of cement industry research, and how do you expand beyond cement applications? Imagine going to the Hill a second time, aiming to broaden your presentation to all industries because some lawmakers don’t have cement plants in their districts or are interested in concrete.

Dr. Moore: “That’s what makes some of the decarbonisation technologies so fascinating – they extend their impact beyond a single industry, impacting a broader range of stakeholders. Carbon capture, for example, or alternative fuels… these are potential strategies that will impact many industries and many communities.

I think looking at carbon capture and how it might impact the power grid is one example. I’ve done a lot of work in other industries, including the mining industry, where we’ve been looking at what the power portfolio of the future will look like, and wondering which technologies will be a part of this? What will be the mix of renewable energy technologies? Which energy storage technologies will support the grid?

For example, we may have renewable energy technologies, but there will be times when the sun isn’t shining and the wind isn't blowing, requiring reliable backup power sources. Beyond its role in decarbonising the cement industry and other hard-to-abate sectors, carbon capture is also being explored as a transitional technology – helping to shift away from fossil fuels and toward a cleaner, more resilient energy portfolio for the future.

I believe discussions with policymakers about carbon capture more in general, across industries is really helpful, and can help to identify some of the challenges that may arise

within their communities from these technologies coming on board.”

Rick Bohan: Considering the power portfolio, what do you as a researcher want the policy people to know, and what do you think the policy people want you as a researcher to know?

Dr. Moore: “From a research perspective, there are different optimisation models that look at costs, emission reductions, some of the regional constraints for deploying these different types of technologies, etc.

For example, in regions like New York, where hydropower is abundant, that resource may be a natural choice. However, in other areas, we assess factors like solar and wind patterns to determine the best energy solutions based on local constraints. By considering the unique resource availability of each location, we can recommend the most suitable technologies for sustainable and efficient decarbonisation. However, these recommendations don’t always account for other constraints, such as community pushback, land use concerns, or policy and regulatory challenges. And I think a policymaker would like me to understand that building these optimisation models is great to show an ideal picture, but in reality, the permitting, the land procurement – there are a lot of elements that go into decision making that researchers are not always thinking about, yet these factors also need to be considered in modelling for the future.

I think what I’d like policymakers to understand is that there are a lot of pieces to this puzzle. And the optimisation results can give us a starting point and a place to start a conversation about which technologies may be best for them to consider for their individual region. We can then work together to iterate on different potential scenarios based on how they see the future rolling out.

I think there’s an opportunity to work together more frequently where historically, that hasn’t always happened on a consistent basis. We should look at ways we can use both our knowledge and our tools for good.“

Rick Bohan: Given this disconnect between policy and research, how can academia address that so you’re working in parallel?

Dr. Moore: “At the CSHub, the research team has been working to connect with policymakers at all levels – from local to international – to share research that can inform better decision-making. We share our research through user-friendly tools, research briefs, and op-eds. Additionally, at MIT, the MIT Policy Lab helps researchers translate their findings into actionable policy insights, while the

new MIT Climate Policy Centre supports efforts to bridge the gap between climate science and real-world policy solutions.

I think more frequent communications with policymakers and researchers can create a dynamic exchange of ideas, allowing policymakers to quickly incorporate the latest research into decisions, while researchers gain valuable insights into practical, real-world challenges.”

Rick Bohan: Any closing thoughts about the work you’re doing now and how you’d like to see things progress in the future?

Dr. Moore: “When I first started with the Hub, I would listen to presentations about cement and concrete, and think, ‘this can’t be that interesting!’ I had an expectation that it was not going to be an interesting research area, and boy – have I been put in my place! This is one of the most fascinating research areas!

I think there is so much opportunity here to build stronger and safer infrastructure in a way that will reduce the environmental impact in the long run.

It’s funny. My family and friends now call me whenever there’s a natural hazard going on and say, ‘Well, how are we going to make sure we’re going to build more concrete structures?” That’s what happened with the California wildfires. My mom called and said, “Elizabeth, do you see that the only structure left standing was the concrete one? Did you tell them?” And I said, “They know, Mom!” And I think this is just an underrated area of research.

In the future, I hope more researchers go into this area with an open mind and see the benefits that concrete can really provide in a community. I’ve been lucky enough to have been with the research from the cement level all the way to the concrete level. I think it’s a fascinating space, and I think there’s a lot of opportunity for growth, and I’m really excited to see the cement industry hit its roadmap targets because – I think they will.”

Rick Bohan, the Senior Vice President of Cement at Portland Cement Association (PCA), has been at the forefront of research and technology throughout his career as a licensed professional engineer. As PCA’s lead on the development and now the implementation of its roadmap to carbon neutrality, Rick is passionate about engaging the industry as the solution to society’s grand challenge of global warming.

About Dr. Elizabeth Moore

Elizabeth Moore is a research scientist and programme manager at MIT’s Concrete Sustainability Hub (CSHub).

With the launch of the ECS/ControlCenter 9.1, we maintain our place at the cutting-edge of industrial process control and provide the foundation for further digital innovation.

Why upgrade?

ECS web app – Real-time data, anytime, anywhere

Seamless integration – Connect plant data via MQTT

AI-powered insights – Optimise with Python-based analytics

Future-ready – Scalable, secure, and hardware-agnostic

– are we there yet?

Anders Noe Dam, FLSmidth Cement, explores why the cement sector lags in embracing Industry 4.0 technologies and highlights key opportunities to accelerate the digital transformation of cement plants.

The world is currently experiencing the fourth industrial revolution – or Industry 4.0. This is an era of digital transformation characterised by the introduction of AI and machine learning, connectivity (the internet of things (IoT)), and big data – all of which are powered by cloud computing. To put it another way, there is much more computing power and much more storage. And, combined together, this is providing data analytics at an entirely new level. These are transformative times, with examples evident in nearly all aspects of life.

The pioneering cement producers who have integrated Industry 4.0 report remarkable benefits. Plants utilising smart sensors, IoT

devices, and real-time data analytics have experienced up to a 20% increase in overall production efficiency, 15% reduction in energy consumption, and a 10% decrease in raw material wastage.1 The tangible benefits of AI-driven tools are many:

f Lower environmental impact – greater efficiency reduces fuel and power use per tonne of cement while optimising clinker quality, enabling a reduced clinker factor.

f Enhanced quality – real-time process adjustments optimise blending, fuel/raw material feeds, and pyro stability for more consistent output.

f Carbon capture readiness – stabilised flue gas composition increases CO2 concentration which simplifies carbon capture implementation – and makes it much more cost effective.

f Increased uptime – continuous monitoring and stability reduce the frequency of issues and prevents minor issues from escalating into major failures.

It is hard to imagine any other investment having a more attractive ROI. One would assume that virtually all plants would be embracing Industry 4.0 immediately, and many are, particularly for applications regarding condition monitoring and proactive maintenance. But, from the perspective of advanced process control, the cement industry is not quite there. That is the inspiration for this article. This is not intended to be an in-depth technical piece, nor is this for the purpose to promote a specific offering. Rather, the objective is to explore why the cement industry seems to be struggling to implement the latest digital technologies at speed and what can be done about it.

The latest estimates suggest that just 30% of cement plants worldwide have begun implementing Industry 4.0 technologies in various stages of the process. That may sound

somewhat respectable, but that figure gives no indication of how far the plants have actually progressed with implementation, or even if the plant intends to rollout Industry 4.0 across the entire flow sheet rather than just isolated applications. So, what is going on here? Well, in short, it is not easy to move to 4.0 unless the plant has fully implemented 3.0 in a way that provides a solid foundation.

Let’s take a step back. Industry 3.0, also known as the digital revolution, initialised the automation and digitisation of manufacturing systems through solutions such as programmable logic controllers (PLCs).

Process control focused on the automation of linear tasks, reducing manual intervention and increasing the precision and speed of processes, resulting in a marked improvement in process efficiency and an easier path to a high-quality end product.

The scope of the solutions was either specific applications such as the pyro process or perhaps even multiple applications at a site. But, with few exceptions, the solutions always stayed within the gates of the plant. Understandably, the cement industry was focused on squeezing out as much value as possible, as soon as possible, and was largely successful. But, at the same time, much less effort was given to laying the groundwork necessary to support easy adoption of 4.0.

What are the barriers of implementing Industry 4.0 at scale?

Given the capabilities of the latest APC solutions, why is it that so many plants are lagging on the adoption of smart technologies?

f Lack of awareness – some in leadership may not appreciate how important it is or have the full perspective of their plant’s situations.

f Change management – embracing advanced process control software is a culture change for some operators. Without reinforcement such as periodic refresher training, there can be a risk of reverting to former practices.

f Trust – between cybersecurity concerns and the range of new solutions on the market, there is a lack of trust around which solution can deliver without risk.

f Immature technology – though there is a lot of potential out there, real impact will only be achieved when APC solutions are mature

enough and designed to be rapidly deployed from site to site, a capability many start-ups lack the experience to deliver.

f Cost – the lack of technical maturity also makes it harder to calculate an accurate ROI as few benchmarks or past examples are available to support estimates for the actual opportunity costs and future benefits.

f Data is not usable at scale – there is a lack of structured, high resolution data – often missing crucial metadata (such as calibration details and process changes) – which is essential for training robust algorithms.

First, plants as well as suppliers must deliberately put Industry 4.0 at the forefront of their automation strategies and make sure the proper foundation is in place. For example, at FLSmidth Cement, R&D roadmaps for each product are designed to capture the benefits of evolving AI solutions or other technologies. This includes the need to support the creation of usable data sets, mobility, and cloud computing so that AI solutions can be most effective.

Data quality and accessibility is the most prevalent and challenging obstacle that cement plants battle. Industry 4.0 solutions – especially AI-driven ones – require more than just sporadic historical records. A robust metadata foundation is essential, including calibration dates, process changes, and measurement precision. For some applications, having a time series of one year at a 10 second resolution is necessary. Without this level of detail, even well-collected data can be difficult for AI to interpret, limiting its ability to predict process behaviour and optimise operations.

To fully unlock AI’s potential, companies must strengthen their data foundations. Start by auditing current automation systems (OT architecture) to identify gaps in data collection and metadata. Ensure sensors are calibrated for and control systems ready for continuous, high-resolution data capture. Standardised, centralised data storage simplifies AI analysis. Next, structure metadata management by documenting process changes, calibrations, and measurement precision. Break down departmental silos and integrate data across systems. Partner with

experienced providers to build a scalable, future-proof architecture.

Sample data is an area of special concern as many plants still operate manual labs, but that data and the surrounding meta data is essential. The lack of such will severely strain efforts for clinker substitution. A sampling and lab audit will reveal a clear view of data quality, accessibility, and consistency, and help identify gaps that could undermine AI-driven optimisation. By tackling these areas early, plants can establish a strong foundation for a smooth and effective digital transformation. This will enable full scale implementation of data driven AI Process optimisation solution as they mature over the coming years.

free from vendor lock-in

In Industry 3.0, proprietary automation solutions were standard, and while not ideal, they were manageable. However, this lack of flexibility is causing frustration in today's digital landscape. Many plants now find themselves locked into vendor-specific systems that hinder integration, delay digital transformation, and drive-up costs. Companies struggle to adapt to new innovations and align with long-term operational goals without the freedom to evolve their technology stack.

It does not have to be this way.

Supplier-agnostic pathways are available to offer an alternative to vendor lock-in. One such pathway is the Open Process Automation Standard (O-PAS) from The Open Group. O-PAS provides comprehensive guidance for developing Industry 4.0 automation systems that are independent of proprietary technologies. It enables seamless integration across diverse systems, giving companies the freedom to create cost-effective, scalable, and interoperable digital transformation roadmaps. Open standards have accelerated innovation outside of cement; the industry must also fully embrace this practice. Is

Many industrial automation systems are typically older, unpatched, and thus more vulnerable to cyberattacks, which was perhaps okay when they worked in isolation. However, advancing digitalisation and connectivity are exposing these systems to greater risks. Industry 4.0 is built on cloud computing. Typically, many AI providers structure and execute their solutions in the cloud. They run their algorithms and then send the outcome (set points and predictions) back to the plant. The IT and OT systems from Industry 3.0 were simply not designed for this as there was much less need for data exchange, which kept the risk of cyberattacks much lower.

Certainly, plants can open up the flow of data, but this is an extra step that tends to act as a speed bump. Although some have matured the ability to send data to the cloud, very few have the systems to take data back at the required speed and scale. Partnering with an experienced supplier who can design a secure architecture and implement best practices is key. FLSmidth Cement is confident of this need as it has been getting frequent requests for assistance from their customers. In fact, there were so many enquiries that FLSmidth Cement was inspired to launch a specific service package for cybersecurity assessments.

To fully harness the potential of next-generation optimisation solutions, all KPIs must be aligned so that the optimisation systems and algorithms are configured to give plants what they really want. However, in working with plants, FLSmidth Cement often uncovers competing priorities which can make everything more complicated and impede the best overall outcome.

What is the right trade between maximising alternative fuels in order to save money, versus getting better clinker quality such that more substitutions can be used to reduce CO2, versus getting a stable and ideal flue gas to enable carbon capture? It is unlikely that one can get them all perfectly achieved at the same time, but which should be prioritised over the others? And who decides?

For a given project, FLSmidth Cement usually have a primary contact at their customer. Sometimes that person will guide FLSmidth Cement to design a system that will achieve their own KPIs without full consideration for the greater good of the entire plant. It is not intentional or self-serving. Rather, FLSmidth Cement believes it is just organisational growing pains – because Industry 4.0 and plant-wide optimisation thinking is not yet fully part of the cultures. Consequently, at times, FLSmidth Cement has found itself playing the role of a detective to get the clarity and alignment

needed so that it can deliver the best overall solution.

In Industry 3.0, the normal go-to market strategy consisted of selling software with a perpetual licence. This model was widely accepted as a best practice by everyone involved. FLSmidth Cement’s customers owned the software outright, and in turn, received full payment upfront. FLSmidth Cement’s competitors did similar. However, updates were not automatic and plants often found themselves running with somewhat outdated versions.

To stay competitive, cement producers no longer have the luxury of waiting for a major upgrade to adopt new features – things are moving too fast. Consequently, FLSmidth Cement has transitioned to offering its optimisation software as a subscription-based service as opposed to a one-time purchase. In other words, rather than owning software, a plant receives optimising services that includes software and proactive monitoring of performance. This concept has been well-received by plants, however many have had the extra administrative hurdle of adapting their approach to budgets and purchasing KPIs. Furthermore, in the same spirit of delivering continuous performance, FLSmidth Cement has seen an uptick in enthusiasm for their PlantLine™ Service Agreements which include secure, trouble-free support with 24/7 coverage and customisable modules for cybersecurity, remote technologies, lifecycle management, and proactive maintenance.

Plants that fully adopt Industry 4.0 will have a powerful competitive advantage, accelerating efforts regarding productivity, decarbonisation, quality cost savings. Much of the technology is already available. And, with the right strategy in place, the obstacles can certainly be overcome. Begin by assessing the current digital maturity of the plant, with particular focus on the OT systems. Conduct audits on data, cybersecurity, and sampling and laboratory processes. Then, collaborate with industry experts to implement the next generation of advanced process control. The sooner action is taken, the sooner efficiency gains and sustainability improvements can be realised. The future of cement production is digital; delay may result in falling behind.

References

1. 'Pioneering the global cement industry', World Cement, 2024 – https://www.worldcement. com/indian-subcontinent/18032024/pioneeringthe-global-cement-industry/

Connect with Regal Rexnord at the 2025 IEEE PCA Cement Conference! Our broad portfolio of dependable products for the cement industry can provide the best solution for your conveyors, crushers, shaker screens, bucket elevators, industrial fan/cooling systems, and other critical applications. We create long-lasting solutions that are designed to withstand extreme temperatures and harsh environments for years of optimal performance.

Explore how Regal Rexnord’s power transmission solutions can help keep your systems running in the toughest cement applications.

Learn more at rrx.link/CementSolutions Visit us at BOOTH

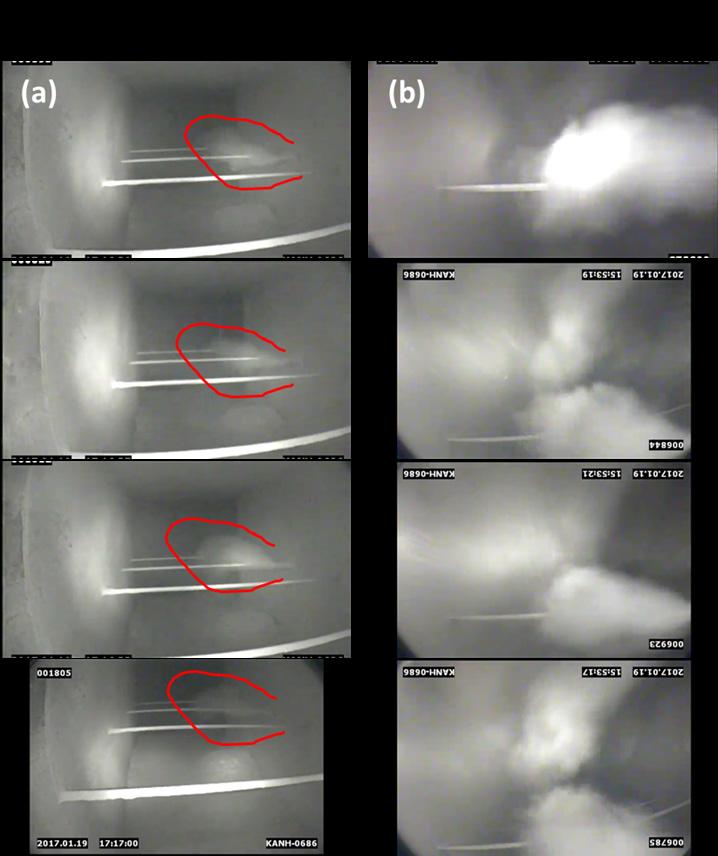

• Plunger prevents blockages at sample gas entrance

• Large filter surface for dust-free gas sample

• Gas sample above water dew point temperature

• Suitable for hot/wet or cold/dry flue gas analysis

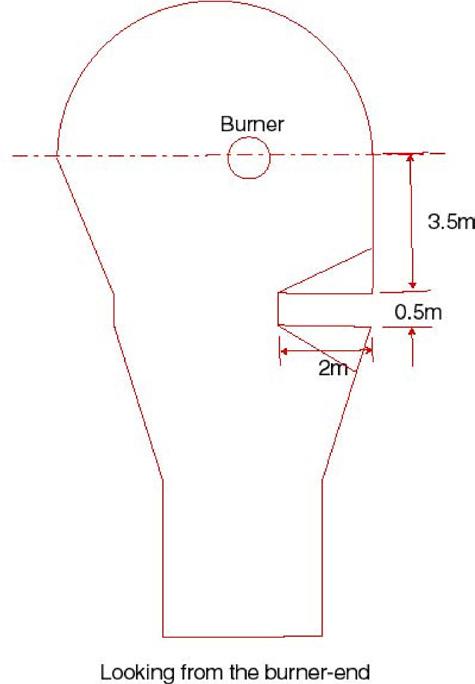

Probe gas entrance inside rotary kiln

• Cyclic plunger movement with 7000 N

• Probe insertion/retraction force 20000 N

• Cyclic anti-stick probe rotation with 700 Nm

Jeff Shelton, Dracyon, outlines a three-step strategy to tackle leaking air cannons and eliminate the 'million-dollar problem' of air leaks.

Air cannons are a mission-critical cleaning device for nearly all cement plants. Their cleaning power depends upon the effective supply of compressed air. Therefore, compressed air is a mission-critical power source for nearly all cement plants.

As referenced in a previous edition of WorldCement, Paul Edwards described compressed air as, “likely the most inefficient source of power in the facility.”1 He identified leaking air cannons (which sometimes consumed 40x their projected air consumption) as a major source of waste. Furthermore, leaking air cannons clean poorly because they often fail to reach sufficient air pressure.

Most plants underestimate the financial impact of leaking air cannons. These leaks waste hundreds of thousands of dollars in compressed air and dramatically increases operational and maintenance costs due to poor cleaning. Leaking air cannons represent a million-dollar problem.

There is, however, a better way. With three simple steps, Dracyon can economise air consumption and increase cleaning efficiency. The result is millions of dollars in ROI.

Step 1: increase the volume

The first step may seem counterintuitive. Economise air consumption by increasing the size of the air tank? Yes.

The first task of any air cannon must be to clean effectively. Many air cannons fail because their air tank is too small. Air stored in the tank is energy. A larger tank increases the kinetic energy and momentum of every discharge. Countless tests have confirmed that larger tanks clean more than smaller tanks.

Before considering how to reduce air leakage, plants must ensure they have enough air in the tank! Larger tanks do not increase air leakage. Therefore, they do not increase wasted air. There is, however,

more to consider. Since larger tanks apply more energy to every discharge, they increase cleaning without increasing air consumption. In fact, they use compressed air more efficiently for the following reasons:

f Increased cleaning energy means fewer discharges are needed. The more powerful blast often reduces the total number of discharge points by as much as 50%. In the article, Edwards claimed that one leaking air cannon consumed as much air as 40.1 20 leaking air cannons would consume as much air as 800!

f Improved technology requires fewer air tanks. Dracyon’s multiplier system supplies air to multiple discharge points with only one tank. With fewer tanks to maintain, maintenance personnel are less likely to leave leaking cannons unaddressed.

f Increased tank size enables superior installation practices. Smaller tanks must be installed very close to the discharge point because long pipe runs reduce their cleaning power. They are often installed in places that are inaccessible for safe and regular maintenance, as shown in Figure 3. If any of those tanks were leaking, it would be difficult to apply online maintenance. Larger tanks, by contrast, can clean effectively with long pipe runs, enabling plants to install them in easily accessible areas. Cleaning efficiency is directly correlated to reliability. When air cannons are easily accessible for regular maintenance, they are more reliable and, therefore, more effective. It does not matter how effective an air cannon is if it does not work!

Though it may seem counterintuitive, larger tanks are the first step to economising air consumption and increasing cleaning efficiency. It all starts with the increase in cleaning energy. This enables plants to clean with fewer discharges, extended pipe runs, and superior installation practices, all while dramatically increasing material movement.

Step one may have been a bit counterintuitive, but step two is just common sense. The prevailing practice in the cement industry is to refill the air cannon immediately after its discharge. This practice stores air and maximises wasted air through leaks. It is irresponsible due to safety concerns and financial waste:

f It is a legitimate safety concern. As a pressurised vessel, air cannons do pose the risk of propelling themselves off the mounting hardware, striking someone, and causing a fatal injury (this has occurred). Given the risk, pressurising the air cannon for the longest time possible is irresponsible.

f It is a financial drain. Filling up a leaky air cannon is akin to pouring water into a holey bucket.

No wonder one leaky air cannon uses as much air as forty! Given the waste of compressed air, pressurising the air cannon for the longest time possible is irresponsible.

The common sense solution to this problem is simple. Instead of filling the tank immediately after discharge, fill it immediately before discharge. Fill and fire. It solves both problems mentioned above:

f It is a safer practice. A non-pressurised air cannon poses no risk propelling itself off the mounting hardware. By filling just before discharge, the possibility of when that could happen is minimised. If an air cannon discharges

4. Despite the long pipe run, this installation cleaned more effectively than previous air cannons. It did so with far fewer reservoir tanks, all of which were easily accessible to maintenance personnel.

every 15 min. and takes 15 sec. to fill, the safety implications of the two practices are as follows:

» Prevailing practice: the air cannon is pressurised for 14 minutes and 45 seconds.

» Fill and fire: the air cannon is pressurised for about 15 seconds.

f It is a shrewd financial practice. Even if an air cannon is leaking, filling and firing reduces the wasted air to nearly zero. Leaking air cannons consume far more air than what is required for a discharge. On a fill and fire system, it would be impossible for one air cannon to use as much air as forty.

It is not a matter of if the air cannon will leak, but when it will leak. All air cannons will leak. The fill and fire technique recognises that reality and minimises safety risk and financial loss in light of it. The result is a safer plant and more economic use of compressed air.

The final step toward economising air consumption and increasing cleaning is to customise the blast. For many years air cannons came with a universal recommendation. Install a fan jet nozzle to discharge every five to ten minutes. That worked for some applications but not all. Each installation should have a customised nozzle recommendation and discharge cycle.

Many plants employ outdated nozzle technology that is unable to meet today’s challenges. Modern nozzles are more effective, more durable, and more affordable. The improvements are so drastic that Dracyon offers a 10-year warranty on its air cannon system, including a 3-year guarantee on the life of the nozzle.

f Finding the right nozzle. One of the challenges to today’s cement industry is the increase of alternative fuel sources which produce difficult buildup. The fan jet nozzle is designed to produce a wide blast over a large surface area. This blast design sacrifices an important factor of cleaning power: velocity. The nozzle supplied by Dracyon, by contrast, has a larger opening (6 in. vs. 4 in.) and produces a more concentrated, high velocity discharge. It is far more adept for applications with difficult buildup or those requiring deep penetration. f Choosing the right discharge cycle. Once the correct nozzle has been selected, the question is, how often should it discharge? Although the standard answer is once every five to ten minutes, that is often inadequate and reveals a lack of process knowledge. Before determining a discharge cycle, the following questions need to be answered:

» What is the fuel source and nature of the buildup?

» What is the rate of buildup in the area before the air cannon?

» What is the needed depth of cleaning in the application?

Those answers will vary for many applications, hence the need for a customised discharge cycle. That said, most applications would benefit by reducing the frequency of their discharge. This enables the buildup to properly accumulate and adhere, which, when the air cannon has sufficient power, yields more material movement. It also leads to lower air consumption and reduced maintenance.

The 'one size fits all' approach to nozzles and discharge cycles has often led to wasted air and poor cleaning. Dracyon’s approach of customising the blast means fitting each air cannon with the right nozzle and discharge cycle. Some installations would benefit from two, back-to-back discharges every twenty minutes, whereas others would require one discharge every ten minutes. Some installations are poorly served by fan jet nozzles, whereas others benefit from them. There are countless variables. Dracyon’s family of air cannons and nozzles, together with extensive experience in cement plants all over the world, make it uniquely equipped to customise the blast. A customised recommendation is a simple way for plants to economise air consumption and increase cleaning efficiency.

Compressed air is likely the most inefficient source of power in the plant. Air cannons, which are a mission-critical cleaning device, are one of the biggest sources of waste. Even worse, many of them do not clean effectively. Leaking air cannons is a million-dollar problem.

But Dracyon’s three step plan (increase the tank, fill and fire, and customise the blast) is scientifically proven to economise air consumption and increase cleaning efficiency. Leaking air cannons is a million-dollar problem, but the three step plan is a million-dollar solution.

Less than 1 month after switching to LE’s kiln lubricant, a cement company reduced its lube consumption by 7 times, achieving approximate annual savings of $63K for a single kiln. At the same time, gear temperatures dropped and maintenance time decreased.

As far back as the 1970s, cement plants in Europe and the US were blending traditional fossil fuels with shredded tyres and waste from timber production. Indeed, the cement sector was one of the first to explore waste feedstocks as effective alternatives to coal and pet coke.

Recently, with fuel accounting for a rising percentage of cement clinker production costs, more and more producers have sought to secure suitable waste streams – for use both as fuel and in their raw feed mix – to achieve cost-effective production that is also recognised as being more sustainable.

Indeed, a handful of cement plants around the globe are able to boast 100% alternative fuels (AFs), raising the bar for the sector and challenging fossil fuel-reliant plants to look to locally available wastes as fuel sources – from non-recyclable plastics, commercial mixed wastes, and shredded upholstery to biomass like rice husks, sugar cane bagasse, and pelletised animal meal.

The choice of AFs requires careful consideration as the implications for productivity and process design can be significant. One of the major differences between solid fossil fuels and waste-derived alternatives is the way they flow through the process, typically determined by their physical properties and moisture content.

Efficient and continuous material flow is a critical element of dry-process cement manufacture, so any accumulation or blockages can choke productivity and profitability. Hang-ups in storage systems and build-ups in chutes and process vessels can cause serious obstructions that impede equipment performance and reduce efficiency.

Material build-up can occur in many places in the plant, and in several forms. Accumulation often occurs in riser ducts, feed pipes, cyclones, transfer chutes, and storage bins, as well as kilns and coolers. In extreme cases, massive buildups can suddenly break loose and suffocate the process, potentially causing significant damage to equipment and

almost invariably prompting the need for unscheduled downtime.

It is worth stating that buildups of AF materials can happen even in well-designed systems. Changes in process conditions, the raw materials themselves or even the weather can have an effect on material flow, and a small amount of accumulation can quickly grow into a serious blockage, with obstructions often leading to secondary problems.

Accumulations of some AFs are even susceptible to spontaneous combustion, while others may accelerate wear, tear, and corrosion of structures, and deterioration of conveyor components. A preventive approach to controlling buildups and blockages is the only way to address these issues and prevent unscheduled downtime.

Lost production is usually the primary cost of flow problems, but the expense can become apparent in a variety of secondary ways. Shutdowns to clear blockages and buildup also cost valuable process time and maintenance hours. That increases maintenance costs and diverts service teams away from core activities, potentially introducing needless safety risks. Refractory walls can become worn or damaged by tools or cleaning techniques. When access is difficult, removing material blockages may also introduce serious risks for personnel. Working platforms are usually needed to reach access points, and there is a risk of exposure to hot debris, dust, or gases when chunks of material stuck to the sides of a silo, hopper, or bin are suddenly released. If the discharge door is in the open position, material can suddenly evacuate, causing unsecured workers to get caught in the flow. Cleaning vessels containing combustible dust – without proper testing, ventilation, and safety measures – could even result in a deadly explosion with as little as a spark from a shovel.

Many of the most common problem areas for accumulation are also classified as confined spaces, requiring a special permit for workers to enter. The consequences for untrained or inexperienced staff can be serious, including physical injury, burial, and asphyxiation.

The most effective way to manage the challenges of using AFs is to design the material handling system around the physical properties of the intended fuel. That means each component is specified and engineered according to the flow characteristics of the material.

In reality, most cement producers will be using existing systems to feed in AFs, which can require some modest retrofitting or a whole new facility. Martin Engineering has been perfecting material handling technologies in sectors like cement for more than 75 years and there are few challenges that Martin technicians have not already faced and overcome around the world.

One approach that brings significant benefits to operators seeking to retrofit material handling systems to accommodate AFs is to use modular components that can be specifically built to handle the cargo (such as transfer chutes with specific flow angles or settling zones of appropriate height and length). Rather than replacing large sections of existing equipment,

modular designs can be engineered to fit into the specific system on hand.

However, Martin’s engineers are also experienced enough to know that designing a single system to handle every type of AF is virtually impossible. Materials with high moisture content can adhere to chute or vessel walls or even freeze during winter temperatures. Continuous operation can compress the material, and physical properties often change due to natural and inevitable variations that are typical in waste-derived fuels. Just a small change can cause a system to become completely blocked in a short amount of time. Most of these issues can be overcome, and a whole-process approach is needed with a selection of flow aids installed to collectively work together to keep things moving.

One of the first challenges to be addressed when using dry AFs is the potential for release of combustible dust, and containment is therefore critical. Successful dust management starts with minimising air turbulence through appropriate transfer point geometry.

Air is very compressible and will find the path of least resistance. Typically, the design of transfer points means that air is most often speeding up to flow under or around a single exit dust curtain with narrow slits, resulting in re-entraining the dust particles in the exhaust. Therefore, it is necessary to create recirculation regions inside a transfer point to improve dust settling and containment.

A transfer point is similar to a gravity settling chamber, which depends on relatively slow air speed without much turbulence. Conversely, the airflow through a conveyor transfer point is almost always turbulent. So, the transfer point enclosure design needs to incorporate a series of curtains to slow and control airflow and promote settling. Used in tandem with adjustable dual skirting, these can create a sealed environment where dust settles back into the cargo flow or is sequestered into a dust bag without spillage or emissions.

To achieve contained and consistent flow on conveyors handling large volumes of AFs, transfer chutes and vessels must be designed to accommodate and facilitate the flow of the materials they will be handling. Even if the operating conditions are expected to be ideal, many engineers include flow aid devices in new designs to ensure delivery of the optimum results but with the agility to deal with changes in AFs and raw materials.

Flow aids is an umbrella term for a complementary set of components installed to promote the transport of materials through an entire system. Because they will affect a conveyor’s loading, flow aid devices can also reduce spillage and help control dust. If not properly managed, buildups that break free – accidentally or intentionally – can produce surges, which result in overloading, spillage, and belt mistracking. By designing active flow aids

into a conveying system, the operation gains a level of control over the material that cannot be obtained with static approaches (such as low-friction liners) alone.

Flow aids come in a variety of forms, including rotary and linear vibrators, high- and low-pressure air cannons and aeration devices, as well as low-friction linings and special chute designs to promote the efficient flow of bulk materials. These systems can be combined in any number of ways to complement one another and are shown to improve performance. They can be as simple as an impacting piston vibrator on a chute wall to dislodge material buildup, or as sophisticated as a multiple air cannon system discharging automatically on a timed cycle to prevent accumulation. The components can be used together to benefit processing of virtually any bulk AF, or hazardous or complex materials.