Rubia EV fluids are developed with major R&D efforts and tailored technical solutions to address the new electrical, thermal and friction constraints of hybrid and electric vehicles.

As a trusted partner to heavy duty manufacturers, TotalEnergies Lubrifiants aims to become the responsible energy company to deliver technical, people-oriented solutions and sustainable performance. Our goal is to promote cleaner mobility that is better for both people and the environment.

lubricants.totalenergies.com

FEU VERT, ELECTRIC VEHICLES: A CHALLENGE FOR OUR WORKSHOPS

COPPOLA, RIDING HIGH: OBSERVATIONS ON THE DEVELOPMENT OF CHINA’S NEW ENERGY VEHICLE MARKET

DIAGNO, ELECTRIFICATION OF THE VEHICLE FLEET IN FINLAND – NEW TECHNOLOGY REQUIRES NEW SKILLS

GiPA, DRIVING CHANGE: HOW BEVS ARE RESHAPING EUROPE’S AUTOMOTIVE FUTURE

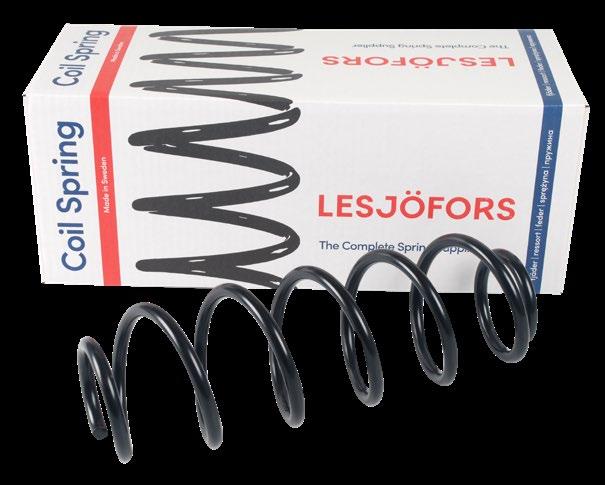

LESJÖFORS BECOMES

FIRST SPRING MANUFACTURER TO BE VALIDATED BY SBTI

NOW AVAILABLE FOR THE AFTERMARKET: BORGWARNER ENGINE TIMING SYSTEMS

ZF AFTERMARKET DOUBLES ITS ZF LIFEGUARD RANGE OF E-FLUIDS FOR ELECTRIC AND HYBRID POWERTRAINS

VALEO INEEZ CHARGING CABLES AND MOBILE CHARGERS

INSIDE 36 | JUNE 2024

NEXUS IN ! SIDE MAGAZINE is published by NEXUS Automotive International, Geneva, Switzerland.

NEXUS Automotive International SA Chemin du Château-Bloch 11 1219 Le Lignon | Geneva | Switzerland T +41 22 306 49 50 www.nexusautomotiveinternational.eu

ams OSRAM, the market leader in automotive lighting, is launching its first street-approved1 LED retrofit lamps for motorcycles. Motorcyclists can now upgrade their old halogen lamps legally, easily and cost-effectively with the NIGHT BREAKER® H4-LED and H7 GEN2-LED. They will then be able to see and be seen better at all times –especially at night.

The award-winning OSRAM NIGHT BREAKER® family is already a firm favorite among motor-ists. Motorcyclists can now also experience the benefits of the product range. NIGHT BREAK-ER® LED is the simple choice for upgrading low beam and high beam to state-of-the art LED technology. They are ideal as replacements for conventional halogen lamps and bases.

The NIGHT BREAKER® LED for motorcycles produces bright white light with a color temperature of up to 6,000 Kelvin. The product is up to 230 percent brighter than conventional lamps , while reducing glare by 50 percent2. What’s more, the NIGHT BREAKER® LED consumes up to 55 percent less energy than conventional lamps and will last up to five times longer thanks to LED technology and the specially developed vibrationresistant design.

The NIGHT BREAKER® H4, H7 GEN2-LED for motorcycles are approved for various models of the manufacturers Kawasaki, BMW and KTM. A list with all approved motorcycles can be found under the link below.

ams OSRAM is constantly working on wider approval of the NIGHT BREAKER® LEDs. In addition to motorcycles, the retrofit lamps are available for a variety of contemporary cars, classic cars, trucks and motorhomes. This is yet another way in which ams OSRAM is making an important contribution to road safety.

1 These offer up to 230 percent brighter light and 50 percent less glare compared to the maximum permissible thresholds of ECE R112

2 Compared to traditional halogen lamps

Join ams OSRAM social media channels:

CHOOSE MAGNETI MARELLI CHECKSTAR FOR HYBRID OR ELECTRIC CARS

Our workshops offer original spare parts and qualified professionals authorized to work on latest-generation motors.

WELCOME FROM THE CEO

Gaël Escribe, CEO NEXUS Automotive International

INSIDERS

FACING THE ELECTRIFICATION

• Riding High: Observations on the Development of China’s New Energy Vehicle Market, Wang Hao, Founder CEO, Coppola Automotive Consulting Services (Qingdao) Co.Ltd • Electrification of the Vehicle Fleet in Finland – New Technology Requires New Skills, Juha Seppälä, CEO, Diagno Finland • Feu Vert, Electric vehicles: a challenge for our workshops

• Driving Change: How BEVs Are Reshaping Europe’s Automotive Future, Amuldena Benedito, CEO, GiPA • N! Service, EVOLT! Workshop Concept: Revolutionizing Workshops for Electric and Hybrid Vehicles

INSIGHTS FROM THE AFTERMARKET WORLD AND BEYOND

• Now available for the Aftermarket: BorgWarner Engine Timing Systems, Borg Warner • Gates e-start start/stop technology: the automotive world is evolving faster than ever, Gates • Lesjöfors becomes first spring manufacturer to be validated by SBTI, Lesöfors • Valeo Ineez charging cables and mobile chargers, Valeo • ZF Aftermarket doubles its ZF Lifeguard range of E-Fluids for electric and hybrid powertrains

The Automotive Aftermarket industry is currently facing multiple challenges: consolidation, digitalization, and sustainability. In this new edition of INSIDE Magazine, let’s focus on electrification.

The somewhat seismic dimensioning of this change, as described before Covid, deserves to be reviewed. Additionally, in the immediate future, the aging of the fleet will greatly attenuate the emergence of EVs in certain regions.

INSIDE is more than just a publication; it’s a platform for collaboration, inspiration, and action. We aim to provide a comprehensive exploration of this electrifying landscape, offering the latest figures, insights, analysis, and thought-provoking perspectives from industry experts, policymakers, and innovators.

Now, enjoy the reading of INSIDE Magazine n°36. We invite you to join us on this electrifying journey as we navigate the opportunities and challenges of the electrification revolution together.

With best regards,

Gaël Escribe CEO of NEXUS Automotive International

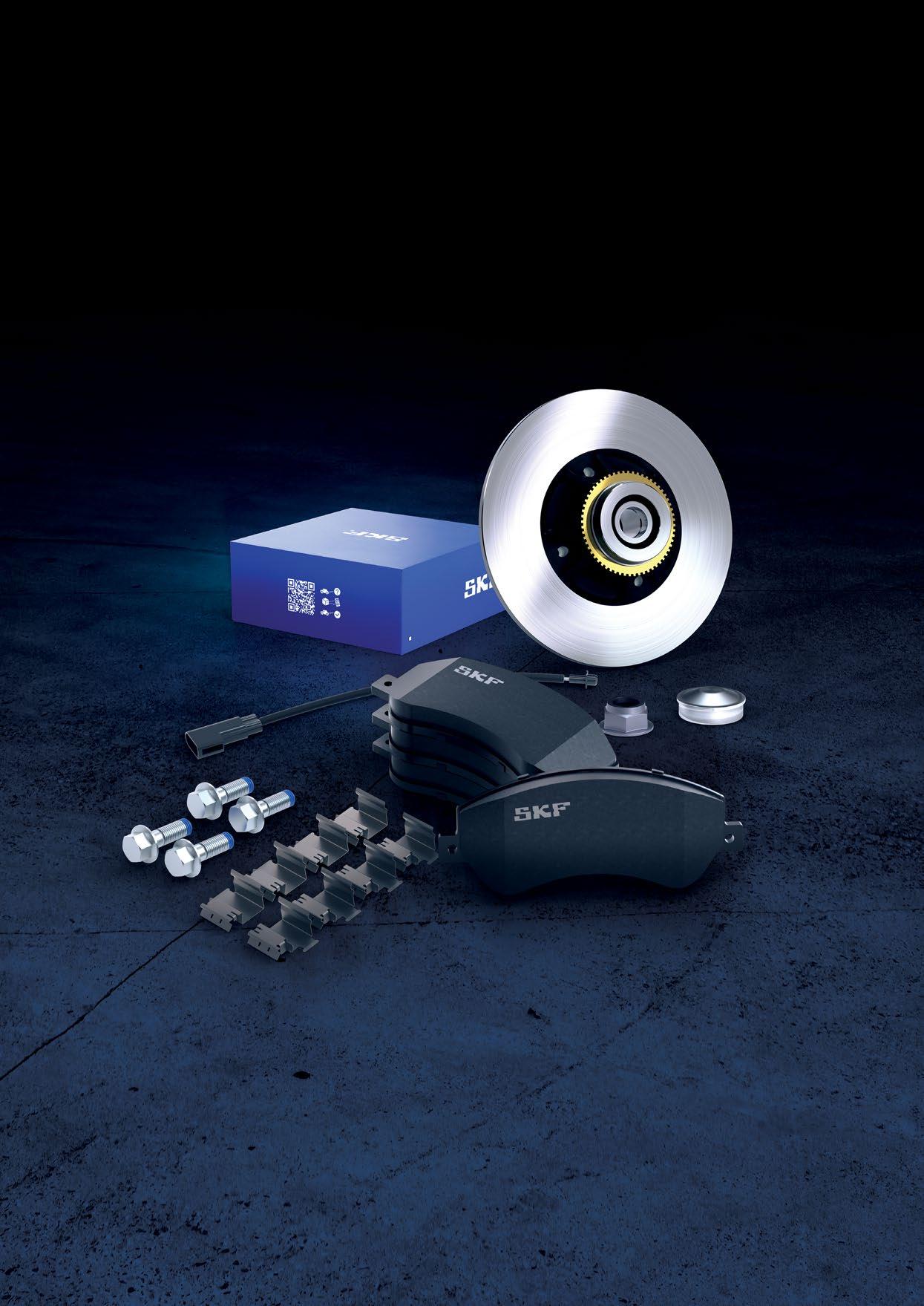

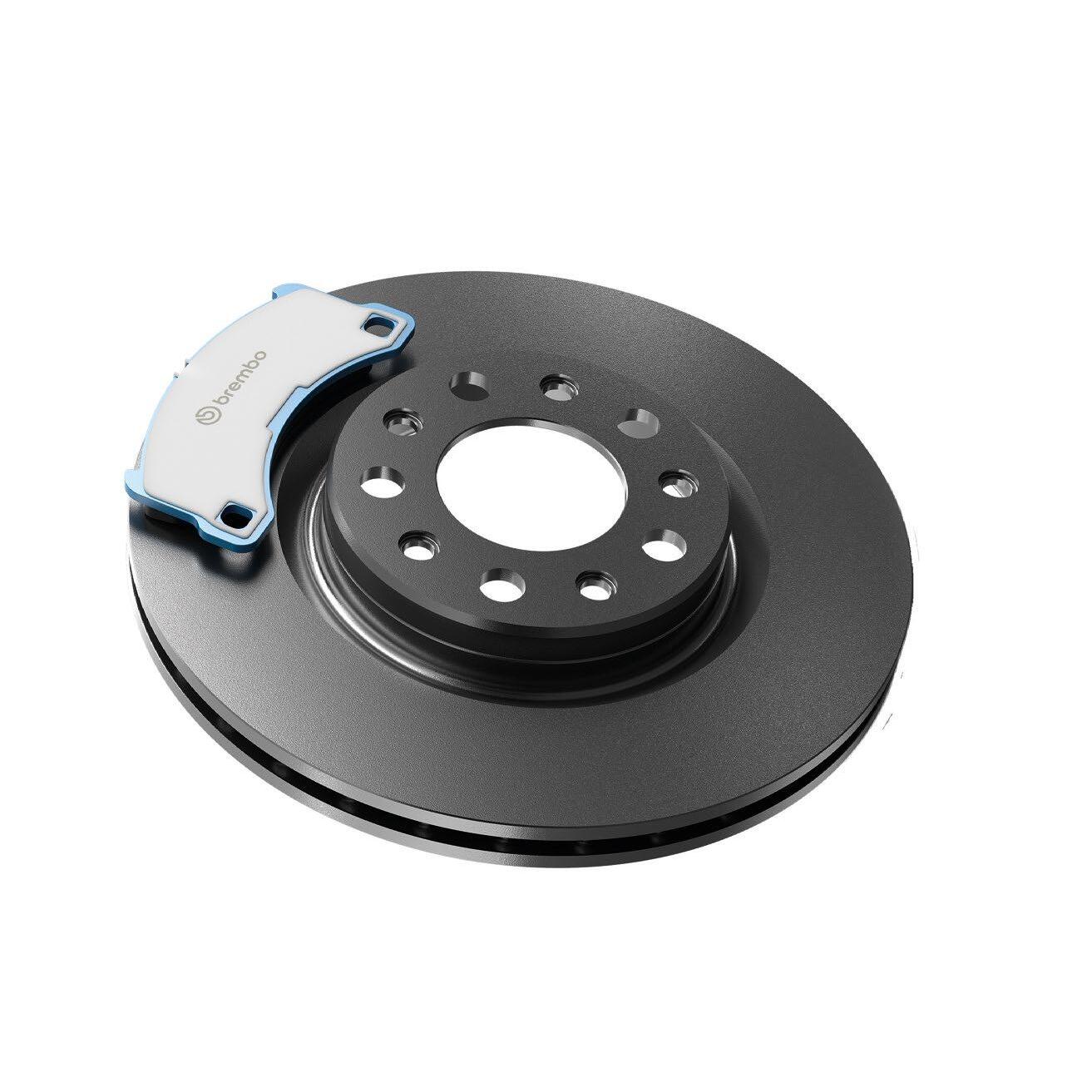

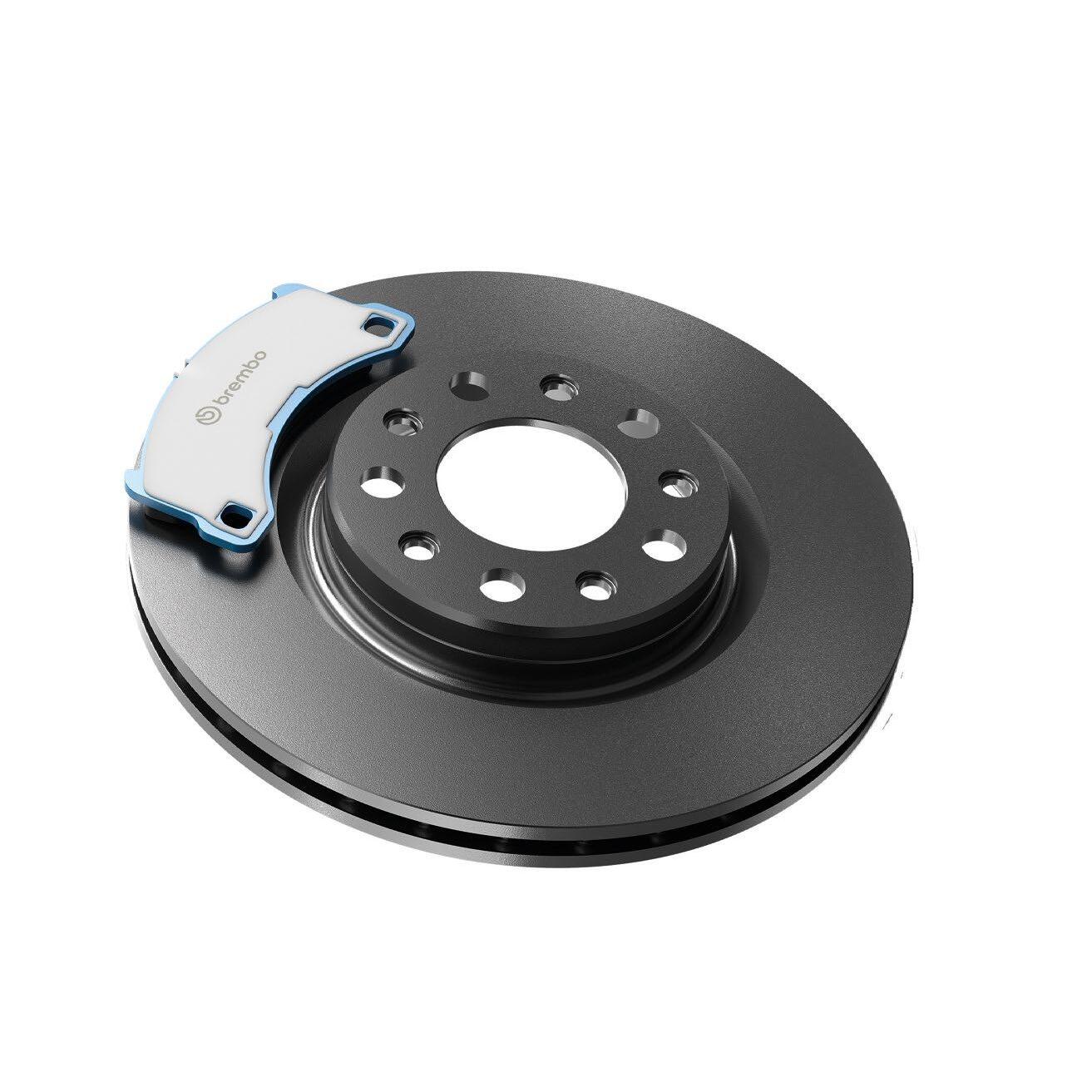

Continental’s premium brake brand ATE offers independent workshops a comprehensive ecosystem for their brake service business, including OEM-quality spare parts, workshop equipment, special tools, a hotline and a full range of training courses.

To provide their customers with a professional brake service, workshops must have access to high-quality parts. However, brake replacement parts such as original equipment quality discs and pads are only one side of the coin – the other is know-how and the right tools. In other words, the necessities that help workshops provide perfect service to their customers. And that’s exactly what Continental has committed to with its premium ATE brake brand. Tools, hotline and training courses are precisely tailored to the requirements of professional brake repair. This simplifies everyday workshop work and ensures safety during every repair step.

in

If brake pads or brake discs are installed with the wrong tool or components aren’t cleaned completely, the result can be discomfort issues like annoying braking noises. This is why Continental offers a full range of special tools for brake service: Test and inspection equipment, bleeding equipment, matching bleeding unit adapters, disposal equipment, and fully equipped workshop trolleys with special brake maintenance and repair tools.

Always up to date – thanks to a hotline and training courses

The ATE hotline is an essential point of contact if you have any technical questions about brakes. The hotline team comprises experienced brake specialists who provide competent assistance. As an original equipment manufacturer, Continental has first-hand information at its disposal – and this knowledge is passed on in practice-oriented and customized training courses and seminars.In this way, independent workshops with a constantly changing fleet of vehicles will always be up-to-date and fully supported with the necessary services and spare parts. Whether it’s special tools such as the “E-Mobility” set of bleeding unit adapters or the relevant training courses that teach workshop staff the necessary knowledge. With the comprehensive range of brake service products, workshops have the opportunity to develop their brake business comprehensively and in a customer-oriented manner –bringing in more business success.

Brake services on e-vehicles will increase:

The ATE “E-Mobility” set of bleeding unit adapters covers the lion’s share of the current electric and hybrid vehicles on the European vehicle market.

The 12V lead-acid battery – the crucial energy source in e-mobility that keeps everything running.

Bright future of the 12V battery as xEV revolution grows

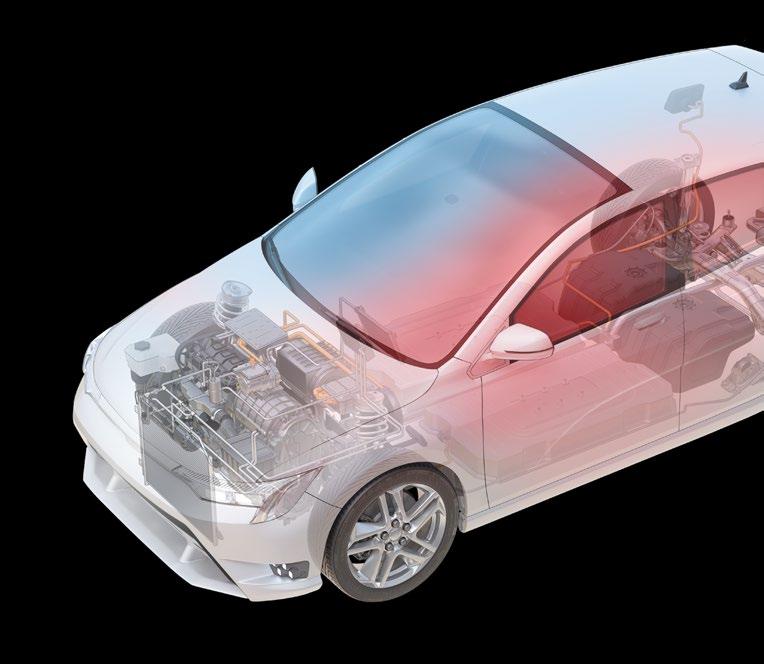

The automotive industry is on the threshold of a major transition. The role of batteries is becoming increasingly evident in special the 12V lead-acid battery has a bright future as xEV revolution grows. In xEVs, the main propulsion is a high-voltage system (300-800V). This is what drives the electric motor and powers the wheels. The other mode of power is a lowvoltage 12V battery, as relied upon in ICE and startstop vehicles. This powers infotainment systems and intricate electronic systems, such as adaptive cruise control, emergency brake assist, automatic emergency brake assist and lane assist – namely ADAS.

Trusted by leading car makers – Exide’s 12V battery portfolio for xEVs

A 12V lead-acid battery comes in various types and technologies, most notably absorbent glass mat (AGM)or enhanced flooded batteries (EFB). As an OEM and first choice for 70% of European car brands. While offering a high lifespan and performance stability it is designed to endure continuous battery discharges and recharges. EFBs are another suitable power source for auxiliary systems in xEVs. They boast a high charge acceptance over their lifespan, a great cyclic durability when operating in a reduced state of charge and offer optimized recuperation from regenerative braking, ensuring maximum fuel savings and less CO2 emissions.

Exide is at the forefront of battery innovation, sustainability, reliability, and performance. By utilizing its knowledge of the existing car parc and available data from the EU27, UK and European Free Trade Association, it can make some considered predictions about the future direction of mobility:

• 100% of all vehicles will still require a 12V power source by 2028.

• 56% of the vehicles in the car parc will feature a startstop system by 2028

• 25% of the car parc will be hybrid (FHEV and PHEV) or fully electric (BEV) by 2030

Indispensable – smart workshop tools and services.

Diagnosis and peventative maintenance are two key areas for mechanics. The primary reason for hybrid and EV failure is the discharge of the 12V battery. Therefore, mechanics should check its status every time a vehicle enters the workshop – using Exide’s EBT-965P tester and EBTP app to carry out this simple and quick diagnostic check. Any vehicle – not just xEVs – fitted with an AGM must be replaced likefor-like. Anything else can lead to premature battery failure. By utilizing the Exide Battery Finder, mechanics can find the correct replacement. It will also inform the user of the battery’s location and whether battery registration is necessary after the replacement. The Exide Battery Finder can be accessed for free online or as Exide Battery Finder App.

As you see, Exide Technologies is more than a battery producer. We are the reliable partner for jointly building the future of electric mobility.

exidegroup.com

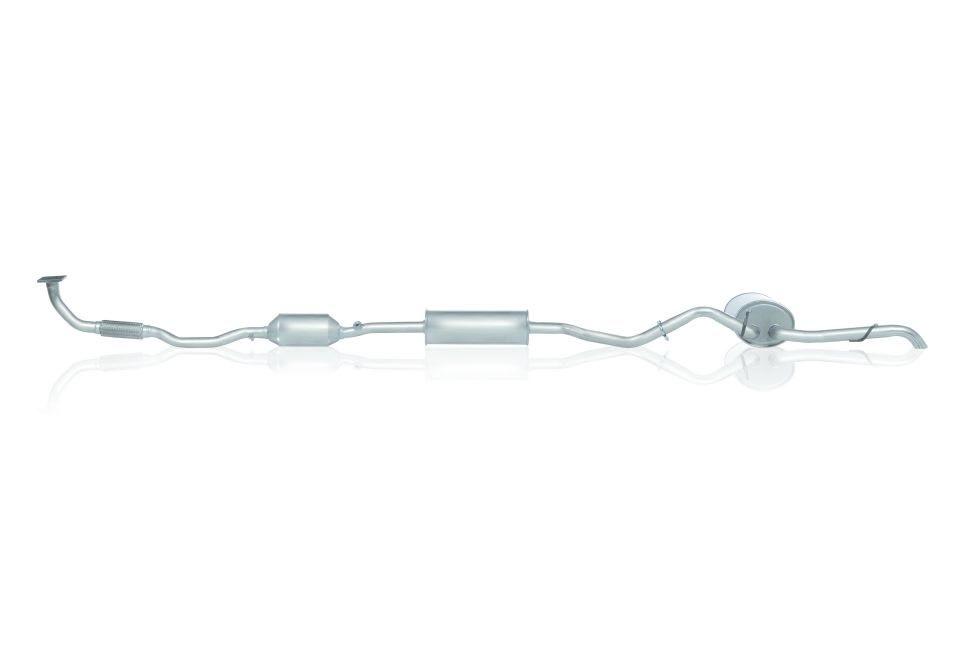

Always premium quality products with BOSAL

Front Pipes & Flexibles Intermediate Silencers Rear Silencers

Our product range

Catalytic Converters & Diesel Particulate Filters

Mounting and Repair Parts Towbars & E-set

Bosal GEN - DPF Additive

Bosal Bicycle Carriers (2 or 3 bikes) are also new to the range and are adapted for all types of bikes, including e-bikes

Our models have an easy fastening system, are foldable, and theft protected

For a complete overview of the range, see www bosal com/aftermarket

Key features

Easy and safe fixation of the bicycles

Practical tiltable mechanism by means of foot pedal for easy trunk access Multifuntional plug (7/13-pin)

NRF offers a wide range of high quality condensers. NRF condensers are known for their excellent performance and reliability. Almost all condensers are Easy Fit, so they are supplied with the correct O-ring.

The NRF condenser range contains 958 references covering over 4.600 OE references and 96% of the European car parc. NRF offers condensers for passenger cars, light commercial vehicles, trucks and agricultural vehicles. Additionally, NRF has a dedicated range for electric vehicles.

EASY AND QUICK INSTALLATION

All NRF condensers have the same connection points as the original parts. As a result, they always fit perfectly.

EASY FIT = SUPPLIED WITH THE CORRECT O-RING

Almost all NRF condensers are Easy Fit, meaning that the condenser is supplied with the necessary O-ring. Easy Fit provides a great advantage for the workshop, because it ensures easy and quick installation of the NRF part. With Easy Fit you save time and money, which results in higher customer satisfaction.

QUALITY TESTED BY NRF IN EUROPE

To ensure high quality, all NRF condensers undergo various tests. Tests include leak tests and high-pressure tests. NRF also conducts salt spray tests to check corrosion resistance. This ensures that the product can withstand real road and weather conditions. Most tests are conducted at in-house test centers in Europe.

NRF condensers are packed in strong and solid boxes. The product is additionally fixed and protected to prevent damage during storage and transportation. The inlet and outlet connections are covered to protect them from impurities.

TOTAL RANGE 958 REFERENCES FOR CARS AND TRUCKS

THE WIDEST AFTERMARKET

RANGE OF CONDENSERS

NRF offers a large range of 958 reliable condensers. Available for passenger cars, light commercial vehicles, trucks and agriculture.

ADVANTAGES FOR THE WORKSHOP

Easy and quick installation

High quality and reliability

Easy Fit: supplied with the correct O-ring

96%

MARKET COVERAGE

ADVANTAGES FOR THE CAR OWNER

Comfortable vehicle climate

Better air quality

Improved safety

WANG HAO, Founder/CEO, Coppola Automotive Consulting Services (Qingdao) Co. Ltd

The entire industry chain of new energy vehicles in China is entering the “market maturity period” and has reached the best development phase in history.

In the new vehicle market, traditional OEMs such as FAW, Dongfeng, Changan, GAC and SAIC are increasing the proportion of their production and sales of new energy vehicles, and the effect of “electrification” transformation is gradually becoming visible. New enterprises such as Huawei,

LI-AUTO, and Xiaomi are entering the new energy vehicle industry from different fields and have established a high brand recognition and user base in the market. Their innovative products are aimed at the future ‘new four modernizations’ route. The innovative products route has established high brand awareness and significant user base in the market. New energy core parts and

components enterprises such as CATL, Fudi and HuiChuan Electronics have achieved the leading position in new energy vehicle segments in terms of technology, product quality and market scale.

In the aftermarket, the annual premium scale of new energy vehicle insurance has exceeded 150 billion yuan and is increasing at an average annual rate of about 40%. New energy taxis, buses, network vehicles, and public sector vehicles are gradually being replaced by millions of “electrified” vehicles every year. The production, sale and operation of charging piles, and the construction and operation of switching stations, have begun in the whole region, and the market has been

expanding rapidly. It has been launched across the whole region, and will continue to accelerate the scale of operation of the first map. In terms of new energy used cars, the annual scale of domestic transactions has exceeded 500,000 units. The scale of exports has reached 100,000 units; along with more than a million new energy private cars, operating vehicles and public vehicles retired every year. The new energy automobile testing and maintenance centers around the core of power batteries, drive systems, motor control systems, high-voltage accessory systems, comprehensive technical services, power battery recycling and maintenance; and the development of new energy automotive industry chain. Comprehensive technical services, power battery recycling and secondary utilisation along with other new industrial opportunities are coming, and a large number of enterprises have started to enter this field.

It is expected that future development of China’s new energy vehicle production and

sales will exceed 11 million in 2024, and the proportion of new energy vehicles in new car sales will exceed 40%. By the end of 2025, the scale of new energy vehicle ownership will be close to 50 million.

The realization of the “electrification” product base and the completion of the initial technical exploration, means that China’s “smart car” will become the most popular vehicle in the world, and the most popular vehicle in China.

Intelligent vehicle technology will also enter a rapid development stage, with more models reaching L3/L4 level autonomous driving and further realization of a “human-vehicle-road-network” synergy. The experience and model of electrification development accumulated and developed by Chinese automotive industry practitioners over the past 15 years will also become the basis for the development of new energy vehicles. These developments will become a valuable asset for countries across the world to learn from.

Sustainable road transport calls for more than one technological arena. Whatever path is right for you, Dinex is ready to join your journey.

The automotive aftermarket is in the midst of transformation: Hybrid and electric vehicle sales are rapidly increasing while strict environmental and emission laws are limiting more and more vehicles with combustion engines from the streets. With the aftermarket, the bilstein group is also changing and adapting in order to continue offering customers the widest range of high-quality repair solutions in the IAM.

The bilstein group already has thousands of parts on offer for the hybrid, electric and alternative-power vehicle sector –be it passenger cars or commercial vehicles. More than 2,000 new articles are being introduced annually for passenger cars, around 1,000+ for commercial vehicles, and there is a database of over 99,000 individual car variants, growing daily, and 323,350 for truck. Additionally, delivering millions of catalogue applications to the screens of distributors and installers around the world puts the bilstein group in a very strong position to provide the aftermarket with the most extensive range of repair and maintenance parts – today and tomorrow.

The bilstein group’s Vehicle & Application Research (VAR) department is constantly studying all cars and trucks with alternative-drive concepts to ensure that it has existing article application coverage visible in the partsfinder online catalogue and various industry alternatives, such as TecDoc. In addition, all associated OE numbers are researched to support future product development requirements. The VAR team has completed a full overview of the top-selling hybrid & electric car models, which include – among others – the Renault Zoe, Nissan Leaf, BMW i3 & Tesla Model S/3/ X/Y. A number of more recently launched models have also been researched, such as the Jeep Avenger, Toyota Prius V, Hyundai Ionic 6, VW ID.7, Volvo EX30, Kia EV9, MG4 and BYD Atto 3/Dolphin/Seal. Furthermore, they focus on commercial vehicles including the Mercedes-Benz eActros, Volvo FH/FM/ FL/FE Electric, Renault D E-Tech, Iveco S-Way/ Stralis LNG+CNG, NIKOLA TRE (BEV), DAF LF/CF Electric, Scania R/S Electric, P/G LNG and MAN eTGM. By that, the bilstein group can continue a ‘Fast to Market’ product introduction strategy; one of its key strengths.

The bilstein group’s strategy of matching the OE specification of articles means that the products are already fit for the existing hybrid and alternativefuel vehicle fleet – and will be for future model releases. Some braking components on alternativefuel vehicles – such as pads and discs – will have a physical reduction in wear. However, the products will continue to require service, maintenance and replacement due to moisture, corrosion and increased stress during use. There already is a broad range of brake pad sets available for these alternative fuel applications today, all with NVH (Noise, Vibration, Harshness)-reducing shims and a low emission, high-performance friction material.

The IAM is changing, but not everywhere in the world at the same speed. ‘Non-electro technical’ components are still incredibly important and they always will be, for any car or truck – no matter what kind of drive they rely on. That is why the family-run company will continue developing its range in order to support the IAM in maintaining and repairing all kinds of vehicles, regardless of whether the engine is powered by fossil fuels, electricity, hydrogen or alternative-power.

• +/- 650 hybrid & electric car models – 3,200+ variants, catalogued in partsfinder & TecDoc

• 8,400 articles (linking to a febi, SWAG, &/or Blue Print reference) applicable for hybrid & electric passenger cars

• Fast to Market: Proactive research of all new models to identify existing & new OE references for immediate cataloguing and developing of key product lines

• Data available promptly to support the product teams in adding new items to range

As a professional installer, it is your priority to ensure that every vehicle that leaves your workshop is not just roadworthy, but optimized for safety and durability. Therefore quality products need to be available for any replacement on any vehicle, when you need them. Monroe understands this, we offer safe and durable products for any application, any vehicle – regardless of its make, model or powertrain.

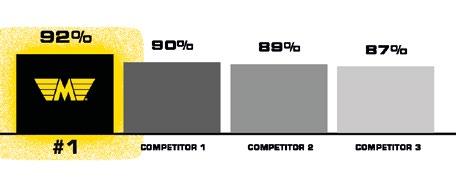

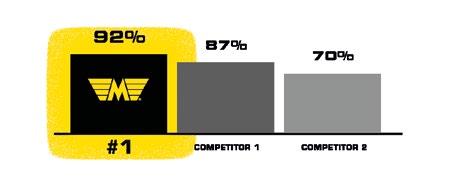

Market leader with the highest coverage*

In the dynamic European car parc landscape, we proudly secure the number one position in coverage* versus premium competition. We meticulously engineer the brand’s product range, providing an impressive 92%* coverage for Shocks & Struts across all light vehicles-in-operation (VIO). Simply put, 92% of light vehicle applications, from any automotive brand, are seamlessly covered by Monroe. In addition, Monroe is also leading with the highest coverage versus competition on the accessories needed to complete the repair: Mounting and Protection Kits.

When you choose Monroe for your replacements, you're not just selecting a product; you're embracing a promise of unparalleled compatibility across a vast array of vehicles, from compact cars navigating city streets to robust SUVs conquering challenging terrains.

Our commitment goes beyond market leadership; it’s about empowering installers like you, fostering trust, and propelling the industry forward. As an Original Equipment supplier, we gain unique insights into vehicle manufacturers' desired ride and handling characteristics, ensuring our products align perfectly with evolving automotive needs.

The future of automotive technology revolves around electrification, and Monroe stands at the forefront of this transformative journey. While electric vehicles currently represent a small segment of the market, their exponential growth demands attention. Monroe’s product range already encompasses electric vehicles, with ongoing investments aimed at expanding coverage to encompass more electric models set to be introduced in the upcoming months. Our focus on electric applications ensures you, as a professional installer, are well-equipped for the electric future.

Our continuous investments in research and development, along with timely product updates, secure our position as the number one market leader.

Choosing Monroe isn’t just about a product; it’s about securing your future. Our dedicated product team is committed to maintaining our position at the top. Our strategic investments guarantee that we continue to provide the most comprehensive, reliable range of shocks & struts, mounting kits, protection kits and springs. Backed by Monroe’s best-in-class 5-year warranty** on all qualifying products, you're not just getting a product; you're gaining peace of mind, knowing that you’re equipped to handle any vehicle that comes your way.

For any application, any vehicle – regardless of its make, model, or powertrain – Monroe has got you covered. Your journey to durable and safe shock & struts replacements starts with Monroe.

Ferodo® is pleased to extend its market coverage with the introduction of new products. Ferodo® Brake Pads help professional installers restore safe, durable, original equipment-style braking performance on the vast majority of passenger vehicles operated worldwide.

www.ferodo.com

JUHA SEPPÄLÄ CEO, Diagno Finland Oy

The vehicle fleet in Finland is being rapidly electrified. Electric cars, including plug-in hybrids and fully electric vehicles, currently represent 8.5 percent of Finland’s passenger car fleet in operation.

In 2023, electric cars accounted for 54% of new registrations and 64% of imported used vehicles. The strong electrification of the vehicle fleet has presented car repair shops with entirely new challenges.

High vehicle taxes favor electric cars: Finland imposes high vehicle taxes on the purchase price of cars. The amount of vehicle tax depends on the vehicle’s carbon dioxide emissions, and the tax is paid both on purchasing a new car and when importing a used car. This made plug-in hybrids very popular in the late 2010s because they could be acquired at the same price, or even cheaper, than an equivalently powerful gasoline - or die -

sel-powered car. As the range of fully electric vehicles has expanded, the proportion of fully electric cars has grown larger than plug-in hybrids in terms of both new registrations and imported used vehicles. Fully electric vehicles are exempt from vehicle tax upon purchase, but they are subject to annual vehicle tax, which is similar to combustion engine cars.

Charging is easy and relatively inexpensive in Finland: Finland’s long distances require a comprehensive fast-charging nationwide network. The fast-charging network has been growing rapidly and expanding steadily as the number of fully electric cars increases.

Currently, Finland has about 3,000 fast-charging points, which equates to one fast charger for every thirty fully electric cars. Two-thirds of these are high-power chargers exceeding 150 kW.

The public basic charging network (<22 kW) has also expanded along with the vehicle fleet, but the ease and affordability of charging at home has had the most significant impact on electric vehicle adoption. Finland’s relatively large household and industrial electricity consumption - due to its weather conditions - has kept electricity prices relatively low compared to many other countries. With fuels expensive in Finland due to heavy taxation, inexpensive home or workplace charging encourages electric mobility.

Workplaces and parking areas are almost always equipped with electrical outlets for engine block heaters. Although using such power outlets for charging electric cars is not straightforward, upgrading parking areas’ electrical infrastructure with charging points is easier than building new network.

Contrary to popular belief, electric car use in sparsely populated northern areas involving long distances and harsh conditions is more convenient and comfortable than using combustion engine car. This is because there’s no need to worry about refueling, and one can set off with a preheated car.

Changes in the work of car repair shops: The electrification of the vehicle fleet also brings changes to car repair shops. Traditional car maintenance tasks, such as changing filters and oils, decrease. However, there is still plenty of work in repairing electric cars. Chassis structures and tires wear out even more in electric vehicles than in lighter traditional cars. Electrical powertrains can malfunction, and batteries require servicing. Breakdowns in electric cars more often lead to a halt in travel than in combustion engine cars. Repairing high-voltage vehicles also requires attention to work safety. When repairing electric cars, one must know what they are doing, and ultimately, the repair shop owner is responsible for the safety of their employees and ensuring that the repaired vehicle is safe for the user.

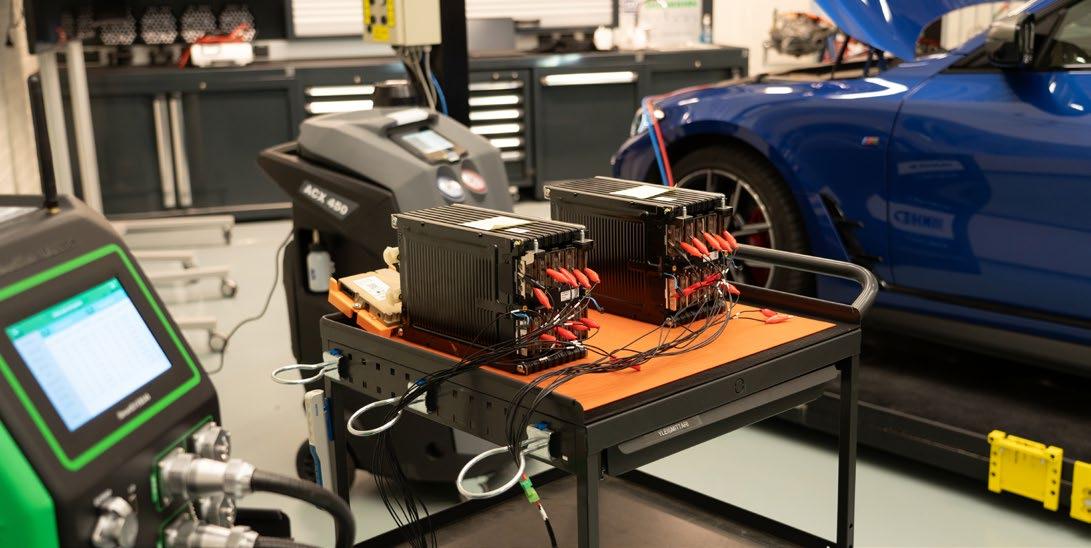

Diagno educates car repair shops in new technology: The evolving automotive technology and electrification of cars require investments in repair equipment but, above all, in skill development. Diagno Finland Oy is Finland’s leading supplementary training provider in the automotive industry and a pioneer in training in electric vehicle technology and battery repairs. In addition to training, Diagno is the market leader in providing technical support, sales and maintenance services for workshop equipment, as well as expert advice on workshop planning. Diagno employs over 50 automotive professionals serving brand-specific and multi-brand repair shops, vocational schools and universities, and vehicle inspections.

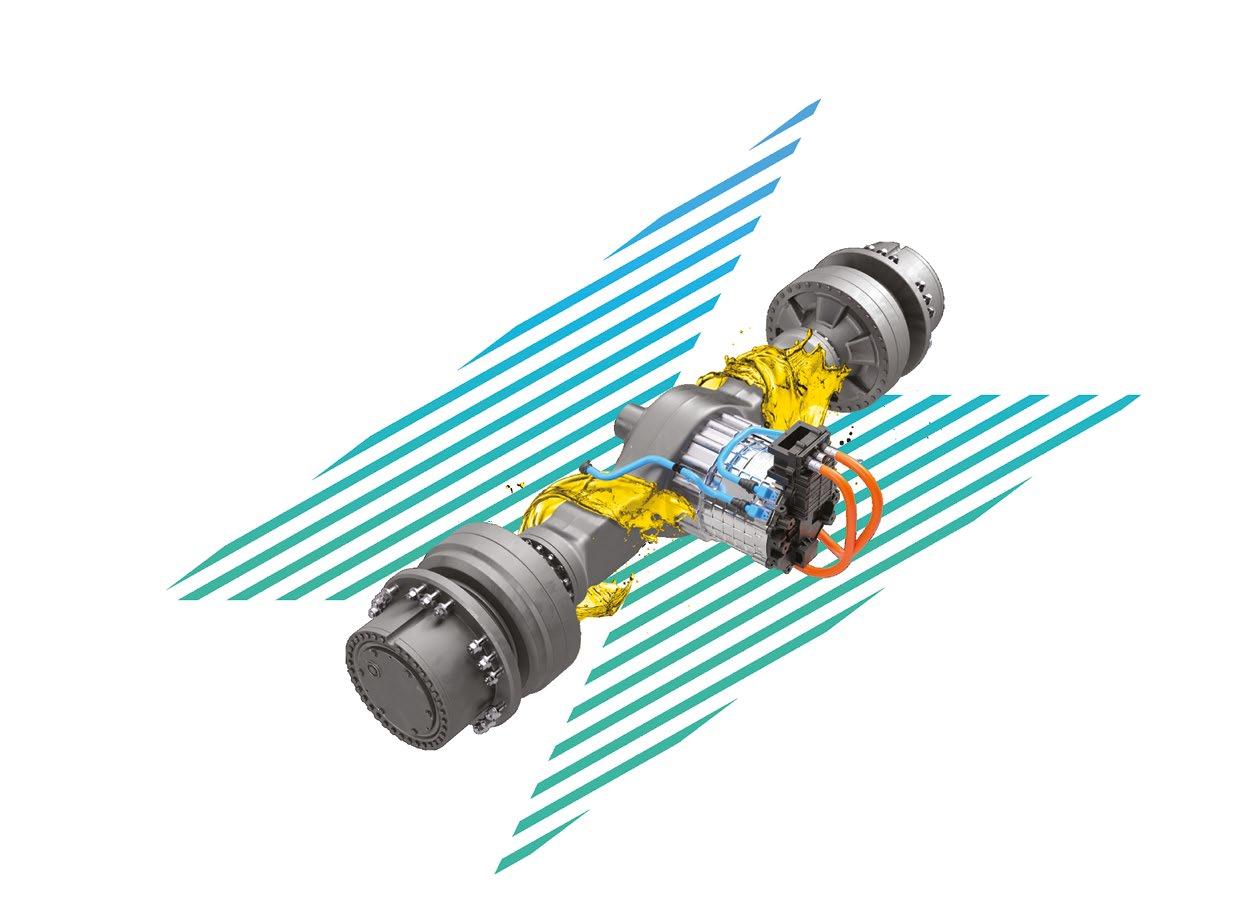

In the summer of 2022, a new electric truck with a slick black paint job arrived at Knorr-Bremse in Budapest. The eCUBATOR team had a clear purpose for the right-hand drive truck from England: the neutral test vehicle, since christened “Eddy”, should play a key role in the continued development of Knorr-Bremse’s e-mobility portfolio.

The eCUBATOR unit is the central hub at Knorr-Bremse for all e-mobility topics in the Commercial Vehicle Systems division. Development teams in Munich and Budapest are working on intelligent solutions – from traction, braking and steering to energy supply – using a holistic systems approach. “We are currently focusing on second-generation electric vehicles, which are expected to be on the market from 2025. Our first series of tests on the eVMC software package is also geared towards this generation,” explains Martin Mederer, Product Line Owner “Brake Control” in the 'eCUBATOR unit.

First of all, the electric truck was equipped with innovative KnorrBremse technology, in line with ideal test vehicle requirements. This work was performed at the Knorr-Bremse prototype workshop in Budapest and at the test track in Zalaegerszeg. The responsible design engineer György Surek recalls: “Among other things, we retrofitted the truck with high-quality measuring systems for data logging, two braking systems (EBS5, GSBC), various driver assistance systems (ABS, ATC, ESP) and a fifth wheel coupling for additional trailer operation. The mechanical modifications were then carried out by a specialist company in Budapest in accordance with all road safety regulations.”

June 2023: Test series eVMC software is ready for launch.

Why is the eVMC software package one of the prioritized projects in the test series? Within the modular system of Global Scalable Brake Control (GSBC), eVMC is designed to recover as much energy as possible via recuperation and to further enhance safety functions such as ABS and ESP.

With the electric test truck named “Eddy”, Knorr-Bremse is making steady progress on the road to e-mobility. At the wheel is the eCUBATOR team, made up of international specialists from Munich and Budapest. Here they report on the latest successful eCUBATOR test series and tell us what added value the eVMC (Electric Vehicle Motion Control) software package brings to electric trucks and therefore to customers.

The test vehicle “Eddy” embodies the transformation of KnorrBremse’s products to e-mobility across all product groups in the CVS division. Eddy’s length of 10 meters, height of 3.50 meters and weight of 15 metric tons are spread over a beautifully crafted body made of high-strength steel with a black paint finish. The electric truck packs quite a punch, with 300 kW batteries and 200 kW power during operation.

The second generation of Knorr-Bremse systems for electric trucks is already on the road. In June 2023, the test series for eVMC (Electric Vehicle Motion Control) started with the first road tests on the state-of-the-art vehicle test track in Zalaegerszeg, Hungary.

October 2023: eVMC to ensure maximum energy efficiency and driving stability.

Between June and October 2023, the eCUBATOR team carried out the eVMC test series on the state-of-the-art, fully equipped ZalaZONE test track in Zalaegerszeg, Hungary.

How do such tests work in practice? Knorr-Bremse has worked meticulously on its test cases, which are often based on legal regulations, over the past 20 years and integrated the latest requirements for electric drives. “We prepare the collected test cases for our series down to the last detail,” reports Surek. “We develop new software and compile EEPROM parameters, which are data required for operation, for further applications of the braking system in combination with the electric drive.”

"Among other things, we retrofitted the truck with high-quality measuring systems for data logging, two braking systems (EBS5, GSBC), various driver assistance systems (ABS, ATC, ESP) and a fifth wheel coupling for additional trailer operation."

György Surek – Design and Test Engineer at eVMC-Software

During the eVMC test weeks, which took place regularly every two to three weeks in the third quarter of 2023, road tests were performed to further optimize and develop the product. The eCUBATOR team used predefined eVMC test series to check and fine-tune the basic functions for energy recuperation.

To improve efficiency, the team aimed to optimize the existing brake blending strategy to maximize energy recuperation during deceleration. As a result, customers benefit from a longer driving range of the electric vehicle.

Another objective was to enhance the stability functions of vehicles with electric drive systems. The team sought to leverage the higher dynamic response of electric drivetrains compared to combustion engines in order to optimize the ABS (anti-lock braking system), ATC (automatic traction control) and ESP (electronic stability program) functions. The stability tests were carried out for both tractors and trailers.

October 2023: eVMC test series delivers compelling results.

The entire eVMC product development was an iterative process based on the SCRUM methodology. A strengths and weaknesses profile for key features, including energy recuperation and braking distance, was used to identify potential improvements and set up follow-up tests. For design engineer Surek, the results were positive: “We managed to increase driving performance with eVMC. The energy balance appears to have improved. Now we have to wait for comparative measurements to obtain a quantitative result.”

“Interdisciplinary and international teams have been working together at Knorr-Bremse since the end of the 1990s. I find the eCUBATOR team spirit inspiring. When we are conducting test series and exchanging our expertise in person, there’s an extremely high pace and efficiency to the process. Everyone is willing to go the extra mile to find the right solutions together.”

Martin Mederer (left) – Product Line Owner “Brake Control” for eCUBATOR

The positive results from the summer test series at the ZalaZONE test track were fully confirmed in winter testing in Arjeplog (northern Sweden). During the driving tests in Arjeplog , the eVMC functions were thoroughly tested under extreme conditions. Particular emphasis was placed on optimizing energy recuperation, but the transitions of the service brake function with recuperation were also examined with regard to ABS/ESP. Overall, the functionality can now be described as having reached stable B-sample status. The eVMC functions are currently being handed over to the Center of Competence (CoC) Brake Control for series application. Following successful implementation in the GSBC, the software package will be available to customers. The specialists at the CoC Brake Control will apply the systems to various vehicle types – because the product must work reliably and efficiently in various truck models with different tonnages and electric motor outputs. In addition, the software has to represent multidimensional drive concepts for trucks: those with a combustion engine, with an electric motor at the wheel end or with one electric motor per axle (outside Europe).

For “Eddy”, the journey continues. In the future, other eCUBATOR products and systems will be installed and tested in electric trucks, such as an oil-free compressor for use in electrically powered commercial vehicles. “Eddy” is therefore playing a key role in the ongoing development of Knorr-Bremse’s e-mobility product portfolio. Martin Mederer is looking forward to the challenges ahead: “It’s an extraordinarily exciting period of development that we are involved in with our eCUBATOR colleagues in Munich and Budapest – and on the road with ‘Eddy’.”

Bosch supports workshops with a comprehensive range of diagnostic solutions, technical spare parts and service parts

Electromobility is on the rise. New registrations of battery-electric and hybrid vehicles (BEV/HEV) are growing. As a result, electrically powered vehicles have long come out of their niche and are increasingly arriving at independent repair workshops. Thus the high-voltage sector is more and more becoming an integral part of traditional workshops. This is also confirmed by the increasing demand for training and workshop equipment

BOSCH – A STRONG PARTNER FOR DIAGNOSTICS AND SPARE PARTS

As a developer of innovative solutions and supplier of hybrid and electric drive technology for original equipment, Bosch is shaping technological change in both the vehicle and workshop market. Bosch is very familiar with the technical requirements of vehicles and its aftermarket range includes high-quality service and spare parts, A/C service units, test equipment, the ESI[tronic] 2.0 Online diagnostic software, as well as training and technical support services. Bosch thus offers workshops a complete package for maintenance and repair support.

MORE THAN 200 ELECTRIC AND HYBRID MODEL SERIES AVAILABLE IN ESI[TRONIC] 2.0 ONLINE

The growing number of hybrid and electric vehicles on the roads poses entirely new challenges for vehicle workshops. Working on electric and hybrid vehicles requires special know-how. In addition, workshop employees must be specially qualified to work on high-voltage systems in electric and hybrid vehicles. Bosch supports the workshops in repair order execution, among other things, with the diagnostic software ESI[tronic] 2.0 Online. It currently covers more than 200 electric and hybrid vehicle

High-voltage expert (HVE)

model series in its standard scope and is continuously being expanded. Also the condition of high-voltage batteries can be read out and documented with ESI[tronic] 2.0 Online.

HIGH-VOLTAGE TRAINING AND QUALIFICATION MEASURES

Many jobs on electric and hybrid vehicles require extensive knowledge of the complex high-voltage technology. This includes modern diagnostics and test equipment, knowledge of legal and safety aspects and information about how to avoid life-threatening electric shocks. To meet these require-ments, Bosch offers training courses for high-voltage experts.

Skilled person for works on live HV components

Level 3E qualification entitles to work on live HV components such as diagnosis and troubleshooting or the repair and disposal of all types of high-voltage vehicles.

Prerequisite for qualification level 3E is the acquirement of level 1 and 2, which can also be completed in Bosch training centers.

bosch-training-solutions.com

Bosch training program for workshops

ContiTech Antriebssysteme GmbH www.continental-engineparts.com aam@continental.com

The upsurge in cars with hybrid drive systems continues: according to the ACEA manufacturers’ association they already come second in the new vehicle registration figures for Europe behind pure gasoline models. Mild Hybrid Electric Vehicles (MHEVs) account for a large number of these, along with plug-in and full hybrid drives. And little wonder, as they help automakers to meet their climate goals and delight drivers with their efficiency, particularly in the compact segment. Consequently, vehicles with belt-driven starter-generators (BSG) and 48V batteries have long since ceased to be a rarity for workshop professionals. And as their popularity continues to spread, they are sure to become an increasingly familiar sight on the lifting platform. More than enough reason to take a closer look at this technology, as it places particular demands on the belt drive …

This is how the technology works

At the heart of the mild hybrid system is the belt-driven startergenerator (BSG), which assists the internal combustion engine when pulling away and accelerating, thereby producing extra torque (boost function). The electrical power needed for this comes from a 48V battery, which the BSG itself recharges during braking and on downhill stretches by converting kinetic energy in a process known as recuperation.

BSG units demand supreme performance from the belt

The task of transmitting power between BSG and ICE is handled by a multi V-belt. Pulling away, braking, automatic stopping and restarting, recuperating energy – the frequent changes of driving mode result in high peak loads, enormous tensile forces and dynamic changes of load direction in both torque directions. As a result of this, the belt in the BSG unit is subjected to extreme levels of strain. To make sure the burden doesn’t become too much, Continental offers specially designed belts for a wide range of different vehicle models.

Quality for the aftermarket Continental is also very quick to make its original equipment expertise available on the independent aftermarket once vehicles have been launched. Here, the belts with special properties have the suffix EXTRA in their name. The most recent example is the 6PK1822 EXTRA K1 kit, which has been designed for numerous MHEV models from Dacia and Renault and is suitable for around 500,000 vehicles throughout Europe. Besides the multi V-belt itself, this handy kit also contains the necessary tensioner and deflection pulleys as well as the various bolts and small parts that are needed. The result is easier, more reliable belt fitting. Also new is the 6PK1179 EXTRA K1 kit for Ford models with the 1.0-litre EcoBoost engine. There are around 270,000 such vehicles on Europe’s roads.

More than just belts

Not only can automotive mechanics rely on Continental’s wide product range and excellent quality, they are offered the additional benefit of attractive services, such as free fitting tips and instructions. Here’s a useful recommendation right now: the 48V mild-hybrid belt drive training course. In this course, our technical trainers explain how this innovative system works, which components are used and how the belts fitted in such systems differ from conventional multi V-belts. More information about the course can be found here: www.continental-ep.com/training

Specific training and qualifications:

At Feu Vert, we are aware of the risks involved in taking charge of electric vehicles in our workshops, including the risk of electrocution or electrification. To reduce these risks wherever possible, we train-up our technicians, and ensure that no electric vehicle is handled by an unqualified technician.

Qualified technicians will have learnt how to identify an electrical hazard and neutralise the problem, in particular by consigning the vehicle. The fleet of electric vehicles is ageing with many modern electric vehicles now more than 10 years old, and have been subjected to numerous shocks during city use, which can create electrical hazards in the underbody, for example.

Concerning the business

At Feu Vert, we’re quite calm about the arrival of electric vehicles on the maintenance and repair market, because for us the main maintenance operations are core business services. These include replacing tyres, running gear parts, etc. Indeed, because of the high weight of these vehicles, and the instantaneous engine torque, all the components that connect these cars to the ground are subject to much greater stress than vehicles with internal combustion engines.

What’s more, the pioneering drivers of the early days of electric vehicles, who adapted their driving to keep energy consumption to a minimum and increase energy recovery, have now been joined by ordinary drivers who use their electric cars in the same

way as their previous combustion-powered vehicles. Increased battery life also explains why these drivers pay less attention.

What is Feu Vert’s strategy for electric vehicles?

To quickly gain expertise in servicing and electric vehicles, and to get to know the new associated car manufacturers better, we have signed servicing, repair and warranty partnerships with 2 brands, as well as with specialists in electric retrofitting, particularly on motorbikes. This has enabled us to gain the equivalent of several years’ experience in just a few months.

This increase in skills has also enabled us to develop a fixed-price maintenance offer for all car brands, allowing us to capture business opportunities right now on a part of the vehicle fleet that is only going to grow in the coming years.

Thanks to these experiences, we were also able to quickly identify and start investing in the specific equipment needed to handle electric vehicles in our workshops. These include, for example, lifting tables for removing traction batteries, and the gradual rollout of adapted lifting lifts enabling the lifting table to be positioned under the vehicle.

We have also equipped our centres with a range of tools dedicated to high voltage, as well as specific personal protective equipment for all our workshops.

What’s our main stumbling block?

The electrification of the vehicle fleet has enabled many new manufacturers, often Asian, to establish themselves on the European market, with distribution networks that are more or less developed. However, it is complicated, if not impossible, to obtain information on the maintenance plans for these vehicles and, above all, to supply us - via our usual wholesalers - with adaptable spare parts compatible with these new brands and models. However, we understand that spare parts manufacturers are waiting to see which brands are sustainable before investing in the production of new parts.

In conclusion, here at Feu Vert we have no doubts about the long-term viability of electric vehicles and, consequently, about the significant market share they will represent in the French vehicle fleet in 5 to 10 years’ time. This is why we have decided, as of now, to transform all the constraints brought about by these new vehicles into commercial opportunities.

FOR THE LAST 100 YEARS, FOR THE NEXT 100 YEARS, THAT’S ELECTRIC THINKING

YOUR PARTNER TO NAVIGATING THE AFTERMARKET OF TOMORROW

FOR MORE THAN 100 YEARS, GATES HAS BEEN AT THE FOREFRONT OF AUTOMOTIVE INNOVATION. OUR TEAMS DESIGN, DEVOLP AND MANUFACTURE PARTS THAT ARE FOUND IN MILLIONS OF VEHICLES ON THE ROAD, ALL OVER THE WORLD. NOW THE HERITAGE AND EXPERTISE THAT HAS SEEN GATES TRUSTED BY DRIVERS AND VEHICLE MANUFACTURERS ALIKE IS DRIVING OUR COMMITMENT TO E-MOBILITY.

No matter the type, make or model, have confidence in Textar to cover more than 99% of all vehicles in the european car parc, and more vehicles than any other braking brand in the aftermarket. Whether it’s for a passenger car, a commercial truck or an electrical vehicle, we go the extra mile to continually expand our portfolio of safe, sustainable and performance-led braking solutions in the pursuit of total coverage.

www.textar.com

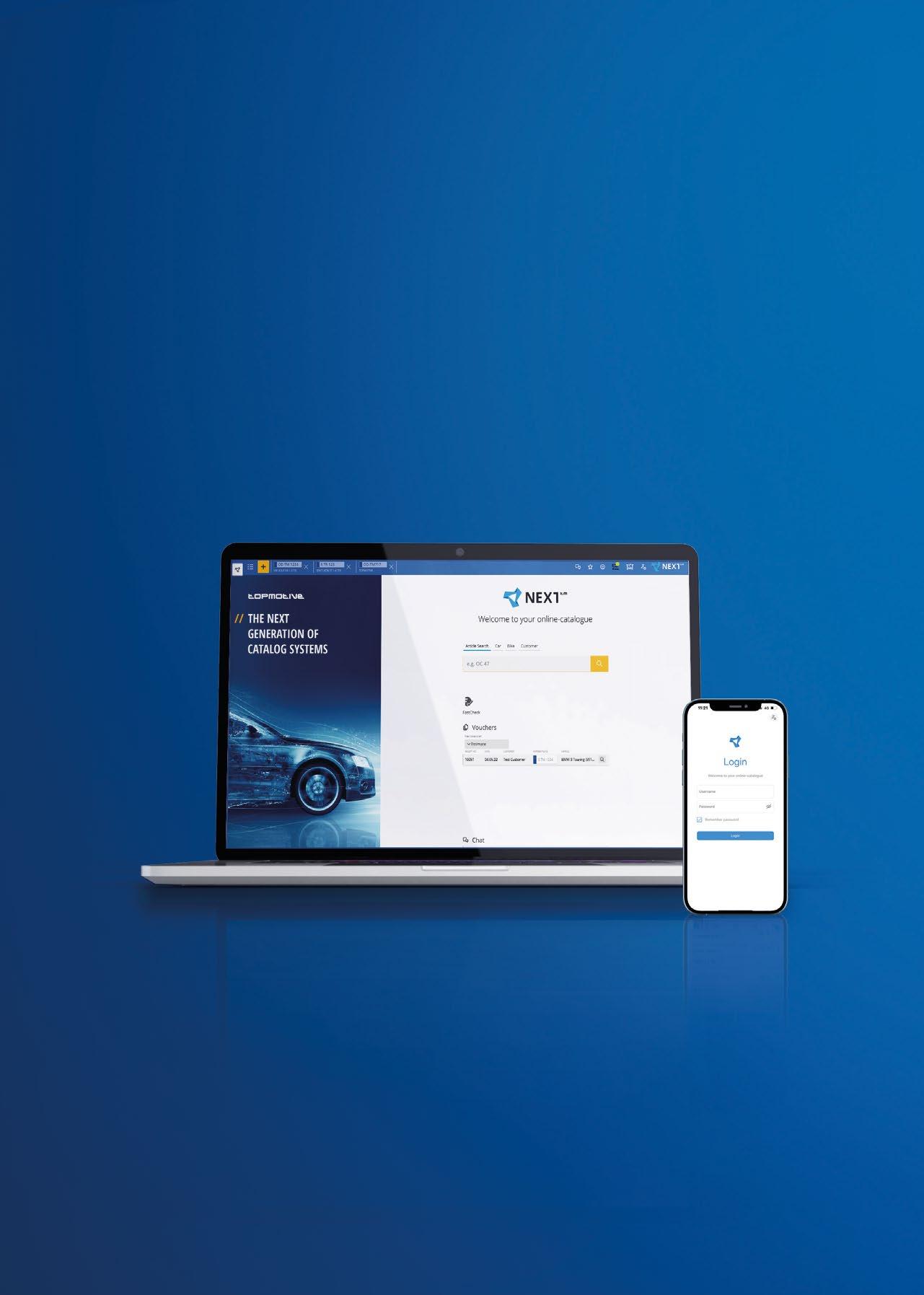

Behind the surface:

Self-learning vehicle file ensures even more precise part identification by combining already “learned” equipment for the selected vehicle with the correct spare parts

Administration of vouchers, customer and vehicle master data

Integrated chat module for optimal communication

Multiple simultaneous independent tasks that are fully synchronized with the native mobile apps and much more

Uncomplicated parts search and graphical part identification based on OE-Data

Telesales: specialized catalog solution designed for telephone and counter sales, allowing salespeople to fulfill orders on behalf of customers

NEXT is the first generation of self-learning information systems with a variety of benefits and added values for wholesalers and their customers (workshops and retailers). It automates the work process and facilitates repeated access to accumulated knowledge for each completed task, ensuring even more precise part identification. Through GSI-Remote, NEXT ensures interactive communication and data exchange between the catalog and other third-party systems. All this and much more is behind NEXT from TOPMOTIVE. Contact us!

Metelli has kept pace with technological evolution by introducing 5 new references of electric water pumps

HOW IT WORKS:

Electric water pumps are driven by a pulse from the control unit, which activates an electric motor inside the pump, allowing it to rotate only when needed, thus reducing CO2 emissions.

PRODUCT RANGE:

• Number of References: 11

• Models/versions: 2.150

• Car Parc: more than 10 MILLION in Europe and U.S.A.

MOST POPULAR VEHICLES:

AUDI: Q5 II - BMW: X5 III / X3 II - HONDA: HR-V III – MERCEDES-BENZ: CLASS C IV / GLC X253 –VOLKSWAGEN: Golf VIII - VOLVO: XC60 II / V40 II (525) - TOYOTA: Prius IV / Yaris III

ADVANTAGES:

• It allows the engine to reach the optimum operating temperature faster, thus reducing consumption;

• Less power as they are decoupled from the engine rotation;

• High efficiency;

• It gives the possibility of using regenerated energy in electric/hybrid vehicles.

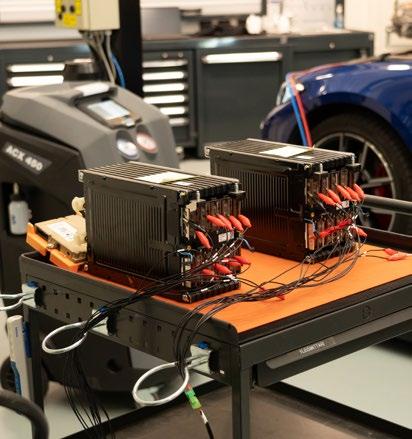

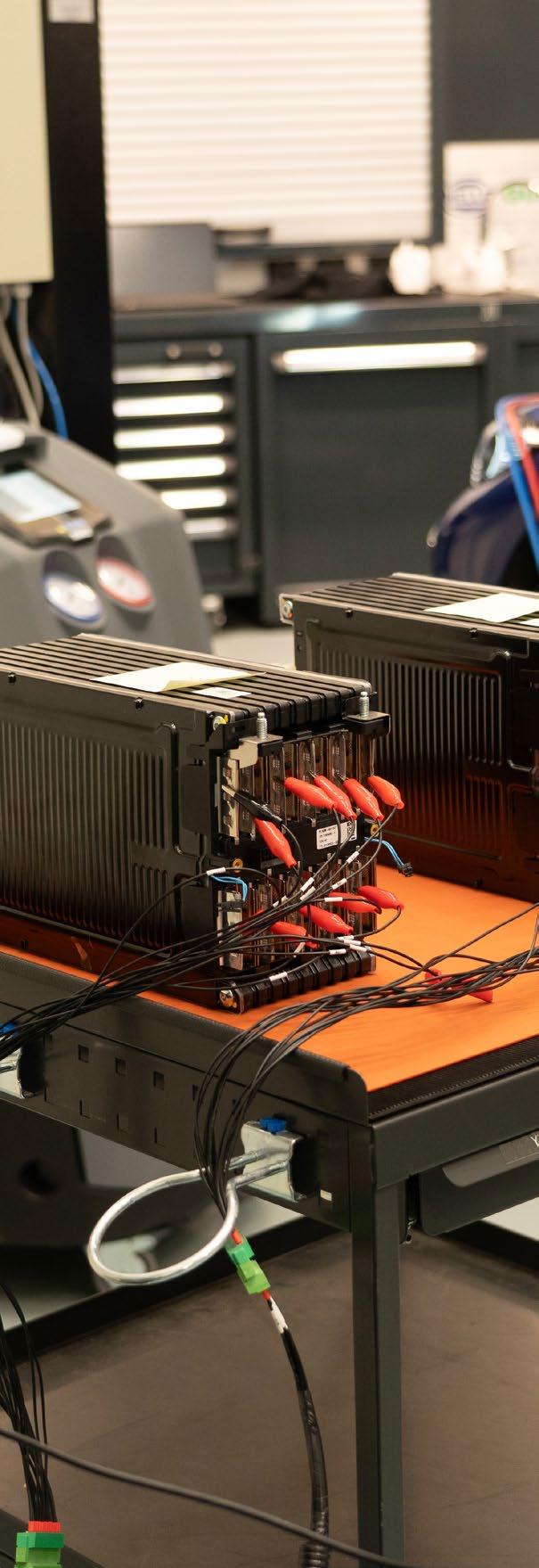

Metelli has specific expertise in the development and testing of both primary and auxiliary electric water pumps. This has been achieved by properly structuring the R&D department with new professionals and by equipping it with specific instruments and test benches. In this way, Metelli is able to carry out indepth analyses and stress tests on components to ensure product compatibility and reliability.

Various tests are carried out: pneumatic leak tests, endurance tests with speed and thermal profiles (working fluid and environment -40°C/+150°C), performance tests for full hydraulic and electrical characterization and functional tests.

For further information, please do not hesitate to contact us

Best Regards

Stefano Monteleone Marketing Manager

S.p.A.

ALMUDENA BENEDITO CEO, GiPA Group

Transforming Mobility Battery Electric Vehicles (BEVs) are not just transforming the auto industry; they are reshaping the entire mobility landscape. The shift towards BEVs is encouraging the development of new mobility ecosystems that integrate transportation with energy and digital technologies. This transformation is evident in the rise of smart charging solutions, vehicle-to-grid (V2G) technologies, and the increasing use of renewable energy sources to power electric vehicles. BEVs are promoting a cleaner environment by reducing emissions and lowering the reliance on fossil fuels. Moreover, the adoption of electric vehicles is encouraging cities to redesign urban spaces, prioritizing pedestrian areas and cycling paths over traditional car traffic, thereby enhancing urban livability.

Norway – State of the art for the BEV GiPA, a market research firm with 38 years expertise in automotive aftermarket insights, has released its comprehensive study on the electric vehicle (EV) landscape in Europe highlighting Norway as the leading country in the adoption of Battery Electric Vehicles (BEVs).

Norway is recognized as the most advanced nation in terms of BEV adoption. As of 2022, BEVs have seen a dramatic increase of 235% in registrations since 2016, signifying a boom in the EV market. This growth contrasts with a 49% decrease in ICE (Internal Combustion Engine) and hybrid vehicles over the same period. Moreover, Norwegians are increasingly opting for electric vehicles due to their environmental benefits and

cost efficiency. The GiPA data also reveals that BEVs generally require less frequent workshop visits compared to ICE vehicles. On average, BEVs have longer intervals between maintenance entries—approximately 1,000 km longer than ICE vehicles. Additionally, the cost of maintenance for BEVs tends to be lower, with a noted 22% reduction in costs for newer BEVs (0-2 years old) compared to their ICE counterparts.

The European BEV (Battery Electric Vehicle) market has seen sustained growth, marked by an increase in sales and market share of electric vehicles. The market share in 2023 reached approximately 15%, with sales increasing by 28% on the previous year, reflecting a growing adoption of these vehicles. This growth has been partly driven by favorable government policies, including tax reductions and subsidies for BEV purchasers, as well as a growing network of charging infrastructures. Additionally, the launch of new models offering improved range and advanced technologies has increased their appeal. However, demand remains uneven across Europe, with Nordic countries leading in adoption, whilst southern European markets show slower penetration.

As mentioned above, GiPA released a BEV study at the beginning of 2024 for the main

European markets - which is now available for order. Therefore, let’s take a look at some key markets and see how nations are driving towards a greener future, equipped with batteries and innovation and how they compare with Norway!

BEV owners are leaning heavily towards digital solutions and connectivity, driven by the promise of cost reductions. A significant 76.5% of respondents across the EU5+ (France, Italy, Germany, UK, Spain, Portugal and Poland) acknowledged fuel savings as a primary motivator for purchasing EVs, reflecting a broader concern for operational costs which manufactur-

ers could capitalize on to promote their cost-efficient models.

The Market Size is close to 4,7 millions of EV cars (43% Plug-in hybrid, 57% Pure Electric) in EU5+ representing only 2,5% of the total car parc.

Germany is charging ahead with an impressive 39% of its car parc made up of BEVs. This is projected to hit 50% next year, demonstrating a solid commitment to electrification. The Germans are not just switching to electric; they’re driving a 40% growth in plug-in hybrids too, reflecting a robust embracing of new technologies.

Over in France, the allure of electric driving has culminated in a significant shift, with new EV registrations capturing a substantial market share. French drivers are increasingly entrusting their new vehicles’ maintenance to VM dealers, emphasizing the market’s move towards newer, more reliable technology.

Italy isn’t just about style; it’s about substance too and the country has seen substantial growth with a notable percentage of the market opting for premium brand BEVs. Italian consumers are aligning with the global trend of lower maintenance for electric vehicles, marking a shift towards more sustainable and cost-effective driving options.

From Germany’s Autobahns to the fjords of Norway, the shift to electric vehicles is not just a policy change—it’s a lifestyle transformation. These countries are not only adopting new technologies but are also enhancing their infrastructure to support a greener future.

The satisfaction and repurchase intentions of owners of Battery Electric Vehicles (BEV) in Europe and globally have shown positive trends, indicating a strong commitment towards electric vehicles over a return to gasoline vehicles. The BEV study by GiPA revealed that the majority of elec-

tric vehicle owners express a clear intention to purchase another electric vehicle in the future.

The study underlines the importance of battery range, charging infrastructure, and cost savings as significant factors that drive customer satisfaction and their decision to stick with BEVs over gasoline-powered cars. Notably, the satisfaction rates and repurchase intentions are particularly high amongst owners of both premium and mass market BEV segments, despite some concerns about vehicle quality and reliability.

User Experience (UX) in BEVs is pivotal in driving consumer adoption and satisfaction. Modern BEVs focus heavily on the user interface (UI) and user interaction, offering advanced infotainment systems and connectivity features that enhance the driving experience. Touchscreens, voice commands, and app integration are standard, providing drivers with intuitive controls and seamless interaction with the vehicle’s features:

• Digital Integration

• Autonomous Features

• Personalization

• Connectivity and Services

As the BEV market continues to evolve, the focus on user experience becomes increasingly important. Manufacturers are not only striving to improve the techni -

cal specifications of their electric vehicles but are also paying close attention to how users interact with them.

The BEV market is expected to continue growing at a rapid pace. However, the transition to electrification faces challenges, such as the need for more affordable BEV models to facilitate mass adoption. Despite current efforts, many European consumers find that BEVs are still prohibitively expensive compared to internal combustion engine vehicles, especially in entry and mid-range segments. Manufacturers are being urged to develop and produce electric vehicles that are both affordable and capable of meeting the needs of the average consumer, which is crucial for achieving long-term climate and sustainability goals.

Are you electrified by the surge of EVs across Europe and curious about deeper insights? Dive into our comprehensive BEV study to discover more about the burgeoning world of electric vehicles. It’s not just about cars; it’s about embracing a sustainable future. Join us, and let’s accelerate into a greener tomorrow together! Grab your copy of our study and stay ahead in the electric revolution.

Souce: GiPA EV Euro Trends Study 2023

As an expert for the entire chassis system, Schaeffler offers a comprehensive product range. This enables uncomplicated installation, shortens expensive downtimes and ensures maximum safety and resilience - especially when the going gets tough.

Excerpt from the Schaeffler product portfolio for electric light commercial vehicles (e-LCV)

Current product overview: https://aftermarket.schaeffler.com/catalog

6110 90

6405 50

6683 20

6911 50

6506 40

Volkswagen E-Crafter; MAN eTGE

Fiat E-Ducato; Citroen e-Jumper; Opel Movano-e, Peugeot e-Boxer

Mercedes-Benz eVito; Mercedes-Benz EQV

Iveco Daily Electric

Citroen E-Berlingo; Opel Combo-e; Fiat E-Doblo

FAG Steering & Suspension

1608 10

1447 10

1079 10

0388 10

0527 10

Mercedes-Benz eSprinter

Volkswagen E-Crafter; MAN eTGE

Nissan e-NV

Fiat E-Ducato; Citroen e-Jumper; Opel Movano-e, Peugeot e-Boxer

Iveco Daily Electric

713 0381 20

713 0774 20

814 0182 10 814 0124 10

0178 10

Advantages at a glance:

Uncomplicated installation

Shortening expensive downtimes

A maximum of safety and resilience

https://aftermarket.schaeffler.com/elcv

Volkswagen ID. Buzz

Opel Combo-e

Renault Kangoo z.E.

Citroen E-Berlingo; Peugeot e-Partner

Mercedes-Benz eVito; Mercedes-Benz EQV

The Schaeffler product portfolio for electric transporters

Our comprehensive product range and customized repair solutions, make us your first choice in an electrified future.

Data expert TecAlliance has reason to celebrate: the TecDoc Standard was launched in 1994 as a uniform format for the entry, publication and distribution of highquality spare parts product information in the independent aftermarket. To this day, TecDoc enables the fast and precise identification of spare parts and vehicles. This is the basis for automated and digitised process solutions along the entire supply chain in the independent automotive aftermarket (IAM).

At the beginning of the 1990s, automotive spare parts data was not standardised and it was not checked whether their assignment to a vehicle type was correct. This uncertainty in selecting the right spare part cost time, and the high error rate was bad for business and customer satisfaction.

In 1994, 21 leading companies in the international automotive spare parts industry therefore launched a standardisation initiative under the name TecDoc. Each vehicle type was clearly and unmistakably defined and linked to the corresponding spare parts. Thanks to the TecDoc Standard and the TecDoc Catalogue spare parts catalogue based on it, it is now absolutely clear which spare part fits which vehicle. With the highest data quality, TecDoc has established itself internationally as the industry standard

The automotive industry is evolving rapidly, driven by new mobility concepts, digitisation and alternative drive types. With the increasing complexity of vehicle configurations and the need for faster product launches, the shift to realtime data processing has become the new reality in the independent automotive aftermarket.

In response to these demands, TecAlliance began rolling out the new TecDoc Ecosystem in late 2023. Parts manufacturers can now manage their catalogue information in near real-time, as opposed to quarterly or monthly data updates asin the past.

In addition, TecAlliance has been working closely with industry and traders since 2021 as part of a data quality initiative to continuously optimise catalogue data.

Further information on the TecDoc Catalogue is available at tec.al/TecDoc

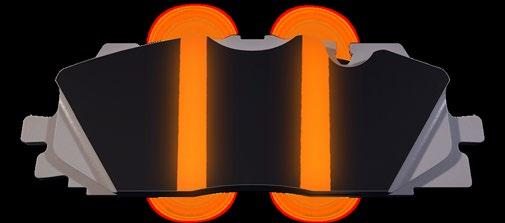

DENSO examines the new era of electrification in the European aftermarket

New energy vehicles (NEV), in whatever form, all have one thing in common: they all incorporate some sort of electrical solution within their powertrains when compared with their traditional petrol or diesel powered cousins, but how does that affect the aftermarket?

Vehicle manufacturers (VMs) universally have all had to respond to the demands of governments around the world, as they have committed their nations to reduce carbon emissions and greenhouse gases, for the sake of the environment and in an attempt to reduce rises in global temperatures. Collectively, the VMs have chosen electrification as the primary solution to these demands and so the growth in the number of NEVs coming into the market has been phenomenal.

The challenges facing all sides of this mobility development have been enormous, whether from the technology and range aspect for the manufacturers, the infrastructure requirements needed from national and local governments, or the expectations of consumers who have been familiar with hassle free refuelling and unconcerned by having to travel long distances.

All this change has a considerable impact on the original equipment (OE) component suppliers that the VMs rely on to produce these NEVs and that in turn has an obvious knock on effect on the replacement parts supply side of the aftermarket, as well as for the workshops and technicians responsible for the service and repair of them

Therefore, traditional aftermarket service providers must adapt to the unique characteristics of NEVs, including specialised components, diagnostic tools and servicing techniques . Technicians require training and certification to effectively diagnose and repair electric drivetrains, battery systems and associated electronics. As a leading OE manufacturer and system supplier, DENSO is well placed to provide this sort of support, and is one of the reasons that it introduced its pan European League of True Mechanics initiative, which combines online training with a competitive

motivational element. While there are significant differences when it comes to their power units and drivetrain, there are still many similarities between NEVs and traditional petrol and diesel powered vehicles when it comes to their driving comfort and safety, for example.

Both of these areas are DENSO OE specialisms, which is why there should be no surprise that air conditioning (AC) products, including cabin filters, as well as wiper blades, form a large part of its NEV replacement parts offering.

Electrification also presents significant opportunities for aftermarket businesses. The increasing complexity of NEVs creates demand for specialised aftermarket services, such as battery maintenance and software updates, but also for AC service and repair

Despite the fact that the AC systems in NEVs and those powered by a traditional combustion engine, have the same function, there are also several distinctions in how they operate, not least the compressor, which is the central component of both.

To thrive in the era of electrification, aftermarket businesses must embrace innovation and adaptability. Investing in training programmes and acquiring the necessary expertise in NEV technology is essential for staying competitive in the market. Collaborating with OE suppliers such as DENSO, can facilitate access to specialised replacement parts and provide the technical support they need to make the transition as smooth as possible.

As electrification continues to reshape the automotive industry, aftermarket businesses must remain agile and forward thinking. So, embracing NEVs presents an opportunity to position themselves as a leader in service and innovation, and by investing in training, forging strategic partnerships and adapting to evolving cu stomer needs, they can thrive in the electric mobility era and at the same time, drive sustainable growth in the aftermarket.

Electrification is revolutioni sing the automotive industry, presenting both challenges and opportunities for aftermarket businesses. By understanding the unique demands of NEVs and adopting a proactive approach to innovation and collaboration where DENSO is actively paving the way , the independent service and repair sector can successfully navigate the transition to electrification.

For further details of the DENSO Aftermarket sustainability programme, please visit DENSO-AM website:

In a market lead by international regulations, the automotive aftermarket industry has to cope with the impact of a new car parc of Electric and Hybrid vehicles. The transformation of the industry is accelerating due to the ongoing ‘drive’ to reduce carbon emissions and, therefore, their impact on public health. The end of combustion-powered vehicles sales (ICE) by 2035 in Europe, and the introduction of ecological bonuses in many countries, has led to the growth of a large proportion of Electric and Hybrid vehicles.

CARBON EMISSION REDUCTION & PUBLIC HEALTH

Electric Vehicles (EVs) are at the forefront of the global transition towards cleaner energy. Operating on electricity, which is increasingly sourced from renewable energy, EVs represent a significant shift from traditional fossil fuel-based transportation. Transitioning to EVs mitigates car-

bon emissions, thereby playing a crucial role in fighting global warming. By reducing the carbon footprint, EVs help create a more sustainable environment for future generations and with zero tailpipe emissions, significantly reducing air pollution. The widespread adoption of EVs can lead to improved air quality, which is directly linked to better public health outcomes and a higher quality of life for communities.

Diversifying transportation energy sources is a strategic move towards greater energy autonomy. EVs can be powered by electricity generated from a variety of renewable sources including solar, wind, and hydroelectric power. This diversification not only enhances energy security but also reduces dependence on finite fossil fuels. A resilient energy infrastructure is crucial for sustainable development, and EVs are a vital component of this strategy.

EVOLT! is designed to be an exclusive label available to N! Members, setting a benchmark for excellence in the maintenance and repair of Electric and Hybrid vehicles. This label signifies a commitment to the highest standards of services and technical expertise.

It complies with current legislation, so the workshops can approach this new opportunity with complete peace of mind.

+ The toolbox & available options include:

• Parts documentation and ordering

• Repair and maintenance information and technical assistance

• Protective equipment, work materials and tools

• Main battery charging

• Main battery and vehicle diagnostics

• Training and certification

• Communication and marketing tools

This new label is the strength of an entire group at garages’ disposal. Deployed by and for NEXUS members and distributors, EVOLT! provides the tools, skills and knowledge needed to ensure that the maintenance and repair of electric and hybrid vehicles holds no secrets for them.

The EVOLT! concept is inclusive, allowing all types of workshops to participate, whether part of the NEXUSAUTO network, powered by NEXUSAUTO, or from independent workshops. All are eligible to join the EVOLT! initiative. This inclusivity ensures that the benefits of the concept can be extended to a wide range of service providers.

As a symbol of repair quality... Thanks to the label and the agreement signed between each distributor and the workshops, the label guarantees wellequipped and well-trained mechanics.

...And cost-effective solutions for customers

The workshop team has access to the latest technical information, the best

When we were asked by our Members to start preparing a concept dedicated to Electric & Hybrid vehicles, we seized the opportunity of starting a pilot phase with our historical French Member, ID Rechange. They were the first to kick off the NEXUSAUTO experience and are now proudly running the new EVOLT! area since January 2024.

diagnostic tools, provide parts of quality equivalent to the original, as well as recharging solutions.

EVOLT! SPECIALISTS are able to maintain and repair all types of vehicles, for the customers of today and tomorrow!

The several benefits of EVOLT!

• Stay customers’ favorite garage with this new concept. They want and need a mechanic they can trust to service and repair all family vehicles, including electric and hybrid vehicles.

• Attract new customers with this specialization. They will only have to travel a few kilometers to the garage. This will reinforce its presence with the local community.

• Maximize the number of people coming into the workshop; whether it’s a tyre needing repair, or a windscreen requires changing for example. Workshops already

see electric or hybrid vehicles passing by from time to time.

• Capture and retain these passing customers by becoming the one-stop shop for servicing and repairing their cars.

• Boost the workshop’s performance: its team will maximize regular entries into the workshop and generate new opportunities. The average shopping basket for an electric vehicle has the same potential as for ICE on a slightly different range of products (tyres, electricity, electrical components, etc.). Hybrid vehicles combine the best of both worlds.

4 SERVICE LEVELS TO MEET CUSTOMER EXPECTATIONS

1 Advisory service

Ability to welcome customers and ensure that all stages of the booking, from reception to health check, are carried out as efficiently as possible.

2 Maintenance

Guaranteeing basic safety and compliance with local regulations for the maintenance of all family cars in the same workshop.

3 Vehicle repairs

EVOLT! specialists know everything about repairing combustion, hybrid and electric vehicles!

4 Battery repairs

Part of the breakdown is attributed to the main battery. The label will ensure that

level 4 workshops are fully capable of meeting customers’ expectations [module under development]

To maintain the high standards associated with the EVOLT! label, there is a strict list of requirements that workshops must meet. These include specific equipment, tools, and the training necessary to service electric and hybrid vehicles effectively. Adherence to these requirements ensures that all EVOLT! workshops are equipped to provide top-notch service.

Compliance with local regulations is a cornerstone of the EVOLT! concept. Its adaptation is managed by N! Members with the assistance of N! SERVICE and local sponsors, ensuring that all operations are 100% compliant with the regulatory frameworks in their respective regions.

This compliance guarantees that EVOLT! workshops operate within legal parameters whilst delivering a high-quality service.

EVOLT! is more than just a workshop concept; it is a comprehensive approach to modernizing vehicle repair and maintenance for a sustainable future. By addressing critical issues such as carbon emission reduction, public health, and energy autonomy; EVOLT! workshops are poised to lead the industry in servicing electric and hybrid vehicles. The international framework, inclusive eligibility, stringent requirements, and regulatory compliance make EVOLT! a benchmark of excellence for the automotive service industry.

A global parking lot comprised entirely of electric vehicles is unlikely to be the future. However, the array of solutions available is extensive and will generate numerous opportunities for the Aftermarket industry, including electric vehicles, hybrids, ethanol-powered vehicles, as well as new vehicle sales, retrofits, repairs, and

The number of loyal partners supporting N! Service is quite large, but DELPHI was the very first to join the adventure of the new EVOLT! concept.

As a reliable and well-known parts and services provider, DELPHI ensures quality and experienced support for NEXUS Members.

maintenance services. In both current and future business landscapes, a streamlined approach will prove advantageous, with workshops positioned at the forefront of impending transformations.

Position your company as an expert and support your customers on their journey to becoming Electric & Hybrid specialists. Contact your NEXUS Business developer or drop us an email @ service@ nexusautomotive.eu

Delphi EV brake pads stand at the forefront of electric vehicle technology. Manufactured to exact OE tolerances, this innovative product range provides unparalleled braking performance right out of the box.

Safety, quality, and performance go hand in hand. The Delphi EV brake pads feature an advanced coating to deliver optimal initial friction performance. The result? Immediate and reliable braking power that ensures safety and efficiency from the first use.

Brakes degrade over time, but we’ve come up with an innovative solution to extend the lifespan of our EV pads—whatever the driving conditions. The silver powder-coated backplate protects each pad from rust, maintaining the integrity and performance of the brake system over time.

Electric vehicles are whisper quiet. Our EV brake pads enhance this driving experience by further reducing noise and vibration. We use a unique multi-layered composition of steel and rubber within the shim to enable a comfortable drive and stable, responsive braking.

We are committed to delivering sustainable products that never compromise on quality or performance. That’s why we are thrilled to report that—like 99% of our brake pads range—our EV brake pads have received the prestigious AASA Leafmark™ ‘N’ rating. This means our brake pads contain less than 0.5% copper by weight. They are heavy-metal free and eco-friendly, resulting in durable, low-dust brake pads that are better for the environment.

Our EV brake pads come ready-to-install. Each set includes all necessary hardware, including abutment clips, caliper bolts with the correct thread lock, electronic wear leads, and a grease sachet. A convenient and hassle-free installation saves time, empowering technicians to provide exceptional service faster

LP5034EV

TESLA MODEL 3

LP5034EV KIA EV9 & GENSIS GV60

LP5034EV

LP5034EV MERCEDES BENZ EQE & EQS

We are proud to provide our environmentally friendly EV brake pads for the Kia EV9, one of the 7-seat electric vehicles. Meeting a unique need in the market, the Kia EV9 sets a new standard in connectivity, comfort, and sophistication.

On the luxury front, the Mercedes-Benz EQE and EQS models represent the pinnacle of electric performance and elegance. The EQE offers economical options with substantial range and power, while the EQS provides a choice between powerful configurations for an incredible on-road experience.

The quality of our Mercedes-Benz EQE and EQS brake pads matches the excellence of the cars they serve. Engineered to meet high standards, they ensure every braking experience is as outstanding as the performance of the vehicle itself.

Delphi also holds the #1 coverage position for EV brake discs, drums and shoes across Europe.

Innovation is the heart of what we do, and looking ahead, we will continue leading the industry with first-tomarket products. To achieve this, we do more than respond to market needs. We anticipate them, shaping the future of the automotive world with forward-thinking designs that deliver on all fronts. There’s more to come, so watch this space.

The Elring spare part brand enjoys worldwide success thanks to ElringKlinger’s innovative force and expertise in the original equipment sector. For years it has stood for maximum safety, service and reliability.

We provide our customers with rst-class service: from the practical spare parts catalogs and technical literature to the service hotline. Wherever and whenever you need us, we are there for you.

Elring engine flyers: Here you nd all gaskets and gasket sets systematically arranged and illustrated for the speci c engine.