10 minute read

A helping hand on the road to decarbonised operations

Richard Irwin, Bentley, UK, explains how improving reliability strategies and asset information reduces both downtime and carbon emissions.

Downtime, especially that which is unplanned, can cost companies upwards of US$500 000/h on average as a result of lost revenue, financial penalties, idle staff time, and restarting lines. As if that was not bad enough, there is also a cost to the environment. As energy providers face pressure to meet challenging sustainability

targets and reduce emissions, there is a growing focus on the environmental impact of unexpected shutdowns at oil and gas refineries. This article examines the implications of unplanned downtime on the environment, and how to improve this in order to help achieve net zero emissions.

Avoiding the unavoidable

In the process industry, it is common practice to add unplanned downtime as a yearly cost. It is something that, while inevitable, can come at any time. While unplanned downtime will always impact productivity and profitability in an oil refinery or petrochemical plant, the effects often have far-reaching implications that go beyond financial costs. Assets that are running inefficiently also use more energy, cost more to run, are more likely to fail, and therefore contribute to increased levels of carbon. While safety is critically important to the plant and the workforce, so too is the damage to the environment and the emissions that shutdowns cause. With the recent push for net zero emission targets, operators have had to adapt and become leaner and more efficient in order to maintain returns and stability. Oil refineries are often the major polluters. They consume substantial amounts of energy and water to operate, produce large quantities of wastewater, release hazardous gases into the atmosphere, and generate solid waste that is difficult to treat and dispose of.

There are many events that can cause unplanned downtime, ranging from equipment reliability and human error, to availability of spare parts and extraordinary events. When one critical component of a facility shuts down, there is a ripple effect on everything else, including a potential shutdown of the entire facility. From a plant or refinery perspective, a shutdown affects production and has financial and safety consequences. Unseen, however, are the consequences on the environment as a result of the sudden release of carbon emissions. Nowhere is this felt more than when a process failure causes gas flaring during an unplanned event.

Flaring indicates that something is not right within the plant. Gas flaring introduces toxic pollutants such as sulfur dioxide (SO2) into the atmosphere, which can lead to environmental problems such as acid rain, as well as the generation of greenhouse gases that contribute to global climate change. In 2020, nearly 142 billion m3 of natural gas was flared, which equates to approximately 265 million t of carbon dioxide (CO2). This flaring will continue for as long as the plant is running inefficiently. Moreover, there are secondary environmental issues that are added into the equation, such as the carbon emissions as a result of additional transportation for spare parts; bringing in maintenance teams or third parties to fix the problem; the energy used from multiple start-ups; and round-the-clock maintenance. Therefore, it is more cost-effective and sustainable to run a plant as optimised and as smoothly as possible, as anything outside of these thresholds spells trouble.

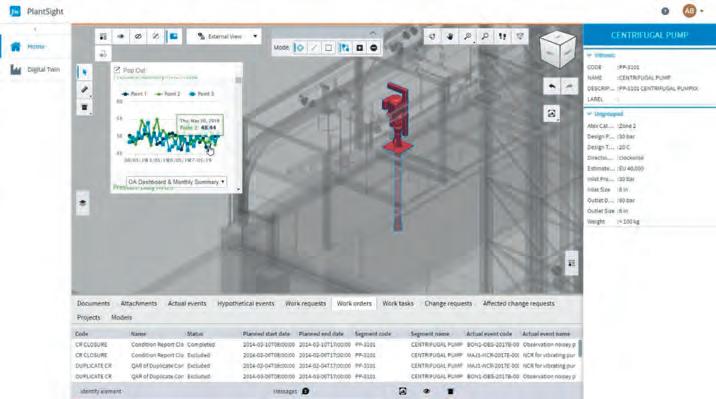

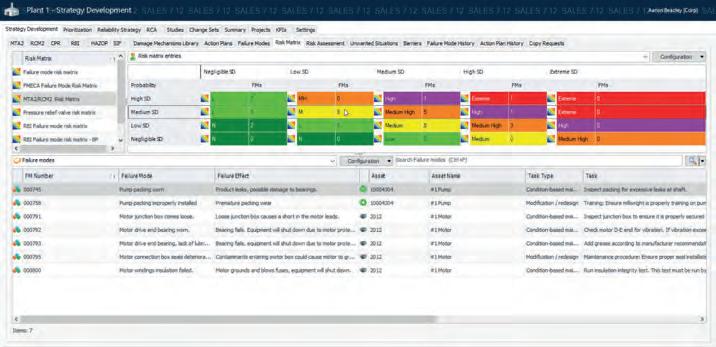

Figure 1. Operators can view the status of any asset within the digital twin. Figure 2. An APM strategy is key to reducing risk, and therefore downtime.

Reducing downtime: the options

So what can organisations do to minimise unplanned downtime and make their processes more sustainable? Thankfully, there are many solutions driven by

innovative software solutions that can help them. Here are a few:

One of the most cost-effective and efficient ways to reduce downtime is to employ asset performance management (APM) strategies and processes that encompass the capabilities of data capture, integration, visualisation, and analytics – all tied together for the purpose of improving the reliability and availability of physical assets. APM uses a variety of approaches and techniques, such as condition and health monitoring, inspection management, reliability centred maintenance (RCM), risk analysis, predictive maintenance, and prescriptive analytics. APM software solutions, such as Bentley’s AssetWise Asset Reliability, provide critical information for assessing equipment criticality and risk, maintenance processes, equipment care strategies, continuous monitoring, and assessing the impact of operations on maintenance across the enterprise. APM solutions provide a more preventative and proactive guide to maintenance and reliability than reactionary fix-when-failed strategies.

Analytical intelligence

While APM software can provide insights into equipment health and reliability, an analytical solution can provide insights and intelligence into the operational performance of the plant or facility to improve asset performance, reduce costs, and facilitate mission-critical decision making at the right time. By connecting multiple data sources together, an analytics solution can provide key functions to the user such as visualisation, reporting, alarm management, and performance dashboards using near real-time data. Its key role though, by combining the above, is to uncover hidden insights within the operation, turning raw data into intelligent information from which accurate decisions can be made. Analytical solutions can be applied to many areas – from production, corrosion and chemical management, flow assurance, and integrity management, to energy and building management. Some vendors combine analytics with their APM offerings, while others offer separate products.

Build a digital twin

A digital twin is a virtual representation of real-world entities and processes, combining engineering and design data/models with operational and IT information. Digital twin systems transform businesses by accelerating understanding, supporting optimal decision making, and enabling effective actions to be taken quickly.

As oil and gas operations become more digitalised to improve operational performance and remain competitive and more sustainable, the role of digital twin technology becomes even more important. Gartner says that by 2024, at least 90% of greenfield investments will already have comprehensive digital twin models, onsite data integration, and dynamic software configuration capabilities.1 That being said, as the need for the transition to renewable energy escalates, then the need for complex oil and gas digital twins may slip down the list of importance. Nevertheless, the benefits that a digital twin brings to any digital operation are attractive. They include: n Enabling automated, remotely-operated, minimally-manned, highly efficient, and more sustainable assets. n Providing access to accurate and reliable single-sourced information across the whole life cycle of the asset. n Accessing and sharing digital twins across multiple teams, from engineering design and handover through to operations and maintenance. n Providing facilities for training and familiarisation (‘walk the plant’) of the operation prior to onsite visits. n Multi-discipline integration of third-party models, data, and information into one application. n Creating a digital twin of the exact conditions of a physical asset, allowing people to review and make faster decisions.

n Improving overall decision making with the addition of simulation and predictive capabilities.

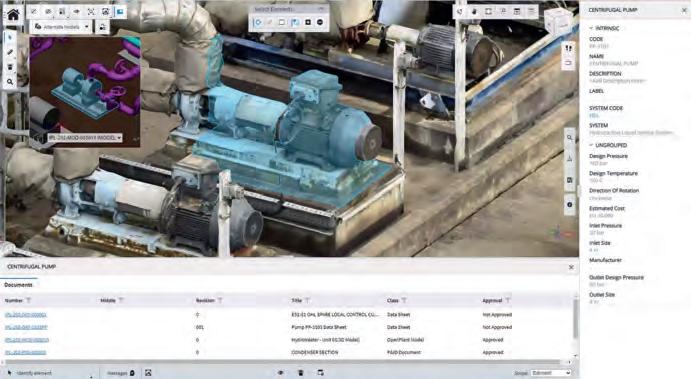

Figure 3. Digital twins can provide multiple views of an asset, from reality meshes to 3D models, and the up-to-date information it contains. Machine learning and artificial intelligence

Machine learning and artificial intelligence (AI) techniques can also be applied to any of the above solutions to help predict equipment failures and other issues that may lead to unplanned shutdowns, therefore reducing carbon emissions and rendering the project more sustainable. This would turn unplanned downtime into planned downtime.

All of the above solutions can be combined into one

Now that’s Reliability!

Nikkiso Clean Energy & Industrial Gases

For more than 50 years Nikkiso Clean Energy & Industrial Gases Group companies have been providing our customers with a wide range of highly-engineered, designed, serviced and supported products; turbo expanders, cryogenic pumps, vaporizers, air separation plants, LNG plants, ORC plants and more.

We stand ready to assist you with equipment and engineering services for upgrade and redesign. We offer a wide variety of services from turnkey solutions to aftermarket support through our 20 service facilities located in the U.S. and across the globe.

Looking for dependable solutions? Ask Nikkiso.

Process Systems – Heat Exchanger Systems – Cryogenic Pumps – Solutions – Service

Find out more at www.NikkisoCEIG.com

The future is now with our technologies for tomorrow.

Think. Create. Change.

Discover our innovative membrane technology and other solution concepts that make you fi t for the future. We look forward to welcoming you at ACHEMA 2022 , stand 4.0 - B 26.

Let’s discover together where our ideas will take you.

22 – 26.08.2022 in Frankfurt am Main, Germany. system of systems. For example, PlantSight, the joint Bentley/Siemens digital twin solution for the process industry, can integrate all engineering information (3D models, reality meshes, P&IDs, and more) from a variety of sources. The solution is able to surface operational information from Bentley’s AssetWise solutions to provide a complete, reliable, and up-to-date solution across the life cycle of the asset or project. This means that all system users are always accessing the same consistent data, and any changes are consistent across the board. As such, any downtime in a section of the operation can be viewed within a model at the click of a button; everything that is affected can be seen; and decisions can be taken to reduce the impact that it causes so that the plant is up and running sooner.

Plan for a greener future

Another way of reducing emissions and becoming more sustainable is to transition to renewables, such as wind, solar, and hydrogen energy. This is a shift that we are seeing more often as companies try to match their ambitious net zero targets, as well as distance themselves from the negatives associated with hydrocarbon production. While our dependency on hydrocarbons will still be around for the next 30 – 50 years, operators have three choices: n Carry on as we normally would – this means maintaining production while demand and prices are still high, and capitalising while the window remains open. n Replacing hydrocarbons completely – this means replacing oil and gas production entirely and switching to renewable energy resources only for a greener and sustainable future. n Transition from hydrocarbons to renewables – this hybrid approach implies carrying on as normal (but cutting back on core activities while reducing carbon emissions), while also investigating and investing in renewable alternatives such as carbon capture, energy storage, electrification, hydrogen projects, solar, and wind. This can be seen by the transition of many large operators – from international oil companies to integrated energy companies, such as

Shell and BP. As with a plant, these new renewable assets also require

APM and analytical solutions for them to operate reliably.

Conclusion: the future does not have to appear bleak

For decades now, oil and gas companies around the world have been generating large returns due to the over-reliance and demand on hydrocarbons. That reliance has made them some of the most profitable companies in the world. Considering recent events such as the COP26 summit, there is greater pressure on hydrocarbon producers to become more climate resilient, offset carbon, reduce emissions, and look at other revenue streams in renewables. While some companies have already become early adopters of renewable alternatives, many operators are looking at substantial changes to their business models.

Those that continue to produce can still have a positive result when it comes to being more sustainable and climate resilient, with the help of technical and software innovation. Some of these advancements have been around for a while, but not always implemented, or information is held in siloes and ignored or unused. Companies that implement digital twin technology to help reduce unplanned downtime can be hugely differentiated from the competition as a result of combining improved safety and production with sustainable performance.

Reference

1. CUSHING, S., and MCAVEY, R., ‘Predicts 2022: Oil and Gas — The Last Golden Era’,

Gartner, (8 November 2021).