Don Beaver was certainly one of a kind. Passionate, hard working, energetic and helpful are just a few of the many ways he’ll be remembered by those who knew and loved him.

He made a very strong impact on others, especially those in the WMABA community and the auto body industry to which he devoted so much of his heart and soul. August 4 was a sad day for all, when the former WMABA president and longtime Board member, body shop manager, expert welder, former I-CAR instructor and friend passed away peacefully in his home surrounded by loved ones at the age of 62.

Whether it was fighting for legislation at the Capitol, promoting WMABA events or just bringing positive light to any situation, Beaver’s devotion and influence was imminent in everything he touched, according to WMABA Executive Director Jordan Hendler.

“He was the salt of the earth,” she

reflects. Beaver was helpful in countless ways, Hendler reminisces, including how instrumental he was with WMABA’s push for parts reform legislation at the state level in Maryland. “Even though we didn’t get it passed, it was a good example of how we can all come together to do something positive.”

Beaver was known for his influence and for sharing his point of view as a body shop manager or I-CAR instructor. “I loved how he was so vocal with his opinions,” says Hendler. “He could bring levity to any situation. No matter how dire something might be, he had a way about bringing out a back slap and a laugh. He was just that positive energy and influence that helped keep us going when it didn’t feel like things were going our way.”

“He really was one of a kind,” says Torchy Chandler, who served with Beaver on the WMABA Board for many years. “He was always patient with people, knowledgeable and just a pleasure to work with.”

Her experience with Beaver was always a pleasant one. “There’s not a negative thing I can say about him,” she

says, recalling how he had that type of positive energy one can just sense when walking into a room. At a time when it wasn’t very common for women to be in the collision repair world, Chandler recalls how he instantly made her feel comfortable. “While walking into a room predominantly of all men, I heard him say a few words, and I could just size him up and know that he was the type of individual I wanted to work with. Don was one of those people who made others want to be involved.”

“He was really passionate about everything that went into the auto body industry,” shares his daughter Jessica Petroff who, along with her siblings, grew up around her father’s work in the auto body world.

Beaver’s devotion to the industry started in high school where he studied auto body at a vocational school, she says. From there he went on to sweep shop floors and began to learn the many skills needed to launch his career.

Beaver had a love for the industry that went beyond the trade and extended into wanting to see to it that technicians were

paid fairly, insurance companies got a better understanding and that cars were fixed correctly. “He fought for what was right and he was always willing to share his knowledge with others,” Petroff says of her father.

Not only is it a loss for the industry as a whole but specifically for the many friends he made over the years.

“Sometimes life just isn’t right, and it certainly isn’t fair,” laments Society of Collision Repair Specialists (SCRS) Executive Director Aaron Schulenburg. “Losing someone like Don so early is heartbreaking proof of that. I had the privilege of working closely with Don during my time on the WMABA Board of Directors from around 2005 to 2008. Don was always so deeply grounded in the realities of our industry and in the people we served. He also had an incredible way of bringing laughter into any room. As part of the executive committee during a pivotal time of transition, Don was instrumental in shaping the path forward. Those of us who served alongside him built bonds that have lasted nearly 20 years – and I know they always will.

“It’s hard to imagine that my friend is no longer with us,” adds Schulenburg. “But when I think of Don, I can’t help but smile at the legacy he leaves behind. He created so many stories – funny, heartfelt, unforgettable – and I hope we all continue to share them often and loudly. That’s one of the best ways we can honor him and carry his memory forward.”

“Don was a great guy and was always willing to offer a hand to help,” remembers WMABA Board member John Shoemaker who worked closely with Don at the various WMABA golf outings.

WMABA Vice President Phil Rice worked with Beaver on the Board for a number of years and also during the time they both served as I-CAR instructors. He remembers him “as a person of integrity. Don was always looking for and willing to try something new. He was just a go-getter.”

Rice notes Beaver was a “phenomenal welding instructor. I can’t tell you how many welding events Don was instrumental in organizing.”

Beaver’s relationships in the industry were about more than business. He was a friend to all. “You couldn’t have a conversation with Don without him asking how your family was doing,” Rice shares. “He’d steer from business and make it personal every time.”

“Don was always the constant professional; he gave so much of his time and energy to the association and to the region,” expresses

BY ALANA QUARTUCCIO

WMABA President Kris Burton. “Serving on the WMABA board is a selfless volunteer position in support of the collision repair industry in the region. You could always count on Don to show up, be present and engaged. It was an honor to work alongside him. He was someone we should all strive to be like. One of the many memories I have of Don was when he’d host several of our annual planning sessions. He was always an amazing host. Everyone would look for these sessions as they were an opportunity for us all to connect and work together. I truly appreciate the countless hours put forth into serving WMABA and its members to make the industry a better place for us all.”

Longtime readers of Hammer & Dolly who remember the anonymously written “Rusty Dent” feature may find it interesting to know all these years later that the voice behind all that industry ranting and raving was none other than Don Beaver.

“Don wasn’t just one of my favorite people from the collision repair industry – he was one of the best people I’ve known from any walk of life,” says Joel Gausten, former editorial director. “He was easily one of Hammer & Dolly’s biggest supporters, always ready to roll up his sleeves and help with whatever we needed. I know everyone who knew him through WMABA would say the same about his commitment to the association. In many ways, Don was like the collision repair industry itself: tough-looking and slightly intimidating to those who didn’t know him, but instantly kind, warm and welcoming to anyone who gave him a chance. A man with a heart as big as Don’s is a rarity in this world. How lucky were we all to have had the blessing of experiencing it?”

“He always wanted to see better for this industry,” adds Hendler. “He’d be frustrated by the same things everyone else was, but Don didn’t just sit back; he jumped in.”

Beaver leaves behind a legacy of community spirit. Upon attending his celebration of life, Hendler noted his patriarchal and community spirit which was imminent not only in the body shop industry but in his family and hometown. “He really brought people together.”

Don is survived by his wife Helen; his children and stepchildren Donnie Beaver (Kirstyn), Stephen Uhler (Emily Becker), Paul Smith, Jacob Pulliam and Jessica Petroff (David); his siblings, Robert Beaver, Diane Bitzer and Gale Kistner; as well as his cherished grandchildren: Mason, Dylan, Kinsley, Benjamin, Nova, Teagan, Chase and Dakota. H&D

THEY’RE CALLED “ORIGINAL BMW PARTS” FOR GOOD REASON. FOR UNCOMPROMISING PRECISION AND INCOMPARABLE QUALITY, YOUR BMW CENTER IS YOUR ONE-STOP SHOP FOR EVERYTHING BMW.

For Original BMW Parts, contact one of these authorized BMW centers:

BMW of Silver Spring 3211 Automobile Blvd

Silver Spring, MD 20904 866-737-8937

Direct: 301-890-3015

Fax: 301-890-3748

Email: wholesaless@mileone.com bmwofsilverspring.com

Passport BMW 5000 Auth Way Marlow Heights, MD 20746

301-423-0733

Fax: 301-423-2717 passportbmw.com

Richmond BMW 8710 West Broad Street Richmond, VA 23294

800-237-0130

Direct: 804-527-6860

Fax: 804-965-6254

Email: tdailey@crownauto.com richmond-bmw.com

BMW of Catonsville 6700 Baltimore National Pike Baltimore, MD 21228

855-996-2906

410-744-2000

Fax: 410-818-2600 bmwofcatonsville.com

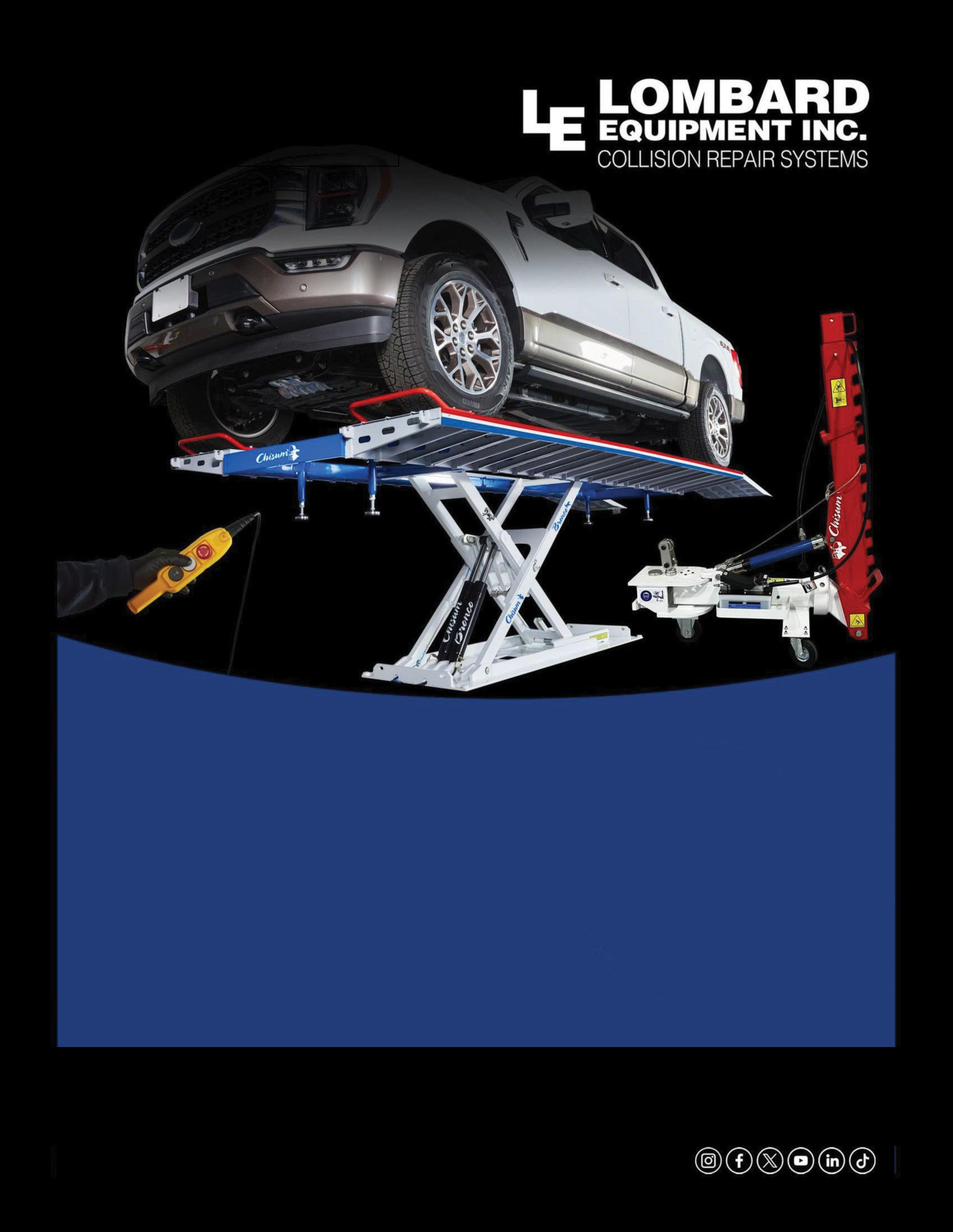

Equip Yourself Against Repair Nightmares.

Old, uncertified tools lurking around? Don’t let them haunt your shop. RAE provides top-of-the-line OEM-approved equipment designed to handle even the most monstrous jobs.

It’s just about time to pack those bags and head to Las Vegas for the 2025 SEMA Show on November 4-8, where there will be plenty to unpack besides that luggage as collision repairers can anticipate another great year learning about the industry’s latest products, innovations and trends – both on the trade show floor at the Las Vegas Convention Center and in the classroom.

As usual, the educational slate being presented by the Society of Collision Repair Specialists (SCRS) and the Collision Industry Conference (CIC) features forward-focused thought leaders who will provide guidance on how the evolution of technology and customer service expectations will next modify the way shops do business. In keeping with that tradition of metamorphosis, both agendas will see some significant changes that may change attendees’ viewpoints, figuratively and literally.

For starters, CIC (taking place on Tuesday, November 4) will see a variance in venue as conference aficionados head across

the Las Vegas Strip to Resorts World Las Vegas for a full day of festivities. This year’s meetings have offered repairers futurefocused discussions and networking opportunities, and the final CIC of 2025 promises to maintain that momentum as participants from all industry segments – including repairers, insurers, paint/ material companies, equipment, vehicle manufacturers, data providers, representatives of trade associations and more – gather for the express purpose of discussing and exploring the issues that occur among them. Through discussion and research during meetings and extensive interim committee work, CIC attempts to form consensus on various issues, aware that all such findings are nonbinding and voluntarily accepted.

After filling attendees’ heads with ideas for improving their businesses during the day, CIC’s day of education will evolve into an ideal networking opportunity at 6pm during the CIC reception, which offers a chance to unplug, unwind…and maybe even wine a

little while preparing to raise a glass to the industry’s movers and shakers as they are recognized during the Collision Industry Red Carpet Awards which will following the reception.

SCRS’ Repairer Driven Education (RDE) series will feature some new faces in 2025 (see the RDE preview at grecopublishing.com/hd0925ntlnews2), as the program seeks to highlight key trends in the collision repair industry, including workforce development, advancing automotive technology and developing more customer-centric practices, while simultaneously expanding on ways for businesses and employees to develop increased financial literacy.

However, Wednesday afternoon’s IDEAS Collide Showcase puts eyes on a brand-new set of ideas with eight presenters who have never before appeared on this unique stage.

SCRS Executive Director Aaron Schulenburg looks forward to “introducing attendees to a number of really phenomenal speakers

who will rattle the status quo with ambitious ideas that could have a transformative effect on the industry and your business.”

Although some names will certainly sound familiar – such as WMABA’s Jordan Hendler, Rachel James (Torque Financial Group) and John Yoswick of CRASH Network – Schulenburg is excited for these first-timers “to spotlight their individual thoughts and ideas on the IDEAS Collide stage” with “TED Talk” styled, fast-paced presentations which are designed to stimulate thought, innovation and resolution of business challenges with brash, outspoken and provoking concepts from thought leaders both in and out of the industry.

Emceed by Micki Woods, president of Micki Woods Marketing and host of The Body Bangin’ Podcast, the 2025 Showcase includes a look at everything repairers should be considering in today’s market and beyond.

Hendler (WMABA / Admin Concepts, Inc.) will kick things off with “Get Far, Stacking Millimeters Towards Progress” as she explores the necessity of flexibility in setting and achieving goals. She insists, “Movement toward achieving goals doesn’t come all at once, but in the daily and weekly pursuit of the smaller, achievable wins.”

How are rapidly evolving mobility trends disrupting traditional business models? Joe Rector (Entegral) will examine how collaboration among industry stakeholders can drive customer and employee satisfaction, reduce cost and friction and contribute to a safe and proper repair during “Toward an Integrated and Open Ecosystem: Envisioning the Future of the Auto Claims Ecosystem.”

Attendees will learn all about “Modernizing Your HR and Employee Benefits” as Richie Seaberry (Decisely) shares ways that collision repair business leaders can become empowered and strengthen workplace culture by leveraging cutting-edge technology, dedicated employee-level support and world-class benefits offerings. While benefits help retain key employees, shops first need to attract and develop their technicians, and 3M’s Shawn Collins will offer advice on “Taking Your Apprentice Technicians to the Next Level with Hands-On Training.”

An increasing number of businesses have begun adding the role of Chief Financial Officer (CFO) over the past two years, but what does a CFO really do? James will examine this growing trend and offer considerations for defining who, what, where, when and how to hire the right person for the right role objectives during “Decoding the Role of CFO.”

Kaye Gitibin (GO Rentals) plans to explore shops’ need to go beyond technical expertise to win customer loyalty in today’s competitive collision repair landscape. “Elevating the Client Experience in Collision Repair: Hospitality-Driven Strategies for Repeat Business and Referrals” will focus on the intersection of customer service and hospitality, offering strategies that collision centers can implement to enhance the customer experience by moving away from the impression of collision repair as a transactional service and creating a welcoming, customer-centered experience.

Veteran industry journalist John Yoswick rounds out this

continued from pg. 23

year’s IDEAS Collide presenters as he examines how shops can benefit by investing just “Three Minutes to Help Drivers Make Better Insurance Choices.” Shops “know not all insurance companies are the same when it comes to handling claims and the customer experience,” according to Yoswick, who offers “an easy way you can communicate that knowledge to consumers.” He suggests that in just three minutes a year, shops can send a clear message to drivers considering their insurance choices – and help increase the number of your customers who have chosen one of the better carriers. At the same time, you’ll help the better insurance companies promote themselves – and maybe give the other insurers some incentive to change!

SCRS’ 2025 OEM Collision Repair Technology Summit will also look a bit different this year. While it will still consist of three back-to-back presentations on Thursday afternoon, beginning at 12:30pm, for the first time ever, all of the

sessions will be centered around one topic – OEM Safety Inspections – and each session will uniquely focus on the ways in which OEM safety inspection procedures affect vehicle technology, consumer interaction, repair quality and safety restoration. Industry icon Mike Anderson (Collision Advice) will facilitate the Summit through its entirety as he welcomes unique presenters and panelists from automakers, collision repair businesses and suppliers, who will collectively contribute to a better understanding of the emerging trends and necessary collision industry response to prioritize the restoration of vehicle safety in the repair process.

Schulenburg believes this conversation “comes at a critical time, as safety inspections find themselves being routinely challenged by carriers both in the claims process and in legislative halls.” Panelists and contributors will be introduced closer to the show.

“When we zoom out and look at the program as a whole – from each

interwoven OEM Summit session, the RDE classrooms and the IDEAS Collide Showcase – there’s a lot of common thread woven between topics, all tying together how we are able to serve the consumer well,” Schulenburg observes. “I’m really excited about the topics we’ll cover in the 2025 program and the impact we can make in the industry through that exchange of information.”

After the education ends, the party begins on Thursday night with the mosttalked-about collision networking event at SEMA each year: the SCRS RDE Afterparty, where collision repairers have a chance to rise to new heights…literally!

The palatial 15,400-square-foot Verona Sky Villa, located in the Westgate, offers a taste of luxury to round out the week of education and exploration. In addition to providing amazing views of the Strip, it gives guests a great opportunity to relax and catch up with industry friends. Tickets are limited, and early registration is encouraged.

There’s tons to see and do at SEMA each year, so set your sights on the future success of your shop by making plans to start your trek upward…the view is so much better from the top!

Registration is now open to automotive and collision industry professionals for the 2025 SEMA Show and SCRS’ RDE, IDEAS Collide and OEM Summit at bit.ly/2025SEMAShow; get the best possible deal on your collision education with the SCRS Full Series Pass, which includes access to one regular session in each available RDE time slot, the IDEAS Collide Showcase, all three sessions of the OEM Collision Repair Technology Summit and one ticket to the SCRS Sky Villa Afterparty. And in yet another update to this year’s SEMA, anyone who forgot to include educational sessions during their initial registration can go back and add classes via the registration resource center.

Learn more about CIC and register to attend at ciclink.com. Stay tuned to Hammer & Dolly for additional updates leading up to the Show and a recap following SEMA 2025. H&D

Safford Brown Mazda Fairfax 10570 Fairfax Boulevard

Fairfax, VA 22030

Toll Free: 800-234-8642

Phone: 703-385-3994

Fax: 703-591-5348

Fitzgerald Mazda 114 Baughmans Lane

MD 21702

Toll Free: 800-545-4745

Fax 877-696-1841

Email: parts@fitzmall.com www.fitzparts.com

Ourisman Mazda of Rockville 801 Rockville Pike Rockville, MD 20852

Parts Direct: 301-340-7668

Phone: 855-417-4511

Fax: 240-499-2488

Email: rockvilleparts@ourismanautomotive.com www.ourismanmazdaofrockville.com

Fitzgerald Mazda of Annapolis 1930 West Street Annapolis, MD 21401

Toll Free: 866-280-8022

Phone: 410-224-4636

Fax: 410-224-4264

www.fitzmall.com

Audi dealers strive to make you an Audi Genuine

Vans. Born to run.

Get your customers back on the road faster with Genuine Sprinter Parts.

Audi Silver Spring 3151 Automobile Boulevard Silver Spring, MD 20904

844.413.6929

Call our Sprinter Certified Parts Advisors today to get started.

Parts Direct: 301.890.3015 Fax: 301.890.3748

Email: wholesaless@mileone.com www.audisilverspringparts.com

301-890-3060 Fax: 301-890-5473

mbsilverspring@mileone.com

Vans. Born to run. Get your customers back on the road faster with Genuine Sprinter Parts.

Call our Sprinter Certified Parts Advisors today to get started.

Sprinter Silver Spring 3301 Briggs Chaney Rd. Silver Spring, MD 20904

301-890-3060 Fax: 301-890-5473

mbsilverspring@mileone.com

Hours: M-F 7:30am-5pm, S 8am-3pm

The perfect fit at the perfect price.

Mitsubishi Genuine OEM parts are designed for optimal performance and fit, engineered to meet the highest standards.

For more information, contact: Younger Mitsubishi 1945 Dual Highway Hagerstown, MD 21740

Direct: 800-296-1190 Fax: 301-733-5465 www.youngermitsubishi.com

Hours: M-F 7:30am-5pm, S 8am-3pm For your

Mercedes-Benz Silver Spring 3301 Briggs Chaney Rd. Silver Spring, MD 20904

301-890-3060 Fax: 301-890-5473

mbsilverspring@mileone.com

Hours: M-F 7:30am-5pm, S 8am-3pm Contact our team of Mercedes-Benz Certified Parts Advisors today to get started.

1. First Place / Lowest Score: BAPS Team 1

2. Highest Score: Radley Auto Group Team

3. Third Place (Drawn): BASF Team (with John Shoemaker)

4. Closest to the Pin Winner (2’3’’): Tommy McDonald (with Jordan Hendler)

5. Tailgate Prize Package Cornhole Contest Winner: Chris Hare (with Phil Rice)

2025 Hole Sponsors: Hammer & Dolly Magazine Rosslyn Auto Body Thomas Greco Publishing WheelsOnSite

Closest to the Hole Sponsor: Dorn’s Body & Paint

ADAS calibration is the precise adjustment of your vehicle’s sensors and cameras, essential for the optimal functioning of advanced safety systems. This process is especially critical following significant repairs, part replacements, collisions, or windshield replacements, as these events can disrupt sensor alignment.

It’s important to avoid driving without proper sensor calibration. Uncalibrated ADAS sensors can compromise your vehicle’s safety features, leading to potential malfunctions and driving hazards.

The calibration of ADAS can be performed in two main ways: static and dynamic. Static calibration takes place in a controlled environment, ensuring accuracy and consistency. Dynamic calibration, on the other hand, involves driving the vehicle under specific conditions to fine-tune the sensors in real-world scenarios. This comprehensive approach ensures that your vehicle’s safety systems are reliable and effective, providing peace of mind on the road.

You’ve got the right tools, staff, technology and procedures to give your customers the best repair possible. The missing piece of the puzzle? Genuine Volkswagen Collision Parts. Contact an authorized dealer today and find your perfect fit.

Alexandria Volkswagen 107 West Glebe Rd. Alexandria, VA 22305

703-684-7007

Fax: 703-684-4138

e-mail: parts@alexandriavw.com

Karen Radley Volkswagen 14700 Jefferson Davis Hwy. Woodbridge, VA 22191

703-550-0205

Fax: 703-643-0081

Fitzgerald Volkswagen 114 Baughmans Lane Frederick, MD 21702

Toll Free: 800-545-4745

Fax: 877-696-1841

e-mail: parts@fitzmall.com www.fitzparts.com

Fitzgerald Volkswagen of Annapolis 34 Hudson Street Annapolis, MD 21401

Phone: 410-224-4636

Fax: 410-224-4264 www.fitzmall.com

Ourisman Volkswagen of Laurel 3371 Ft. Meade Rd. Laurel, MD 20724

Phone: 301-498-6050

Fax: 301-498-0157 www.laurelvolkswagen.com

Ourisman Volkswagen of Rockville 801 Rockville Pike Rockville, MD 20852

Parts Direct: 301-340-7668

Toll Free: 855-417-4511

Fax: 240-499-2488

e-mail: rockvilleparts@ourismanautomotive.com www.ourismanvolkswagenofrockville.com

“Volkswagen“ and the Volkswagen logo are registered trademarks of Volkswagen AG. ©2025 Volkswagen of America, Inc.

Wholesale Parts

Join Reliable Automotive Equipment’s Dave Gruskos for conversations with industry leaders sharing their insights and the latest from the world of certified collision repair. This month, Dave talks with Vartan H. Jerian, Jr., CEO and co-founder of Vive Collision.

Dave Gruskos: VIVE Collision locations are known for operating with advanced technology and a strong commitment to safe repairs. Why is this philosophy so important to the way your locations do business?

Vartan Jerian: When you leave your vehicle with us, you’re trusting us with something that carries your family every single day. That’s a responsibility we don’t take lightly. By combining advanced technology with the skill of our technicians, we make sure your car is repaired to the best of human ability. A big part of this comes from our Ambassador Program, which is designed to grow our technicians, build apprenticeships, and strengthen our culture from the shop floor up. It’s how we make sure quality repairs are not only consistent but part of our DNA and our values of People, Process and Passion for the collision industry.

D.G.: How does VIVE define “quality” in terms of collision repair, and what steps do you take across all locations to consistently deliver on those standards?

V.J.: For us, quality means doing it right the first time and giving you complete confidence in your vehicle when you leave our shop. We achieve that by investing in technician training, apprenticeships, and programs like our Ambassador Program that help teammates take ownership of both the repair and the culture in the shop. Quality is more than the end result — it’s the process, the teamwork, and the pride our technicians put into every repair.

D.G.: The investment in tools, equipment, and technology is significant. How much weight do you place on the importance of a good vendor relationship in comparison to price or capabilities?

V.J.: Price matters, but trust matters more. That’s why we partner with companies like Reliable Auto Equipment, who not only provide the right tools but also support us in technician training and development. These vendor relationships ensure

Current number of locations: 64 States Represented: CT, DE, MA, ME, NH, NJ, NY, PA, RI, VT

OEMs Represented: 26

our people always have the right resources to deliver safe, consistent repairs. The cheapest option may save a dollar today, but the right partnership pays off in the long run — for our technicians and for our customers.

D.G.: How do you feel repairers can best prepare to create a shop culture where every repair is done right?

V.J.: Culture comes from the ground up and the top down. At VIVE, we invest heavily in our technicians — because they are the ones repairing vehicles and shaping the customer experience. Through our Ambassador Program, we give technicians the tools, training, and mentorship opportunities to grow their careers, while also reinforcing the pride and accountability needed for every repair. When teammates feel supported, respected, and part of a bigger mission, the culture naturally becomes one of excellence.

D.G.: What message would you share with shops about the role of training in maintaining a successful collision repair facility?

V.J.: Training is the most important investment a shop can make. Cars evolve every year, and without ongoing training, even the most skilled technician can fall behind. That’s why we’ve made training a pillar of our culture — with structured apprenticeships, advanced development programs, and the Ambassador Program helping teammates grow into leaders. Training ensures every repair meets the highest standards, but it also strengthens careers, builds loyalty, and creates the culture that customers can feel the moment they walk in.

807 Rockville Pike

Rockville, MD 20852

Toll Free: 800-345-4640

Direct: 301-424-5332

Fax: 301-294-6381

www.rockvillechevrolet.com

4400 Branch Avenue

Temple Hills, MD 20748

Phone: 301-899-6990

Fax: 301-899-9375

www.ourismanchevrolet.com

This year, as Albert Kemperle Inc. celebrates its 83rd anniversary, BASF also celebrates its 158th anniversary. We are proud of our decades of partnership with BASF and years of serving the auto paint and body industry together. Kemperle’s founders would be proud of this relationship and the growth their company has experienced because of it.

Today, as we look forward to many more decades of service to our customers, we find ourselves filled with gratitude. The creativity, hard work, and sense of responsibility of the people working for our two companies have made us what we are today.

Thank you for your many years of loyalty.

626 E. Elizabeth Ave., Linden, NJ 07036 Phone: (908) 925-6133

(908) 925-4344 414-416 Madison Ave., Paterson, NJ 07524 Phone: (973) 279-8300

631 Clifton Ave., Toms River, NJ 08753 Phone: (732) 797-3942

(973) 279-9030

(732) 797-0774 100 Melrich Road, Cranbury, NJ 08512 Phone: (609) 860-2800

(609) 860-2801 4 Emery Ave., Randolph, NJ 07869 Phone: (862) 244-4818

(862) 244-4822 www.kemperle.com

This month, we “Ask Mike” to share his thoughts on how the industry can better ensure consistency and accuracy in ADAS repairs. We at Hammer & Dolly hope you find the following exchange useful, and we encourage you to reach out to us if you have a question for Mike on this or any industry-related matter that he can answer in a future issue.

Hammer & Dolly: This month, I’d like to tackle the topic of creating stability in the changing ADAS segment of repair. To do that, we should probably frame our conversation around what’s causing instability. What are the most significant problem areas you’re seeing with this particular procedure?

Mike Anderson: First and foremost, most of the industry isn’t doing ADAS properly. We still see people doing it in parking lots, doing it without the right equipment or not knowing how to do a proper calibration or even how to prep the vehicle before that point. Simple things, like making sure the gas tank is full and verifying tire pressures, aren’t being done. We also see reports of third-party software suggesting calibrations that weren’t needed or not identifying calibrations that were needed. Software can streamline the process, but you still need to research the OEM repair procedures on every vehicle. I still see many estimates that don’t include calibrations. For example, I recently saw one for a Toyota Prius that didn’t have any calibrations.

I’m deeply concerned about the industry’s response to ADAS. There are people performing calibrations who are not properly trained. Although I do welcome third-party software because it provides a marginal benefit, we can’t just assume it’s going to be accurate all the time. That software shouldn’t be considered the end-all, be-all until it gets better. Again, people are overlooking the simple things, like thinking they can perform a calibration in a parking lot or on an uneven floor in the shop.

A lot of shops are slow right now, and people in the industry wonder why. I saw some data recently that said automatic emergency braking reduces front-to-rear collisions by 50 percent and blind spot monitors decrease lane-change accidents by 27 percent. ADAS is absolutely impacting accident frequency. It does work, so we must make sure that it’s done properly. At the same time, software companies have a moral obligation to do a better job of vetting their products to make sure they’re accurate. If insurers want to mandate the use of that software, they also have an obligation to set up some kind of feedback hotline to receive updates on what’s wrong with the software and put pressure on those companies.

H&D: On the flipside, there are shops that have been very proactive with ADAS, going as far as to create secondary businesses and locations for that purpose. What are some oversights or pain points you’re seeing even those businesses face?

MA: There’s a considerable need for training across the board. I-CAR and a few of the EV OEMs offer classes. OEMs need to make more collision-specific ADAS classes available as well as hands-on training on how to utilize their OEM scan tools

Using proper scan tools and performing test drives under the proper conditions are also important. If a blind spot monitor

What businesses are missing out on.

WITH MIKE ANDERSON

doesn’t activate until the vehicle reaches a certain MPH, then it makes sense to test drive that vehicle at that MPH. If the vehicle has a backup camera, you’ll need to test drive that vehicle in reverse below a certain MPH. People are not test-driving vehicles under the correct setting conditions to ensure those ADAS components activate properly. The lack of knowledge and awareness in that area is concerning.

H&D: It’s also concerning that we’re still having this conversation after so many years. Why is this procedure so challenging for the industry to embrace? Is it just about getting paid for it? Does it come down to shops not wanting to invest in equipment? Why are we still kicking the ball around on this topic?

MA: When ADAS rolled out, shops looked at it as a profit center and jumped into it without the proper training. There still isn’t adequate training available; certain classes are only available to certified shops.

First, shops need to identify what repair operations will require an ADAS calibration(s), know how to identify the ADAS

Mike Anderson is an Accredited Automotive Manager (AAM) and the former owner of Wagonwork Collision Centers, two highly acclaimed shops located in Alexandria, VA. He has served as a member of many industry organizations throughout his career, including the WMABA Board of Directors, the Mitchell Advisory Board, the MOTOR Advisory Board, the ASE Test Review Committee, the National Auto Body Council, the Collision Industry Conference and the Society of Collision Repair Specialists. Additionally, he is a past Virginia SkillsUSA chairman, serves as a facilitator for Axalta Coating Systems’ highly recognized Business Council 20 Groups in both the US and Canada and facilitates numerous courses for Axalta Coating Systems’ Educational Series. He currently offers expert industry consulting via his latest venture, Collision Advice (collisionadvice.com) H&D

components in every vehicle that comes in, understand the required calibrations and necessary vehicle prep and have the correct tooling, equipment and space. From there, they must perform the calibration correctly, understanding the conditions needed to complete the process. There are so many steps to ADAS that no one has really come up with a standard for what the workflow should be.

H&D: What are some potential challenges you’re seeing with ADAS in the future?

MA: ADAS is going to become more prevalent, and the days of the Wild West are over. Obviously, insurers are attempting to rein in the pricing piece and control costs. However, if you’re trying to control costs based on people who are doing it wrong, that’s not the right approach to take. The process needs to be validated in collaboration with the OEMs to ensure that whatever the insurers are going to pay is based on the procedure being performed properly – and that includes test drives and everything else.

At your local MINI dealer, we believe that using Original MINI collision replacement parts will speed your repairs and increase your profitability. Original MINI parts assure an absolute perfect fit and function.

For Original MINI parts, contact:

MINI of Annapolis

25 Old Mill Bottom Road Annapolis, MD 21409

410-349-2565

fax: 410-349-2586

MYMINIANNAPOLIS.COM

Crown MINI 8710 West Broad Street Richmond, VA 23294

804-527-6860 fax: 804-965-6254

CROWNMINI.COM

•

•

•

•

womensindustrynetwork.com

CHECK