9 minute read

Sparking a safety culture

Alec Cusick, Owens Corning, USA, explores the various considerations when designing a passive fire protection system.

Wherever flammable materials are present, so is the risk for a fire. Facilities that work with flammable petrochemicals or hydrocarbons must look beyond detection systems such as alarms, and even active systems such as extinguishing technologies, to consider the role of passive fire protection. In industrial environments that use, process or store flammable materials, an ignition source or spark may be all that is needed to trigger a fire.

Ignition sources are abundant in industrial facilities. Welding, maintenance, electronic malfunctions, static electricity, lightning or autoignition can all trigger a fire. Passive fire protection systems support both detection and active systems and bring an additional safety element to these sites when applied to critical assets such as piping, equipment, structural elements, tanks and storage vessels.

While the word ‘passive’ typically does not imply ‘urgent’, passive systems are a non-negotiable factor for supporting safety in any environment where flammable chemicals are present. Considering that structural steel can lose up to 50% of its load bearing ability when heated to 538°C (1000°F), the importance of protecting the structures supporting volatile processes is evident. A loss in load bearing capacity could cause storage containers and equipment to buckle or collapse, potentially adding additional fuel to a fire.

What components make up a passive fire protection system? Many consist of single or multi-layer jacketed insulation systems to slow the spread of heat into the material that is being protected (i.e. pipes/vessels/ structural beams). This strategy may allow additional time for occupants to evacuate the site or for employees to safely shut down equipment. Providing additional time may also support emergency responders’ efforts to fight the fire.

When selecting insulation and designing passive fire protection systems, several elements should be considered. These factors include the performance of a material using standards-based testing methods, including but not limited to combustibility; smoke production; and flame spread characteristics.

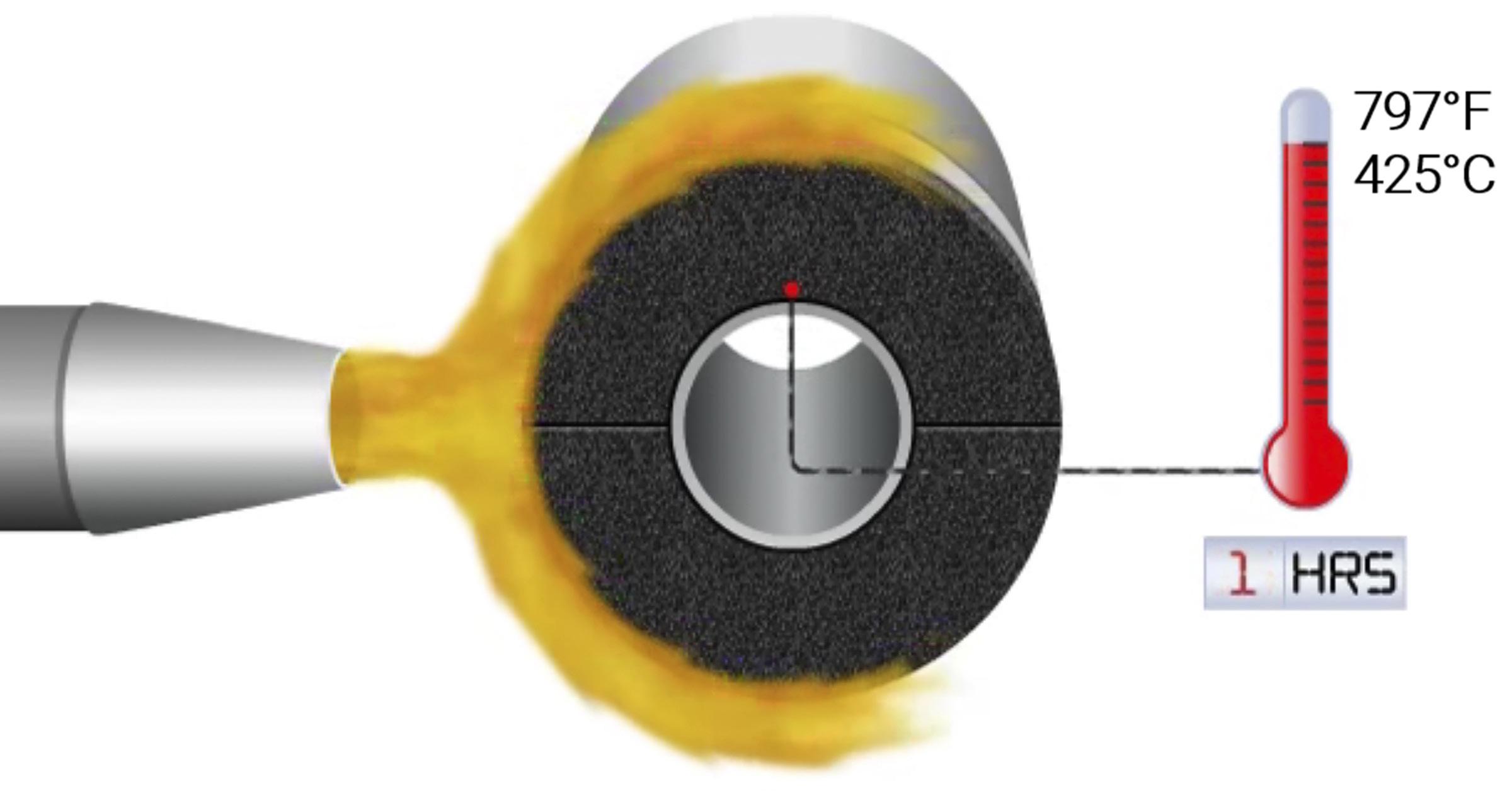

Figure 1. The furnace-based UL 1709 test establishes how long an insulating system is effective for, in terms of protecting the underlying structure and delaying heat penetration.

Figure 2. Jet fire testing determines a material’s resistance to high velocity flame and a rapid change in temperature.

Figure 3. Mineral wool insulation has been evaluated for use in passive fire protection systems because it is non-combustible and has a high service temperature.

Testing standards

Two commonly referenced standards for passive fire protection systems are UL 1709, the standard for rapid rise fire tests of protection materials for structural steel, and ISO 22899, which determines the resistance of passive fire protection materials and systems to jet fires.1,2

UL 1709 measures how long a given system can offer protection to underlying equipment during a fire. Initially used with structural steel, this test has been expanded to address process piping, equipment and storage tanks or vessels. During the test, thermocouples are attached to a steel substrate and the passive fire protection system that is being tested is installed over the thermocouples and steel. The structure is placed in a furnace and heated to 1093°C (2000°F) over 5 minutes. The test stops when either a group of the protected thermocouples reaches 538°C (1000°F) or a single thermocouple reaches 649°C (1200°F).

ISO 22899, sometimes called the ‘jet fire test’, examines the ability of a system to offer protection to underlying equipment during high velocity jet fire scenarios. During testing, thermocouples are again attached to a steel substrate under the passive fire protection system that is being evaluated. A directional, high intensity flame is then applied to the test specimen and time is recorded. The test stops when a single thermocouple reaches 400°C (752°F) above the initial ambient temperature at the beginning of the test.

The presence of passive fire protection systems may also impact sizing requirements for relief valves used within a facility. Because keeping hydrocarbons in a safe, liquid form means that they are at extremely low temperatures, in many instances depressurising systems need to be incorporated into the designs of tanks and vessels. This allows for the safe release of pressure that could build up from the vaporisation that occurs during a fire. The amount of protection provided by passive fire protection may be considered when deciding how large a relief valve is needed for the depressurisation system. Relevant standards exist to aid the design of these relief valves, including API 2000 – venting atmospheric and low-pressure storage tanks – and NFPA 30 – the flammable and combustible liquids code.3,4 These standards provide equations to help establish the thermal credit provided by insulation, should a fire occur.

Evaluating insulation properties

When evaluating insulation for use in passive fire protection systems, it is important to consider several qualities. Typically, a material intended for use in a passive fire protection system should be examined for combustibility. It should also be checked for flame spread and smoke development properties in the event of a fire. The intention is to find materials that will not burn,

will not allow flames to move across a surface, and will not generate dense smoke, which could obscure escape paths and increase risk of smoke inhalation.

Other elements to evaluate include the thermal conductivity of a material – how efficiently heat is able to pass through it. The specific heat of an insulation is also important to know, as it depicts how much heat must be applied to raise one unit of the material by one unit of temperature. For example, the specific heat of water is 1.001 Btu/lb·°F (4.187 J/g·K) at 60°F (15°C).

The maximum service temperature of the insulation material is also an important factor for design. However, the service temperature range on product data sheets often reflects the fitness for use of insulation for process control, condensation control or personnel protection, and not for performance of the material for passive fire protection. While a high service temperature could be beneficial for passive fire protection, it is not uncommon for this published service temperature to be exceeded in the event of a fire. In this case, the material may still provide passive fire protection as a sacrificial material. When evaluating a material for use for passive fire protection, one may prioritise finding insulations that have low thermal conductivity, high specific heat and fitness for use as passive fire protection.

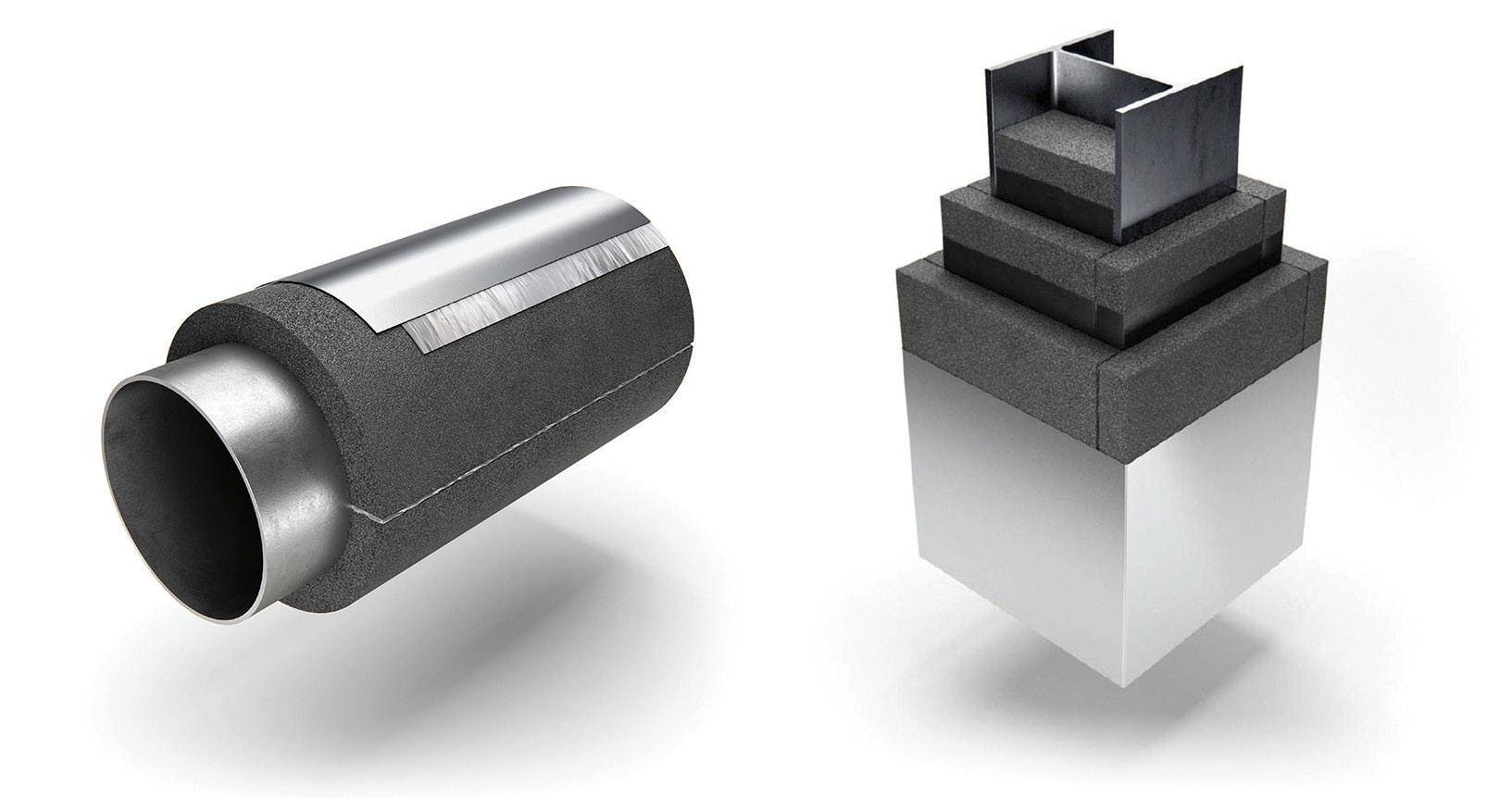

Figure 4. Insulated systems can provide piping and structural elements protection against both rapid rise and jet fire type situations.

Figure 5. Combining insulation types helps create passive fire protection systems that can address more than one facility challenge.

Figure 6. Hybrid systems can also be used to provide passive fire protection at facilities with fire concerns.

Material matters when insulating passive systems

Insulating materials deliver different performance properties that affect their ability to function in different applications, including passive fire protection. Mineral wool has long been renowned for its fire resistant properties. The composition of the material helps explain its performance in passive fire protection systems. For example, Owens Corning’s mineral wool insulation is an inorganic fibre made from rock and recycled slag. This composition contributes to an insulation that is non-combustible, with a maximum service temperature of up to 649°C (1200°F) and flame resistance of 1093+°C (2000+°F). The material also has low flame spread, is water resistant, provides acoustic dampening, and is available in a range of shapes, sizes and flexibilities to promote easy application.

Another non-combustible material is cellular glass insulation. In addition to its non-combustible properties, cellular glass insulation is also trusted in industrial and mission-critical applications, as it is impervious to moisture. Again, material composition contributes to performance. For example, FOAMGLAS® cellular glass insulation is a lightweight insulation comprised of completely sealed glass cells. The material is inorganic, non-permeable and has a wide service temperature range from -268°C to 482°C (-450°F – 900°F). It is dimensionally stable, non-combustible, will not give off smoke and has a high compressive strength. Additionally, it is easy to cut and handle on the jobsite and can be prefabricated into multiple shapes for easy application.

The insulation(s) selected are typically paired with additional materials, such as jacketing. In some hybrid systems, the insulation is combined with an intumescent coating to provide extra protection. When exposed to high levels of heat, intumescent coatings char and expand to further slow heat reaching the underlying structure.

Tested systems

Studies designed to evaluate the material performance validate use for passive fire protection. A series of insulation systems incorporating cellular glass and/or

mineral wool insulation along with jacketing and other accessories was tested using either ISO 22899 or UL 1709. Findings offer insight into the types of time ratings achieved by different passive system designs. For example, insulation intended for use on ambient or below ambient equipment, including piping, tanks, or structural steel, could consist of one layer of FOAMGLAS OneTM cellular glass insulation with PITTSEAL® sealant, PITTWRAP® B100 jacketing and 0.016 in. stainless steel cladding. When tested using UL 1709, this set-up provided up to 30 minutes of protection. The same insulation system with 0.027 in. stainless steel cladding also achieved 30 minutes of protection when tested according to the ISO ‘jet fire test’.

Beyond providing passive fire safety, insulating systems can also address other issues at a facility, such as noise reduction. A different type of passive fire protection design combined cellular glass insulation with mineral wool pipe insulation, mass loaded vinyl, and stainless steel cladding. In addition to providing 120 minutes of protection in a jet fire situation and 180 minutes in a rapid rise fire, the insulating system has been tested to ISO 15665 for sound isolation performance.5

Additionally, passive fire protection systems can combine different materials to optimise performance. Owens Corning’s hybrid design combines cellular glass insulation, PC® 88/62 adhesive, PITTWRAP B100 jacketing, PPG Pitt-Char® NX and carbon mesh. This hybrid system can be adapted for both below and above ambient conditions, and provides up to 240 minutes of protection in a jet fire situation.

Conclusion

Safety will always be a top priority in any system design. The considerations discussed in this article can spark approaches to support life safety via passive fire protection systems and potentially deliver ancillary benefits such as noise reduction. It is important to seek technical expertise on insulation systems when designing a passive fire protection system, as results will vary with each unique project.

References

1. ‘Standard for rapid rise fire tests of protection materials for structural steel (UL 1709)’, Underwriter Laboratories, (2017), https://standardscatalog.ul.com/ProductDetail. aspx?productId=UL1709 2. ‘Determination of the resistance to jet fires of passive fire protection materials – Part 1: General requirements (ISO 22899-1:2007)’, International Standards Organization, (2007), https://www.iso.org/standard/39750.html 3. ‘Venting atmospheric and low-pressure storage tanks (API 2000- 7ed)’, American Petroleum Institute, (2014), https://www.apiwebstore.org/publications/item. cgi?78c81e7e-5e5d-4d09-a5bf-c0d3a65b868e 4. ‘Flammable and Combustible Liquids Code (NFPA 30-2021)’,

National Fire Protection Association, (2021), https://www. nfpa.org/codes-and-standards/all-codes-and-standards/listof-codes-and-standards/detail?code=30 5. ‘Acoustic insulation for pipes, valves and flanges (ISO 15665:2003)’, International Standards Organization, (2003), https://www.iso.org/standard/28629.html

Vacuum Systems

Process-integrated solutions for Ejector Vacuum Systems

GEA supplies steam jet vacuum systems and hybrid vacuum pumps, optimizing production processes to reduce both costs and carbon

emissions.

With over 90 years of experience and thousands of references from satisfied

customers from diverse industrial

sectors all over the world, GEA is the partner you are looking for.

Get in touch: gea.com/contact