CIRCULAR ECONOMY

Did you know that the solutions which are the best for our planet, is often also those that are best for your operating costs?

Get the best from 2 worlds: Instead of buying new to get the best fuel economy, save 97% CO2 by getting a reconditioned DPF. You get performance like a new DPF, and you save the climate for the same burden of producing a new, as traditional cleaning would – at the expense of fuel economy.

So, if you’re not already familiar with Reconditioning, then it’s about time to get you introduced.

Definition: To restore a used product back to a near-new state of functionality.

Application: Diesel Particulate Filters.

Dinex has introduced Reconditioning as a central concept, defined as the restoration of a used product, particularly exemplified in Diesel Particulate Filters (DPF). DPFs play a crucial role in trapping over 99% of particulate matter in exhaust gases, preventing environmental pollution. However, over time, accumulated ash in the filter necessitates attention.

When facing filter maintenance, users typically choose between installing a new filter (costly), cleaning the existing one (only partially effective), or opting for a reconditioned filter. Dinex distinguishes between cleaning and reconditioning, emphasizing that reconditioning goes beyond mere cleaning. It involves a chemical dissolvent process that removes hardened ash, fully restoring the catalytic coating and bringing the filter close to a new state.

Dinex’s Recon-RX service stands out for its comprehensive offering. With a distribution network in Europe and North America, Dinex provides an array of reconditioned filters at attractive prices, backed by a two-year warranty. The service includes all necessary clamps and gaskets for a quick and seamless filter replacement.

Furthermore, Dinex facilitates a responsible return process for used filters, offering a cash-back deposit after quality inspection. Returned filters undergo a three-step reconditioning process, ensuring compliance with emission regulations and environmental sustainability. Notably, reusing filters through reconditioning contributes to a significantly lower carbon footprint compared to manufacturing new ones, with up to a 97% reduction.

In conclusion, Dinex’s Recon-RX service embodies the principles of Circular Economy, offering type approved, cost-effective, environmentally friendly alternatives in the Automotive Aftermarket.

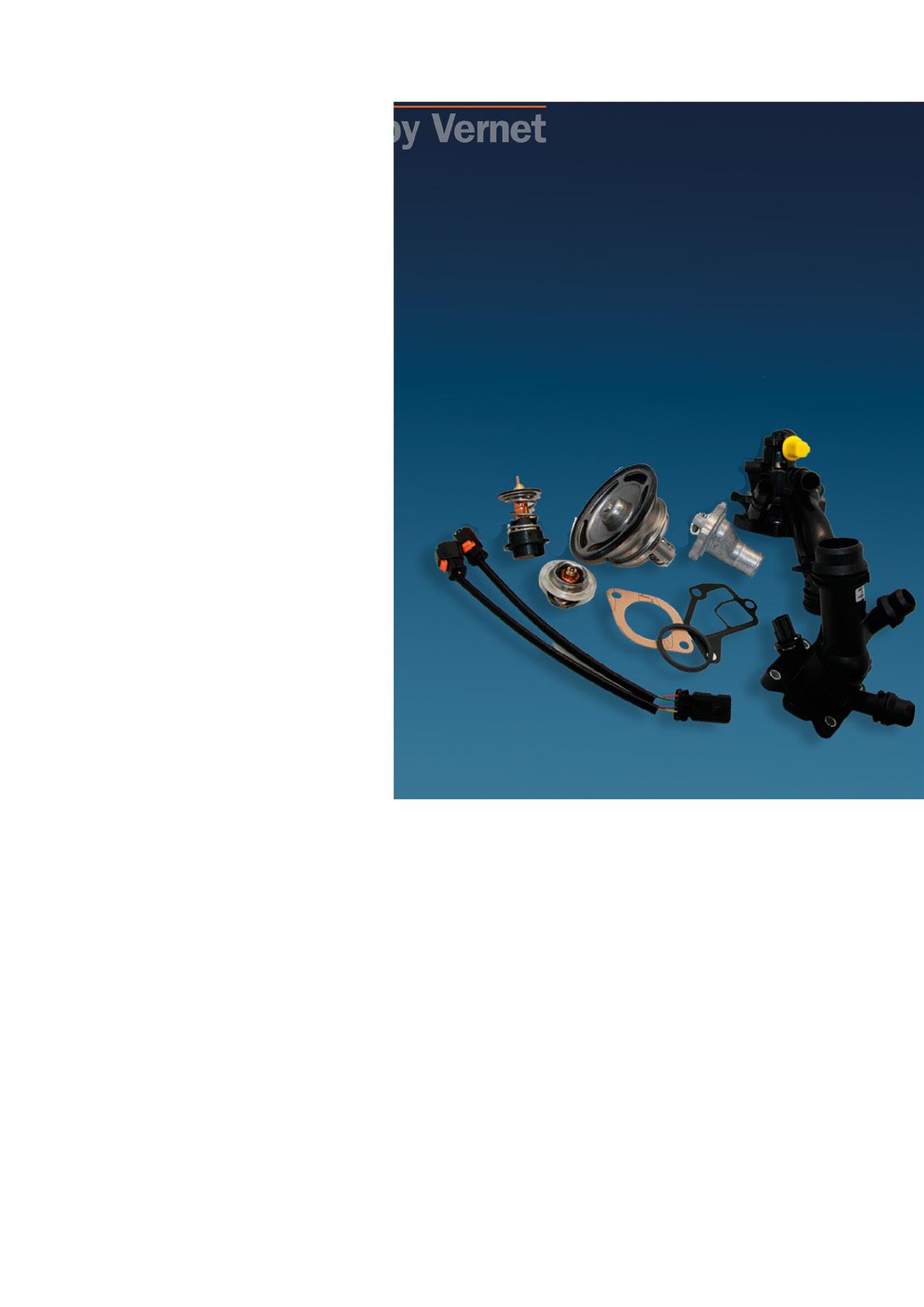

Independent workshops are now also able to flush the cooling circuit of certain engines according to the manufacturer’s specifications.

One of the crucial steps when carrying out maintenance on cooling systems is to flush the system thoroughly. Doing so prevents premature failure of newly installed components after replacing parts such as the heat exchanger, water pump or charge air cooler. This is because coolant quality deteriorates over the course of vehicle operation due to the additives contained in the fluid breaking down over time, and corrosion, calcium scale, traces of oil and other particles contaminating the coolant. Flushing removes deposits from the cooling circuit and ensures flawless engine cooling and anti-freeze protection once it has been refilled. Fresh coolant additionally coats the surfaces of aluminum parts with a protective film that inhibits corrosion.

If a new part is fitted without changing the coolant, its surfaces will lack this protection. This is because the fluid remaining in the cooling circuit will have no more additives left for the new surfaces, as they will already have been used to coat the removed part. Plus, it’s no use simply pouring in extra coolant as the additives are not able to target just unprotected surfaces and settle on them. In short, there is only one solution for professional mechanics. Namely, drain everything, flush thoroughly and completely refill!

This is why some manufacturers explicitly specify that certain engines must be flushed – as Volkswagen does for the EA288 and EA288 evo units, for example. And it is this requirement that has posed a problem for many independent workshops in the past, as usually only authorized workshops are able to obtain the right flushing device. Now, though, there is a compact solution designed to also allow independent workshops to flush these engines according to the manufacturer’s specifications: the TOOL BOX W04 from Continental.

Two cases, one solution

Continental’s new flushing kit fits into two handy cases. These contain the flushing and vacuum unit together with all the hoses required. Mechanics will find the necessary adapters and connectors in TOOL BOX W01. “Many workshops already use this TOOL BOX for cooling system diagnostics, meaning they already have all the adapters,” explains product manager

Maximilian Pape. “So we decided not to add these components to the new Tool Box W04 as well, to avoid needless duplicate purchases.” Now all that workshops need are the canisters for flushing and filling; the TOOL BOX even contains the requisite covers complete with connector.

The two boxes complement each other perfectly. The TOOL BOX W01 and the new TOOL BOX W04 provide mechanics with everything they need to carry out the complete flushing procedure, even when dealing with very intricate cooling systems – from bleeding and vacuum checking to creating a vacuum and the actual task of flushing. All connector systems and adapters have been designed so that they each fit just one mating part, thereby eliminating the possibility of connection errors.

Universal usability

Continental’s solution offers the added benefit of being universally suitable for all vehicles, and not just the aforementioned Volkswagen engines – an additional adapter also included with the kit allows the cooling system of non-VW vehicles to be flushed via the return line too. This is particularly important for older or second-hand cars. Maybe the previous owner topped up the system with hard water instead of distilled water. Or when fitting the water pump, the last workshop used sealing paste that has started to contaminate the coolant. TOOL BOXES W01 and W04 now enable workshops to put an end to the associated risks once and for all.

Venturi nozzle instead of an extra pump

“Instead of using an additional pump to create the vacuum, we have opted for a Venturi nozzle that is simply placed on the expansion tank,” explains Maximilian Pape. “This makes the complete system more compact and easier to use.” Speaking of ease of use: the manual supplied with the TOOL BOX describes exactly how to proceed.

‘Made in Germany’ seal of quality

TOOL BOX W04 is available from retailers now. All components are finished to a high standard and come with the ‘Made in Germany’ seal of quality.

www.continental-engineparts.com

48

SUSTAINABILITY, REMANUFACTURING AND CHARGING FORWARD TO NET ZERO

KEEPING PACE AND STRIVING FOR GROWTH

36

60

GENERALIZING THE COLLECTION OF USED PARTS IN WORKSHOPS

NRF APPLIES STRATEGY OF REDUCE, REUSE AND RECYCLE

...there was one system for all processes.

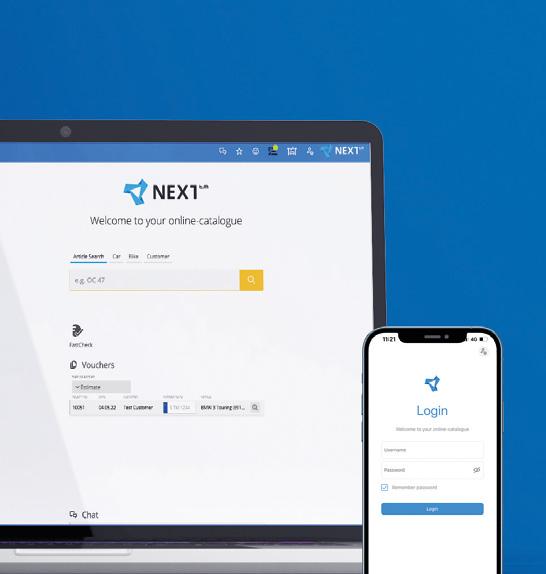

Behind the surface: Self-learning vehicle file ensures even more precise part identification by combining already “learned” equipment for the selected vehicle with the correct spare parts

Administration of vouchers, customer and vehicle master data

Integrated chat module for optimal communication

Multiple simultaneous independent tasks that are fully synchronized with the native mobile apps and much more

Uncomplicated parts search and graphical part identification based on OE-Data

Telesales: specialized catalog solution designed for telephone and counter sales, allowing salespeople to fulfill orders on behalf of customers

NEXT is the first generation of self-learning information systems with a variety of benefits and added values for wholesalers and their customers (garages and retailers). It automates the work process and facilitates repeated access to accumulated knowledge for each completed task, ensuring even more precise part identification. Through GSI-Remote, NEXT ensures interactive communication and data exchange between the catalog and other third-party systems. All this and much more is behind NEXT from TOPMOTIVE. Contact us!

www.topmotive.eu

The automotive industry is rapidly evolving, driven by new mobility concepts, digitisation and alternative drive types. With the growing complexity of vehicle configurations and the demand for faster product launches, the shift to real-time data processing in the automotive industry has become the new reality. To keep pace with these changes, TecAlliance has introduced the new TecDoc Ecosystem.

This pioneering ecosystem marks a pivotal shift in how businesses access, manage, and process catalogue data on a local, regional, and global scale. It empowers businesses with instant data management, enabling them to stay synchronised with the rapidly changing automotive landscape.

At the core of this new ecosystem is Instant Data Processing (IDP), which processes and updates data instantly, as opposed to quarterly or monthly submissions as in the past. IDP replaces full dataset uploads with easy-to-automate updates of data via web services, saving time and reducing errors.

„TecAlliance remains committed to delivering cuttingedge solutions that transform the automotive data landscape,“ said Jürgen Mehlis, Executive Vice President Data Manager Products. ”With the introduction of IDP technology to TecDoc, a new era of e ciency, accuracy, and business growth has arrived for our customers.”

The new TecDoc Ecosystem also provides benefits to TecDoc Data Users, such as traders, distributors and e-commerce platforms.

As the demand for timely and precise data in trade catalogues/ecommerce continues to grow, the need for innovative data solutions to streamline data management processes becomes increasingly vital. Thanks to IDP technology, TecDoc Data Users can now work with the most up-to-date data to benefit from immediate updates in the TecDoc Web Service and Catalogue.

TecDoc Data Package customers have options for accessing product data. They can use the new IDP Data Receiver API, which seamlessly retrieves the latest product data directly from the IDP channel. This enables users to access real-time product data as soon as TecDoc Data Suppliers provide it.

As another option, they can continue to use the TecDoc Data Packages, which are based on a weekly snapshot of the IDP Database in TAF Standard.

Instant data improves demand planning, inventory management, and procurement planning. It also reduces response times and improves e ciency and quality in the daily data management process.

For more information about the TecDoc EcoSystem and its o erings, please visit tec.al/Data_Delivery.

The ‘end of life’ inert waste streams generated from the Dumfries Site had historically been routed to landfill, and the weight generated had increased year on year, culminating in

For the first time in Dumfries site existence, we are so proud to have achieved the target of Zero inert waste to landfill as of May 2023.

Gates feels privileged to have been able to complete an environmental project that delivers such a historic / Game-changing moral, ethical, and projected financial positive return. By fulfilling its environmental obligations, Gates has not just reduced its footprint but completely eliminated its inert waste environmental impact.

As a responsible producer, Gates has initiated full site ownership and accountability for all inert waste streams generated from our process.

■ Reduction of Scope 3 Emissions: 370,644.438 Kg CO2e (95.45% Reduction) utilising 2022 data

■ Cost saving of £34,337.46 (16.55% Reduction) utilising 2022 data

■ Diversion of 829.78 Tonnes of waste from Landfill to Incineration – utilising 2022 data

■ Initiation of Dumfries site ‘Zero to Landfill’ for inert waste streams – First time ever that this has been achieved

■ Utilisation of a local, family / privately owned Business (Oakbank already has a Zero Landfill Policy)

■ Supporting and bolstering local jobs, community, and economy.

WELCOME FROM THE CEO Gaël Escribe, CEO NEXUS Automotive International

NEWS FROM N!

10

14

• N! launches its brand-new NEXUS website: A cutting-edge platform to shape the next decade of opportunity • N! Business Forum, Monaco March 5 – 7 • Stellantis and NEXUS Automotive International announce a strategic business partnership • DRIVE+: new ambitions, new identity and new tagline for NEXUS’ global aftermarket brand

Systems division, and Alexander Wagner, Vice President Aftermarket/TruckServices EMEA at Knorr-Bremse

46

INTERVIEW

36

• Knorr Bremse, Keeping pace and striving for growth, Bernd Spies, Member of the Executive Board of KnorrBremse, responsible for the Commercial Vehicle

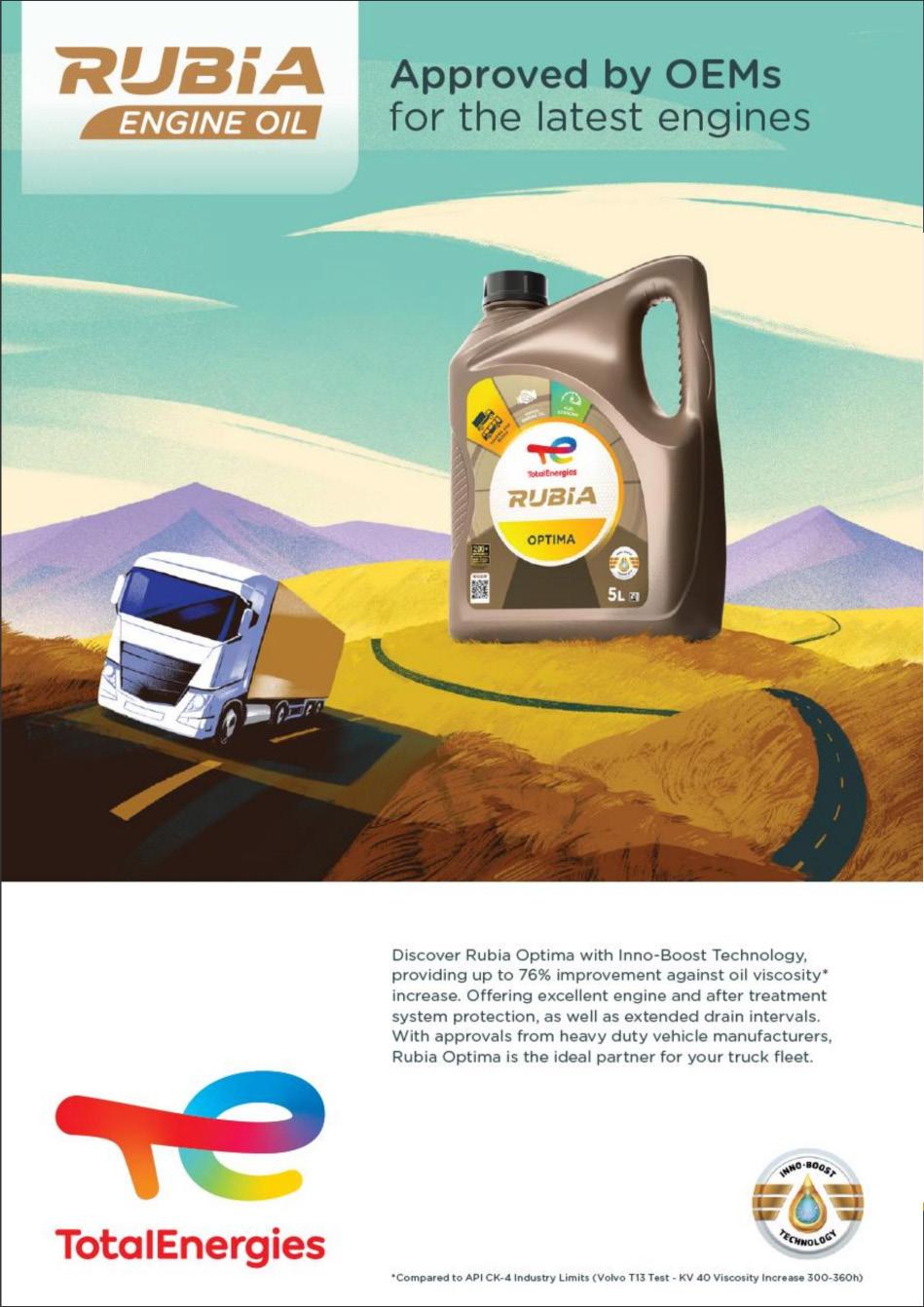

• Borgwarner, Sustainability, Remanufacturing and Charging Forward to Net Zero • Orum, EV Battery Repair in the Aftermarket, and The Role of Recycled Parts • Mobilians Remanufacturing, Generalizing the collection of used parts in workshops, Julien Dubois, President • N!Climate Day, Reverse Logistics: The waste of today are the markets of tomorrow! • NRF applies strategy of Reduce, Reuse and Recycle, Ángela García Maraver Director Industrial & Marine • Remanufacturing Industries Council, The importance of collaboration and education for reman organizations, Jeffrey Stukenborg, Chairperson • TotalEnergies Lubrifiants, Leading the way in sustainable packaging • Valeo Service, Come Rain Or Shine! • ZF, Remanufacturing - a vital element of ZF’s sustainability strategy

In an era where environmental consciousness is steering the course of industries across the globe, the automotive aftermarket is certainly not lagging behind.

As we navigate towards a more sustainable future, the spotlight is on recycling, reuse, reverse logistics, and remanufacturing in order to transform the aftermarket landscape into a hub of sustainability.

In this edition, we focus on the trailblazers within the automotive aftermarket who are championing the cause of sustainability. From recycling initiatives through to pioneering reverse logistics models and cutting-edge remanufacturing technologies, these visionaries are reshaping the industry’s future. We delve into their success stories, innovations, and the transformative impact they are having on the environment and the bottom line.

As we navigate the fast lane towards a more sustainable future, the automotive aftermarket is not just keeping pace; it’s taking the lead. Join us on this journey of innovation, responsibility, and commitment to a greener tomorrow. Together, we can drive sustainability and revolutionize the road ahead.

Now, enjoy the reading of INSIDE magazine n°35!

Gaël Escribe CEO of NEXUS Automotive International

The bilstein group is a family-owned group of companies in its seventh generation, headquartered in Ennepetal, Germany. As a medium-sized company, the bilstein group has always taken its environmental responsibility seriously. For us, sustainability is more than just a mandatory obligation. In the coming years, we want to align all our actions with it. Every important operational decision will be planned with sustainability in mind – because as a family business, we know that only sustainable business processes are models with a future.

We continuously work on making our packaging more sustainable.

We started with the elimination of ‘Combi packaging’, i.e. packaging made of a combination of cardboard and plastics. Additionally, we guide our logistics employees as well as our external partners as to what types of packaging material may be used.

For using plastics, the following rules apply: When using plastics is necessary, only PE (polyethylene), PP (polypropylene) or PET (polyethylene-terephthalate) can be used and the quantity is kept to a minimum. The use of PVC (polyvinylchloride) is strictly prohibited and the use of polystyrene should always be avoided (and is only permitted for moulded parts).

In 2019, we conducted an analysis on the usage of bubble wraps and used the results to reduce quantities by 24.5 tonnes by the following year. In 2022, we went one step further and switched to bubble wrap consisting of 50% recycled plastic.

With the recyclable bubble wrap, the bilstein group is taking another step towards greater sustainability. However, we will not stop there – our goal is to minimize the usage of plastic as much as possible. Therefore, until 2024 we will further increase our share of recycled plastic (depending on the type of packaging between 10% and 30%) and reduce the thickness of plastic foil from 100 µm to 80 µm.

In 2023 aftermarket service provider PARTSLIFE honoured the bilstein group with the environmental award for our commitment to sustainability. The award was presented for the high environmental and sustainability standards applied during the construction of the logistics centre in Gelsenkirchen.

In addition to district heating, the site also has a photovoltaic system with an area of around 6,000 square metres. The annual output of this system is around 700,000 kilowatt-hours, which is primarily used to operate the automated logistics systems. This intralogistics system, which has been tried and tested in the group since 2004, has been proven to save up to 40% of energy compared to conventional warehouses.

The logistics hub, which opened in 2022, is built to the KfW Efficiency House Standard 55. This means: the 45,000 square metre site requires 45% less primary energy than comparable new buildings without these efficiency measures.

The new logistics centre was designed and planned to be sustainable from the outset: from the possibility of urban working and integration into the existing environment to the reduction of noise emissions and the promotion of biodiversity through specially designed outdoor facilities and 15,000 square metres of green roofing. In addition to environmental aspects, this creates further benefits, such as improving the indoor climate in the halls below.

Further information on our path to sustainability can be found in our sustainability report.

“We see ecological responsibility not as a burden, but as an opportunity. Our declared aim is to reduce emissions along the entire value chain of our products. We will therefore continue to increase our efforts in terms of energy efficiency, resource conservation and energy management in the future,” says Jan Siekermann, Managing Director of the bilstein group.

This new website is not just a milestone but a testament to N! relentless pursuit of excellence. Designed to articulate N!’s pioneering vision for the aftermarket automotive industry, this website represents an embodiment of innovation and interactive engagement.

It serves as a dynamic space to spotlight the rich tapestry of the N! culture, and is a powerful digital arsenal for disseminating vital information and exclusive promotions from N! esteemed suppliers. As a successor to the previous website, this window exemplifies N!’s unwavering commitment to fostering meaningful dialogues and nurturing a vibrant community rooted in shared values and aspirations.

The focus is the Customer Experience to provide an easy way to find all the information about N! group (key figures, N! Team, N! news, etc.), the N! Community (N! manufacturers, N! Regional structures, N! Distributors members, etc.) as well as introduce the aftermarket initiatives.

Gaël Escribe said: “We are very happy to unveil this new website. This new window perfectly reflects our activities & initiatives comprising: N! Services and Solutions, N! Investments & Innovation Solutions and N! Sustainability; and provides our vision for the automotive aftermarket and sustainable mobility of tomorrow.”

N! will proudly celebrate its 10th anniversary in 2024. Over the past decade, N! has transformed into a global leader in the automotive aftermarket industry. N! is very excited to unveil its revamped corporate website, a showcase for NEXUS expertise, but also an excellence and resource center for the entire aftermarket industry. TO

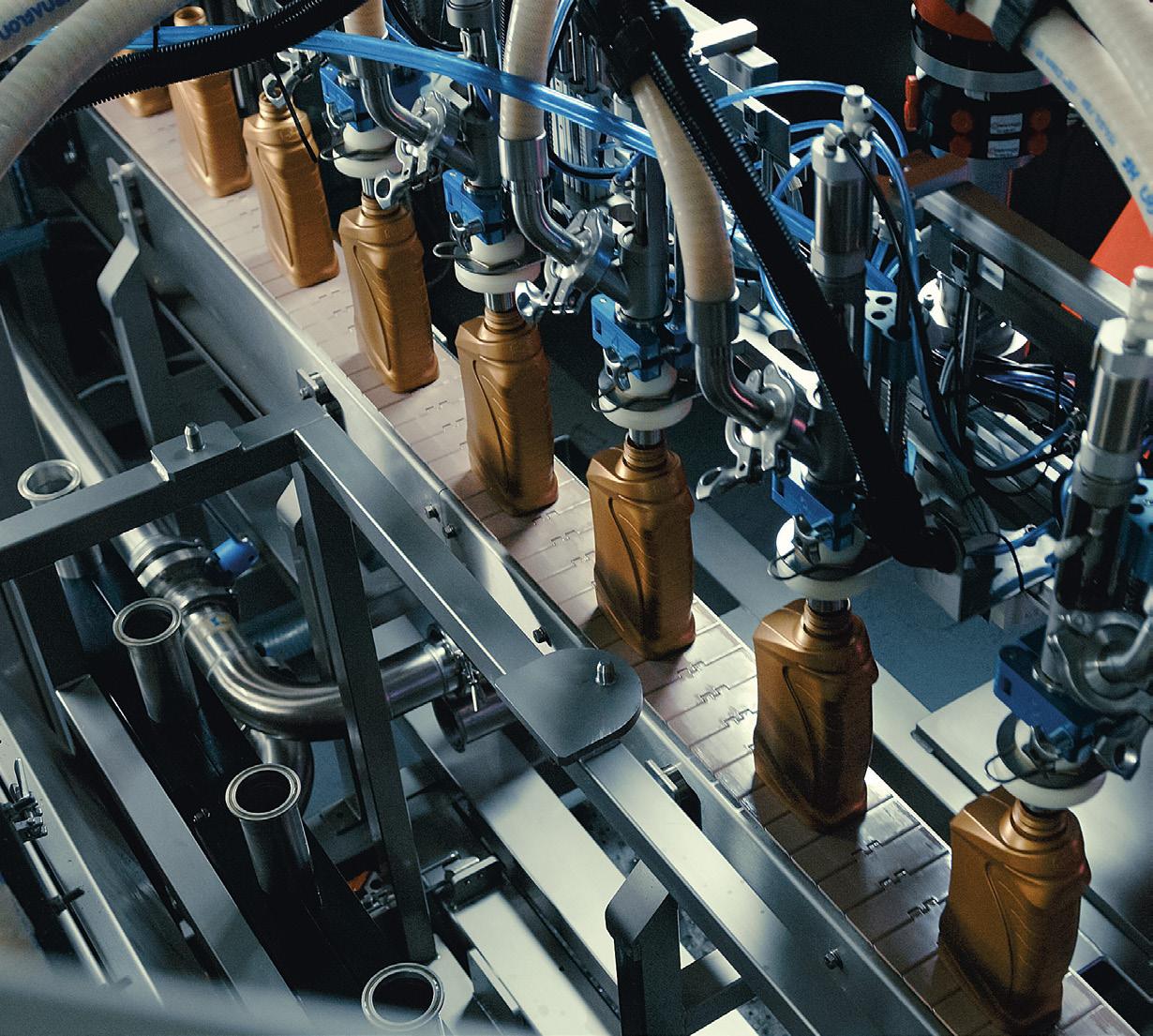

ASD Filling Station for container and drums

(Part no. 3384)

Rapid Cleaner 60 l (Part no. 3333)

Air spray can Rapid Cleaner (Part no. 6630)

Riser Rope for drums (Part no. 3386)

Disposable packaging costs money, and is also expensive to dispose of. Our filling station makes filling and transferring standard workshop products child’s play. The special valve on the base of the air spray can allows it to be filled with compressed air and liquid in a single operation without having to unscrew it. That saves you time and makes your work both cleaner and more cost-efficient.

The ease of handling and the ability to use free air as a propellant means this system pays off particularly quickly. There is no need for an additional drip pan for storage and transfer

ASD at a glance

We supply the Rapid Cleaner in a 60 l disposable drum (Part no. 3333).

Connection accessories required for containers and drums:

• part no. 7847: Adapter with side connection for container or

• part no. 3386: Riser pipe for filling station System for refilling the Air Spray Can (part no. 6630) with Rapid Cleaner/compressed air mixture.

www.liqui-moly.com

Shock absorbers play an important role in stabilising the movement of a car by using hydraulic pressure and friction. Hydraulic oil supports this operation. Without this oil, the shock absorber cannot perform efficiently. Conventional hydraulic fluids are packed with years of research, know-how and advanced technology, but many of their main components are base oils derived from petroleum. The newly developed SustainaLubTM aims to be a truly environmentally friendly shock absorber hydraulic fluid that eliminates the environmental risks associated with petroleum. SustainaLubTM is a sustainable product that is both carbon neutral and recyclable. Full release to the market is planned for 2026.

This new fluid contributes to carbon neutrality by switching from petroleum derived base oil to naturally derived base oil. It absorbs CO2 from the atmosphere during cultivation of the plants used for the base oil raw materials, also reducing CO2 emissions during transportation. It is biodegradable up to 60% or more according to the Eco Mark certification standard (OECD301). The base oil and additive formulation is recyclable, reducing environmental issues in the long term.

As a specialised global manufacturer of hydraulic equipment, KYB has long been involved in maintaining and improving the safety and comfort of automobiles. Using that experience, we are striving to achieve environmental balance without compromising performance or reliability. Not only does SustainaLubTM improve manoeuvrability and stability by applying it to the various damping force valves that we already offer, but it also improves the feel of the product by applying friction control technology, for example KYB Prosmooth® shock absorbers. With Prosmooth®,

internal shock absorber friction is controlled by using newly developed materials for sliding parts, and variable hydraulic fluid additive adjustment technology. This product delivers both a luxurious ride and superb cornering.

All new KYB products undergo reliability evaluation at the KYB Development Centre in Japan. Thorough performance and quality evaluation involves both bench tests and actual vehicle testing on our state-ofthe-art test track. This in-house design of a hydraulic oil recipe is unique to a manufacturer specialising in shock absorbers.

The KYB team participating in the All Japan Rally Championship JN-2 class introduced SustainaLubTM to their vehicles from round 6 onwards. They analysed and verified the performance and durability in the harsh race environment (see https://kybsport.com/ teams/kayaba-rally-team for more information on this vehicle). In addition, SustainaLubTM was trialled in the vehicle used in the LEXUS ROV (Recreational off-Highway Vehicle) Concept customer experience program. It was used for LEXUS’ first ROV equipped with a hydrogen engine. The data accumulated also contributes to technology development for future practical applications, and work toward the realisation of a carbon-neutral society.

Replacing petroleum based oil in KYB shock absorbers with this new hydraulic fluid will save up to 15.6 million litres of oil per year

KYB plans to ultimately apply this technology to all hydraulic products involved in realising a sustainable mobility society. As a specialised manufacturer of hydraulic equipment, KYB has long been working to improve the ride comfort and handling stability of automobiles. Based on this experience, KYB will continue to pursue advances in performance and reliability while keeping environmental impact at the forefront of development.

A 10-year anniversary event to unveil how NEXUS will continue to be a gamechanger and address the challenges of the AA: ‘Building the next decade together’

March 6th, 2024 – As part of celebrating its achievements over the past decade, NEXUS Automotive International hosts its most significant event ever organized, bringing together the largest community gathering in its history. This event comprised over 700 leaders, including 72 global suppliers and more than 400 members.

A very special event took place in Monaco, the temple of Formula 1 racing

During the plenary session, N! seized the opportunity to:

• Feed its community with insights from GiPA and Roland Berger experts.

• Display how to strengthen growth and increase the compliance ratio in a global fast changing market.

• Outline the workshop roadmap as a growth accelerator.

• Introduce Smartparts to the N! community.

• Keep maintaining a strong focus on innovation.

• Share Gaël Escribe’s vision for N! for the next decade:

He explained the rationale to transform N! ITG into N! Group, positioning it as the leading independent automotive aftermarket group.

The roadmap for future years will focus on 3 pillars:

1. Consolidate NEXUS as a leading ITG and bring the compliance ratio over 50% globally.

2. Develop transactional activities (primarly DRIVE+ related), and make DRIVE+ a leading brand of the global AA by 2030, hand-in-hand with N! best suppliers / partners.

3. Invest in innovative initiatives, as well as providing support for consolidation initiatives undertaken by NEXUS members to strengthen N! footprint in certain regions.

Last but not least, there is no future roadmap without making sustainability a competitive advantage.

The NEXUS Climate Day

A triumphant second edition of the NEXUS Climate Day attracted almost 150 attendees. This included the European association FAAS, the US associations Autocare and MEMA; along with the N! community, representing the entire supply chain, all united for a common cause: sustainability.

The NEXUS Climate Day actively pursued tangible solutions, initiatives, and best practices, fostering shared testimonials and insights in order to chart a more sustainable roadmap encompassing all three scopes.

Notably, several Proof of Concepts (POCs) were initiated between key suppliers and members, evolving into new NEXUS standards.

These included founding partners: Bosch, Delphi/ Phinia, Mahle, Schaeffler, SKF, TotalEnergies & Valeo with the support of Bilstein, Elring, KYB, Mecafilter, Mobilion, NTN-SNR, NRF & Smartparts.

Gaël Escribe said: “We were delighted to gather N! community in Monaco for this very unique edition of the Business Forum. This event provided an opportunity to reaffirm that the AA has a bright future ahead and to emphasize the necessity to draw a sustainable roadmap for our industry!”

ThenewContinentalUltraContactNXT. Maximumsafety,minimumimpact.

> Experienceourmostsustainabletirewithashare ofupto65%*recycledandrenewablematerial.

> Enjoyoutstandingmileagethankstoour provenYellowChilicompound.

> Relyonasafe,efficientandcomfortable

Winnerof theSAS Innovation Award2023

Learnmore: www.continental-tires.com

Compatiblewith

Energetic® filter inserts are a modern and sustainable alternative to conventional spin-on filters. The environmentally friendly technology from Hengst reduces waste by 90 percent and protects the environment in the long term.This is because the metal-free filter insert is simply replaced, while the housing remains on the engine block for the rest of its life. This ensures economical and environmentally friendly servicing with high usage intensity.

Energetic® filter inserts: Saving raw materials – for the sake of the environment. pan.

Spin-on filters have to be completely replaced and disposed of when servicing is required - over one billion spin-ons pollute our environment every year. Energetic filter inserts are therefore a resourcesaving alternative.

Changing a spin-on filter is time-consuming and can be an oily affair. Uncontrolled oil leakage into the engine compartment, incomplete retention of the used oil in the filter housing and the time-consuming disposal make spin-on filters costly and time-consuming.

The Energetic® system enables a clean oil filter change, shortens maintenance times thanks to good accessibility and a central service point. The filter can be changed quickly and cleanly from above without oil escaping. The integrated drain valve ensures controlled oil return to the oil

• Leveraging the strengths of both companies, Stellantis and NEXUS Automotive International SA enter a strategic global partnership that aims at creating a highly competitive, 360° offer, combining spare parts, and aftersales services around the world.

• Stellantis strengthens its position in several regions entrusting NEXUS members consistently with the established distribution model in the countries. Parallelly, NEXUS enlarges its community with distribution companies under Stellantis ownership.

• Companies intend to develop a global framework designed to accelerate and expand global sales by leveraging Stellantis’ extensive product and services offering and NEXUS’ aftermarket know-how around the globe.

AMSTERDAM & GENEVA, March. 6th, 2024 - Stellantis and NEXUS announced today their strategic and innovative business partnership. The partnership aims to further boost Stellantis’ aftersales brands while leveraging NEXUS’ established global distribution presence to significantly accelerate

in the independent aftermarket channel, starting with North America, Middle East, and Asia Pacific.

NEXUS members will access Stellantis’ 360° product & services offering that is complementary to their current portfolio, bringing more extensive and affordable solutions to global customers, consistently with the established distribution model in the countries (Selective Distribution, Authorized dealers).

This transformation from a conventional car maker and IAM leader to a more innovative and win-win partnership aligns with both Stellantis’ and NEXUS DNAs and long-term goals. The purpose of Stellantis is to “Lead the way the world moves” bringing clean, safe, and affordable mobility solutions as well as providing a full range of parts & services to create a lifetime relation with its customers and drivers.

As a growth accelerator, N! aims at shaping the aftermarket mobility of tomorrow and providing new business opportunities to its members.

This partnership also brings the possibility to further explore mutually beneficial synergies. These may include global purchasing consolidation, digitalization projects, leveraging both companies’ distribu-

tion footprint and commercial know-how, and also mobility solutions and circular economy initiatives. It will enhance the sustainability of their business model. This partnership also greatly expands the options Stellantis and NEXUS customers will have in a purely customer centric approach.

“This agreement is part of a global development initiative, in full coherence with our authorized repairers and Eurorepar Car Service network activity. Leveraging NEXUS’ community and footprint and Stellantis’ 360° product offering will reinforce our positions and strengthen our growth in line with our Dare Forward 2030 strategic plan goals. We are delighted to announce the ratification of this partnership with NEXUS that will benefit both our companies.” Said Sylvie LAYEC, Senior Vice President for Global Sales and Marketing at Stellantis Parts and Services.

“Being the leading AA community in the world and having an extremely progressive mindset, it is crucial to establish business relationships with leading players of the global automotive aftermarket. Shaping-up a fruitful roadmap for both Stellantis and NEXUS provides a lot of benefits to our respective companies and will help us to design the automotive aftermarket of tomorrow” said Gaël Escribe, CEO of NEXUS Automotive International.

In 2023, BOSAL has made a decision to move our central warehouse from Jirny to Ústí nad Labem, the Czech Republic.

Moving our central warehouse to this new location is testament to our dedication to providing a professional service to our clients. This new location provides us with greater visibility, a large space of 10,000 m2 and advanced technology that will allow us to streamline the operations and enhance our customer service capabilities throughout Europe.

In order to be able to make use of the improved infrastructure and services of this new central warehouse, we have decided to move the distribution for our DACH customer to this new central warehouse as well.

To create a similar benefit for our Benelux customers, it has been decided to move their distribution to our central warehouse in Béthune, France from 2024 onwards. This central hub promises improved efficiency, faster order fulfillment, and fast transit times, ensuring that our products reach the Benelux market swiftly and reliably.

We look forward to assisting you from our new warehouse location.

Our new address: Bosal Neovia, VGP Park, Tovární 3667/28, CZ - 400 01 Ústí nad Labem, Czech Republic

BOSAL aftermarket provides innovative product solutions within the emission control and chassis market.

As a family-owned global leader, with an established OE pedigree & more than 100-year history, BOSAL has long experience and knowledge in the manufacturing of aftermarket exhaust and chassis parts. Through state-of-the-art development competencies, strict selection and purchase of raw materials, our products are developed with the use of latest technology in manufacturing. Our high-quality product range is extended with an all-round service to the customer, strong availability and fast delivery.

For a complete overview of the range, see www.bosal.com/aftermarket

OUR

Working for a better future:

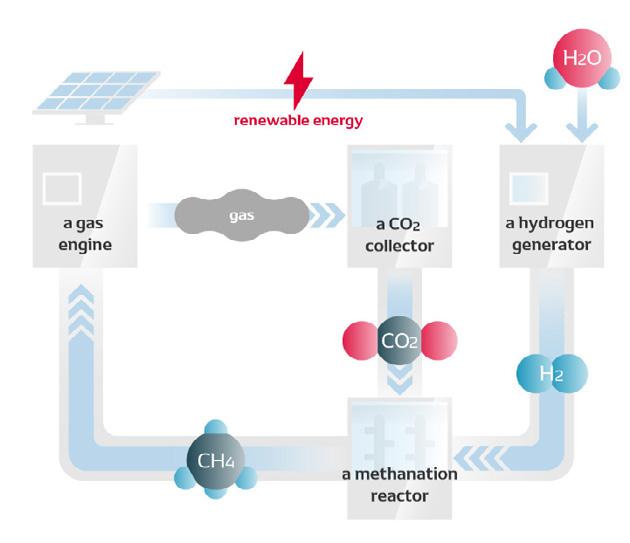

DENSO aims for Zero CO2 emissions as a norm for manufacturing!

From a problem to an asset:

CO2 emissions is captured and reuse through the development of CO2 recycling plant technologies.

Environmentally friendly & OE Quality. No Compromise!

DENSO & TOYOTA Joint CO2 recycling plant Aichi Prefecture, Japan.

DENSO & TOYOTA Joint CO2 recycling plant Aichi Prefecture, Japan.

The Philips Ultinon Pro6000 Boost range has been approved for road use in several European Union countries*, making it compliant with road-traffic regulations. Our bulb features a 30% smaller footprint than its predecessor, improving mechanical fit in the narrowest headlights

Drive in confidence with our new Philips Ultinon Pro6000 Boost LED bulbs!

* The Philips UltinonPro6000 LED Boost range is approved for road

PASCAL POPIS, CEO of SmartParts

PASCAL POPIS, CEO of SmartParts

Geneva, March 7th – At the NEXUS Business Forum in Monaco, DRIVE+, the exclusive global aftermarket brand for NEXUS members, is unveiling its updated brand identity and new tagline, “The workshop’s choice.” The DRIVE+ offer complement NEXUS’ core emphasis on premium brands, with a specific focus on ageing car parc.

In November 2023, the SmartParts entity was founded with the goal of deploying DRIVE+, the exclusive global aftermarket brand of N! members, to promptly respond to the evolving global aftermarket landscape and the ageing of the global car parc. Today, the brand is already established in more than 40 countries worldwide.

As part of its strategic investment in the DRIVE+ global aftermarket brand, SmartParts is excited to unveil its new global image, set to be launched worldwide before the semester concludes.

The focus is on mechanics, making them central to DRIVE+’s vision. The goal is to answer directly to the needs of mechanics worldwide, providing

quality products that offer excellent value for money and simplicity. The upcoming changes highlight DRIVE+’s commitment to creating a user-friendly experience for mechanics on a global scale.

The brand’s new tagline, “The workshop’s choice,” embodies DRIVE+’s core ambition: providing a comprehensive alternative range to workshops across the globe, focusing on cars older than 10 years with a minimum 80% potential market coverage.

Currently comprising 9,000 part numbers across 10 product categories, the range is poised for rapid expansion. Over 2,000 new part numbers

are already in the pipeline for 2024. The DRIVE+ range is developed in collaboration with NEXUS’ partner suppliers, presenting an additional growth opportunity.

In Europe, the comprehensive range is efficiently delivered to all NEXUS members from the central SmartParts Distribution Center located in Poland, ensuring an excellent service level and minimal lead times.

To complement this brand transformation, SmartParts proudly introduces the redesigned website driveplusinternational.com, that is not only more informative but also more user-friendly, reflecting the brand’s human-centric approach, fostering a close connection with repairers.

In a strategic initiative to boost brand visibility, DRIVE+ is gearing up to take part in the upcoming GT4 Europe series and the French GT series with two Porsche 718 Cayman CS GT4. The goal is to not only highlight the exceptional quality of DRIVE+ products but also to spark a renewed passion for the brand.

Pascal Popis, CEO of SmartParts, comments: “The segment of cars older than 10 years constitutes today a significant 47% in Europe G5 and 52% in LATAM. In the five major European markets, it is anticipated that by 2026, 27% of the car parc will consist of vehicles older than 15 years. Recognizing the undeniable trend of an ageing car parc in the coming years, DRIVE+, available from NEXUS members worldwide, emerges as the solution delivering products that offer excellent value for money, complementing premium brands”

From the ocean’s depths to outer space. Thousands of applications, one trusted choice.

Fit to more vehicles, increase customer satisfaction and boost your battery business.

More types than any other manufacturer

World-famous for exceptional quality

Unrivalled OE performance and reliability

Consumer website: yuasa.com

Trade battery lookup: fit.yuasa.com

Social @GSYuasaUK UPS

In a bold move towards sustainable operations, we recently inaugurated our new remanufacturing plant in Wroclaw, Poland. This plant represents a major landmark in Delphi’s dedication to ecological responsibility and cutting-edge remanufacturing practices.

The new plant showcases Delphi’s dedication to its sustainability agenda. It’s not just a factory — it’s a hub of green innovation.

Strategically located close to our central distribution centre in Europe, this facility is engineered to minimise our ecological footprint. As an example, the plant’s architecture features expansive windows to harness as much natural light as possible, reducing reliance on artificial lighting to cut our energy consumption.

Each part is disassembled, cleaned, inspected, and then rebuilt using new components.

A product that works just as well as a new one but with a smaller environmental footprint. It reduces waste, saves energy, and offers consumers high-quality products at a lower cost.

Delphi’s innovative approach is expected to have a significant environmental impact, with an estimated 18+ tons of material either being reused, saved, or prevented from reaching landfills.

With the capacity to process over tens of thousands of parts annually, our new facility is truly redefining industry standards. More than that, it is a core aspect of our ethos. Alongside offerings like Delphi’s authorised repair programs, it highlights our dedication to an environmentally mindful business approach. This plant is a proactive stride into a future where automotive sustainability is not just envisioned but actively realised.

The state-of-the-art facility is projected to be a cornerstone of business in the region with plans to expand the portfolio of fuel system technologies which can be remanufactured. This expansion will serve more customers and foster a team of experts dedicated to sustainable automotive solutions.

The Delphi remanufacturing plant in Poland sends a powerful message. It showcases how technological advancements can be harnessed to combat environmental challenges, paving the path for a cleaner, greener future for the automotive industry.

As good as new

Our broad REMAN turbocharger portfolio provides sustainble, cost-effective, high-quality solutions for vehicles in the later stages of their life cycles.

Our value propositions, reliable, sustainable, ready for tomorrow

Brakes are not only essential for safety; they can also make a decisive contribution to sustainability. As one of the leading suppliers, the company plays a key role in developing pioneering future technologies for brake systems and is therefore a strong partner for independent workshops on the road to more sustainability. Continental also offers everything to do with brakes from a single source in the aftermarket – such as spare parts from the premium brake brand ATE as well as services and advice on all aspects of the brake system.

Environmentally friendly solutions for the brake caliper

Based on its many years of expertise in original equipment, Continental has developed the “Green Caliper”. The compact green brake caliper has excellent properties for e-vehicles, in particular low thermal load and low weight, which contributes to a longer range of the vehicle. A solution for greater sustainability in the brake caliper value chain is remanufacturing. This tried-and-tested deposit system for workshops ensures a reuse and equips the calipers with spare parts of high original equipment quality standards in the remanufacturing process.

Euro 7 emissions standard requires lower emissions from brakes and tires

When it comes to braking systems, the increasing number of new registrations for electric vehicles leads to a comeback of the drum brake. It can have an environmental advantage over the disc brake because most of the abrasion from the brake lining remains within the encapsulated brake system. Instead of being dispersed on the road, it’s removed during the next workshop visit. Continental equips the VW ID family and vehicles of other

e-car manufacturers with drum brakes, already meeting the future Euro 7 emissions standards for emissions from brakes.

The ATE Ceramic brake pads are also an excellent brake product choice – the test winner in the 2021 ADAC accessories test with excellent marks for tire abrasion, low rim contamination and low brake pad and brake disc wear.

Automechanika 2024: First “green” brake fluid from ATE At Automechanika 2024 in Frankfurt, Continental will be focusing, on the topic of sustainability, among other things. Workshops can look forward to a premiere: Continental will be presenting its first “green” ATE brake fluid – just in time for the trade fair.

BERND SPIES, Member of the Executive Board of Knorr-Bremse, responsible for the Commercial Vehicle Systems division

ALEXANDER WAGNER, Vice President Aftermarket/ TruckServices EMEA at Knorr-Bremse

Like so many companies, Knorr-Bremse is feeling the current global economic impacts of the pandemic and the shifting international political landscape. In an interview with WERKSTATT aktuell, Bernd Spies, Member of the Executive Board of KnorrBremse, responsible for the Commercial Vehicle Systems division, and Alexander Wagner, Vice President Aftermarket/TruckServices EMEA at Knorr-Bremse, explain how the market leader for braking systems is nevertheless keeping pace in the truck business and also pursuing growth ambitions.

The last few years have been a real challenge for all companies operating in the truck segment. How did you and Knorr-Bremse experience this period?

Bernd Spies: From where I am today, I can look back on 30 years in the automotive business, over 15 of them in the truck sector. I would say that 2008 and 2009 were not easy years. But what we’ve been dealing with since 2020 has taken the challenges to a new level. For the entire team,

for all the people who work at Knorr-Bremse, these have been the most difficult years to date. The Covid pandemic has also changed how people live and work. For companies, it has altered working rhythms. That alone is a huge challenge. But also the pandemic period, when business activities started up again and new and existing supply chains still needed to be found or set up, was a huge feat. We focused and concentrated on our core business and prioritized ensuring the

smoothest possible supply to our customers. The fact that we succeeded in this is a huge achievement on the part of our employees.

The Covid pandemic and the war on European soil have disrupted supply chains and caused sales markets to collapse. How is Knorr-Bremse currently faring in terms of spare parts supply and overall economic development?

Bernd Spies: Due to inflation, we currently operate in an environment that creates very difficult conditions. We are confronted with inflationary effects and supply chains are not yet fully normalized, but we are getting a better grip on the situation. On top of that, we have a war in Europe, which generates uncertainty for all parties, be it for longer-term demand, energy supply or the future outlook for products and markets. So Knorr-Bremse is certainly facing plenty of challenges, but as a company we are steadily improving our ability to master them. We are also currently experiencing very healthy demand. In some cases, it is so high that we have to prioritize between different supply channels.

Alexander Wagner: We are also seeing high demand for Knorr-Bremse spare parts in the aftermarket. This is another area where we have managed supply bottlenecks very well and responded effectively to our customers’ needs.

Bernd Spies: One thing that has always been crucial is that our customers can rely on us – even at the expense of our stock at times. And this approach pays off. We have a high order backlog and can generate additional business. What’s more, our

core markets of North America and Europe are stable and developing positively. The Chinese market is also recovering steadily, but has yet to return to the level of three years ago.

What impact are the current high raw material prices having on Knorr-Bremse’s business?

Bernd Spies: It is important to draw a distinction here, because Knorr-Bremse does not buy raw materials but primarily manufactured parts. Raw materials follow certain indices, and these are currently showing signs of easing. But unfortunately we are not yet experiencing any effect from this. A significant recovery of prices is not in sight, as energy prices and labor costs have risen dramatically and transportation costs are significantly higher than before the crisis. Despite a slight easing, we cannot say that the market has recovered. Nor are we expecting a swift return to the pre-crisis market level.

So do you think the industry is over the worst impacts?

Bernd Spies: As things stand, I would say that we have learned to optimally manage crisis situations. But we are far from over the impacts of the crises. There is a lot of movement in the market due to supply chain difficulties and high inflation. This is felt acutely by suppliers, who have historically been the engine of the industry. But suppliers also need to benefit from the current market recovery and higher prices. We need higher margins again so that the industry can continue to develop positively – with e-mobility and automated driving, major changes are on the horizon, and they require very high levels of investment.

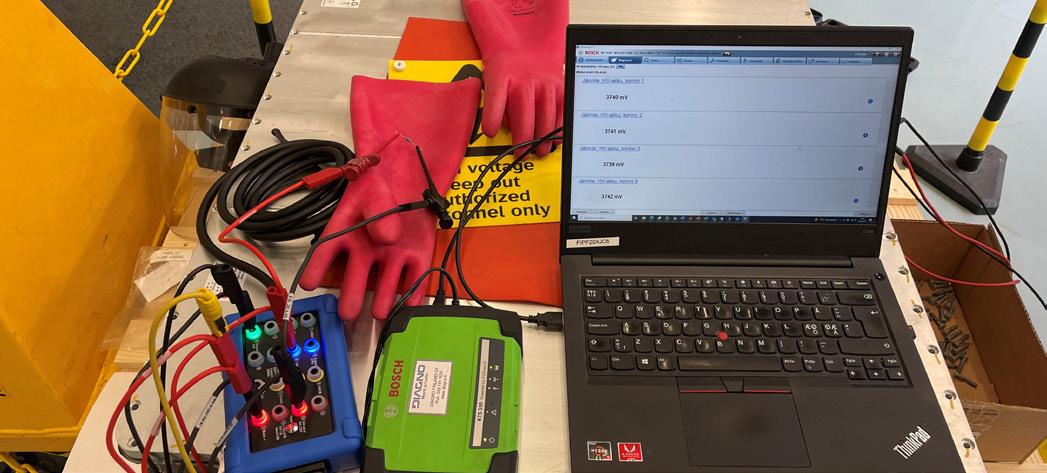

Despite this, Knorr-Bremse announced back in June last year that it had acquired a majority stake in the Spanish mobility services provider Cojali. Who is Cojali and what is the company’s position in the market?

Alexander Wagner: Cojali is one of the world’s leading suppliers of workshop equipment, and specifically in the field of commercial and special vehicles. It is a Spanish company with a successful history spanning more than 30 years, offering customers not only workshop equipment in the form of hardware and software, but also extensive technical support.

How financially sound is Cojali and how does the digital diagnostics provider fit into Knorr-Bremse’s portfolio?

Alexander Wagner: Cojali generated sales of around €90 million in 2022 and achieved low double-digit growth in recent years. In the medium term, we are convinced that the company will reach sales in the hundreds of millions and con-

tinue to grow. In terms of the portfolio, Cojali’s flagship is diagnostics. The company is one of the leading providers in this area. The Jaltest Diagnostics multi-brand diagnostic system covers the requirements of an entire commercial vehicle, both the tractor and the trailer, regardless of the vehicle manufacturer’s brand. Moreover, diagnostics is of course the foundation when it comes to big data analysis. It makes it possible to analyze which faults occur on which vehicle in which time period as well as which products are affected by the fault. This gives us a crucial basis for offering even more solutions in the area of digitalization in the future.

Given the know-how of Cojali, will KnorrBremse be offering predictive maintenance solutions in the future?

Alexander Wagner: We are currently talking about condition-based maintenance in the context of remote diagnostics. This involves the vehicle reporting faults that we can already cluster accor-

ding to their urgency using fault codes. The data we generate with Jaltest Diagnostics will then help us to further expand the area of predictive maintenance.

At the same time, Knorr-Bremse already offers NEO, an established workshop diagnostics system. What are the differences between the two diagnostic systems?

Alexander Wagner: The NEO workshop diagnostics solution focuses on the Knorr-Bremse portfolio and therefore also offers fault-guided diagnostics for systems developed by Knorr-Bremse. Jaltest Diagnostics, on the other hand, works across brands and vehicles. As a result, the two system solutions complement rather than compete with

each other. We are currently working on an integrated solution with diagnostic hardware for these two diagnostic worlds.

So NEO will not be discontinued?

Alexander Wagner: No, it will remain available to workshops as a module for the Jaltest Diagnostics solution. NEO will then be provided as a software solution, developed further and run on Jaltest devices. NEO will also be available to download for the existing Jaltest end devices under a licensing model. However, the ongoing development of NEO will then be pursued jointly by the two platform partners.

How many users use the Jaltest Diagnostics solution?

Alexander Wagner: What I can tell you on this is that Cojali is a global leader and Jaltest Diagnostics currently covers more than 6,300 truck models from more than 200 brands. Remote diagnostics, which takes place while the vehicle is on the road, is also enjoying great popularity with customers in combination with Jaltest Telematics, with more than 20,000 vehicles already on the road worldwide using this system.

Are any additional costs involved for Neo’s and Jaltest’s existing customers?

Alexander Wagner: A separate license is available to purchase for the NEO module. We will make a commercial offer to the existing users of NEO and Jaltest hardware, respectively, to make the switch to a complete Jaltest Diagnostics package attractive.

How does Knorr-Bremse TruckServices support its customers in integrating the two diagnostic systems?

Alexander Wagner: Integrating the two systems is actually self-explanatory, as the scope of NEO services will still be available, but now as integrated software. Nevertheless, we will also offer appropriate training to support users. In addition, the technical hotline of both Knorr-Bremse and Cojali will be on hand to assist customers as required.

Currently, diesel remains the drive concept of choice in freight transport. Nevertheless, battery electric and hydrogen electric mobility are

gradually finding their way into fleets – both for tractor and trailer units. This also presents a new set of challenges for predictive maintenance. How are Cojali and Knorr-Bremse positioned to meet these challenges?

Alexander Wagner: As I said, we already offer a remote diagnostics solution. This gives us access to everything in the vehicle that is relevant for diagnostics. And regardless of how the vehicle is driven, the system will thoroughly check the condition of the vehicle in order to provide the fleet operator or the workshops with information on the presence and description of any faults. We will continue to expand this topic in the direction of predictive maintenance – also with an eye on vehicles with alternative drives. Of course, this journey will also involve checking the battery status, e.g. how quickly the battery is discharging, how long it takes to fully charge the battery, the temperature of the storage medium – all of this will come.

Bernd Spies: Another aspect that will prove important is user behavior, which is bound to change as e-mobility progresses. In the medium to long term, these trucks will be more expensive and will therefore be left idle less. That means more time on the road, which makes remote diagnostics and predictive maintenance extremely important. Besides, e-mobility is going to alter the entire transportation landscape. In the future, freight forwarders may no longer purchase the new trucks, but lease them instead. Pay-per-use models are also conceivable, given the high purchase price. If we now add automated driving to the mix, plus frequent update requirements for the vehicle’s software,

user behavior is going to change accordingly. And Knorr-Bremse is ideally positioned to respond to this, especially with a company like Cojali.

Whether it’s a combustion engine or an electric vehicle – they all need to hit the brakes. How do Knorr-Bremse and Knorr-Bremse TruckServices view the transformation in mobility?

Bernd Spies: That’s true. But the shift toward e-mobility also places new demands on brakes. Today’s e-trucks are diesel vehicles with e-motors. Tomorrow’s e-trucks will be built around this new drive and technology, with different approaches and different platforms. Perhaps these vehicles will require smaller brakes, but they will still have to provide the same power for emergency braking. There is a lot of discussion on this topic. One thing is certain: brakes will continue to evolve. Many customers are already willing to engage in these discussions with us and enter into more in-depth partnerships. We are also actively exchanging ideas with our customers about brake dust emissions so that we can offer new solutions. Aside from the brakes, however, the existing infrastructure must be adapted to the new trucks. On the subject of charging infrastructure, I don’t think the government is moving fast enough to help the industry push the issue forward. More urgency is needed

here, otherwise the transport industry will have the wind taken out of its sails.

Alexander Wagner: E-mobility will not be the only challenge for commercial vehicle workshops in the future. The topic of sustainability will also become increasingly prominent for workshops. We already began developing a broad portfolio for remanufactured products in 2013 (see box) and launched our own plant for remanufacturing activities. Electronic repairs will be a growing focus of workshops as the proportion of electronic components continues to rise. To this end, we are already working on solutions that enable guided electronics repair, including end-of-line testing. In addition, new vehicle brands will steadily gain ground in the European commercial vehicle market. Already today, there are new Chinese and Turkish manufacturers that are quickly establishing themselves. For them too, we are working flat out to develop technical solutions to support workshops in servicing these vehicles. And with regard to talent shortage, we are trying to reduce the entry hurdle for using the workshop tools, particularly by improving user guidance.

In October 2023, this interview appeared in WERKSTATT aktuell, issue 3/2023.

The meaning of sustainability in the Automotive Aftermarket continues evolving as the industry faces significative transformations. This is a major challenge that companies must embrace with decisiveness and adaptability.

We at Dolz try to apply a sustainable approach throughout the organization, as reusing energy during the production process, with major steps to improve our sustainability efforts and become a company with a positive impact. We think that quality and environmental protection should go hand in hand.

The extensive product assortment offered by Dolz includes hybrid and electrification solutions. With over 1,300+ references of water pumps including electric water pumps and auxiliary water pumps with a coverage of 95% for all popular vehicle types in Europe.

Demonstrating our commitment to a more sustainable future, at a global level to efficiently sustain combustion, hybrid, and electric vehicles of today and tomorrow

Dolz is ISO 14001:2015 certified. The international standard specifies the conditions for developing an environmental management system (EMS) for a company that effectively and consistently oversees all potential responsibilities in this area within an organization.

• Water and Waste Management with an evaporator to obtain process water and concentrated oil waste.

• Shavings compactor and lubricoolant oil recirculation in machining operations.

• Removal of an emission source (drying chamber).

• Energy Management and Emissions.

• Adaptive packaging.

Further information about Dolz is available at www.idolz.com

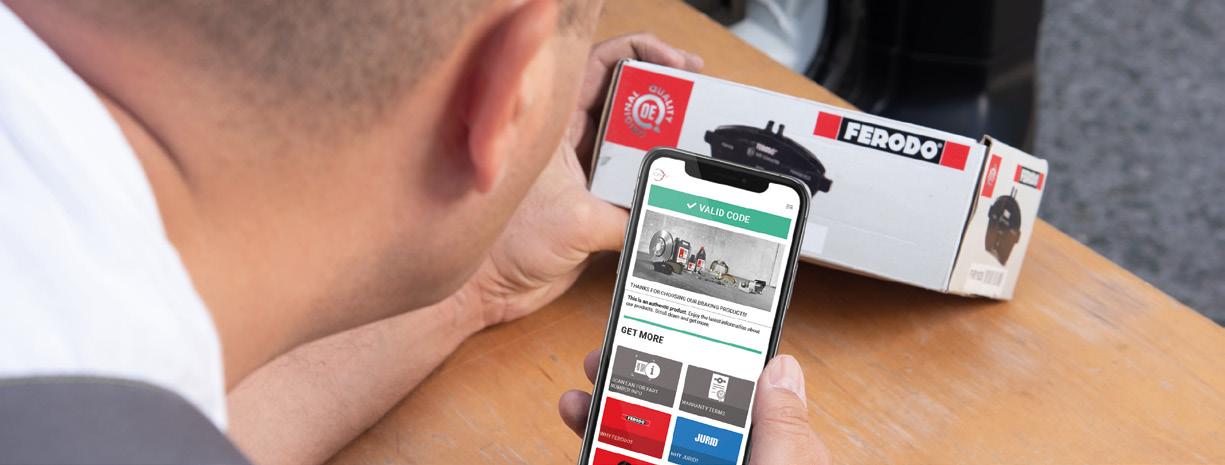

DRiV is making the QR codes on its product packaging even more essential to those who work in the automotive aftermarket with the addition of recycling instructions

The details on how to correctly dispose of the packaging complement the comprehensive information that can already be gained via the scannable codes. It also reinforces how the QR code’s digital communication supports sustainability, avoiding the need for any printed communications.

To access the recycling details, all that’s needed is an initial scan of the QR code with a smartphone that has an internet connection. The menu button for the information is then displayed, and a quick press takes the user to the relevant pages on the DRiV website.

The inclusion of the relevant recycling instructions conforms with recent Italian legislation that dictates such information must be available, but DRiV has also implemented an English version to help a wider audience in the automotive aftermarket to be more environmentally aware and remove any doubt as to how the packaging can be recycled.

Long before sustainability became a popular mainstream concept, BorgWarner developed a vision of a clean, energy-efficient world – and today we’re still committed to being a sector leader in this regard. While the vision hasn’t changed, our sustainability strategy now drives a wide range of environmental and social initiatives intended to benefit all of our stakeholders.

There are a number of ways in which we’re advancing our environmental stewardship. It begins with our products – we’re constantly expanding our electrification offerings to improve efficiency and reduce emissions. It also extends to our global operations; as we create a new facility, or expand a site, or update one of our existing

factories to accommodate business growth, environmental sustainability is at the forefront of our planning. Projects already implemented across our global plants include installing solar panels, converting to low-friction compressed air supplies, employing heat recovery systems on air compressors, installing more energy-efficient lamps,

treating, and reusing wastewater, and sourcing 100% renewable electricity. These actions have already contributed to a CO2 equivalent reduction of more than two thousand metric tons and a reduction of roughly four gigawatt-hours of electricity usage.

Social responsibility is essential to the sustainability of BorgWarner operations if we’re to continue to succeed long into the future. That’s why we’re nurturing the talent pipeline – for example, we have a specialized training program called ‘Power to Evolve’ that enables our engineers to acquire the new hands-on skills and expertise needed to work on electric drive systems. It’s also why we continually strive to create and maintain a diverse and inclusive working environment, where our people enjoy harnessing their collaborative power to achieve excellence.

Before explaining how remanufacturing contributes to our sustainability goals, it’s perhaps useful to summarize how we go about the process. We separate the individual components of a used part into those that must always be replaced –such as bearings – and those that can potentially be reused. The latter are cleaned, then checked against original specifications to ensure they are within tolerance for remanufacturing. We replace components that don’t meet the criteria with new OE items and combine them with the reusable components to complete the parts list for a remanufactured assembly.

We’ve been supporting the circular economy by remanufacturing parts for nearly 30 years, including turbochargers, alternators, generators, electronic unit injectors, and exhaust gas recirculating valves. During that time, we’ve reused more than 24,500 metric tons of cast iron and aluminum. Our turbocharger remanufacturing program alone has saved some 5.2 million turbines, compressor housings and bearings from landfill. Across our product lines, approximately 36% of our input in 2022 came from recycled or remanufactured material.

We’ve made significant progress towards our sustainability goals over the past two years,

despite significant headwinds and market volatility. In 2021, we announced our Charging Forward strategy, designed to increase production of electric and other vehicle parts that enable zero- and lower-emissions transportation – and in 2023 we invested approximately 19% of net eProducts sales into eProducts R&D to maintain our position at the forefront of electric vehicle technology. The rapid gain in momentum means we now expect to achieve our 2025 goals well ahead of schedule, so we’ve evolved our strategy to Charging Forward 2027, which aims to achieve 49% of sales revenue from eProducts by 2027. Our ultimate goal is to achieve carbon neutrality – Net Zero – by 2035.

You really can get more brightness from the same light output now. The Philips Ultinon Pro6000 Boost bulbs feature automotive industry-exclusive LEDs and a revolutionary architecture that ensures unique optical performance. The result is an impressive boost in brightness on the road, up to 300% more!

*Compared to the minimum legal standard for halogen bulbs. The Philips UltinonPro6000 LED Boost range is approved for road traffic in the respective countries where approval exists and for the listed range of vehicle models and lighting functions only. For more information about the legal requirements that apply in your country and to consult our latest compatibility list, visits Philips.com/roadlegalLED. You are responsible for complying with legal requirements applicable in your country.

Genuine, economical, sustainable

EconX® products are the ideal solution for repairing older vehicles: sustainable and especially economical, because their lifetime expectancy is tailored to the remaining service life of the vehicle without compromising safety or reliability – thanks to a remanufacturing process that meets the quality standards of our OE-products.

EconX products allow every commercial vehicle to stay on the road for longer –always cost-effective, technically on the best possible level and geared towards safety!

| truckservices.knorr-bremse.com |

Sustainability is more than just a “green wash”. There are three dimensions to sustainability – ecological, economic and social factors. At MANN+HUMMEL, we see ourselves as pioneers and are adding a fourth dimension to these concepts.

As a technology-driven company, we have now been developing innovative solutions for over eight decades. We firmly believe that technology is an essential dimension of sustainability. In the case of MANN+HUMMEL, the technology dimension is the filtration dimension. Our filtration solutions enable our customers to produce and operate in a more environmentally friendly and sustainable manner. Filtration separates the useful from the harmful and ensures, among other things, that machines can be operated for longer, clean breathing air is available and the scarce resource of water is conserved. In this way, we contribute to clean mobility, clean air and clean water. At the same time, we focus on a sustainable use of resources in the manufacture of our products and solutions.

The improved MANN-FILTER C 24 005 air filter, for example, contributes to this with its evolved filter medium made from recycled plastic fibers. „One square meter of filter medium now contains plastic from up to six 1.5-liter PET bottles. This has enabled us to triple the proportion of recycled fibers and consequently make an important contribution to the careful use of resources,“ explains Jörg Schömmel, Senior Range Manager for Air Filters at MANN-FILTER.

More air filters like the C 24 005 with this medium will be launched on the market. Their green, recycled fibers distinguishes these air filters from others. They meet the replacement intervals prescribed by vehicle manufacturers even under dusty conditions, and are characterized by their flame-retardant properties. The new MANN-FILTER air filters are also supplied in OEM quality.

Thanks to the multilayer MICROGRADE A-S medium, the separation efficiency of C 24 005 air filters is up to 99.5 percent, when tested with ISO-certified test dust. Thanks to its high dirt holding capacity throughout the entire service interval, the air filter requires only 30 percent of the filter medium area of traditional air filters based on cellulose media. The fibers of the evolved medium are certified according to Oeko-Tex Standard 100, meaning they are tested for pollutants and declared non-harmful.

Filters from MANN+HUMMEL are in continuous development. As well as meeting technical specifications, one of the most important factors for MANN+HUMMEL is sustainability.

MANN-FILTER air filter with increased proportion of recycled fibers

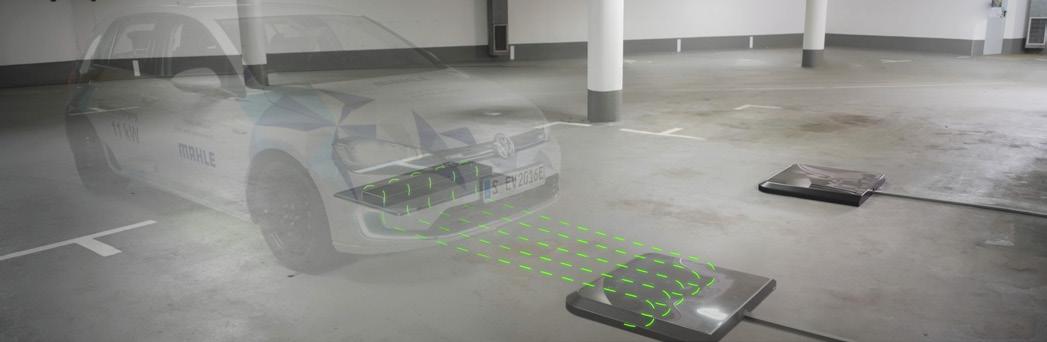

• SAE International chooses the MAHLE positioning system as the global standard solution for the wireless charging of electric vehicles

• Key technology closes the crucial gap in standardization

• Cross-manufacturer solution enables a comprehensive and rapid market launch

• MAHLE CEO Arnd Franz: “A strong impetus for e-mobility.”

Inductive – i.e. wireless – charging of electric vehicles is much more convenient as there is no need to fiddle with cables or search for a charging station with a suitable plug. MAHLE has developed a positioning system that allows an electric vehicle to be simply, reliably and precisely aligned above the charging coil in the floor. SAE International has now chosen the MAHLE positioning system as the global standard solution for wireless charging. The internationally renowned non-profit association for the progress of mobility technologies, based in the USA, thus closes the last gap in standardization of inductive charging that has been unfilled for ten years. The cross-manufacturer solution from MAHLE now paves the way for the comprehensive and rapid market launch of this attractive alternative to wired charging for batteries and electric and hybrid vehicles.

“MAHLE is setting standards. The renowned SAE’s decision in favor of our technology confirms the systems expertise of MAHLE in electrification as well. This will be a strong impetus for e-mobility,” said Arnd Franz, Chairman of the MAHLE Management Board and CEO.

The MAHLE positioning system DIPS (Differential Inductive Positioning System) represents a paradigm shift in the field of emobility. It is based on a magnetic field and automatically establishes a connection with the controlled charging point as the electric vehicle approaches. A special navigation system in the vehicle display supports the driver, and the car is soon in the ideal position. The charging process begins automatically. This also works with an autonomous parking vehicle, where the parking system receives the necessary positioning instructions instead of the driver. Thanks to the unique MAHLE positioning system, the parking process can be carried out very easily and reproducibly in one go. And this also applies to unfavorable environmental conditions such as snow cover or wet leaves on the bottom plate.

For the wireless charging of electric vehicles, all components relating to both the infrastructure and the vehicle side must be standardized. Only then can both the vehicle manufacturers and the

infrastructure providers bring a solution to market that ensures compatibility regardless of the manufacturer. MAHLE will make its solution accessible to the entire industry via a license model under FRAND (fair, reasonable, and non-discriminatory) conditions.

The broad applicability of the system will also enable mobile applications in the future, such as charging via induction coils while driving. MAHLE has also formulated the standard for this together with Electreon Wireless.

In terms of charging infrastructure, MAHLE has long relied on wireless charging, which is a convenient and promising alternative for electric vehicles. “Siemens and Witricity are two strong partners at our side with whom we are jointly advancing the complete system of charging infrastructure and automotive engineering,” said Dr. Harald Straky, Head of Corporate Research and Advanced Engineering at MAHLE.

More than 128,000 engineers and technology experts from the aerospace, automotive and commercial vehicle industries are organized in SAE International. SAE develops global technology standards, including the standardization of the vehicle identification number.

Looking for a partner to enhance your business operations and achieve your sustainable goals ?

The first sustainability and business rating solution dedicated to the automotive aftermarket

www.inteliam.eu

JULIEN DUBOIS, President of Mobilians Remanufacturing

JULIEN DUBOIS, President of Mobilians Remanufacturing

What does the Mobilians branch represent?

Julien: Mobilians is the French employers’ organization. It was founded in 1902, to defend the interests of distribution and automotive services companies in France. Mobilians Remanufacturing was created in 2023 to bring together around 40 players - from family-owned SMEs to major suppliers. Our mission is to promote the circular economy.

What does remanufacturing represent in the aftermarket today?

Currently, used + remanufactured parts represent about 5% of the aftermarket market

in France. This figure is expected to triple in the coming years; we project 15% by 2032. In comparison, this activity already accounts for 15% of the Swedish aftermarket and 20% of the American aftermarket. In the US, up to 100 different parts are disassembled per end-of-life vehicle, compared to only 15 in France, making the raw material much more abundant.

If so, few parts are disassembled in Europe. How do you source your parts?

From workshops! This is mainly due the treated fleet being younger, more representative and closer to our needs than end-of-life vehicles.

How do you encourage garages to return disassembled parts to you?

Nothing new here: the secret is the deposit! The distributor invoices the garage for the cost of the deposit and reimburses it upon receipt of the old material. It’s simple, effective, and it works. We estimate the return rate to be around 90%. The reverse logistics chain is straightforward: from

the garage to the distributor, who then sends the parts back to the remanufacturer. At Mobilians Remanufacturing, our focus is on generalizing collection at the garage.

Is the remanufactured part a sustainable alternative to a new part?

Yes - on all fronts. Firstly, it is about 50% cheaper for the consumer, and a good response to inflation and purchasing power issues. Secondly, the material savings are absolutely enormous: around 80%, not to mention energy savings of around 60% to 70%. Finally, this sector creates skilled and local jobs, close to customers. 90% of parts collected in Europe are remanufactured in Europe!

The remanufacturing success story requires the involvement of all the supply chain stakeholders: suppliers, distributors and workshops. Every player has indeed a key role!

Continental’sadvancedhotandcoldretreadingsolutions provideforadditionalmileagebygivingyourtyreasecond oreventhirdlife.Thisnotonlybenefitsyourbudget,but theenvironment,too–reusingthetyrecasingsaves energyandresources.

Continental’srangeofpre-curedtreads forcoldretreadingisbasedonnew tyretechnology.Toensurethehighest productandprocessquality,retreading iscarriedoutbyacertifiedpartner network.

Hot-retreadedtyresarerenewedfrom beadtobead,applyingthesame technologiesusedinnewContinental tyres,andthoroughlytestedforquality.

Learnmore:

www.continental-tires.com

The internal combustion engine will keep us busy for quite a while. But the future belongs to e-mobility and other emission-free drives. On the street and in the workshop.

That is why we take care of one thing without leaving the other: MAHLE develops and offers the right products and solutions as well as a comprehensive service for sustainable mobility, whether with an internal combustion engine, electric drive or alternative technologies and fuels. Our range extends from engine cooling and air conditioning to engine parts and filters, to workshop equipment and diagnostics.

At a time when mobility is changing rapidly, we need an experienced, trustworthy and innovative partner. Someone who

not only guarantees quality, reliability and expertise, but also knows the ways that no one has “driven” before.

With MAHLE, your workshop delivers 100% performance –today and tomorrow.

mahle-aftermarket.com

NEXUS Automotive International emerged as a pioneer when it committed to addressing sustainability issues by 2018. The challenges of sustainability are deeply embedded in NEXUS values and mission statement and are tackled with a ‘hands-on’ operational approach.

NEXUS Climate Day’s ambition is to unify the entire aftermarket supply chain from manufacturers through to distributors and garages. Concepts are tested to ensure that they not only offer value, but open up new business opportunities – prior been established as NEXUS standards.

In this context, the AA industry needs to switch:

• from abundance to restriction

• from benefits to sobriety

• from recycling to a circular economy

This is the reason why the latest edition of the N! Business Forum held in Monaco addressed the topic of reverse logistics.

Reverse logistics in the automotive aftermarket industry refers to the process of managing

the return of automotive parts, components and products from customers - or retailers - back to the manufacturer or distributor. This aspect of logistics involves handling returned goods, remanufacturing, recycling, and disposing of automotive products in an efficient and cost-effective manner. The goal is to optimize the entire product lifecycle and minimize waste whilst recovering value from returned items.

The automotive aftermarket industry faces unique challenges in reverse logistics, such as the diversity of parts, the need for accurate identification and testing, and the impact of evolving technology on older components. Efficient reverse logistics processes not only contribute to environmental sustainability but also help companies recover value from returned products and build customer trust through responsive and reliable return services.

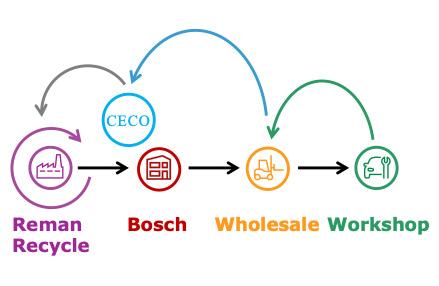

During the N! Climate Day, which took place in Monaco on March 5th, BOSCH used the occasion to

share the status of the Proof of Concept, launched in conjunction with Alternative Autoparts last year and dedicated to reverse logistics.

Peter Lukassen, Director of Sustainability at BOSCH and Marie-Jo Faivre, Operations Director at Alternative Autoparts (France) introduced their common proof of concept which consists of collecting boxes full of old spark plugs and wipers from workshops during the delivery run and to send them on to R-destination.

This take-back process needs to optimize logistics but the benefits of this is to maximize the reusage of material.

Our industry has traditionally focused on collecting old cores from workshops for products such as rotating machines, transmissions, and calipers. However, this marks the first occasion when we have conducted such a test on commodity products with a low unit value. One of the key challenges of this Proof of Concept (POC) lies in establishing an efficient reverse logistics system to drive down transportation costs to their absolute minimum.

Learn more now!