As the final issue of 2025, I realize there are things to put behind us this year, with the downturn of not just amount of work but also in relationships among the market with shops and insurers. The slowing in the market has emboldened some claims handling practices from some companies to get uglier than they’ve been in many years. Why sugarcoat the issues, when we can look them right in the eye? Instead of putting our head down, let’s grow up.

I’m getting complaints from shops more than ever, about the frustrations over unpaid required operations, capping of reimbursement rates, and more. Things they spent years giving documentation to, met with agreement and payment, now are suddenly back to square one. It’s demoralizing to have found progress to only have it backslide. Rightfully so, because it is also frustrating the relationship between the shop and the customer. Telling them their vehicle repair is going to be different than previously outlined, even from a payment standpoint, is not a place anyone in the ecosystem wants to be. I’m frustrated for our shop community.

What are some of the solutions possible?

I don’t want to talk like you don’t know the obvious, but maybe saying it again is helpful as a reminder when irritation flags and distraction happens.

First solution, you must talk to the customer throughout the entire repair process. I realize some who read this aren’t at that point yet, trying to “keep the peace” and bearing the burden of the tension. You need to give them all the information and details, because at the end of the day you, as the repairer, are not party to the policy contract. For them to advocate for themselves requires them to be armed with all the particulars. They can take that to the BOI, they can invoke the Right to Appraisal, they can sue their

PRESIDENT Kris Burton kris@rosslynautobody.com - 703-820-1800

VICE PRESIDENT Phil Rice price@bapspaint.com - 540-846-6617

TREASURER John Shoemaker john.a.shoemaker@basf.com - 248-763-4375

SECRETARY Barry Dorn bdorn@dornsbodyandpaint.com - 804-746-3928

IMMEDIATE PAST PRESIDENT Steven Krieps steve@gregclineauto.com 304-755-1146

BOARD OF DIRECTORS

Rodney Bolton (boltonconsulting61@gmail.com) 443-386-0086 Tom Brown (thbrown@ppg.com) 703-624-5819

ADMINISTRATION

EXECUTIVE DIRECTOR

Jordan Hendler (jordanhendler@wmaba.com) 804-789-9649

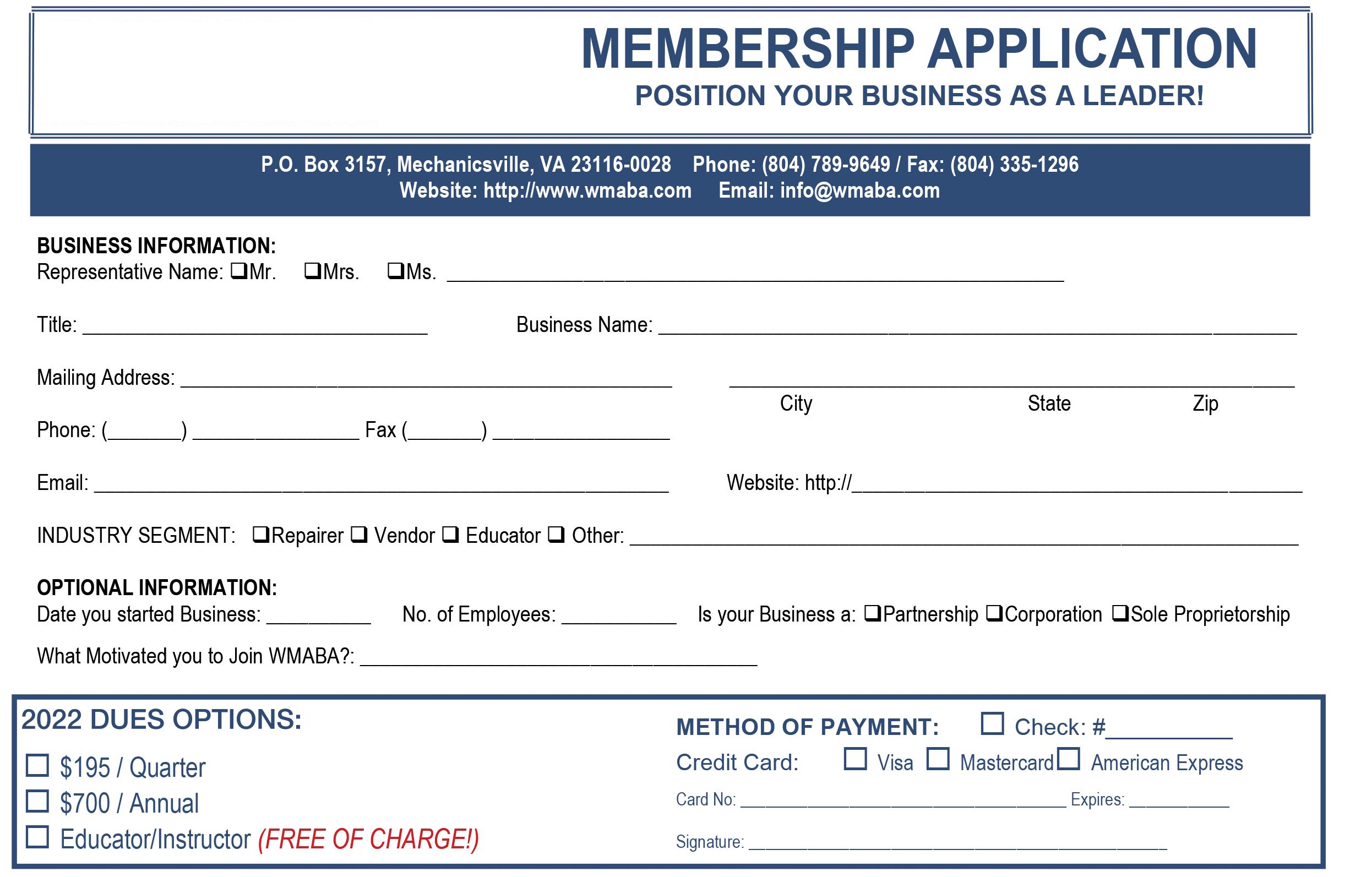

WMABA CORPORATE OFFICE

P.O. Box 3157 • Mechanicsville, VA 23116

insurance company. But they cannot take authority without the facts.

As the repairer, you speak the language of the repair plan. Second option, still as important as the first, is to have all the documentation – repair procedures, images, historical instances – so you can make the educated and rational argument for proper repair. If reimbursement is still not agreed upon, again, the customer must be involved. They could request a denial in writing, attempt to gain a decision reversal themselves, or then move to next steps.

If disagreement and denial is set, you then have the choice to do the proper repair with a balance bill to the customer, or you perform it at a loss. What should not be an option: Not performing the proper repair, especially given the documentation you’ve in hand. Doing so is opening yourself to liability for an improper repair YOU DIDN’T EVEN GET PAID FOR. Why would you want to do that?!

Bad decisions by the insurance company do not make you responsible for making the customer happy on their behalf.

Say that again out loud if you need to.

You are an educated, Tooled, Trained and Trusted Collision Repair Professional. Your business has Integrity and is in the Local Community.

Never allow someone else’s bad decisions to take you off that mantel. Decide that 2026 will be the year you uphold to those values despite the pressure, bullying or downright unlawful actions of those only seeking to keep a buck in a pocket that is already overflowing.

Jordan Hendler (804) 789-9649 jordanhendler@wmaba.com

HAMMER & DOLLY STAFF

PUBLISHER Thomas Greco thomas@grecopublishing.com

SALES DIRECTOR Alicia Figurelli alicia@grecopublishing.com

EDITORIAL DIRECTOR Alana Quartuccio alana@grecopublishing.com

SENIOR CONTRIBUTING Chasidy Rae Sisk EDITOR chasidy@grecopublishing.com

Torchy Chandler (torchy.chandler@gmail.com) 410-309-2242 Tracy Dombrowski (tracy@collisionadvice.com) 571-458-0648

OFFICE MANAGER Donna Greco donna@grecopublishing.com

PRODUCTION Joe Greco COORDINATOR joe@grecopublishing.com

www.grecopublishing.com @grecopublishing

Safford Brown

10570 Fairfax Boulevard

Fairfax, VA 22030

Toll Free: 800-234-8642

Phone: 703-385-3994

Fax: 703-591-5348

Toll Free: 800-545-4745

Fax 877-696-1841

Email: parts@fitzmall.com www.fitzparts.com Ourisman Mazda of Rockville 801 Rockville Pike Rockville, MD 20852

Parts Direct: 301-340-7668

Phone: 855-417-4511

Fax: 240-499-2488

Email: rockvilleparts@ourismanautomotive.com www.ourismanmazdaofrockville.com

Fitzgerald Mazda of Annapolis 1930 West Street

Annapolis, MD 21401

Toll Free: 866-280-8022

Phone: 410-224-4636

Fax: 410-224-4264

www.fitzmall.com

Audi Silver Spring

Direct: 301-890-3015

Fax: 240-471-6103

Email: wholesaless@mileone.com

Hours: M-F 7:30am - 5:00pm S 8:00am - 3:00pm

Mercedes-Benz Silver Spring

Direct: 301-890-3060

Fax: 301-890-5473

Email: mbsilverspring@mileone.com

Hours: M-F 7:30am - 5:00pm S 8:00am - 3:00pm

Porsche Silver Spring

Direct: 301-890-3015

Fax: 240-471-6103

Email: wholesaless@mileone.com

Hours: M-F 7:30am - 5:00pm S 8:00am - 3:00pm

Sprinter Silver Spring

Direct: 301-890-3060

Fax: 301-890-5473

Email: mbsilverspring@mileone.com

Hours: M-F 7:30am - 5:00pm S 8:00am - 3:00pm

Free delivery on our fleet of 15 GPS-equipped delivery trucks - delivering all Silver Spring brands on the same truck throughout Maryland, D.C. and Virginia

We use IRF automotive systems including CCC, CollisionLink, OPSTrax, partslink24, PartsTrader & RepairLink

Highly knowledgeable, experienced and dedicated wholesale specialist team

Large inventory of OEM parts and tires

Contact our dealers for all your Genuine Parts needs!

BMW of Silver Spring

Direct: 301-890-3015

Fax: 240-471-6103

Email: wholesaless@mileone.com

Hours: M-F 7:30am - 5:00pm S 8:00am - 3:00pm

Herb Gordon Subaru

Direct: 301-890-3065

Fax: 301-847-2239

Email: herbgordonsubaruwholesaleparts@mileone.com

Hours: M-F 7:30am - 5:00pm S 8:00am - 3:00pm

Volvo Cars Silver Spring

Direct: 301-890-5456

Fax: 301-847-2239

Email: herbgordonvolvowholesaleparts@mileone.com

Hours: M-F 7:30am - 5:00pm S 8:00am - 3:00pm

MileOne Ineos Grenadier

Direct: 301-890-3015

Fax: 240-471-6103

Email: wholesaless@mileone.com

Hours: M-F 7:30am - 5:00pm S 8:00am - 3:00pm

Service. Trust. Genuine Parts. It’s what we do.

This year, as Albert Kemperle Inc. celebrates its 83rd anniversary, BASF also celebrates its 158th anniversary. We are proud of our decades of partnership with BASF and years of serving the auto paint and body industry together. Kemperle’s founders would be proud of this relationship and the growth their company has experienced because of it.

Today, as we look forward to many more decades of service to our customers, we find ourselves filled with gratitude. The creativity, hard work, and sense of responsibility of the people working for our two companies have made us what we are today.

Thank you for your many years of loyalty.

626 E. Elizabeth Ave., Linden, NJ 07036

(908) 925-6133

(908) 925-4344 414-416 Madison Ave., Paterson, NJ 07524

(973) 279-8300

(973) 279-9030 631 Clifton Ave., Toms River, NJ 08753

Melrich Road, Cranbury, NJ 08512

(732) 797-3942

(609) 860-2800

(732) 797-0774

(609) 860-2801 4 Emery Ave., Randolph, NJ 07869

(862) 244-4818

They say that “you get what you put in.” The road to progress takes a commitment to learning and growing, and SEMA 2025 offered every opportunity a collision repair professional could ever possibly want! From engaging panel discussions at the Collision Industry Conference (CIC) to the Society of Collision Repair Specialists’ (SCRS) thought-provoking Repairer Driven Education (RDE) series of educational events, there was so much knowledge and inspiration spread throughout Las Vegas. Turn the pages to check out our exclusive coverage of SEMA 2025.

The acronym CIC may stand for the Collision Industry Conference, but it represents a whole lot more. CIC also stands for its mantra – connect, influence and collaborate – yet it still goes even further than that. CIC brings all stakeholders who make up this great industry together four times a year with a shared end goal of keeping consumers safe.

CIC’s final meeting of the year took place in conjunction with SEMA in Las Vegas. From telematics to legislative goals and exploring business opportunities, every topic, every discussion, every takeaway was centered on making the industry a better place for the sake of the “empty chair” because protecting consumers is at the forefront of what this industry represents.

Various important points were made on the Las Vegas CIC stage, but most notably perhaps was Aaron Schulenburg’s (Society of Collision Repair Specialists) message that “a growing number of collision repairers from all over the country are voicing concerns about insurers lowering reimbursement rates for essential repair operations.” During the open mic portion, the executive director of the national collision repair association stressed that shops in every region and every state are “facing this pressure. We’re seeing a shift from prevailing competitive price to ‘reasonable rates’ without any definition of what ‘reasonable’ means. Zero documentation is being presented to repair facilities, yet somehow they have simply determined it’s enough, even though they’ve lowered these rates significantly from what they had recognized before.”

are restored. It’s important that we talk about it, address it and figure out a path.”

In the words of Jill Tuggle (Auto Body Association of Texas), Right to Appraisal (RTA) is a “hot topic” right now. On behalf of the Governmental Committee, the Texas association’s executive director held a “fireside” chat with Justin Lewis (Accurate Auto Body and Washington Independent Collision Repair Association) to share the processes, struggles and wins both associations experienced getting mandatory RTA legislation passed in their respective states.

As was evident by a polling of the room, not everyone has a clear understanding of what this consumer right actually is, although it’s been a provision in insurance policies since the 1800s, Tuggle explained. As more consumers began to utilize the Appraisal Clause to recoup some out-of-pocket expenses, insurance companies started removing the clause from their policies. “We saw that trend, and we wanted to help solidify RTA for our customers,” said Lewis.

Great lobbying support was beneficial to both associations, and Tuggle stressed that grassroots efforts were a valuable tool as well. “Reach out to your local legislators and say you’d love to speak to them about what it looks like to be a collision repairer.”

It doesn’t have to be about any current problem or legislative efforts. Taking the time to establish key relationships “lays the groundwork” for when it’s time for issues to cross their desk.

Schulenburg suggested all stakeholders need to come together “for the sake of restoring vehicle safety and for the sake of the motoring public who return to the roadways after leaving our businesses every day. The industry has to remain focused on fairness and reasonableness that actually supports and upholds safety, quality and sustainability in this industry. Consumers expect to be made whole, and they expect that every repair upholds the standards that we have addressed today to ensure that their vehicle, trust and safety

“If you do bring legislation, be very thorough. Don’t try to rush to try to get things done as it may not wind up being what’s best for consumers,” suggested Lewis.

The newly formed Business Operations and Management Committee made their CIC debut with the first part of a series that directly addresses collision repair facilities on how to strategically plan for the future. “You don’t want to wait until your business is in trouble and you’re worried about cash flow to make a plan on how to get out of that,” proposed Jeff Burton (Quality Collision Group) who moderated panelists Chris Chesney (Repairify), Jason “Buck” Zeise

(LaMettry’s Collision; MN) and John Walcher (Focus Advisors) on how to diversify one’s business.

Subletting mechanical work is a big thing, but as Zeise suggests, “Let’s keep those dollars inside instead of sending them across the street.” He pointed to “modest growth” projections for the collision repair market of $37 billion (2024) to $42 billion in 2032 versus the “tremendous growth” on the mechanical side with $147 billion to $435 billion in 2032.

“People are keeping their cars longer, and people are fixing their cars. As collision repairers, we need to embrace some mechanical repairs and bring mechanical in-house to broaden the spectrum.”

The collision repair space doesn’t allow much opportunity for a shop owner to develop a relationship with a customer. As Chesney pointed out, it’s not common for a consumer to say “I got a guy” when it comes to the body shop. However, there are ways to develop a bond while the customer is in the shop. “Vehicles are complex, so there are a lot of things that you can do in the time that you have the vehicle in for a collision event to illustrate that there are things wrong with their vehicle, things that need to be serviced and maintained in a way that creates a relationship with them, so that you can perform some of those maintenance services without a huge capital investment in equipment.”

For those who do need to make a financial investment, Walcher suggests making a project plan. “When you’re looking at the ROIs, it isn’t the gross revenue that matters. That won’t get you your payback. It’s the net profit.”

The podcast-styled “The Industry Experiment” segment made its return to CIC, bringing Frank Cote, former chief deputy insurance commission and government affairs director for the Montana Commissioner of Securities and Insurance, to the stage to chat with segment host Schulenburg about what works and what doesn’t when it comes to consumer advocacy. Schulenburg posed the question, “What does consumer protection really mean to the Department of Insurance?” Cote referenced his state’s insurance code which “literally says in the statute that the Montana insurance department shall interpret these laws to the benefit of the consumer. That is very clear to me that we’re not there to represent the insurance industry or the body shops or whoever. We’re there to represent the consumer.”

The main reason consumer complaints

would often be denied by the Consumer Affairs Division was because “consumers don’t understand what they are fighting for,” Cote explained. As a solution, they allowed body shops to file complaints on consumers’ behalf, so “an educated person was on the other side to respond to that complaint, and that ultimately helped resolve a lot of complaints in favor of the consumer.”

Cote confirmed that insurance departments are not very educated about issues as well, and he encouraged the

collision repair industry to educate them, calling it “critically important.” In the few hours he spent at CIC, he became “fascinated by some of the things discussed on these panels. I’m sitting here wondering why aren’t insurance departments people in the room? It would be beneficial to have them be invited to this program, so they can see and understand the importance of OEM repairs and those kinds of things.”

THEY’RE CALLED “ORIGINAL BMW PARTS” FOR GOOD REASON. FOR UNCOMPROMISING PRECISION AND INCOMPARABLE QUALITY, YOUR BMW CENTER IS YOUR ONE-STOP SHOP FOR EVERYTHING BMW.

For Original BMW Parts, contact one of these authorized BMW centers:

BMW of Silver Spring 3211 Automobile Blvd

Silver Spring, MD 20904 866-737-8937

Direct: 301-890-3015

Fax: 301-890-3748

Email: wholesaless@mileone.com bmwofsilverspring.com

Passport BMW 5000 Auth Way Marlow Heights, MD 20746

301-423-0733

Fax: 301-423-2717 passportbmw.com

Richmond BMW 8710 West Broad Street Richmond, VA 23294

800-237-0130

Direct: 804-527-6860

Fax: 804-965-6254

Email: tdailey@crownauto.com richmond-bmw.com

BMW of Catonsville 6700 Baltimore National Pike Baltimore, MD 21228

855-996-2906

410-744-2000

Fax: 410-818-2600

bmwofcatonsville.com

ADAS calibration is the precise adjustment of your vehicle’s sensors and cameras, essential for the optimal functioning of advanced safety systems. This process is especially critical following significant repairs, part replacements, collisions, or windshield replacements, as these events can disrupt sensor alignment. It’s important to avoid driving without proper sensor calibration. Uncalibrated ADAS sensors can compromise your vehicle’s safety features, leading to potential malfunctions and driving hazards.

• Ensures all required calibrations are performed, even with no warning lights present

• Provides fast, accurate & simple calibration identification

• Includes links to OEM Requirements; and

• Your report goes to our team for a

ADAS calibration is the precise adjustment of your vehicle’s sensors and cameras, essential for the optimal functioning of advanced safety systems. This process is especially critical following significant repairs, part replacements, collisions, or windshield replacements, as these events can disrupt sensor alignment. It’s important to avoid driving without proper sensor calibration. Uncalibrated ADAS sensors can compromise your vehicle’s safety features, leading to potential malfunctions and driving hazards.

We are thrilled to announce that ADAS Elite customers now have free access to 1Source ADAS reporting! Simply contact us to get set up in the 1Source ADAS portal at no charge.

The calibration of ADAS can be performed in two main ways: static and dynamic. Static calibration takes place in a controlled environment, ensuring accuracy and consistency. Dynamic calibration, on the other hand, involves driving the vehicle under specific conditions to fine-tune the sensors in real-world scenarios. This comprehensive approach ensures that your vehicle’s safety systems are reliable and effective, providing peace of mind on the road.

The calibration of ADAS can be performed in two main ways: static and dynamic. Static calibration takes place in a controlled environment, ensuring accuracy and consistency. Dynamic calibration, on the other hand, involves driving the vehicle under specific conditions to fine-tune the sensors in real-world scenarios. This comprehensive approach ensures that your vehicle’s safety systems are reliable and effective, providing peace of mind on the road.

Rockville Pike

Rockville, MD 20852

Toll Free: 800-345-4640

Direct: 301-424-5332

Fax: 301-294-6381 www.rockvillechevrolet.com

CHEVROLET 4400 Branch Avenue Temple Hills, MD 20748

Phone: 301-899-6990

Fax: 301-899-9375 www.ourismanchevrolet.com

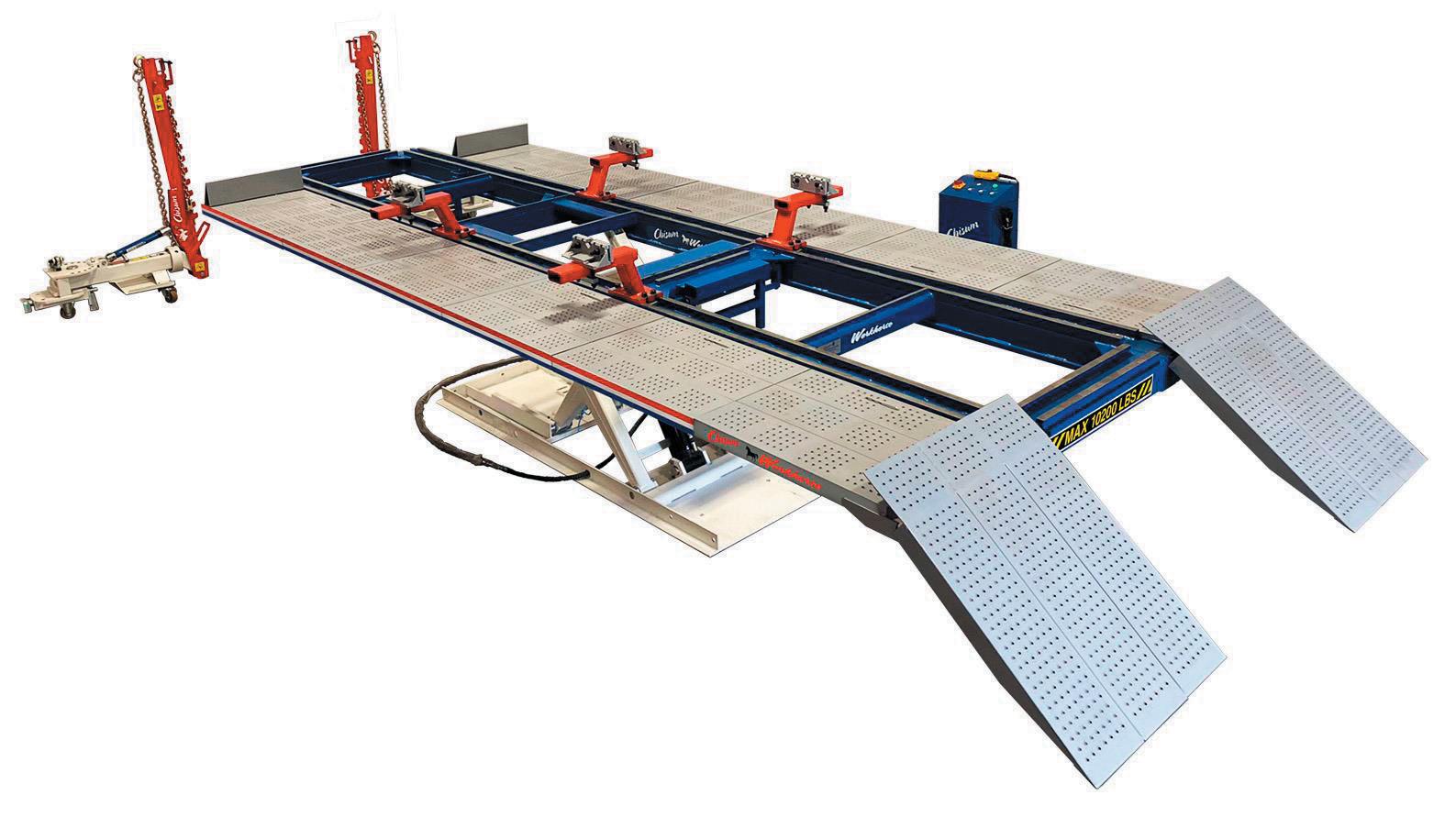

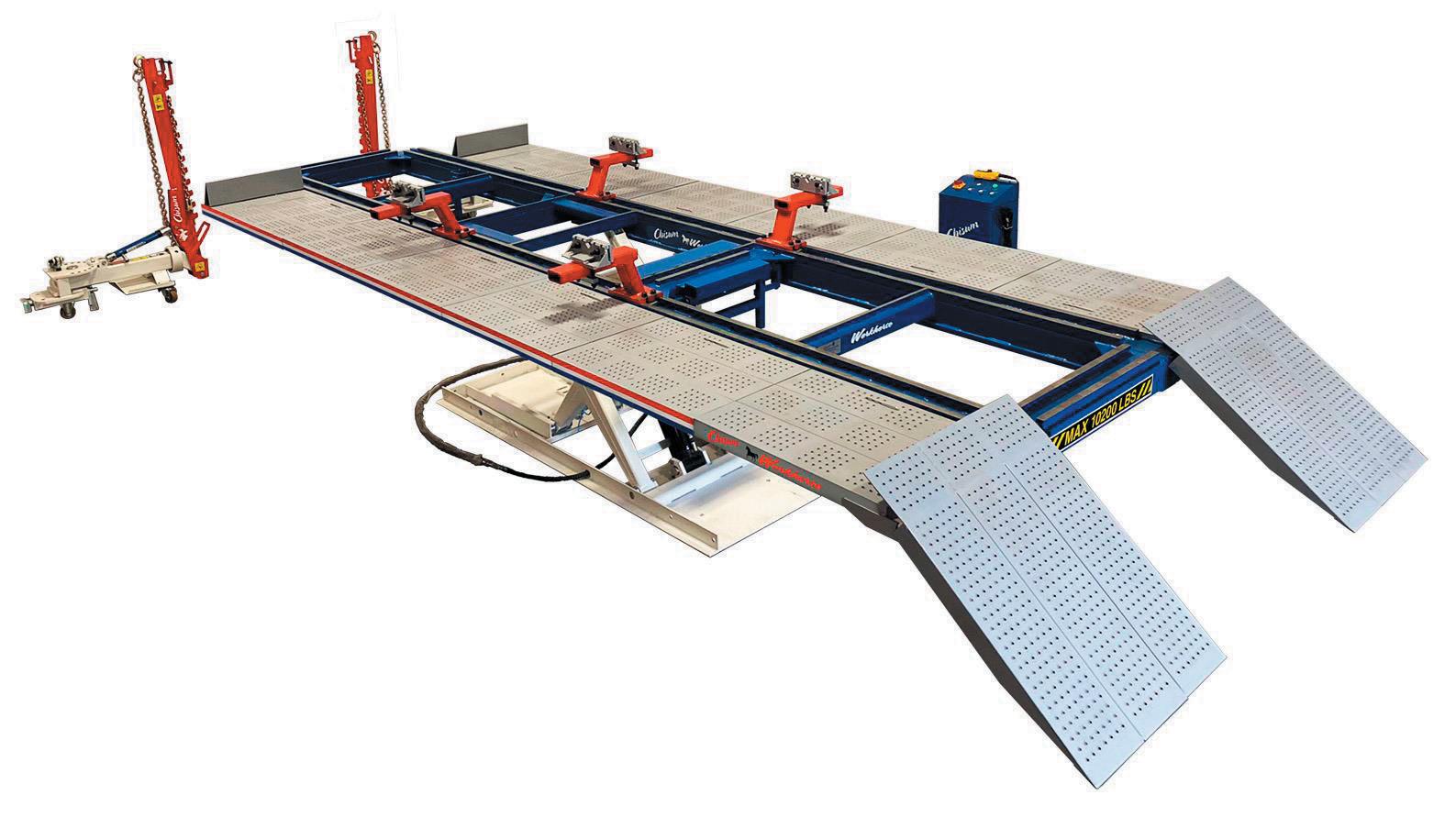

PRECISION TOOLS FOR PROFESSIONAL REPAIRS

CUTTING TOOLS

OEM APPROVALS

FUME EXTRACTION

DENT PULLING AND MUCH MORE!

The value of education is immeasurable. Everyone who spent time in the Society of Collision Repair Specialists’ (SCRS) Repairer Driven Education (RDE) classes at SEMA walked out with tremendous knowledge to take back to their shops – you just can’t put a price on that type of training experience!

The educational slate had something for everyone as subject matter experts from all segments of the industry set out to inform collision repair professionals about everything from ADAS and business finances to repair planning and new technologies.

Leadership does not start with a management title, as Sheryl Driggers (Collision Advice) revealed with her “Winning Leadership: Influence, Impact and Driving Results in Collision Repair” discussion. “Every single person in this room can be a leader. If you have air in your lungs, you can influence someone else,” she stated, stressing that leadership comes from how one impacts the people around them.

The pathway toward good leadership starts with “creating a work environment where employees feel valued and appreciated. If they are committed to the mission of the organization and committed to each other, that is huge.”

time. “Don’t expect to go in on a Monday and know your employees well by the end of the day.”

Setting clear goals is also key. “Everyone on your team should know what it looks like to win.”

Maria Quintero and Tracy Dombrowski, also of Collision Advice, delivered pertinent financial insight to a packed house of repairers interested in getting a better understanding of how to manage their operations’ finances.

While making money is definitely a goal in business, offering money as a “bonus” does not necessarily have the positive impact that business leaders believe it will. Andrew Batenhorst (Pacific BMW) and Melissa McFarlane (Leaders Way) spoke about “The Unseen Effect of Bonus Plans in Your Shop.”

offering monetary bonus incentives that only backfired. Positive outcomes will come from “tapping into intrinsic motivation.” People are not robots. He suggested finding out what keeps them engaged. “Creating conditions that will interest employees starts with getting the right people on the team.”

Danny Gredinberg of the Database Enhancement Gateway (DEG) showed collision repairers how to unlock accuracy with resources to help one’s team develop their best blueprints. Resources like the DEG can help correct labor times for certain operations; the information providers do consider the inquiries that come from the DEG. Every little win “moves the needle in the right direction.”

When setting out to lead others, one must be mindful of their own emotions. Leading with negative emotions, such as fear and anger, will only lead to poor effects on the team.

Driggers suggested spending time getting to know team members and to not expect this to happen overnight. It’s a journey that takes

McFarlane sparked shop owners to think hard when she asked, “What if everything you knew was wrong?” People want more than having their basic needs met. Using the Pyramid of Peak Performance Conditions to illustrate the point, she showed them just how many things go into helping a person reach their full purpose.

Only 31 percent of the workforce is engaged in their work. That doesn’t just apply to the collision repair industry – it’s prevalent in all industries. Throwing money at people just doesn’t work. “Understanding the difference between a person’s needs and how they are related to money will help you understand that having bonus plans isn’t a great way for engagement and motivation.”

Batenhorst shared real experiences of

Educating customers upfront is crucial as he suggested repair professionals “be proactive, not reactive.”

He spoke of how the “power of .1 works” in repair planning.

A repairer may think a .1 line item must be an “easy” task when compared to a “complex” one-hour procedure.

“What if we took the one-tenth of an hour and looked at it in minutes. If instead of saying .1, I say six minutes, does it seem more complicated? Not everything has to be a .5 or one hour increment. If that is what it takes, that’s what it takes. Don’t be scared of the .3s or .8s. Now, you are validating and supporting what it takes to perform that step.”

Josh McFarlin (AirPro Diagnostics) and Adi Bathla (REVV) teamed up to address “Shaping the Future of ADAS in Collision Repair: A Community-Driven Approach.”

McFarlin challenged the audience to think about what their confidence level is knowing the ins and outs of every ADAS feature their own personal vehicle has.

While pulling too fast into a parking spot recently, his vehicle’s automatic braking system stepped in. At that moment, it occurred to McFarlin that he was unaware of the exact speed that causes the system to kick in. Overall, the industry as a whole may still not have a full understanding of every single ADAS component, yet one must get past the learning curve in order to help customers get a full understanding of how these features in their vehicle work.

Communication with customers is key. It’s the repairer’s job to put the vehicle’s features back to the customer’s expectations before they

Cote didn’t even hesitate to answer “No” when Schulenburg asked the million dollar question: “Do you think consumers get the representation that they deserve in the process?” He observed negative changes over the past 20 years which finds state workers underpaid, overworked and lacking education on the issues. He referred to one deputy commissioner who “pushed the department in a way that made it more aligned with the insurance industry that’s going to take years to overcome.”

His words of advice to repair professionals is to “work within your state associations, and make sure to get a good lobbyist. Work amongst yourselves to figure out what are the biggest challenges that you’re seeing and how you can address them. It’s important that you build relationships with the insurance department and your legislature.”

Moderated by Chuck Olsen (AirPro Diagnostics), the Emerging Technologies Committee expert panel weighed in on how to “buckle up” as software-defined vehicles, AI, telematics and more continue to infiltrate vehicles. Panelists agreed one of the big roadblocks is the lack of standardization among manufacturers when it comes to things like telematics.

had the accident. “If a customer has a feature turned off, find out why. It’s possible the customer doesn’t understand what the feature does.”

Attendees who spent time in “Automotive Advertising: The Road Map to Building a Successful Online Presence” learned about online tools to help promote their brand.

Content should be honest, suggested panelist Jasmine Shaw (Sokal) who explained why overly sensational claims otherwise known as “click bait,” a dishonest piece of media that won’t build any trust with one’s client base.

Be sure to check back with SCRS to find out when RDE courses will be available online at rde.scrs.com. H&D

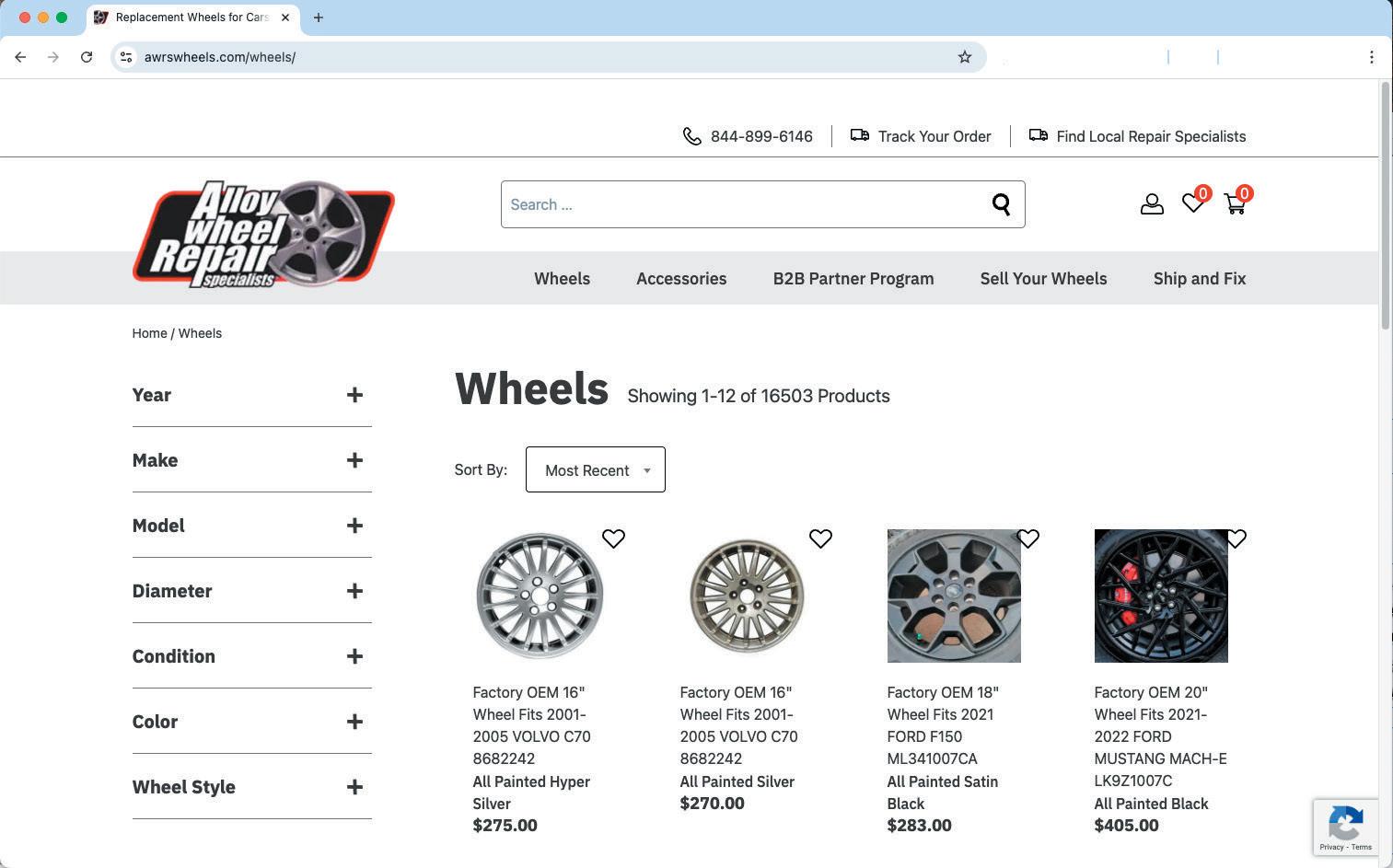

Andrew Batenhorst (Pacific BMW; CA) led the Parts and Materials Committee panel, made up of shop owners and parts suppliers, in talks about the issues surrounding OEM parts procurement strategies and conquest programs. Panelists weighed in on everything from customer expectations, the role of parts providers, alternative parts options and maintaining profit margins. Kyle Bradshaw (K & M Collision; NC) alluded to how “so many factors throughout the repair process can really derail” the process, so getting everything up front is key because “if it’s broken on the front end, you will start and stop, start and stop.”

Mike Anderson (Collision Advice) took the mic to call attention to the misrepresentation of the wholesales parts managers in this equation. “The wholesale parts managers do not have a voice in our industry, and they absolutely deserve one.”

“The way automakers provide the information is not consistent,” Donny Seyfer (DLS Consulting – National Automotive Service Task Force). “Sometimes it’s not even present.” Information may be attached to a technical service bulletin, but “technicians don’t want to read that far down. So that’s where it would be much more efficient to have something that tells them what to do. Some brands have that, but it’s not consistent across the board.”

continued from pg. 15 Genuine

“We’re all over the map,” observed Bernie Carr (CarrPoint Consulting). Ideally, “having something standardized so that the information coming off that vehicle, whether its brand A or brand Z would be the same.”

“The more data you throw at the technician, the less interested they will be in going through it,” suggested Florian Rhode (iProcess LLC) who called for a “consistent system that actually guides them through the steps based on the data. Not every technician has to be trained to understand tons of data just to do a simple replacement.”

Robert Vogt IV (Iosix) took things even further suggesting, “The whole industry should be ashamed of itself for making up targets. There’s no reason we can’t use the same targets. That was a complete miss.”

As he observed from having done 42 wholesale parts managers workshops over the past 18 months, Anderson reported, “There are some wholesalers whose margins are shrinking so badly that they’re considering getting out of the wholesale parts business. If that happens, that is not good for any industry stakeholder. If you think we have cycle time issues today, wait until some wholesalers start getting out of this business. You’ll need to get parts from other markets, and there will be transportation costs. If our industry does not wake up and look at this, especially with the game of utilizing software to manipulate price matching for shops…It’s not good for our industry.”

Start making plans now for the first CIC of 2026 when the conference returns to Palm Springs, CA on January 22. For more information, visit ciclink.com H&D

The perfect fit at the perfect price.

Mitsubishi Genuine OEM parts are designed for optimal performance and fit, engineered to meet the highest standards.

For more information, contact: Younger Mitsubishi

1945 Dual Highway Hagerstown, MD 21740

Direct: 800-296-1190

Fax: 301-733-5465

www.youngermitsubishi.com

844-413-6929

Direct 301-890-3015

Fax 301-890-3748

wholesaless@mileone.com silverspring.porschedealer.com

euroclassics.porschedealer.com

You’ve got the right tools, staff, technology and procedures to give your customers the best repair possible. The missing piece of the puzzle? Genuine Volkswagen Collision Parts. Contact an authorized dealer today and find your perfect fit.

Alexandria Volkswagen 107 West Glebe Rd. Alexandria, VA 22305

703-684-7007

Fax: 703-684-4138

e-mail: parts@alexandriavw.com

Karen Radley Volkswagen 14700 Jefferson Davis Hwy. Woodbridge, VA 22191

703-550-0205

Fax: 703-643-0081

Fitzgerald Volkswagen 114 Baughmans Lane Frederick, MD 21702

Toll Free: 800-545-4745

Fax: 877-696-1841

e-mail: parts@fitzmall.com www.fitzparts.com

Fitzgerald Volkswagen of Annapolis 34 Hudson Street Annapolis, MD 21401

Phone: 410-224-4636

Fax: 410-224-4264 www.fitzmall.com

Ourisman Volkswagen of Laurel 3371 Ft. Meade Rd. Laurel, MD 20724

Phone: 301-498-6050

Fax: 301-498-0157 www.laurelvolkswagen.com

Ourisman Volkswagen of Rockville 801 Rockville Pike Rockville, MD 20852

Parts Direct: 301-340-7668

Toll Free: 855-417-4511

Fax: 240-499-2488

e-mail: rockvilleparts@ourismanautomotive.com www.ourismanvolkswagenofrockville.com

“Volkswagen“ and the Volkswagen logo are registered trademarks of Volkswagen AG. ©2025 Volkswagen of America, Inc.

Wholesale Parts

Everything begins with an idea, and the collision repair industry continues to evolve thanks to thought-provoking ideas and conversations. That is why the Society of Collision Repair Specialists’ (SCRS) IDEAS Collide Showcase is one of the most popular segments in its annual Repairer Driven Education series at SEMA.

SCRS Executive Director Aaron Schulenburg shared his enthusiasm for this year’s slate of IDEA makers who “have spent their careers learning and growing and have gotten to a place where they can share what’s in their heart about what they want to see come about in this industry in positive ways.”

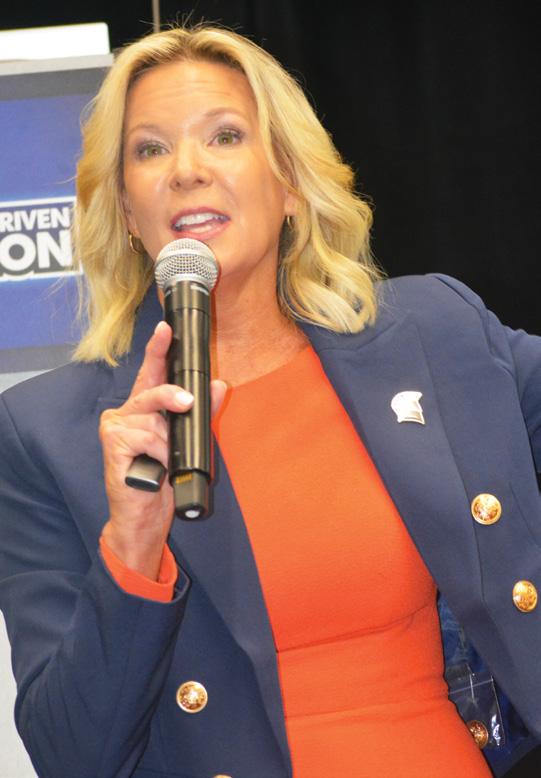

WMABA Executive Director Jordan Hendler kicked off the series of 10-minute “TED talk” styled conversions with “Get Far, Stacking Millimeters Toward Progress.” Hendler shared her inspirational journey via yoga to demonstrate that one can set goals and achieve them with focus and accountability. “Part of the journey taught me about other aspects of my life,” she explained that it made her take a deep look at the most important areas of her life from her spirituality to her family. “I love the phrase ‘choose your hard.’ We are collision repairers. It is so hard. But we love it. Once it’s in your blood, you

can’t get it out.”

Having an accountability partner was key in her journey. “You have to have a goal; you have to have vision.”

Joe Rector (Entegral) delivered his insight for “A Harmonized Auto Claims Ecosystem.” The collision repair industry is segmented among the OEMs, insurers, the body shops and other partners. They surround the customer who most often is drowning in a chaotic sea of pain due to the murky ecosystem.

“We are all equally valuable in the eyes of the customer.” Rector believes the industry needs to work together seamlessly, “so when a customer makes a decision, everyone involved is connected.”

He believes the industry needs to examine the idea of working together in harmony “to improve the overall customer experience.”

One of the biggest issues plaguing shops all around the nation is the technician shortage. Finding good help and keeping people on board is one of the biggest frustrations felt by shops all over. Richie Seaberry (Decisley) believes that offering good benefits in the workplace is the solution to this problem. His delivery of “Modernizing Your HR and Employee Benefits” unveiled that offering benefits makes employees likely to stay with your business twice as long, as has been proven via SCRS’ health benefits package which works with Decisely.

Seaberry spoke of the concerning fact that many people don’t seek mental health treatment due to the extreme costs, but the SCRS plan has “a quality mental health care solution. We opened up the ability for your employees to seek that type of care, and that is instantaneously being discussed at the break room table and in their communities.”

Hands-on training is the ideal experience, according to 3M’s

Shawn Collins who presented “Taking your Apprentice Technicians to the Next Level with Hands-on Training.”

“These techs got into the industry because they like using their hands, so why not train them hands-on?” Collins queried. 3M’s facility accommodates all skill levels. “They get exposed to tools they may not have in their shop and into an environment that offers them different experiences they may not get otherwise.”

Rachel James (Torque Financial Group) encouraged shop owners to think about the benefits of bringing a CFO on board with “Decoding the Role of the CFO.”

“If finances are not your strong suit, consider hiring someone to take on this role,” she suggested, noting that she’s seen many shops over the past three years hire someone to serve as the CFO for their shop. “They will help you navigate your business. Imagine playing football without a quarterback. That’s kinda tough, right? A CFO on your team can help you make the hard decisions.”

In an industry that is continuously evolving, “a CFO can help you determine the value of your business.”

Offering an excellent customer experience is critical to success in today’s collision repair space, according to Greg Tabak (Go Rentals) who shared tips for “Elevating the Client Experience in Collision Repair: Hospitality-Driven Strategies for Repeat Business and Referrals.”

Vehicle repair can be a stressful situation for a client, especially if it’s the first time they are dealing with an accident. “Clients need to feel taken care of and valued,” Tabak pointed out.

Hospitality starts at the very beginning. “Provide them with updates. Be clear and upfront with the information. Give them everything they need, so they don’t have to come to you in search of answers.”

Sharing the repair process with clients makes it personal and allows them to “feel connected.”

Veteran collision industry journalist John Yoswick (CRASH Network) closed out the IDEAS Collide showcase with “Three Minutes to Help Drivers Make Better Insurance Choices.”

“As much as we all like to share a good war story, there are things we could do instead to help improve the industry,” Yoswick recommended. One big way is by taking the Insurance Report Card survey which is open every November.

The three minutes it takes to complete the survey can help consumers make better choices about what carrier to use. The grades that shops assign insurance companies are based on customer service and quality repairs. “It’s not just about price. It provides a tool for consumers to help them determine what is the right carrier for them.”

Schulenburg commended all the speakers for their insight and for inspiring others with their words in just 10 minutes. He encouraged the audience to “think about how you can think big and boldly in this industry, use your voice and be part of the programs, communities and organizations that can let that voice shine. Think about how you can use your ideas to inspire others.” H&D

ADAS calibration is the precise adjustment of your vehicle’s sensors and cameras, essential for the optimal functioning of advanced safety systems. This process is especially critical following significant repairs, part replacements, collisions, or windshield replacements, as these events can disrupt sensor alignment.

It’s important to avoid driving without proper sensor calibration. Uncalibrated ADAS sensors can compromise your vehicle’s safety features, leading to potential malfunctions and driving hazards.

Turnaround • Free Pick Up, Delivery and Transport Experience added peace of mind

At ADAS Elite, we run all processes and check all systems to ensure your customers are back on the road quickly and safely, with a focus on transparency and warmth. Our I-CAR Platinum ADAS Certified technicians hold one of the highest, most prestigious achievements in the collision repair industry!

Shops looking to maintain Gold Class status must staff or sublet Platinumlevel technicians per recent I-CAR requirements in all roles, including ADAS. Choose ADAS Elite for

vehicle’s sensors and cameras, essential for the optimal functioning of advanced safety systems. This process is especially critical following significant repairs, part replacements, collisions, or windshield replacements, as these events can disrupt sensor alignment. It’s important to avoid driving without proper sensor calibration. Uncalibrated ADAS sensors can compromise your vehicle’s safety features, leading to potential malfunctions and driving hazards. The calibration of ADAS can be performed in two main ways: static and dynamic. Static calibration takes place in a controlled environment, ensuring accuracy and consistency. Dynamic calibration, on the other hand, involves driving the vehicle under specific conditions to fine-tune the sensors in real-world scenarios. This comprehensive approach ensures that your vehicle’s safety systems are

The calibration of ADAS can be performed in two main ways: static and dynamic. Static calibration takes place in a controlled environment, ensuring accuracy and consistency. Dynamic calibration, on the other hand, involves driving the vehicle under specific conditions to fine-tune the sensors in real-world scenarios. This comprehensive approach ensures that your vehicle’s safety systems are reliable and effective, providing peace of mind on the road.

Mike Anderson (Collision Advice) wasted no time getting right down to the point. “Safety inspections are the number one thing keeping me up at night. And they are the single biggest friction point between insurance companies and collision repairers.”

This year, the Society of Collision Repair Specialists’ (SCRS) designed its OEM Technology Summit to address the big concerns surrounding this crucial step that experts believe 98 percent of the body shops across the country are not performing.

Anderson moderated three panel discussions centered on OEMrequired safety inspections for steering columns, SRS and airbags and seat belts, illuminating the fact that manufacturers state these inspections are crucial in a “safe and proper repair.” But the problem is that most shops are not doing them.

Proof lies in the minimal amount of mechanical labor hours shops are reporting nationwide. “When I see the average mechanical hours is less than two hours, I can tell you this industry is not performing safe and proper repairs,” Anderson relayed.

He welcomed Gerry Rosenbarker and Tyler Foote, both of Mohawk Collision (Schenectady, NY), and Andrew Batenhorst (Pacific BMW; Glendale, CA) to weigh in on the steps involved with inspecting steering columns as most OEMS state this step must be done following a collision. For example, Subaru has a nine-page document for the 2024 Outback specifying “all the things you’re supposed to inspect when the vehicle has been in a collision. We actually did a study in conjunction with a Subaru dealership, at a collision center out in Washington state, and we found that 26 percent of the steering columns we inspected were collapsed. Now let that sink in – 26 percent. Now, some people will question why they have to pay for that because they are focusing on the 74 percent that are not collapsed, but what is the value of a life?”

He pointed to the fact that “there is a lot of room for inaccuracy when measuring with tram gauges,” suggesting computerized measuring systems are superior. Anderson encouraged a loud “Amen” from audience members when he asked, “How many of you think that computerized measuring systems, if we have the steering column specs, would be much more accurate than tram gauges?”

customers. Batenhorst showed off a prop of the steering gear from a 2020 BMW X7 which he displays outside his office.

“There are two different electric motors that are belt driven inside the casing,” he explained. “They have precise machine teeth on the gears. These steering gears are not designed to take a shock load laterally without chipping the teeth off. When the teeth get chipped, you wind up getting a notchy feeling in the steering gear, and the motors can’t operate correctly. The problem is that none of that is visible from the outside, so I created this so the adjusters and customers can see what’s really going on inside.”

Showing an adjustor the procedures can also send the message home. For example, General Motors has a procedure for a safety inspection that is “three-inches thick,” according to Anderson. “It makes quite an impression on an adjustor if you show them something that looks like an encyclopedia,” Rosenbarker suggested.

Involving the customer in conversations about what is in the best interest of the vehicle also plays a huge role as it encourages them to make the necessary outreach to their insurance carrier. Ultimately, people want to feel safe. “Most customers purchase their vehicle based on safety ratings. They want to make sure it’s checked, and there is literally no way of inspecting it, without inspecting it,” he added.

Tyler Smith (Rick’s Paint and Body; Augusta, GA) joined the panel for the second session which dove into SRS and airbag inspection requirements. Upon following the safety inspection requirements for a Lexus vehicle, Smith’s shop discovered the airbags had been separated on the backside. Smith said, “They were bulging and the stitching was coming loose as well.” The mounts were also determined to be deformed. It was disturbing to note that “there were no warning lights on the dash and no diagnostic trouble codes on a pre-scan, but when his shop removed the airbags, there was actual damage,” Anderson pointed out.

“Understand that whether the insurance carrier pays for it or not, you must do it,” Anderson stressed. “It’s the right thing to do for consumer safety.”

Third-party payers may argue that a steering column inspection only has to be done in a front-end collision, but Anderson righted that misbelief. “We probably see as many, if not more, collapsed steering columns from rear-end collisions than we do front-end collisions.”

Visual cues are key in helping to educate third-party payers and

Smith’s shop is so committed to doing the right thing that they lost their business relationship with an insurance carrier that comprised 27 percent of their business, due to the carrier’s reluctance to follow through with the facility’s commitment to safe repairs. “They told us ‘We don’t want to pay you for it, and we don’t care about it,’” Smith disclosed.

Unfortunately, collision repair facilities like Smith’s and Rosenbarker’s aren’t necessarily the norm. What may be even more frightening is that when prompted by insurance companies, there are certified shops and dealerships claiming safety inspections are not necessary.

Shedding even more light on how many shops appear to not be following procedures, Anderson noted one manufacturer that requires door replacements to have the airbag sensor also replaced. “They sold 13,000 doors this year and less than 78 airbag sensors.

“Ninety-eight, or maybe even 99.9 percent, are not performing inspections,” Anderson lamented. “We have to look in the mirror first before we look for an easy button. It starts with us. It’s a problem when carriers call a certified shop, and they tell them ‘safety inspections are not necessary.’ It’s a problem when they call the service department at a dealership, and an uneducated person says ‘you don’t have to do it.’ And

it’s a problem when people do know about it, but don’t do it because a carrier won’t pay for it. That’s not right for the consumer.

“Every vehicle manufacturer says that seat belts must be inspected after a collision,” Anderson stated at the start of the third session. “And that is not just limited to seat belts used in an accident but any unused as well as child safety seat latches and tetherpoints.”

There is some good news as per the latest Who Pays for What? Survey, which shows 49 percent of shops in the country report they “always or most of the time” get an insurance carrier to pay for seat belt inspections. “That’s actually increased by 4.7 percent over the previous year. While we should be happy that shops are getting reimbursed,. based on my 300 days a year of travel, my concern is that most shops are not performing seat belt inspections properly. This is the one that keeps me awake at night the most.”

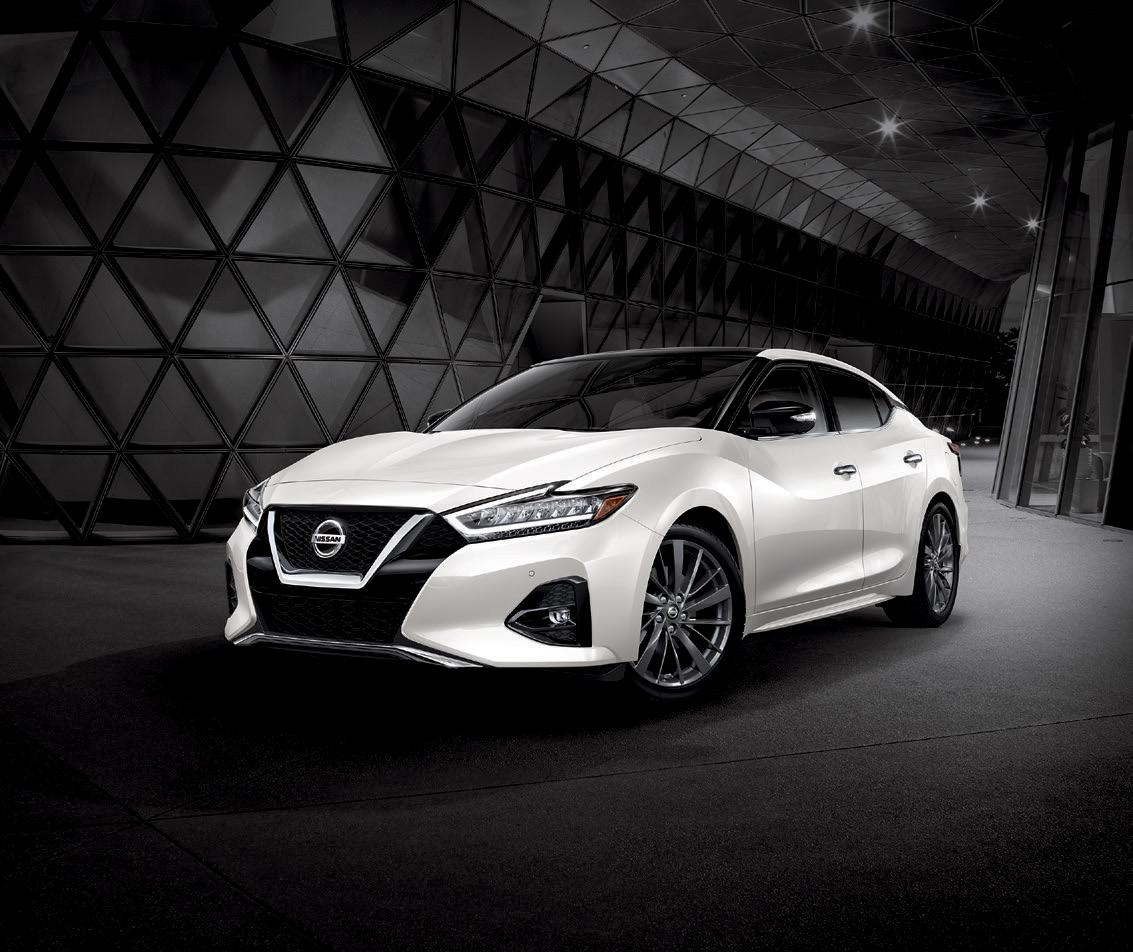

Nissan/Infiniti has a position statement that requires that all seat belts be inspected and that failure to do so can result in bodily injury or worse yet death. “That’s a pretty serious deal,” Anderson stressed the potential death sentence failing to inspect could cause. He recommends asking customers’ permission to remove the owner’s manual from their glove box and show them the cited seat belt inspection requirement, suggesting they contact their insurer and request the inspection be done.

Joining the third session panel, Bud Center (I-CAR) spoke of the feedback I-CAR seeks from shops by way of its Repairability Technical Support (RTS) portal created to learn about challenges and issues related to safety inspections. In the five years since the portal was created, only 96 shops have issued complaints. “There’s 40,000 body shops in the US. Every OEM says you need to measure

steering columns or inspect steering gear, air bags and seat belts, and [I-CAR has received] only 96 [complaints] in five years?!” Anderson emphasized the troublingly low response.

“The good news is that the OEMs understand that it can be challenging and time consuming to put this information in, so they know it’s an issue,” Center explained. “We continue to have conversations with them to try to figure out how we can help with this.”

He announced I-CAR will host a virtual repair summit on December 4 “to get insurers and collision repairers together to understand the friction point from each side’s perspective. We can take that back to the OEMs to figure out how to address it and fix it.”

Join Reliable Automotive Equipment’s Dave Gruskos for conversations with industry leaders sharing their insights and the latest from the world of certified collision repair. This month, Dave talks with Mark Allen, manager of Collision, Equipment and EV after sales service at Audi of America.

Dave Gruskos: How does Audi recommend shops best approach how they prioritize the investment in tools, equipment or facility upgrades needed to maintain certification and repair to OEM standards?

Mark Allen: Shops need to look at the ROI every time they look at a piece of equipment. They should look to see whether they have future intention of getting onto a program. If I have to invest in a welder, for example, and I’m going to look at becoming Audi, and that may happen, then I want to look at the welder that is required by the program. Some of the programs are not specific; others have certain specifications. If you’re going to one company that only gives you specifics, you can look and see if it fits those specifications, and whether it will fit in a future attempt to get on the program. And you’d do that for every auto manufacturer that you want to serve. Now, it takes homework, and people like Mike Anderson and Collision Advice and others out there are pretty sharp at helping people walk through this. The other thing is knowing how to future-proof yourself when ordering new equipment. Are you using appropriate accounting principles to write off the welder in a short enough time to save money in buying the next welder? Cleanliness and servicing is a way to extend the life of equipment, but accounting principle is how you plan for future investment.

D.G.: A recent press release from the manufacturer noted a strong demand continues for Audi electric vehicle production. On the aftersales side, what guidance do Audi Certified collision centers receive to help them navigate the constantly increasing complexities of EV repair?

M.A.: The standard is to take it to a dealer. We make everyone take high voltage awareness training, which advises them on how to recognize whether a vehicle is an EV of some sort, whether it’s a full-on electric or a plug-in hybrid electric vehicle (PHEV) or any of the others, in an effort to build a

ABOUT THE PROGRAM

Total # of Audi Authorized Collision Repair Facilities: 209

*An additional 41 facilities are currently undergoing the process to become certified.

# of Dealer-Owned locations: 55 43 Ultra Certified; 12 Hybrid Certified

# of Independent locations: 154 84 Ultra Certified; 70 Hybrid Certified Ultra Certified: Can work on vehicles with advanced materials, such as carbon fiber.

Hybrid Certified: Can work on vehicles constructed with high-strength steel, steel and aluminum.

deeper awareness. If you’re not at Audi authorized shop, however, and you’re not a high voltage technician, put your hands in your pockets and walk away from the car. Drive it over to the dealer and have them do the high voltage work, or have the dealer send someone over, and then, get everything out of the way, where it’s safe and de-energized, and then do your work.

D.G.: In your opinion, how does the adherence to OEMrequired equipment and tooling practices, combined with manufacturer-required procedures, contribute to a quality repair?

M.A.: The OEM-required procedures have been crash tested. When you see a several-hundred-thousand-dollar Lamborghini Quattrovalvole run into a wall and rebuilt, it makes your heart hurt. But doing that gives you a repeatable outcome. Just follow the procedure. We’ve even gone so far as to publish a book where we explicitly call out what to do and not to do. No pulling, for example. Do not cut.

If the repair that was done in the John Eagle case was followed that way, there’s a much better chance that the Seebachans may not have been injured, or injured as badly. As a shop, following procedures gives you a level of legal protection, as well. If you do exactly what the OEM said, following the methodology with their products, it puts the onus back on the auto manufacturer, and the independent repairer has a legal leg to stand on.

Body Shop Business

Single-Shop Executive of the Year Award: Andrew Batenhorst (Pacific BMW)

Multi-Shop Executive of the Year Award: Joshua Fuller (Fuller Collision Group)

Collision Industry Electronic Commerce Association (CIECA)

Outstanding Contribution Awards: Abhijeet Gulanti (Mitchell), Don Porter (United Recyclers Group), Roy Schnepper (Automotive Service Association)

Electronic Commerce Company Award: IAA

Collision Industry Conference

Volunteer of the Year Award: Chuck Olsen (AirPro Diagnostics)

Collision Repair Education Foundation

Fueling the Future Award: Auto Collision Experience (ACE) Volunteers

FenderBender

Best Repair Planner/Estimator Award: Will Barkley (K&M Collision) FenderBender Award: Jon Sommers (Winner Automotive Group)

Hall of Eagles

2025 Hall of Eagles Induction: Charles Edward “Chad” Sulkala (posthumous)

I-CAR

Jeff Silver Memorial Award: April Lausch (Faulkner Collision Center)

Russ Verona Gold Class Shop Award: Faulkner Collision Center

National Auto Body Council

Changing and Saving Lives Awards: John Hamdan and Anne Kolea (Dynasty Auto Body) and Bob Waldron (CARSTAR Waldron)

Society of Collision Repair Specialists

Affiliate Association Award: Washington Independent Collision Repair Association

National Lifetime Achievement Award: Darrell Amberson (Quality Collision Group)

March Taylor Kina’Ole Award: Tim Ronak (AkzoNobel)

High-quality painting processes

Reduced energy consumption

Lower management costs

Optimal finishing results

Increased productivity

Lessened processing times

operation

This month, we “Ask Mike” to share his thoughts on how ADAS maintenance can be a revenue source for collision repair shops. We at Hammer & Dolly hope you find the following exchange useful, and we encourage you to reach out to us if you have a question for Mike on this or any industry-related matter that he can answer in a future issue.

Hammer & Dolly: We’ve been discussing ADAS repairs after accidents for years, but it’s equally important for the industry to begin viewing ADAS as ongoing maintenance items – and as an additional, consistent revenue source. There’s plenty of material out there about collision-related ADAS work, but what are your thoughts on shops focusing on it before the vehicle even gets into an accident?

Mike Anderson: I recently attended a phenomenal conference hosted by CEICA [Collision Industry Electronic Commerce Association], where a presenter discussed Zoox, which are basically self-driving cars used for rideshare services similar to Uber. He noted that Zoox requires its vehicles to be ADAScalibrated every two weeks. Other presenters discussed the level of maintenance calibrations that should be performed on vehicles, especially as they get older. I can envision ADAS becoming part of certain states’ inspection programs at some point in the future. Some of the shops I’ve talked to out in the field have said they’re starting to see vehicles come in with deteriorating ADAS components caused by heat, inclement weather and other factors. At some point in the future, the need for maintenance calibrations will grow, and that will present new business models for shops.

H&D: The industry is still grappling with adapting to the need of post-collision ADAS work, and we’re now seeing this pre-accident demand grow. I’d imagine that the OEM repair procedures are the definitive source of information, as always.

MA: That’s correct. Anyone who knows me knows I’m very proOEM tools and targets, including those not manufactured by or for the OEM but still approved by them. Hunter Engineering recently announced that they’ve been approved by Toyota-Lexus. As more companies get approved by the OEMs, the process will become a little more streamlined, but those procedures will still need to be performed by people with the correct technical knowledge. The scenario with ADAS maintenance is similar to alignments. There are maintenance alignments, and there are alignments that need to be done after a collision. People will need to understand that the process for a maintenance calibration will be different from one needed for a vehicle that’s been in an accident.

H&D: As we’ve discussed in the past, performing ADAS repairs correctly often requires shop owners to open secondary, standalone businesses due to space requirements and other factors. I’d imagine the maintenance side would have similar requirements.

MA: It really is something for those standalone ADAS businesses to offer and market. There was a time when muffler shops just did exhaust systems, but they eventually had to adapt to changes in the industry when those systems stopped rusting out the way they did in the past. They started doing brakes, tires and other services. ADAS maintenance could have a similar impact on the collision repair industry, and there will be opportunities for shops that have invested in standalone ADAS facilities as part of their business models. Of course, you’ll need enough business to have an ROI on the equipment and training required to have ADAS as part of your services. Most importantly, you’ll have to research the procedures every time you perform an ADAS maintenance calibration, as things can change – just as they can with any collision repair procedure you perform. You need to research ADAS maintenance with each job, just as you would when welding a quarter panel. The competitive advantage a collision repair shop has over an independent mechanical facility is that if something on the vehicle doesn’t calibrate, we have the technical knowledge to understand that maybe it has been in a minor accident, and a unibody misalignment may be impacting the situation. An independent mechanical shop may not understand the correlation between

Vans. Born to run.

ADAS accuracy and the unibody of the vehicle.

Get your customers back on the road faster with Genuine Sprinter Parts.

Call our Sprinter Certified Parts Advisors today to get started.

H&D: The dark cloud over ADAS repair has always been whether shops are getting paid adequately by insurers for these procedures. Are you seeing the same issue with the maintenance side, especially since it’s an issue with the life of the components and not an accident-driven situation?

Sprinter Silver Spring 3301 Briggs Chaney Rd. Silver Spring, MD 20904

301-890-3060 Fax: 301-890-5473

mbsilverspring@mileone.com

Hours: M-F 7:30am-5pm, S 8am-3pm

MA: I haven’t heard too much on the maintenance side yet, beyond one or two cases where the age of the component was a factor and the vehicle wasn’t brought in due to an accident. The car parc is still old enough that we’re not seeing many of the newer vehicles yet, but I expect this topic will gain traction as time goes on.

H&D: Are there other aspects regarding ADAS that may present future opportunities for collision repairers that aren’t necessarily clear right now?

MA: I would say glasswork, windshields. A few states understand that consumers shouldn’t be driving around with cracked or broken windshields, so they’ve passed legislation saying that insurers can’t cancel somebody or raise their premiums based on a glass claim. Glass goes hand in hand with ADAS today, and collision repair shops should consider bringing their glasswork in-house. Windshield replacement is going to grow in the future.

Mike Anderson is an Accredited Automotive Manager (AAM) and the former owner of Wagonwork Collision Centers, two highly acclaimed shops located in Alexandria, VA. He has served as a member of many industry organizations throughout his career, including the WMABA Board of Directors, the Mitchell Advisory Board, the MOTOR Advisory Board, the ASE Test Review Committee, the National Auto Body Council, the Collision Industry Conference and the Society of Collision Repair Specialists. Additionally, he is a past Virginia SkillsUSA chairman, serves as a facilitator for Axalta Coating Systems’ highly recognized Business Council 20 Groups in both the US and Canada and facilitates numerous courses for Axalta Coating Systems’ Educational Series. He currently offers expert industry consulting via his latest venture, Collision Advice (collisionadvice.com) H&D

Fax: 301.890.3748

Email: wholesaless@mileone.com www.audisilverspringparts.com

Give your customers the reliability and quality of Genuine Parts.

Contact our team of Mercedes-Benz Certified Parts Advisors today to get started.

Mercedes-Benz Silver Spring 3301 Briggs Chaney Rd. Silver Spring, MD 20904

301-890-3060 Fax: 301-890-5473

mbsilverspring@mileone.com

Hours: M-F 7:30am-5pm, S 8am-3pm

For Volvo Genuine parts at the right price, right

please contact:

Fax: 301-847-2239

herbgordonvolvowholesaleparts@mileone.com

3161 Automobile Blvd. Silver Spring, MD 20904 301-890-3065 Fax: 301-847-2147 herbgordonsubaruwholesaleparts@mileone.com www.herbgordonsubaru.com

8710 West Broad Street Richmond, VA 23294 804-527-6860 fax: 804-965-6254 CROWNMINI.COM