EXECUTIVE COMMITTEE

Bucky Pescaglia, Chairman Missouri-Pacific Lumber Co., Inc.

Stephanie VanDystadt, Vice Chairman Hull Forest Products

Jon Syre, Past Chairman 2022-2024 Cascade Hardwood, LLC

Greg Fitzpatrick, Finance Chair Fitzpatrick & Weller, Inc.

MISSION LEADERS

Rob Cabral, Market Impacts UCS Forest Group

Bill Courtney, Membership & Networking Services Classic American Hardwoods

Sam Glidden, ITS and ITSEF GMC Hardwoods, Inc.

George Swaner, Information Services Swaner Hardwood Co., Inc.

Vince Catarella, Convention Baillie Lumber Co.

Trent Yoder, Lumber Services Yoder Lumber

DEPUTY MISSION LEADERS

Tom Coble, Market Impacts Hartzell Hardwoods, Inc.

Jason Sencaj, Convention Adentra Companies

Brant Forcey, ITS and ITSEF Forcey Lumber Company

Chris Rider, Membership & Networking AHC Hardwood Group

Matt Gutchess, Information Services Gutchess Lumber Co., Inc.

Tim Pleimann, Lumber Services Farrow Lumber Co.

COMMITTEE CHAIRMAN

Sam Glidden, Rules GMC Hardwoods, Inc.

THE VOICE OF THE HARDWOOD INDUSTRY

National Hardwood Lumber Association PO Box 34518 • Memphis, TN 38184-0518 901-377-1818 • 901-382-6419 (fax) info@nhla.com • www.nhla.com

To serve NHLA Members engaged in the commerce of North American hardwood lumber by: maintaining order, structure and ethics in the changing global hardwood marketplace; providing unique member services; promoting North American hardwood lumber and advocating the interest of the hardwood community in public/private policy issues; and providing a platform for networking opportunities.

NHLA STAFF

Dallin Brooks, Executive Director dallin@nhla.com

Desiree Freeman, Chief Financial Operating Officer d.freeman@nhla.com

John Hester, Chief Development Officer j.hester@nhla.com

Natalie Thelen, Chief Marketing Officer n.thelen@nhla.com

Dana Spessert, Chief Inspector d.spessert@nhla.com

ACCOUNTING

Jens Lodholm, Database Manager j.lodholm@nhla.com

Kathryn Mitchell, Office Assistant k.mitchell@nhla.com

INDUSTRY SERVICES

Sailesh Adhikari, Director of Research and Development s.adhikari@nhla.com

Tom Byers, National Inspector t.byers@nhla.com

Simon Larocque, National Inspector s.larocque@nhla.com

Benji Richards, Industry Services Sales Manager b.richards@nhla.com

Drew Snider, National Inspector d.snider@nhla.com

Marty Westeen, National Inspector m.westeen@nhla.com

INSPECTOR TRAINING SCHOOL

Roman Matyushchenko, Instructor of the Inspector Training School r.matyushchenko@nhla.com

MARKETING/MEMBERSHIP

Melissa Ellis Smith, Creative Director m.ellis@nhla.com

Brennah Hutchison, Hardwood Industry Liaison & Content Director b.hutchison@nhla.com

Ashley Johnson, Convention and Events Director a.johnson@nhla.com

Jared Klepko, JD, MBA, Corporate Partnership and Retention Manager j.klepko@nhla.com

Darci Shannon, Member Services Advisor d.shannon@nhla.com

The RossiGroup has been helping customers navigate the global hardwoods industry for almost a century.

We have raised the bar with our new state-of-the-art Emporium Mill and kiln facilities, our long-term supply agreements, and our uniquely personal brand of customer service.

We deliver a world class selection of hardwoods – including the gold standard in cherry – all sorted, milled and dried to tolerances, consistencies, and yields that were not even possible five years ago. Visit us www.rossilumber.com or call 860-632-3505

Reflections from the San Antonio Convention

In this edition of Hardwood Matters, we’re highlighting technological advances that have had—and will continue to have—a positive impact on our industry. The leading edge of that innovation was on full display in the exhibit hall last month at the San Antonio Convention, and it was truly impressive. One hundred twenty vendors came ready to showcase their latest developments, and they certainly did not disappoint.

As I walked through the rows of booths, I couldn’t help but think about how my grandpa, Louie Pescaglia, would react to the technologies now commonplace in our members’ facilities. His first sawmill, built in 1935, required a great deal of thought and sweat to convert logs into lumber. Those skills remain essential today, but not to the same degree. Our most modern mills now integrate computers into nearly every aspect of production.

We have 3D scanning systems that not only gather data on a log’s diameter, length, and contour, but also generate optimized cutting programs to yield the most value from each log. Optimized edgers and trimmers remove the guesswork from machining, allowing producers to program precise parameters for the wane permitted on each piece. Automatic stick placers increase efficiency when preparing bundles for air and kiln drying. Advanced kiln technology—such as high-frequency vacuum drying and intelligent control systems—accelerates drying, improves wood quality, and enhances energy efficiency.

We even have automated systems that determine lumber grades, robots that stack lumber, and machines that strap finished bundles for shipment. Lumber can now be accurately measured and tallied using a variety of tools—even a cell phone. Inventory and accounting can be managed with intuitive digital systems that handle everything from log tallies to invoicing at the touch of a button.

I’m sure my grandpa would have been thrilled to see how far technology has come, and I can only imagine what tools my grandchildren will have at their disposal in the future.

As Chairman of the Board of Directors, I also want to recognize those members whose terms concluded at the convention. They

were celebrated at Wednesday evening’s Board of Directors meeting, where each received a solid hardwood plaque as a token of appreciation for their years of service and dedication to NHLA and the hardwood industry.

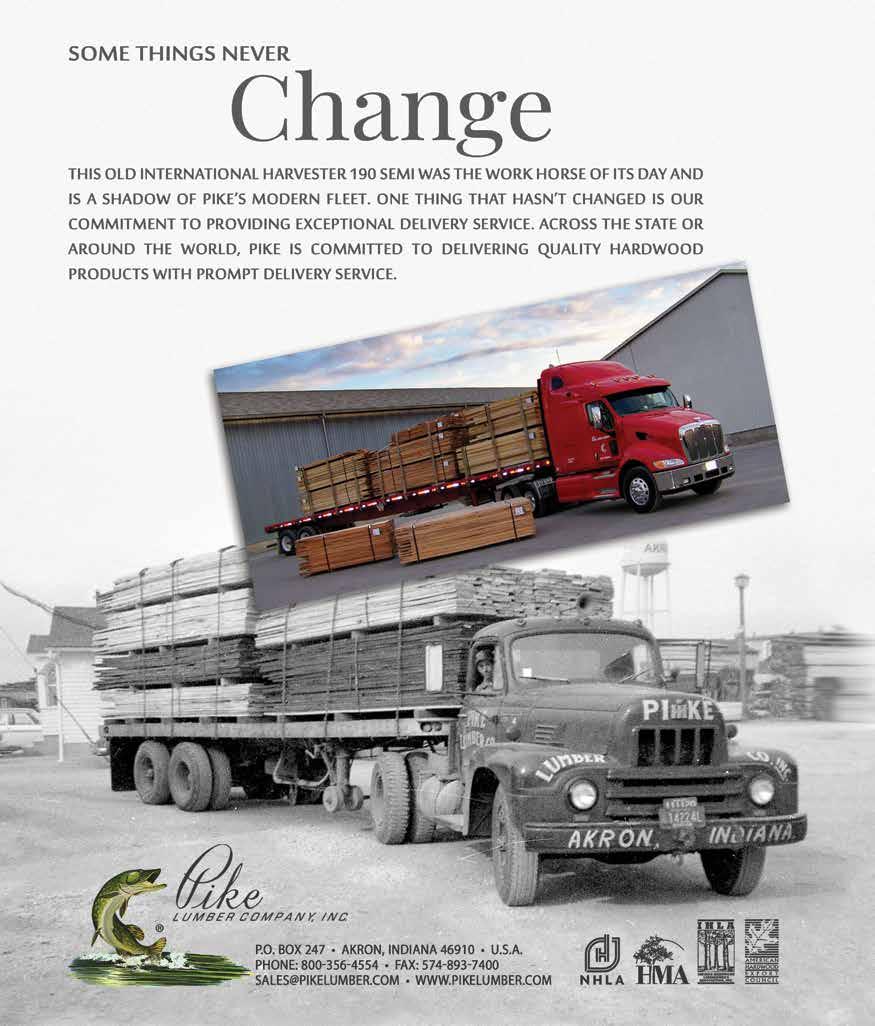

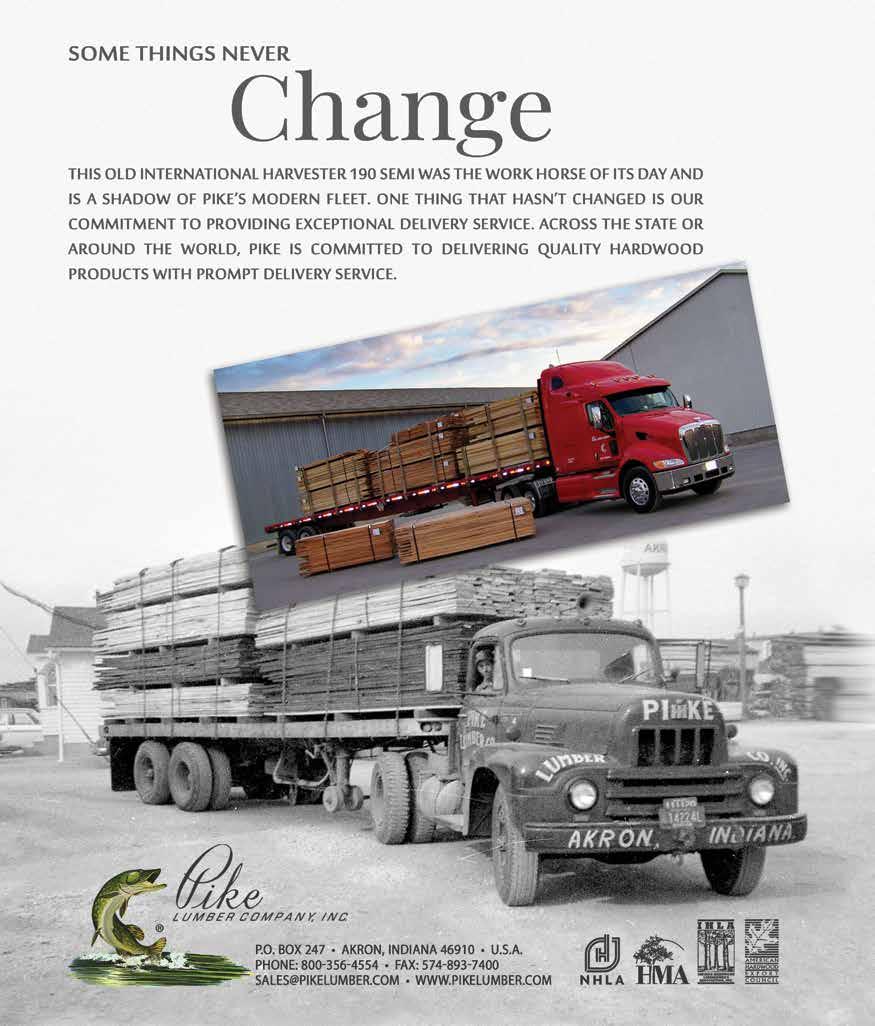

Honorees included five board members: Eric Boer of Mason’s Mill and Lumber, Josh Brennan of Frank Miller Lumber, Bill Buchanan of Buchanan Hardwoods, Brin Langmuir of Falcon Lumber, and Tom Oilar of Cole Hardwoods. Three members of the Executive Committee were also honored: Ray White of Harold White Lumber Co., Joe Pryor of Oaks Unlimited, and Rich Solano, recently retired from Pike Lumber Co. It has been an honor and a privilege to serve alongside each of these gentlemen. They’ve left a lasting imprint on our association, and I’m deeply grateful for their contributions and friendship.

The convention also marked the swearing-in of six new members to our Board during the General Session on Friday morning. The Nominating Committee, led by Chairman Jon Syre, presented an outstanding slate of nominees, all elected to their first of two threeyear terms. Those sworn in were Jesse Lason of The Rossi Group, Scott Wesberry of Fred Netterville Lumber Co., Patti Heintzelman of Keiver-Willard Lumber Corp., Tyler Kamps of Kamps Hardwoods, Inc., Alex Fischer of Maley & Wertz, Inc., and one to be announced soon.

I look forward to the fresh ideas and perspectives this talented group will bring as we continue our mission to grow and strengthen our industry.

Bucky Pescaglia NHLA Chairman | Missouri-Pacific Lumber Co., Inc.

Every organization has defining moments and new chapters that set the course for the future. For NHLA, the past 127 years have been marked by steady leadership, a commitment to hardwood rules and education, and a focus on supporting the industry through changing times. Today, we stand at another such chapter.

I learned this lesson early, when I was 15 years old and serving as the youth leader for my Boy Scout troop. That year, we decided to do something ambitious: retrace Alexander Mackenzie’s historic crossing of North America. It wasn’t just a hike; it became a yearlong project of preparation and perseverance. We didn’t just buy gear, we made it. We brain-tanned buckskins, steam-bent wood for backpacks and canteens, dried our own food, and trained until we could hike 42 km before school. The number of participants dropped from 20 to 5, but those who stayed committed experienced something unforgettable.

When we finally hiked the 360 km “grease trail” through British Columbia, we carried 80-pound packs and relied on the gear we had built with our own hands. It was hard. We battled mosquitoes, wet gear, and exhaustion, but it was also transformative. Each night, we read Mackenzie’s journal and marveled at how our experiences matched his from 200 years earlier. In the end, standing on the rock where Mackenzie carved his name, I learned something about leadership: if you are going to lead, you must commit fully, prepare well, and set a vision that others can believe in. The reward of hard work and good planning is not just reaching the destination; it is creating an experience that changes those who take the journey with you.

NHLA is in a similar moment now. Our industry has relied on time-tested tools and traditions: our rules, inspector training, and advocacy, to keep us strong through recessions, wars, and technological change. Like my troop’s journey, much of our work is in the

preparation: planning ahead, building the tools our members will need, and getting our industry “in shape” for what’s to come.

But now it is time to start the next chapter of NHLA’s saga. We must use the wisdom and traditions that have served us for generations while also embracing innovation, new markets, and new ways of telling the hardwood story. Some of what we try may not work perfectly, just like our rain gear didn’t, but the effort will move us forward. What matters most is that we are committed to the journey, together.

NHLA is already taking action: strengthening partnerships, growing educational offerings, advocating for our industry, and launching initiatives like Real American Hardwood™ to increase market demand. Every step is about preparing for a future where hardwood remains vital and valuable.

As Executive Director, my role is to guide the NHLA staff and board — your elected representatives — in leading this next journey. We are not abandoning our roots; we are using them as the foundation to grow stronger and reach further. Together, we can ensure that the next “hardwood saga” is one of renewal, growth, and pride for generations to come.

Let’s honor the past by building a future that those who come after us will look back on with the same sense of accomplishment I felt on that rock in Bella Coola. The journey starts now. The Hardwood Saga is not complete, but the NHLA saga is common ground on which we can build.

Dallin Brooks NHLA Executive Director dallin@nhla.com

| 901-377-0182

The demand for thermally modified wood is growing rapidly across the U.S. market. Thanks to its superior durability, dimensional stability, and eco-sustainable profile, it’s becoming the preferred choice for both architects and manufacturers seeking high-performance and green solutions.

At WDE MASPELL, we specialize in thermal modification systems designed to enhance the quality and performance of hardwood, softwood and tropical species. This advanced process uses controlled heat and steam—without any chemical additives—to improve the wood's resistance, dimensional stability, and lifespan.

Our technology allows manufacturers and designers to work with a natural, uniform, and long-lasting material, suitable for both interior and exterior use. Whether you're building for durability, sustainability, or aesthetics, thermally modified wood is the smart choice for the future of design and constructions

The National Hardwood Lumber Association is proud to announce the upcoming launch of our revamped website—a faster, clearer, and more accessible digital home built entirely around our members. Designed in partnership with Heartwood Brands, this upgrade marks a major step forward in how NHLA connects with the hardwood community—making it easier than ever to find the tools, training, and support you need.

For more than a century, NHLA has supported the hardwood industry with resources that strengthen business operations, education, and advocacy. Over time, our website grew to reflect that mission—but as we expanded, navigation became more complex and access less intuitive.

Working closely with Heartwood Brands, a creative agency specializing in branding and digital solutions for the hardwood industry, NHLA set out to change that. Together, we’ve built a faster, smarter platform designed for today’s pace of business—making it easier for members to find what they need, when they need it.

The new NHLA.com features cleaner navigation, streamlined menus, and organized pathways to programs, services, and events. The result is a seamless experience that reflects NHLA’s commitment to clarity, connection, and community—helping members stay informed, engaged, and moving forward.

This redesign also enhances access to NHLA’s most popular features:

• Member Services – Log in, renew, or manage your profile effortlessly.

• Education & Events – Explore upcoming classes, webinars, and conventions.

• Industry Resources – Get direct access to publications, standards, and training tools.

The new NHLA.com isn’t just an update—it’s a foundation for growth. Built with flexibility in mind, the platform will allow us to continue adding new features and digital services in the months ahead. Whether you’re a long-time member or visiting for the first time, you’ll find a modern, responsive site that reflects NHLA’s vision for a stronger, more connected industry.

NHLA extends special thanks to Heartwood Brands for their creative partnership throughout this project. Their understanding of the hardwood industry—and their passion for storytelling and design—helped ensure the new website not only looks great but works beautifully for our members.

You can learn more about Heartwood Brands and their work at www.heartwoodbrands.com or contact them directly at hello@heartwoodbrands.com.

The new NHLA.com launches this fall—faster, clearer, and built around you. Explore it soon and experience how digital design, powered by collaboration and member insight, can make your connection to NHLA stronger than ever.

Iswear, next year I’m going to try not to reference a single movie or TV show, but I have to do it here.

We can all think of movies where technology is the “Bad Guy.” Two notable examples are Westworld (1973) and WarGames (1983). In Westworld, Yul Brynner is an unstoppable, gun-slinging robot in a high-tech theme park. In WarGames, Matthew Broderick is a computer hacker who accidentally breaks into a military supercomputer and nearly starts World War III. Westworld scared me to death, and WarGames, I wanted to be Matthew Broderick because I had a crush on Ally Sheedy, but both stories are about technology that slips out of human control. Machines are acting independently and creating chaos. For anyone who grew up watching these types of movies, they left an impression. It’s frightening to think that machines could be unpredictable or even develop a life of their own.

Today, the story is very different. In the hardwood industry, technology, including AI, is no longer the villain. It is a tool that can make us better, wiser, and faster. From optimizing sawing patterns and improving grading accuracy, to predicting yield, tracking inventory, and even helping manage sustainability efforts. Technology is helping to reduce waste, save money, and make better decisions across every part of the business.

One of the biggest concerns people have is that technology will replace humans. I think we’re far from that. The industry still runs on experience, instinct, and human judgment. Machines can process data, detect patterns, and automate repetitive tasks. Still, they cannot replace craftsmanship, relationships, or the intuition that comes from decades of working in the mills, yards, and shops.

Technology enhances what we do; it does not replace it. Technology frees people to focus on the work that truly requires skill, creativity, and attention.

So, while movies warned us that machines might take over one day, what we are finding instead is that technology is helping us take control of processes, profits, and our future. With people at the center and machines helping to do the heavy lifting, the hardwood industry is more innovative, stronger, and more capable than ever before, and the possibilities are truly remarkable.

I know what you’re thinking. “That sounds exactly like what a robot would say.”

John Hester Chief Development Officer

Every NHLA member contributes to something bigger — a united effort to promote, protect, and strengthen the hardwood industry. Through partnerships with the Real American Hardwood Coalition® (RAHC) and the Hardwood Federation, your membership helps shape how our industry is seen, valued, and supported across the nation.

The Real American Hardwood Coalition® was founded to tell a unified story about what makes hardwood truly exceptional — real, renewable, and naturally sustainable.

For decades, competing materials have outspent and outmarketed wood. RAHC is changing that through:

• National marketing campaigns reaching designers, builders, and consumers

• Digital storytelling and education that highlight hardwood’s beauty and benefits

• Partnerships that increase hardwood’s visibility in design and construction

• Hardwood & Design drives awareness and appreciation for hardwood in modern architecture and interior design

Every NHLA membership directly supports these efforts, ensuring hardwood stays top of mind - and top of spec sheets.

While RAHC drives promotion, the Hardwood Federation leads our advocacy efforts in Washington, D.C. Representing hardwood businesses from sawmills to exporters, the Federation ensures lawmakers understand our industry’s impact on:

• Rural economies and American jobs

• Forest management and sustainability

• Trade, transportation, and tax policy

Your membership gives the hardwood sector a powerful, voice in shaping policies that keep our businesses strong and competitive.

By supporting NHLA, you’re investing in:

• Greater visibility for real wood products

• Stronger advocacy for fair, pro-industry policy

• A more connected, future-focused industry

Together, we’re ensuring that the story of hardwood — its beauty, sustainability, and authenticity — is heard loud and clear.

Real advocacy.

Real promotion.

Real American Hardwood® .

How concrete is marketing “biophilic design”— and how hardwood can lead with the real thing

Concrete is having a biophilia moment. In CEU decks and webinars—like Architectural Training & Seminars’ October Biophilic Design North America webcast—manufacturers are framing concrete as biophilic by proximity: plazas ringed with planters, interior water walls, daylight through big apertures, and “natural” colorways. Biophilic design—the practice of connecting people to nature through the built environment—is driving much of today’s wellness-focused architecture. It’s a clever strategy—attach the product to a wellness story most clients already want.

But here’s the opportunity for wood: biophilia isn’t a design trend; it’s a material truth. Hardwood isn’t “biophilic by association”—it’s intrinsically biophilic in its texture, scent, warmth, and ability to age beautifully. If specified with intention, hardwood can lead the biophilic conversation, not follow it.

Concrete’s biophilia narrative hinges on association. In the ATS webcast, presenters emphasized familiar principles—visual connections to nature, sensory variety, and stress reduction—before positioning concrete as an unavoidable partner in biophilic spaces. Water features, urban gardens, and daylight become excuses for concrete to participate. The narrative centers on engineering: if concrete can be made more durable, porous, or “green,” then it can coexist with biophilia. The underlying message: concrete can imitate harmony with nature through technology.

Wood doesn’t have to imitate nature—it is nature. Its grain patterns mirror fractal geometry, its surfaces invite touch, and its thermal qual-

ities foster comfort. Over time, hardwood develops a patina rather than decay, offering longevity that feels alive rather than static. And unlike concrete, it doesn’t need chemical innovation to participate in biophilic design—it simply needs to be detailed and respected.

Hardwood also carries an authentic carbon story. Trees absorb carbon throughout their growth, and solid wood continues storing it inside buildings. Repairable and refinished instead of replaced, hardwood products support circular design with minimal energy input, where concrete engineers compatibility, wood embodies it.

Talking Points for Clients

• On authenticity: “Hardwood provides direct, daily contact with a living material—not a simulation.”

• On well-being: “Biophilia happens where hands and eyes meet the building—floors, rails, and stairs.”

• On longevity: “We refinish, not replace. That’s real sustainability.”

The Honest Comparison

Concrete can support biophilic spaces, especially as structure or site hardscape. But when the goal is human connection to nature inside the built environment, hardwood does what concrete only gestures toward. Concrete can frame the natural world; wood lets people touch it.

Biophilic design isn’t a marketing adjective—it’s an evidence-based commitment to human well-being through natural contact. Concrete can coexist with nature. Hardwood lets people live in it.

THERMAL MODIFICATION MAKES WOOD MORE STABLE, DURABLE, AND BEAUTIFUL — A PREMIUM MATERIAL BUILT TO LAST IN BOTH EXTERIOR AND INTERIOR APPLICATIONS. THE PROCESS USES ONLY HEAT, STEAM, AND WATER WITHOUT HARMFUL CHEMICALS.

JARTEK IS A WORLD LEADER IN THERMAL MODIFICATION EQUIPMENT, WITH AROUND 100 CHAMBERS DELIVERED WORLDWIDE.

KILNS ARE TAILORED TO YOUR NEEDS: BATCH SIZES 8,000–55,000 BD FT (20–130 M³) AN D FLEXIBLE ENERGY SOURCES THERMAL OIL OR ELECTRIC HEATING CHOOSE WHAT FITS YOUR SITE AND ENERGY PRICES.

DISCOVER MORE AT WWW.JARTEK.COM

DISCOVER THE TECHNOLOGY BEHIND THERMOWOOD®

For more than 75 years, the NHLA Inspector Training School has stood as the foundation of hardwood lumber education. Generations of inspectors, graders, and industry leaders began their careers there, learning the standards that keep our industry strong. That proud legacy isn’t disappearing — it’s expanding.

This fall, NHLA’s education wing is stepping forward under a new name: the National Hardwood Academy.

The National Hardwood Academy unites the Inspector Training School, NHLA’s short courses, webinars, and new educational offerings under one clear and credible umbrella — a single identity that reflects both the strength of our history and the scale of our future.

Let’s be clear: the Inspector Training School remains the heart of NHLA education. The hands-on training, respected certification, and tradition of excellence are unchanged. What’s new is how all our educational offerings connect.

By bringing every learning opportunity under the National Hardwood Academy, NHLA is creating a cohesive, accessible education experience for both current members and new audiences beyond the hardwood industry. The change isn’t about rebranding what works — it’s about making it easier for everyone to see the value of what we’ve built.

The new brand was brilliantly previewed at this year’s NHLA Annual Convention in a short video produced by our creative partners at Heartwood Brands. The reveal captured what makes NHLA education so unique — heritage, craftsmanship, and a forward-looking spirit. Members saw firsthand how the National Hardwood Academy honors our roots while opening doors for the next generation of students, inspectors, and leaders.

The National Hardwood Academy was designed to make education more accessible, more visible, and more connected. Whether you’re a mill owner sending employees for training, a student exploring career options, or a designer learning about hardwood grading, the Academy simplifies how you find and engage with NHLA programs.

All courses — from week-long instruction to one-hour webinars — now share a consistent message: real-world training, rooted in tradition, driven by innovation. With the new NHLA website also launching this fall, registration, resources, and learning opportunities will be easier to access than ever before.

Change can be uncomfortable, especially in an industry built on tradition. But the National Hardwood Academy isn’t about replacing the Inspector Training School — it’s about elevating it. The Academy gives us the structure and brand power to reach new learners while ensuring that every NHLA educational experience continues to meet the highest standards our members expect.

As the industry evolves, so must the way we teach, inspire, and connect. The National Hardwood Academy ensures that NHLA’s legacy of education will continue to grow — stronger, smarter, and more inclusive than ever.

New name. Same integrity. Infinite potential.

By DANA COLE, Executive Director of the Hardwood Federation

Over the August recess, when Members of Congress were back home in their states and districts, there was a fair amount of media attention surrounding lawmakers’ calls to enact a Farm Bill this fall, dubbing the effort Farm Bill 2.0. The “2.0” modifier refers to the fact that significant portions of the Farm Bill—namely, Title 1, which governs commodities such as row crop agriculture and dairy, as well as Title IV, which covers nutrition programs—have already been addressed in the comprehensive budget reconciliation bill signed by the President on July 4. What is left represents a small percentage of Farm Bill spending, but that portion has an outsized impact on the forestry and forest products value chain, including the hardwood sector.

The impact of Congress addressing the two biggest Farm Bill titles earlier this year is now being felt. In the past, Farm Bills have faced serious consequences if Congress failed to act in reauthorizing a Farm Bill. If the process dragged on too long, farm policy would revert to the Agricultural Act of 1949, which would result in automatic, draconian cuts to row crop and dairy subsidies, causing severe harm to our country’s farmers. The specter of that scenario ultimately enticed lawmakers to come together and forge a comprehensive 5-year farm policy bill. Title 1 was effectively the engine that drove the Farm Bill rewrite process, and without it, the sense of urgency and motivation for action is not there.

For those hardwood sawmills that also produce wood pellets, the Bioenergy Program for Advanced Biofuels has provided a substantial revenue stream as pellets qualify for this payment program.

So, what is at stake? Thankfully, a key Hardwood Federation deliverable as part of the Farm Bill is trade promotion, and that was addressed in the budget reconciliation bill. Both the Market Access and Foreign Market Development programs received double funding for their ongoing work in opening up markets overseas for domestically produced hardwood lumber. That was a significant win, and one that we worked hard for. Outside of trade, the primary items authorized by the Farm Bill for which we advocate are in the Forestry and Energy Titles. Under Forestry, many hardwood manufacturing companies have received funds under both the Wood Innovation (WIG) and Community Wood Grant programs. These two funding streams have provided substantial, critical capital for projects ranging from replacing biomass boilers and other necessary sawmill upgrades to the production of mass timber, as well as projects that convert woody biomass into biofuels. At a time when domestic markets for lumber and residuals are desperately needed, these two programs are essential.

Also in the Forestry title is the Forest Inventory and Analysis (FIA) Program. This is essentially our country’s tree-counting tool, which tracks the forested acreage in the U.S. and growth/drain ratios across our nation’s forests. The forest products supply chain relies on updated FIA data to back up our claims that wood and paper production is sustainable and that our fiber baskets are healthy. Increasing funding for FIA so that it is adequately staffed and forest data collection is timely and accurate is a high priority not only for the hardwood sector, but for every link in the value chain.

Other vital programs in the Farm Bill Energy Title have benefited hardwood manufacturers. For those hardwood sawmills that also produce wood pellets, the Bioenergy Program for Advanced Biofuels

has provided a substantial revenue stream as pellets qualify for this payment program. Also important is the Biomass Research and Development Initiative (BRDI), which provides grants for wood processing facilities to innovate and upgrade their facilities. And finally, the Biobased Markets Program, which is both a federal procurement preference and a voluntary labeling initiative for renewable materials, is housed in this title.

In conversations we have had with USDA officials and Congressional staff, inaction on a Farm Bill 2.0 will not mean that these programs lapse. Any continuing resolution that comes together in the next week or so (hopefully) will extend funds for these programs. However, it does underscore the need to focus advocacy on the appropriations process in the future and work to ensure that these vital Farm Bill programs, from which we benefit, are funded appropriately. What is lost due to Farm Bill inaction is the ability to update and revise these programs to better reflect the current needs of the forest, the forest products industry, and the overall bioeconomy.

In meeting personally with House Agriculture Committee Chairman Glenn Thompson (R-PA) late last month, he remained optimistic that a Farm Bill 2.0 effort would ultimately move forward and become law later this fall. The Hardwood Federation team has been working hard in both the House and Senate to support this goal and will continue our advocacy efforts in the coming weeks to make this outcome a reality.

For over a century, Comact has been at the forefront of wood processing innovation. While our history is long, our focus remains firmly on the future: helping hardwood producers maximize value, efficiency, and consistency with solutions built on cutting-edge technology.

Hardwood grading and defect detection remain some of the toughest challenges in the industry. Dirt, spots, and chain marks often mimic natural defects, complicating machine grading and placing additional strain on already limited human resources. Additionally, mills across North America are facing a shortage of experienced graders.

Comact’s answer is artificial intelligence. We are the only company to have trained our AI models specifically on hardwood species, which ensures unmatched precision in defect detection. With AIpowered solutions like TrimExpert, EdgExpert, GradExpert, and

ResawExpert, mills can achieve significant gains in yield and grade recovery, often seeing improvements of up to 10% in productivity and higher proportions of prime-grade outturns.

Just as important, our scanners and AI models cover more than 35 hardwood species, from walnut and maple to red and white oak. That flexibility allows mills to respond quickly to market demands, optimize both green and dry lines, and consistently meet NHLA grade standards. Whether you’re running high-volume production or smaller specialized operations, our technology has proven to deliver measurable ROI, often within remarkably short payback periods.

By combining innovation with a deep understanding of hardwood, we aim to help producers maximize value from every log, every board, and every block.

The labor shortage isn’t unique to graders; it extends across the entire mill operation. Robotic automation offers an answer. Comact has pioneered AI-powered robotic systems that transform how mills handle board stacking.

At facilities like Batesville Casket Co. in Vicksburg, MS, four robots have successfully replaced four operators, cutting the required labor from six to just two while handling over 1,000 unique products with consistency and precision. These systemes aren’t just replacing labor. They’re reimagining production. Our robots adapt in real-time to recipes, detect warps, separate touching boards, and even handle narrow or sensitive products with ease. This innovation enables mills to remain productive despite staffing challenges.

The result? Smoother operations, higher throughput, and peace of mind, knowing that production won’t be interrupted by labor shortages.

Our relationship with NHLA has been instrumental in driving these innovations forward. By engaging with NHLA members, Comact has gained invaluable insights into the unique challenges facing hardwood producers today. These conversations have helped us refine our AI models, tailor our robotic systems, and ensure that our solutions support NHLA grading rules and customer expectations.

The NHLA community also provides a platform for collaboration and knowledge sharing. Whether at the annual convention or through technical exchanges, these connections enable us to test ideas, pilot solutions, and stay aligned with the needs of the hardwood market. We view NHLA not only as an association but as a partner in our shared mission to elevate the industry.

Three qualities set Comact apart in hardwood optimization:

1. Proven AI Technology for Hardwood – Unlike generalpurpose solutions, our AI is trained directly on hardwood, delivering unmatched accuracy in defect detection.

2. Robotics Designed for Wood Processing – Our systems are purpose-built to handle the complexity of hardwood fiber, stacking, and trim block sorting with intelligence and precision.

3. Customer-Centric Approach – At our Mirabel facility, we offer free scanner testing, ensuring our customers not only adopt technology, but also fully succeed with it.

The hardwood industry is steeped in tradition, yet it thrives on adaptation. As markets evolve, customers demand greater consistency, flexibility, and proof of sustainability. Comact is proud to support mills in meeting these challenges head-on, with AI-driven scanners, robotic automation, and a relentless focus on results.

By combining innovation with a deep understanding of hardwood, we aim to help producers maximize value from every log, every board, and every block. And thanks to our ongoing collaboration with NHLA, we know we’re building solutions that truly make a difference for the hardwood industry today and in the future.

Ready to see how our hardwood solutions can support your success? Contact our team today at info@comact.com or visit www.comact.com to learn more about our services.

By BRENNAH HUTCHISON, Hardwood Industry Liaison & Content Director

Walk into a hardwood mill today, and you might find more than sawdust and grit. You’ll find smart cameras, robotic arms, and data dashboards quietly transforming how people work. New vision systems and robotics aren’t here to edge out seasoned crews, but to amplify their skill, give them safer tasks, and connect them to the bigger picture of production.

Still, not everyone feels at ease about the shift. A recent Microsoft Work Trend Index found that 53% of people who use AI at work worry that using it on important tasks makes them look replaceable (Microsoft, 2024). That tension is exactly why this conversation matters. While AI is a major driver of this transformation, it’s part of a broader wave of new technologies, automation, robotics, sensors, and smarter systems that are reshaping how work gets done. In hardwood, innovation isn’t about replacing people. It’s about refining how craftsmanship and technology work side-by-side. And nowhere is that balance clearer than on the mill floor, where companies like Zira and Sync Robotics are blending human judgment with smart, responsive tools to make everyday production faster, safer, and more connected.

Zira, an AI vision company, has developed AI-based, universally sensing-mounted cameras that watch the process the way a great supervisor would, only they never blink. The system detects boards, measures dimensions, counts throughput, and tracks safe-zone behavior. Managers get real-

“Give us your toughest, most repetitive job. If a robot can take it, your veterans can stay longer and focus on quality and safety.”

time performance dashboards showing Overall Equipment Effectiveness (OEE) and Overall Labor Effectiveness (OLE), while operators track their progress and targets on a screen right in the cab.

“We consistently see 30% more throughput once operators and managers have real-time data,” says Elhay Farkash, CEO of Zira. “And dynamic cut plans add about a 5% yield improvement.”

Instead of stepping away from the saw with a tape measure and flipping through a wall chart, a sawyer now views a live cut plan directly on-screen—3 x 52.5 in—and gets on with cutting. The hardware is simple (camera + display), installation is quick, and the upside is immediate: fewer stoppages, tighter cuts, and a crew that knows exactly how the day is going now, not after shift end.

Hardwood lines run at a more deliberate pace than softwood operations—prioritizing precision, quality, and yield over sheer speed. That’s good news for robots. Sync Robotics, a custom robotic system integrator, designs cells that match your actual rate—50–80 boards per minute, not 200+. Projects range from ~$100k single-task cells (labeling, stacking, stapling) to multi-million-dollar heavy-lift systems.

“Hardwood doesn’t require the 200 boards per minute or more that a typical softwood producer would require,” says Tyler Boulley, Sales Director at Sync Robotics. “Give us your toughest, most repetitive job. If a robot can take it, your veterans can stay longer and focus on quality and safety.”

Sync Robotics emphasizes documentation and training so plants can own their equipment. That helps with staffing, too: many regions struggle to hire line labor but can attract automation techs who prefer stable roles overseeing several cells.

Allen Keller of Keller Lumber & Logging says the biggest change from adopting newer tools hasn’t just been production and planning, it’s mindset.

“Once they’re able to see the bigger picture—what goes on beyond their part in production with these tools—they become more aware of how they impact more than just their role.” —Allen Keller, Keller Lumber & Logging.

Zira Dashboard

Keller’s perspective came after participating in the NHLA’s Yield Analysis Study, which measured the efficiency of his mill in turning logs into lumber. The results revealed untapped potential and inefficiencies, prompting Keller to explore advanced technology as a way to bridge the gap. By combining NHLA’s data-driven insights with new digital tools, he was able to translate findings into action and elevate production standards.

Keller’s point shows up on the floor as fewer bottlenecks and better handoffs. When operators can see upstream and downstream status and daily targets, they avoid “tunnel vision,” adjust sooner, and collaborate across stations.

Fear of job loss is real. Sync Robotics’ first install met resistance: workers wore “union strong” shirts and sabotaged equipment at night. No one got laid off. Two people were trained to run what had taken six to eight; they earned raises and new titles in Quality Control and oversight. On the next project, the same crew asked, “Can you put a robot on this line, too?”

“AI didn’t replace operators—it gave them targets and tools,” Boulley adds. “People started competing with their own best day.”

Both Zira and Sync Robotics argue the secret is early, collaborative

training: bring in operators, leads, maintenance, and management; make the data visible; set clear daily targets; and document so the plant isn’t dependent on outside help. As NHLA member Allen Keller notes, operators stop working in silos and start acting on the bigger picture, which lifts quality and throughput across shifts.

Zira’s AI vision hardware and software costs a few thousand dollars, depending on the number of cameras needed, and pays for itself rapidly through downtime avoided and yield gained. For robotics, Sync Robotics’ “right-sized” scope keeps capex in line with hardwood volumes. The results NHLA members care about—fewer injuries, higher retention, steadier output, and promotable skills— are where these systems shine.

The hardwood industry’s craft isn’t going anywhere. What’s arriving—quietly, helpfully—is a set of tools that let experienced people do more of what they do best.

NHLA Yield Analysis Study — Unlock your mill’s full potential with a Yield Analysis at 75% off; contact Chief Inspector Dana Spessert at d.spessert@nhla.com to learn how data can reveal hidden efficiency gains.

Zira — Turn everyday mill activity into actionable insight with AI-powered vision systems that boost throughput, safety, and real-time awareness. Learn more at joinzira.com

Sync Robotics — Automate your most repetitive, high-risk jobs with custom robotic solutions built for hardwood-scale operations. Discover how at syncrobotics.ca

Keller Lumber & Logging — A long-standing NHLA member sawmill in Stevenson, Alabama, delivering quality green lumber and byproducts from trusted hardwood species. Connect with Allen Keller at allen@kellerlumber.net or call (256) 437-3155 to learn more.

Sources • Microsoft Work Trend Index. AI at Work Is Here: Now Comes the Hard Part. Microsoft, 2024. https://www.microsoft.com/en-us/worklab/work-trend-index/aiat-work-is-here-now-comes-the-hard-part

By DANA SPESSERT, Chief Inspector

ith the new technology available in the hardwood industry today, there are numerous opportunities for growth in the skilled trades through machine calibration and adjustments. I like to use the phrase, “Is it optimized or automated?” because a machine can be automated without being optimized—it can repeatedly perform the wrong task efficiently.

The most common issue we observe during our Yield Studies and Quality Control programs is that companies are often operating equipment that hasn’t been calibrated recently—or was never set up correctly in the first place. This leads to significant waste and profit loss in most cases.

This is where an opportunity exists in the industry. A well-trained hardwood lumber inspector who understands the grades can identify areas within the mill that are not operating at optimal levels. Miscuts, over/under edging, over/under trimming, inconsistent thicknesses, very few narrow boards, cross ties with FAS faces, and other wasted dollars are all areas where a sawmill can create a profit from assuring that the lumber is being sawn correctly.

The NHLA is offering Quality Control, along with Yield Analysis, to help identify these types of issues. These issues can sometimes only be found through consistent and objective measurements. The QC measuring and data collection process has already been created and is currently being used by many NHLA members, who have capitalized on the benefits of this program.

We’ve helped companies recover millions of dollars each year by identifying issues that often go unnoticed. It’s easy for these problems to be overlooked when managers are focused on simply keeping

the mill staffed and running—checking whether it’s operating at peak performance is rarely top of mind.

The NHLA would like to help train your best inspectors to become your eyes and ears of the sawmill and dry kilns through our QC program. We want you to have the people on your team who can perform tests to optimize your operation’s performance and maintain it at its peak.

We can help your company identify the savings to fund a full-time quality manager—and still come out ahead.

Stop leaving money on the mill floor. NHLA National Inspectors can help you boost quality, efficiency, and profitability.

Learn more at nhla.com/services/national-inspectors.

This

month, we’re featuring our National Inspector, Drew Snider, whose work takes him deep into the evolving heart of the hardwood industry. Drew has witnessed firsthand how technology is reshaping the way mills operate — blending time-honored craftsmanship with modern efficiency.

hat I enjoy most about my role is getting to see how technology is reshaping the hardwood industry in real time,” Drew shares. “For years, mills depended almost entirely on manual processes and the experience of their crews. That knowledge is still at the heart of what we do, but now I’m watching automation, robotics, and digital tools come alongside those skills to make operations more efficient and reliable. It’s rewarding to be in a position where I can help bridge the old with the new.”

One of Drew’s most memorable experiences in the field took place at a mill that had just installed an automated grading system. Lumber that once took hours to sort and measure was now processed in a fraction of the time, with remarkable precision. But what stood out to Drew wasn’t the technology itself—it was the reaction from the seasoned graders. “Instead of feeling replaced,” he recalls, “they recognized how the system freed them up to focus on higher-level quality decisions where their experience mattered most.”

That moment underscored what excites Drew most about the industry’s direction: a balance between craftsmanship and innovation.

tracking, predictive maintenance, or yield optimization, these systems give mills the insight they need to run leaner and cut down on costly downtime. “In today’s market,” he explains, “even small gains in efficiency can make a real difference to the bottom line.”

Recently, Drew has seen more mills in his region adopt robotics and automation in handling and stacking systems—improvements that enhance throughput, safety, and worker satisfaction. “Mills that implement these technologies often have an easier time attracting and keeping employees,” he notes. “The jobs become more sustainable and engaging than they used to be.”

Over time, Drew has developed a specialty in helping mills integrate digital tools into daily operations. Whether it’s real-time production

These shifts couldn’t come at a better time. With increased global competition, shifting demand, and sustainability expectations, mills face pressure to adapt quickly. Drew sees his role as helping members navigate those changes—showing them how to put technology to work without losing the human touch that defines the hardwood industry.

“At the end of the day,” Drew reflects, “technology doesn’t erase craftsmanship— it enhances it. It ensures that the knowledge and tradition of this industry continue to thrive for the next generation.”

November 5-7

Hardwood Processing 101

NHLA will host a workshop to broaden the knowledge of hardwood processing for those industries and people who support sawmills and mill operations. The 3-day workshop will explore the process path from tree to kiln and includes a tour of a local sawmill and concentration yard. Housing and meals are included.

Venue: NHLA Headquarters Location: Memphis, TN

December 1-12

Inspector Training School Online Program MODULE 1 Two weeks of hands-on training.

Venue: Yoder Lumber Co., Inc. Location: Millersburg, OH

Module 2: Online study

Module 3: Three weeks handson training and final testing at NHLA headquarters.

Instructor:

Roman Matyushchenko, NHLA ITS Instructor

December 3-5

Intro to Hardwood

Lumber Grading

A two-week Intro class to gain a basic understanding of the NHLA hardwood lumber grading rules and how the rules affect the value of lumber. Housing and weekday meals are included.

Venue: NHLA Headquarters Location: Memphis, TN

Instructor:

Roman Matyushchenko, NHLA ITS Instructor

December 10-11

$PC, Control the Process to Improve Lumber Value

A 2-day course to teach your team the first steps in implementing your own Yield Improvement program using statistical process control techniques adapted to a sawmill environment

Venue: NHLA Headquarters Location: Memphis, TN

December 10-12

Band Saw Filing Class

Fast-paced, hands-on training to build core skills in benching & tensioning, fitting, and sharpening—ideal for experienced filers, newcomers, and recent hires.

Venue: Yoder Saws Location: Kahoka, MO

Instructor: Levi Yoder, Yoder Saws

Seeking durable, sustainable, and beautiful materials, architects are increasingly turning to thermally modified wood.

By ASA BUTCHER

Material choices are rarely black and white in contemporary architecture. Sometimes, regular wood suffices when designs include traditional roof overhangs that shield exterior walls from the elements. But today’s buildings often favor sleek lines and exposed surfaces, leaving materials vulnerable to weathering. In these cases, thermally modified wood (TMW) is becoming an increasingly popular choice.

This shift is about performance, client expectations, aesthetic preferences, and sustainability goals. Across North America, in particular, architects are under pressure to deliver buildings that combine strong design with measurable environmental responsibility. As such, TMW is gaining attention as a material that meets these demands, offering durability, visual appeal, and a lower ecological footprint.

Architect Mari Hunt, whose practice frequently centers around wooden structures, explains that her interest in TMW has always been rooted in the architecture itself, such as how a structure connects with its surroundings and reflects the client’s vision. “The material supports that vision beautifully.”

Hunt’s micro hotel Kaseke in Estonia’s Maidla Nature Resort is a striking example of TMW’s versatility. From terraces and façades to the roof and interior surfaces, the cozy cabin is entirely clad in thermally modified wood. “I wanted to

use the same material throughout the building. TMW was the only choice to achieve the aesthetic of a unified material that feels both durable and soft for visitors.” According to Hunt, other materials, such as stone, glass, or plastic, don’t offer the same flexibility or natural warmth as wood.

From residential homes to commercial buildings, TMW is being used in a wide range of projects. Hunt recently designed an eco-hotel in Spain, mainly using thermally modified wood. “Given the intense sun exposure there, we chose TMW because it weathers beautifully, turning gray over time, which we thought would look great.”

She adds, “Thermal pine is the most common thermally modified wood that I work with. We often use it as a more affordable option for terraces. For interior design, especially in saunas, we use thermally modified deciduous trees.”

While architects like Hunt approach thermally modified wood as a means to support architectural vision and harmony with surroundings, manufacturers see growing interest from designers who are also drawn to the material’s environmental credentials. Jason Martell, Project Manager at Thermalwood Canada, notes that profiled thermally modified wood “looks stunning,” and that many architects are choosing it as a responsible alternative to exotic woods sourced from rainforests and other environmentally compromised regions.

“Once architects use thermally modified wood in a project, they keep coming back,” says Martell. “They hear the positive feedback and see the results. Architects want a reliable, predictable product that delivers durability, stability, and aesthetics – and TMW has proven time and again to be a great fit.”

The sustainability story behind TMW is compelling. Thermalwood Canada uses clean-burning propane to power its kilns, and the modification process relies solely on heat and steam. “We source almost all of our wood from Quebec,” says Martell. “Some modifiers ship wood overseas for treatment and back again, which makes net-zero emissions projects difficult for architects to achieve.” A local-first approach aligns well with certifications like LEED and WELL, which reward projects for using low-emission, responsibly sourced materials.

Consistency and quality control are also essential for architects working on high-profile or long-lasting projects. To ensure reliability across applications, thermally modified wood produced under the ThermoWood® trademark follows strict guidelines developed by the International ThermoWood Association (ITWA). These standards include a recipe-based approach, where each wood species is treated using a specific combination of temperature, time, and steam conditions.

This process permanently alters the wood’s chemical structure, improving its durability, dimensional stability, and long-term resistance to rot, decay, parasites, and harsh climates. “We have a 25-year warranty on our decking and a 60-year warranty on our cladding,”

Martell explains. “Architects also appreciate its better fire rating compared to rough lumber.”

The ITWA also enforces an audited quality control system, meaning only certified producers can use the ThermoWood® name and quality logo. This makes sure that architects and designers can trust the material’s performance and consistency across projects.

Despite its growing popularity, TMW still faces misconceptions, particularly around cost and implementation. “Architects sometimes think it will be over budget,” says Martell. “But because we use species like Canadian Ash consistently, we’ve been able to deliver a high-quality product at a great price.”

Another issue arises during construction. “Architects assume that because they specified TMW, it will be used. But we often see contractors pivot to a lower-grade product to cut costs, despite what was chosen,” he adds.

Looking ahead, the future for TMW in North America seems bright. Consumption reached over 850,000 cubic meters in 2024, driven by the U.S. and Canada’s booming housing sector and rising interest in sustainable construction. In fact, TMW decking sales grew by 22% year-over-year in 2022, and a 2023 survey found that 32% of North American architects now specify TMW for moistureprone areas, up from 18% in 2020.

The rise of thermally modified wood reflects a broader shift in the lumber industry toward trust, precision, and sustainability. Manufacturers are delivering customized, high-performance products and supporting architects throughout a project’s lifecycle, which is a testament to their dedication to meeting the evolving demands of modern construction.

Looking to improve your wood processing operations with more innovative, more sustainable technology? Partner with Jartek – we’re engineered for performance, built for longevity, and trusted by industry leaders worldwide.

Hardwood Markets Matter, and it is important for NHLA to share market details of the entire Hardwood Industry. We appreciate the support of allied associations and publishers in gathering and sharing this important market information that can help you understand the complete hardwood industry picture.

The Forest Service’s 2025 Resources Planning Act (RPA) Assessment won’t be released for another 2-3 years, but we have obtained the 2022 forest inventory data that will be contained therein. The good news is that hardwood growing stock inventory (5+” diameter) on timberlands in the eastern U.S. rose 12% in the five years between 2017 and 2022. The great news, from a timber sustainability perspective, is that only 39% of net hardwood growth (total growth – mortality) was removed by harvesting or land clearing in 2022—the lowest rate of removal in at least 45 years. Evidence is mounting, however, that the downside of that sustained underutilization is stagnating hardwood forests.

Hardwood growing stock inventory growth slowed from 2012 to 2017. This may partially be explained by the explosion in Chinese demand for hardwoods in the mid-2010s and the ramped up harvesting and lumber production to meet it. That assertion is supported by the fact that growing stock inventory shot higher in the five years thereafter, during a period of sharply reduced domestic and global demand due to the first U.S.-China trade war and the COVIC pandemic. However, it is also true that steadily rising hardwood

mortality rates—often associated with over mature, crowded and less vibrant forests—are diminishing net annual inventory growth. In 2022, for the first time in at least 60 years, more hardwood growing stock was lost to mortality than to harvesting and land clearing combined. Cutting much less than we grow has been a cornerstone of our industry’s sustainability pitch for decades, and a key reason hardwood growing stock inventories have more than doubled since 1963. Yet, the data suggest a new urgency to grow market demand for hardwood lumber and products to sustain increased hardwood timber utilization and keep inventories growing into the future.

www.hmr.com

The HMR Demand Index (HDI) is a feature in HMR Executive® that illustrates monthly trends in reported demand from 10 major domestic markets for hardwood lumber. Components of the index are color coded with various shades of blue when demand is slow, they transition to gray when demand is fair, and then to light red and deep red when demand moves from good to strong.

Index for September which is published the first week of October.

By Nathan E. Irby, Ph.D., Railway Tie Association Executive Director

The Railway Tie Association (RTA) is dedicated to fostering advocacy, community, and sustainability throughout the entire wood crosstie life cycle. At the heart of RTA’s mis sion is a commitment to ensuring a strong and sustainable future for wood crossties. Please help us shape the future of this great association.

Our association is calling all members for feedback and direction according to a 2030 strategic plan initiative draft. Your engagement in this process is integral to our ongo ing success and positive energy momentum. We are a membership organization, driven to support membership needs and steward our industry through forward-thinking, data vetting, providing outreach opportunities through education, networking/engagement, and so much more. The proceeding is a summarized collection of where we are and a prophecy of where we need to be, with your input and direction required.

Networking Objectives Act

Education Objectives

Offer

Tech/R&D

Establish

Assess

Methodically, we break down our outreach into three pillars: networking, education, and technology/R&D (transfer). We are the conduit for our industry to foster those three constants to develop and grow bilaterally.

• So, how are we doing in general?

• Equally as important, what is NOT working?

• Is this venn diagram an accurate summation of our output? Any suggestions?

For the networking component, we have received feedback on a revamp of the annual member field trip to be more inclusive of railroaders. This perhaps translates to the addition of an educational component geared to spark their attendance and provide purposeful, and more targeted context—no problem, can do. The annual conference is our premier event, from a volume perspec-

tive, and represents a long-lasting tradition. Our shift in conference programming in recent years has been positively received: half day of sessions, afternoon free time, available meeting space for supplier/customer interactions, and enhanced optional tours.

• What else can we do for better membership networking?

Our educational event, the annual Tie Grading Seminar (TGS), with its growth and prestige, speaks for itself with accolades of recordbreaking enrollment (timing and size), record-breaking railroader participation, higher test scores, etc. Over the past several years, it has become an institution for wood tie education across the landscape, and its primary focus is feedback-based integration

and adaptation. We aspire to have similar results with this strategic plan initiative.

• What are the member optics on additional RTA education events?

Technology transfer is also key to our survival. We disseminate state-of-the-art information about wood ties in a variety of ways: Crossties magazine, press releases, social media posts, and presentations at allied associations/forums all over the country. Beyond the large, comprehensive Alternative Wood Preservative Research Project (AWPRP) being conducted in conjunction with Mississippi State University, what is relevant for today in terms of wood crosstie research and development?

• How can we better serve our members in this forum?

• What information gaps are present?

So, in summary, where do we need to be to remain viable and remain focused on membership relationships? What about this draft venn diagram resonates with you, our trusted member? What does not resonate with you?

Please email Rtastrategicplan@rta.org with your answers, suggestions and input.

www.nwfa.org

Nearly six in 10 wood flooring businesses expect stronger sales in 2026, according to Hardwood Floors magazine’s annual National Wood Flooring Association (NWFA) Industry Outlook survey. At the same time, rising interest rates, slowing remodeling activity, uncertainty around tariffs, and questions around consumer confidence are tempering expectations.

www.ahec.org

By Tripp Pryor, International Program Manager, AHEC

Through September, the latest available data, China has imported roughly $490 million of hardwood lumber from the United States in 2025. This is a decrease of 8% from last year, but still enough for us to be the second largest trading partner after Thailand. As the graph in Figure 1 shows, there was a significant drop in lumber exports to China in June, coinciding with the potential implementation of tariffs that have since been rolled back.

However, the most interesting change in China this year comes from a country that has only exported $143 million of lumber through September but is growing fast. Vietnam has gone from a minor player in the market to now one of the top three suppliers of hardwood lumber to China since they surpassed Russia in August. Unlike Thailand, which exports almost exclusively their native rubberwood, Vietnam does not have native hardwood production. Vietnam’s top species of lumber exports are walnut, ash, cherry, oak, and maple. In fact, for the “other” hardwood lumber HS code 440799, which includes walnut, hickory, western red alder, and “other species not elsewhere specified”, Vietnam exported a higher value of lumber to China than the United States did for the months of June, August, and September 2025.

offset their lost market in China since the log ban. US log exports to Vietnam increased 318% by volume through July (last US customs data available) compared to last year, but total log exports are still down 14% by volume in 2025 because of the closure of the Chinese market.

In this “other” category, it’s no mystery what the big money maker is. China has had a massive appetite for walnut for decades, and with the ban on importing US logs still in effect, they are looking for suppliers for their vertically integrated manufacturing. Instead of sawing the logs in China, several Chinese companies set up large, modern sawmills in Vietnam, often staffed with Chinese workers, and are producing lumber and components to the specification of the mainland factory.

These new factories in Vietnam have been a significant growth opportunity for US companies exporting logs and have helped

Long term, this large sawmill infrastructure in Vietnam will continue to need logs and could become a larger regional player in the wood processing supply chain. Vietnam Customs data shows 82% of their lumber exports have gone to China this year, but exports are increasing to other regional markets like Japan ($4.6 million through August), Taiwan ($4.1 million), South Korea ($1.3 million), and India ($1.2 million). Vietnam even exported $3.7 million of lumber to the United States this year, mostly walnut and ash, and over $3 million to the Netherlands, more than the US shipped to them in the same period.

SCAN TO WATCH

Premier Sponsor

SII Dry Kilns

UCS Forest Group of Companies

PINNACLE LEVEL

Baillie Group

ALDER LEVEL

Cascade Hardwood, LLC

WALNUT LEVEL

Classic American Hardwoods, Inc.

Jartek

NWH

CHERRY LEVEL

Comact

Continental Underwriters

DMSi Software

Hermitage Hardwood Lumber

Sales, Inc.

MO PAC Lumber Co.

Nyle Dry Kilns

Pennsylvania Lumbermens Mutual

Insurance Co.

WDE Maspell

MAPLE LEVEL

Breeze Dried, Inc.

Onsite Technologies

USNR

RED OAK LEVEL

Adentra Group

Alan McIlvain Co.

Anthony Oak Flooring

A.W. Stiles Contractors, Inc.

Brenneman Lumber

Cole Hardwood

Eagle Machinery & Supply, Inc.

East Ohio Lumber Co.

Farm Credit East

Farm Credit Mid-America

Farrow Lumber Co.

FedEx

Fitzpatrick & Weller

Frank Miller Lumber

Froedge Machine & Supply Co., Inc.

Gutchess Lumber Co.

Hardwood Industries, Inc.

Harold White Lumber

Heartwood Brands

Holt & Bugbee

The Horton Group

Horizon Farm Credit

Hurst Boiler & Welding Co., Inc.

Matson Lumber Co.

Baird - The Mazelon Chambers

Neff Group

McClain Forest Products

Pike Lumber Company, Inc.

Ressources Lumber, Inc.

Stephens Hardwood

Sunset Transportation

Swaner Hardwood

TMX Shipping Co.

Yoder Lumber