BUILDING THE NEXT DECADE TOGETHER

BUILDING THE NEXT DECADE TOGETHER

Gaël Escribe, CEO & Janusz Zielinksi, N! Global Heavy-Duty Business Development

NEW MEMBERS

• Bodipasa, FC Repuestos & Örum

NEW SUPPLIERS

• Corteco, Green Energy & Webasto

NEW PRODUCTS LAUNCH

• Brembo

• Mann-Filter

N! HD COMMUNITY NEWS

• VIPAR Impact Conference October 21-25

• NEXUS and NEXUSTRUCK is proud to announce its sponsoring cooperation with Garrett Truck Sport Racing Team from UK

• N! Business Forum, Monaco March 5 – 7 - A 10-year anniversary event to unveil how NEXUS will continue to be a game-changer and address the challenges of the AA: ‘Building the next decade together’

• Stellantis and NEXUS Automotive International announce a strategic business partnership aiming at further boosting parts and aftersales services developments at global level.

• Borgwarner, Sustainability, Remanufacturing and Charging Forward to Net Zero • Dinex, Fuel, Costs, Time & CO2: Reconditioning of Particulate Filters is a big win for everyone • Exide, Exide energizes the circular economy with sustainable battery solutions • Jupojos Technika, The winner of the “Young Truck Mechanic 2023” competition has been revealed

• NRF, NRF applies strategy of Reduce, Reuse and Recycle • N!SERVICE, NEXUS Service offers support to truck and trailer workshops / NEXUS Service add-on for circular economy • Schaeffler, Long distance runner, • Valeo, SWF Valeo AquabladeTM, the Latest Innovation for Commercial Vehicle Wiper Blades • Wijlhuizen Group, Wijlhuizen Group increases strength in Belgium with acquisition of Remco • ZF, Sensors for driver assistance systems expands ZF Aftermarket’s commercial vehicle range

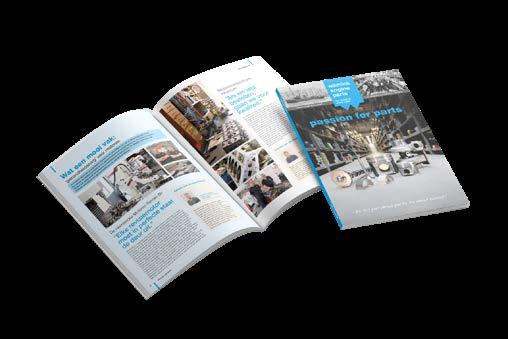

INSIDE TRUCK 10 | JUNE 2024

IN ! SIDE TRUCK Newsletter is published by NEXUS Automotive International, Geneva, Switzerland.

NEXUS Automotive International SA Chemin du Château-Bloch 11 1219 Le Lignon | Geneva | Switzerland

T +41 22 306 49 50 www.nexusautomotiveinternational.eu

Truckers, the unsung everyday heroes. They navigate the roads alone, at all hours and in all weathers, ensuring the world keeps turning; relying not only on their own strength and skill but on the quality of the parts that keep their wheels rolling.

Whether you’re an everyday hero behind the wheel of a truck, a highly skilled technician, a meticulously planning fleet manager, or a dedicated retailer, febi has your back.

febi Truck is the trailblazer of the Automotive Aftermarket, committed to supporting the unsung heroes who keep our world in motion.

febi is your No 1. Solution Provider for the Mobility of Today and Tomorrow

With everything on our books supplied in tested OE-matching quality, we take pride in being your No. 1 in the Automotive Aftermarket for commercial vehicle replacement parts.

One-Stop Solution - Streamlined procurement process for wholesalers and fleet managers.

Wide Coverage - With a vast selection across 20 product groups, febi Truck ensures that you will find the exact part you need, no matter the requirement. From Air Conditioning to Wheel Fastening, we’ve got you covered.

Constant Innovation - Our range is not static; it’s always evolving and growing to meet the everchanging needs of the Automotive Aftermarket. Count on febi Truck for complete ranges and for the swift introduction of parts for the latest ‘BIG 8’ models.

Heritage of Excellence - Manufacturing competence since 1844, an unrivalled legacy of quality.

Gaël Escribe N! CEO

Dear Readers,

Janusz Zielinski N! Global Heavy Duty Business Development

As the excitement builds for the upcoming N! Annual HD Summit in Antwerpen in June, 17-18, we are thrilled to present a special edition of Truck Inside magazine, tailored to address the key themes and developments shaping the heavy-duty (HD) transportation industry.

1. Fostering HD Community Growth and stability: N! continues its unwavering commitment to nurturing the HD community, with remarkable growth numbers achieved in 2023 serving as a testament to this dedication.

Experts and investors alike acknowledge the HD aftermarket as a safe and stable business segment. We firmly believe that our comprehensive HD activities will empower our members to elevate their parts distribution companies to new heights of professionalism and profitability.

2. Embracing and Promoting Sustainability in HD Transportation: In an era where sustainability is paramount, HD transportation remains at the forefront of this movement. The aftermarket sector, in particular, plays a pivotal role in influencing green transportation practices. As N!, we are steadfast in our mission to promote sustainable and green parts and services catered to truck workshops. Our focus on remanufactured products and circular economy principles will be further emphasized in the coming year.

3. Securing Your Future in the HD Aftermarket: For those aspiring to thrive in the HD aftermarket, being a member of N! Truck is the ultimate assurance of a prosperous future. Our collective efforts ensure that your business remains on the path to profitability and success.

4. Supporting Truck Racing Championship: We are proud to announce our continued support for the European Truck Racing Championship in the 2024 racing season. Collaborating with the GARRETT TruckSport Racing team, we will be present at four exhilarating racing events in Misano, Zolder, Nürburgring, and Jarama.

Join us as we delve deeper into these pivotal topics and celebrate the spirit of innovation, collaboration, and sustainability within the HD transportation industry. Together, let’s pave the way for a brighter and more prosperous future.

Now, enjoy the reading of INSIDE Truck!

Warm regards,

Gaël Escribe & Janusz Zielinski

Ferodo® Brake Pads are officially part of the MB eActros LongHaul

– Winner of the 2023 Innovation Award.* With a winning score of 112 votes, Mercedes-Benz Trucks’ battery-electric truck (BEV) fought off the competition. The Mercedes-Benz eActros LongHaul opens a new chapter towards e-mobility. It’s proof that the transition to CO2-neutral long-haul transport is an achievable target, relying on hi-tech solutions and continuous R&D efforts. To ensure supreme braking performance and safety during operations, Mercedes-Benz chose Ferodo® as their preferred OE partner in advanced technology. So just sit back and discover the future of commercial driving.

Ferodo® Brake Pads use innovative friction materials, specifically designed to meet and exceed the many different OE requirements of the Mercedes-Benz eActros LongHaul front and rear axles. They have been specially developed by our R&D team.

Description Ferodo CV Brake pad

Part Number FCV4417PTS

Caliper Knorr SM7

Friction Material MB7122-0 WVA 29246 / 29247 Copper Free**

Dimensions (mm) 244,6 x 113,7 x 30/35

Notes Original Knorr-Bremse accessories included EAN 4044197632428

R90 E1 90 R - 02A0798/0039

Description Ferodo CV Brake pad

Part Number FCV4418PTS

Caliper Knorr SL7

Friction Material MB7222-0 Copper Free** WVA 29244/29245

Dimensions (mm) 207,6 x 113,7 x 30/35

Notes Original Knorr-Bremse accessories included EAN 4044197632435

R90 E1 90 R - 02A0819/0040

RECENTLY ADDED TO THE RANGE

Truck Turbos Including gaskets & mounting bolts when needed

THE DIFFERENCE

Genuine Nissens Quality

DEVELOPED AND TESTED FOR HIGH PERFORMANCE AND EXTENDED DURABILITY

THE HIGHEST PERFORMANCE & DURABILITY

Regular Nissens’ stock items support most teams and trucks of the FIA European Truck Racing Championship.

SUPREME CAR PARC COVERAGE, MANY EURO 6 STANDARD APPLICATIONS

HIGHLY ROBUST BRAZED ALUMINUM RADIATOR CORES

With over a century of experience in spare part design and manufacturing, our product knowledge is unparalleled. We take pride in our Genuine Nissens quality standard, ensuring easy product installation, excellent performance, and reliable operation in your vehicle. Our parts are widely recognized and trusted by professionals as the top choice.

Boost your truck parts business with our competitive and versatile truck parts program.

Reach out to your Nissens counterpart to know more about Nissens’ Truck program.

FACTORY NEW COMPRESSORS PRE-FILLED WITH PAG OIL

CORROSION PROTECTED AND NITROGEN-FILLED CONDENSERS

PROVEN, RELIABLE, LONG LIFESPAN

EASY INSTALLATION, IMPORTANT PARTS INCLUDED (FIRST FIT)

Bodipasa is a company with 50 years of experience in the auto parts trade for trucks, tractors, and other heavy vehicles in Brazil, especially diesel injection and motor components, turbochargers and filters. We have more than 300 employees in 20 branches throughout Brazil.

Bodipasa has joined NEXUS Automotive Brazil starting 01.01.2024.

FC Repuestos is a mid-size Chilean company founded in 2009, 100% dedicated to the HD Business. Thanks to a central warehouse located in Los Angeles (Chile), FC Repuestos distributes truck parts for the whole Chilean territory for the main European brands like Volvo, Mercedes Benz, Scania, Renault and MAN.

FC Repuestos has joined NEXUS Automotive International starting 01.05.2024.

Örum Oy Ab is a Finnish automotive spare parts wholesaler that also operates in Estonia through its subsidiary, Merantile AS. We cater to both PC and CV customers. Together with our sister company, Diagno Finland Oy, Örum offers the widest range of workshop services on the market, including training, technical support, workshop equipment, and equipment services. Additionally, we oversee three garage concepts: Autoasi, Autonomi, and eExpert.

Örum’s Commercial Vehicle division provides both aftermarket and industrial services. Our aftermarket product range features top-tier products from leading manufacturers, with particular expertise in pneumatics and vehicle lighting. In the industrial (OE) segment, Örum Commercial Vehicles represents selected manufacturers in Finland, providing storage, logistics, and serving industry needs for both individual components and component assemblies. The cornerstone of our CV operations lies in our long-term supply relationships with established industry names such as Wabco, Kongsberg, Hella, Bosch, Italtergi, Motometer, and other brands and sourcing channels that complement them.

Orum has joined NEXUS Automotive International starting 01.01.2024.

Air Springs for Euro 6 Vehicles. Reducing costs while protecting the environment and the climate – just two of the benefits of modern Euro 6 vehicles. Lightweight air springs from Continental ensure that these benefits are also retained – or even enhanced – after fitting a replacement part.

The Euro 6 standard, which has been in force since 2013, also changes the requirements relating to aftermarket components: If, for example, consumables have to be replaced after a few years, these components must not adversely affect the vehicle’s original consumption and emissions benefits. Continental has developed lightweight axle air springs for commercial vehicles for precisely this purpose.

Significant weight saving

In these components, metal parts such as the piston are replaced by synthetic parts that are lighter but offer the same load capacity. The piston seating and the attachment method have also been optimized. All that ensures a significant weight saving that can quickly amount to several kilograms for a complete vehicle unit.

And that has a number of benefits in terms of fuel consumption and the associated costs and emissions. Further benefit: The vehicles’ maximum possible payload remains unchanged or is even increased.

The portfolio currently encompasses numerous air springs for the Euro 6 models of the major commercial vehicle manufacturers. These products, manufactured to the current makers’ specifications, can be installed without any problem in the latest vehicle generations.

QUALITY, RELIABILITY, DURABILITY - WHEN IT TRULY MATTERS MOST.

MORE THAN 2,500 HEAVY DUTY APPLICATIONS IN OE QUALITY FOR THE INDEPENDENT AFTERMARKET.

CORTECO is one of the leading suppliers of components for the Independent Automotive Aftermarket. As a member of the global Freudenberg Group, they supply over 26,000 products in OEM quality. Independent garages trust in CORTECO spare parts and therefore benefit from the original quality made by Freudenberg. CORTECO has manufacturing plants/ distribution centres in over 15 different countries, but through the Freudenberg Group, they reach customers in 60 countries around the world.

Corteco has joined NEXUS Automotive International as a Listed Supplier from 01.01.2024.

Green Energy, a Danish green tech company, was founded in 2017 with a clear purpose: to reduce the use of fossil fuels and promote green mobility by utilising renewable energy. From the start, the company had a vision to reduce CO2 emissions by 50 million tonnes by 2050 and has since committed to encouraging a more cost-effective and sustainable transport sector.

Green Energy has developed a solar energy solution specifically tailored for life on the road to achieve these goals. It includes the latest CIGS solar panels and a charge controller with an IoT solution that enables monitoring and reporting of fuel consumption and CO2 emissions through a mobile application. This solution ensures significant fuel savings, reduced CO2 emissions, increased comfort and efficiency, and less wear and tear on the generator, turning sustainability into profitability.

Green Energy has officially become an Innovation Supplier for NEXUS Automotive, starting from 01.04.2024.

In the fast-moving transition towards sustainability, heavy-duty transportation has lacked alternative solutions to reduce its environmental impact. While the electrification of passenger cars and smaller vehicles has gained momentum, heavy-duty vehicles require alternative green solutions. This is where Green Energy’s CIGS solar technology plays a key role.

While conventional methods focus on reducing fuel consumption and CO 2 emissions while driving, Green Energy’s solar solution addresses an overlooked area: idling. Designed for transportation, this solar solution utilizes cutting-edge CIGS (Copper Indium Gallium Selenide) technology to eliminate the need for idling, increase comfort, reduce operating costs, double battery lifespan, decrease wear and tear on generators, and improve environmental performance.

Data shows that a long-haul truck equipped with this technology saves between 500 and 700 litres of diesel and up to 1.88 tonnes of CO2 annually, which results in a return on investment (ROI) within two years. Not only are these savings good for the bottom line, they will become even more important as the requirements and regulations for the future of transport become more stringent.

The solution also includes an MPPT charge controller that not only provides comprehensive insight into the efficiency of your solar panels, but also enables accurate reporting of fuel and CO 2 reductions via an app. This ensures transparency and provides eco-friendly data for CO 2 reporting, in line with regulations such as Scope 1 and 3 emissions, which will serve as your license to operate in the future.

As a global innovative systems partner to the mobility industry, Webasto is one of the 100 largest suppliers to the automotive sector worldwide. Beside innovative roof and electrification components for passenger cars, Webasto has a strong footprint in the field of efficient heating and cooling solutions for commercial vehicles such as trucks. While electric high-voltage heaters, traction batteries and thermal management solutions drive ambitious electrification projects, fleet managers, system integrators and OEMs count on the extensive heating and cooling portfolio from Webasto. In 2022, the Group generated sales of over 4 billion euros and employed about 16,800 people at more than 50 locations. The headquarters of the company, which was founded in 1901, is located in Stockdorf near Munich (Germany).

For more information, please visit www.webasto.com Webasto is joining NEXUS Automotive International as Preferred Supplier starting 01.07.2024 .

Drive with comfort: Premium heating and cooling solutions for every truck

For commercial-vehicle workshops, it is becoming increasingly important to consider a vehicle‘s age and therefore its fair value in relation to its purpose in the customer’s fleet as a whole. Bosch eXchange offers a wide range of replacement parts for the repair of commercial vehicles in line with their current value. This supports commercial vehicle workshops to meet their customers’ demand for high-quality, valuebased vehicle repairs. Peter Lukassen, responsible for the operative sustainability at the Bosch Mobility Aftermarket division, answers questions about the sustainability strategy of Bosch eXchange.

Question: Reuse of products supports the sustainable use of natural resources. How important is circular economy for Bosch and how does Bosch Mobility Aftermarket contribute to this

PL: For decades, circular economy has been a key component of the aftermarket offer. Circular business models are not only more sustain-

able, but also more robust. Accordingly, they are ever more important. Bosch has already developed different solutions within its program and will continue to expand them even further. As interface towards the market, the Mobility Aftermarket division sees its task in aligning the circular economy and its different business models with one another thus making them twice as sustainable.

Question: Value-based repairs are in higher demand than ever before – and not only for older vehicles. Why should workshops choose Bosch eXchange products?

PL: Sustainability means using things as long as possible and as long as it makes sense. However, as the age of the vehicles increases, the purchase of new replacement parts becomes more difficult and more expensive. For many years, Bosch eXchange has been offering the possibility of carrying out valuebased and sustainable repairs of high quality. The importance of exchange programs for long-term maintenance of vehicles increases concomitantly with the growing electrification of vehicles and components. Based on the comprehensive understanding of systems, Bosch eXchange is consistently and continuously further developed in line with the customers’ requirements. As partner of workshops, Bosch foresees a huge, common and sustainable business potential in this field.

Question: Diesel engines dominate the commercial vehicle segment. However, the relevance of electric drives is expected to increase gradually. What about the future perspectives?

PL: Bosch eXchange has evolved over the years just as the vehicles did. As Bosch complemented its portfolio including exchange parts for diesel direct injection in addition to distributor pumps, solutions for future forms of mobility will also be developed.

Brembo, a global leader in the production of high-performance braking systems, also offers quality solutions for the commercial vehicle sector. Thanks to continuous research and development for original equipment and the creation of specific technologies and materials for heavy vehicles, Brembo Prime is the comprehensive offering that meets all needs.

This product line includes discs, pads, and floating calipers. Brake discs with CO-CAST technology and RING discs, manufactured in European plants, provide an advanced and secure solution to optimize the performance and lifespan of commercial vehicle braking systems. These enable better heat dissipation and increased resistance to thermal cracks, extending the lifespan of both the disc and pad, even under the most extreme conditions.

Brembo Prime not only ensures excellence in discs but also in brake pads, ensuring reliability, safety, and long-term durability, establishing itself as an essential component of braking systems for commercial vehicles. Developed to further enhance disc performance, Brembo pads for commercial vehicles stand out for the use of selected compounds that, through the combination of 30 different components, ensure better performance in all situations and for extended periods.

Furthermore, Brembo offers a selected range of brake pads utilizing ProTecS® technology by Knorr-Bremse. Characterized by the special connection of the spring with the pad plate, this technology allows for optimal driving, reducing residual torque and increasing the durability of friction material, especially on rough roads.

Finally, Brembo’s offering for commercial vehicles is completed with original equipment floating calipers for the aftermarket. The Brembo solution does not only include the caliper but, for a portion of selected vehicles, can be paired with the Brembo caliper carrier bracket for a comprehensive and secure overhaul of the braking system.

In the third and final part of this series, MANN-FILTER takes a look at future filtration solutions for the electromobility sector.

Millions of people around the world are suffering from the effects of polluted air, not only outdoors in spaces with a lot of traffic, but also inside vehicles. It is therefore becoming essential to improve air quality by reducing particulate matter and harmful gasses. With its latest innovation in cabin air filtration, global filtration expert MANN+HUMMEL is concentrating on a particle size that is becoming increasingly important – so-called ultra-fine particles (less than 0.1 micrometer). These can get particularly deep into the human body and cause harmful damage there. The World Health Organization (WHO) is also paying particular attention to ultra-fine particles and in its latest air quality guideline has called for this particle size to be included in routine measurements.

Regardless of the drive system, cabin air filters play a major role in providing drivers and occupants with clean and healthy air. In electric vehicles, there is also a trend toward improving air quality through multi-stage filter systems.

The future of cabin air filtration: multi-stage HEPA filter systems

MANN+HUMMEL has developed HEPA filter systems to effectively protect people from these microscopic impurities. The abbreviation HEPA stands for High Efficiency Particulate Air. It is not a protected term, so special care must be taken here. The addition of “in accordance with DIN EN 1822 and ISO 29463” indicates whether a filter actually meets the high requirements of European and international standards. “Our filter media meet these requirements,” explains Christiane Michel, Business Development Manager Cabin Air Quality at MANN+HUMMEL.

„Our multi-stage cabin air filter systems with highly efficient HEPA filters offer protection through clean room quality air filtration, as is also the case in operating rooms, for example. Depending on the HEPA class, at least 99.95% of the particles are reliably removed from

the air, including harmful bacteria, viruses and other microorganisms, even the previously mentioned ultrafine particles. These are so small that they can easily penetrate into the bloodstream, cause severe damage to organs and be carcinogenic,“ Michel adds. „We now know that more than 90 percent of the particles in the air are ultra-fine particles. Whether they are safe or not depends on their source and chemical composition.“

MANN+HUMMEL uses the HEPA filter as part of a threestage system along with a prefilter and a cabin air filter. Both can be equipped either as pure particle filters, in combination with activated carbon or as a third version with biofunctional and microbial coating. The particle filter uses a special nonwoven material that efficiently retains dust, soot and pollen, while the activated carbon filter adsorbs harmful gasses and odors. A biofunctional coating binds allergens that can be released from pollen and provides additional protection against the growth of mold and bacteria on the filter medium.

Michel describes the situation: „Since a HEPA filter can capture much finer particles than a conventional cabin air filter, its fiber structure is significantly denser, which results in significantly lower air permeability. To com-

pensate for this, a HEPA filter has more media surface area and thus achieves the lowest possible pressure drop. In fact, the surface area of the filter media in our HEPA filters is about five times larger than in a conventional element, thanks to a smaller pleat spacing. It is therefore currently not possible to replace a standard cabin air filter with a HEPA element. Air conditioning systems are not built for these high efficiency filters. Instead, the HEPA filter is located in a separate system – usually outside the air conditioning system – together with a prefilter, as protection for the HEPA filter.“

Smart solution to prevent air pollution in vehicle interiors

Smart multi-stage HEPA filter systems are also designed to ensure that filtration only takes place when it is needed. An intelligent control system records the air quality and provides data on the basis of which the system decides which of the three filters the air should flow through. „This ensures that the HEPA filter is activated automatically as the final filtration stage only when required, for example, when the outside air is heavily contaminated, such as in tunnels or in traffic jams. This allows the size of the system to be kept small and extends the life of the HEPA filter,“ according to Michel.

Future filter technology ensures less particulate matter

Another future filtration solution from MANN+HUMMEL for the independent aftermarket is the reduction of particulate matter generated in road traffic. These particulate emissions include not only exhaust gasses, but also particles that enter the air as a result of braking and the wear of tires and road surfaces. The problem of particulate matter is therefore independent of the drive system and also applies to electric vehicles. To prevent this particulate matter from entering the atmosphere in the first place, the experts at MANN+HUMMEL take care of

these particles as soon as they are created. They have developed a wide range of solutions to improve the particulate matter balance of vehicles. In addition to a brake dust particle filter that reduces brake dust emissions directly at the source, there is also a filter for the roof or underside of vehicles that collects particulate matter from the ambient air.

Cabin air filters will remain an essential component of future vehicles – regardless of the drive system. Up to 540,000 liters of air per hour can flow into a vehicle via the ventilator. In this way, pollutants can enter the vehicle interior from the outside and remain there for a long time – increasing the air pollution in the vehicle interior. This is precisely where multi-stage cabin air filter systems with their advantages come into play, but also effective cabin air filters such as the innovative MANN-FILTER FreciousPlus with its biofunctional coating and effective protection against allergens, harmful gasses and particulate matter. In order for a cabin air filter to function properly, it is important to replace it regularly. The recommended replacement interval is 15,000 kilometers or once a year.

Multi-stage filtration concept

“Our goal for the future is to offer further cutting-edge technologies for inside the vehicle, such as digitally displaying the filter status and air quality in real time – for health and comfort in the vehicle,” concludes Michel.

Around the world, MANN-FILTER offers a comprehensive range of filter products in original equipment quality for the aftermarket. With innovative solutions to new filtration challenges, the experts at MANN+HUMMEL are developing the filters of tomorrow in today’s vehicles and machines. Because in the future, customers must also be able to rely on MANN-FILTER – Perfect parts. Perfect service.

MANN+HUMMEL, global filtration specialist and global market leader in air dryer cartridges, bundles all its expertise and years of experience in the premium brand MANN-FILTER. Various types of air dryer cartridges in original equipment quality are available. MANN+HUMMEL is virtually the only manufacturer of double-layer technology worldwide.

MANN+HUMMEL is not only one of the world’s leading filter manufacturers, but also the world’s largest manufacturer of air dryer cartridges with 100 million units. The figures speak for themselves: The filtration expert produces up to seven million units per year alone in the world’s largest filter plant in Marklkofen, Bavaria. From there, the air dryer cartridges are delivered across the globe. The family-owned company’s brand portfolio includes the global premium filtration brand MANN-FILTER with its comprehensive range of air dryer cartridges in original equipment quality.

In trucks, buses, and tractors, various vehicle systems are operated with compressed air, including the brake system. Operational safety is paramount. This applies in particular to the compressed-air system, which must be dry, free from oil, and clean. The reason for this is that moisture in the compressed-air lines can lead to corrosion, icing and abrasion, causing high repair costs and also reducing the brakes‘ output. Air dryer cartridges from MANN-FILTER reliably dehumidify and clean the compressed air in compressedair systems.

Various air dryer cartridges available

MANN-FILTER currently offers three different types of high-quality air dryer cartridges that differ in their functionality as well as appearance: A white version as a standard solution for optimal drying performance, a silver box with a coalescing filter for improved system protection against harmful oil droplets, and a gold premium version with additional, staged drying and optimized oil separation for maximum protection in the toughest operating conditions.

For more than 30 years, the Ludwigsburg-based filter manufacturer has been producing air dryer cartridges in series production for well-known system suppliers worldwide and thus for almost all truck manufacturers.

Premium for the highest demands in the toughest operating conditions

Specialized vehicles, such as city buses in stop-and-go traffic, refuse collection vehicles, and tractor-trailers in ports, are exposed to extreme operating conditions. The intensive use of the brake system, air suspension, door controls, etc. leads to a high demand for compressed

air. The compressor runs more frequently and is therefore subject to more abrasion to meet this demand. This, in turn, increases the amount of oil droplets penetrating the system, which represents a hazard that must not be underestimated and may lead to malfunctions of the system components. All systems require dry, clean, and oil-free compressed air to operate properly.

MANN+HUMMEL has developed the MANN-FILTER premium cartridge for these tough operational conditions. It combines an air dryer and oil separator in a single unit and thus ensures the highest drying performance with efficient oil separation.

In all three versions, MANN-FILTER relies on an openpore desiccant with high drying performance that is also used as original equipment. With its large active surface, it adsorbs large quantities of water while remaining mechanically stable. Thanks to its great adsorption capacity under pressure, the desiccant can optimally adsorb and bind the air humidity that has penetrated the system. One gram of desiccant has an active surface area of up to 700 square meters. An average truck uses about one kilogram of desiccant, which corresponds to an area of around 100 soccer pitches.

the only manufacturer of double-layer technology worldwide

MANN+HUMMEL is virtually the only manufacturer in the world that uses so-called double-layer technology for its air dryer cartridges. This technology is based on the positive properties of two different desiccant layers with different moisture absorption capacities. It consists of a layer of water-stable silica gel and a molecular screen layer. This combination improves the drying performance by making optimal use of the respective absorption capacities and provides additional protection against sudden water penetration caused by condensation. The excellent adsorption properties of the individual layers are specially adapted to the varying humidity levels along the direction of flow.

High levels of component strength and corrosion protection

MANN+HUMMEL uses high-quality steel from renowned manufacturers for its screw-on and spin-on cartridges. This results in a robust component with high pulsation and burst pressure resistance as well as comprehensive corrosion protection. Air dryer cartridges are exposed to

high pressures and frequent changes in pressure, with all the associated mechanical loads. All components are therefore manufactured exclusively from materials that have successfully passed MANN+HUMMEL‘s demanding tests and approval processes. MANN-FILTER products are subjected to the same stringent approval tests as original equipment parts.

Coalescing filter separates the smallest oil droplets

The silver and gold air dryer cartridges both have a coalescing filter that effectively retains fine oil droplets – in addition to the standard drying and particle filtration functions. The smallest oil droplets are merged to form large droplets and effectively filtered from the compressed-air system. This extends the service life of the compressed-air and brake system components, reduces service costs and shortens downtimes.

Innovative strength

MANN+HUMMEL has been granted several patents by the German Patent and Trademark Office as well as offices in other countries for the premium cartridge technology. This solution is one of the filtration expert’s more than one hundred patent applications each year, with a patent pool of over 4,600 patents. Under the MANN-FILTER brand, customers on the independent aftermarket benefit from this innovation in the usual original equipment quality.

Regular replacement is pivotal

Like any other filter, the air dryer cartridge must be replaced regularly in line with the replacement intervals specified by the vehicle manufacturer. Upgrading a standard cartridge to a cartridge with a coalescing filter is easy and improves the protection of systems operated with compressed air – especially the brake system –using basic means.

Always the right solution

With 15 different air dryer cartridges in original equipment quality, MANN-FILTER offers solutions for 98 percent of the existing truck and bus fleet in Europe.

MANN-FILTER – Perfect parts. Perfect service. www.mann-filter.com

The TRUCKSTAR® LED | H7 – 24 is ams OSRAM’s first road-approved 24V LED H7 lamp for low and high beam.

· ams OSRAM offers a wide range of main and additional headlights for large vehicles, each designed to improve visibility on the road.

Intelligent accessories ensure that even minor breakdowns, such as a flat battery or loss of pressure in a tire, can be easily rectified by the driver.

Commercial vehicles are not only larger and heavier than cars, they also face tougher demands in terms of difficult traffic situations and longer hours of nighttime driving. And that also obviously applies to their lighting. ams OSRAM is therefore launching the TRUCKSTAR® LED H7, a retrofit solution for low- and high-beam headlights which has been specially developed for trucks and commercial vehicles. State-of-the-art LED technology provides increased visibility and greater safety. Vehicles that have the complete package including powerful LED additional headlights and smart on-board tools will be ideally equipped for the demands of the road.

Robust, bright and reliable –TRUCKSTAR® LED | H7 – 24V.

ams OSRAM’s first road-approved 1 24V LED H7 lamp for low and high beam will enable trucks and commercial vehicles to pierce the darkness. With its impressive day-like color temperature of 6,000 K, this cold white retrofit LED lamp is up to 230 percent brighter while producing 50 per-cent less glare 2 . The lamp has a vibration-resistant design and will also last up to five times longer thanks to the LED technology 3. With its leading-edge LED technology, ams OSRAM is setting new standards in high- and low-beam headlights for trucks, buses, emergency vehicles and haulage vehicles.

More light: additional headlights for commercial vehicles

Additional headlights provide light suitable for a variety of situations, either on-road or off-road, on rural lanes at night or on forest paths. The headlights in the Functional series, for example, offer the reliability needed in such cases. An LED headlight such as the OSRAM LEDriving Lightbar FX1000CB SM GEN 2 has a range of up to 635 meters, creating ideal illumination over a wide area. The additional headlights are designed to deliver long-range focused illumina-tion as well as broad illumination close to the vehicle. These ECE-certified additional LED head-lights do not need to be registered or entered in the vehicle documentation. They may be in-stalled in compliance with the relevant installation and operated on public roads.

The OSRAM LEDriving Lightbar VX1000-CB DR SM headlight delivers up to 10,100 lumens with uniform distribution. 84 high-performance LEDs create a beam of light with a range of up to 385 meters. This product combines focused high-beam distribution with excellent near-field illumination. High-quality materials such as the aluminum housing and the sturdy polycarbonate cover make the OSRAM LEDriving Lightbar VX1000-CB DR SM particularly lightweight yet robust and durable. It is therefore ideal for mounting on cars, trucks, agricultural machinery, commercial vehicles, construction vehicles, caravans, off-road vehicles and quad bikes.

Battery charger always on hand

Even the best vehicle lamps are of no use if there is no juice left in the battery. To avoid this problem on the road, ams OSRAM has developed the OSRAM BATTERYcharger 908, a smart 8A charger and battery maintenance unit for 12V to 24V vehicles such as most cars, vans and small trucks. It is the easy way to start a 7-stage charging cycle for lithium batteries and a 9-stage charging cycle for lead-acid/AGM batteries to bring them back to full

power. The built-in digital display shows the current charge level, even in low light conditions. As well as the battery charger, it is useful to have a booster cable in the vehicle. The STARTcable 1200A provides a quick and easy way to be back on the road again if the battery is flat.

Well equipped: products for every situation

A good flashlight is essential for working in low light conditions. The LEDinspect WEARABLE NECKLIGHT leaves both hands free. This rechargeable neck light has two individually detach-able flashlights and is perfect for working in and on the vehicle. Either of the flashlights can be used to illuminate areas that are difficult to access. It has two light settings of 265 lm (high) and 130 lm (low) and can be adjusted through 90 degrees for a variety of tasks. To ensure it does not run low on power it is best also to have an OSRAM POWERinvert PRO in the vehicle. This high-quality inverter is a clever product that connects directly to the vehicle battery and converts the 12V or 24V from the battery into 230V AC so that small devices and even laptops can be powered directly from the vehicle.

1 Approved LED vehicle light. Applies only to countries in which approval has been granted or for which a comparable approval applies, and to vehicle models and lighting functions currently indicated in the compatibility list. For more details go to http://www.osram.com/nb-led.

2 Compared to the minimum requirements of ECE R112, while glare is up to 50% below the maximum permissible values

3 Compared to traditional halogen lamps.

The VIPAR Heavy Duty Family of Companies is pleased to host the 2024 IMPACT Conference at the JW Marriott Marco Island in beautiful Marco Island, Florida, October 21-25, 2024. VIPAR is looking forward to connecting with the community for a productive week of programming including a Supplier Meeting, Trade Show, 1:1 Meetings, ample time for networking, and more. Power Heavy Duty Members will again be invited to the IMPACT Conference, bringing together all distributors at the network-wide Trade Show during the marquee event. With the VIPAR Heavy Duty Family of Companies now represented by nearly 1,000 points of distribution across North America, it’s a great time to be in the heavy duty truck parts business.

Showcase the products at the network-wide Trade Show attended by VIPAR Heavy Duty and Power Heavy Duty distributors!

Pre-scheduled 1:1 Meetings offer valuable dedicated time with VIPAR Heavy Duty distributors all in one place, at one time.

Enhance existing relationships and establish new friendships at numerous networking events and activities during the week.

When business is done, take in the beautiful scenery, enjoy an activity, or explore the many wonderful restaurants located on the island.

In heavy commercial vehicles with multiple-steered front axles or rear axle steering, the hydraulic steering system is supported by working cylinders. This eases the turning of the wheels and improves the vehicle’s directional stability. In particular, working cylinders are used in vehicles with very high axle loads or a high degree of maneuverability. These include, for example, concrete mixers, buses, refuse collection vehicles, agricultural and construction vehicles. The Bosch range of working cylinders includes over 125 part numbers in original equipment quality. As a high-quality alternative for repairs in line with the vehicle’s current value, a large number of the working cylinders are also available in the Bosch eXchange program.

High vehicle coverage with over 125 part numbers

High availability helps to ensure that commercial vehicles are quickly back on the road

Quality and reliability according to the same standards as for original equipment parts

The Bosch program includes working cylinders for commercial vehicles from the following manufacturers:

◾ ASTRA

◾ DAF

◾ Demag

◾ ENASA

◾ ERF

◾ FIAT

◾ Foden

◾ Ford

◾ GROVE

◾ Gräf & Stift

◾ Hestair

◾ HanomagHenschel

◾ Hyundai

◾ IVECO

◾ Leyland

◾ Magirus-Deutz

◾ MAN

◾ MercedesBenz

◾ Paccar

◾ Renault

◾ Scania

◾ Sisu

◾ Seddon Atkinson

◾ Steyr

◾ Tatra

◾ TITAN

◾ Volvo

◾ Youngman

◾ Auwärter

◾ BMC

◾ Coles

◾ ENASA

◾ Foden

◾ Hyundai

◾ Irisbus

◾ IVECO

◾ Leyland

◾ Magirus-Deutz

◾ MAN

◾ MercedesBenz

◾ Neoplan

◾ Renault

◾ Scania

◾ Sisu

◾ Seddon Atkinson

◾ Steyr

◾ Tatra

◾ TITAN

◾ TEMSA

◾ Viseon

◾ Volvo

◾ Youngman

◾ Demag

◾ Fendt

◾ FIAT

◾ FIAT OM Carrelli Elevatori

◾ Foden

◾ Ford

◾ Hestair

◾ HanomagHenschel

◾ Leyland

◾ Magirus-Deutz

◾ MAN

◾ MercedesBenz

◾ MANNESMANN DEMAG

◾ MULAG

◾ Porsche

◾ Renault

◾ Sisu

◾ Steyr

◾ TITAN

◾ Terex

◾ Volvo

DISCOVER OUR OEM SPECIFIC PRODUCT RANGE

SCAN

DESIGNED TO MEET THE LATEST OEM SPECIFICATIONS, INCLUDING ACEA E8 AND E11

THE HIGHEST QUALITY BACKED UP BY +110 APPROVALS

COVERING THE LATEST GENERATIONS OF TRUCKS AND BUSES

As proven in previous years, ETRC championship is the best platform to promote all N! Truck community to the Truck industry.

Next ETRC Truck racing weekend in Misano, Italy on 25-26 May

NEXUS x Garrett Racing Team will attend 6 racing weekends during 2024 season:

● May 25 - 26: Misano (ITA) sponsored by PASCOLI S.P.A.

● June 8 - 9: Slovakia Ring (SVK)

● June 22 - 23: Zolder (BEL)

● July 13 - 14: Nürburgring (GER)

● September 28 - 29: Le Mans (FRA)

● October 5 - 6: Jarama (ESP)

Racing Driver presentation: https://lnkd.in/e_WAumY6

Discover all sustainable truck races: https://lnkd.in/eV2KUyAy

Thanks to all our proud sponsors:

A 10-year anniversary event to unveil how NEXUS will continue to be a game-changer and address the challenges of the AA: ‘Building the next decade together’.

As part of celebrating its achievements over the past decade, NEXUS Automotive International hosted its most significant event ever organized, bringing together the largest community gathering in its history. This event comprised over 700 leaders, including 72 global suppliers and more than 400 members.

A very special event took place in Monaco, the temple of Formula 1 racing During the plenary session, N! seized the opportunity to:

● Feed its community with insights from GiPA and Roland Berger experts.

● Display how to strengthen growth and increase the compliance ratio in a global fast changing market.

● Outline the workshop roadmap as a growth accelerator.

● Introduce Smartparts to the N! community.

● Keep maintaining a strong focus on innovation.

● Share Gaël Escribe’s vision for N! for the next decade: He explained the rationale to transform N! ITG into N! Group, positioning it as the leading independent automotive aftermarket group.

The roadmap for future years will focus on 3 pillars:

1. Consolidate NEXUS as a leading ITG and bring the compliance ratio over 50% globally.

2. Develop transactional activities (primarly DRIVE+ related), and make DRIVE+ a leading brand of the global AA by 2030, hand-in-hand with N! best suppliers / partners.

3. Invest in innovative initiatives, as well as providing support for consolidation initiatives undertaken by NEXUS members to strengthen N! footprint in certain regions.

Last but not least, there is no future roadmap without making sustainability a competitive advantage.

A triumphant second edition of the NEXUS Climate Day attracted almost 150 attendees. This included the European association FAAS, the US associations Autocare and MEMA; along with the N! community, representing the entire supply chain, all united for a common cause: sustainability. The NEXUS Climate Day actively pursued tangible solutions, initiatives, and best practices, fostering shared testimonials and insights in order to chart a more sustainable roadmap encompassing all three scopes. Notably, several Proof of Concepts (POCs) were initiated between key suppliers and members, evolving into new NEXUS standards. These included founding partners: Bosch, Delphi/Phinia, Mahle, Schaeffler, SKF, TotalEnergies & Valeo with the support of Bilstein, Elring, KYB, Mecafilter, Mobilion, NTN-SNR, NRF & Smartparts.

We were delighted to gather N! community in Monaco for this very unique edition of the Business Forum. This event provided an opportunity to reaffirm that the AA has a bright future ahead and to emphasize the necessity to draw a sustainable roadmap for our industry!”

Gaël Escribe

2’700 speed dates meetings and workshops were organized to facilitate connections within the community and accelerate business opportunities, addressing key topics and fostering discussions among members of the N! Community.

The NEXUS 10-Year Anniversary Gala dinner ceremony took place at the Salle des Etoiles on Wednesday evening. Maxime Picat, Chief Global Purchasing & Supply Chain Officer in Stellantis, was presented with a 10 years Excellence Award.

Regarding the annual 2023 awards, Ferdinand Bilstein was awarded Supplier of the Year and Mahle (HD Supplier of the Year), Automotive Parts Services Group & GSF Members of the Year, Autos (HD Member of the Year).

Leader in engineering and production of OE HD tensioners. OE HD belts designed for diesel grade HD applications. High performance and reliability. The preferred partner of the most important OE truck brands and engine equipment.

...yes we have!

Welcome to PHINIA, where we’re passionate about commercial vehicles and the aftermarket. With a robust line-up of brands— including Delphi, Delco Remy® (Delco Remy® is a registered trademark of General Motors LLC, licensed to PHINIA Technologies Inc.) and Hartridge—we deliver advanced, tailored aftermarket solutions for a diverse range of commercial vehicles.

PHINIA’s approach to the commercial vehicle aftermarket segment is not just about providing parts—it’s about offering a complete solution that includes advanced diagnostics, training, and unparalleled technical support.

We are dedicated to innovating and adapting to the evolving needs of the commercial vehicle market. Our focus is ensuring that your vehicles operate seamlessly, allowing you to enjoy all the benefits for your business while maintaining dependable and environmentally friendly trips.

Delphi is a leader in powertrain and aftermarket technologies, offering robust solutions for the commercial vehicle industry. Here’s a closer look at how Delphi stands out:

EURO 6 REPAIR PROGRAMME

NOx SENSORS

WORKSHOP SOLUTIONS: DIAGNOSTICS & TRAINING

Delco Remy is a name synonymous with quality and reliability in the commercial vehicle industry and has been a market leader for over 125 years. Delco Remy products are the go-to choice for commercial trucks, buses, and off-highway applications across the globe.

STARTERS

ALTERNATORS

BENCHMARK IN TESTING AND REPAIR

Backed up by over 90 years heritage & OE engineering standards, the Hartridge portfolio has a diverse range of solutions to serve diesel and gasoline technologies.

HK1500

AVM2-PC

CRi-PRO TEST BENCH

● Leveraging the strengths of both companies, Stellantis and NEXUS Automotive International SA enter a strategic global partnership that aims at creating a highly competitive, 360° offer, combining spare parts, and aftersales services around the world.

● Stellantis strengthens its position in several regions entrusting NEXUS members consistently with the established distribution model in the countries. Parallelly, NEXUS enlarges its community with distribution companies under Stellantis ownership.

● Companies intend to develop a global framework designed to accelerate and expand global sales by leveraging Stellantis’ extensive product and services offering and NEXUS’ aftermarket know-how around the globe.

AMSTERDAM & GENEVA, March. 6th, 2024 - Stellantis and NEXUS announced today their strategic and innovative business partnership. The partnership aims to further boost Stellantis’ aftersales brands while leveraging NEXUS’ established global distribution presence to significantly accelerate in the independent aftermarket channel, starting with North America, Middle East, and Asia Pacific.

NEXUS members will access Stellantis’ 360° product & services offering that is complementary to their current portfolio, bringing more extensive and affordable solutions to global customers, consistently with the established distribution model in the countries (Selective Distribution, Authorized dealers).

This transformation from a conventional car maker and IAM leader to a more innovative and win-win partnership aligns with both Stellantis’ and NEXUS DNAs and long-term goals. The purpose of Stellantis is to “Lead the way the world moves” bringing clean, safe, and affordable mobility solutions as well as providing a full range of parts & services to create a lifetime relation with its customers and drivers.

Being the leading AA community in the world and having an extremely progressive mindset, it is crucial to establish business relationships with leading players of the global automotive aftermarket.”

As a growth accelerator, N! aims at shaping the aftermarket mobility of tomorrow and providing new business opportunities to its members. This partnership also brings the possibility to further explore mutually beneficial synergies. These may include global purchasing consolidation, digitalization projects, leveraging both companies’ distribution footprint and commercial know-how, and also mobility solutions and circular economy initiatives. It will enhance the sustainability of their business model. This partnership also greatly expands the options Stellantis and NEXUS customers will have in a purely customer centric approach.

“This agreement is part of a global development initiative, in full coherence with our authorized repairers and Eurorepar Car Service network activity. Leveraging NEXUS’ community and footprint and Stellantis’ 360° product offering will reinforce our positions and strengthen our growth in line with our Dare Forward 2030 strategic plan goals. We are delighted to announce the ratification of this partnership with NEXUS that will benefit both our companies.” Said Sylvie LAYEC, Senior Vice President for Global Sales and Marketing at Stellantis Parts and Services.

“Being the leading AA community in the world and having an extremely progressive mindset, it is crucial to establish business relationships with leading players of the global automotive aftermarket. Shaping-up a fruitful roadmap for both Stellantis and NEXUS provides a lot of benefits to our respective companies and will help us to design the automotive aftermarket of tomorrow” said Gaël Escribe, CEO of NEXUS Automotive International.

DENSO is a world leader in the design and manufacture of original equipment (OE) alternators and starters for vehicle manufacturers across the globe, a specialism it delivers to the passenger car, light commercial vehicle and heavy duty sectors

Among the numerous criteria required to supply these products to such demanding customers, is the ability to manufacture them to stringent standards and precise specification, and then to thoroughly test them to ensure their durability and reliability.

Nowhere is quality and performance more important than in the heavy duty sector, where vehicle breakdown and unscheduled downtime is so costly, not only financially, but in terms of missed delivery deadlines, for example. DENSO’s heavy duty alternators and starters are therefore engineered to survive and thrive in the harshest of conditions and the extreme operating environment of the engine bay.

In addition, as DENSO produces its alternators or starters on the same production lines, irrespective of whether they are destined for OE or aftermarket channels, the independent service and repair sector can have complete confidence in installing these components when carrying out product replacement.

Designed to deliver higher output at lower RPM and with a corrosion resistant rectifier and rotor, DENSO’s 24-volt heavy duty brushless alternator, which features high load rated front and rear bearings to provide greater durability, also has compact dimensions, meaning it’s easy to fit, another factor that helps to minimise unproductive downtime. Its brushless construction contributes to its heat enduring ability and this, combined with its many other qualities, ensure its reliability and earns it the industry’s lowest returns rate.

Available with either a J180 or pad mount, the DENSO 24-volt heavy duty brushless alternator comes with outputs of 95 or 150 amps, although both specifications deliver 20 amps at engine idle, making them highly efficient, as well as robust and durable

Further details can be found in the full product bulletin here:

Oliver Stahnke, Sales Manager, BorgWarner, Inc. discusses what sustainability means to the company and explains the part that remanufacturing plays in achieving sustainability goals.

Long before sustainability became a popular mainstream concept, BorgWarner developed a vision of a clean, energy-efficient world – and today we’re still committed to being a sector leader in this regard. While the vision hasn’t changed, our sustainability strategy now drives a wide range of environmental and social initiatives intended to benefit all of our stakeholders.

There are a number of ways in which we’re advancing our environmental stewardship. It begins with our products – we’re constantly expanding our electrification offerings to improve efficiency and reduce emissions. It also extends to our global operations; as we create a new facility, or expand a site, or update one of our existing factories to accommodate business growth, environmental sustainability is at the forefront of our planning. Projects already implemented across our global plants include installing solar panels, converting to low-friction compressed air supplies, employing heat recovery systems on air compressors, installing more energy-efficient lamps, treating, and reusing wastewater, and sourcing 100% renewable electricity. These actions have already contributed to a CO2 equivalent reduction of more than two thousand metric tons and a reduction of roughly four gigawatt-hours of electricity usage.

Social responsibility is essential to the sustainability of BorgWarner operations if we’re to continue to succeed long into the future. That’s why we’re nurturing the talent pipeline – for example, we have a specialized

training program called ‘Power to Evolve’ that enables our engineers to acquire the new hands-on skills and expertise needed to work on electric drive systems. It’s also why we continually strive to create and maintain a diverse and inclusive working environment, where our people enjoy harnessing their collaborative power to achieve excellence.

Before explaining how remanufacturing contributes to our sustainability goals, it’s perhaps useful to summarize how we go about the process. We separate the individual components of a used part into those that must always be replaced – such as bearings – and those that can potentially be reused. The latter are cleaned, then checked against original specifications to ensure they are within tolerance for remanufacturing. We replace components that don’t meet the criteria with new OE items and combine them with the reusable components to complete the parts list for a remanufactured assembly.

We’ve been supporting the circular economy by remanufacturing parts for nearly 30 years, including turbochargers, alternators, generators, electronic unit injectors, and exhaust gas recirculating valves. During that time, we’ve reused more than 24,500 metric tons of cast iron and aluminum. Our turbocharger remanufacturing program alone has saved some 5.2 million turbines, compressor housings and bearings from landfill. Across our product lines, approximately 36% of our input in 2022 came from recycled or remanufactured material.

We’ve made significant progress towards our sustainability goals over the past two years, despite significant headwinds and market volatility. In 2021, we announced our Charging Forward strategy, designed to increase production of electric and other vehicle parts that enable zeroand lower-emissions transportation – and in 2023 we invested approximately 19% of net eProducts sales into eProducts R&D to maintain our position at the forefront of electric vehicle technology. The rapid gain in momentum means we now expect to achieve our 2025 goals well ahead of schedule, so we’ve evolved our strategy to Charging Forward 2027, which aims to achieve 49% of sales revenue from eProducts by 2027. Our ultimate goal is to achieve carbon neutrality – Net Zero – by 2035.

With the entry of Ford Trucks into the European market in the Year 2019 a new era dawned for Ford. This move strengthen Ford’s presence and influence in commercial vehicle market. Equipped with powerful EcoTorq diesel engines, the Ford F-MAX offers unmatched performance and efficiency, highlighting the company’s commitment to innovation and quality in this sector.

febi is constantly expanding the product range for the Ford F-Max. With our commitment to innovation and OE Matching quality, we’re dedicated to providing you with the best-in-class solutions for the transportation requirements.

Discover our product offer! With over 38 specialized items across key product categories, we’re proud to provide a comprehensive selection for the Ford F-Max. From Drag Links to interior Filter, each item is developed on highest quality standards.

Paired with its luxurious interior and cutting-edge technological features like adaptive cruise control and lane-keeping assist, the F-Max redefines what it means to drive in comfort and style. febi 185528

Diesel Particulate Filters (DPF) remove over 99.9% of harmful particles from the exhausts of Euro VI trucks, but to remain functional they need to be cleaned from time-to-time. Most workshops offer simple 2-stage cleaning, but the advantages of a full 3-stage Reconditioning is worth noting.

As the filter traps particles and soot, and incinerates it during regeneration, a layer of ash starts to form. Over time, the layer grows and obstructs free flow through the filter and, more importantly, shades the catalytic coating on the filter’s surface and reduces its ability to passively regenerate. As back pressure increases, engine-controlled active regeneration occurs more frequently. The ash-layer hardens due to extreme temperatures, and all together the engine’s fuel efficiency reduces.

Eventually, the engine says: “STOP!” and lights up the DPF warning symbol, telling you it’s about time for filter service.

How is Reconditioning different?

During a regular 2-stage cleaning the DPF is heated up to loosen ash, and then flushed using pressurized air or hot water. It’s a cheap & simple method, but unfortunately ineffective with hardened ash, and usually requires a downtime of 24-48 hours – unless the workshop has a spare DPF.

A 3-stage cleaning adds Reconditioning as an additional step, during which hardened ash is removed using a chemical solvent in an ultrasonic bath. This removes up to 90% more ash than a simple 2-stage cleaning, and “re-activates” the catalytic coating, restoring the filter to nearly new condition.

It also takes more time, but thanks to a core exchange cycle where used filters are looped in, refunded, and a reconditioned

replacement is purchased. Following this work, truckers can be back on the road in less than an hour.

What’s in it for you?

Longer Cleaning Intervals: A 2-stage cleaned DPF is expected to have a 30% shorter cleaning interval than one which is brand new – or a 3-stage reconditioned – saving workshop visits, downtime and service costs. Better Fuel Efficiency: With a better flow and improved ability to passively regenerate, a recon-DPF allows the engine to run more efficiently, thus saving on fuel consumption and costs.

Durability: Hardened ash increases mechanical and thermal stress of the DPF. As traditional cleaning fails to remove this, a DPF is rarely expected to endure more than 1.000.000 km of operation, but with reconditioning it is not uncommon to last up to twice as long.

For your business, and our planet

Altogether those 3 advantages may result in cost savings of nearly 2.000€ over a 2.000.000 km cycle. And, as if that weren’t enough, there’s also a fourth advantage, but that’s for the planet - thanks to reduced CO2e-emissions arising from the fuel saving and extended filter durability. Such savings can accumulate to over 3 tons!

Dinex offers an extensive reconditioning program for all European makes and models. Using OE-endorsed equipment and validation procedures and accepting only type-approved filters in our core exchange loop, we’re proud to offer yet another solution: For the industry and our planet.

Choose Haldex range of original spare parts:

More than 3500 items and over 100 years of innovation. Our Product catalogue and Trailer Application Guide are available online to quickly find your products.

Guido Scanagatta, Director of Product Management and Application Engineering, Exide Technologies

The integration of circular economy principles, reverse logistics, and the reduction of emissions and fuel consumption are all vital for mitigating environmental impact and driving cost savings. They are also essential in ensuring businesses comply with regulations compliance – but how do lead-acid batteries play their part? Exide Technologies’ Director of Product Management and Application Engineering, Guido Scanagatta, explains.

Exide Technologies is an original equipment manufacturer (OEM) and global leader in battery storage solutions. It is on a journey towards a sustainable and net-zero future, and has committed to Environmental, Social, and Governance (ESG) practices.

Aligned with global standards and the European Green Deal, Exide Technologies places environmental responsibility and product quality at the forefront of its operations. In line with the company’s claim “Energizing a new world,” it has set ambitious targets, including a 30% reduction in emissions and a commitment to derive at least 20% of its energy from renewable sources by 2030. These targets are crucial steps towards aligning with the European Union (EU)’s 2050 climate neutrality objectives.

The company operates recycling facilities and energy-efficient plants with integrated photovoltaic installations in Portugal and Spain. This demonstrates that Exide prioritizes longevity and environmental responsibility from design and manufacturing through to end-of-life recycling.

Can you elaborate on Exide’s approach to circular economy principles, particularly in relation to the recycling of lead-acid batteries?

Guido Scanagatta: These are exemplified in our lead-acid battery recycling initiatives. Across Europe, we operate three recycling centers, staffed by about 140 employees.

Lead-acid batteries are not only essential power sources but are also completely recyclable. In Europe, 99% of all automotive lead-acid batteries are recycled, with Exide playing a significant role in this process. The batteries undergo the recovery of valuable materials, like lead, sulphuric acid and plastic.

Through our recycling efforts, we conserve natural resources and energy whilst cutting harmful emissions. This approach contributes to environmental preservation and an efficient battery lifecycle, from production to disposal.

Can you explain how Exide collects the used batteries before they’re sent to recycling centers?

G. S.: We operate an efficient battery collection scheme aimed at responsibly managing ‘end-of-life’ batteries. Through trusted partnerships with retailers, workshops, and other collection points, and by collecting the batteries ourselves, we ensure convenient drop-off locations for consumers. Schemes vary depending on the country’s regulations and infrastructure.

How does Exide’s policy specifically impact the commercial vehicle (CV) sector?

G. S.: We have a rich history of pioneering innovative technologies to address sustainability challenges in CV batteries; notably, our collaboration with OEMs which led to the introduction of High Vibration Resistant (HVR) technology in 2008, specifically designed for truck batteries. This, integrated into various products within our automotive aftermarket portfolio, proved pivotal during the transition to Euro 5 and 6 standards. As battery positions shifted to accommodate AdBlue tanks, standard heavyduty batteries faced more intense and also lateral vibrations, leading to premature failures; however, our HVR technology overcame these challenges, resulting in fewer breakdowns, and compliance with stringent EU emissions regulations.

What solutions does Exide have in its Commercial Vehicle battery portfolio?

G. S.: We offer an extensive range of CV solutions - for example, we have the unique Endurance+PRO GEL in our portfolio. This VRLA lead-acid battery is robust and has outstanding deep cycle properties; for instance, it gives a safe Depth of Discharge (DoD) of 90%, which significantly enhances its range and lifetime. By extending the product lifetime, we are promoting fuel and energy efficiency.

Can you highlight some of the key features of the Endurance+PRO GEL battery?

G. S.: We are proud that gel technology was developed by Exide almost 70 years ago, and we think this is the best fit for demanding CV applications. Unlike conventional batteries with liquid electrolytes, our technology fixes electrolytes in a gel. This results in significantly enhanced cycle life. Specifically, our Endurance+PRO GEL battery offers double the lifespan of equivalent AGM batteries and ten times that of an equivalent standard flooded battery.

Designed to withstand deep discharges, the Endurance+PRO GEL battery offers outstanding reliability, even in challenging conditions. With very low self-discharge rates, the lead-acid battery retains its charge for extended periods. This means it’s ready whenever required. Additionally, being maintenance-free, the Endurance+PRO GEL battery requires very little upkeep. This reduces both downtime and operational costs for fleets. Specifically tailored for OE applications, the battery easily integrates into various vehicle models.

For more information about the Endurance+PRO GEL, visit: www.exidegroup.com/eu/en/product/exide-endurancepro-gel

Ideal for use in construction and agricultural machinery & trucks

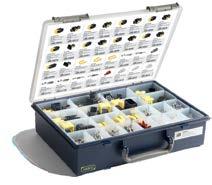

Herth+Buss has expanded its Elparts range with a practical plug-in housing assortment. The range contains 3 to 16-pole receptacles and connector housings of the HDSCS series (Heavy-Duty Sealed Connectors) and consists of 335 parts. The heavy-duty connectors are especially suitable for use in construction and agricultural machinery as well as in trucks, for example, of the DAF, Iveco, MAN, Mercedes-Benz, Scania and Volvo brands.

The range includes 22 different connector types. The scope of delivery also includes crimp connectors, seals and locking devices for connectors with flanges to ensure a secure connection. Workshops thus have everything they need for repairs at their fingertips in the practical range.

Another particularly practical feature is that all individual parts can be reordered separately. To identify the item number of the individual parts, just look at the included insert, which contains all the important information.

The refill packs fit exactly into the respective compartment of the assortment box. This gives workshops maximum flexibility and they only receive the parts that are really needed.

FIND THE MATCHING VIDEO OVER HERE!

The perfect complement: plug-in housing range for MAN and Mercedes Herth+Buss also offers additional plugin housing assortments especially for MAN (art. no.: 54290020) and Mercedes (art. no.: 54290030) truck and bus vehicles. The MAN range consists of 241 parts and contains the most common sockets and housings for MAN vehicles. It can be used to repair various interfaces. The Mercedes range, on the other hand, consists of

136 parts and contains plug-in connectors that are installed in the Actros MP5 from Mercedes-Benz. The focus here is on repairing the plug connection on the fuse relay box. The newly included HDSCS plug-in housing assortment is the perfect addition to the assortments already available!

Assortment, plug-in housings HDSCS

Article number: 54290700

There is a shortage of heavy duty mechanics in Lithuania. Although society has stereotyped this specialty as unpopular due to its difficult and specific work, specialists reveal another reason - our country there is only one vocational school with a separate curriculum for training truck mechanics. In order to motivate the young generation and increase the number of professionals in this field, business representatives need to create new initiatives and establish close cooperation with educational institutions.

Why young people choose a different path

There are many reasons why there is a shortage of heavy duty mechanics in Lithuania. However, the majority of higher or professional schools claim this program is rejected due to its unpopularity. According to school representatives, young people choose a different career direction – that of specialty - passenger car mechanic.

Although there is a large shortage of heavy duty mechanics, there are several initiatives aiming to increase the number of specialists within this field in Lithuania. One of them is the “TruckLab” training initiative, which is coordinated by the “NexusTruck Lietuva” association, which started its activities at the beginning of 2020.

This initiative was established to provide targeted professional training for participants in the heavy duty/commercial transport market.

“The business of heavy duty transport companies and cargo transportation in Lithuania has a very significant value in terms of GDP. A conducted study found that, for example, in the city of Šiauliai, almost a quarter of all residents are directly or indirectly receiving industrial income from cargo transportation - in other words, from the heavy duty market. At that time, there was a great lack of service for heavy duty mechanics”, reveals Remigijus Vaitkus, Director of Development and Innovation of the company “Jupojos technika”, coordinator of the “TruckLab” initiative.”

The interviewer reveals that young people, focusing on the specialization of a car mechanic, do not pay attention to today’s work realities: “A truck mechanic earns much more serious money, and demand for them is huge.”

One of the goals of TruckLab is to popularize the direction of heavy duty mechanics. The aim is to encourage young people who have entered the auto mechanics department to choose the heavy duty transport profile. To help change this situation, close relations have been established with twenty higher and professional schools.

Commenting on the positive changes that have taken place, Remigijus Vaitkus said: “We were faced with the problem that schools didn’t have the good conditions to train specialists - there was either no literature or it was outdated, as well as a lack of training tools. Therefore, in order to enable schools to teach, we gave them such tools to be able to do so. Special classrooms have been equipped with learning equipment and trainings are

held. We can see that things are improving, with schools at least adding a heavy duty vehicle mechanics module to the curriculum. In this way, the little touches on the intricacies of the truck mechanic specialty are making a significant difference. Schools are now encouraging future specialists to do internships not only in car repair shops, but also in heavy machinery.”

“The companies that make up the association “NexusTruck Lietuva” provide schools not only with educational materials, but also with various specific parts of trucks.”

“Schools in cities do better because there are businesses that want to contribute towards the training of young professionals. I’m not just talking about financial support, but in terms of tangible, practical support. For example, companies invite schoolchildren to their workshops, show them how truck repair work is actually done. However, the situation is worse in smaller towns. In general, the educational materials of many schools are about Soviet trucks”, reveals the coordinator of the “TruckLab” initiative.

One of the tools is a competition

The finals of the “Young Truck Mechanic” competition took place on December 5.This was another initiative to popularize the profession of heavy duty mechanics. This year, 290 participants from 17 Lithuanian higher and professional schools competed in the competition. According to the organizers of the contest, 6 prize packages were distributed and 49 participants competed in the final.

Remigijus Vaitkus explained: “The remote competition is organized on the principle of questions, where participants have the opportunity to choose the correct answer. Comments are an important part of the questionnaire. When students choose an incorrect answer option, they receive an explanation to understand how it really is. So this competition is educational at the same time.”

The organizers said that during the competition final, observers - partners of the association “NexusTruck Lietuva” - are sent to the educational institutions whose students participate in the competition. The mission of the latter is to ensure the transparency of the competition and bring business representatives closer to educational institutions

The winner of the 2023 “Young Truck Mechanic” competition was Gantas Brazaitis, a second-year student at Alytus College. This future specialist does not hide the fact that this award is a big surprise to him.

“I did not expect to achieve such good results, but I am very happy about it. Not only myself, but the whole college is happy. I participated as I felt motivated by the competition and, of course, the teachers encouraged me. And winning is an important result of this work.”

Gantas, who is a student of automotive transport engineering, admits he is not yet sure what kind of technology he will work on in the future. However, he has no doubt that the knowledge gained during the competition will be useful.

During the competition, not only is the future specialist category awarded, but also an award for the school whose representatives performed the best in the competition. This year, Klaipėda State College won this. The educational institution delegated 11 students to the competition this year, with two of them making it into the top three winners.

Jūratė Liebuvienė, representative of Klaipėda State College, told journalists: “This is a great appreciation to both the entire college community and the Department of Transport Engineering. We are proud of our students. Although we do not train heavy duty transport specialists, we integrate educational material about it into some lectures, and we also invite students to do internships at companies that repair heavy duty vehicles. As of today, we can see that the result is there.”

The head of the Department of Transport and Engineering is happy with the initiative that this competition brings and says that it is an excellent example of a partnership between business and educational institutions. In J. Liebuvienė’s opinion, the number of participants in the competition should increase next year, as this year’s results and the prizes won will inspire and motivate the youth.

Žilvinas Plikūnas, a member of the “NexusTruck Lietuva” Association and CEO of the “Kelio servisas Panevėžyje” service, emphasizes the importance