C 30 M 20 Y 10 K 40 C 90 M 45 Y 0 K 15 Magazine for maritime professionals | Volume 145, May 2024 | www.swzmaritime.nl 5 At the MEPC81 Elene Prato discusses whether IMO can keep up with the EU Making dredging more sustainable Nature-based solutions UK commits to sustainable shipping TIME TO DO BUSINESS IS NOW Being prepared for every scenario MARIN simulator centre

SUBMARINE DESIGN & ENGINEERING SINCE 1935

Nevesbu holds a unique position in submarine design & engineering. Since it’s establishment in 1935, Nevesbu continuously works on submarines for the Dutch navy and foreign navies. In addition to the upkeep programme for the Walrus class, Nevesbu currently works on the construction, upkeep and modification of submarines in four other countries worldwide.

Scan the QR-code to read more about Nevesbu’s submarine services and experience.

Autonomous Shipping Everything under control for the optimal route Smart Maintenance Efficient maintenance and monitoring availability Eco-Friendly Redundant, safe and environmentally friendly OpenBridge, MTP Standards for more security and smooth installation The Future in View. Always on Course. Our Competence. Our Responsibility. Our new M100 I/O System www.bachmann.info YPEAPPROVEDPRODUC DNV.COM/AF

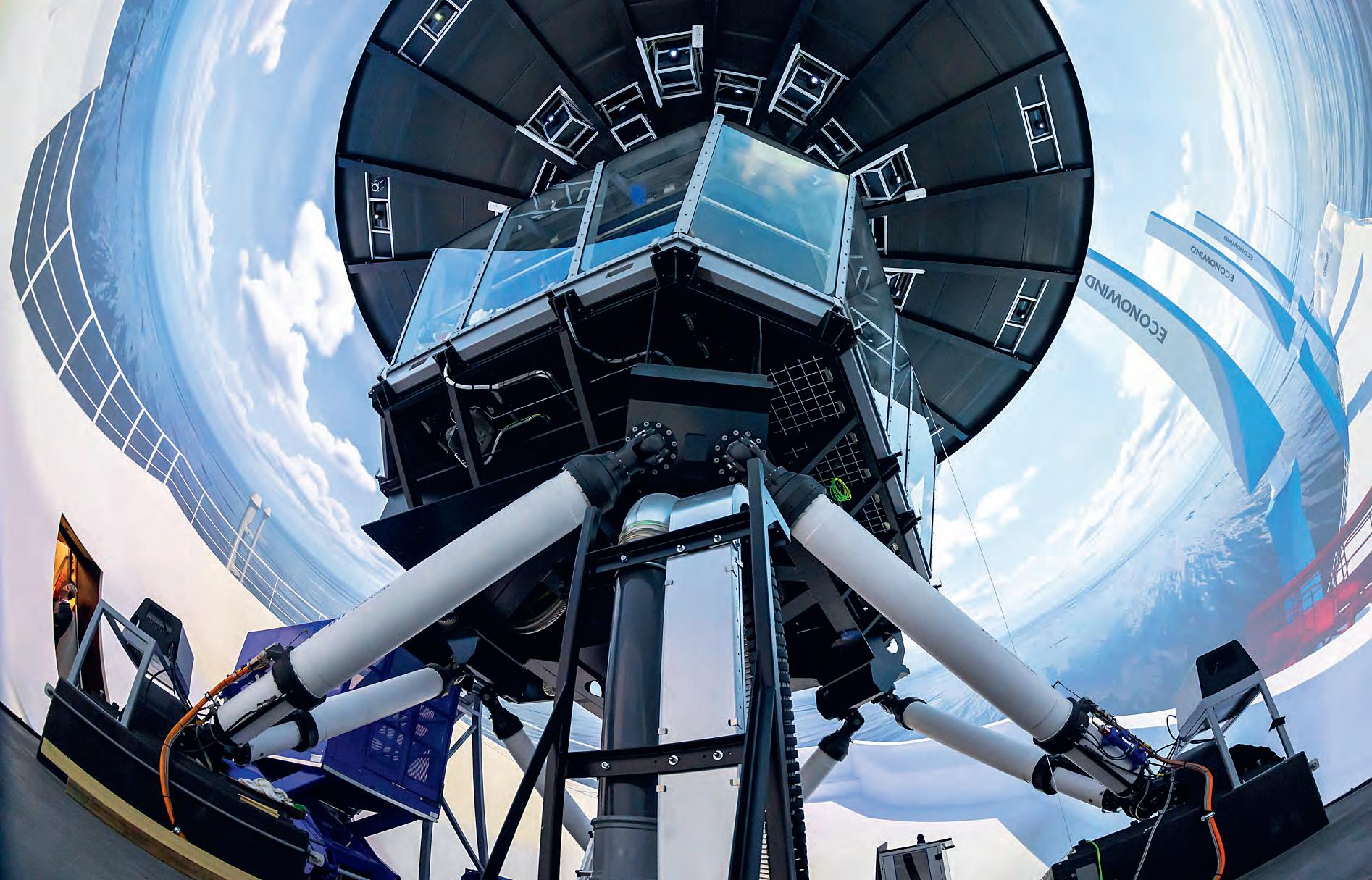

Ten years ago, the first ideas about replacing MARIN's simulator centre were launched. The new centre is now open. It focuses on research and provides the maritime industry with a platform to try out new concepts.

Seawork marks 25th year: Dutch NMT pavilion debut

T he British workboat fair Seawork is celebrating its 25th edition this year. For the first time, there will be a Dutch pavilion. A sign that the UK maritime market is becoming of increasing interest to Dutch maritime technology suppliers.

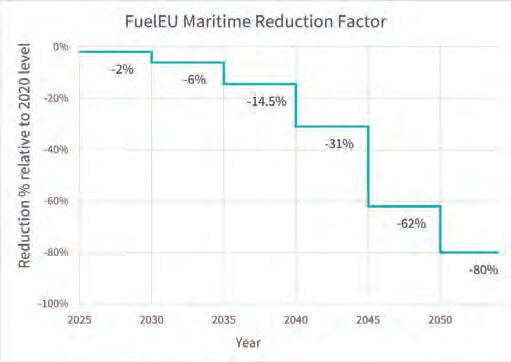

In its headquarters in London, the IMO hosted the 81st session of the Marine Environment Protection Committee (MEPC) in March. Where does the IMO currently s tand when it comes to decarbonisation of shipping?

It’s good to be nice to your neighbours

Dutch shipbuilders and suppliers often travel all around the globe to promote their products hoping to do business. But interesting markets and willing clients can also be found just around the corner. And don’t get me wrong, this doesn’t mean you shouldn't take a plane to South America, Africa, Asia, Australia, or other interesting markets overseas to make deals and bring in money. But sometimes the deals can also be found right here in Europe itself.

Big, world-class Damen, as well as Holland Shipyards, Neptune, both Bodewes yards, Ferus Smit and, in this May edition, Nauplius and NG Shipyards know that there are also orders to be won and money to be made in Europe itself. And not, like the Spanish used to do and the French recently did with the acquisition of the submarine order by buying orders, but by offering craftsmanship and quality at a fair price.

Fascinating is the story of Damen sales manager Frederik van der Linde on how Damen has secured a very strong position in the British market. Damen's success there is partly based on what has made Damen great, ships large and small based on standard designs that function well for years and provide income for their owners.

The invitation came from the organisation behind the Seawork exhibition, but some research revealed that the British market is quite important for many Dutch shipbuilders. And the UK may have left the EU because, in Boris Johnson's caricatured depiction, it no longer wanted to be dictated by the tyranny of the European Commission. But that does not mean that the UK, unlike the EU, has suddenly fallen into barbarism. The UK is also seriously working on making shipping more sustainable.

In that respect, it was very instructive for yours truly to see what the Brits are doing and, in my opinion, this has resulted in an interesting series of articles on maritime business in the UK and what Dutch shipbuilders are successful with in this market. And as a Dutchman, you can be quite proud if, when visiting a British port, especially a smaller one, it turns out to be full of ships made in the Netherlands.

But this May edition also offers real firsts in the form of articles by new, young contributors to SWZ|Maritime. Italy's Elena Prato reports first-hand on IMO's deliberations in its efforts to make shipping more sustainable. A second article worth reading is by Rui Costa, from Portugal, who gives us insight into the latest developments in maritime drones.

Antoon Oosting Editor-in-Chief swz.rotterdam@knvts.nl

Antoon Oosting Editor-in-Chief swz.rotterdam@knvts.nl

IN THIS EDITION

SWZ MARITIME • MAY 2024

Contents

MARIN

introduces its Seven Oceans Simulator Centre

Cover: The UK aquaculture industry has become an important market for Dutch shipbuilders. In 2023, for example, Nauplius Workboats delivered the Isaac Eslea, a hybrid aquaculture service vessel, to Inverlussa Marine Services (photo Nauplius). Can IMO catch up with the EU Green Deal? 12 9 36 4 Dutch news 6 Markets 8 Global news 14 Flourishing maritime trade between UK and NL 19 UK provides important and loyal clients for Damen 22 NG-designed monomaran crew tenders save fuel 26 Nauplius builds boats for fish farming 29 The EU and the decarbonisation of ships 32 Unmanned: An ongoing naval technology revolution 39 Passing the baton of the CEDA presidency 42 Mars Report 44 Verenigingsnieuws KNVTS 46 Advancing sustainability in dredging 3

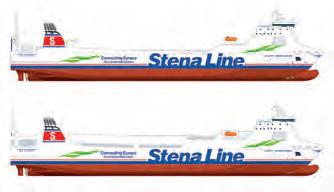

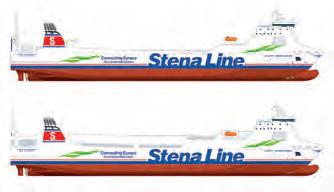

Stena Line converts two vessels to increase cargo capacity

On behalf of Stena Line, Stena RoRo has signed a conversion contract with China Merchants Jinling (Weihai) Shipyard for the installation of an additional cargo deck, increased thruster capacity and preparations for shore power on board Stena Foreteller and Stena Forerunner. Both ships sail under the Dutch flags on the routes Rotterdam-Harwich and Rotterdam-Immingham. With the refit, the cargo capacity will increase by thirty per cent. The vessels will after conversion also be ready to meet future efficiency requirements. The conversion for both vessels will be finalised during 2025 after which the vessels will be

deployed in the Stena Line route network. In 2023, both vessels were decarbonised by changing propellers, applying silicone paint

EMSA deploys RPAS in North Sea with Danish navy

EMSA has begun a four-month remotely piloted aircraft system (RPAS) service in the North Sea, supporting the Royal Danish

Navy and Danish Customs with surveillance. EMSA delivers the RPAS service through the contractor Nordic Unmanned AS, operating a new Aerosonde Hybrid Quadcopter. The Quadcopter has both a fixed wing, enabling it to cover long distances, and four propellers, providing it with vertical take-off and landing (VTOL) capabilities. It is the first time this model has been deployed in an EMSA RPAS operation.

During its deployment, the RPAS will carry out maritime surveillance tasks in the busy waters around the north coast of Denmark.

Oceanco’s H3 wins Best Rebuilt Yacht Award

Oceanco’s H3 took home the prestigious award for Best Rebuilt Yacht at the World Superyacht Awards Gala in Venice, Italy. The goal of the H3 rebuild was to bring a very high-tech yacht from twenty years ago to today’s highest standards in terms of technology, safety, capability and sustainability. The World Superyacht Awards Gala was organised by Boat International Media and took place 3-4 May.

Under the careful supervision of The A Group and Oceanco, H3’s transformation is practically unprecedented in its scale and nature. H3 now also meets the latest environmental standards, including full IMO Tier III compliance.

Although the majority of the yacht’s original

hull remains, practically every other element on board – both technical and aesthetic – has been transformed and modernised, and its length overall now measures 105 metres. H3 displays a modern exterior look, including a completely new superstructure design, with both exterior and interior design provided by Reymond Langton Design.

New data from Oceanco’s Research and Development team shows that thanks to its Tier III compliant set-up, particularly the emission of nitrous oxide has been drastically reduced. As a result, H3’s operational footprint has been reduced by at least sixty per cent. When using an alternative fuel, such as HVO, the operational footprint re-

and adding interceptors, and the additional cargo deck will further decrease the carbon intensity index factor and further reduce CO2 emissions per cargo unit.

Niclas Mårtensson, CEO at Stena Line: ‘The conversion of the Stena Forerunner and Stena Foreteller fits with our ambition to reduce our CO2 emissions. In addition to increasing the cargo capacity by thirty per cent on both the Stena Forerunner and Stena Foreteller, we also take this opportunity to invest in onboard shore power.’ Stena recently also ordered two NewMax hybrid vessels for the Irish Sea routes with China Merchants, to be delivered in 2025.

Environmental monitoring is a key aspect of this service. The RPAS can provide information on potential oil spills and discharges at sea, complementing the CleanSeaNet satellite-based oil spill and vessel detection service provided by EMSA. The RPAS model has more than seven hours of endurance and a radio range of 140 km along the coastline, based on a ground relay station. It also has infrared and optical cameras and is equipped with an embedded automatic maritime scanning sensor.

duces further due to lower CO2 emissions by almost ninety per cent compared to before its rebuild. Furthermore, figures suggest that carbon emissions related to the re-use of steel and aluminium for H3 saved approximately 2000 tonnes of carbon.

4 DUTCH NEWS SWZ MARITIME • MAY 2024

SWZ'S EDITORS

The Stena Forerunner before and after conversion (picture Stena Line).

For the first time, EMSA will deploy an Aerosonde Hybrid Quadcopter (photo EMSA).

H3’s operational footprint has been reduced by at least sixty per cent (photo Oceanco).

Growth spurt for Van Oord’s heavy-lift vessel Svanen

In just a night, Van Oord’s heavy-lift installation vessel Svanen grew 25 metres taller.

As part of a major upgrade, a huge Aframed gantry extension, weighing 1200 tonnes, has been installed on top of the vessel. The operation increased the total height of the Svanen to 125 metres, making it one of the largest heavy-lift vessels in the world.

The extension had been constructed by Holland Shipyards. One of the largest cranes in the world was used for the installation at Mammoet Schiedam. Besides the gantry extension, the upgrade

includes a modernisation of the lifting hooks that will increase the lifting capacity of the vessel from 3000 tonnes to 4500 tonnes, an improvement of the gripper to handle increased loads and a modification of the structure of the vessel to accommodate the latest hammer size. The improved Svanen will be ready for operation in the third quarter of 2024.

MAMII identifies tech that slashes methane slip

London-based Safetytech Accelerator, in collaboration with Capital Gas Ship Management, MSC, and Seapeak, has completed four technology feasibility studies as part of its flagship Methane Abatement in Maritime Innovation Initiative (MAMII). The outcomes of these studies showed strong potential to cut methane emissions in the maritime industry.

Daphne Technology, CDTi Advanced Materials, Inc. (CDTi), Rotoboost, and Plenesys were selected by MAMII from amongst twenty companies to help address the critical challenge of mitigating methane emis-

sions from the exhaust stacks of LNGfuelled ships.

Daphne Technology's methane abatement system outlined a potential reduction of up to 440 metric tonnes of methane annually in container ships. CDTI’s results highlighted how a proven engine catalyst could offer increased methane conversion at lower temperatures than industry norms, with minimal operational adjustments for fleets. Plenesys demonstrated a solution which can effectively reduce methane slip by 78 per cent by converting it to hydrogen, while Rotoboost’s system was found to offer sev-

Feadship launches 118.80-metre fuel-cell yacht

When the drydock doors slid open on 4 May at Feadship’s Amsterdam shipyard, Project 821 emerged, the world’s first hydrogen fuel-cell superyacht. It is also the largest motor yacht ever launched in the Netherlands.

The size of the yacht – 100-metres-plus –made it a good candidate to explore pure green hydrogen as the fuel-cell source. Feadship’s R&D team has been researching hydrogen, among other fossil-free fuel options, as part of the company’s pledge to develop “net zero” yachts by 2030. There were no regulations for hydrogen storage and fuel-cell systems at class, flagstate or even IMO level. Seeking expert partners from allied industries, Feadship, Edmiston and Lloyd’s Register developed

appropriately scaled equipment, protocols and safety regulations simultaneously. From the beginning, one of the biggest hurdles would be developing a reasonable way to store compressed liquid hydrogen below deck at -253°C aboard a luxury yacht. This requires a double-walled cryogenic storage tank. Also, it takes eight to ten times more space to store hydrogen than the energy equivalent in diesel fuel. The fuel cells developed for Project 821 can also use easier-to-store methanol, a liquid fuel in ambient conditions. Steam reforms methanol into hydrogen before the electrochemical reaction in the fuel cell. Even a yacht the size of Project 821 cannot carry enough liquid hydrogen to power a crossing, but it can serve the hotel load.

Due to the worldwide demand for renewable energy, wind farm technology is progressing swiftly, with turbines continually increasing in size. This major upgrade is preparing the Svanen to handle the next generation of monopile foundations for offshore wind projects.

eral benefits including additional revenue from carbon by-products. MAMII hopes to progress these research projects to onship trials as soon as possible.

MAMII was launched in September 2022 by Safetytech Accelerator, bringing together industry leaders, technology innovators, and maritime stakeholders to advance technologies for measuring and mitigating methane emissions in the maritime sector and promote the adoption of validated solutions. It currently has twenty leading shipping and energy companies as anchor partners.

For longer travels or when pure hydrogen is not available, the electricity powering the 3200 kW ABB pod drives comes from MTU generators combusting HVO, a second-generation biofuel that reduces harmful emissions by ninety per cent.

Project 821 is being offered for sale by Edmiston.

5

SWZ MARITIME • MAY 2024 FOR MORE NEWS, VISIT OUR WEBSITE WWW.SWZMARITIME.NL AND SUBSCRIBE TO OUR NEWSLETTER

DUTCH NEWS

Installation of the new A-frame on the Svanen at Schiedam (photo Van Oord)

At 118.8 metres, Project 821 is the largest motor yacht ever launched in the Netherlands.

UNITED KINGDOM OFFERS OPPORTUNITIES FOR MARITIME SECTOR

The United Kingdom (Great Britain and Northern Ireland) may not have been a member of the European Union for four years, but the British maritime market may be more interesting than ever. This is mainly due to the many investment projects launched by the British government, especially in recent years, to make shipping and ports more sustainable. The only condition for sharing in British government support may be to officially open a branch in the UK, which is still fairly easy despite the UK no longer being an EU country. This follows from the “UK market report – Opportunities & developments in the maritime sector”.

This recently released report was written by Els Steger and Maxime Dalida of the Netherlands Business Support Office in Manchester on behalf of the Netherlands Enterprise Agency. It provides a concise overview for SMEs and research institutions of trends, developments and opportunities in the area of making shipping and ports sustainable in the UK maritime sector.

‘North Sea neighbours’

‘The Netherlands and the United Kingdom are both countries in which the maritime sector has traditionally played a major role. Our highly developed relationship of trade and mutual investment go back many centuries. The so-called “North Sea neighbours both have a strong reputation when it comes to shipbuilding, navigation, maritime technology,

ports, logistics and innovation. Building on our shared maritime specialism, we are striving for a green, smart, and sustainable future for this sector. We are pleased to invite you to help us do so,’ write the report's compilers.

The rapporteurs foresee that most opportunities for cooperation and opportunities for Dutch entrepreneurs to enter the UK market are in the area of sustainability: ‘The high level of government attention in the UK to making the maritime sector more sustainable creates opportunities for sharing infrastructure and knowledge, among other things.’

Creating smart ports

Solutions to improve sustainability and digitalisation will create opportunities for Dutch entrepreneurs. 'The British government wants to grow and strengthen the maritime sector, including through investments for economies of scale. Partly due to the emergence of “smart ports”, the demand for products and services for digitalisation and automation is increasing, in addition to sustainable solutions,’ write the compilers of the report.

According to the report, there is a successful and established shipping industry in the UK. The industry contributes £ 10 billion (€ 11.6 billion) to the gross domestic product, provides 240,000 jobs and pays £ 2.5 billion in taxes in the UK. This does make the British sector a bit smaller than the Dutch. In the Netherlands, the direct added value of the combined port and maritime cluster was a whopping € 50.4 billion in 2022. The combined direct employment in the port and maritime cluster in 2022 (measured in employees) accounted for 303,960 jobs in the Netherlands.

Demise of shipbuilding

That significant difference is due in part to the almost complete demise of the UK’s still sizeable shipbuilding industry just after the war, especially in the 1950s and 1960s. The fact that the Netherlands did manage to keep a respectable shipbuilding industry afloat provides the Dutch, with their shipyards and extensive maritime supply industry, with opportunities to participate in the sustainability of British shipping. Because if there is one thing that has always remained very important in the UK, it is the shipping industry that keeps the archipelago accessi-

MARKETS

SWZ MARITIME • MAY 2024 6

MARKETS

ble for the extensive import trade. British exports are considerably smaller. The researchers note that the UK shipping industry still emits too many greenhouse gases and pollutants. UK short sea shipping contributed roughly 5% of the UK’s total domestic greenhouse gas emissions in 2020. ‘That is more than those from all buses and trains in the country combined,’ according to the researchers.

Work to be done

So in that regard, there is plenty of work to be done. ‘Products and services that provide a solution for making this sector more sustainable and developing it further bring opportunities both for further cooperation between our countries, and for entering the British market,’ state the researchers.

After pursuing an absolute laissez-faire policy since the coming to power of British Conservative “Iron Lady” Margaret Thatcher, British politics and government started getting involved in the maritime sector again in 2019 with the release of the Maritime 2050 Strategy. In it, the government sets out how best to respond to future challenges and opportunities. In this policy document, the government makes concrete recommendations for the short, medium and long term within various themes such as technology, infrastructure and environment.

Clean Maritime Plan

This strategy has since led to the formation of organisations, collaborative initiatives and funding opportunities discussed in the report. In turn, the Maritime 2050 Strategy has led to a series of plans such as the Clean Maritime Plan, which describes exactly how the route to achieving the goals around zero-emission shipping should sell.

At the United Nations annual climate summit in Glasgow in November 2021, the Clydebank Declaration was launched in which 24 countries, including the Netherlands, pledged to develop zero-emission maritime links between countries. These so-called “green shipping routes” are to become sea routes that are emission-free from start to finish, including landside infrastructure and the ships that use them.

An update to the National Shipbuilding Strategy launched in 2017 followed in March 2022, which initially focused on naval shipbuilding. With the update, the UK encourages civilian shipbuilding in the UK as well.

Green shipping routes

At the UN climate conference COP27 in November 2022 in Egypt, the Netherlands and the UK followed up on the Clydebank Declaration. Together with Norway and the US, they pledged to create six green corridors. Creating these routes is important for both the Netherlands and the UK to meet the climate goals of the Paris Agreement. Making them a reality will require, among other things, zero-emission fuel, charging points in ports and environmentally friendly ships.

The British government has allocated a maximum of £ 300 million for decarbonising the maritime sector and has set up a new division for this within the Department for Transport, the UK Shipping Office for Reducing Emissions (UK SHORE). UK SHORE is implementing a comprehensive research and development programme in partnership with industry to help build greener ships, from cruise ships to tankers and pleasure craft. The organisation aims to transform the UK into a world leader in the design and production of clean marine technologies. UK SHORE may

distribute £ 206 million in grants, which are also available to Dutch companies registered in the UK.

Great importance

The UK's many ports are of great importance. The researchers found the UK port industry is the second largest in Europe with more than 500 million tonnes of goods shipped annually and more than 60 million international and domestic passengers. The total value of cargo traffic through British ports is estimated at £ 500 billion a year. 95% of the country's imports and exports are through its ports, including 48% of its food and 25% of its energy (oil, gas and coal). The UK has over 120 commercial ports, with the largest twenty accounting for 88% of total cargo traffic.

‘ There are opportunities both for further cooperation, and for entering the British market’

The UK government envisions that UK ports will become part of a digitised and efficient supply chain that is pioneering new business models. Digitalisation and automation are to improve safety and security and reduce labour costs while creating new, highly skilled jobs. In its 2021 budget, the UK government announced investment for a range of maritime initiatives, including the designation of eight Freeports in England, the establishment of a UK Investment Bank and funding for port infrastructure to support the offshore wind energy supply chain.

Netherlands number 1

For the Netherlands, developments in UK ports are very important. With a 13% share of total UK imports, the Netherlands is the UK's main importing country, ahead of the US (11%), Norway (10%), France (8%) and Belgium (6%). The Netherlands is also the leading country for UK exports with a 21% share far ahead of France (9.2%), Belgium (8.3%), Ireland (8.3%) and Germany (5.5%).

According to the researchers, the opportunities that the British market offers to the Dutch maritime sector are the new economic clusters to be created in British port areas through the implementation of Freeports, taking advantage of the benefits of new digital and automated processes through smart ports, the increased demand for storage locations, improving connectivity through digitisation and blockchain technology and the increased need for cyber security.

Antoon

Oosting

Freelance maritime journalist and SWZ|Maritime’s

Editor-in-Chief, swz.rotterdam@knvts.nl

SWZ MARITIME • MAY 2024 7

18

Preventing the loss of seaborne containers

IACS Unified Requirements strive to improve box industry safety

GLOBAL NEWS

By Hyungmin Cho, IACS Hull Panel Chair

TPreventing the loss of containers

issues, jeopardise safe vessel traffic, and even pose an environmental hazard, if they contain dangerous goods. As illustrated in Figure 1, it is noticeable that the approximate number of containers lost at sea has recently increased. This contradicts the zero-containerloss policy that the stakeholders of the maritime container segment are striving for.

Despite efforts and technological advances towards minimising container loss, there are still serious concerns regarding this subject. The graph below show the approximate number of containers lost at sea.

he maritime container sector is the backbone of world trade and covers the worldwide carriage of some 80% of all goods. The 102 million metric tons of containerised goods transported in 1980 had grown to about 1.83 billion metric tons by 2017ii, demonstrating the importance of container trade to global commerce. Despite efforts and technological advances towards minimising container loss, a large increase in the number of transported containers has reaffirmed concerns regarding the loss of containers. Containers lost overboard imply economic

Following the investigation report of the MSC Zoe incident prepared by the IMO SubCommittee III-8 Correspondence Group (III8 CG), and interaction with the International

Figure 1: Approximated number of containers lost at sea i

Approximated number of containers lost at sea.

i IMO CCC8/11 2022, Development of measures regarding the detection and mandatory reporting of containers lost at sea that may enhance the positioning, tracking and recovery of such containers. Estimate of containers lost at sea, submitted by the World Shipping Council (WSC). ii iUNCTAD, 2017. Review of Maritime Transport 2017. United Nations Conference on Trade and Development.

The International Association of Classification Societies (IACS) assessed the safety issues related to the loss of containers and initiated a task force project. Comprising experts from member societies and approaching the problem from three aspects: operation, design and maintenance. This work should lead to unified requirements for container securing systems, lashing software and requirements of allowable wear, tear and corrosion of securing systems. These unified requirements are planned for completion in 2024 with implementation by member societies in 2025. (IACS Annual Report)

Sailing on cashew nut shells

Shipping company United European Car Carriers (UECC) collaborates with Wärtsilä, Lloyd’s Register and biofuel supplier ACT group to assess and evaluate a cashew nut shell liquidbased (CNSL) biofuel. ACT created a CNSL-based biofuel known as FSI.100, achieved through a development process including extensive engine testing and a controlled supply chain. Following testing on various blend combinations, FSI.100 received approval from engine manufacturers as a thirty per cent blend component in an ISO 8217 DMA grade distillate fuel to carry out sea trials. CNSL-derived fuels reduce waste and increase resource efficiency, aligning with circular economy principles. FSI.100 uses sustainable land use practices and exhibits maritime fuel properties, such as ultra-low sulphur and winter spec pour points. It delivers significant greenhouse gas savings. (electrichybridmarinetechnology)

Union of Marine Insurance (IUMI), IACS assessed the safety issues related to the loss of containers and initiated a task force project within the Association’s Hull Panel. The project comprises experts from different member classification societies and approaches the problem of container loss at sea from three aspects: operation, design, and maintenance.

Piracy up, hostages need saving

Lashing software is deemed to be the dominant solution in enhancing the safe seaborne transportation of containers. The Hull Panel is therefore developing Unified Requirement C6 (UR C6) to harmonise the performance standards and requirements for lashing software. Furthermore, the Hull Panel’s submission to IMO’s CCC8 to recognise lashing software as an additional means to supplement container stowage and securing plans, included in approved cargo securing manuals, received support in principle. However, the general view of the sub-committee was that harmonised performance standards and guidelines are required to permit the approval of lashing software to be carried out in a consistent manner. Consequently, a new output proposal was prepared by the Hull Panel and submitted to MSC 107 to introduce the supplementary use of lashing software together with the development of performance standards for lashing software to allow for uniform approval by flag State Administrations. Additionally, a follow-up proposal to revise the ‘Revised Guidelines for the Preparation of the Cargo Securing Manual’, (MSC.1/Circ.1353/

Global piracy and armed robbery incidents increased again in 2023 after a two-year drop, with the first quarter of 2024 following suit. While the Gulf of Guinea waters and the Singapore Strait stand out as long term piracy hotspots, the return of Somali pirates in the Western Indian Ocean raises concerns, as does the increasing use of violence against crews. On a related subject, the world leading shipping associations have highlighted the inequality seafarers face as hostages. In April, the Iranian Navy hijacked the 15,000 TEU MSC Aries. Meanwhile a car carrier, the Galaxy Leader, having been hijacked months ago by the Houthis, was held in Yemeni waters. Somali pirates have abducted two ships off the Horn of Africa. An open letter by sixteen shipping organisations to the United Nations secretary-general, Antonio Guterres, states: ‘Innocent seafarers have been killed, seafarers are being held hostage. This would be unacceptable on land, and is unacceptable at sea. The world would be outraged if a couple of airliners were seized and held hostage with innocent souls on board. Regrettably, there does not seem to be the same response or concern for the commercial vessels and their crews being held hostage.’ (Lloyd’s List, Gard and Splash247)

EU fishermen catch fewer fish

In 2023, EU fishermen caught 2.8 million tonnes of live weight fish. Down from around 6 million tonnes in 2000, according to EU figures. As the effect of Brexit will take place over the period 2021 to 2026, these figures have not yet been seriously affected by Brexit. It has been a more or less gradual downturn from 2000 to 2023. In the same period, the amount of fish produced within the EU by aquaculture was about constant at 1 million tonnes. As a consequence, the EU needs to import much more fish. According to figures recently reported by the Dutch fish processing and wholesale organisation, the demand for fish of EU consumers is such that each year some 9 million tonnes of fish have to be imported from outside the EU. Our country needs 2.1 million tonnes of imported fish for its total consumption of about 2.5 million tonnes. In the Netherlands, these relatively fast changes in the fishing industry have led to a growing fish processing and trading business, importing, processing and selling fish, in total employing some 7000 workers with a turnover of about € 4.5 billion. (Visserijnieuws and EU figures)

Global news gathers news from different media. Our website, www.swzmaritime.nl, also covers global maritime news. Receive the latest maritime news directly in your inbox by subscribing to our newsletter. Scan the QR code now!

8

SWZ MARITIME • MAY 2024

IR WILLEM DE JONG, WILLEM.DEJONG3@GMAIL.COM

6000 5000 4000 3000 2000 1000 0 3 Year moving average Total loss 20082009 2010201120122013201420152016201720182019 20202021

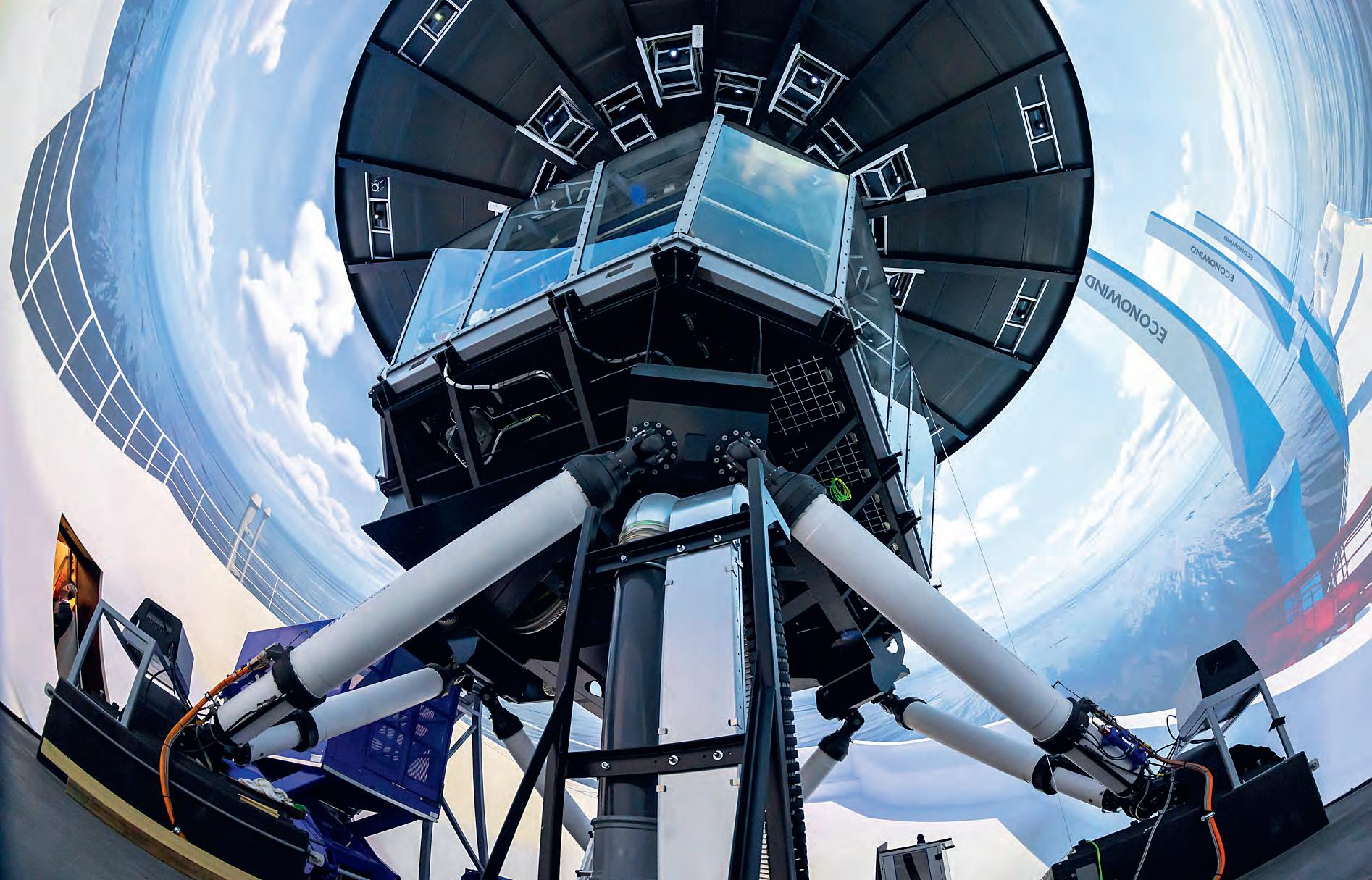

MARIN INTRODUCES ITS SEVEN OCEANS SIMULATOR CENTRE

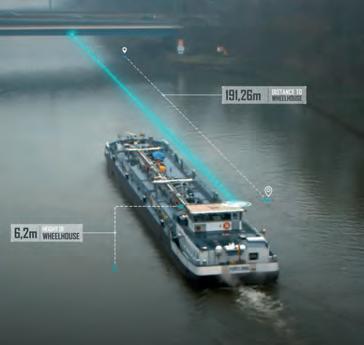

The Maritime Research Institute Netherlands (MARIN) is perhaps best known for its tank test facilities. But since the early seventies, bridge simulations have played a significant role. Between 1992 and now, a bridge simulator centre was operated consisting of several full mission bridges and a number of small part task simulators. Ten years ago, the first ideas about replacing this centre were launched. The new simulator centre is focused on research and provides the maritime industry with a platform to try out new concepts.

Bridge simulators have always played an important role in MARIN’s portfolio. Since long, they have been the link between the operational concept and the actual operation on board. This link is even stronger now with the Seven Oceans Simulator Centre (SOSc). New state-of-the-art simulators offer unprecedented possibilities to simulate all aspects of operations at sea and give the human operator a central stage. Having access to modern test basins and the latest computational fluid dynamics (CFD) tools, the hydrodynamic and seakeeping behaviour of our manoeuvring and motion models has always been our strong point. Together with the inhouse developed Dolphin simulation software. Now, this is complemented with brand new simulator facilities and up to date visual rendering techniques. The ambition is to make maritime operations, port and fairway lay-outs and ships (equipment) safer and more efficient with the most realistic simulations of the behaviour and interactions of maritime constructions, the environment and the human operator.

Wide views, motions and manoeuvring

The working horses of the SOSc are the two large ship simulators

LMS and FMB. LMS stands for Large Motion Simulator, and that is exactly what it is. This is truly a one of a kind facility, consisting of a ship’s bridge fitted on a motion base assembly. Unique is that the bridge is surrounded by a spherical screen on which the outside world is projected. This gives a very large vertical field of view that makes it possible to see the quay directly next to the ship, when mooring. This is also very relevant in ship-to-ship, seabasing and launch and recovery operations. This large vertical field of view is also necessary to ensure that the bridge team remains immersed in the scene, whilst undergoing large motions. The motion platform is capable of angles up to 30°. All ship operations in which motions play a significant part can be simulated realistically. Think of, steering in high waves, operating wind-assisted vessels, parametric rolling or research into capsizing events. Now, this facility offers the opportunity to conduct human factor research and development under these conditions with a team of operators.

The Full Mission Bridge (FMB) is a very large bridge simulator. It is 16 metres wide and equipped with two bridge wing positions. It provides sufficient room for a large bridge team, with multiple flexible work spaces. Flexibility is the key word here. Not only the controls

9 SWZ MARITIME • MAY 2024 RUBRIEK SIMULATIONS

Photo: The Large Motion Simulator is a 6° of freedom motion-based bridge of 4x5 metres on a hexapod with a payload of 14,000 kg and 360° projection in a large spherical dome with a diameter of 16 metres (all pictures by MARIN).

SIMULATIONS

The Full Mission Bridge is a 16-metre wide bridge with a forward and backward (flat screen) view on a cylindrical screen (240° horizontally and 42° vertically). Both bridge wings have 6-metre diameter domes to allow for forward, backward, downward and upward views.

All simulators in the SOSc can be coupled and operated from various operating stations

can be easily changed, also the set-up of the consoles can be re-arranged, ranging from a typical T-console and a one man bridge, to a twin battery of consoles typically found on cruise vessels. A lot of attention has been paid to details, creating the look and feel of a large modern ship. The bridge wings have their own spherical projection domes and together with the main projection, they provide 360° coverage. From the bridge wings, you have excellent views along the ship, perfect for manoeuvring close to the berth, side-by-side another ship or when conducting launch and recovery operations. In essence, this simulator is ideal for manoeuvring simulations with a large variety of ship types.

Multi-Purpose Simulators

For the simulation of smaller ships, four Multi-Purpose Simulators (MPSs) are available. These versatile simulators can be used for smaller vessels, such as tugs, inland vessels and suppliers. They

consist of a one-man bridge set up, with radar, ECDIS, conning and alarm screens. Visuals are provided through large TV screens in portrait mode, providing a 360° view. Two of the MPSs are equipped with additional screens on floor and ceiling, so they can be used for crane operations.

All simulators in the SOSc can be coupled and operated from various operating stations. This makes it possible to conduct simulations where a large ship (on the LMS or FMB) is assisted by one to four tugs operated from MPS simulators. In the near future, MARIN will also couple to other simulators outside MARIN.

Traffic & Mission Control and Maritime Experience lab

One of the new features in the SOSc is a Traffic & Mission Control room. The T&MC will function as a laboratory to test new Vessel Traffic Services (VTS) concepts and innovative solutions for remote/ unmanned control operations. It can be coupled to the other simulators, and as such, it also provides the capability for large scale crisis response exercises, in which manned simulated vessels can cooperate in coordinated rescue operations.

Another novelty is the Maritime Experience lab. The MX lab with its large open floor plan, offers the possibilities to mix virtual reality applications (virtual, augmented and mixed reality) with all kinds of motion platforms. With this mix, MARIN is able to include other parts of the operations on board of vessels, beside the navigation bridge. For example, the sailors working on the deck of an offshore

10 SWZ MARITIME • MAY 2024

RUBRIEK

RUBRIEK SIMULATIONS

supply or navy vessel can now be included. The Fast Small Ship Simulator with its motion base and a cable robot are some of the features of the MX lab. One of the projects already scheduled in the MX lab is the development of a set-up to test concepts for pilot boarding.

Human operator in focus

All the calculations and visualisations necessary to run the simulations are performed in the high performance computer centre. The computers are connected through a fibre optics network to all the controls and displays of the simulators. The combination of central processing units (CPUs) and graphics processing units (GPUs) provide the computing power to include highly complex hydrodynamic calculations.

Wearable sensors enable MARIN to “catch” the human factor even better

However, the human operator will be the centre of focus. For this reason, a specially developed toolkit with wearable sensors has been developed that allows

the researcher to observe specific human factor measures (eye-trackers, heartrate, galvanic skin response and so on) and log this data together with all technical data coming from the simulators. This will enable MARIN to “catch” the human factor even better.

Safer and more efficient

The SOSc includes four fixed and two mobile Instructor Operator Stations from which the simulations are controlled. It is possible to simulate with whatever combination of simulators in one scenario. Excellent debriefing facilities offer extensive replay functionality. Everything with the aim to provide the research facility with which MARIN can make maritime operations safer and more efficient with the most realistic simulations of the behaviour and interactions of maritime constructions, the environment and the human operator. The SOSc will be officially opened on 28 May.

Dimitri van Heel Senior projectmanager/teamleider Maritime Operations, d.v.heel@marin.nl

Dimitri van Heel Senior projectmanager/teamleider Maritime Operations, d.v.heel@marin.nl

11 SWZ MARITIME • MAY 2024

The Traffic&Mission Control room is a multi-purpose and flexible control room with projection on three walls to simulate command and control centres on board or ashore, and operator stations for VTS and remote control operations.

SEAWORK MARKS 25TH YEAR: DUTCH NMT PAVILION DEBUT

The British workboat fair Seawork is celebrating its 25th edition this year. For the first time, there will be a joint stand of Netherlands Maritime Technology (NMT), the Dutch maritime manufacturing industry's interest organisation. A sign that the UK maritime market is becoming of increasing interest to Dutch providers of maritime technology, from working vessels to a broad package of maritime equipment that the UK desperately needs to make its shipping and ports more sustainable.

The fair takes place from 11-13 June at Mayflower Park, in the old part of port city Southampton's centre on the River Test. It is near the cruise terminal at the site from where the disaster ship Titanic once departed for what would be its first and last dramatic crossing of the Atlantic. The fair includes 12,000 m2 of exhibition space. NMT is at the fair with a Dutch pavilion that houses fifteen Dutch maritime small or medium-sized enterprises (SMEs). In addition, there are about fifteen more Dutch suppliers with their own stands, such as Damen Shipyards, offshore shipowners Acta Jifmar from Den Helder and Seazip Offshore Service from Midlum, and shipbuilders Nauplius Workboats from Groningen, Next Generation Shipyards from Lauwersoog and Neptune Marine from Hardinxveld-Giessendam. NMT is hosting an NL Networking Event with drinks on Wednesday, 12 June, between 3 and 5 pm at the Waterfront Restaurant.

Demonstrations with ships

As a trade fair, Seawork has grown steadily since its inception in 1998. From 1000 visitors in its inaugural year, last year's show at-

tracted 7200 visitors from sixty countries. The fair also incorporates sister event Marine Civils, Europe's leading event dedicated to showcasing the latest equipment and solutions for marine, coastal and other challenging civil engineering projects with unique landscape features. Adjacent to the waters of the Port of Southampton, the fair also provides an opportunity to exhibit and demonstrate workboats. More than seventy vessels and other types of craft are expected for demonstrations on the water. The eighteen conferences were attended by more than 1000 visitors last year, and forty new products and services were presented at the fair itself. Seawork also provides an opportunity to get in touch with organisations and governments for a chance to participate in the many projects especially in the field of achieving climate goals. Also see our Markets section on pages 6-7 of this issue of SWZ|Maritime.

Conferences

The popular and highly regarded conference programme for Seawork 2024 will be focussed on “The future fuel matrix & OPEX reduction”. Decarbonisation to reduce emissions and costs remain

12 SWZ MARITIME • MAY 2024 SEAWORK

Photo: More than seventy vessels and other types of craft are expected in Southampton for demonstrations on the water (photo Seawork).

SEAWORK

top of the agenda at Seawork. The conferences will share insights and learnings on key themes that are at the forefront of discussions across the industry. The free to attend bitesize sessions will tackle how the latest regulations are driving change for fleet operators, vessel manufacturers and designers, what cutting edge technology is delivering for the commercial marine sector in the race to provide future fuel options, plus, the advantages and challenges with battery technology for commercial marine applications including workboats in meeting their day-to-day operational needs.

Session 1 is on green technology – the impact of regulatory changes for workboats and how this is driving change. The session “The future fuel mosaic” deals with the latest developments in methanol, hydrogen, and sustainable future fuels. The third session is about battery technology, an opportunity, or a challenge for workboats?

Government services

Government agencies such as the National Shipbuilding Office (NSO), the Ministry of Defence (MoD) and the Department for Business and Trade (DBT) have a strong presence at the fair to inform and, where possible, encourage developments and innovations. The NSO oversees implementation of the National Shipbuilding Strategy Refresh, providing strategic oversight of all the government's interests in UK shipbuilding and its supply chain. The NSO's mission is to collaboratively support growth across the sector, encouraging innovation, promoting skills, improving productivity, and driving international competitiveness.

The MoD is always looking for good suppliers or providers of maintenance both nationally and internationally, and the DBT has budgets available for innovative projects in which Dutch companies may be able to participate through collaboration.

Increasingly international

Since its inception in 1998, the fair in Southampton has become increasingly international. Last year, more than a quarter of exhibitors came from overseas, with twenty per cent from Europe and the rest from elsewhere in the world. To further facilitate the international exhibitors, this year, for the first time, there are two country stands. In addition to that of NMT, Seawork also welcomes an Italian pavilion, organised by the Italian Maritime Industry Association Confindustria Nautica, a national non-profit institute representing the Italian superyacht industry nationally and internationally since 1976.

Opening by Princess Royal Mercator Media, organiser of Seawork, is delighted to announce that Her Royal Highness The Princess Royal Anne MountbattenWindsor, sister of King Charles, will officially open Seawork on Tuesday, 11 June, marking Seawork's 25th anniversary. The Princess Royal has visited Southampton many times, but this will be her first visit to the city’s Mayflower Park for the Seawork exhibition. Seawork offers a combination of purpose-built undercover exhibition space, open air displays and over seventy vessels, floating plants and equipment on the quayside and pontoons. Attendees include representatives of the UK government and agencies, industry associations and experts, port users and customers, maritime chari-

ties, apprentices and academia. Seawork has many longstanding strategic partnerships with relevant industry associations that offer support to their members at the event.

Very special year

Decarbonisation to

reduce emissions and costs remain top of the agenda at Seawork

Andrew Webster, chief executive, Mercator Media, says: ‘Seawork is honoured that Her Royal Highness the Princess Royal has chosen to officially open the 25th anniversary edition of Seawork. Her visit marks a very special year for Seawork and for everyone involved in this vibrant sector of the maritime industry. Seawork is the key meeting place for the commercial marine industry, welcoming an international audience of visitors and exhibitors each year. The exhibition provides an international platform for commercial marine businesses to connect with buyers, network with their clients and discuss innovations and solutions within their respective industries.’

Innovation Awards

To celebrate the 25th edition, new categories have been introduced of the European Commercial Marine Innovation Awards (ECMAs). The awards are designed to showcase the extensive progress made in design and technology in the commercial marine industry. The new Innovation Awards reflect the shifts in industry focus, towards decarbonisation, sustainability, automation, alternative energy, and propulsion. Judged by a panel of industry experts, chaired by the editor of Maritime Journal, the ECMAs are presented at the awards evening on Tuesday, 11 June. The categories for the Innovation Awards are Vessel Design & Construction, Marine Power & Propulsion, Safety & Training, Underwater Intervention (Diving & Underwater Technology), and Marine Equipment & Materials. New are Electronic & Electrical Systems, Navigation & Communication, Autonomy, Environmental/Renewable Energy and Deck Equipment. The categories for the People & Project Awards are Marine Civils Best Project, Maritime Sustainability, Young Person’s Development, Maritime Professional of the Year, and Lifetime Achievement.

Antoon Oosting

Freelance maritime journalist and SWZ|Maritime’s editor-in-chief, swz.rotterdam@knvts.nl

13 SWZ MARITIME • MAY 2024

FLOURISHING MARITIME TRADE BETWEEN UK AND NL

Over 25 Dutch companies at Seawork

More than 25 Dutch companies exhibit at Seawork, the largest wet shipping fair for commercial marine and workboats in Europe. It takes place in Southampton from 11 to 13 June.

One of the Dutch companies is Fender Innovations from Wieringerwerf, manufacturer of flexible custom-made fenders for work vessels, naval vessels, SAR vessels, superyacht tenders, and so on. The fenders can be produced in any desired shape and length, have a smooth surface and are up to twelve times lighter than traditional rubber fenders, which can result in significant operational cost savings.

Since 2012, Fender Innovations has been present at every exhibition and operational manager Sylvia Ruizendaal is still enthusiastic about it. ‘It is a relatively small exhibition that really focuses on the smaller work vessels, ribs and fast-sailing work vessels. The exhibition is excellently organised. The fair is visited by large and small shipowners looking for solutions to issues they encounter in practice. As a specialist in fender systems, we can provide solutions for issues in this area.’

The fenders from Fender Innovations have a closed cell foam core protected by a strong layer of polyurea, reinforced with other materials if necessary. ‘All materials we use for production are adapted to our wishes,’ says Ruizendaal. ‘As technical development never stands still, new materials and techniques are being tested thoroughly and added to improve our fender systems. We are an innovative company in that respect. From the start, we have been building fenders that will last a ship's life under normal use, but when you compare the fenders of the past with those of today, they have be-

come even better. We have excellent in-house draftsmen, milling programmers and instructors. We train our employees internally and have sufficient staff with sufficient recruitment. We are a great family that helps and supports each other.'

Sturdy workboats

A completely different Dutch company at the fair is Tideman Boats from Hoorn, which specialises in the construction of fast workboats. The black high-density polyethylene (HDPE) hulls of these boats are maintenance-free and do not require fenders at all. According to director and owner Bruno Tideman, the material is indestructible. This year Tideman will be at Seawork for the fifteenth time. ‘Seawork is one of the few wet shows for workboats,’ says Tideman. ‘Every workboat has its unique selling point and sells best when the customer can take a test run. That is better than standing at a dry fair with a boat on a trailer in a large hall. Furthermore, in the workboat world, it is important to show that you are still there. That works better than fancy websites. Customers want to see the product and the people behind it.’ Tideman also experiences the fair in Southampton as a bit of a holiday. ‘The weather is always nice, and it is nice sailing on the Solent.’

Yet, it may be the last time Tideman exhibits at Seawork. ‘We are organising a wet workboat show in Hoorn with all Dutch workboat

14 SWZ MARITIME • MAY 2024 SEAWORK

Photo: Tideman Boats built a series of fast pilot boats for P&O. This pilot boat (11 x 3.20 metres) is now sailing in the port of Maputo (Mozambique), where P&O provides pilotage and other services (photo Tideman Boats).

SEAWORK

builders on October 15, 16 and 17. If it is a success, we will organise it again in spring next year. Then our Dutch customers no longer have to come to England to test the workboats, which is simply not very convenient for them. Moreover, there are no speed restrictions on the Markermeer, and you have plenty of space. In Hoorn, we are with six boat builders close together and are having a party in October. So, it is probably the last time I'll be at Seawork.’

Financial innovation

‘Customers want to see the product and the people behind it’

Beequip MKB Equipment Lease from Rotterdam is specialised in financial engineering. Beequip exhibits at Seawork for the second time. The company provides financing with lease constructions for heavy equipment such as cranes, trucks and ships. A shipping company can sell ships to Beequip and rent them back via a Sale & Lease Back contract. The company pays back an agreed amount per month and at the end of the contract it regains full ownership of the ships. The money released in this way can be used for growth or the acquisition of another company.

‘We find anything larger than a company van interesting for this kind of financing, including ships,’ says Beequip's marketing and events coordinator Kevin van ‘t Oor. ‘When we provide financing, we strongly focus on the equipment's value. This also allows financing of used equipment, which

DCBright developed the world's first full 316 Stainless Steel LED floodlight. With 42,000 Lumens, it can light up an area of up to 600 metres (different beam options available). The 316 stainless steel housing offers protection against corrosion and weighs just 16 kilogrammes (photo DCBright).

is of interest to SMEs. We look at the equipment and share our risks with several financiers. For us, the maritime market is an interesting market where the equipment keeps its value well. The UK is interesting in this respect as an island. Everything is by ship and the laws and rules are like those in the Netherlands. That is nice, and the UK is by nature a leasing country. That makes it easier to talk.’

15 SWZ MARITIME • MAY 2024

The Bolder is the first of a series of three fully electric Harbour 110 Line Handling Workboats that Stormer Marine is building for the Royal Netherlands Navy (photo Royal Netherlands Navy).

SEAWORK

In addition to financing used ships, Beequip offers financing with lease contracts for new ships. Beequip has a strong financial partner. ‘We apply our own rules and operate independently. We work with the NIBC Bank for our financing.’ This investment bank is based in The Hague and has belonged to the Blackstone Group since 2021.

According to Van 't Oor, Beequip’s employees have in-depth knowledge of the equipment they finance. ‘Our people have years of experience in the field of heavy equipment, trucks, or ships. They are all people who come from the market. During Seawork, I will be at the fair with sales director workboats and maritime equipment Joost van den Berg. He worked at Damen for years, knows how ships work, understands the customers, and can assess the risks well. At our coffee stand at the Workboat Association, you can get a nice barista coffee.’ Companies and their customers can go to Beequip, have coffee, and talk about financing. ‘Last year, it was very busy,’ says Van 't Oor. ‘It is an interesting fair for us.’

Innovative battery systems

Est-Floattech from Badhoevedorp specialises in maritime battery systems. It presents an innovative “Octopus Series” battery system at Seawork. This system is specifically designed and certified (DNV, Bureau Veritas and Lloyd’s Register) for commercial maritime applications.

For EST-Floattech, the UK is a potential growth market. ‘We see that electrification of the maritime sector in the UK is catching up. This transition is partly accelerated by local government subsidies,’ says marketing and communications manager Frederique Hoppe. ‘That makes Seawork interesting as it is known for the high visitor numbers and the strong focus on workboats.’

EST-Floattech is involved in several British projects, including the supply of a 2400-kWh EST-Floattech Octopus High Energy battery system for the E-LUV (Electric-Landing Utility Vessel), which is being built on the Stornoway-based shipyard of Coastal Workboats. The E-LUV will be the UK's first fully electric workboat.

EST-Floattech also supplies the Shore-based Power Supply System (SPSS) for the E-LUV and an additional 1200-kWh Octopus High Energy battery system in a 20-foot container to support the charging of the vessel's battery system. It is also possible to place the energy container on board as a range extender.

EST-Floattech will also deliver battery systems to the Wight Shipyard for installation in new ships for London's Thames Clippers. Service engineers from EST-Floattech take care of the commissioning of the battery systems in the UK.

Azimuth thrusters

Azimuth thruster producer Hydromaster from Rotterdam exhibits at Seawork for the eighth time. Hydromaster specialises in the production of azimuth thrusters in a power range of up to 1 MW. The originally British company came into Dutch hands in 2015 and moved production completely to the Netherlands after Brexit. In recent years, Hydromaster strengthened its position on the Dutch and European market, and also remained active in the UK, where it is still an established name.

‘We have several contracts in England for the supply of azimuth thrusters,’ says sales director Jan Terlouw. ‘We are currently building a set of azimuth thrusters for a 24-metre fully electric ferry currently under construction for Thames Clippers by Wight Shipyard. It will sail in the area around Canary Wharf crossing the Thames river. We also supply two 210-kW azimuth thrusters for the fully electric E-LUV workboat that Coastal Workboats builds (in collaboration with Damen).’

Hydromaster is building fifteen heavy-duty deck mounted azimuth thruster units for the British Ministry of Defence (MOD) to propel so-called Mexeflote pontoons. These modular landing vessels are used by the United Kingdom's Royal Logistic Corps (RLC) to move goods and vehicles between navy ships and the shore. ‘This is a great contract we have been working on for years,’ says Terlouw. The RLC is based at Marchwood, opposite the Seawork venue at Mayflower Park.

Another project Hydromaster is working on is the build of a 40-metre DP2 diesel electric multi-role vessel, currently under construction at Freire Shipyard in Spain for UK operator Briggs Marine. This vessel is being equipped with two 640-kW Hydromaster azimuth thrusters in combination with two 315-kW tunnel thrusters.

Another vessel getting close to completion is a research vessel for Marchall Jakeman Marine Ltd, fitted with an azimuth thruster for DP purposes.

A long-standing reference in the UK for Hydromaster are the two 60-metre double ended ferries operated by Transport for London. For over six years, these ferries have been crossing the Thames River at Woolwich.

Rim drives

RIM Drive Technology from Wanraay exhibits at Seawork for the first time. RIM Drive makes electric shaftless pod propellers and bow thrusters, known as rim drives.

‘We started development in 2016 and officially founded the company in 2019,’ says sales associate Lennaert van den Berg of Rim Drive

16 SWZ MARITIME • MAY 2024

Mounting of an 11-kW rim drive pod in the workshop of RIM Drive Technology at Wanraay (photo RIM Drive Technology).

SEAWORK

Technology, which builds E-pods with power ranges from 0.5 kW to 50 kW. A 75-kW RIM Drive is currently under development.

‘We are showing our entire product range at Seawork, including a steerable RIM drive pod propeller. We will hang it in a water container to be able to demonstrate our innovative rim drive technology. Visitors will have the chance to experience our steerable pod in action. You don't see many shaftless propellers yet, so we expect that we will be quite unique at the fair. Entering the British market more actively is a strategic goal for us at this exhibition.’

‘Entering the British market more actively is a strategic goal for us at this exhibition’

The Rim Drive pods from RIM Drive Technology have an aluminium housing, filled with epoxy. The tube of the RIM Drive contains a stator with a permanent magnet. The rotating inner ring with the propeller blades holds the rotor. The propeller blades are made of plastic composite. The pods are offered in capacities from 0.5 to 50 kW. The Rim Drive azimuth thruster is a direct electric drive thruster using permanent magnet

technology, with low environmental footprint. The permanent magnet (PM) motor does not need an internal cooling system or lubrication pumps.

Crew agencies

Two Dutch crew agencies are active at Seawork, Orca Crew Services from Middelburg, and Delta Marine Crewing from Vlissingen. Delta Marine wants to further increase its customer contacts and maintain the existing contacts.

‘There are crew shortages across the EU that will only increase in the coming years and the UK is no exception to this,’ says Jack Zeijderveld of Delta Marine. Recruiting sailors in countries where this does not yet happen offers new opportunities to solve this problem. ‘But when all the maritime companies subsequently appear there, a source from which we can recruit well quickly produces fewer candidates,’ says Zeijderveld. ‘And new countries must be recognised by the Ministry. You cannot recruit everywhere. There must be a plan behind it and that differs per country.’

Although there are crew shortages in the UK, Delta Marine works with English sailors on certain projects. ‘On some projects, this is extremely attractive, and it works well. These are tailor-made solutions for specific situations that require attention. But we can still meet the needs of our shipowners quite reasonably.’

Innovative work deck lighting

The Dutch-Chinese company DCBright is exhibiting for the first time at Seawork. DCBright manufactures efficient LED lighting products

17

In November 2023, Fender Innovations supplied the engineering, production and mounting of an innovative, ultra light fender system for the new pilot vessel Golden Gate of the San Francisco Pilots USA (photo Fender Innovations).

for industrial, construction, sports, and off-road applications. It is now expanding its activities to the maritime world.

‘DCBright will be at the fair with fixtures and floodlights for ships and platforms,’ says contact person Jaap de Graaf. ‘A good example of our maritime activity is the deck lighting on the Bokalift 2 from Boskalis. We are also doing projects with Mammoet. With our new floodlight line, we focus on the maritime sector.’

For the maritime floodlight line, DCBright uses stainless steel fixtures and housings. ‘That is quite unique because stainless steel conducts heat much worse than aluminium,’ says De Graaf. ‘Stainless steel lamps from competitors often contain aluminium parts for the heat transfer, but this is no longer present in these fixtures.’

DCBright makes lighting plans to properly illuminate work decks.

‘On fishing vessels, they often hang a few lights and when it is not enough, they hang up some more,’ says De Graaf. ‘We first make a 3D drawing of the ship and look where the lights can hang best and how we can illuminate the ship properly from there. Our stainlesssteel fixtures may be more expensive, but if you need fewer fixtures, due to a good lighting plan, it may still be cheaper. The Dutch installer Piet Brouwer, from Urk, is now testing our new floodlight line on a fishing vessel. We will receive his feedback soon.’

The 316L stainless steel LED floodlight fixtures should last a ship's life or longer. DCBright's production in China is managed by Dutchman Niels Woelders, who emigrated with his family to Shanghai. Woelders is the managing director of DCBright. The

designing offices are in the Netherlands and Australia and the production base is in China.

Stormer Marine

Stormer Marine has a shipyard in Hoorn and builds aluminium workboats for professional clients worldwide. The company has a lot of experience in building electric and hybrid workboats. Using aluminium makes them considerably lighter than when steel is used.

Stormer builds workboats for different applications such as tugs, patrol boats, rescue boats, porter boats, harbour boats, and RIBs. Motorisation options are gasoline, diesel, electric or hybrid.

All technical components come from renowned suppliers such as Yanmar, Steyr, Volvo Penta, Yamaha, Mercury and Vetus. Stormer always pays special attention to the electrical system, a prerequisite on aluminium vessels. For The Royal Netherlands Navy, Stormer Marine is building three electric Line Handling Workboats (LHWBs).

Hans Heynen

Hans Heynen

Maritime journalist, hans.heynen@casema.nl

18 SWZ MARITIME • MAY 2024

SEAWORK

Hydromaster supplied, among other things, the rudder propellers for two Woolwich ferries (62 x 19 metres). They sail between Woolwich and North Woolwich, linking the north and south circular roads, across the Thames (photo Jan Terlouw).

UK PROVIDES IMPORTANT AND LOYAL CLIENTS FOR DAMEN

Companies in the UK maritime sector are very important and loyal customers for Damen Shipyards. Since the 1970s, Damen has delivered an impressive 300+ ships to a high variety of customers and industries in the United Kingdom and Ireland. Some ten to twelve vessels are currently under construction as well.

This makes the United Kingdom and Ireland ‘a very important market’ for Damen, says Frederik van der Linde, sales manager United Kingdom and Ireland, and one of the two permanent salespeople Damen has within its organisation in this market. In June, he is one of Damen's hosts at the Seawork exhibition in Southampton. That will mark the 25th time in Seawork's 25-year history. ‘Damen supported Seawork from the beginning as it’s a great way to get in contact with clients and industry people off the ground,’ says Van der Linde. He works on the UK market together with his colleague Mike Besijn with the support of colleagues at the shipyards and other offices.

Dredging and offshore wind

The vessels that Damen delivers to clients in the United Kingdom and Ireland originally involved a lot of small workboats for the local dredging industry such as Stan Tugs, Pushy Cats, and other types of

workboats. Later, these were supplemented by Shoalbusters and Multi Cats. With the rise of the offshore wind industry, Fast Crew Suppliers (Crew Transfer Vessels) also find their way to clients. ‘Our customers are spread throughout the UK and the Damen portfolio turned out to be very well suited to demand,’ Van der Linde explains Damen's success in the UK market.

The UK government, including the UK Ministry of Defence, also appreciates Damen's products. A recent noteworthy example is the 42-metre axe bow type XV Patrick Blackett (X01), an experimental ship used by the Royal Navy as a testbed for new technologies, including unmanned underwater and surface vehicles, and quantum navigation. Its namesake is Patrick Blackett, a Royal Navy veteran, and Nobel Prize-winning British physicist.

Painted matte black

The Patrick Blackett is an adapted Fast Crew Supplier 4008 (FCS

19 SWZ MARITIME • MAY 2024 RUBRIEK WORKBOATS

Photo: The Patrick Blackett is an adapted Fast Crew Supplier 4008 (FCS 4008), designed and built by Damen Group and painted matte black (all photos by Damen).

4008), designed and built by Damen Group. It is painted matte black, rather than the Royal Navy's standard Pusser's Grey, complete with NavyX insignia on both sides of the hull. Its pennant, X01, is also uniquely highlighted in gloss paint and large QR codes are painted to either side of the superstructure, allowing smartphone users to scan them and view NavyX content. It is capable of speeds more than 20 kn (37 km/h; 23 mph), with a range of more than 3000 nautical miles (6000 km) at 20 kn (37 km/h).

pin the Damen ships in the UK as well as provide support with original construction drawings and maintenance instructions when docking, for example. The Damen Hub also offers its support to nonDamen ships.

Larger ships

‘We feel welcome in the UK. It's good business there.’

The breakthrough to the UK government market was the delivery of four Stan Patrol 4207 patrol vessels in 2007 for British Customs and later the UK Border Force. This made British Customs the second customer for Damen for this type of vessel after the delivery of the Sea and Osprey in 2001 to the Dutch Coast Guard. And even though they are almost twenty years old, they are still doing very well.

Damen Service Hub

Van der Linde: ‘We opened a Damen Service Hub in Southampton in 2021 with four full time FTEs including an ex-Royal Navy man and a technician.’ In doing so, the Damen Service Hub should help under-

Damen Shipyards builds between six and nine vessels annually for UK clients. These have increasingly been larger vessels in recent years. Multi Cats nowadays range from 12 to 37 metres in length. Two years ago, Damen delivered the second Marine Aggregate Dredger, a MAD 3500, to Hanson UK following an earlier one to Cemex UK Marine, for winning aggregates from the seabed for the construction industry. The MAD 3500 has a hopper capacity of 3500 m3. In 2017 and in 2019, Damen delivered two Walk-to-Work Vessels to Bibby Marine, the Bibby Wavemaster 1 and Bibby Horizon. At that moment, the first purpose-built design Walk-to-Work Vessels for the offshore wind industry.

Much success has also been achieved recently by Damen in the delivery of FCSs, also known as Crew Transfer Vessels (CTVs), a catamaran for fast transport of technical personnel for the maintenance of offshore wind turbines. ‘In the construction of offshore wind farms, the UK industry is very advanced,’ Van der Linde says in clarification. Meanwhile, Damen has delivered over thirty FCSs to customers in the UK over the last fifteen years. One example is UKbased High Speed Transfers (HST), which started in 2018 with an order for the delivery of one FCS 2710, followed by three more very quickly.

20 SWZ MARITIME • MAY 2024

RUBRIEK WORKBOATS

Purus Wind ordered no less than eight vessels from Damen in one go, includig one 90-metre Construction Service Operation Vessel (CSOV).

RUBRIEK WORKBOATS

‘Our very diverse portfolio allows us to serve a lot of different customers’

Orders keep coming in

Following Purus Wind's acquisition of HST, three more FCS 2710 Hybrids were contracted at the end of 2022. An even larger follow-up order followed in March last year for eight new vessels: four Damen FCS 2710 Hybrids, three FCS 3210 Hybrid CTVs, and one 90-metre Construction Service Operation Vessel (CSOV). The FCS 3210s and the CSOV are equipped for ultra-low emission operations and have been designed to be upgraded to methanol-fuelled engines when the time comes. The order is part of Purus Wind's strategy to be a leading provider of low-carbon, offshore wind support vessels. The FCSs were initially built at the Damen yard in Singapore, but nowadays mainly at its yard in Turkey. The CSOV will be built in Vietnam. According to Van der Linde, the order also contributes to Damen's aim of becoming the most sustainable shipbuilder itself. Meanwhile, Damen also builds in the UK together with Coastal Workboats in Exeter, Devon. Two years ago, this allowed the UK yard to deliver a so-called Landing Utility Vessel (LUV) 2208 to an operator of salmon fish farms in Scotland's Western Isles. An LUV has a large deck space for fish cages and nets. An LUV order has now also been booked from Penzance-based (Cornwall) Isles of Scilly Steamship Group, which will operate it as a freight vessel around the Isles of Scilly. Damen plans to have the yard in Exeter build two more LUVs on stock.

In August last year, Damen signed a contract with UK Dredging for the delivery of a Shoalbuster 2711 Water Injection Dredger (WID). Based on a proven design, the vessel nonetheless represents a unique and innovative approach to water injection dredging. UK

Dredging, part of Associated British Ports (ABP), operates Britain’s largest dredging fleet. It already has a number of Damen dredgers and workboats, including two Multi Cat Plough Vessels. The company undertakes maintenance dredging in ABP’s ports, for which it typically operates a number of hopper dredgers. The WID will enable the company to extend the intervals in between hopper dredging operations, thereby considerably increasing efficiency.

The yard of Damen Hardinxveld is currently finishing two Damen multi-purpose Shoalbusters 2208 for Cory, one of the UK’s leading waste management and recycling companies, The vessels will be used to manoeuvre the barges that transport waste down the River Thames to Cory’s sorting facilities for either recycling or energy recovery. The new vessels will join four Shoalbusters 2208S that Cory Group bought ten years ago for the same purpose. They will look similar to their counterparts, but will feature a wide range of updates and upgrades. These include being IMO Tier III compliant with compact selective catalytic reduction systems fitted to fuel-efficient MAN engines to minimise NOX emissions. The fender arrangement is also being upgraded to provide all-round protection to the topsides as they manage their barges.

‘This way, we built a longstanding relationship with our clients and the wider industry,’ Van der Linde states. ‘It’s always a joy to travel to the UK and cooperate closely on all sort of projects. We seem to have a lot in common, have nice conversations and know how to find each other.’

Seawork exhibition

The Seawork show will have its 25th anniversary this year, where Damen will welcome its returning customers and relations with as much enthusiasm as 25 years ago. Many starting companies and captain-owners have visited the show and even purchased their first Damen workboat on the spot.

Unlike last year, when the X01 Patrick Blackett was moored at the Mayflower Park jetty during Seawork as a showcase of Damen's capabilities, there will be no full-size Damen ships on display. Van der Linde: ‘Over the last few years, we always managed to bring ships. And we did try this time too, but the workboat market is doing very well now, and all available tonnage is needed.’

Priority for Van der Linde at the show is to show the progress Damen has made in making its vessels more sustainable. ‘For the FCS 2710 for example, we are looking at whether we can get a methanol option ready. We have calculated that the space for the tanks is there. All this fits into our roadmap to eventually get to delivering zero- emission ships,’ concludes Van der Linde.

Antoon Oosting

Freelance maritime journalist and SWZ|Maritime’s editor-in-chief, swz.rotterdam@knvts.nl

21 SWZ MARITIME • MAY 2024

UK Dredging ordered a Shoalbuster 2711 Water Injection Dredger. Although based on a proven design, it represents an innovative approach to water injection dredging.

NG-DESIGNED MONOMARAN CREW TENDERS SAVE FUEL

Next Generation Shipyards BV (NG Shipyards), located at the outer port of Lauwersoog since April 2014, designs, builds, repairs and maintains workboats up to 35 metres. For account of Coastwise, NG Shipyards recently delivered three innovative crew tender vessels (CTVs).

The yard was established by owner/director Albert Keizer. Son Dirk Keizer has been strengthening management as a second owner/director since 1 January 2022. Innovation and sustainability are top of mind and the yard continues to search for durable applications and technologies to reduce its ecological footprint. The further development of the yacht Ecolution on behalf of the late Wubbo Ockels is one example of this commitment. For 24/7 repair and maintenance, a shiplift with a lifting capacity of 242 tonnes is available for vessels with a beam of up to 10 metres. NG Shipyards builds survey/research/hydrographic vessels, crew tenders for the offshore wind industry, pilot vessels and harbour support patrol vessels for account of among others Dutch Pilots, Rotterdam; Zeeland Seaports, Terneuzen; NIOZ, Texel; Geo Plus, Scheemda; Jan De Nul, Aalst; and Braveheart Shipping, Urk. The order backlog includes three M-class pilot tenders (as part of an order for a series of five, including the protoype Mira) for the

Dutch Pilots, one pilot tender for Milford Haven Port Authority and a Wadden Sea Taxi for AG Reederei Norden-Frisia.

Coastwise orders crew tenders

Coastwise Offshore Services BV was established in 2002 as a traditional captain/owner shipping company by captains/owners Eelko Wijdieks and Douwe van den Berg. They have gained years of experience on board low air draught sea/river vessels, multi-purpose vessels, container ships and with the transportation of various types of cargo.

At a later stage, the captains combined their knowledge for the design of a new type of energy-efficient and fuel-saving aluminium crew tender, a monomaran with two side supporting hulls. The crew tender was designed by NG Shipyards in close cooperation with naval architect Fred van Dorresteijn (VDD-Design), Dordrecht. Coastwise contracted NG Shipyards for the construction and delivery of

The three aluminium monomaran crew tenders that NG Shipyards built for Coastwise Offshore Services.

22 SWZ MARITIME • MAY 2024 SHIP IN DETAIL

tender

Name Imo Yard number Keel laid Launched Delivered COS Mate 9929417 NGS-33 30-09-2021 20-08-2022 01-11-2022 COS Master 9929405 NGS-34 30-11-2020 09-11-2021 20-12-2022

NGS-36 28-06-2022 25-02-2023 24-03-2023

Photo: The COS Master was the second crew

to be delivered to Coastwise in 2022 (all photos by NG

Shipyards).

COS Mariner 9972294

23 SWZ MARITIME • MAY 2024

SHIP IN DETAIL

The shiplift being used to launch the COS Mariner.

SPECFICATIONS OF THE CREW TENDER NG ENDURANCE 2727

Dimensions

Length over all: 27.27 metres

Length hull:

Length waterline:

Length loadline:

Beam over all:

Beam hull:

Depth:

metres

metres

metres

metres

metres