DO MORE WITH LESS

eLIMBS | Agility | TallyExpress | Neural Grader

Ease the pain of staffing shortages with inventory management solutions made for hardwoods. DMSi is your one software partner from timber to consumer.

FRANK MILLER

LUMBER CO

WHAT'S INSIDE

EXECUTIVE

Bucky

Chairman Missouri-Pacific Lumber Co., Inc.

Stephanie VanDystadt, Vice Chairman Hull Forest Products

Jon Syre, Past Chairman 2022-2024 Cascade Hardwood, LLC

MISSION LEADERS

Sam Glidden, ITS and ITSEF GMC Hardwoods, Inc.

Ray White, Lumber Services Harold White Lumber, Inc.

Joe Pryor, Education Services Oaks Unlimited, Inc.

Rich Solano, Convention Pike Lumber Company, Inc.

Bill Courtney, Membership & Networking Classic American Hardwoods

Rob Cabral, Market Impacts UCS Forest Group

DEPUTY MISSION LEADERS

Chris Rider, Membership & Networking AHC Hardwood Group

Tom Coble, Market Impacts Hartzell Hardwoods, Inc.

Greg Fitzpatrick, Convention Fitzpatrick & Weller, Inc.

Tom Oiler, Lumber Services Cole Hardwood, Inc.

Trent Yoder, Lumber Services Yoder Lumber

Brant Forcey, ITS and ITSEF Forcey Lumber Company

George Swaner, Education Services Swaner Hardwood Co., Inc.

COMMITTEE CHAIRMAN

Sam Glidden, Rules GMC Hardwoods, Inc.

HARDWOOD MATTERS

THE VOICE OF THE HARDWOOD INDUSTRY

National Hardwood Lumber Association PO Box 34518 • Memphis, TN 38184-0518 901-377-1818 • 901-382-6419 (fax) info@nhla.com • www.nhla.com

THE MISSION OF NHLA

To serve NHLA Members engaged in the commerce of North American hardwood lumber by: maintaining order, structure and ethics in the changing global hardwood marketplace; providing unique member services; promoting North American hardwood lumber and advocating the interest of the hardwood community in public/private policy issues; and providing a platform for networking opportunities.

ADVERTISER INDEX

NHLA STAFF

Dallin Brooks, Executive Director dallin@nhla.com

John Hester, Chief Development Officer j.hester@nhla.com

Natalie Thelen, Chief Marketing Officer n.thelen@nhla.com

Dana Spessert, Chief Inspector d.spessert@nhla.com

ACCOUNTING

Desiree Freeman, Controller d.freeman@nhla.com

Jens Lodholm, Database Manager j.lodholm@nhla.com

Carol McElya, Staff Accountant & Administrative Assistant c.mcelya@nhla.com

INDUSTRY SERVICES

Tom Byers, National Inspector t.byers@nhla.com

Simon Larocque, National Inspector s.larocque@nhla.com

Brooke Pajkurich, Hardwood Technical Design Director b.pajkurich@nhla.com

Benji Richards, Industry Services Sales Manager b.richards@nhla.com

Drew Snider, National Inspector d.snider@nhla.com

Marty Westeen, National Inspector m.westeen@nhla.com

INSPECTOR TRAINING SCHOOL

Roman Matyushchenko, Instructor of the Inspector Training School r.matyushchenko@nhla.com

MARKETING/MEMBERSHIP

Melissa Ellis Smith, Creative Director m.ellis@nhla.com

Brennah Hutchison, Content Strategist & Editor b.hutchison@nhla.com

Ashley Johnson, Convention and Events Director a.johnson@nhla.com

Darci Shannon, Communication & Outreach Specialist d.shannon@nhla.com

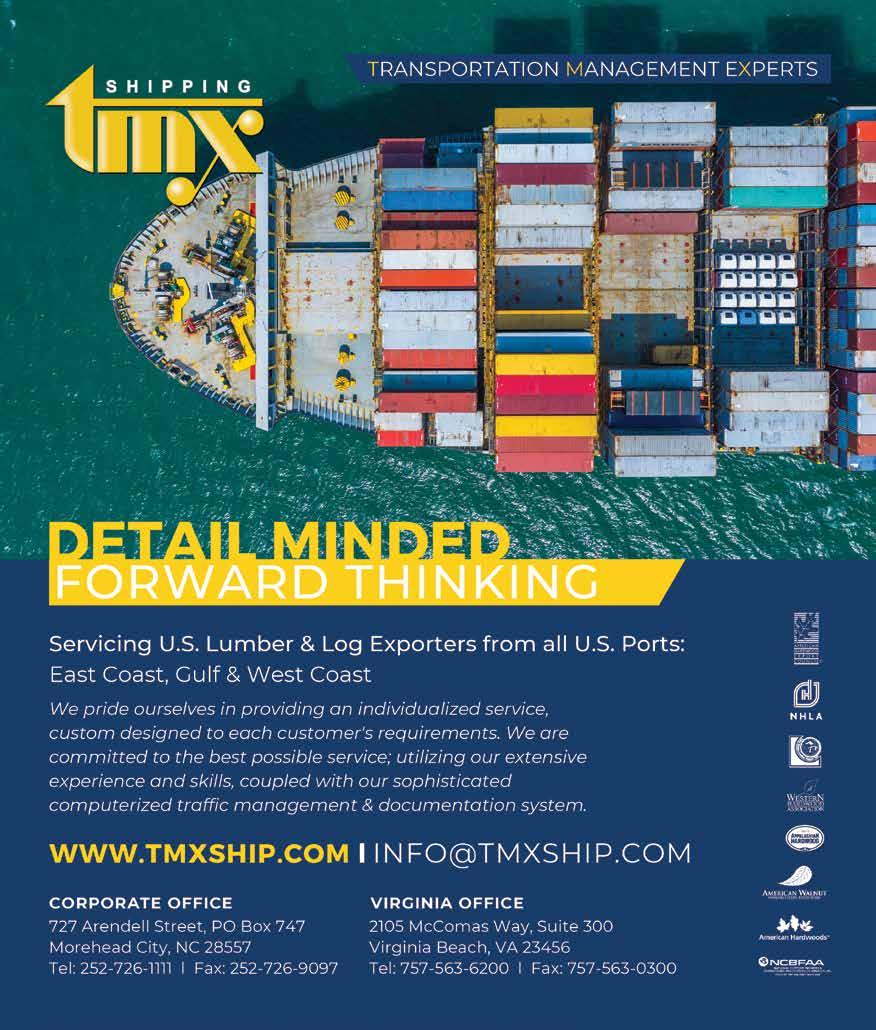

The RossiGroup has been helping customers navigate the global hardwoods industry for almost a century.

We have raised the bar with our new state-of-the-art Emporium Mill and kiln facilities, our long-term supply agreements, and our uniquely personal brand of customer service.

We deliver a world class selection of hardwoods – including the gold standard in cherry – all sorted, milled and dried to tolerances, consistencies, and yields that were not even possible five years ago. Visit us www.rossilumber.com or call 860-632-3505

Webinars: A Modern Tool for Industry Advocacy

In the 1960s and ’70s, if I wanted to learn more about a particular topic, I would go to our bookshelf and pull out the best resource available, our complete set of World Book Encyclopedias. I’d search the corresponding volume to find indepth articles and pictures on almost any subject. Of course, we have many more options to access real-time information on nearly any imaginable topic today.

One of these modern “encyclopedias” is the webinar, a virtual town hall-style meeting that shares valuable knowledge on specific topics. Webinars can be watched live, allowing participants to engage with presenters, or viewed later from a growing on-demand library.

NHLA regularly hosts webinars, often twice a month, on topics critical to the hardwood industry, free to our members. These sessions aren’t just educational, they’re strategic tools for advocacy. By sharing insights, data, and policy updates, our webinars help members stay informed and empowered to represent and protect their interests in a rapidly evolving landscape.

Our Chief Inspector, Dana Spessert, has presented on topics like Understanding Statistical Process Control ($PC), Introduction to North American Hardwoods, and the details of the Rules Change process. NHLA staff and guest experts have covered everything from Controlling Lumber Stain to The Future of Structural Hardwoods. These webinars equip members with the knowledge they need to elevate quality, improve operations, and strengthen their voice in the market.

We also address issues with wide-reaching advocacy implications, such as EU Deforestation Legislation, Trends in Domestic Furniture, and the Hardwood Market Outlook. These sessions help members stay ahead of regulatory shifts and economic trends that directly affect their businesses. In this way, education becomes advocacy; it empowers our members to navigate challenges and speak up for the hardwood industry with confidence and credibility.

Thanks to our webinar archive, members can continue learning from industry leaders like the late Gene Wengert, known to many

as “The Wood Doctor.” His webinars, on topics ranging from Proper Air and Shed Drying to Drying Oak, remain among our most-viewed resources, a testament to the lasting value of shared expertise.

You can register for upcoming webinars or explore past recordings anytime at nhla.com under the Education tab. Topics on the horizon include AI Grading, Biophilic Design, Explaining Carbon, and Automation and Optimization. We encourage members to let us know what topics matter most—your feedback helps us ensure that our webinars reflect the industry’s current concerns and future direction.

At my age, I’ve never been known for my tech skills. I type with two fingers, text with one, and frequently holler for one of my boys to rescue me from whatever computer mess I’ve created. But participating in these webinars is a new trick this old dog is proud to have learned. I encourage all our members to take advantage of this benefit. Because what you know and how you use that knowledge can help all of us advocate for a stronger, more stable hardwood industry.

Bucky Pescaglia NHLA Chairman | Missouri-Pacific Lumber Co., Inc.

S C A L E D S M A

The NHLA Evaluation and the Rules Discussion

The NHLA Board of Directors asked the NHLA staff to do a threepart study.

PART 1: An evaluation of the resources the NHLA provides to the industry. This resource assessment allowed us to do an analysis and determine critical activities.

PART 2: A financial viability analysis that organized the resources by committee objectives that were determined as part of the 2023 strategic plan. This also coincided with a financial analysis of the NHLA committees, objectives, and essential elements.

PART 3: A look at what the NHLA would look like if it started today instead of 127 years ago. This meant that nothing was off limits; all areas of the NHLA were reviewed for long-term viability and improvements.

The results were presented to the Executive Committee in July and will be refined for the Board of Directors in the fall.

The long and the short of it is that associations need to be more like the businesses we serve, constantly analyzing and improving our operations to ensure that we are financially stable and accomplishing our mission of growing and stabilizing the hardwood industry. The NHLA is and always will be a rules-based organization.

The NHLA rules for yield (appearance) and structural grading are the founding resources the association provides. Strengthening the rules is better for the hardwood industry and the NHLA. When I hear members say things like, “The rules are just guidelines—we have to produce better-graded lumber than the rules allow, or our customers won’t accept it,” that tells me it’s time to modernize and update the rules.

The rules are not guidelines or a fallback. If you have a claim, there are rules to be followed. There are three possible reasons why the rules would not be followed. First, a customer needs something different, and the producer wants to make them happy. Second, a producer wants to sell something different, either because they have it in inventory or they are willing to circumvent the rules for

financial reasons. Third, the rules are not commercially viable, so they are not followed. You may disagree with my three reasons, but I’d argue that most objections can be traced back to one of them or a combination.

Teaching and enforcing the rules is essential to strengthening them and sustaining the long-term value of the NHLA. While better enforcement is needed, that effort depends on keeping the rules clear, current, and relevant. NHLA is currently undergoing a rules revision process, and as someone observing it for the first time, I’ve realized how important member input truly is. Every perspective matters, and increased engagement helps ensure the rules reflect the realities and needs of our industry today. If you haven’t been part of the process before, I encourage you to take part in the future. Your insight can shape the standards that guide us all.

I urge you to attend the NHLA convention and join the Rules Change Open Forum, hear the proposals, share your input, and help shape the future of our rules. Then, submit the changes you want to see. Don’t wait four more years. Get engaged now and tell us how you want to see things improve. When the NHLA continues to improve, we create the foundation for a stronger, more stable industry, one where we’re all working toward the same grade together. Just like your business, the NHLA needs to constantly improve. That is one common ground we all stand on.

Dallin Brooks NHLA Executive Director dallin@nhla.com

BRUTE FORCE. BRUTE FORCE.

Precision Husky Corporation has produced the highest quality, most rugged equipment in the industry for over six decades. Today’s products are ready to lead the way for many more.

The DC-4042 is a drum style chipper, providing an additional option for biomass fuel applications, where a paper chip or a clean chip is not required. It is designed for blowing chips into closed trailers. It is offered with Tier4F Caterpillar or Cummins engines up to 600

horsepower, or a Caterpillar C-18 up to 800 horsepower, with a hydraulic clutch. The DC-4042 may be trailer mounted or track mounted, and operates with a radio remote control.

You can invest in our equipment with confidence, and know it will perform for many years to come. Call us today to discuss your needs, as well as the newest options available for our line of sawmill, logging and wood waste recycling equipment.

MAY WE INTRODUCE SOME OTHER MEMBERS OF OUR FAMILY...

Uninsured on the Highway, Uninvested in the Industry

Ihave so many reasons why Memphis is a cool place to live. We have the best food in the world, great music, and great people. But one of the worst things about living here is the cost of car insurance. The average annual cost of full-coverage car insurance in Memphis is $3,460, compared to $2,644 statewide, meaning Memphis drivers pay about $816 more per year, according to NerdWallet and Insurify. The average for the state of Tennessee is $2,308. That is more than $700 higher than the rest of the state! And why is it higher, you may ask? The number one reason is uninsured motorists. And we all know that when drivers without insurance cause wrecks, the costs don’t just disappear. They land on the rest of us who do pay for insurance. Our insurance rates increase to offset the costs caused by uninsured drivers. The more people on the road without insurance, the more the rest of us have to pay. It frustrates me when I think about it, but I can do nothing. I have no way of knowing who’s insured and who isn’t. If I could, I’d avoid uninsured drivers entirely. The same thing applies when you compare NHLA members and non-members but the difference is you can do something about it.

NHLA works hard to create value for the hardwood industry. We fight regulations, promote the benefits of hardwood, provide education, training, and technical standards, and even help bring buyers

and sellers together. And you know what? That’s all funded by members. When your company pays dues, you invest in work that benefits the entire industry. The non-members are still benefiting from market development and advocacy. They still rely on the standards that the NHLA maintains. But they are not paying in. You are. And just like with uninsured motorists, the fewer companies paying their share, the more it costs those who do. Dues rise, costs rise, or worse, services get cut. And that’s not good for anybody.

The solution is simple. More members mean a lower cost per member, a stronger industry, and better results. So, when doing business with a supplier, a mill, or a customer who is not an NHLA member, ask them, “Why not?” Please encourage them to join. The more companies that stand together, the better off we all are.

John Hester Chief Development Officer

NEW THIS MONTH: MORE PERKS JUST ROLLED IN!

Being part of NHLA isn’t just a badge of industry credibility. It’s a direct line to exclusive savings, smarter business tools, and partnerships that work as hard as you do.

NOW AVAILABLE: NEW BUSINESS SUPPORT PARTNERS

Ryan & Jacobs

NHLA members now have access to Ryan & Jacobs, a commercial collections firm that has helped businesses recover up to 90% of invoices aged 60–180 days, typically without litigation. With no upfront fees, NHLA members receive priority service, discounted contingency rates, and a dedicated recovery portal to track results in real-time. Email: ryo@ryanandjacobs.com with subject line “NHLA Cash Boost – Code NHLA25.”

Southern Cross Trading Co.

NHLA members now receive exclusive tire discounts through Southern Cross Trading Co., including free shipping on qualifying orders.

• Order online at southcrosstrd.com or email directly

• Use code “NHLA” to unlock discounts

• Tires ship directly to you or your servicing dealer

• Pay upfront by credit card or ACH

• Most orders arrive within 5 business days

• Questions? Call Mark at 904-608-2099

TOP MEMBER BENEFITS YOU SHOULD BE USING

Business Discounts

• Bass Pro Shops & Cabela’s: Up to 30% off private label gear and discounts on Ariat, Columbia, Carhartt, YETI, and more

• FedEx: Save up to 75% on shipping—plus enroll in FedEx Rewards for free gifts

• Dell Technologies: Extra 5% off select products and free IT consultation

• Lenovo: Member-only pricing on laptops, software, and accessories

• Paychex: 25% off payroll, HR, and retirement services

Boost

Your Business

• Labor Solutions: Promote job openings in the NHLA Career Center, Hardwood Matters, and our social channels—free

• Corporate Training & Services: Reduced rates on inspection services, in-house training, and kiln-drying certification

• Convention Discounts: Save on booths and registration at the NHLA Annual Convention

Don’t leave value on the table.

Explore your full list of perks at nhla.com/members/member-benefits

TRADE CONCERNS CONTINUE TO DOMINATE

By DANA COLE, Executive Director of the Hardwood Federation

The continuing evolution of the Trump Administration’s trade policy remains the top issue for the Hardwood Federation. . . and most of Washington, D.C., as we hit the midway point in the President’s first year of his second term. Although tariff increases are currently on “pause” for most countries until August 1, new announcements are rapidly emerging, including new rates for Canada, Mexico, and the EU; standard tariffs of 10–15% for others; and promises of finalized trade deals on the horizon.

So, how does the Federation stay on top of a constantly changing status? The only honest answer is that we are doing our best, which is challenging. Like other local trade organizations, the Hardwood Federation team also struggles to stay current. However, we have some strategies to keep current and proactively advocate for the U.S. hardwood industry as the situation develops.

First, we are in regular contact with key Administration officials and Congressional offices that provide information and are available to answer questions. We also follow D.C.-based information networks that distribute updates, often in real time, of official Administration news alerts and the unofficial comments shared on social media channels like X or Truth Social.

that is unavailable in media accounts or formal Congress or Administration updates. This is also an excellent example of the benefits of having a D.C. presence.

The Hardwood Federation is a tiny team comprised of dedicated professionals! However, additional help can be necessary (and welcome) to meet the goals we set for ourselves and those set by the Federation Board and industry expectations. This year, the Federation has brought short-term assistance from a D.C.-based consulting firm to increase our firepower on the Hill and with the Administration. Monument Advocacy has been on board for three months to increase our capacity to educate Hill and Administration leaders about the potential impacts of a drawnout trade war and possible retaliatory actions on the U.S. hardwood industry. We have worked closely with the American Hardwood Export Council (AHEC) and others to develop materials that succinctly demonstrate the impacts of the 2019-2020 dispute, have created a formula for potential financial relief should it become necessary, and are planning mill tours for key members of Congress, including press coverage, to stress the importance of including hardwood concerns in all negotiations with trading partners. And if that fails, we will support the industry while the dust settles on negotiation outcomes.

Regarding trade specifically, I serve as Vice-Chair of the U.S. Department of Commerce’s International Trade Advisory Committee on Building Materials. In this role, I provide input and advice to Commerce staff on international trade and business issues. I also hold a security clearance, albeit a modest one, that allows me to receive confidential updates on ongoing trade negotiations. This allows input into negotiations and helps inform and direct Federation advocacy efforts.

As an industry association in Washington, D.C., we meet with peers from other organizations regularly in scheduled meetings and as part of daily casual interactions. These exchanges often provide insight

We will also be looking for those industry members with political connections to continue to reach out and tell their story. If you haven’t been active in the past, there’s no better time to get involved! Let us know how we can help.

We look forward to sharing the outcomes of these efforts in the coming months. While we expect the Administration to announce trade deals before the August 1 deadline, we also hope that trade policy will continue evolving and the status quo will never be longterm. The Administration shows no signs of slowing down, and neither does the Federation!

With hardwood lumber, we enhance our customers' business's and the health of the planet. From responsible harvest to fabrication and installation, from use and re-use, hardwood lumber enriches and sustains the places we live, work, and play. As North America's leading distributor of hardwood lumber, we are proud to partner with you to bring unique products to the market through the untold possibilities of hardwood lumber.

What you need. When you need it. By people that know and care.

ADVOCACY 101:

The Best Defense Is a Good Offense

By JENNA REESE, Executive Director of the Ohio Forestry Association

When it comes to advocacy, the best defense is a good offense. This isn’t about being combative or striking first; it’s about proactively building relationships with elected officials. The goal is to engage them regularly, so they understand your business, don’t impose harmful policies, and ultimately see you as a trusted industry resource when they need insight or guidance. This is easier said than done and certainly cannot be treated as a quick fix. But with time and patience, it can pay dividends for your operation in the long run.

Many membership organizations employ a dedicated individual or team to manage advocacy efforts because it’s one of the most significant values an association can offer its members. These professionals work full-time on your behalf, so you can stay focused on running your business. Their role is critical: they provide policy expertise, draft legislative or regulatory language, follow up with officials, monitor government activity, and guide the association’s objectives.

Association advocacy is a powerful part of your offensive strategy, but it can’t carry the whole game. Think of it like baseball: you might have the best closer in the league, but if your team doesn’t score runs in the first eight innings, even the strongest closer can’t win it alone. Advocacy works best when it’s backed by steady, proactive engagement throughout the game, not just a final push in the ninth inning.

Similarly, associations need designated hitters to be effective. Elected officials are most interested in pleasing individuals and business owners in a voting district. Your association’s advocacy team does not vote in every district that affects your business, but you do. Your township trustee, county engineer, state senator, and member of Congress care about your vote. That means they’re far more likely to take action based on your personal story than any amount of data, studies, or maps an association presents.

To be successful, advocacy efforts must include personal relationships with elected officials at all levels of government. This means going to them, attending fly-ins, legislative receptions, council meetings, and inviting them to come to you for a site visit. It may seem daunting, but every relationship starts with a single conversation.

One common issue for loggers and sawmills in Ohio is weight limits on local roads. Local officials often do not understand that timber is agriculture and cannot be treated like oil and gas or mining minerals. This misunderstanding makes road bonding a good place to begin the conversation. Local governments would not ask a livestock truck, grain hauler, or hay wagon to bond a road, and they cannot require it for a log truck either.

However, local authorities are permitted to require annual written permits and charge fees for heavy hauling on posted local roads (Ohio Revised Code 4513.34). Governments have imposed different permit fee rates in some counties based on the material being hauled. Unfortunately, the only recourse in these cases is to either pay the fee or file a legal challenge if you believe the fee is being applied unequally. No state law or entity can override a local government’s authority due to Ohio’s “home rule” provision (Article XVIII, Section 3 of the Ohio Constitution).

Litigation is expensive in terms of both time and money. The best way to avoid those costs is by building strong personal relationships and resolving issues outside the courtroom. Always approach conversations with officials diplomatically, cautiously, and armed with facts. Your relationships with elected officials, especially at the local level, can significantly affect your bottom line, for better or worse.

You know what’s best for your business and how to navigate challenges. But by working together—through personal engagement with elected officials and strategic advocacy—we can shape a regulatory environment that supports the forest products industry at the local, state, and national levels.

Jenna Reese, Executive Director of the Ohio Forestry Association

Thermal Modification: Advancing Sustainability, Durability, and Advocacy in the Hardwood Industry

In recent years, thermal modification has become a transformative force in the hardwood industry—enhancing durability, promoting sustainability, and encouraging smarter, more responsible wood use. At the forefront of this movement is BigonDry, a global leader in thermal modification kiln technology, working in partnership with its North American distributor, Carolina Machinery Sales (CMS).

CMS and BigonDry are proud to be new members of the National Hardwood Lumber Association (NHLA) and are excited to attend the 2025 NHLA Annual Convention in San Antonio. This partnership reflects the shared values that define the hardwood community—innovation, resilience, and a commitment to continuous improvement.

A Proven Industry Partnership

Carolina Machinery Sales, a trusted machinery dealer in the sawmill and wood products industries, has been serving customers for 18 years. Known for specializing in used equipment across sectors like sawmill, pallet, woodworking, panel processing, and biomass, CMS brings deep experience and market insight to every transaction. In 2020 CMS was introduced to BigonDry, and the connection was immediate. By 2025, the partnership has grown into a robust collaboration, with over a dozen BigonDry kilns installed in operations across the U.S. and Canada. Current kiln owners span states includ-

ing North Carolina, Louisiana, Georgia, Maryland, Idaho, New York, and Ontario, Canada.

BigonDry’s kilns are self-contained, turn-key systems that are pretested in Italy before shipping. CMS works closely with clients to ensure seamless delivery, installation, training, and support. "Head

Left to Right: Josh Chambers, Tony Mazelon, and Sarah Neff

to head, we believe we provide our customers with the best bang for the buck in the thermal modification class," said Ralph Viegelmann, President of CMS. "We’re proud to offer advanced European technology backed by responsive U.S.-based service."

What Is Thermal Modification?

Thermal modification is a chemical-free process that uses high heat— typically between 160°C and 250°C—in a controlled environment to alter wood's physical and chemical structure. This process reduces moisture content and increases resistance to decay, insects, and environmental exposure. Unlike traditional chemical treatments, thermal modification enhances wood performance naturally, aligning with growing ecological standards and consumer expectations.

Popular species treated in BigonDry kilns include Pine, Poplar, Ash, and Red Oak. The flexibility to treat hardwood or softwood lumber, veneer, or beams makes these kilns a valuable asset across the spectrum of wood processing applications.

Why It Matters—Especially Now

The advantages of thermal modification are wide-ranging and timely:

• Improved Durability: The process neutralizes hemicellu loses—components in wood that attract moisture, resulting in a product that can endure harsh climates and resist rot and insects.

• Dimensional Stability: Wood’s natural tendency to warp or crack under humidity is significantly reduced, making thermally modified wood ideal for high-performance applications.

• Aesthetic Enhancement: The process deepens wood’s color and grain character, giving it a premium, exotic look without additional finishing.

• Sustainability: Free of added chemicals and built to last, thermally modified wood supports environmentally friendly construction and design practices.

These benefits are more than product features—they represent an opportunity for the hardwood industry to advocate for itself in a time when sustainability, durability, and performance are more than market trends—they’re necessities.

NHLA Membership: A Platform for Progress

For CMS and BigonDry, joining NHLA isn’t just a business decision—it’s a way to align with the hardwood industry’s values and contribute to its evolution. "Being part of NHLA gives us a platform to advocate for technology and sustainability, and to connect with partners shaping the industry's future," said Viegelmann.

CMS and BigonDry are particularly excited to showcase their work at the 2025 NHLA Annual Convention, where attendees can learn more about the impact of thermal modification and its role in enhancing the hardwood sector’s environmental credibility.

As advocacy becomes a growing priority within the NHLA and the wood products industry, companies like CMS and BigonDry play a key role. Their work helps demonstrate that innovation doesn’t have to come at the expense of tradition—it can support it. From betterperforming products to sustainable practices, thermal modification is helping the hardwood industry tell a stronger, smarter story.

Looking Ahead

As the demand for high-performance, environmentally conscious building materials continues to rise, the thermal modification market is poised for growth. With their expanding footprint across North America and their investment in NHLA membership and industry advocacy, CMS and BigonDry are committed to helping the hardwood sector lead that movement.

To learn more about BigonDry kilns or CMS’s complete services, visit www.carolinamachinerysales.com.

From internal benchmarks to collective impact, sawmills use yield studies to improve decision-making, build team culture, and advocate for more innovative, sustainable industry practices.

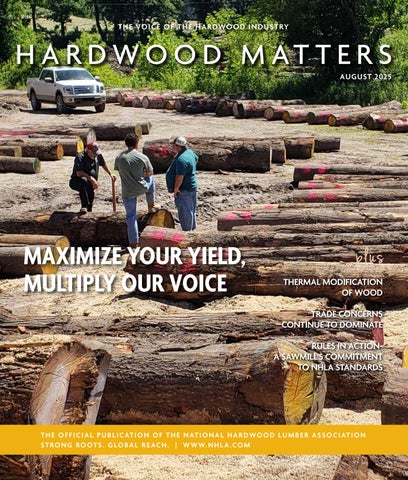

Maximize Your Yield, Multiply Our Voice

By BRENNAH HUTCHISON, Content Strategist & Editor

The Power of Measurement

In a time when the hardwood industry is facing unprecedented challenges, from rising log costs to tightening margins, NHLA’s Yield Study offers more than just a snapshot of your production data; it’s a grant-funded, on-site service that helps sawmills recover lost profits, improve log-buying decisions, and identify precisely where value is being left on the table. Tailored for operations of all sizes, the study delivers a clear, customized report with actionable steps that often translate into hundreds of thousands of dollars in regained revenue. But it’s not just about individual improvement; it’s about advocating for the industry. Every participating mill contributes to a broader efficiency, accountability, and sustainability narrative. When we take the time to measure what matters, we gain the power to manage what counts, and that’s how we move forward together.

Real-World Impact: Why One Sawmill Signed Up

As things can be unpredictable, being confident about business decisions is essential, but you must know where to start. For many hardwood operations, that starting point is data. NHLA sat down with Josh Peachey, spokesperson at Eagle Lumber Company, to gain insight on how participating in the NHLA Yield Study helped build that foundation. “We were relatively new to the sawmill business and were not confident that the decisions and choices we were making about log pricing were accurate . . .” Peachey shared. His team searched for validation and clarity, especially given that log costs account for as much as 75–80% of operating expenses at sawmills, according to a U.S. Forest Service analysis published late last year. The Yield Study offered exactly that: on-site expert analysis and a full breakdown of where value was being left behind. For Eagle Lumber, the real value was seeing how measurable data could immediately inform better log purchasing and cutting decisions. Across the industry, mills participating in the NHLA Yield Study report an average of $400,000 in recovered value annually, with one mill reporting gains of over $500,000 just weeks after implementing NHLA’s recommendations. For newer operations like Eagle Lumber, that kind of insight isn’t just helpful, it’s transformative.

Creating a Culture of Accountability and Learning

The impact of the NHLA Yield Study often goes far beyond numbers. It can transform company culture from the inside out. For many operations, the study becomes a catalyst for improved pricing strategies, deeper employee engagement, and shared responsibility. As Peachey explained, “The biggest change was that we started doing our own yield studies a lot more often. Involving all the employees in the yield studies helped create a culture of everyone looking out for each other.” The study fostered a sense of ownership, accountability, and teamwork by including staff at every level in measuring and improving yield. This cultural shift, where employees aren’t just doing their jobs but actively working to improve outcomes, represents a powerful, often overlooked form of industry advocacy. When workers understand the product’s value, their role in maximizing it, and how it affects the company’s long-term viability, the result is more than just a more efficient mill; it becomes a workforce personally invested in the industry’s success.

WHAT IS A YIELD STUDY?

An NHLA Yield Study is a customized, on-site analysis of your mill’s operations, from log intake to final product. NHLA’s National Inspectors evaluate every process step, identify where value is lost, and deliver a detailed report with actionable recommendations. It’s a lowdisruption, high-impact service that helps you maximize every log, boosting profitability, reducing waste, and empowering smarter decisions across your team. Just as important, the insights you gain become part of a larger story that shows the hardwood industry is continuously improving, working smarter, and advocating for a sustainable future.

Big Picture Thinking: Why Yield Studies Matter for the Whole Industry

The true strength of the NHLA Yield Study lies in its ability to provide individualized insight, helping mills understand how they perform and why. As Peachey noted, “I believe yield studies can help the entire industry by helping each company realize their strengths and weaknesses in different areas. What is a perfect log for one mill might be a loss for another mill. It's almost impossible to be all things to all people." On a broader scale, this kind of data-driven precision gives the hardwood industry a stronger voice in policy and sustainability conversations. When we understand and articulate our operations through facts and metrics, we not only improve our businesses but also equip the entire industry to advocate with clarity, credibility, and purpose.

Insight into Industry Leadership

The Yield Study is more than a performance check. It’s a path to leadership. In a market where every decision counts, this program helps sawmills survive and thrive. In one 12-month period alone, NHLA Yield Studies helped mills collectively recover nearly $3.9 million in lost profits. However, the actual impact goes further: by participating, mills contribute to a more innovative, accountable industry that can advocate for itself with clarity and credibility. The hardwood community is strongest when it leads with data, and the Yield Study is how we get there, together.

To learn more or request a study, contact NHLA Chief Inspector Dana Spessert at d.spessert@nhla.com or nhla.com/yield. Thanks to a generous grant from the U.S. Forest Service, 75% of the study cost is covered for NHLA members, making this one of the most accessible and impactful investments you can make in your operation’s future.

Thermal Modification of Wood: Pioneering

Sustainability and Performance in the Hardwood Lumber Industry

As the global demand for sustainable building materials accelerates, the hardwood lumber industry must examine the applicability of current methods and the sourcing of raw materials. One promising path is the thermal modification process, which improves wood performance while aligning with core environmental principles. At Jartek, we are proud to stand at the forefront of this evolution, having delivered over 80 thermal modification chambers across 20 countries. We’re committed to innovation and sustainability, and we aim to be a trusted partner for sawmills and wood processors seeking an eco-friendly alternative to tropical hardwoods and chemically treated materials.

ADVANTAGES

OF THE THERMOWOOD®

PROCESS

The ThermoWood® process, utilized in all Jartek thermal modifi-

cation chambers, is carefully optimized to reach the desired characteristics of the end product. By subjecting the wood to controlled heat and steam, without chemicals, the process improves the wood’s dimensional stability, durability, and biological resistance. Tailored to the specific properties of each species, the ThermoWood® process broadens applications for domestic wood and reduces dependence on imported tropical materials.

Jartek is part of the International ThermoWood Association (ITWA), which owns the concept of ThermoWood® and ensures the technical and ecological quality of products sold under the trademark. The main benefit of the standardized process offered by the ITWA is that it provides clear guidelines and consistency for thermally modified wood products. By following these processes, we at Jartek wish to build trust through predictable product characteristics and quality.

Thermally modified wood has demonstrated its potential to broaden the use of locally available species in various applications – from cladding and decking to interior finishes and furniture.

EXPLORING THE BENEFITS OF THERMALLY MODIFIED WOOD

Thermally modified wood aligns well with the principles of the circular economy by offering a longer service life, reduced need for chemical treatments, and recyclability at the end of its use. Its enhanced durability and dimensional stability mean fewer replacements over time, which helps reduce overall material consumption and waste. As a non-toxic material that requires no biocides or preservatives, thermally modified wood supports a more sustainable material life cycle from start to finish.

Jartek has been pioneering the advancement of thermal modification technologies for over two decades. Our engineering expertise and understanding of the hardwood lumber industry allow us to define the process continuously, and each of our thermal modification chambers is custom designed to fit client needs. In exploring the benefits of thermally modified wood, we have focused our innovations on the chamber’s operational performance and energy efficiency. The lowemission process utilized in Jartek chambers through ThermoWood® technology comes from a method based on only high temperature and steam, which means no additional harmful by-products are released in the ground or air. For our customers, this means that it is easier to meet environmental regulations and expectations from endproduct users and maintain economic viability.

Aesthetics and performance requirements are key for designers, manufacturers, and other industry experts. Tropical wood, such as Ipe,

Teak, and Merbau has been a solution for many due to their naturally beautiful texture, coloring, and moisture resistance. However, as environmental considerations play an increasingly important role in the hardwood lumber industry, there is growing interest in shifting away from long-distance transport and intensive harvesting toward more localized and responsible sourcing strategies. Thermally modified wood has demonstrated its potential to broaden the use of locally available species in various applications, from cladding and decking to interior finishes and furniture. From the perspective of designers and manufacturers of wood, this offers an opportunity to work with familiar and locally available wood species in new ways, expanding both commercial and creative possibilities.

LOOKING AHEAD: CREATING AWARENESS AND ALIGNMENT

As thermally modified wood gains traction, the next step for the hardwood lumber industry is increasing awareness and aligning around shared goals. To help bring thermal modification into the market’s consciousness and cement its role in a more sustainable future, Jartek has partnered with the National Hardwood Lumber Association (NHLA). We see significant value in moving toward an industrywide standardization of all thermally modified wood from different processes. Standardization supports quality assurance and makes it easier for end-users to select thermally modified wood confidently. With this journey still in its early stages, we look forward to sharing more about our ambitions—and the collaborative path with NHLA going forward—in upcoming issues of Hardwood Matters.

Rules in Action –A Sawmill’s Commitment to NHLA Standards

By DANA SPESSERT, Chief Inspector

After spending many years in the hardwood industry, I’ve had the opportunity to visit numerous sawmills, dry kilns, and finished goods operations. On a recent trip to a mill in Kentucky, I was truly impressed by the progress this operation has made in just a few short years.

Like many small mills I’ve seen over the years, this one had been struggling to stay afloat. Faced with the possibility of shutting down, the leadership made a bold decision: they would invest in their facility and seek guidance to turn things around. As part of that process, they partnered with NHLA National Inspectors to support their efforts through our Quality Control and Yield Analysis programs.

The results have been remarkable. Even amidst challenging economic conditions, the company has grown steadily and now ranks among the highest-producing sawmills in the region.

A key factor in this success has been their Team: hardworking, dedicated employees whose attention to detail and commitment to improve and stand out in the hardwood industry. Much of this can be attributed to a profit-sharing and compensation model built on biblical principles: every employee shares in both the successes and challenges of the business.

The team’s mindset is equally impressive. When NHLA Inspectors visit, they don’t just comply, they engage. “Is there anything we can do better?” they ask. That kind of proactive thinking, combined with a willingness to do more with less, is exactly what it takes to maximize profit and efficiency from raw materials.

NHLA is here to help, whether you’re a sawmill, dry kiln, or finished goods operation. Our mission is to support your profitability and growth. A thriving industry depends on continuous improvement in operations, in strategy, and especially in people. No matter the economic climate, that’s what makes the difference.

For more details, visit nhla.com or contact me directly at d.spessert@nhla.com with any questions.

A key factor in this success has been their team: hardworking, dedicated employees whose attention to detail and commitment to improvement stand out in the hardwood industry.

From the Field: Tom Byers

Building Skill, Building Confidence, and Giving Back

This month, we’re proud to feature National Inspector & Technical Services Advisor Tom Byers, a seasoned lumber professional whose passion for teaching is only matched by his deep respect for the industry and its people.

Tom has traveled across North America representing NHLA, and he credits his career with connecting him to a community of genuinely kind, hardworking people. “The many places I’ve been able to go around the country and the great people I’ve met have made it a great experience. There are a lot of good, kind people in the lumber industry.”

His favorite moments on the job come when he gets to teach others and see their success unfold firsthand. “Anytime I teach someone to grade hardwood lumber, and they go on to better themselves and the mill they work, it makes me feel like I’ve given back some of what other lumber workers have taught me.”

That spirit of mentorship was especially present during his most memorable experience: teaching his first NHLA class, Class #198, in March 2022, hosted by Haliburton Forest and Wildlife Reserve and Quality Hardwoods in Ontario, Canada. “I had 13 students from those mills and others. They were a great bunch, eager to learn. After almost two months with them, I felt like I had made some new friends and had an all-around great experience with the students and the many others who helped with the class. Also, spending all that time in Canada, Canadians are wonderful to be around.”

Tom’s skill set goes far beyond the classroom. “I have run everything in a lumber mill except the head saw. I’ve operated high lifts and loaders, the planer, straight-line rip saws, and chop saw.” His technical

knowledge gives him a unique perspective when conducting QC work and NHLA Yield Analysis studies, which are services he particularly enjoys. “I enjoy QC work and like doing the Yield Analysis studies and other tests offered by the NHLA.”

Tom believes deeply in the importance of education and consistency in the hardwood industry. “I feel that the rules are the root of the industry. Keeping people educated on the rules gives the industry a baseline from which to work to buy and sell hardwood lumber.”

In an industry where advocacy begins with knowledge, Tom’s work exemplifies how teaching, technical services, and standards enforcement strengthen individual operations and the hardwood community as a whole. From the classroom to the mill floor, he reminds us that progress is personal and that investing in people is one of our strongest forms of advocacy.

EDUCATIONAL OPPORTUNITIES

Register for classes at www.nhla.com/Education.

August 4-6

Walnut Grading Rules

Walnut is one of those species with a number of exceptions to the Rules. It is also one of the most highly valued species. Join us in Memphis for instruction on getting the most value out of your walnut production.

Who should attend: Experienced graders and inspectors, who grade walnut or will grade walnut.

Venue: NHLA Headquarters Location: Memphis, TN

August 11-22

Inspector Training School Online Program MODULE 1

Two weeks of hands-on training.

Venue: NHLA Headquarters Location: Memphis, TN

Module 2: Online study Module 3: Three weeks handson training and final testing at NHLA headquarters.

Instructor:

Roman Matyushchenko, NHLA ITS Instructor

August 12-14

Intro to Hardwood

Lumber Grading

Intro class to gain a basic understanding of the NHLA hardwood lumber grading rules and how the rules affect the value of lumber.

Host: Forcey Lumber & Veneer

Venue: YMCA Bigler

Location: Bigler, PA

Instructor: Tom Byers, NHLA ITS Instructor

August 18-29

Spanish Language Intro to Hardwood

Lumber Grading

For Spanish speakers, a two week Intro class to gain a basic understanding of the NHLA hardwood lumber grading rules and how the rules affect the value of lumber.

Housing and week-day meals are included.

Venue: Robinson Forest of KYU Location: Clayhole, KY

Instructor: Mark Bear, National Inspector

August 25-29

Intro to Hardwood

Lumber Grading

Intro class to gain a basic understanding of the NHLA hardwood lumber grading rules and how the rules affect the value of lumber.

Host: Indiana Hardwood Lumbermen's Association

Venue: Wood-Mizer, LLC

Location: Indianapolis, IN

Instructor: Benji Richards, National Inspector

Sept 8-Oct 31

Inspector Training School 210th Class

Traditional 8-week hands-on training to achieve a certificate of completion in Hardwood Lumber Inspection.

Venue: NHLA Headquarters Location: Memphis, TN

Instructor: Roman Matyushchenko, NHLA ITS Instructor

September 15-26

Intro to Hardwood

Lumber Grading

A two week Intro class to gain a basic understanding of the NHLA hardwood lumber grading rules and how the rules affect the value of lumber.

Housing and week-day meals are included.

Venue: Robinson Forest of KYU Location: Clayhole, KY

Instructor: Mark Bear, National Inspector

November 5-7

Hardwood Processing 101

NHLA will host a workshop to broaden the knowledge of hardwood processing for those industries and people who support sawmills and mill operations. The 3-day workshop will explore the process path from tree to kiln and includes a tour of a local sawmill and concentration yard. Housing and meals are included.

Venue: NHLA Headquarters Location: Memphis, TN

HARDWOOD MARKETS MATTER

Hardwood Markets Matter, and it is important for NHLA to share market details of the entire Hardwood Industry. We appreciate the support of allied associations and publishers in gathering and sharing this important market information that can help you understand the complete hardwood industry picture.

www.nwfa.org

SUPPLY CHAIN IMPROVEMENTS

While most NWFA members are experiencing improvements with the supply chain, some reported in Hardwood Floors magazine’s 2025 Industry Outlook survey that extended lead times or unpredictable supply for raw materials: hardwood (29 percent), solid hardwood flooring (16 percent), and finishes (14 percent). Several stated that obtaining white oak was among the biggest challenges in 2024.

www.hmr.com

The HMR Demand Index (HDI) is a feature in HMR Executive® that illustrates monthly trends in reported demand from 10 major domestic markets for hardwood lumber. Components of the index are color coded with various shades of blue when demand is slow, they transition to gray when demand is fair, and then to light red and deep red when demand moves from good to strong.

Index for June, which is published the first week of July.

HMR Demand Index (HDI)

Railroad Ties

Economic Uncertainty Continues Affecting Tie Demand Outlook

By Petr Ledvina

Tariffs & Trade Policy Drive Market Uncertainty

Table 1

New Wood Crossties (in thousands)

Standard & Poor’s

The labor market remains resilient, with unemployment holding steady at 4.2 percent—a rate widely regarded as the natural level. Initial jobless claims have remained low, and labor force participation stands at 62.6 percent—in a tight range for more than a year. Personal Consumption Expenditures (PCE) were somewhat softer, increasing by annualized 1.2 percent. Meanwhile, interest rates on government bonds have inched up, pushing mortgage rates close to 7 percent. Added to this complex landscape is the unpredictable nature of U.S. tariff policy, which contributes to uncertainty in trade and pricing. Still, inflation indicators showed some moderation in April, with the Consumer Price Index (CPI) rising just 2.3 percent year-over-year, slightly below expectations and easing fears of immediate price surges from import taxes.

RR Performance Amid Challenges

Partially because of container imports, Class I railroads posted good results despite several challenges. For some, it was a tough winter where the RRs had to reduce train speed when the temperature dropped below -13 degrees Fahrenheit (-25C). For others, it was torrential rains causing some parts of the tracks to be washed away as well as a bridge in Arkansas, for example. On average, revenue was up in the lower single-digit percentage points with volume up by 4.5 percent carloads (AAR week 13 report). Most of the gains came from the intermodal category, as the trains carried the influx of imports from ports inland. For smaller railroads, the picture looked similar in terms of carloads. The total volume increased by 0.6 percent, carried by a 7 percent increase in intermodal.

Hardwood Market Faces Uncertainty

It is an understatement that current economic uncertainty also weighs on sawmills. David Caldwell of Hardwood Market Report (HMR) stated that “China is the largest trading partner for grade hardwood lumber. The 90-day pause on escalated tariffs only allows sellers to ship for about three weeks in order for lumber to reach China before the pause expires. Until there is a permanent solution to the trade war, sawmills and concentration yards are unsure how to proceed.” He also expressed concerns that if this uncertainty does not end soon, more sawmills will close.

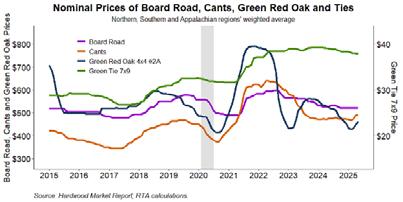

Industrial Lumber Demand & Pipeline Projects

When it comes to industrial lumber, the situation is evolving. Demand for board road is on the upswing, driven not only by seasonal factors but also by pipeline construction projects (HMR). Additional growth

may be on the horizon, as there has been a notable increase in applications for pipeline projects since late last fall (Federal Energy Regulatory Commission). Demand and pricing for hardwood pallet cants has marginally improved, likely due to an increased demand for container shipping and lower velocity of pallet circulation as importers stockpiled inventories (Figure 1). Purchases of ties were good in 2024. In fact, they exceeded RTA’s forecast by nearly 6 percent, largely due to a 74 percent increase in Consolidated Rail Infrastructure and Safety Improvements (CRISI) grants compared to the previous fiscal year. However, in Q1, tie purchases slowed down. In conjunction with this, increased tie inventories put the inventory-to-sales (ISR) ratio at an extremely high level. In turn, the high ISR put marginal pressure on pricing.

RR CapEx & Small Market Demand Outlook

Tie demand outlook for the remainder of the year is virtually unchanged from the previous forecast despite macroeconomic uncertainty. Starting with the Class I demand, RRs expect lower freight volume in Q2, especially from intermodal, as the front-loading wave should end soon. (A note of a caution: It is likely that when imports swing the other direction, making GDP look better, RRs will have fewer containers to carry). They also expect a slight rebound in the second half of the year. As such, RRs confirmed their outlook for CapEx spending in 2025 – virtually the same level as last year in nominal dollars (Class I Q1 earning calls).

CRISI Grants & Tie Demand

When it comes to the small market, the situation has been clouded by the unpredictability of the CRISI grants provided by Congress. For this year, RTA assumes the level of the grants to be about half of the prior year. Assuming this holds, the total demand for ties is estimated to decline by about 6.4 percent (Table 1). For the 2026 outlook, great uncertainty remains for the economy and for the CRISI grants.

www.ahec.org

Global Markets Slow in Early 2025, Trade Deals Could Be Light at the End of the Tunnel

By Tripp Pryor, International Program Manager, AHEC

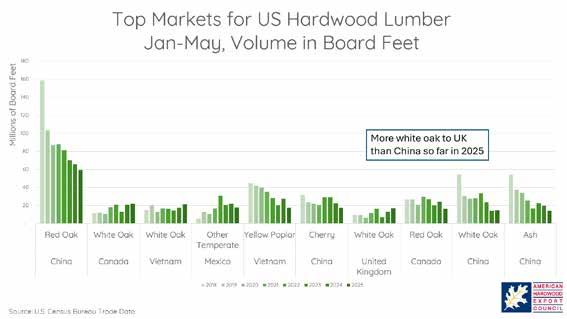

Exports of US Hardwood Lumber were down 13% by volume through May of 2025 compared to the same period last year, as many of our largest markets have faced tariff whiplash through the spring. This graph shows the 10 largest markets for lumber products through the latest available data (May 2025), and the historic trade levels for the first five months of previous years. Volumes declined in 2025 for most of these species and markets –particularly in China.

Through May, China has dropped 18% by value and 23% by volume since last year as the market continues looks at increasing economic uncertainty and high potential tariffs. Although our data only goes to May, a “framework” of a deal with China was announced in June that will drop tariffs down from 145% on Chinese products coming to the US and 125% on our products going to China to 30% and 10% respectively. Although this number is still an additional cost for international trade, it represents a much more manageable number and should provide some stability for the markets. China’s total imports of hardwood lumber are down 9% from all sources in 2025, and Thailand has surpassed the US to be their largest supplier of lumber. Looking at individual species of US lumber going to China, our red oak exports are down another 10% by value, and are down 38% from their peak in 2018. While other markets like Europe and Vietnam have increased their consumption of red oak, we have still not fully replaced the drop in China since 2018. Red oak exports to all markets are down 4% through May.

White oak lumber exports to China have also declined, and for the first time we exported more white oak lumber to the UK, Canada, and Vietnam than to China. This is a massive shift. For reference, in 2018 China imported 54.5 million board feet of white oak through May, and the UK imported just 9.4 million board feet. The Chinese white oak market was more than five times the size of the UK white oak market, and larger than Canada (12 million bf), Vietnam (15 million bf), and the UK market combined. Now, all three of those markets are buying more white oak than China.

The UK market has gotten a boost from stable trade relations and is up 19% through the first five months. By volume the UK increased by 4.4 million board feet from last year, which was the largest growth for any country. Compared to 2023, the market increased by 10.7 million board feet. Another factor boosting the UK’s trade is that the market does not have to comply with EUDR regulations unless the material is being traded into Europe at a later date.

As more trade deals are hopefully announced in the coming weeks, we look forward to a busy international calendar promoting American hardwoods all over the world. AHEC will host pavilions at trade shows in Mexico in August, China, India, and Indonesia in September, and Vietnam in November along with numerous design and educational projects. For more information on AHEC, please visit www.americanhardwood.org.

THE COUNTDOWN IS ON: JUST 2 MONTHS UNTIL THE 2025 NHLA ANNUAL CONVENTION

October 22–24 | San Antonio, TX

We’re less than two months away from the most important event on the hardwood calendar—the NHLA Annual Convention & Exhibit Showcase—and this year, we're heading to San Antonio for three days of connection, strategy, and momentum.

WHY YOU CAN’T MISS IT:

• Industry-led education tackling your real-time challenges

• A dynamic Exhibit Showcase packed with innovation and opportunity

• Access to decision-makers and market-shapers from across the globe

• Inspiring keynotes, powerful networking, and high-value conversations

• And yes—two free Randy Travis concert tickets, one night hotel stay, and an Uber voucher are up for grabs for one lucky early registrant!

Whether you're focused on workforce development, advocacy, innovation, or simply growing your business in a shifting market, this is the room where it all comes together.

This isn’t just another event. It’s your opportunity to move the industry forward—together. Don’t miss out. www.nhla.com

Premier Sponsor