by Chasidy Rae Sisk

NATIONAL

by Alana Quartuccio

ABAT’S Jill Tuggle Hosts CIC Legislative

ABAT FEATURE by Alana Quartuccio

Kevin Ellison Retires After Four Decades of ‘Doing the Right Thing’

ASK THE EXPERT by Robert L. McDorman How Do the Texas Mandatory Binding RTA Rules Affect State Farm Policy Holders?

of

President Burl Richards White Sands Collision Center burl.richards@proton.me (903) 392-0047

Vice President Eric McKenzie Park Place Dealerships emckenzie@parkplace.com (214)

Chuck Baldridge Mike Calvert Collision cbadridge@mikecalverttoyota.com (713) 558-8282

Larry Cernosek Deer Park Paint & Body lcwrecker@comcast.net (281) 930-1539

Chevy Corn Corn’s Collision chevy@cornscollisioncenter.com (979) 279-3310

Brandon Gillespy Park Place BodyWerks bgillespy@parkplace.com 214-443-8250

Chad Kiffe Berli's Body & Fine Finishes chadk@berlisbody.com (512) 251-6136

Greg Luther Helfman Collision gluther@helfman.com (713) 574-5060

Logan Payne Payne & Sons Paint & Body logan@paynescollision.com (214) 321-4362

Anthony Palomo West Texas Auto Color japalomo3@yahoo.com (806) 831-7765

Corey Pigg S&W Expert Collision Repair coreyp@swcollision.com (936) 634-8361

Manuel Rubio Miracle Body & Paint manuelr@miraclebp.com (210) 843-9564

Darrell Smith McDaniel’s Quality Body Works Inc. darrell-mcdaniels@sbcglobal.net (903) 753-5391

Published by: Thomas Greco Publishing, Inc. 244 Chestnut Street, Suite 202, Nutley, NJ 07110

Corporate: (973) 667-6922 / FAX: (973) 235-1963

PRESIDENT/PUBLISHER

Thomas Greco / thomas@grecopublishing.com

VICE PRESIDENT/SALES DIRECTOR Alicia Figurelli / alicia@grecopublishing.com

EDITORIAL DIRECTOR Alana Quartuccio / alana@grecopublishing.com

SR. CONTRIBUTING EDITOR Chasidy Rae Sisk / chasidy@grecopublishing.com

PRODUCTION COORDINATOR Joe Greco / joe@grecopublishing.com

OFFICE MANAGER Donna Greco / donna@grecopublishing.com

SPECIAL CONTRIBUTORS: Burl Richards / Jill Tuggle

Robert L. McDorman / Mike Anderson

www.grecopublishing.com

AAs I write this month’s message, I’m freshly home from Las Vegas where I attended SEMA 2025. Outside of ABAT’s Texas Auto Body Trade Show, SEMA is one of my favorite industry events to attend each year because it presents a great opportunity to check out new tools and equipment, expand knowledge through the available training and catch up with industry friends and colleagues from all over. More often than not, those conversations are the most enlightening since they provide an opportunity to find out what’s going on in other markets, to step outside of Texas and see what’s happening around the country.

Now, this isn’t the first time I’ve used this space to lament about the slowdown in volume in my market…and I’m not the only one who has been contending with this challenge. Conversations with friends from the east coast, the west coast, the midwest and around the US confirmed that most markets are struggling with the same decreased workload. Some markets have managed to avoid this difficulty – for now at least – due to weather-

related conditions and natural catastrophes that have kept them busy. But the majority of shops are struggling.

Of course, there are outliers. A handful of shop owners aren’t feeling the crunch, and when I asked how they were maintaining their volumes, the answers were pretty consistent: they’ve figured out ways to adapt to the situation by changing their business models. Some are trimming back in certain areas to focus on specializing, while others are going after different types of sales than they did in the past.

Albert Einstein once said, “In the middle of every difficulty lies opportunity,” and that’s exactly the mentality that these shops are embracing. Rather than rolling over because it’s hard right now, they’re seeking out the opportunity; they’re willing to adapt their

AAs we close out another remarkable year, I want to extend my heartfelt gratitude to everyone who stood shoulder to shoulder with ABAT in 2025. This has been a year of real progress – hardwon, deeply meaningful progress – and it would not have been possible without the unwavering support of our members, partners and advocates across the state.

To our members who fought tirelessly, showed up at the Capitol and contributed generously to help pass SB 458: thank you. Your commitment to protecting and advancing our industry is the backbone of everything we do. I want to especially recognize Burl Richards, Robert McDorman and his expert team and our tireless lobbyist, Jacob Smith. Their dedication, expertise and persistence played a crucial role in securing this victory for Texas shops.

I also want to extend sincere appreciation to the attendees and vendors who showed up for this year’s Texas Auto Body Trade Show. We know how hard it is to step away from your business, even for a couple of days, and your presence is what makes this event the premier gathering for our industry. Your support,

engagement and energy fuel the momentum that keeps ABAT moving forward. ABAT’s annual operating costs are covered by the generous support of the show’s exhibitors and sponsors, so make sure that you shop with them first if you’re in the market for something!

Looking ahead, I’m more optimistic than ever. 2026 is going to be an innovative year for ABAT. We have boots-on-the-ground plans for every chapter across the state, and we’re coming to your town with hands-on education, advanced training and certification opportunities that raise the bar for our industry.

So get ready, because ABAT is bringing the goods in 2026, and we can’t wait to share it with you.

Thank you for your trust, your passion and your partnership. Here’s to another strong year for Texas collision repair.

Buying a paint booth is a huge investment, and there are many factors to carefully consider before selecting one Will the booth work well in a region where there’s a ton of humidity and with drastic changes in the weather? How long do you think the booth will last and will it require a lot of maintenance? Will your painters be comfortable using it ever y day and finally, will the company making the booth provide solid training and reliable customer ser vice?

To answer these questions before acquiring two Chronotech spray booths and a prep deck from USI ITALIA back in 2004, Collision Center Manager Kevin McIllveen at Russell & Smith Body Shop in Houston, TX spent six months studying the market He was looking for the best booths that matched his needs to use in a brand-new 36,000 sq ft facility that the company built from the ground up

Mcllveen, age 56, entered the industr y more than three decades ago as an estimator and has worked for Russell & Smith Body Shop since 1993 His goal with his new spray booths was to improve the efficiencies in his paint department and to accommodate his production, he said, while simultaneously saving time and energy if possible

The vetting process was arduous but worth it in the end. "We did our research so that we could make an educated decision," he said "I went to NACE two years in a row and talked to literally ever yone and asked a lot of questions We knew that this was going to be a ver y significant investment, so we took the time to perform our due diligence to cover all our bases We invested in their prep stations as well, which was another good decision, because my guys can work so much faster and effectively with five different places where we can spray We put a curtain up in the prep booth that provides us two additional spaces that are heated and properly ventilated So, when we are really jammed, we can handle the workload and maintain our cycle time without interrupting or slowing down our production "

After using them for a ver y short time, Mcllveen could clearly see that his Chronotechs were more than capable as they quickly became a centerpiece in his new, high-end, modern shop

"We have four paint teams here, consisting of a painter and a painter’s helper and we consistently log approximately 600-700 paint hours weekly,” he said “We switched to waterborne paint when we opened this facility because we want to provide a healthier climate for our employees and the community as a whole ”

we push these booths and they never let us down ”

Any issues that Russell & Smith Body Shop have encountered with their USI ITALIA booths have been rare and far between But Mcllveen feels good knowing that if called upon, the company will respond and find solutions promptly “If you do your scheduled maintenance and keep ever ything clean, these booths will last you 30 years and maybe even longer The issues that we have encountered with the Chronotechs have been minor and quickly solved, which is impressive when you think that we have been using these booths daily for the last 16 years. I tell people that these booths will be here long after I’ve retired!”

Why was Mcllveen able to improve his numbers by simply adding two USI booths? “In the end, it all comes down to their airflow because we never need blowers or additional air to cure these vehicles The fans in these Chronotechs are exceptional because they feature variable speeds, so we can switch depending on the parameters of each job. Our painters are producing an impressive product day after day, so these booths are saving us both time and money We paint an average of 400 cars ever y month, so

After training provided by USI ITALIA, Mcllveen’s painters were able to start spraying after one day, he said "The Chronotechs are designed to work with waterborne paint, which makes it easier for our painters to do their work After a ver y short time, all of our guys were comfortable and the results were consistently exceptional.”

Mcllveen is also impressed by the Chronotech's sturdy construction and durability "Some booths are just a box, but these are wellbuilt," he said “I know, because I've seen them all and there isn't anything like a USI ITALIA booth "

His career in collision repair industr y has been a great experience and products like his USI ITALIA spray booths and prep station are a part of that, he said “We haven’t had to furlough anybody here and that’s because we value our people and, in the end, our Chronotechs are part of the team ”

ABAT’s Jill Tuggle surely is the hostess with the mostess. From ABAT events here in the Lone Star State to gracing the stages at various regional events, Tuggle continues to leave her mark as an industry leader all around the country.

Last month, Tuggle played some critical roles during SEMA week in Las Vegas on the Collision Industry Conference (CIC) stage and as host of the Collision Industry Red Carpet Awards celebration at Resorts World.

As co-chair of the Governmental Committee, Tuggle sat down with Justin Lewis (Accurate Auto Body and Washington Independent Collision Repair Association) for a “fireside” chat about Right to Appraisal (RTA). Tuggle and Lewis shared their processes, struggles and wins in their journeys to make RTA mandatory in their states.

Tuggle informed the CIC audience of what a “hot topic” RTA is right now, pointing out that other states like Illinois and New Jersey have recently filed bills in favor of mandatory inclusion of the Appraisal Clause.

As was evident by a polling of the room, not everyone has a clear understanding of what this consumer right actually is, although it’s been a provision in insurance policies since the 1800s, Tuggle

utilize the Appraisal Clause to recoup some out-of-pocket expenses, insurance companies started removing the clause from their policies. “We saw that trend, and we wanted to help solidify RTA for our customers,” Lewis shared, referencing the impetus for WICRA’s efforts.

Great lobbying support was beneficial to both associations. Lewis shared that WICRA’s lobbyist started out as one of his customers who happened to see a flyer in his shop about their efforts and inquired. “It was night and day how much further we got with this bill,” thanks to the lobbying efforts, he stated.

Tuggle stressed that grassroots efforts were a valuable tool as well. “If I could go back in time, I’d empower our members to constantly talk to their local legislators.” She advised CIC attendees, “If you are passionate about making changes in this industry, especially your local industry, reach out to your local legislators and say you’d love to speak to them about what it looks like to be a collision repairer.”

It doesn’t have to be about any current problem or legislative efforts, she stressed. Taking the time to establish key relationships “lays the groundwork” for when it’s time for issues to cross their desk as “it will be more of a personal and real issue.”

She also spoke of the major role played by tools like ABAT’s one-page document which “dumbs down the appraisal process in a way that people could understand it. RTA is not something that's been really widely talked about in our industry, and it certainly is not something that a legislator is familiar with.”

“If you do bring legislation, be very thorough. Don’t try to rush to get things done as it may not wind up being what’s best for consumers,” advised Lewis.

Later that evening, Tuggle held the distinction of serving as host of the Collision Industry Red Carpet Awards. “It really is an honor to be up here. Just two years ago, I was on this stage on behalf of ABAT, accepting the Society of Collision Repair Specialists’ Affiliate of the Year Award. That was truly a high honor for us, so it means a lot to me to be up here tonight to celebrate those who will take home awards this evening. The industry's never been easy. It's full of challenges, evolving technology and changing expectations, yet it's full of people who have risen to all of these challenges. And that's who we celebrate tonight. The people in the industry who've got the grit, integrity and the love for what we do and who we serve.” TXA

Anyone who believes the collision repair industry to be a “man’s world” would be largely mistaken given how many amazing ladies call this field their home. To date, Texas Automotive has featured ladies in just about every facet of the industry. This month, we spotlight Emma White of KECO Body Repair Products, a company that is revolutionizing glue pull repair. She may be somewhat of a new face to the industry, but she is most certainly not a newcomer as she’s put in a lot of time behind the scenes prior to coming on full time with KECO. Since then, she’s already presented at the 2025 Texas Auto Body Trade Show and attended various industry events around the country. Read on to learn more about Emma.

Texas Automotive: Tell us about what brought you to the industry and what role you play.

Emma White: I made my official start in January of this year, but I’ve been around

the industry for awhile. Back in 2010, my father, Chris White, started KECO Tabs or KECO Body Repair Products, which is what it is now. The summers between 2012 and 2015, I came to work for him packaging tabs at the plastic injection molding plant, where KECO products are manufactured. My role now is MSO/OEM Relationship Manager. I also head up our sales department. Before coming on board with KECO, I worked for the insurance industry.

TXA: What made you decide to make the switch over to the collision repair side?

EW: The funny thing is that, when I first graduated college, my dad encouraged me to find work outside of his business as he didn’t intend to hire me at the time. That’s what led me to my former job with the insurance industry. But then this past January, he asked me to come on board. I had been interested in working for the company based on my prior experience over the summers, and it appeared to be a really cool industry to work in. Glue pull repair (GPR) is different, and it’s cool to be on the cutting edge of a revolution of the industry. Safe and proper repairs via glue pull repair, being the least invasive way to repair, is exciting to me. I was interested in hopping on board and to learn more about what I could do at KECO and in the industry. Working for family and with family has its challenges, but I wouldn’t trade it for anything. My dad’s passion for his business is infectious. I’m so grateful for the way he pours into me, pushes me and encourages me.

TXA: Did any of your prior experience being on the other side assist in your current role in all?

EW: Somewhat! It was my first time in a sales role. I worked for an insurance aggregator so I didn’t sell insurance, but I did have an insurance license. I think that the experience helped me understand some of the topics and concerns that come up at the Collision Industry Conference (CIC) and the Society of Collision Repair Specialists meetings. I think I may have had a much harder time following along during those meetings had I not had experience in the insurance industry.

TXA: What do you think are some of the biggest challenges women face, and have you faced any yourself?

EW: Being new to the industry, I haven’t experienced anything too difficult. I became involved with the Women’s Industry Network (WIN) this year. They say there aren’t a great deal of women in the industry, but I was surprised to be welcomed by so many women in this industry. I’ve found that everyone really rallies together and is more than willing to help others and make introductions that will be beneficial. Everyone has been so welcoming and willing to help in whatever way they can.

TXA: What do you love about the industry the most?

EW: It’s definitely the people. I’ve gone to quite a few events this year, including eight trade shows and all the CIC meetings, and I love seeing all the familiar faces. Everyone has been so welcoming and eager to help me learn. I look forward to getting more involved in industry organizations, growing current friendships and meeting new people!

by Alana Quartuccio

TXA: Let’s talk about life outside the body shop. Are there any interesting hobbies you’d like to share?

EW: I have a theater background, which started in freshman year of college. My interest moved from theater to film as I eventually majored in creative media productions, a marketing type of degree. I still have a love for it, and I make short films with a couple of friends of mine. I try to do it as much as I can.

TXA: Do you have any encouraging words to give other women interested in pursuing a career in collision repair?

EW: Be bold. I know it can be scary, especially when you are new to an industry and feeling like a minority, but if you put yourself out there, meet new people, learn as much as you can and just be a sponge, it is definitely possible to excel quickly and move forward.

TXA

WIN offers education, mentoring and leadership development opportunities to build critical skills for success in the collision repair market.

• Local/Regional Networking Events

• Annual Education Conference

• Educational Webinars

• Mentoring

• Scholarship Program

• School Outreach Program

• Most Influential Women (MIW) Award

PRECISION

CUTTING TOOLS FUME EXTRACTION

DENT PULLING AND MUCH MORE!

Operating a collision repair facility is similar to a marriage in many ways; both require commitment, communication and resilience, especially when times get tough. As we learned from local and national industry experts, in order to survive and ultimately thrive, shops now must get creative, adjusting strategies and riding the unpredictable waves of economic uncertainty to stay afloat and emerge successfully.

After several years of nurturing a heavier workload than normal, the market began shifting downward last year.

“Not since the pandemic year of 2020 have so many US shops reported six-month sales and net profit being below the same period a year earlier,” CRASH Network reported in April, citing its recent “Collision Industry Business Perspectives” survey. “Nearly half (46 percent) said their sales and net profit in the second half [of] 2024 were down from what they were in the second half of 2023. It’s the fourth survey in a row where that percentage has risen (from a low of just seven percent who said six-month sales were down in 2022)

and is almost as high as when 53 percent of shops reported sales down in the second half of 2020.”

Although the CRASH Network survey indicated 39 percent of shops had seen no change in sales and net profit over a six-month period, only 15 percent reported an increase in the second half of 2024 compared to the same period in 2023. “It hasn’t been since 2020 when [so] few shops were seeing an uptick.”

According to Focus Advisors’ "2024 Year in Review: Some Excel on a Bumpy Road,” some operators reported “their trailing 12-month sales were down as much as 20 to 30 percent.”

Texas repairers indicate similar experiences, though the severity of the slowdown varies by shop. “Our body shop business is down 30 percent, close to COVID levels, but not quite that bad just yet,” shares Greg Luther (Helfman Collision; Houston).

“We are definitely down this year compared to last year,” says Eric McKenzie (Park Place Dealerships; Dallas/Fort Worth). “Our best year after COVID was 2023. This year’s numbers are similar to

2019, which was our best year before COVID.”

For Burl Richards (White Sands Collision Center; Lindale), “The workload has decreased pretty significantly over the last year and a half and is currently less than it was pre-COVID.”

During an ABAT webinar earlier this year, Mike Anderson (Collision Advice) offered a nationwide perspective. “It’s not a new normal. It’s the old normal. I’ve been to 32 states this year, and I can tell you that with the exception of Indiana and Nebraska, the next appointment for most shops is either tomorrow or as soon as one hour from now. Smaller shops doing about $200,000 in sales may be booked out about a week. Larger shops doing $400,000 to $500,000, their next appointment is tomorrow. Is this the new normal? No. We just went back to the way things were before COVID; we merely forgot what it was like.”

In a marriage, when a relationship gets rocky, outside intervention may be necessary, and many shops looked forward to the country’s administrative change as exactly the change the industry needs, due to President Donald Trump’s promises to “end inflation and make America affordable again,” yet a year into his second (though non-consecutive) term, costs continue to rise. As of September, inflation is up around three percent, an increase that can be partially attributed to tariffs which affect a plethora of products, including automotive parts. Combined with the industry’s ongoing challenges related to advancing technology, these higher prices have also contributed to a spike in repair costs, allowing insurers to justify raising premium costs, with projections of a seven percent increase by the end of 2025; in turn, consumers are more hesitant to file claims after minor collisions.

With so many interrelated components married together to create a perfect storm of circumstance, it’s difficult to pinpoint a single factor to blame.

“Claims volume is down, total losses are up, and vehicle owners are broke,” Luther laments. “People are choosing to survive rather than get their vehicles fixed. We went through the same thing in 2008-2009.” Although he acknowledges that tariffs are likely a factor, he believes, “Tariffs have given many businesses an excuse to raise prices and blame those increases on trade policy. In reality, I’m not sure how much direct impact tariffs have had on our specific operations. From what I can tell, much of the tariff activity so far has been more about political posturing and threats between countries rather than widespread implementation that directly affects our industry.

“I believe the challenges currently facing the collision industry and small businesses stem largely from inflationary pressures that began under the previous administration. These were driven by extensive COVID-19 stimulus programs and the widespread fraud and abuse that followed – both inside and outside of government,” he continues, optimistically suggesting that things will turn around soon. “The Trump administration is now taking a strategic approach aimed at exposing that corruption and stabilizing the economy in the long run. By allowing short-term market corrections and focusing on rooting out fraud, the administration

may be setting the stage for lower interest rates and greater accountability within government systems. While this approach can create temporary strain for small businesses, it could ultimately lead to a more transparent and sustainable economic environment.”

Acknowledging the aforementioned factors, McKenzie suggests, “What’s also affecting our high line vehicles is the overseas salvage values being so high that it’s causing insurers to total out late model vehicles as low as 20-30 percent of the vehicle values. Also, the lack of lease vehicles since COVID has really affected our business.” He does not see tariffs as problematic “since parts price increases get passed on to insurance companies,” and he also remains positive about the industry’s future. “The sooner the economy improves, the sooner our business will also.”

Richards agrees that tariffs have not presented challenges, instead attributing the majority of the industry’s workload concerns to “higher premiums which make people more reluctant to file a claim due to the risk of further increases, fewer repairs caused by more total losses based upon insurance companies lowering the threshold on when they determine a total loss and less severe wrecks due to ADAS features in modern vehicles.”

Regardless of what is causing the decreased workload, the problem remains the same, so what can shops do to tackle these issues? Well, it goes back to treating the business like a marriage. Maintaining any relationship requires commitment and clear communication but also flexibility and innovation, so successful shops are evaluating how they can do things differently. McKenzie’s shop has taken a different approach to “the way we submit supplements and how we communicate about fake totals to our guests. We’ve started submitting skinnier first supplements with only the essential items to complete body repairs so that the vehicles won’t be totaled prematurely.”

Helfman Collision has also transformed some practices, maintaining their commitment to doing the right thing for their customers. “We’ve adjusted our approach by capturing keys up front and stepping back from the practice of insisting that insurers complete a full supplement before repairs begin,” Luther explains. “With many carriers now totaling vehicles at 50 percent or less of their value, preparing full and comprehensive repair plans is no longer in our best interest – or the customer’s.

“Most of our customers want their vehicles repaired rather than totaled, since they often can’t afford the financial impact of a total loss,” he elaborates. “We’ve found that a segmented supplementation process – handling supplements in stages as repairs progress – has proven to be a more effective strategy for both our business and vehicle owners. It keeps repairs moving forward efficiently while still allowing for accurate cost adjustments along the way.”

Richards agrees that a shop’s most important relationship is with its customers. “It is more important than ever to please the customer, not only with the repairs, but by becoming head and shoulders better than the competition in customer satisfaction on continued on pg. 18

many levels, not just quality and customer service.” One way his shop has accomplished that is by investing in loaner cars to better support clients. Efforts like these go a long way toward building trust and customer loyalty, a vital component toward a successful “marriage” with one’s business.

While Richards’ focus for the past 27 years has been on performing safe and proper repairs with investments in OEM certification and specialized equipment over the past decade, he acknowledges, “While this is still my main focus, it isn’t enough anymore.” He has been exploring different business strategies like expanding his offerings to service more fleet accounts as well as investing in marketing. “We hired an in-house sales and marketing professional to promote the shop to local vehicle owners and businesses.”

Anderson supports the idea that marketing is key to surviving the market downturn. “In the past, shops only spent one percent or even less on marketing. The shops I see that are still doing well and maintaining profitability are spending four to six percent — and making sure they use their marketing efforts to inform customers of who they are before they wreck their vehicles.” And once those marketing efforts convince customers to walk through the shop’s doors, it’s imperative to actually sell one’s services. “When shops were busy a year or two ago, many of them lost the ability to be

salespeople and instead became order-takers. When I first started in the industry, we’d try to upsell all the time by offering to fix door dings and anything else we saw. If we want to increase our sales, we must get back into the habit of being salespeople.”

Shops must also remember that challenges are inevitable; success comes from investing in the business, maintaining patience while navigating the ups and downs and always and finding support when it’s needed. ABAT shares the same vision of a better industry for all Texas shops and is planning ways to help shops address these challenges as we all move into the new year (see Richards’ message on page 4).

And many retain faith in a positive future. “Since mid-2024, it’s been clear that 2025 would present challenges and that many people and businesses would experience some economic strain; however, I believe that by the spring of 2026, we’ll begin to see an upward trend,” Luther optimistically predicts. “Regardless of personal opinions about Trump, I don’t believe he will allow the economy to remain in a downturn heading into the 2026 midterm elections. Whether the recovery is driven by genuine improvement or political motivation, I expect we’ll see noticeable economic momentum before the elections, allowing his administration to highlight progress and stability heading into that critical period.”

TXA

over

shop is inundated with solicitations; advertising with Greco Publishing breaks through the noise to align your company as an association ally, and get you in front of your next customer.

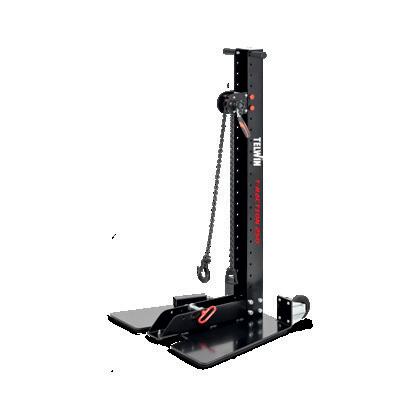

Rivian, a manufacturer of passenger and commercial electric vehicles, has recently approved the Telwin SpA Inverspotter 14000 Smart Aqua Squeeze Type Resistance Welder for structural repairs on its passenger and fleet delivery vehicles. With this approval, the 14000 welders can be used throughout Rivian’s quickly expanding global network of Certified Collision Centers.

“We are proud that Telwin’s Welding Technologies have met the engineering welding requirements set by Rivian,” said Telwin SpA Chief Executive Officer Stefano Spillere. “As we continue to grow in the global market, this approval strengthens our North America offerings.”

The Made-in Telwin technology Smart Autoset allows automatic detection of material and thickness not relying on manual settings or reference tables. Its up to 15,000 amp capabilities allows proper welds every time.

Additionally, the Telwin Technomig 243 Wave three-torch welder has met the specifications set by Rivian and will be offered as an option to the Certified Collision Network as a MIG/MAG welding solution.

Rivian Certified locations have been specifically chosen for their expertise in proper repairs of Rivian vehicles and providing

must meet specific training, tooling, and facility requirements to assure that Rivian collision repairs are performed to OEM standards. With the number of people driving Rivian vehicles expanding by the day, Rivian encourages repair centers to join the Rivian Certified Collision Network of repairers. The first step in that process is to submit an application at https://usa.itascore. com/rivian.

About Telwin SpA: For over 60 years Telwin has been a worldwide leader in the manufacturing of welding machines, cutting systems, battery chargers, and starters based in Italy Telwin is present on all five continents, on over 120 markets with a range of products that, for variety and richness, has no equal on any market; products tailored to all production fields, from the automotive to industry, from the building sector to shipyards, from all professional divisions to DiY. Telwin means state-of-theart, innovative and technologically advanced solutions, aimed at improving productivity, optimizing intervention times, minimizing operative costs and always guaranteeing excellent performance

t.morgan@telwin.com

Kevin Ellison based his entire career on simply “doing the right thing.” No matter what the role – manager of dealership body shops, active member of ABAT’s Board of Directors or mentor and friend – Ellison’s dedication and commitment have always shone through. Earlier this year, he made the decision to enter into retirement. He may have stepped away from the body shop and association work, but Ellison’s lifelong commitment to the industry will never falter as he’s inspired, mentored and friended many along the way to do things right.

“I really just wanted to be the guy who did the right thing,” Ellison humbly reflects. “I think one of the things I did best was build a good team around me, wherever I was. I always wanted to attract people who shared my desire to do the right thing because it was just the right thing to do.”

To Ellison, success wasn’t measured by numbers. His shops were always busy; surrounding himself with like-minded folks

led the operations to maximize business, but he’s most proud of the culture and teams he built along the way. Recognition and winning awards was never important to him.

It’s surprising to learn that someone who devoted so many years to an industry initially didn’t have an interest in pursuing a career in collision repair.

“I’m second generation. My father, Harold Ellison, was very well respected in the industry.” The young Ellison spent summers working with his father and later went on to college with “no intention of getting into the collision repair industry.” But then, like it was just meant to be, “I looked up one day in need of a job, and I went where I was supposed to be all along.”

His first industry role was as an estimator working for a few different shops. He went on to spend the majority of his career managing body shops at different dealerships. “My first manager job was at North Central Ford where I worked for a wonderful family for a few years. Most of my career was spent working for dealerships, mostly Ford stores. Before I retired, I was with Westway Ford in Irving for seven years. Prior to working for Westway, I was with Bob Tomes Ford in McKinney for 15 years.”

When Ellison heard an auto body association – the early formation of ABAT – was working to get off the ground in East Texas, he answered the call by gathering up a few fellow like-minded body shop managers to attend a meeting in Dallas.

“I went to that first meeting with the thought that if it was just simply a bunch of shop owners getting together to bash insurance companies, I was probably not going to be interested. But what I found were some very articulate, intelligent individuals who shared the same passion and wanted the same things I wanted for the industry.”

At that point, Ellison had been in the industry long enough to see changes taking place that were not in favor of collision repairers, and he believed, “A unified voice was needed.

“In my early years, I felt that shops had some semblance of control over the repair process. I felt like we controlled that, and we were paid accordingly by insurance companies. But through the years with the onslaught of DRPs, we saw so many changes that did not benefit collision repair.”

He believed the industry sold out. “Everybody started doing whatever they could to get on DRPs, whether that be based on parts discounts, labor discounts or parts usage.”

The need for one voice is what sparked his interest in the developing association. “I recognized this was an organization interested in advancing knowledge and communication among shop owners. Even though I was a seasoned veteran at that time, I was not fully aware of some of the issues addressed during that first meeting. I was excited about sharing that information. It became ABAT’s mission statement to educate everyone in the industry.

Not too long after, ABAT sought to build a chapter in Dallas, and Ellison was nominated to serve on the Board of Directors. It’s a role he maintained until his retirement.

He was instrumental in bringing Jill Tuggle on board as ABAT’s executive director. “I first met Jill when she worked on a route for a wheel repair company. She was always willing to get her hands dirty and do whatever the job demanded. I got to know her in her early years and saw her progress from running a route to becoming a marketing person.” Tuggle came on board to run a marketing program for one of his

shops, and “it was exactly where she needed to be.”

When ABAT took off and there was a need for someone to steer the ship, Ellison nominated Tuggle. “Oddly enough, she said, ‘No,’ but I told her I didn’t think that was the right answer. She eventually accepted, and she’s done an amazing job in that capacity.”

Tuggle credits Ellison “as a big part of my growth and success in this business. Not only has he acted as a friend to me, but also a mentor. Kevin offered me a part-time job many years ago that was profound in two ways: I loved my current job so much that I initially declined interviewing for the position he had. That’s when Kevin said, ‘I’m not gonna let you off that easily. I want you to at least hear me out.’ I did, and I’m so glad that I heard him out, because not only did I take that job, but it sparked something inside of me that made way for me to create an entire business of it. That’s where my entrepreneurial journey began.”

Tuggle admits she turned the role down when Burl Richards approached her about the position with ABAT, but then, “I heard Kevin’s voice in my head from the day he asked me to at least hear him out, so that’s what I did with Burl. Once again, I was so glad

by Alana Quartuccio

that I did because as you can see, the rest is history.

“Personally, he has always walked alongside me through many of the pivotal moments in my life,” Tuggle continues. “He has watched my kids grow and walked along some of the harder things in life with me like the death of my dad. Kevin has always been a phone call away, whether I had car trouble or I was gutting a deer

continued on pg. 24

by Robert L. McDorman

Dear Mr. McDorman,

I own and operate a collision facility in East Texas. Thank you and all others who have worked diligently these past eight years to secure motor vehicle mandatory appraisal rights for the insureds in Texas. It is my understanding this went into effect in September and will be a requirement for every auto insurance policy beginning in January. Over the past several years, many of my clients who have State Farm insurance have had to pay a significant difference between their actual repair bill and what State Farm claimed they owed for the repair, with no rights to invoke appraisal to contest the short pay. It is my understanding sometime around 2017, State Farm removed their policy holders' right to invoke appraisal for repair procedure disputes. With the passing of the Mandatory Appraisal Bill, I assume State Farm will now have to rewrite their motor vehicle policy to include a Right to Appraisal for motor vehicle repair procedure disputes, but can you please confirm?

Thank you for your comments and questions. Yes, this is correct on all counts. The Texas Mandatory Appraisal Rights Bill SB 458 went into effect on September 1, 2025. The policies issued or renewed on or after January 1, 2026 must include a mandatory Right to Appraisal (RTA). So yes, I can confirm that with the passing of SB 458, all Texas motor vehicle policies are required to have an appraisal process for both repair and total loss disputes between the insurer and the policy holder, including State Farm.

The Mandatory Appraisal Rights Bill is currently in the rule making and appraiser/umpire requirements phase. As we wrote last month, Auto Claim Specialists and many others have turned in public comments to the Texas Department of Insurance (TDI) addressing their informal working draft of the rules and criteria. We are truly thankful for TDI's work on these rules and appreciate that the residential property and auto appraisal processes have been somewhat separated to allow for the quicker resolution of auto claims. We look forward to seeing the final rules and appraiser/ umpire criteria along with the punishment guidelines when one of the rules is broken. In my professional opinion, the tougher the rules and the bigger the fines when a rule is broken, the fairer and more efficient the appraisal process will be for all interested parties.

For the Mandatory Appraisal Bill rule making and appraiser/ umpire criteria phase now under review and in process,

Commissioner Brown must adopt rules related to the period for appraisal, which is critical to the process. Equally critical are the qualifications and selection criteria for appraisers and umpires involved in the appraisal process which were also addressed in our comments related to the working draft. As I have stated several times, we have done an excellent job making legislators problemaware to give Commissioner Brown the backing she needs for adapting rules and requirements. We now must make her solutionaware. I am confident with the right information and data, she will set the correct rules and qualifications in place for motor vehicle loss disputes. I have complete faith in her to do this.

As an insured citizen in Texas, I will do everything in my power to educate my fellow Texans about their legal Right to Appraisal when a dispute arises between them and their insurer. These under-indemnification issues on motor vehicle claims are harmful to Texans and can be detoured or stopped with widespread consumer awareness.

As I have spoken about and written about for many years, the under-indemnification in repair procedure and total loss claims in Texas is rampant. Most of the estimates and supplements we see for repair claims have many overlooked (by design) safety and OEM-required operations needed to restore the loss vehicle to its pre-loss condition to the best of one's human ability. Now, with the passing of SB 458, when a dispute arises over the loss on a motor vehicle repair claim, there will be a binding Appraisal Clause in the policy allowing these disputes to be turned over to industry professionals to determine the loss.

Robert is a recognized Public Insurance Adjuster and Certified Vehicle Value Expert specializing in motor vehicle-related insurance claim resolution. Robert can be reached by phone at (800) 736-6816, (817) 756-5482 or via email at AskTheExpert@autoclaimspecialists.com. continued on

The spirit of the Appraisal Clause is to resolve loss disputes

continued from pg. 21

by myself for the first time. I don’t know how I got so lucky to have a friend and mentor like Kevin. I’ve met a lot of good men in my life, and Kevin Ellison is at the very top of that list.”

Retirement had been on Ellison’s mind for some time as “I’m an old country boy at heart, and I was getting tired of the metroplex and the rat race. I’m 64 now, and I planned to work three more years, and my wife and I planned to move to the country.”

Then this past April, Ellison suffered heart failure when the lower part of his heart quit working. After spending weeks in hospital, followed by physical therapy and more recovery at home, he fought his way back, but his decision was made.

“I just recognized from reflection and prayer that I had given 40 years of my life to an industry that has been good to me, but it’s very time consuming. Working

60 hours a week and being responsible for a shop and employees, as much as I love it, had really taken its toll.” His health made him “step back and realize none of us knows how much time we have left. I anticipate living a long life, but I made the determination that whatever time I have left, I want to spend it with my family and not on a 60-hour work week.”

He, his wife and their 14-year old grandson moved to a small town of Albany. He’s enjoying relaxing, some golf, taking his grandson to activities and most important “not getting up at 4:30 in the morning.”

Ellison admits he’ll miss the people and the relationships he made the most. “At the end of the day, it’s another wrecked car we have to fix, but it’s about the relationships you build.” TXA

continued from pg. 22

fairly and to do so in a timely and costeffective manner by unbiased industry qualified appraisers and umpires. Invoking the Appraisal Clause removes the inexperienced and biased carrier appraisers and claims handlers from the process, undermining their management’s many tricks to undervalue the loss settlement and under-indemnify the insured. Through the Appraisal Clause, loss disputes can be resolved relatively quickly, economically, equitably and amicably by unbiased, experienced, independent third-party appraisers as opposed to more costly and time-consuming methods such as mediation, arbitration and litigation.

In today’s world, regarding motor vehicle insurance policies, frequent changes in claim management and claim handling policies and non-standardized GAP Addendums, we have found it is always in the best interest of the insured or claimant to have their proposed insurance settlement reviewed by an expert before accepting. There is never an upfront fee for Auto Claim Specialists to review a motor vehicle claim or proposed settlement and give their professional opinion as to the fairness of the offer.

Please call me should you have any questions relating to the policy or covered loss. We have most insurance policies in our library. Always remember that a safe repair is a quality repair, and quality equates to value. Thank you for your question and look forward to any follow-up questions that may arise.

Sincerely,

Robert L. McDorman TXA

Join Reliable Automotive Equipment’s Dave Gruskos for conversations with industry leaders sharing their insights and the latest from the world of certified collision repair. This month, Dave talks with Mark Allen, manager of Collision, Equipment and EV after sales service at Audi of America.

Dave Gruskos: How does Audi recommend shops best approach how they prioritize the investment in tools, equipment or facility upgrades needed to maintain certification and repair to OEM standards?

Mark Allen: Shops need to look at the ROI every time they look at a piece of equipment. They should look to see whether they have future intention of getting onto a program. If I have to invest in a welder, for example, and I’m going to look at becoming Audi, and that may happen, then I want to look at the welder that is required by the program. Some of the programs are not specific; others have certain specifications. If you’re going to one company that only gives you specifics, you can look and see if it fits those specifications, and whether it will fit in a future attempt to get on the program. And you’d do that for every auto manufacturer that you want to serve. Now, it takes homework, and people like Mike Anderson and Collision Advice and others out there are pretty sharp at helping people walk through this. The other thing is knowing how to future-proof yourself when ordering new equipment. Are you using appropriate accounting principles to write off the welder in a short enough time to save money in buying the next welder? Cleanliness and servicing is a way to extend the life of equipment, but accounting principle is how you plan for future investment.

D.G.: A recent press release from the manufacturer noted a strong demand continues for Audi electric vehicle production. On the aftersales side, what guidance do Audi Certified collision centers receive to help them navigate the constantly increasing complexities of EV repair?

M.A.: The standard is to take it to a dealer. We make everyone take high voltage awareness training, which advises them on how to recognize whether a vehicle is an EV of some sort, whether it’s a full-on electric or a plug-in hybrid electric vehicle (PHEV) or any of the others, in an effort to build a

ABOUT THE PROGRAM

Total # of Audi Authorized Collision Repair Facilities: 209

*An additional 41 facilities are currently undergoing the process to become certified.

# of Dealer-Owned locations: 55 43 Ultra Certified; 12 Hybrid Certified

# of Independent locations: 154 84 Ultra Certified; 70 Hybrid Certified Ultra Certified: Can work on vehicles with advanced materials, such as carbon fiber.

Hybrid Certified: Can work on vehicles constructed with high-strength steel, steel and aluminum.

deeper awareness. If you’re not at Audi authorized shop, however, and you’re not a high voltage technician, put your hands in your pockets and walk away from the car. Drive it over to the dealer and have them do the high voltage work, or have the dealer send someone over, and then, get everything out of the way, where it’s safe and de-energized, and then do your work.

D.G.: In your opinion, how does the adherence to OEMrequired equipment and tooling practices, combined with manufacturer-required procedures, contribute to a quality repair?

M.A.: The OEM-required procedures have been crash tested. When you see a several-hundred-thousand-dollar Lamborghini Quattrovalvole run into a wall and rebuilt, it makes your heart hurt. But doing that gives you a repeatable outcome. Just follow the procedure. We’ve even gone so far as to publish a book where we explicitly call out what to do and not to do. No pulling, for example. Do not cut.

If the repair that was done in the John Eagle case was followed that way, there’s a much better chance that the Seebachans may not have been injured, or injured as badly. As a shop, following procedures gives you a level of legal protection, as well. If you do exactly what the OEM said, following the methodology with their products, it puts the onus back on the auto manufacturer, and the independent repairer has a legal leg to stand on.

continued from pg. 4

thinking and try something different. Easier said than done, I know, but I truly believe that’s the secret to getting through this.

At my shops, we’ve been doubling down. This situation isn’t going to defeat us! We’re still investing in tools and equipment to keep up with the constant changes in vehicle technology, but we’re also looking at other opportunities to bring in sales. We’re operating more like an auto center by performing some smaller mechanical repairs and stocking tires; we’re willing to branch out and try something new since the old way just isn’t working right now. I’m convinced that business breeds business and sales breeds sales. Even if a customer comes in to look at tires, at least we’re getting people through the door.

That’s not to say that it’s been easy. In my many years in collision repair, I cannot recall the industry ever being in such a poor state as it is right now, and the change happened relatively quickly. It seems like ADAS suddenly started doing its job, reducing the number of accidents, at the same time that total losses spiked and increases in premium rates deterred many customers from filing claims. There are definitely a lot of factors coming into play in this situation, but together, we can rise above the challenges.

Each month, I share my experiences in hopes that others will

reciprocate because ABAT wants to hear from you. We want to know what you’re doing differently, and that requires starting the dialogue. We want to know who has found successful ways to adapt their business models and what they’re doing differently. Are you finding new ways to boost sales, or have you implemented lean strategies that allow you to remain profitable with fewer sales?

In the coming year, the association will be largely focused on the state of the collision industry. We’ll be planning lots of virtual meetings with nationally-recognized presenters as well as getting back out to markets all over Texas for in-person meetings. The goal of these events is to provide opportunities to show up, engage with your peers, share your experiences, learn from others and identify ways to adapt to the new market.

These difficulties don’t seem to be going anywhere anytime soon, so rather than moan and complain, we are going to find a way to deal with the challenges we’re facing in the market. We’re going to find the opportunities that will allow us to all thrive!

burl.richards@proton.me

Designed for high production, the Italia comes with the Timeless Series Direct Drive Air Make Up Unit, completely integrated intake, heat,

system.

The Italia includes (2) 10hp VFDs, digital PLC control panel, full lower LED lighting package (every wall), and SmartPad digital control panel with EnergySmart Package, which automatically drops to idle when no spraying is detected.

The exterior of Accudraft’s Dual Skin Finishing Equipment is available in FOUR colors: