MIG/MAG PULSE SYNERGIC

Instant precision or total control Switch modes and master any job.

Weld from 10A to 220A with full pulse control.

The P3 accommodates input voltages from 185V to 265.

3 MIG/MAG welding modes: Standard Dynamic, Pulse & Manual.

4-roller wire feeder with digital encoder for precise wire feed.

IP23S rated for use in the harshest shop environments. Support for two gas cylinders.

Digital arc control with instant ignition. Excellent arc stability to minimize spatter.

Auto torch detection and built-in programs get you welding fasterno wasted time dialing it in.

New 3.5” intuitive multilingual interface.

Stores up to 200 welding programs for recurring job applications.

saved/transported using a USB drive.

Our flagship dealerships are pleased to offer a wide selection of authentic genuine parts so you can repair your customer’s luxury car to the highest quality.

We not only sell WHOLESALE GENUINE PARTS across the tri-state area, but we also offer a knowledgeable team of parts specialists who will find the component you need for a seamless vehicle repair. WE WILL GO THE EXTRA MILE FOR YOU!

AUDI QUEENS

30-35 College Point Blvd. Flushing, NY 11354

Wholesale Direct: 929.297.0788

parts@audiqueens.com audiqueens.com

MERCEDES-BENZ OF BROOKLYN 1800 Shore Pkwy. Brooklyn, NY 11214

Wholesale Direct: 718.258.7055

parts@mbofbrooklyn.com mbofbrooklyn.com

MERCEDES-BENZ OF CALDWELL 1220 Bloomfield Ave. Caldwell, NJ 07006

Wholesale Direct: 973.808.0204

Parts@mbofcaldwell.com mbofcaldwell.com

JAGUAR BROOKLYN 809 Neptune Ave. Brooklyn, NY 11224

Wholesale Direct: 929.583.6492

parts@jlrbrooklyn.com jaguarbrooklyn.com

LAND ROVER BROOKLYN 809 Neptune Ave. Brooklyn, NY 11224

Wholesale Direct: 929.583.6492

parts@jlrbrooklyn.com landroverbrooklyn.com

LEXUS OF BRIDGEWATER 1550 US-22 Bridgewater, NJ 08807

Wholesale Direct: 866.679.7054

parts@lexusbridgewater.com lexusofbridgewater.com

LEXUS OF EDISON 711 US Highway 1 Edison, NJ 08817

Wholesale Direct: 732.593.6860

parts@lexusedison.com lexusofedison.com

You’ve got the right tools, staff, technology and procedures to give your customers the best repair possible. The missing piece of the puzzle? Genuine Volkswagen Collision Parts. Contact an authorized dealer today and find your perfect fit.

Paul Miller Volkswagen 118 Morristown Road

Bernardsville, NJ 07924

TOLL FREE: 877-318-6557

LOCAL: 908-766-1600

FAX: 908-766-6171

Email: aaitchison@paulmiller.com www.paulmillervw.com

Douglas Motors

491 MORRIS AVE.

SUMMIT, NJ 07901

PHONE: 908-277-1100

FAX: 908-273-6196

TOLL FREE: 800-672-1172

Email: douglasparts@douglasautonet.com www.douglasvw.com

Trend Motors 221 Route 46 West Rockaway, NJ 07866

TOLL FREE: 888-267-2821

FAX: 973-625-4985

Email: dreinacher@trendmotors.com www.trendmotors.com

Crestmont Volkswagen 730 ROUTE 23 NORTH

POMPTON PLAINS, NJ 07444

TOLL FREE: 800-839-6444

FAX: 973-839-8146

Email: vwparts@crestmont23.com www.crestmontvw.com

P.O. Box 734 Neptune, NJ 07753

EXECUTIVE DIRECTOR

Charles Bryant 732-922-8909 / setlit4u@msn.com

2023-2025 OFFICERS

PRESIDENT

Ken Miller, 821 Collision, LLC (973) 949-3733 / kmiller@821collision.com

COLLISION CHAIRMAN/

PAST PRESIDENT ATTENDING

Jerry McNee, Ultimate Collision Repair, Inc. 732-494-1900 / ultimatecollision@att.net

MECHANICAL CHAIRMAN

Keith Krehel, Krehel Automotive Repair, Inc. 973-546-2828 / krehelauto@aol.com

TREASURER

Tom Elder, Compact Kars, Inc. 609-259-6373 / compactkars@aol.com

SECRETARY

Thomas Greco, Thomas Greco Publishing, Inc. 973-667-6922 / thomas@grecopublishing.com

BOARD

Nick Barbera, Union Collision 908-964-1212 / nick@unioncollision.com

Dennis Cataldo, Jr., D&M Auto Body 732-251-4313 / jr@dnmautobody.com

Brad Crawford, Livingston Collision, Inc. 973-992-5274 / livingston.collision@gmail.com

Todd Fontana, Proline Body & Chassis 201-398-1512 / todd@prolinebody.com

Gary Gardella, Jr., County Line Auto Body 732-363-5904 / countylineautobody@gmail.com

Dean Massimini, Autotech Collision Service, Inc. 856-232-1822 / autotechnj@comcast.net

Jeff McDowell, Leslie’s Auto Body 732-738-1948 / chacki@aol.com

Danielle Molina, 821 Collision (973) 949-3733 / dmolina@821collision.com

Ted Rainer, Ocean Bay Auto Body 732-899-7900 / ted@oceanbayautobody.com

Anthony Trama 973-818-9739 / anthonytrama@aol.com

BOARD ALLIED

Joe Amato, The Amato Agency 732-530-6740 / joesr@amatoagency.com

Mike Kaufmann, Mike Kaufmann Dealer Group 973-332-7014 / mkaufmann@adps.com

PRESIDENT/PUBLISHER

Thomas Greco / thomas@grecopublishing.com

VICE PRESIDENT/SALES DIRECTOR

Alicia Figurelli / alicia@grecopublishing.com

EDITORIAL DIRECTOR

Alana Quartuccio / alana@grecopublishing.com

SENIOR CONTRIBUTING EDITOR

Chasidy Rae Sisk / chasidy@grecopublishing.com

OFFICE MANAGER

Donna Greco / donna@grecopublishing.com

PRODUCTION COORDINATOR Joe Greco / joe@grecopublishing.com

CONTRIBUTING

Published by: Thomas Greco Publishing, Inc. 244 Chestnut Street, Suite 202, Nutley, NJ 07110

Corporate: (973) 667-6922 / FAX: (973) 235-1963

www.grecopublishing.com @grecopublishing

11 NORTHEAST® 2026 is coming to you March 20-22, 2026! LOCAL NEWS

16 Dave Gruskos Sheds Light on OEM Certification Mastery at AASP/NJ Meeting by Alana Quartuccio

AASP/NJ MEMBER PROFILE

18 AASP/NJ Honors Peotter’s Auto Body and Spa as 2025 Body Shop of the Year by Chasidy Rae Sisk

22 Shop Secrets Revealed: Results of the 2025 New Jersey Automotive Survey by Jaquelyn Bauman

36 Wharton Insurance Briefs by Mario DeFilippis

George Petrask

Ted Rainer

Russ Robson

Jerry Russomano

George Threlfall

Anthony Trama

Cynthia Tursi

Lee Vetland

Paul Vigilant

Rich Weber

Brian Vesley

Glenn Villacari

Stan Wilson

Did you know this time of year always brings my wife and me to the edge of divorce? No, it isn’t my horrible eating habits or money problems or my crazy night owl lifestyle. And it isn’t jealousy or relatives or kids, either. It’s just one little word that causes so many big problems: tinsel.

That’s right. Tinsel. Allow me to explain.

When I was growing up, we always had a real Christmas tree. My dad was fanatical about that. He loved to pick it out, tie it to the top of his “Carry All” (that’s what we called his work truck) and put it up in our parlor right in front of our picture window so anyone who passed by the house could see.

Once the tree was in the stand, he got his six pack of Schaefer beer, lit up his Lucky Strikes and sat back patiently as my mom and the five of us kids strung the lights and hung

the ornaments. Once that was done, we all took our seats on the floor, my dad took one last swig of the “one beer to have when you’re having more than one,” snubbed out his unfiltered “Luckies” and headed for the box of tinsel. Now, when I say box, I don’t mean singular. I mean a literal CASE of what had to be at least a dozen individual boxes of tinsel. I can still remember the white and red plastic wrapping with the little window in the corner (so you could see the tinsel). He would cautiously unwrap the first box and walk around the tree, gently throwing handfuls of tinsel from the very top to the very bottom. Once he got through the first couple of boxes, he would call us up one at a time and instruct us on the proper way of applying the tinsel. Of course, me being the youngest, I threw it on like I was throwing snowballs. I can still hear him say, “Tom, son…you’re making Daddy mad…” So, then I would just

by THOMAS GRECO, PUBLISHER

throw it on our German Shepherd, Queenie, instead. Neither Dad nor Queenie appreciated that.

Honestly, by the time my dad was done, the tree was no longer green. It looked like a giant silver cactus. And that was exactly how he wanted it. He would stand back and admire his work, then light the fireplace and another Lucky and sit back down and finish the six pack.

Fast forward 25 years. My wife and I are putting up our first Christmas tree. She goes along with the real tree tradition, the ornaments and the lights, but then when I start to open the tinsel…

“I hate tinsel.”

“How can you hate tinsel???”

“It’s so messy and gets everywhere. I don’t think the tree needs it.”

I resisted the urge to call the divorce lawyer and talked her into compromising. We ended up putting only a couple of boxes on the tree.

Then, the next year, it was one box. The year after that, it was a few strands. Before I knew it, there was no more tinsel on the tree.

Mrs. Scrooge had effectively banned tinsel from our household. Bah humbug!

But that doesn’t stop me from asking every year. I’ve tried bribing, begging, you name it. She just won’t budge. Maybe I’ll get lucky one of these Christmases.

Speaking of Luckies, I’m sure my dad is looking down, a Schaefer in one hand and a Lucky in the other, and shaking his head. And I just can’t have that.

So, you know what? I’m putting tinsel on my tree this year! I may end up sleeping in my basement, but dammit, I’m gonna drink a six pack of Diet Coke, buy some candy cigarettes and throw a shitload of tinsel on that tree!!!

Just don’t tell my wife.

I sincerely wish you all a very Merry Christmas and a healthy, happy New Year!

Since I regularly kick the hornets’ nest with this topic on my social media channels, I thought I would bring the conversation here for those who do not follow me. The issue is safety inspections. Nearly every major vehicle manufacturer requires post-collision safety inspections whenever a vehicle has been involved in a crash. These inspections are written directly into the OEM procedures, often scattered in various sections or placed deep within the airbag, restraint and occupant protection sections of the repair manual. They exist to verify whether the vehicle’s critical safety systems were compromised during impact. These inspections determine whether the vehicle will protect its occupants in the next collision. Despite that, the vast majority of shops are not performing them, and some insurers refuse to reimburse for these inspections. In my opinion, that combination has created one of the most overlooked safety failures in modern collision repair.

I have my own view about why these inspections have not been adopted, and it is based on years of watching how repairs unfold in the real world. First, the inspections are complicated, time-consuming and require a skilled

by KEN MILLER

technician who can completely dismantle the interior of a vehicle and put it back together without any issues. We are not talking about a quick look at a seat belt or a simple diagnostic scan. A proper safety inspection requires detailed examination of restraint components, seat frames, anchors, mounts, sensors, wiring harnesses, steering and suspension components, occupant detection systems, airbag assemblies and everything else involved in crash protection. It can take hours. Sometimes, it can take days. That level of work disrupts production flow in a shop that is already buried in cycle time expectations.

Second, the procedures themselves are difficult to locate. Many repairers simply do not know they exist, nor do they have the time to search for them. They are rarely found under familiar categories like structural repair or mechanical operations. Instead, they are embedded in sections of the manual that technicians may only visit when replacing a specific airbag or diagnosing a restraint system fault. Identifying the full list of inspection steps often requires searching through multiple pages, cross-referencing different sections and carefully reading language that many shops

In today’s competitive marketplace, it is imperative that you regularly evaluate your business model for long term success. Defining how and where you want your company to go is the beginning of your long-term goals. This means objectively assessing its strengths, weaknesses and adaptability to changing market conditions.

Every day as I visit shops or speak with owners and managers, I come across a few repetitive concerns. How do I get and keep employees? How do I increase revenue, and how do I cut costs? Let’s take a look at employee retention and accountability.

Education is number one, not only for yourself but for your employees. Did you know that statistics say you should be investing two to five percent of your annual profits for education? By doing this on a yearly basis, not only will you attract and retain key employees, you will also increase your ROI. Comebacks will decrease, profitability will increase, employee turnover will decrease, customer satisfaction will increase, and shop safety will increase. I’m sure you could add a lot more benefits.

I know some will say, “I invest all this time and money into a technician only to have them move on or get stolen

by JOE OCELLO

by another shop.” I don’t discount this; it has happened to me over the years. This is why your relationship with your managers and employees is important. If employees are treated fairly and know they are an integral part of your team, they are more likely to stay and make a home with you. Make them feel like family because, in a sense, they are. Where would you be without them? Create events, purchase lunch occasionally, give them a shout out for a job well done or maybe a new tool. There is so much you can do with minimal expense. AASP/NJ can help. We have added so many new programs for both the mechanical and auto body division. Give us a call – really, I look forward to speaking with you! Want to increase your ROI? Again, the statistics say 20 to 50 percent of your profits should be allotted to equipment upgrades, image upgrades, new business marketing and analyzing your cash flow. The list can be endless, but the bottom line is – change. New and improved. Look at the big box stores. They are always advertising the new this or that. Every time you enter a store, things are moved here or there. Add new services or products for your customers. Faster, easier and more personal service will keep your

Being an AASP/NJ member has its privileges. Between savings and revenue generated by AASP/NJ member benefits, discounted education and training opportunities, access to the AASP/NJ Labor Pool and Hotline, advocacy in Trenton and exclusive members-only access to documentation, forms and regulations on aaspnj.org, you simply can’t afford NOT to be an AASP/NJ member!

AASP/NJ Health Benefits ProgramSave on Insurance!

BMW of Springfield

391-399 Route 22 E. Springfield, NJ 07081

Toll Free: 800-648-0053

Fax: 973-467-2185

bmwofspringfieldnj.com

BMW of Bridgewater

655 Route 202/206

Bridgewater, NJ 08807

PH: 908-287-1800

FAX:908-722-1729

bridgewaterbmw.com

©️2025

Circle BMW

500 Route 36

Eatontown, NJ 07724

Parts Direct: 732-440-1235

Fax: 732-440-1239

wholesale@circlebmw.com circlebmw.com

Park Ave BMW

530 Huyler Street

South Hackensack, NJ 07606

PH: 201-843-8112

FAX:201-291-2376

parkavebmw.com

Paul Miller BMW 1515 Route 23 South Wayne, NJ 07470

PH: 973-696-6060

Fax: 973-696-8274 paulmillerbmw.com

BMW of Bloomfield

425 Bloomfield Avenue Bloomfield, NJ 07003

Parts Direct: 973-748-8373

psantos@dchusa.com

World has been specializing in complete insurance coverage for the automotive services industry for more than 30 years. We partner with carriers to design coverage enhancements, dividend programs, and new products specific to the automotive services industry.

An exclusive program administered by trade professionals who are ASE Master Certified and I-CAR Certified technicians.

ALL-IN-ONE, NON-AUDITABLE POLICY

• Commercial auto

• Commercial property

• General liability and umbrella

• Garagekeepers

• Cyber liability

• Employment practices liability

PLUS, SPECIAL INCREASED LIMITS

• Pollutant clean up

• False pretense

• Employee tools

• Extended Garagekeepers

• Autonomous car coverage

• Customer complaint defense

• And many more

An exclusive workers compensation safety group program, only available for auto service businesses.

•Great pricing for qualified shops

•Optional managed care premium discounts

• Potential dividend plans available

GROUP HEALTH PLANS

Health Plans with Fortune 500 benefits for small and mid-sized auto service employers.

• Competitive Rates

• Two participant minimum

•Multiple plan design options

• Multiple provider networks in all 50 states

• Dental and vision plans available

• Supplemental benefits available

OEM certifications can be a great thing for an auto body business, provided one knows how to successfully pursue and make the most out of the investment involved.

AASP/NJ hosted an OEM certification master class last month featuring Dave Gruskos (Reliable Automotive Equipment). Gruskos, an industry expert who has been instrumental in molding today’s OEM certification programs, provided great insight on every consideration a shop owner needs to weigh before going after certifications, as well as how to best leverage them.

Gruskos highlighted the many expected investments shops will need to make. Investment is not just monetary, he pointed out. Training plays a huge role in obtaining OEM certification. He warned, “Your A-tech will be gone for about three weeks the first year for that one certification. You’ll be losing productivity. The equipment cost is nothing compared to what you lose in labor.”

Representing a brand goes deeper than training and equipment. “Everything to do with certifications is about relationships. Your business is going to be built on relationships with the dealership.

“If you have a dirty shop, you will get red-flagged

before you even start the process,” he continued.

For example, BMW will send someone to inspect the shop. If the operation appears disorderly and disorganized, it will stop the certification process in its tracks. “Operate a nice clean shop, and then start your processes for certification,” Gruskos recommended. “It will pay off 10 times over.”

Gruskos stressed the importance of truly being aware of everything involved before pursuing certifications. “Don’t do something just to put plaques on the wall. It will be a race to the bottom, and you will go out of business,” he warned.

For more information on AASP/NJ’s educational schedule, please visit aaspnj.org

• Audi Parts Professionals are your subject matter experts on collision parts, replacement components and mechanical items.

• Many Audi dealers offer technical service support hotline access that can reduce your repair times and help you meet an on-time promised delivery.

• Installing Audi Genuine Parts contributes towards improved cycle time that makes both your customer and their insurance company happier.

Helping you do business is our business. Order Audi Genuine Parts from these select dealers.

Paul Miller Audi

179 Route 46 East

Parsippany, NJ 07054

Toll Free: 800.35.MILLER

Parts Direct: 973.575.7793

Fax: 973.575.5911 www.paulmiller.com

Bell Audi

782 Route 1

Edison, NJ 08817

732.396.9360

Fax: 732.396.9090 www.bellaudi.com

Jack Daniels Audi of Upper Saddle River

243 Route 17

Upper Saddle River, NJ 07458

201.252.1500

Fax: 201.254.1552

tbabcock@jackdanielsmotors.com www.jackdanielsmotors.com

Audi Bridgewater

701 Route 202-206 N Bridgewater, NJ 08807

929.600.9156

Fax: 908.595.0237

parts@audibridgewater.com www.audibridgewater.com

AASP/NJ’s goal is to create a community of collision and mechanical shops that collaboratively advance and elevate the repair industry, and year after year, during its Annual Meeting, the association recognizes an outstanding member business with the Stan Wilson/New Jersey Automotive Body Shop of the Year Award.

Peotter’s Auto Body and Spa (Summit) was named the 2025 honoree for being a “unique shop that does amazing work,” as AASP/NJ President Ken Miller explained as he presented the award. Shop manager/CEO Larry Peotter feels “truly honored and grateful” for the recognition, but he is especially proud of his team for making it possible.

“This one’s for the Peotter’s family, the people who show up every day with pride in what they do and care in how they do it, those who’ve built this place piece by piece over the years. Earning ‘Body Shop of the Year’ means a lot, but sharing it with this team means everything! Awards recognize a shop, but it’s the people behind it who make it what it is, including the network of people who make what we do possible – our technicians, partners, vendors, clients and fellow shops who all share the same goal of doing right by the customer.”

buildings. Our unique layout has helped us become a one-stop shop for our customers’ automotive needs.”

In addition to offering full collision repairs, Peotter’s Body Shop and Spa performs light mechanical work, such as wheels, tires, alignments and brakes, plus the shop offers a full detailing spa to “elevate each vehicle’s aesthetics and protection.”

Although the state-of-the-art facility participates in direct repair programs for a couple small insurers, Peotter’s emphasis is on performing quality repairs that safely restore his customers’ vehicles to their pre-accident condition. By investing in the right tools, equipment and hands-on factory training, the shop has obtained certifications from several high-end vehicle manufacturers, including Tesla, Lucid, Rivian and Jaguar Land Rover.

The award serves as a meaningful tribute to his father, Timothy, who began the business back in 1985 alongside his mother, Joanne. Peotter was “born into the business; I’ve been here since I was in diapers, and I never wanted to leave.” Although his parents encouraged him to earn an accounting degree to ensure he would have opportunities outside the industry, he “always knew this is what I wanted to do. From a young age, my goal was to run the business some day. I never really dreamed about doing anything else.”

After college, Peotter returned to the family business, working alongside his parents and two sisters until he took the helm with Joanne in 2012 after his father passed away. His mother and siblings, Renee and Nicole, still work alongside him, but over the past decade, the shop’s staff has grown from 10 to 50 employees. “My father laid the groundwork for what we’ve become. Although our facility sits on a small piece of land, he designed the original building with three levels and a car elevator, and over the years, we’ve expanded to add additional

Peotter believes the shop’s certifications demonstrate its commitment to “investing in our employees and our company to ensure we stay ahead of the curve.”

The shop’s focus on electric vehicle (EV) certification is reflective of “the shift in the market as a lot of people turn to alternatively fueled vehicles,” and Peotter’s attention to these shifts also extends to his marketing efforts. “We’ve invested a lot of time and energy into developing our social media presence to stay relevant to our customers. These days, everyone – from toddlers to grandparents – has access to these platforms, and sharing posts about what we do each day has helped make us recognizable.”

Brand recognition is particularly important in the era of MSOs, which Peotter sees as one of the biggest challenges Garden State shops are facing. “A lot of MSOs have been coming into New Jersey and buying up the shops, so that takeover certainly presents its challenges.” However, he also has concerns with insurers’ tendency to group all shops into one bucket. “There are over 2,000 shops in this state, but a lot of them don’t invest in their people, training or equipment; they’re still repairing cars like it’s 1980. Yet, insurers want to compensate those guys the same as shops that have invested millions into properly equipping their facilities and training their team. I wish there was some sort of ranking system that

recognized those efforts and which would encourage other shops to elevate their standards and catch up with what’s necessary in today’s collision repair world.”

Peotter strives to stay ahead through his involvement with AASP/NJ and has been attending the classes and training offered by the association since he was in his early 20s, yet the shop’s involvement goes even further back. “My parents have been members of AASP/ NJ since the beginning because they recognized the value of keeping up with changes in the trade, and as technology advances more rapidly than ever before, it’s even more important to stay up-to-date on what’s going on. Membership allows us to stay relevant and maintain involvement in our community and our industry. A lot of shops are afraid to venture outside their own circle, and as a result, they get left behind because they’re unaware of what’s happening outside their own business.”

As a result of his passion for helping other shops and effecting meaningful change in the industry, Peotter was pleasantly surprised when the association recognized his facility as body shop of the year. “To be recognized by such a respected association is something we don’t take lightly. It really shows that our hard work and dedication to the industry is paying off, that we’re making a positive and lasting impact on this industry that I’ve devoted my life to. It inspires me to continue helping as many people as possible along the way.”

Despite his pride in being honored, Peotter insists, “Being part of an organization like AASP/NJ means more than just awards – it represents a community that pushes this industry forward. Their commitment to education, integrity and advocacy continues to raise the standard for collision repair professionals across New Jersey, and I’m proud to be a part of a group that continues to push for better craftsmanship, better service and better care for every vehicle and every person who walks through our doors.”

We

ROUTE 22 WEST UNION, NJ 07083 TOLL FREE: 800-964-7281

FAX: 908-851-5631

“The more things change, the more they stay the same.”

The old quote rings truer every passing year for automotive repair shop owners in New Jersey. This year’s New Jersey Automotive industry survey results expose many shared struggles across repairers in the Garden State and how our readers are navigating the numerous obstacles they encounter in their daily business. Find out what shops are charging for their labor rate, how they’re

handling employee recruitment, what they’re doing about Right to Appraisal (RTA) and if they clash with the same insurance carriers as you do. All that and more will be unearthed in the following pages with the report of this year’s NJA reader survey results. We hope that you find this information enlightening and that it helps you feel less alone in an increasingly isolated automotive repair landscape.

Collision repair: 80%

Mechanical repair: 10%

Collision & Mechanical repair: 10%

Collision shops:

Are you a DRP?

Yes, 1-5 programs: 71%

Yes, 6-10 programs: 7%

Yes, more than 10 programs: 4%

No: 18%

How many employees do you have, including yourself?

1-5: 26%

6-10: 26%

11-20: 26%

Over 20 employees: 22%

Approximately how old are your youngest and oldest employees?

Average youngest age: 24

Average oldest age: 66

The most shocking detail revealed in the responses to this question was the broad spectrum of ages for both the youngest and oldest employees at our readers’ shops. Even though the average age of the youngest employee for most Garden State shops is 24, the answers in our survey ranged from 15 to 47 years old. For the oldest employee at our readers’ shops, despite averaging 66 years old, the spread reached all the way from 40 to 82 years old.

Last year, 91 percent of survey respondents shared that their oldest employee was over 50. This year, that number is up to 97 percent, showing how quickly many are approaching retirement.

How many employees have you hired in the past year?

None: 22%

1: 10%

2-4: 52%

5 or more: 16%

While these stats are relatively on par with previous years, there has been a significant increase in those hiring more than one employee in 2025. Compared to last year’s survey results, there has been a 55 percent increase in those hiring two or more employees in the last 365 days.

What is your current labor rate?

$50-$60: 14%

$61-$70: 41%

$71-$80: 21%

$81-$90: 3%

More than $90: 21%

In 2021, 70 percent of survey respondents had a labor rate between $50-$60 per hour. That bottom tier continues to shrink, decreasing 18 percent just since last year. The amount of shop owners who are charging over $90 has more than doubled from our 2024 results.

What do you think your labor rate should be?

Less than $90: 17%

$91-$100: 38%

$101-$110: 10%

$111-$120: 0%

More than $121: 35%

In 2024, only 13 percent of our survey takers thought they should be getting over $120 per hour for their labor rate. This year, that number has more than doubled at 35 percent.

What is your current storage rate?

$50-$60: 17%

$61-$70: 4%

$71-$80: 0%

$81-$90: 10%

More than $90: 69%

If applicable, what is your current backlog of work?

N/A, no backlog: 33%

Less than 14 days: 37%

14-30 days: 30%

Would you say that business in your company is up or down compared to last year?

While repairers across the Garden State have many things in common, one thing that this year’s survey has revealed is that the current state of automotive repair work in 2025 looks very different from shop to shop. With a nearly even one-third split between those believing their business to be up from last year compared to those who think their business is down and those who see their business as the same, the perception of the automotive repair industry is extremely varied across New Jersey shop owners.

“We stay very involved in our community,” shares one Union Countybased shop owner who indicated that his business was up compared to last year. “Working with how people manage their savings and supporting our community members has helped us maintain our business.”

How else are shops seeing either continued or improved business in 2025? We hope that you will find some of the answers to this question in the results of our survey below.

How would you rate your current state of business?

Last year, our survey respondents shared one of the highest ratings on their current state of business, averaging a 7.3 rating across shop owners. Unfortunately, even though

For over 80 years, the industry

Kemperle represents hundreds of the industry’s top manufacturers and stocks thousands of their superior products. With more than 50,000 products available to our customers, Kemperle’s locations are uniquely equipped to find the products you need.

KEMPERLE PERFORMANCE DRIVEN PRODUCTS

Abrasives | Adhesives | Body Fillers & Polyester Putty | Clearcoats

Detailing Products | Hardware | Masking Products | Prep Solvents/Cleaners Primers/Sealers | Reducers | Spray Suits | ...and more

PINNACLE EQUIPMENT

U.S. Importer for Car Bench International

NJ TRAINING CENTER

• Hands-on technical training

• Classroom seminars

ON-SITE MOBILE DEMONSTRATIONS & TRAINING

626 E. Elizabeth Ave

Linden, NJ 07036

P: (908) 925-6133

F: (908) 925-4344

414-416 Madison Ave

Paterson, NJ 07524

P: (973) 279-8300

F: (973) 279-9030

Corporate Headquarters

Albert Kemperle, Inc.

8400 New Horizons Blvd.

Amityville, NY 11701

100 Melrich Rd

Cranbury, NJ 08512

P: (609) 860-2800

F: (609) 860-2801

Instagram.com/albertkemperleinc

Facebook.com/albertkemperleinc

Linkedin.com/company/albertkemperleinc

For information on Careers please send inquiries to WWW.NJMARKETING@KEMPERLE.COM

631 Clifton Ave

Toms River, NJ 08753

P: (732) 797-3942

F: (732) 797-0774

4 Emery Ave

Randolph, NJ 07869

P: (862) 244-4818

F: (862) 244-4822

30 percent of survey respondents reported that their business has improved in the past year, the average rate of the industry is back to our pre2024 average rating of 6.7. In 2024, 100 percent of our readers rated their current state of business at a five or higher – a number which has dwindled by 13 percent in 2025.

How does your shop handle ADAS calibrations?

Repair in-house: 43%

Sublet to dealership: 18%

Sublet to ADAS calibration center: 39%

If you calibrate ADAS in-house, who performs the calibrations?

Repair planner: 6%

Dedicated calibration tech: 69%

Whoever is handling the repair job: 13%

Other: 12%

The fact that over two-thirds of shops employ a dedicated calibration technician demonstrates an understanding of the advancing complexity of this task while creating a new career path for aspiring industry professionals

How are you incorporating Artificial Intelligence (AI) into your business?

The future is knocking on the bay doors of New Jersey shop owners, and as our survey reveals, Garden State repairers are starting to get on board. Last year, 60 percent of our survey respondents informed New Jersey Automotive that they had yet to implement any Artificial Intelligence into their business practices. In 2025, that number has decreased by 20 percent as more repairers see the value in this new tool to run their shops.

As for how our readers are using this technology, 31 percent reported that they are employing AI for their day-to-day communications, a number which more than doubled from last year’s survey.

“ChatGPT is great,” a North Jersey

repairer confessed. “We can use it to explain things to the customer in layman’s terms. You can explain to them what a one-time use part is. It’s also great for making your case to insurers. It helps us justify why they should pay for certain things.”

Although the use of AI is increasing in our state, not everyone is excited by the prospect of this new technology. As one Passaic County shop owner joked, “I’m still working hard to find actual intelligence.”

are your biggest concerns about AI?

A little over one-fifth of survey respondents shared that they had no concerns about the rise of AI, but the majority still maintain reservations about this new technology.

“Insurance companies are using it to their advantage by writing more incomplete estimates,” a Jersey City survey respondent conveyed. “They’re writing estimates that are extremely incorrect.”

In addition to the unsatisfactory applications of AI in writing estimates that already exist, our readers predicted the insurers will inadequately use this technology to cover their staffing shortages in the days ahead.

“They’re going to take it overboard,” suggested one Union County shop owner. “We already know they hate paying for things. They’re going to use it to replace

employees and communications. It’s going to make the already nonexistent customer service worse.”

“There will be no human interactions at all,” a Hillsborough repairer added. “There will be no flexibility or compromise. It’s all going to be transactional.”

What, if anything, gives you optimism about this industry over the next few months?

Over the past five years, New Jersey repairers have been experiencing increasing heights of unprecedented change and uncertainty in the future of the industry. With such a persistent sense of unease across shop owners, we wanted to know what might give our survey respondents a glimmer of hope in the coming months.

For a number of our readers, they believe a tide has turned in our government and that they might see changes in legislation sometime soon.

“We finally have leaders who know and respect capitalism,” expressed one shop owner from Essex County. “They’ll fight for us.”

“The legislation we put forward [regarding RTA] gives me hope about what’s in front of us,” shared a shop owner from Somerset County. “There’s the potential for a lot of rage and frustration for the customer with RTA. I think it will put gas on the fire to spark some change.”

For other shop owners, an increase in training and education is their guiding light in the days ahead.

“I’m excited about the continued education we’re providing to our staff,” explained a Bridgewater-based shop owner. “We know more, so we’re better able to explain to customers and vehicle owners the proper repair process. It helps us continue to justify the cost of our repairs.”

Another survey respondent from North Jersey agreed that the increase in education is an exciting opportunity for the automotive repair industry.

“The fact that I’m seeing our

industry and AASP/NJ work more with CREF, CCC and I-CAR is a positive sign,” he expounded. “By bringing in education, youth and shops are coming together at one level.”

What do you feel is the most critical issue affecting the industry right now?

Labor Rates: 11%

Insurer involvement in the repair process: 44%

Lack of qualified help: 15%

Increasing costs: 19%

Lack of consumer education: 11%

In 2024, 35 percent of NJA survey respondents indicated that the insufficient Labor Rate was their biggest pain point as repairers, while 44 percent felt that the lack of qualified help was the most pressing issue they were facing as shop owners. Although insurer involvement in the repair process has always been a problem for repairers, it appears something has shifted for the worse, as this year’s survey revealed insurer interference as the largest grievance for shop owners in 2025 by a wide margin.

“Insurers are united, and it allows them to keep us down,” explained a repairer from Union County. “If we want to have any kind of bargaining power in the labor rate or the repair process, we need to unite on the same platform.”

For some shop owners, in addition to the regular industry issues they’ve always faced, a new decrease in volume of work is weighing heavily on their minds.

“We’re seeing a decrease in repair volume,” lamented a survey respondent from South River. “Consolidation is killing us.”

“Claim count is down, and total loss severity is up,” another Freeholdbased repairer agreed. “I don’t know how we’ll survive if this keeps up.”

Which insurers are the most difficult to deal with?

For the ninth year in a row, New Jersey Automotive readers have

reported that the top three worst insurers to deal with are Progressive, Allstate and State Farm, with Progressive leading the pack by a wide margin, appearing in 68 percent of survey respondents’ answers. For comparison, the second most-reported difficult insurer, State Farm, only came up in 26 percent of responses.

But just what is it that makes these insurers so much worse to deal with than their counterparts?

“Progressive and State Farm basically disregard any OEM documentation,” reported a Central Jersey shop owner. “These procedures are overridden by their staff’s opinions, and their staff are ill-informed and have all been indoctrinated into their ecosystem.”

“Progressive just keeps going backwards,” another repairer from

Middlesex County agreed. “Things they paid for years, they now go back on.”

“Progressive needs supervisor approvals to get any parts replaced or repairs justified, which affects turnaround time,” a reader from Bridgewater continued. However, Progressive was not the only insurer on his list. “State Farm is the worst with denying supplements, plus they need insane documentation, which they don’t even include, and then require another supplement. The amount of work isn’t worth it.”

“For us, State Farm is the worst,” a Sussex County repairer concurred. “One time, while negotiating a claim via telephone, a claims person told me that he ‘hates New Jersey body shops.’ He went on to state that if a New Jersey body shop is asking for eight hours to repair a panel, he lowers it to two hours. I swear, he told me that he wants our technicians to not be able to purchase food so that they can starve. The vilest person I’ve ever dealt with at an insurer or otherwise.”

Another reader shared that he navigates some abysmal insurer dynamics by being a part of a DRP but recognizes that his business would be very different were this not the case. “We have an issue with any insurer that we are not a DRP with,” the South Jersey shop owner explained. “The worst we deal with is Progressive, but I know lots of shops who are DRP for them and have minimal issues.”

How do you feel insurer-shop relations have worsened over the past 12 months?

Insurer interference and control over the repair process have been longstanding impediments for Garden State shop owners, and with each passing year, it feels like it gets worse. For a number of our survey respondents, the insurance industry’s deeply entrenched manipulation tactics continue to make running their businesses a challenge.

“The insurance industry wants to control the automotive industry,” lamented one repairer from Mercer County. “DRPs need to be abolished.”

“We do almost no work for nonDRP carriers,” a Toms River shop owner agreed. “They have done a great job of steering customers to their shops and made it so that non-DRP shops don’t want the hassle of doing their work.”

“There are 15 other shops on my block, and the insurers play bingo with us,” described an Elizabeth-based survey respondent. “It makes it harder on us. There is no scale of proper labor rate within a 25-mile city. Because

continued from pg. 27

we’re not united, we have no power in these conversations with insurers.”

As New Jersey Automotive readers reported, the headaches caused by insurers don’t end once the car finally rolls into their bays.

“Insurers simply ignore the shop’s positions and arguments on safe and proper repair practices,” a Monmouth County repairer shared. “They say everything is included when it’s not and then stomp their feet and refuse to even discuss it.”

Yet, these well-established hassles of steering and refusal to negotiate were not the only aspects of the insurance industry that are causing issues for New Jersey repairers, according to our survey results. Like many other industries, insurers are also experiencing staffing shortages that are creating new challenges for shop owners to navigate.

“There’s no more one-on-one communication,” an Eatontown reader explained. “The companies are so understaffed; it’s taking a toll on shops. You can’t call and discuss anything with the insurance companies unless they are calling to let you know they’re not paying for something.”

Another Central Jersey shop owner agreed.

“They don’t have any qualified appraisers, and the insurance companies don’t understand the repair process,” he pointed out. “They don’t care. The employees have become bean counters at the consumer’s expense.”

In your opinion, has the increase in consolidation been helpful or harmful to the industry?

Helpful: 19%

Harmful: 81%

While some repairers believe that creating a coalition amongst shop owners will help strengthen the automotive repair industry against the goliath of insurers, our readers overwhelmingly agree that this strength in numbers will not be reached through consolidation.

For a number of our readers, the

threat of consolidation puts smaller shops on the chopping block.

“MSOs are the Walmarts of the automotive industry,” observed a repairer from Elizabeth. “It makes it harder for regular shops’ wants and needs to be respected.”

“It will lead to forcing smaller shops to either close or sell,” another responder from Freehold predicted. “When the MSO has a big enough footprint, they will attempt to suffocate the smaller shops into submission by putting pressure on insurance companies to either remove the smaller shop from their DRP or steer work away from them.”

As some survey respondents noted, these practices are already occurring in New Jersey.

“Insurers are pushing all the work to them, even though they know it’s substandard work,” revealed a Somerset County repairer. “They turn a blind eye to it, and it’s lowering the standards of quality repair for the rest of us. Some of us see the writing on the wall. All my friends are getting out of the industry and selling to consolidators.”

Even those who are part of an MSO recognized the impact consolidation has on the industry.

“We are a CARSTAR Store and considered an MSO by carriers, so it has been good for us,” said a South Jersey survey respondent, though he admitted, “If we were not an MSO, I would not like it at all.”

If approached by an MSO, would you consider selling your shop?

Yes: 30%

No: 47%

Not sure: 23%

As the shadow of consolidation looms larger over the automotive repair industry, the question of selling one’s shop is creeping into the minds of repairers around the Garden State. Our survey reveals that less than half of our respondents are firm in continuing their business, while 30 percent would be open to selling their shop, and nearly a quarter aren’t sure of their future.

“Owning a shop is the American Dream,” declared one respondent from Newark. “I’m definitely not going to sell it.”

His sentiments were shared by another repairer from Toms River.

“I would never sell to an MSO,” he echoed in his survey response. “They don’t care about employees in their takeovers. For them, it’s all about numbers. I have a duty to my staff, and I won’t leave them hanging.”

For those who would consider selling if the opportunity presented itself, a long tenure in the industry is a major contributing factor in their decision.

“I’ve been doing this for 47 years,” one Hackensack-based shop owner shared. “I don’t have anyone lined up to take over when I retire. The time is right for me.”

As another survey respondent from North Jersey acknowledged, their answer to the question of selling all boils down to the almighty dollar.

“Depends on what they offer,” he joked. “They could make it worth my while.”

Are you aware of AASP/NJ’s legislative efforts regarding Right to Appraisal (RTA)?

Yes: 87%

No: 13%

Even though the majority of our survey respondents were cognizant of AASP/NJ’s legislative efforts regarding Right to Appraisal (RTA), there were still some of our readers who missed the association’s efforts in this fight. In response to some New Jersey insurance carriers removing or limiting the Appraisal Clause in their policies, AASP/NJ has been working with New Jersey State Senator Paul Moriarty on Senate Bill 4534, which would require all automotive insurance policies in the Garden State to include the Appraisal Clause.

Many shop owners recognize the importance of this legislation in protecting the consumer and, as such, are making efforts of their own to get this critical law passed.

“We’ve asked our county representative to help,” one survey respondent from Sussex County announced. “I believe this could really make a difference in our industry.”

“I became aware of this legislation through attending AASP/NJ meetings,” shared another North Jersey reader. “I plan on meeting with [AASP/NJ Executive Director] Charlie [Bryant] to learn more.”

If you have ever had a customer invoke the Appraisal Clause, please share your experience.

The Appraisal Clause in insurance policies is an important tool for consumers in the fight against insurers, but as some NJA readers shared, the insurance companies will do everything in their power to prevent it from being used properly.

“We had one customer try to use the Appraisal Clause against Allstate,” recounted one Paterson shop owner.

“The insurance company employed every tactic to delay and dissuade customers from being able to use RTA effectively.”

Even though it is discouraging to discover that insurance companies will try to thwart a driver’s efforts to advocate for themselves through the Appraisal Clause, it isn’t surprising –and it makes it even more rewarding when this tool is used to its fullest potential and brings the insurers to heel.

“We have customers almost every day who do it,” a repairer from Allentown disclosed. “There are so many insurers who will not negotiate except when the Appraisal Clause is invoked. But I’ve seen customers get them there many times.”

In the last two iterations of the New Jersey Automotive survey, 58 percent of our readers indicated that one of their biggest challenges in attracting and retaining employees was the lack of qualified technicians available. In 2025, only one quarter of our respondents mentioned the quality or quantity of the labor pool, but 42 percent expressed their biggest difficulty in attracting and retaining employees is now the challenge of paying them an adequate wage.

“A lot of new employees want a higher rate,” cautioned a South Amboy

shop owner. “They’re going to the MSOs to get paid a high dollar. It’s hard being competitive.”

Another survey taker from Central Jersey shared his pain.

“We get very few qualified applicants, and when we do, it’s hard to give them what they’re asking for,” he divulged. “They are looking for a particular level of pay and perks that we can’t offer them.”

For the lucky 29 percent of our survey respondents who expressed that they had no challenges regarding their staff in 2025, the ‘secret sauce’ appears to be investing in their existing employees.

“We haven’t had any issues because we treat our team as the incredibly valuable part of the business that they are,” a Red Bank shop owner boasted. “I know that if I treat them well, they will treat my customers well, and the business will do well.”

Staying informed and at the forefront of the industry could be the difference between a bay full of cars and a permanent ‘closed’ sign on the doors for New Jersey shop owners. Nearly a third of survey respondents specified that the most beneficial training their staff could receive is any courses from I-CAR. The second most popular response regarding what training their staff could most benefit from was OEM-training, with 14 percent specifically indicating training on new technology.

Soft skills training also appeared in several responses, covering everything from leadership training to sales techniques to customer service.

What do you do in your business to promote a positive work culture?

Now that retaining employees has become increasingly critical to sustaining business operations, shops around the state are employing a

Rivian, a manufacturer of passenger and commercial electric vehicles, has recently approved the Telwin SpA Inverspotter 14000 Smart Aqua Squeeze Type Resistance Welder for structural repairs on its passenger and fleet delivery vehicles. With this approval, the 14000 welders can be used throughout Rivian’s quickly expanding global network of Certified Collision Centers.

“We are proud that Telwin’s Welding Technologies have met the engineering welding requirements set by Rivian,” said Telwin SpA Chief Executive Officer Stefano Spillere. “As we continue to grow in the global market, this approval strengthens our North America offerings.”

The Made-in Telwin technology Smart Autoset allows automatic detection of material and thickness not relying on manual settings or reference tables. Its up to 15,000 amp capabilities allows proper welds every time.

Additionally, the Telwin Technomig 243 Wave three-torch welder has met the specifications set by Rivian and will be offered as an option to the Certified Collision Network as a MIG/MAG welding solution.

Rivian Certified locations have been specifically chosen for their expertise in proper repairs of Rivian vehicles and providing best-in-class collision repair. Rivian Certified Collision Centers must

meet specific training, tooling, and facility requirements to assure that Rivian collision repairs are performed to OEM standards. With the number of people driving Rivian vehicles expanding by the day, Rivian encourages repair centers to join the Rivian Certified Collision Network of repairers. The first step in that process is to submit an application at https://usa.itascore.com/rivian

About Telwin SpA: For over 60 years Telwin has been a worldwide leader in the manufacturing of welding machines, cutting systems, battery chargers, and starters based in Italy. Telwin is present on all five continents, on over 120 markets with a range of products that, for variety and richness, has no equal on any market; products tailored to all production fields, from the automotive to industry, from the building sector to shipyards, from all professional divisions to DiY. Telwin means state-of-theart, innovative and technologically advanced solutions, aimed at improving productivity, optimizing intervention times, minimizing operative costs and always guaranteeing excellent performance under any operative condition.

For more information, visit telwin.com or contact: Timothy Morgan at t.morgan@telwin.com

have never taken the time to explore. When you combine that with a fastpaced environment, the inspections are often dismissed before they are ever considered.

Third, there is a perception among some repairers that these inspections are too invasive or unnecessary. It is common to hear statements like “the vehicle did not get hit hard enough” or “nothing appears damaged.” That mindset comes from decades of repairing vehicles where crash energy transfer was simpler and safety systems were less integrated. Modern vehicles do not behave that way. Seat frames and belt anchors can shift or twist slightly out of position. Airbags can initiate but not fully deploy. Sensors can exceed tolerance levels without showing any visual clue. A vehicle can look fine and display no DTCs and still be unsafe. Without the manufacturer’s inspection routine, there is no way to know.

Fourth, insurer reimbursement has played a role. Many carriers refuse to pay for these inspections. Some claim they are not necessary. Others believe they fall outside the scope of what should be charged. Inspections slow down production and increase severity, so they do not fit neatly into insurer cost containment goals. A shop already fighting for nearly every operation looks at the situation and decides the battle is not worth it. That reluctance grows when the shop itself does not fully believe in the inspection process or does not understand the safety implications behind it. The end result is predictable. Inspections that should be performed are never even added to the repair plan.

Finally, cycle time pressure has created a culture where anything that slows down the repair is viewed as a liability. A true safety inspection can add one to three days to a repair. That affects scheduling, rental days, insurer scorecards and customer expectations. Therefore, a repairer may think the easiest way to keep everything on track is to avoid the inspection entirely. In my opinion, this is one of the most damaging habits our industry has developed, and it will only get worse as vehicles become more complex.

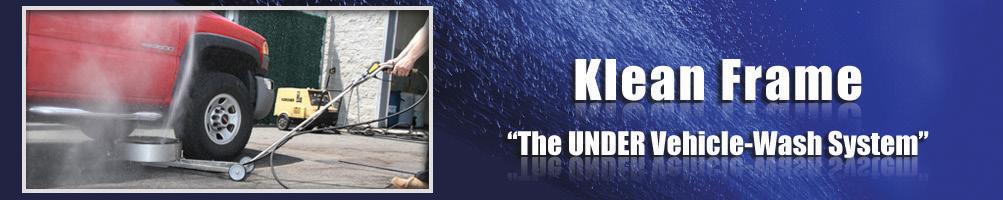

What is Klean Frame?

Klean Frame is a machine that, when attached to a pressure washer, will spray, rinse and clean the underside of vehicles. This allows for the quick removal of corrosive salts, chlorides and debris, thereby extending the life of the vehicle.

Unlike other wash systems that focus on the top and sides of the vehicle, Klean Frame concentrates on the UNDERSIDE only. You’ll be amazed at how “klean” your frame will be!

A Klean Frame model for every use!

HR21 (designed for medium duty trucks, full size vans, pick-ups, SUVs and more)

HR30 (designed for dump trucks, tractor trailers, construction vehicles, fire trucks, etc.)

LP21 (designed for cars, small SUVs, vintage autos, boat trailers, etc.)

LP30 (designed for large equipment including buses, motorhomes and car trailers)

continued from pg. 29

variety of different methods to create an environment that staff are happy to return to day after day. Survey respondents shared their tactics, which ranged from the small, everyday delights like morning pastries and pizza lunch days, to the occasional surprises such as team building events, holiday parties and gift certificate rewards.

Outside of special, feel-good benefits, New Jersey shop owners are focusing on cultivating practices that bring their team together and uplift their employees.

“We gather for monthly meetings and functions to keep morale high,” a Sayreville business owner shared. “We make sure there’s constant recognition for good employees who excel in their work.”

Another Kearny-based shop owner who responded to our survey outlined a similar tactic.

“We make the shop feel like a family where everyone feels valued,” he wrote. “Our employees are stakeholders in the business, and with what they do, they are like artists or magicians. I make sure my customers know who fixed their car.”

How do you educate your current and potential customers?

Being an automotive repairer already comes with a slew of unique and deep-seated challenges, many of which are out of the control of independent shop owners. One area in which repairers have some agency to prevent additional problems from occurring down the line is keeping their customer base well informed.

Communicating sometimes complex information to a population that often has little to no idea how vehicles work can be a daunting task, but as our survey reveals, New Jersey shop owners are up to the challenge.

“We explain the entire process of the repair to them as we look at the job,” detailed a Bridgewater-based repairer. “We make sure they’re aware

of any other outcomes or possibilities. We outline the minimally necessary repairs but make sure to inform them about the ‘ifs, ands and buts’ of doing it minimally. If the customers know the least amount they could do, but also why that may not be the best solution, they better understand why it’s best to go with doing it the right way, even if it’s more costly.”

Another shop owner from Wayne agreed, specifically noting that they employ various methods of communication, including emails, texts and phone calls to keep their clients up to date.

“It’s important to keep the customer engaged,” he shared. “We email them the estimate of what’s approved and follow up with a call to review and explain policy and parts so there are no surprises.”

“We have multiple notices that we send out at various intervals,” another reader from Atlantic City described. “We also send a letter outlining the responsibility of the insurance company versus the shop versus the clients, so there is no misunderstanding as to who’s responsible for what.”

Of course, running a shop is a herculean task in and of itself, so not every shop owner has time to walk through every minute detail with all of their customers. In these instances, our survey respondents shared some of the other methods they employ for their clients.

“We’ve got a great resource right at our fingertips,” an Asbury Park repairer stated in his response. “We share articles from New Jersey Automotive. It helps the customer understand.”

If you could transform or fix any part of this industry, what would it be?

The hurdles that automotive repairers have to navigate just to stay afloat in this industry are infinite and varied. Topping the list of aspects of the industry that are most in need of

change for our survey respondents was the role of insurance companies in the repair process. Whether it was insurers’ refusal to negotiate, the need for regulation of their industry, the substandard dynamics between shops and insurance companies or the overbearing control they lord over the repair process, many of our readers agree that insurance companies are the source of most of their problems as shop owners.

“With advanced tech on cars these days, it’s more important than ever that shops have more control over the repair process,” a respondent from Lodi shared. “Insurance companies don’t know as much as we do as repairers. They shouldn’t have this much control. It’s not safe.”

A shop owner from Parsippany echoed these sentiments, focusing on the relationship between the repair and insurance industries.

“We need to have better relations with insurance carriers,” he expressed. “Most on both sides are decent people just trying to do right by their mutual customer. There needs to be understanding established between us if anything is going to change.”

Outside of insurer influence, 27 percent of survey responses mentioned the subpar labor rate as the facet of the repair industry most in need of change.

“Something needs to change with how we’re paid,” a Trenton repairer lamented. “Either the labor rate needs to increase overall, or there needs to be tiers set to differentiate the quality of shops across the state. We need to level the playing field.”

Whatever pain point our survey respondents conveyed, many of them shared that their problems could be alleviated if the industry came together.

“We need to unite as shop owners,” one Piscataway reader wrote. “It’s David versus Goliath. If we want anything to change, we need to do it together.”

rr: ITT] u mJ rr: M U ER

EFFICIENCY AT ITS BEST

OEM APPROVED PRODUCTS

Introducing the Bench Rack™ Versa, the latest in-ground innovation in collision repair technology from Car-0-Liner® Engineered for excellence, the BenchRack™ Versa is designed to revolutionize your workshop by providing unm atched lifting capabilities, enhanced ergonomics and compliance with OEM requirements.

Contact us now to experience the future of collision repair efficiency!

Low-Clearance Ready: Seamlessly loads sports cars and EVs without extended ramps.

Optimize Shop Workflow: Drive-over design enhances shop layout and accessibility.

Boost Productivity & ROI: Reduce setup times-complete jobs faster, increase throughput, and maximize profits.

Precision-Crafted in Sweden: Built with quality and durability to outperform the competition.

David Yeager - EL & M Auto (800) 624-2266 / elandmauto@aol.com

Ed Silipena - American II Autos (609) 965-0987 / esilipena@yahoo.com

Norm Vachon - Port Murray Auto (908) 689-3152 / portmurrayauto@yahoo.com

Dillon Rinkens - East Brunswick Auto (732) 254-6501 / ebautonj@comcast.net

President - Rodney Krawczyk Ace Auto Wreckers (732) 254-9816 / aceautonj@comcast.net

1st Vice President - Daryl Carman Lentini Auto Salvage (908) 782-4440 / darryl@las-parts.coms

2nd Vice President - Mike Ronayne Tilghmans Auto Parts (609) 723-7469 / tilghmans@snip.net

Past President - Bob Dirkes Dirkes Used Auto Parts (609) 625-1718 / dirkesauto@gmail.com

The Automotive Recyclers Association of New Jersey

The December issue of New Jersey Automotive marks our 23rd year of providing insurance briefs for the association. On behalf of the Wharton Group, I’d like to thank you for allowing us the opportunity to participate in the Automotive Recyclers Association. For your information, the New Jersey Workers’ Compensation Rating and Inspection Bureau released the newly promulgated rates for 2026:

• Auto Dismantling rate increased from $17.10 to $18.074.

• Auto Body Repair increased from $2.83 to $2.889.

• Auto Repair decreased from $4.73 to $4.688.

• Clerical decreased from $0.14 to $0.136.

• Iron or Steel Scrap Dealer decreased from $6.99 to $6.702.

• Salesperson decreased from $0.33 to $0.293.

• Store: Retail Accessories (counterperson) decreased from $4.10 to $3.892.

• PLEASE NOTE: The Store (counterperson) code must be approved prior to use. The operation must be physically separated from salvage and parts storage and must not have any interchange of labor. This code does not include drivers.

Also, the executive officer’s annual minimum payroll is $44,720 and annual maximum payroll is $178,360. Lastly, if your insurance policy is written in the New Jersey State Plan, you are going to be charged an additional 20 percent (minimum) for the Plan Premium Adjustment Program and will also lose the premium discount.

As always, if you have any questions regarding your insurance coverage, please contact us.

Mario DeFilippis

AAI Vice President

Wharton

Insurance Group

Our wholesale parts team is here to make sure you find the exact Genuine Subaru Parts you need for every repair

• Competitive prices

• Fast, accurate deliveries

• Genuine Subaru Parts that drive your business

Paul Miller Subaru 3469 Route 46

Parsippany, NJ 07054

Phone: 973-658-5714

Fax: 973-402-9591

mdaltilio@paulmiller com www paulmillersubaru com/parts

(732) 686-7020 (direct line) (908) 513-8588 (cell) mdefilippis@whartoninsurance.com

continued from pg. 31

The truth is that none of these reasons justify skipping a required safety inspection. Manufacturers call for them because modern vehicles are engineered around a network of components that work together to protect occupants. If these components have been compromised, the vehicle cannot perform as designed in the next collision. When a shop completes a repair without performing the OEM inspection, the shop is assuming responsibility for a safety system it never verified. Insurers will not be the ones answering for a restraint system failure. The liability always sits with the repairer.

The industry needs to be honest about this. Shops cannot return vehicles to the public with unverified safety components and believe that a structural or cosmetic repair alone is enough. Insurers cannot claim to prioritize safe repairs while refusing reimbursement for the steps that determine whether the restraint system will work in a second crash. Regulators cannot continue to rely on outdated assumptions about repair processes while vehicles become more advanced every year. Somewhere along the way, the basics of occupant protection were overshadowed by cycle time and cost control.

What is missing is a broader commitment across the industry to treat safety inspections with the importance they deserve. The manufacturers have already provided the roadmap. It is now up to us to follow it. If we expect consumers to trust that their vehicles are safe when they leave our facilities, we must begin verifying the systems that make them safe. Anything less leaves too much to chance.

Join Reliable Automotive Equipment’s Dave Gruskos for conversations with industry leaders sharing their insights and the latest from the world of certified collision repair. This month, Dave talks with Mark Allen, manager of Collision, Equipment and EV after sales service at Audi of America.

Dave Gruskos: How does Audi recommend shops best approach how they prioritize the investment in tools, equipment or facility upgrades needed to maintain certification and repair to OEM standards?

Mark Allen: Shops need to look at the ROI every time they look at a piece of equipment. They should look to see whether they have future intention of getting onto a program. If I have to invest in a welder, for example, and I’m going to look at becoming Audi, and that may happen, then I want to look at the welder that is required by the program. Some of the programs are not specific; others have certain specifications. If you’re going to one company that only gives you specifics, you can look and see if it fits those specifications, and whether it will fit in a future attempt to get on the program. And you’d do that for every auto manufacturer that you want to serve. Now, it takes homework, and people like Mike Anderson and Collision Advice and others out there are pretty sharp at helping people walk through this. The other thing is knowing how to future-proof yourself when ordering new equipment. Are you using appropriate accounting principles to write off the welder in a short enough time to save money in buying the next welder? Cleanliness and servicing is a way to extend the life of equipment, but accounting principle is how you plan for future investment.

D.G.: A recent press release from the manufacturer noted a strong demand continues for Audi electric vehicle production. On the aftersales side, what guidance do Audi Certified collision centers receive to help them navigate the constantly increasing complexities of EV repair?

M.A.: The standard is to take it to a dealer. We make everyone take high voltage awareness training, which advises them on how to recognize whether a vehicle is an EV of some sort, whether it’s a full-on electric or a plug-in hybrid electric vehicle (PHEV) or any of the others, in an effort to build a

ABOUT THE PROGRAM

Total # of Audi Authorized Collision Repair Facilities: 209

*An additional 41 facilities are currently undergoing the process to become certified.

# of Dealer-Owned locations: 55 43 Ultra Certified; 12 Hybrid Certified

# of Independent locations: 154 84 Ultra Certified; 70 Hybrid Certified Ultra Certified: Can work on vehicles with advanced materials, such as carbon fiber.

Hybrid Certified: Can work on vehicles constructed with high-strength steel, steel and aluminum.

deeper awareness. If you’re not at Audi authorized shop, however, and you’re not a high voltage technician, put your hands in your pockets and walk away from the car. Drive it over to the dealer and have them do the high voltage work, or have the dealer send someone over, and then, get everything out of the way, where it’s safe and de-energized, and then do your work.

D.G.: In your opinion, how does the adherence to OEMrequired equipment and tooling practices, combined with manufacturer-required procedures, contribute to a quality repair?

M.A.: The OEM-required procedures have been crash tested. When you see a several-hundred-thousand-dollar Lamborghini Quattrovalvole run into a wall and rebuilt, it makes your heart hurt. But doing that gives you a repeatable outcome. Just follow the procedure. We’ve even gone so far as to publish a book where we explicitly call out what to do and not to do. No pulling, for example. Do not cut.

If the repair that was done in the John Eagle case was followed that way, there’s a much better chance that the Seebachans may not have been injured, or injured as badly. As a shop, following procedures gives you a level of legal protection, as well. If you do exactly what the OEM said, following the methodology with their products, it puts the onus back on the auto manufacturer, and the independent repairer has a legal leg to stand on.

continued from pg. 12

customers happy and coming back, time after time. Stay up with the current trends and advertise, whether digitally, via local media or you can even consider billboards. Get your name out there. The time and effort will be an astounding reward, both professionally and monetarily.

2026 is going to be a great year if you start your preparations now. Never ever get comfortable with your business and think it will just be status quo: “I’m a good technician, I’ve been here for so many years, and people trust me.” These are all good things, but they won’t always propel you into the future. Most importantly, please remember AASP/NJ is here for you. Our mission is to help you accomplish your goals and dreams. We have a vast variety of programs and resources to assist you. Check out page 13. Do not underestimate the power of numbers. We will always have your back, today, tomorrow and in the future here at AASP/NJ.