A guide for all automotive training and courses offered at MTA Training and Employment.

Our Promise

Our Vision, Mission and Purpose

Trainer Charter

Student Charter

Industry Partners

Automotive

Why train with MTA Training and Employment

MOTA / Employer Progress Portal

Apprentice Mentoring Program

Graduation and Awards

Trades we train

Prepare for the future with dual trade apprenticeships

Dual Trade FAQs

Automotive

Certificate III in Light Vehicle Mechanical Technology

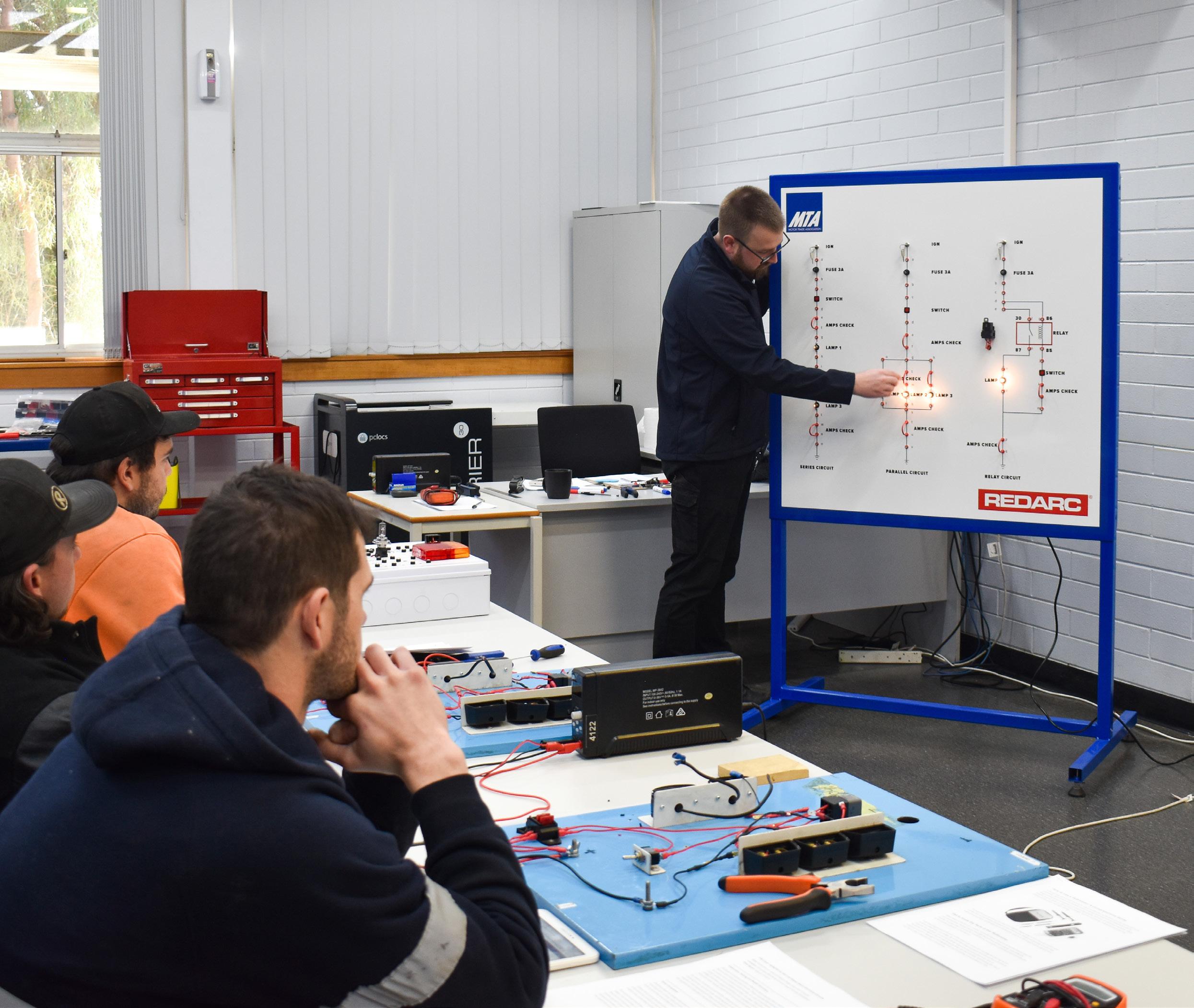

Certificate III in Automotive Electrical Technology

Certificate III in Heavy Commercial Vehicle Mechanical Technology

Certificate III in Agricultural Mechanical Technology

Certificate III

Certificate

Keep your team at the forefront

Accredited Courses

ADAS

Basic

Automotive Metal Finishing Training for Penal Technicians

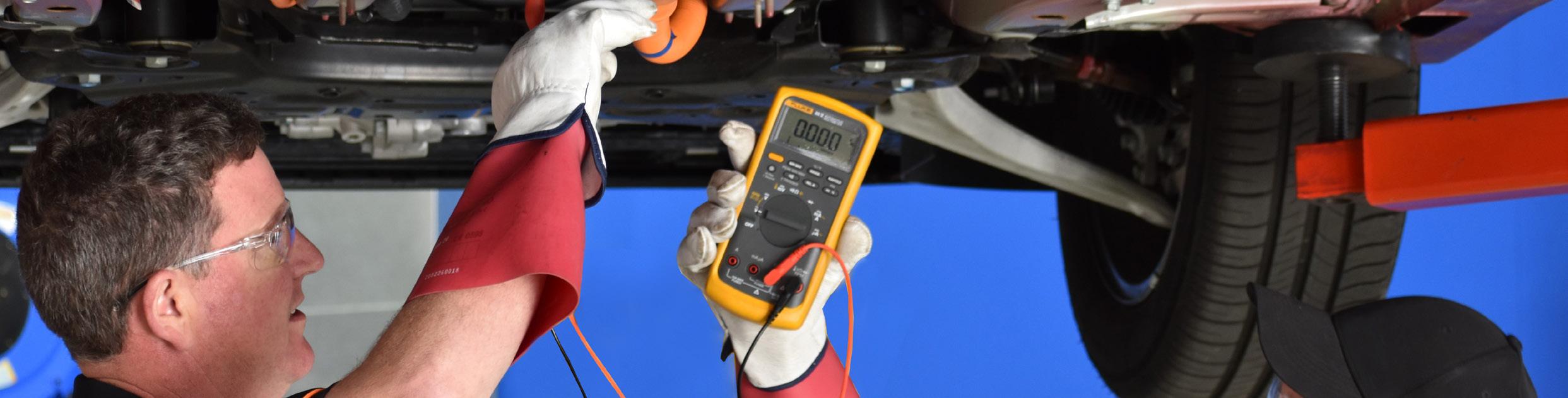

Automotive Diagnostics Training

Aftermarket 4WD Suspension Upgrades

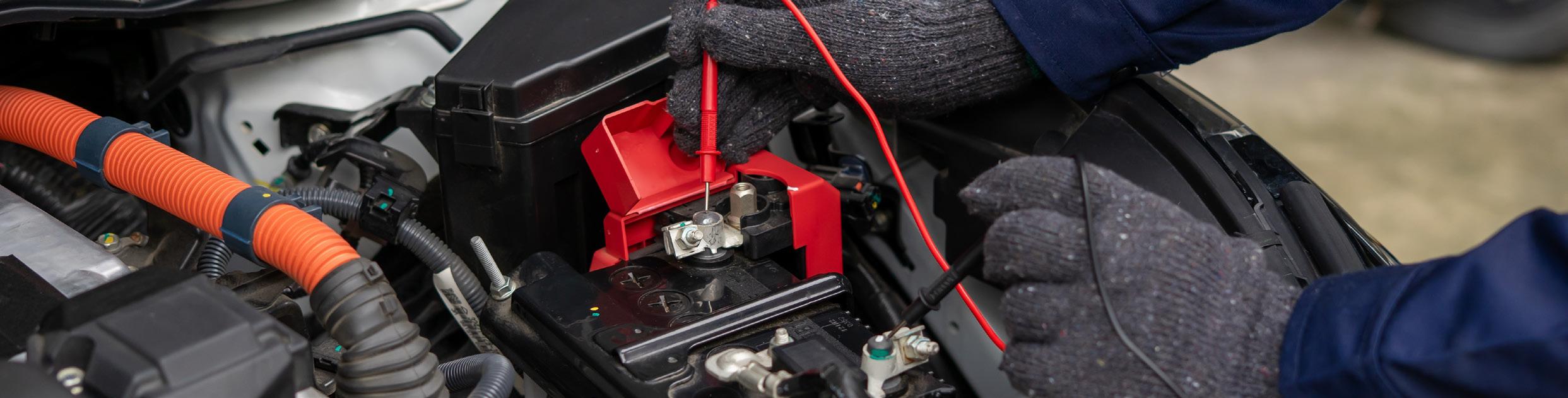

EV Training

Hybrid & Battery Electric Vehicle Training - Depower & Reinitialise

Hybrid & Battery Electric Vehicle Training - Operations & Servicing

Electric Vehicle Depower & Inspection

Hybrid Depower & Service

EV Safety Awareness

Dual Trade Bridging Programs

MTA Qualified Technician to Auto Electrician Program

MTA Qualified Technician to Electric Vehicle Technician Program

Occupational

apprentices signed up to the mentorship program 800+

With our mentor program, we have a

retention rate of 1st and 2nd year apprentices 90%

450+

apprentices employed by MTA Training and Employment and hosted out to employers

schools engaged in the pathways program 90+

350,000+

nominal training hours provided in 2024

1,100+

apprentices in training

qualified technicians upskilled in the last year

1 in 2

3x automotive apprentices train with MTA Training and Employment

1st Automotive Dual Trade Apprenticeships

270+ employer in South Australia to offer Automotive Dual Trade Apprenticeships

General Manager Apprenticeships

Jodi Ryan 0473 508 046 – jryan@mtasant.com.au

Training Operations Manager

Lachlan Fotheringham 0417 898 027 – lfotheringham@mtasant.com.au

Training & Employment Administration Manager

Rosemary Mercorella 08 8440 2656 – rmercorella@mtasant.com.au

Education & Program Development Manager

Scott Hahesy 08 8440 2681 – shahesy@mtasant.com.au

School Pathways & Engagement Officer

David Warren 0401 674 272 – dwarren@mtasant.com.au

At MTA Training and Employment, we remain steadfast in our commitment to delivering industry-leading automotive skills training for apprentices and businesses alike.

Guided by our vision to be the best Automotive Services, Skills and Careers provider in South Australia, we are committed to ensuring apprentices gain the skills needed to succeed in the fastchanging automotive industry.

Our deep connection with industry shapes not only our training model but also drives innovation through initiatives such as Australia’s first and only automotive dual trade apprenticeships, pioneering

Darrell Jacobs Chief Executive Officer, MTA SA/NT

school pathways, and our nation-leading apprentice mentoring program.

In recognition of our ongoing commitment to training excellence, MTA Training and Employment was named Large Training Provider of the Year at the 2025 SA Training Awards.

We are proud to deliver training that is guided by industry and reinvested into industry, ensuring the best outcomes for apprentices, employers and the broader automotive community.

Together, we will continue to drive progress and secure a strong future for our industry.

The MTA is the only employer-based organisation dedicated to supporting, growing and protecting the automotive retail, service and repair sectors across South Australia and the Northern Territory.

As South Australia’s leading body for automotive apprentice employment and training, we play a pivotal role in preparing the motor trade industry for the future.

Our Group Training Organisation is the state’s leading provider of automotive apprentice employment and training. We employ more than 450 apprentices and trainees and deliver training to over 1,100 apprentices through our state-of-the-art training centres located in Royal Park and Cleve.

MTA Training and Employment is a leader in hybrid and battery electric vehicle training, launching South Australia’s first dedicated Electric Vehicle Training Centre in June 2023. Since then, we have upgraded our Royal Park facility to meet the growing demand for EV skills.

We have also invested in state-of-the-art automotive refinishing facilities to give apprentices the best hands-on learning

experience in the country. In November 2025, we launched our new Alpha E Low Bake spray booths with an immersive classroom in between the spray booths — the only ones of their kind in Australia — featuring energy-efficient heating and rapid air-drying technology to deliver next-generation training in automotive refinishing.

In an Australian first, we introduced the nation’s first and second automotive dual trade apprenticeships, Light Vehicle Mechanical Technology and Automotive Electrical Technology, and Heavy Commercial Vehicle Mechanical Technology and Automotive Electrical Technology. In July 2025, a third dual trade apprenticeship in Agricultural Mechanical and Automotive Electrical was launched.

As the winner of Large Training Provider of the Year 2025, MTA Training and Employment remains dedicated to being the best in developing the next generation of South Australian automotive apprentices. We’re helping to build a bright future for the state’s automotive industry.

We work together, empower and support one another to achieve our common goals.

We do our best to exceed expectations, striving for innovation in our delivery of relevant and valued services.

We take ownership of all that we do, each taking responsibility for our part in delivering high quality services.

We understand, acknowledge and appreciate the needs, opinions and values of everyone by embracing the diversity we have within our organisation.

We strive to do and be the best in all that we do every day.

We are committed to a safe workplace for all.

We will supply our products and services with the highest customer care in mind.

We will conduct business with the highest level of skill.

We will tell you the truth in all our interactions with you.

We will be proactive in meeting your needs and expectations. We will explore different options in order to do so.

We will comply with all regulatory frameworks and industry codes of practice. Beyond our legal obligations we have our own moral standards we will always uphold.

We will live up to our obligations. We will carry out all operations and transactions in good faith.

We will be open and transparent with you. We will stand behind our promises to you.

The best automotive services, skills and career provider in SA/NT

Protect and grow our member businesses through providing the best services, skills and career solutions

Grow, support and protect member businesses.

Be the best training provider for apprenticeships and upskilling in the automotive industry.

Attract, prepare and retain the best apprentice workforce available to automotive hosts.

Our trainers work together to ensure our training is of the highest quality. Helping each other is the core of what we do.

Our trainers lead by example, wearing and endorsing PPE and safe systems of work. Safety is in our culture.

We promote open conversation and value each other’s opinions. We always value respectful communication.

Our trainers are subject matter experts in their field, role models, mentors and professional technicians, modelling professional behaviour at all times.

Our trainers work together to ensure our training facility and training aids are of the best quality, and replicate industry practices. Our trainers support each other in ensuring training aids are fit for purpose, vehicles are fully functional and charged, and accurate record keeping of faults is maintained.

Our students will work together in a team environment, assisting fellow students. Helping each other is the core of what we do.

Our students are learning a trade, and are expected to be respectful to trainers and fellow students at all times.

Our students will promote open conversation and value each other’s opinions. We always value respectful communication.

Our students will work together to ensure our training facility is kept tidy and safe at all times. Students are expected to clean their work environment and take directions form their trainer.

Our students will lead by example, wearing and endorsing PPE and safe systems of work.

Our students will participate in safety walks, reporting any concerns to WHS immediately.

Our students must promote a clean and safe environment with appropriate housekeeping in all workshops at all times.

Our industry partners play a vital role in MTA Training and Employment, providing the tools, technology, and innovation that ensure our apprentices learn with the same equipment and standards used across today’s automotive industry.

Leading provider of testing and calibration for industry advanced driver assist systems. Helping apprentices stay ahead with cutting-edge automotive technology.

Myenergi

Provides DC chargers, along with energy management systems, for our Electric Vehicle Training Centre. Supporting apprentices by giving them access to the latest equipment used in modern EV workshops.

Specialists in advanced automotive refinishing technology, including energy-efficient spray booths. Providing apprentices with the most advanced automotive refinishing technology, helping reduce application times and lower emissions, with booths powered by electricity, solar and designed for future hydrogen integration.

It’s one thing to learn in a classroom, but getting to work with the tools and

technology

I’ll use in the industry makes all the difference.”

– MTA Apprentice Ellly Brake Hosted at Eblen Crash Repairs.

Sherwin Williams

Experts in automotive coatings and refinishing solutions, helping apprentices achieve precision and excellence.

PPG

A world-leading coatings company, providing apprentices with innovative paint technology.

Australia’s leading retailer for hardware and tools, supporting apprentices with access to discounted supplies through the PowerPass Program.

Gives apprentices and employers access to expert superannuation support with dedicated advisers to help them and their team stay compliant and well-informed.

Changing the future of automotive body repair by equipping apprentices with cutting-edge Glue Pull Repair (GPR) systems and tools, designed for precision, durability and controlled application.

Global leader in coatings and refinishing solutions, proudly supporting MTA Training and Employment as a Gold Sponsor, providing apprentices with the latest application techniques to master the art of automotive refinishing.

Premium manufacturer of tools for automotive professionals, giving apprentices access to industry-standard equipment at discounted prices.

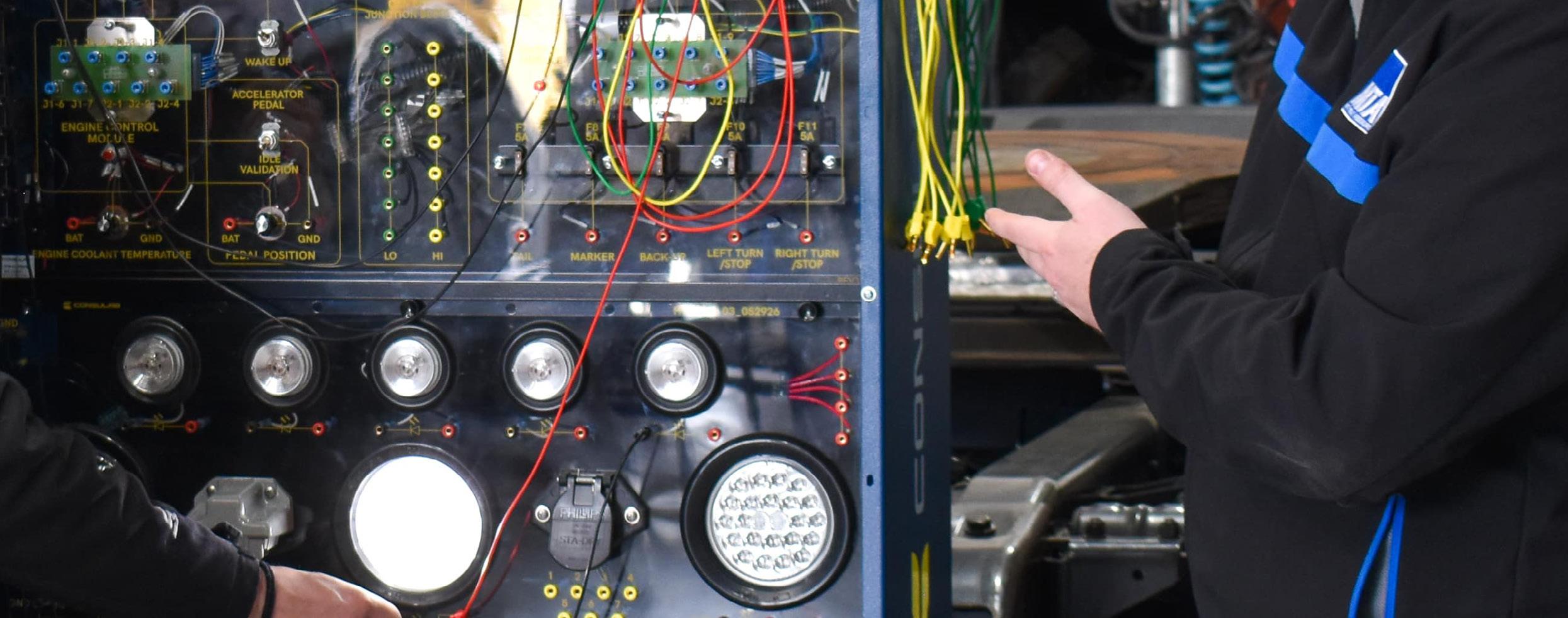

Specialists in advanced automotive control systems, driving the automotive electrical industry forward through cutting-edge research and development, and providing apprentices with hands-on insights into modern vehicle electronics.

One point of contact to answer all your questions

You can enrol your apprentice to start training at any time

MTA Training and Employment do all your apprentice’s scheduling

Receive your apprentice schedules up to a year in advance so you can plan your workforce

We have a wide range of innovative equipment and tools

Apprentices train using the latest vehicles and technology

Students are future-ready with our modern EV Training Centre and AirConditioning Hub

We have multiple training locations – Royal Park and Cleve Australia’s only Low Bake Alpha-E paint booths

First in SA to offer Dual Trade Apprenticeships

Simple, interactive and up-to-date training material

Students can access their learning material online - anywhere, at anytime

Electric Vehicle and Hybrid Safety courses are standard across relevant qualifications

Air-conditioning units are included with most qualifications

We have the perfect mix of learning in the workshop and at trade school

Learning is supported by an easy-to-use online system

Apprentices collect training evidence in line with day-to-day work tasks

Each apprentice has one-on-one access to an MTA Training and Employment Trainer and Career Mentor

Experts in their fields, connected and up-to date with industry

Dedicated to your apprentice

Will visit your workshop regularly

Can be contacted directly

Our business depends on a future-ready workforce. The MTA’s training on new technology is unmatched.”

— Jenny Seal People & Safety Manager SA, Eagers Automotive

MTA Training and Employment is recognised as the automotive skills and training provider of choice by the industry.

MOTA is MTA Training and Employment’s purpose-built Learning Management System (LMS), designed to support a modern, flexible approach to automotive training.

Our LMS complements traditional, hands-on training with an interactive online learning platform, giving apprentices the freedom to learn when and how it suits them — whether they’re in the workshop, at home, or on the go.

Blended learning experience: Combines face-to-face and online learning for maximum flexibility and engagement.

Accessible 24/7: Apprentices can log in anytime to complete lessons, review course materials, or reinforce their knowledge.

Interactive content: Engaging videos, quizzes, and resources to support different learning styles.

Supports individual progress: Encourages self-paced study and deeper understanding of core automotive concepts.

By integrating digital learning with real-world training, MOTA ensures apprentices build the skills, confidence, and knowledge needed to succeed in today’s evolving automotive industry.

Our Employer Progress Portal gives you real-time visibility over your apprentice’s training and development journey — keeping you connected, informed, and involved every step of the way.

With simple, secure online access, employers can view training updates, track attendance, and monitor progress with ease.

Track progress in real time: See how your apprentice is progressing through their training modules.

Trainer feedback at your fingertips: Access regular comments and evaluations from MTA trainers.

View training schedules: Stay up to date with upcoming classes and block release dates.

Encourage collaboration: Work in partnership with trainers to support your apprentice’s success.

The Employer Progress Portal ensures transparency, accountability, and better communication between MTA Training and Employment, employers, and apprentices — helping everyone stay on track toward achieving training goals.

MTA Training and Employment offers a FREE mentorship program designed to support all apprentices employed by or training with MTA Training and Employment.

With over 820 apprentices enrolled into the program and a 90% retention rate, the program has become a vital part of sustaining South Australia’s automotive workforce.

Offers guidance on balancing work, study and personal life

Helps apprentices overcome challenges that could impact their training journey

Provides personalised support, career advice and mental health resources

Includes regular check-ins every 16 weeks to assess progress and address any issues

Our dedicated mentor, Ben Monro, draws on his extensive experience in the trade to provide this program.

“I don’t know what I would have done without the support of a mentor helping me navigate the struggles I faced in the trade!"

– Eden Sullivan a first-year apprentice, highlighting the program’s impact

Ben Monro, MTA Automotive Careers Mentor

bmonro@mtasant.com.au

8241 0522 or 0411 802 220

Each year, MTA proudly celebrates our automotive apprentice graduates at a special event, where students receive their certificates on stage, surrounded by dignitaries, industry representatives, employers, family, friends, and peers. We also recognise excellence across the industry, presenting awards in multiple categories, honouring the best and brightest apprentices and employers in the field.

Enquire about the trades we train across our Royal Park and Cleve training centres.

more information: www.mtasant.com.au mtatraining@mtasant.com.au | 8241 0522

Light Vehicle / Automotive Electrical Technician

AUR30620 Certificate III in Light Vehicle Mechanical Technology and AUR30320 Certificate III in Automotive Electrical Technology

Heavy Vehicle / Automotive Electrical Technician

AUR31120 Certificate III in Heavy Commercial Vehicle Mechanical Technology and AUR30320 Certificate III in Automotive Electrical Technology

Agricultural Mechanical Technology / Automotive Electrical Technician

AUR30420 Certificate III in Agricultural Mechanical Technology and AUR30320 Certificate III in Automotive Electrical Technology

Light Vehicle Mechanical Technician

AUR30620 Certificate III in Light Vehicle Mechanical Technology

Automotive Refinishing Technician

AUR32420 Certificate III in Automotive Refinishing Technology

Heavy Commercial Vehicle Mechanical Technician

AUR31120 Certificate III in Heavy Commercial Vehicle Mechanical Technology

Agricultural Mechanical Technician

AUR30420 Certificate III in Agricultural Mechanical Technology

Automotive Electrician

AUR30320 Certificate III in Automotive Electrical Technology

Mobile Plant Diesel Technician

AUR31220 Certificate III in Mobile Plant Technology

Automotive Body Repair Technician

AUR32120 Certificate III in Automotive Body Repair Technology

Heavy Commercial Trailer Technician

AUR31820 Certificate III in Heavy Commercial Trailer Technology

Automotive Parts Interpreter

AUR31020 Certificate III in Automotive Sales

For more information: www.mtasant.com.au

mtatraining@mtasant.com.au | 8241 0522

Training is delivered by MTA Training and Employment | RTO Code: 2293

MTA Training and Employment is the first in South Australia to offer automotive dual trade apprenticeships, preparing the industry for the future and giving young people the opportunity for a lifelong career.

Light Vehicle / Automotive Electrical Technician

Heavy Vehicle / Automotive Electrical Technician

Agricultural Mechanical / Automotive Electrical Technician

In today’s automotive landscape, versatility is key to success. That’s why investing in a dual trade apprentice can be a game-changer for your business.

Apprentices with dual qualifications in both mechanical and electrical trades gives your business a multifaceted skill set capable of tackling a diverse range of automotive challenges.

Ultimately your workforce becomes more productive.

Your customers are driving more advanced cars, including hybrid and electric vehicles, and this number is only set to rise.

By investing in dual trade apprenticeships, you are futureproofing your business, ensuring that you have the expertise needed to stay ahead of the curve and meet the evolving needs of your customers.

With a dual trade technician on your team, there will be no need to coordinate multiple technicians or outsource specialised tasks – saving your business time and money.

By leading the charge in dual trades, you position your business as a forward-thinking industry leader, attracting top talent and earning the trust of your customers.

Get your workshop ready as the uptake of hybrid and electric vehicles or agricultural machinery increases. Future-proof your business with the expertise and skills needed to stay ahead of the curve. No need to coordinate multiple technicians or outsource specialised tasks – saving your business time and money in the future.

Light Vehicle / Automotive Electrical Technician

AUR30620 Certificate III in Light Vehicle Mechanical Technology and AUR30320 Certificate III in Automotive Electrical Technology

Heavy Vehicle / Automotive Electrical Technician

AUR31120 Certificate III in Heavy Commercial Vehicle Mechanical Technology and AUR30320 Certificate III in Automotive Electrical Technology

Agricultural Mechanical Technology / Automotive Electrical Technician

AUR30420 Certificate III in Agricultural Mechanical Technology and AUR30320 Certificate III in Automotive Electrical Technology

Training delivered by MTA Training and Employment Centre.

Available as a school-based apprenticeship

5 years full-time

On and off-the-job training model Weekly Intakes

An Australian citizen or Permanent Resident.

Currently living in South Australia.

16 years of age or older.

Willing to commit to a 5-year apprenticeship.

Driver’s Licence - full-time apprentices must have Ps & school-based apprentices must have Ls.

Apprentices undertaking a dual trade are required to be supervised by an automotive electrical technician and a suitably qualified light vehicle, heavy vehicle or agricultural technician. If your business does not have a qualified automotive electrical technician currently employed, technicians with qualifications in light vehicle, heavy vehicle or agricultural technology can undergo the Qualified Technician to Automotive Electrician Program, offered by MTA Training and Employment. Only after your qualified technician has achieved their automotive electrical qualification can they fill the role as a supervisor.

For further details, visit mtasant.com.au and browse our upskilling training.

Your apprentice may be eligible for incentives of up to $10,000 under the Commonwealth Government’s New Energy Apprenticeships Program.

For further details, visit apprenticeships.gov.au and browse the New Energy Apprenticeship Program page.

Apprentices have access to our state-of-the-art facilities.

Your apprentice will receive practical insights from industry experts.

Emphasis on hands-on workshop experience.

Flexible training model.

Rolling intakes. Apprentices can commence training at any time.

Receive a yearly training plan.

Our trainers visit your workshop.

Students undertaking these apprenticeships will enrol in the following qualifications:

Light Vehicle / Automotive Electrical Technician

AUR30620 Certificate III in Light Vehicle

Mechanical Technology and AUR30320

Certificate III in Automotive Electrical Technology

Heavy Vehicle / Automotive Electrical Technician

AUR31120 Certificate III in Heavy Commercial

Vehicle Mechanical Technology and AUR30320

Certificate III in Automotive Electrical Technology

Agricultural Mechanical / Automotive Electrical Technician

AUR30420 Certificate III in Agricultural Mechanical Technology and AUR30320

Certificate III in Automotive Electrical Technology

I currently have an apprentice – can I transfer them to the dual trade program?

Yes, you can. If your apprentice is pursuing a light vehicle, heavy vehicle, agricultural mechanical or automotive electrical apprenticeship, they can transfer to a dual trade.

What year does my apprentice need to be in to transfer to a dual trade apprenticeship? Is there a cut-off year for this?

We recommend that students in their first or second year can transfer without any disadvantage in most cases. However, students in their third or fourth year will need to be assessed individually to determine if they will be disadvantaged. In such cases, we may recommend they complete their current apprenticeship before starting MTA Training and Employment’s Qualified Technician Program. Students transferring from other RTOs will also need to be assessed individually.

How long does the dual trade apprenticeship last?

The term is 5 years, or 60 months. This is 1 year longer than traditional apprenticeships.

What is the apprentice salary/award payment for the 5th year?

We recommend 95% of the current award rate for qualified technicians. The 4th year is currently calculated at 88% of the current award rate for qualified technicians.

What qualification will an apprentice receive upon completing the dual trade?

An apprentice will receive two qualifications upon completion of their dual trade:

Light Vehicle Dual Trade: AUR30620 Certificate III in Light Vehicle Mechanical Technology and AUR30320 Certificate III in Automotive Electrical Technology.

Heavy Vehicle Dual Trade: AUR31120 Certificate III in Heavy Commercial Vehicle Mechanical Technology and AUR30320 Certificate III in Automotive Electrical Technology.

AUR30420 Certificate III in Agricultural Mechanical Technology and AUR30320 Certificate III in Automotive Electrical Technology

How much extra time, compared to a traditional apprenticeship, is my apprentice required to spend outside of my workshop?

Light Vehicle: 20 blocks of training VS Dual Trade LV/AE: 23 blocks of training.

Heavy Vehicle: 20 blocks of training VS Dual Trade HV/AE: 26 blocks of training.

Agricultural Mechanical: 21 blocks of training VS Dual Trade AG/AE: 27 blocks of training.

What is the situation regarding supervision in the workshop for dual trade apprentices?

Current supervisor ratios remain the same (high 1:3), but each workshop must have a suitably qualified or experienced Light or Heavy Vehicle or Agricultural Mechanical Technician and an Auto Electrician.

My employer is already registered to employ apprentices in light vehicle, heavy vehicle, agricultural mechanical and automotive electrical trades. What steps do they need to take to employ a dual trade apprentice?

All registered employers must log into their MySkillsSA account and apply to become a registered employer for the dual trade. Even if they are already registered for both trades individually, they will still need to update their registration to include the dual trade.

How can I get a qualified automotive electrical tradesperson if my business does not currently have one?

You can upskill a current Light Vehicle, Heavy Vehicle or Agricultural Mechanical Technician to an Automotive Electrical Technician through MTA Training and Employment’s Qualified Technician to Automotive Electrician Program in as little as 6 months. This needs to be completed under a feefor-service arrangement, as you cannot have a supervisor under an apprenticeship supervising an apprentice. For more information, visit: https://members.mtasant.com.au/training-courses/upskillingtraining/qualified-tech-to-auto-electrician-program/

Is a dual trade apprenticeship government-funded like a traditional apprenticeship?

Yes, it is. Employer and Apprentice incentives may be available under the Commonwealth Government’s Australian Apprenticeships Incentive Scheme https://www.dewr.gov.au/skills-and-training (Contact your Apprenticeship Connect Australia Provider (ACAP) for further details).

Are there any subsidies for apprentices doing the dual trade?

Apprentices may be eligible for incentives of up to $10,000 under the Commonwealth Government’s New Energy Apprenticeships Program https://www.dewr.gov.au/australian-apprenticeships/resources/ new-energy-apprenticeships-program-flyer (Contact your AESN for further details).

Does my apprentice finish one apprenticeship (for example a light vehicle apprenticeship) and then move onto the other apprenticeship (automotive electrical)?

No, these dual trades are completed concurrently to ensure a continuous flow of learning, allowing apprentices to build their skills progressively and add value to your business immediately.

What are the next steps and how do I transfer my apprentice to a dual trade apprenticeship?

Apprentice Directly Employed by Industry

If you directly employ your apprentice, you will need to contact your Apprenticeship Connect Australia Provider (ACAP) to complete the transfer of qualification form. If you have any further questions, please email our customer service team E: mtatraining@mtasant.com.au or fill out our online enquiry form: https://members.mtasant.com.au/training-courses/dual-tradeapprenticeships/#dual

Apprentice Employed by MTA Training and Employment and Hosted to Your Business

If your apprentice is employed by MTA Training and Employment and hosted by your business, you should first talk to your apprentice’s assigned Employment Officer. MTA Training and Employment will need to contact the relevant Apprenticeship Connect Australia Provider (ACAP) to complete the transfer of qualification form. If you have any further questions, please E: grouptrainingadmin@ mtasant.com.au or fill out our online enquiry form: https://members.mtasant.com.au/trainingcourses/dual-trade-apprenticeships/#dual

UNIT CODE

AURASA102 Follow safe working practices in a automotive workplace

AURAEA002 Follow environmental and sustainability best practice in an automotive workplace

AURTTK102 Use and maintain tools and equipment in an automotive workplace

AURETR125 Test, charge and replace batteries and jump-start vehicles

AURETR112 Test and repair basic electrical circuits

AURETK002 Use and maintain electrical test equipment in a workplace

AURTTF101 Inspect and service petrol fuel systems

AURTTB101 Inspect and service braking systems

AURTTX102 Inspect and service manual transmissions

AURTTA104 Carry out servicing operations

AURTTE104 Inspect and service engines

AURTTA118 Develop and carry out diagnostic test strategies

AURTTC103 Diagnose and repair cooling systems

AURLTB103 Diagnose and repair light vehicle hydraulic braking systems

UNIT CODE COMPETENCY DESCRIPTION

AURLTD104 Diagnose and repair light vehicle steering systems

AURLTD105 Diagnose and repair light vehicle suspension systems

AURLTD106 Carry out light vehicle wheel alignment operations

AURLTQ102 Diagnose and repair light vehicle drive shafts

AURLTE102 Diagnose and repair light vehicle engines

AURETR129 Diagnose and repair charging systems

AURETR130 Diagnose and repair starting systems

AURETR131 Diagnose and repair ignition systems

AURLTZ101 Diagnose and repair light vehicle emission control systems

AURETR123 Diagnose and repair spark ignition engine management systems

UNIT CODE COMPETENCY DESCRIPTION

AURETR124 Diagnose and repair electronic compression ignition engine management system

AURETR132 Diagnose and repair automotive electrical systems

AURETR143 Diagnose and repair electronic body management systems

AURETR120 Diagnose and repair network electronic control systems

AURETR122 Diagnose and repair vehicle dynamic control systems

AURETD101 Diagnose and repair electronically controlled steering systems

AURETR144 Diagnose and repair integrated engine and transmission management systems

UNIT CODE COMPETENCY DESCRIPTION

AURETH011 Depower and reinitialise hybrid electric vehicles

AURETH101 Depower and reinitialise battery electric vehicles

AURVTA002 Remove and replace vehicle supplementary restraint systems

AURETU103 Service air-conditioning and HVAC systems

AURETU104 Diagnose and repair air-conditioning and HVAC systems

UNIT

AURASA102 Follow safe working practices in a automotive workplace

AURAEA002 Follow environmental and sustainability best practice in an automotive workplace

AURTTK102 Use and maintain tools and equipment in an automotive workplace

AURETR125 Test, charge and replace batteries and jump-start vehicles

AURETR112 Test and repair basic electrical circuits

AURETK002 Use and maintain electrical test equipment in a workplace

AURETR135 Apply knowledge of petrol and diesel engine operation

AURTTE104 Inspect and service engines

AURETR006 Solder electrical wiring and circuits

AURETR116 Read and apply vehicle wiring schematics and drawings

AURETR007 Apply knowledge of automotive electrical circuits and wiring systems

AURETR009 Install vehicle lighting and wiring systems

AURETR010 Repair wiring harnesses and looms

AURETR027 Install ancillary electronic systems and components

AURTTA118 Develop and carry out diagnostic test strategies

AURTTC103 Diagnose and repair cooling systems

AURETR132 Diagnose and repair automotive electrical systems

AURETR129 Diagnose and repair charging systems

AURETR130 Diagnose and repair starting systems

AURETR131 Diagnose and repair ignition systems

AURETR120 Diagnose and repair network electronic control systems

AURETR128 Diagnose and repair instruments and warning systems

AURETR143 Diagnose and repair electronic body management systems

AURETR144 Diagnose and repair integrated engine and transmission management systems

UNIT CODE

COMPETENCY DESCRIPTION

AURETR123 Diagnose and repair spark ignition engine management systems

AURETR124 Diagnose and repair compression ignition engine management systems

AURETR122 Diagnose and repair vehicle dynamic control systems

AURETH011 Depower and reinitialise hybrid electric vehicles

AURETH101 Depower and reinitialise battery electric vehicles

AURVTA002 Remove and replace vehicle supplementary restraint systems

AURETU103 Service air-conditioning and HVAC systems

AURETU104 Diagnose and repair air-conditioning and HVAC systems

UNIT CODE COMPETENCY DESCRIPTION

AURASA102 Follow safe working practices in a automotive workplace

AURAEA002 Follow environmental and sustainability best practice in an automotive workplace

AURTTK102 Use and maintain tools and equipment in an automotive workplace

AURETR125 Test, charge and replace batteries and jump-start vehicles

AURETR112 Test and repair basic electrical circuits

AURETK002 Use and maintain electrical test equipment in a workplace

AURTTQ001 Inspect and service final drive assemblies

AURTTA006 Inspect and service hydraulic systems

AURTTB101 Inspect and service braking systems

AURTTA104 Carry out servicing operations

AURTTE104 Inspect and service engines

AURTTA118 Develop and carry out diagnostic test strategies

AURTTC103 Diagnose and repair cooling systems

AURHTB101 Diagnose and repair heavy vehicle air braking systems

UNIT CODE COMPETENCY DESCRIPTION

AURHTD102 Diagnose and repair heavy vehicle steering systems

AURHTD103 Diagnose and repair heavy vehicle suspension systems

AURHTQ103 Diagnose and repair heavy vehicle drive shafts

AURHTY102 Diagnose and repair mechanical connections of heavy vehicles and trailers over 4.5 tonnes

AURHTE102 Diagnose and repair heavy vehicle compression ignition engines

AURETR129 Diagnose and repair charging systems

AURETR130 Diagnose and repair starting systems

AURHTZ101 Diagnose and repair heavy vehicle emission control systems

AURETR124 Diagnose and repair electronic compression ignition engine management systems

AURTTF102 Inspect and service diesel fuel injection systems

AURHTF102 Diagnose and repair heavy vehicle diesel fuel injection systems

UNIT CODE COMPETENCY DESCRIPTION

AURHTQ102 Diagnose and repair heavy commercial vehicle final drive assemblies

AURTTF105* Diagnose and repair engine forced induction systems

AURETR132 Diagnose and repair automotive electrical systems

AURHTX104 Diagnose and repair heavy vehicle clutch systems

AURHTX101 ^ Diagnose and repair heavy vehicle manual transmissions

AURVTW109# Carry out basic metal arc welding

AURVTW018 Carry out oxyacetylene welding, thermal heating and cutting

UNIT CODE COMPETENCY DESCRIPTION

TLILIC003 Licence to operate a forklift truck

AURETR122 Diagnose and repair vehicle dynamic control systems

AURETU103 Service air-conditioning and HVAC systems

AURETU104 Diagnose and repair air-conditioning and HVAC systems

^ Specialist Elective A

UNIT CODE COMPETENCY DESCRIPTION

AURASA102 Follow safe working practices in a automotive workplace

AURAEA002 Follow environmental and sustainability best practice in an automotive workplace

AURTTK102 Use and maintain tools and equipment in an automotive workplace

AURETR125 Test, charge and replace batteries and jump-start vehicles

AURETR112 Test and repair basic electrical circuits

AURETK002 Use and maintain electrical test equipment in a workplace

AURTTQ001 Inspect and service final drive assemblies

AURTTA006 Inspect and service hydraulic systems

AURTTB101 Inspect and service braking systems

AURTTA104 Carry out servicing operations

AURTTE104 Inspect and service engines

AURTTA118 Develop and carry out diagnostic test strategies

AURTTC103 Diagnose and repair cooling systems

AURKTB101 Diagnose and repair mobile plant braking systems

UNIT CODE COMPETENCY DESCRIPTION

AURKTA111 Diagnose and repair mobile plant hydraulic systems

AURKTD102 Diagnose and repair mobile plant steering systems

AURACA101 Respond to customer needs and enquiries in an automotive workplace

AURKTQ101 Diagnose and repair mobile plant final drive assemblies

AURHTQ103 Diagnose and repair heavy vehicle drive shafts

AURHTE102 Diagnose and repair heavy vehicle compression ignition engines

AURETR129 Diagnose and repair charging systems

AURETR130 Diagnose and repair starting systems

AURETR124 Diagnose and repair electronic compression ignition engine management systems

AURTTF102 Inspect and service diesel fuel injection systems

AURHTF102 Diagnose and repair heavy vehicle diesel fuel injection systems

UNIT CODE

COMPETENCY DESCRIPTION

AURKTX101 Diagnose and repair powershift transmissions

AURTTF105 Diagnose and repair engine forced induction systems

AURHTZ101 Diagnose and repair heavy vehicle emission control systems

AURETR132 Diagnose and repair automotive electrical systems

AURETR120 Diagnose and repair network electronic control systems

AURETR128 Diagnose and repair instruments and warning systems

AURVTW109 Carry out basic metal arc welding

AURVTW018 Carry out oxyacetylene welding, thermal heating and cutting

TLILIC003 Licence to operate a forklift truck

AURETU103 Service air-conditioning and HVAC systems

AURETU104 Diagnose and repair air-conditioning and HVAC systems

UNIT CODE COMPETENCY DESCRIPTION

AURASA102 Follow safe working practices in a automotive workplace

AURAEA002 Follow environmental and sustainability best practice in an automotive workplace

AURTTK102 Use and maintain tools and equipment in an automotive workplace

AURETR125 Test, charge and replace batteries and jump-start vehicles

AURETR112 Test and repair basic electrical circuits

AURETK002 Use and maintain electrical test equipment in a workplace

AURTTQ001 Inspect and service final drive assemblies

AURTTA006 Inspect and service hydraulic systems

AURTTB101 Inspect and service braking systems

AURTTA104 Carry out servicing operations

AURTTE104 Inspect and service engines

AURTTA118 Develop and carry out diagnostic test strategies

AURTTC103 ^ Diagnose and repair cooling systems

AURKTB101 ^ Diagnose and repair mobile plant braking systems

UNIT CODE COMPETENCY DESCRIPTION

AURKTA111 ^ Diagnose and repair mobile plant hydraulic systems

AURKTD102 ^ Diagnose and repair mobile plant steering systems

AURKTA005 ^ Inspect, service and repair track type drive and support systems

AURKTQ101 ^ Diagnose and repair mobile plant final drive assemblies

AURHTQ103 Diagnose and repair heavy vehicle drive shafts

AURHTE102 ^ Diagnose and repair heavy vehicle compression ignition engines

AURETR129 ^ Diagnose and repair charging systems

AURETR130 ^ Diagnose and repair starting systems

AURETR124 ^ Diagnose and repair electronic compression ignition engine management systems

AURTTF102 Inspect and service diesel fuel injection systems

AURHTF102 ^ Diagnose and repair heavy vehicle diesel fuel injection systems

UNIT CODE COMPETENCY DESCRIPTION

AURKTX101 ^ Diagnose and repair powershift transmissions

AURTTF105 ^ Diagnose and repair engine forced induction systems

AURHTZ101 Diagnose and repair heavy vehicle emission control systems

AURETR132 Diagnose and repair automotive electrical systems

AURKTD101 Diagnose and repair mobile plant suspension systems

AURTTA105 Select and use bearings, seals, gaskets, sealants and adhesives

AURVTW109 Carry out basic metal arc welding

AURVTW018 Carry out oxyacetylene welding, thermal heating and cutting

TLILIC003 Licence to operate a forklift truck

AURETU103 Service air-conditioning and HVAC systems

AURETU104 Diagnose and repair air-conditioning and HVAC systems

^ Specialist Elective A

UNIT CODE COMPETENCY DESCRIPTION

AURASA102 Follow safe working practices in a automotive workplace

AURAEA002 Follow environmental and sustainability best practice in an automotive workplace

AURTTK102 Use and maintain tools and equipment in an automotive workplace

AURETR125 Test, charge and replace batteries and jump-start vehicles

AURETR112 Test and repair basic electrical circuits

AURETK002 Use and maintain electrical test equipment in a workplace

AURTTB101 Inspect and service braking systems

AURHTB101 Diagnose and repair heavy vehicle air braking systems

AURTTB015 Assemble and fit braking system components

UNIT CODE COMPETENCY DESCRIPTION

AURTTD004 Inspect and service suspension systems

AURTTB004 Inspect and service air braking systems

AURHTD103 Diagnose and repair heavy vehicle suspension systems

AURETR009 Install vehicle wiring and lighting systems

AURETR006 Solder electrical wiring and circuits

AURETR010 Repair wiring harnesses and looms

AURTTE104 Inspect and service engines

AURTTA104 Carry out servicing operations

AURTTA105 Select and use bearings, seals, gaskets, sealants and adhesives

AURETR132 Diagnose and repair automotive electrical systems

UNIT CODE

COMPETENCY DESCRIPTION

AURTTA118 Develop and carry out diagnostic test strategies

AURHTJ103 Remove, inspect and refit heavy vehicle wheel and tyre assemblies

AURACA101 Respond to customer needs and enquiries in the workplace

AURHTY001 Inspect and service mechanical connections of heavy vehicles and trailers over 4.5. tonnes

AURHTY102 Diagnose and repair mechanical connections of heavy vehicles and trailers over 4.5 tonnes

AURAFA103 Communicate effectively in an automotive workplace

AURETR122 Diagnose and repair vehicle dynamic control systems

AURVTW109 Carry out basic metal arc welding

AURVTW018 Carry out oxyacetylene welding, thermal heating and cutting

UNIT CODE COMPETENCY DESCRIPTION

AURASA102 Follow safe working practices in a automotive workplace

AURAEA002 Follow environmental and sustainability best practice in an automotive workplace

AURETR125 Test, charge and replace batteries and jump-start vehicles

AURTTK102 Use and maintain tools and equipment in an automotive workplace

AURVTN003 Remove and store body components

AURVTN005 Remove and replace adhesive attached components on vehicles

AURVTP101 Remove paint from vehicle painted surfaces

AURVTP002 Mask vehicle panels and components

AURVTP103 Prepare vehicle spray painting equipment for use

AURVTP005 Apply rust prevention and sound deadening materials to vehicle body components

AURVTN116 Repair vehicle body panels using filler

AURVTN017 Repair vehicle thermoplastic body panels and components

AURAFA108 Interpret and apply automotive repair instructions

UNIT CODE COMPETENCY DESCRIPTION

AURVTP110 Prepare and operate vehicle paint drying equipment

AURVTP113 Prepare vehicle substrates for refinishing

AURVTP006 Apply refinishing primers to vehicle surfaces

AURVTP104 Apply basic colour matching techniques using vehicle paint codes

AURVTP115 Match direct gloss solid paint colour on vehicles or components

AURVTP111 Apply solid acrylic two-pack materials to vehicle components

AURVTP019 Prepare and paint plastic and composite vehicle surfaces

AURVTP020 De-nib, buff and polish vehicle painted surfaces

AURVTP107 Touch up minor vehicle paintwork damage

AURVTP114 Colour match multi-layer and clear over base two-pack paints on vehicles and components

AURVTP123 Apply clear over base two-pack refinishing materials to vehicle body components

AURVTP117 Rectify and touch up vehicle paint faults using clear over base two-pack systems

AURVTP125 Apply water-based refinishing materials to vehicle bodies and substrates

AURVTP124 Apply clear over base multi-layer and pearl refinishing materials to vehicle body components

AURVTP118 Rectify vehicle multi-layer and pearl paint faults using two-pack systems

AURVTN132 Inspect vehicle damage and determine repairs

AURVTP128 Carry out custom painting techniques to vehicle body panels

UNIT CODE COMPETENCY DESCRIPTION

AURASA102 Follow safe working practices in a automotive workplace

AURAEA002 Follow environmental and sustainability best practice in an automotive workplace

AURTTK102 Use and maintain tools and equipment in an automotive workplace

AURETR125 Test, charge and replace batteries and jump-start vehicles

AURETH011 Depower and reinitialise hybrid electric vehicles

AURETH101 Depower and reinitialise battery electric vehicles

AURVTA002 Remove and replace vehicle supplementary restraint systems

AURETR042 Remove, refit and operate electrical components following body repair activities

AURVTN104 Remove, replace and align bolt-on vehicle body panels and components

AURVTN003 Remove and store vehicle body components

AURAFA108 Interpret and apply automotive repair instructions

AURVTN116 Repair vehicle body panels using filler

AURVTN102 Carry out non-structural vehicle panel repairs

AURVTN127 Repair vehicle aluminium body panels using filler

UNIT CODE COMPETENCY DESCRIPTION

AURVTP005 Apply rust prevention and sound deadening materials to vehicle body components

AURVTN017 Repair vehicle thermoplastic body panels and components

AURVTW103 Carry out advanced gas metal arc welding on vehicle body sections

AURVTW007 Carry out oxyacetylene thermal heating and cutting on vehicle body sections

AURVTN115 Repair vehicle body panels using metal finishing

AURVTN025 Repair corroded vehicle body panels and components

AURVTW105 Carry out spot welding

AURVTN128 Identify and repair high strength steel vehicle components

AURVTN123 Repair adhesive bonded structural damage on vehicles

AURVTN120 Remove and replace major welded panels on vehicles

AURVTN031 Carry out vehicle sectional repairs

AURVTN029 Set up and operate universal vehicle measuring systems

AURVTN135 Apply original manufacturer repair procedures during vehicle repairs

AURVTN132 Inspect vehicle damage and determine repair procedures

AURVTN022 Repair vehicle body misalignment

AURVTN039 Set up body alignment equipment on vehicles

AURTTY001 Repair vehicle chassis, frame and associated components

UNIT CODE COMPETENCY DESCRIPTION

AURASA102 Follow safe working practices in a automotive workplace

AURAEA002 Follow environmental and sustainability best practice in an automotive workplace

AURTTK102 Use and maintain tools and equipment in an automotive workplace

AURETR125 ^ Test, charge and replace batteries and jump-start vehicles

AURACA101 Respond to customer needs and enquires in an automotive workplace

AURSAA001 Process customer complaints in an automotive workplace

AURAFA104 Resolve routine problems in an automotive workplace

AURAFA103 Communicate effectively in an automotive workplace

AURSLA001 Comply with legal requirements when selling automotive products and services

AURSCA106 Promote automotive products and services

BSBPRO401 ^ Develop product knowledge (SUPERSEDED) (Group A)

AURSBA001 ^ Carry out warehousing procedures in an automotive workplace (Group A)

SIRRINV002 ^ Control stock

TLIA2012 Pick and process orders (Group A)

TLILIC003 Licence to operate a forklift truck

AURSCA105 Sell automotive products and services

AURSCA101 ^ Select and supply automotive parts and products (Group A)

AURSCA102 Present automotive products and services for sale

AURSCA111 Conduct online transactions in an automotive workplace

BSBTEC201 ^ Use business software applications (Group A)

^ Specialist Elective A

UNIT CODE COMPETENCY DESCRIPTION

AURASA102 Follow safe working practices in a automotive workplace

AURAEA002 Follow environmental and sustainability best practice in an automotive workplace

AURTTK102 Use and maintain tools and equipment in an automotive workplace

AURETR125 Test, charge and replace batteries and jump-start vehicles

AURETR112 Test and repair basic electrical circuits

AURETK002 Use and maintain electrical test equipment in a workplace

AURETR006 Solder electrical wiring and circuits

AURETR116 Read and apply vehicle wiring schematics and drawings

AURETR007 Apply knowledge of automotive electrical circuits and wiring systems

AURETR135 Apply knowledge of petrol and diesel engine operation

AURTTE104 Inspect and service engines

AURTTF101 Inspect and service petrol fuel systems

AURTTB101 Inspect and service braking systems

AURTTX102 Inspect and service manual transmissions

UNIT CODE COMPETENCY DESCRIPTION

AURETR009 Install vehicle lighting and wiring systems

AURETR010 Repair wiring harnesses and looms

AURETR027 Install ancillary electronic systems and components

AURTTA118 Develop and carry out diagnostic test strategies

AURTTC103 Diagnose and repair cooling systems

AURLTB103 Diagnose and repair light vehicle hydraulic braking systems

AURLTD104 Diagnose and repair light vehicle steering systems

AURLTD105 Diagnose and repair light vehicle suspension systems

AURLTD106 Carry out light vehicle wheel alignment operations

AURLTQ102 Diagnose and repair light vehicle drive shafts

AURLTE102 Diagnose and repair light vehicle engines

UNIT CODE COMPETENCY DESCRIPTION

AURETR129 Diagnose and repair charging systems

AURETR130 Diagnose and repair starting systems

AURETR131 Diagnose and repair ignition systems

AURLTZ101 Diagnose and repair light vehicle emission control systems

AURETR132 Diagnose and repair automotive electrical systems

AURETR123 Diagnose and repair spark ignition engine management systems

AURETR124 Diagnose and repair compression ignition engine management systems

UNIT CODE COMPETENCY DESCRIPTION

AURTTA104 Carry out servicing operations

AURETR143 Diagnose and repair electronic body management systems

AURETR120 Diagnose and repair network electronic control systems

AURETR128 Diagnose and repair instruments and warning systems

AURETR122 Diagnose and repair vehicle dynamic control systems

AURETD101 Diagnose and repair electronically controlled steering systems

AURETR144 Diagnose and repair integrated engine and transmission management systems

UNIT CODE COMPETENCY DESCRIPTION

AURETH011 Depower and reinitialise hybrid electric vehicles

AURETH101 Depower and reinitialise battery electric vehicles

AURVTA002 Remove and replace vehicle supplementary restraint systems

AURETU103 Service air-conditioning and HVAC systems

AURETU104 Diagnose and repair air-conditioning and HVAC systems

UNIT CODE COMPETENCY DESCRIPTION

AURASA102 Follow safe working practices in a automotive workplace

AURAEA002 Follow environmental and sustainability best practice in an automotive workplace

AURTTK102 Use and maintain tools and equipment in an automotive workplace

AURETR125 Test, charge and replace batteries and jump-start vehicles

AURETR112 Test and repair basic electrical circuits

AURETK002 Use and maintain electrical test equipment in a workplace

AURETR006 Solder electrical wiring and circuits

AURETR116 Read and apply vehicle wiring schematics and drawings

AURETR007 Apply knowledge of automotive electrical circuits and wiring systems

AURETR135 Apply knowledge of petrol and diesel engine operation

AURTTE104 Inspect and service engines

AURTTQ001 Inspect and service final drive assemblies

AURTTA006 Inspect and service hydraulic systems

AURTTB101 Inspect and service braking systems

UNIT CODE COMPETENCY DESCRIPTION

AURETR009 Install vehicle lighting and wiring systems

AURETR010 Repair wiring harnesses and looms

AURETR027 Install ancillary electronic systems and components

AURTTC103 Diagnose and repair cooling systems

AURTTA118 Develop and carry out diagnostic test strategies

AURHTB101 Diagnose and repair heavy vehicle air braking systems

AURHTD103 Diagnose and repair heavy vehicle suspension systems

AURHTD102 Diagnose and repair heavy vehicle steering systems

AURHTQ103 Diagnose and repair heavy vehicle drive shafts

AURHTY102 Diagnose and repair mechanical connections of heavy vehicles and trailers over 4.5 tonnes

AURHTE102 Diagnose and repair heavy vehicle compression ignition engines

UNIT CODE COMPETENCY DESCRIPTION

AURTTF102 Inspect and service diesel fuel injection systems

AURHTF102 Diagnose and repair heavy vehicle diesel fuel injection systems

AURHTQ102 Diagnose and repair heavy commercial vehicle final drive assemblies

AURTTF105 Diagnose and repair engine forced induction systems

AURETR129 Diagnose and repair charging systems

AURETR130 Diagnose and repair starting systems

AURETR131 Diagnose and repair ignition systems

AURETR132 Diagnose and repair automotive electrical systems

UNIT CODE COMPETENCY DESCRIPTION

AURETR123 Diagnose and repair spark ignition engine management systems

AURHTZ101 Diagnose and repair heavy vehicle emission control systems

AURETR124 Diagnose and repair compression ignition engine management systems

AURHTX104 Diagnose and repair heavy vehicle clutch systems

AURHTX101 ^ Diagnose and repair heavy vehicle manual transmissions

AURTTA104 Carry out servicing operations

AURETR143 Diagnose and repair electronic body management systems

AURETR122 Diagnose and repair vehicle dynamic control systems

UNIT CODE COMPETENCY DESCRIPTION

AURETR120 Diagnose and repair network electronic control systems

AURETR128 Diagnose and repair instruments and warning systems

AURETR144 Diagnose and repair integrated engine and transmission management systems

TLILIC003 License to operate a forklift truck

AURETU103 Service air-conditioning and HVAC systems

AURETU104 Diagnose and repair air-conditioning and HVAC systems

^ Specialist Elective A

UNIT CODE COMPETENCY DESCRIPTION

AURASA102 Follow safe working practices in a automotive workplace

AURAEA002 Follow environmental and sustainability best practice in an automotive workplace

AURTTK102 Use and maintain tools and equipment in an automotive workplace

AURETR125 Test, charge and replace batteries and jump-start vehicles

AURETR112 Test and repair basic electrical circuits

AURETK002 Use and maintain electrical test equipment in a workplace

AURETR006 Solder electrical wiring and circuits

AURETR116 Read and apply vehicle wiring schematics and drawings

AURETR007 Apply knowledge of automotive electrical circuits and wiring systems

AURETR135 Apply knowledge of petrol and diesel engine operation

AURTTE104 Inspect and service engines

AURTTQ001 Inspect and service final drive assemblies

AURTTA006 Inspect and service hydraulic systems

AURTTB101 Inspect and service braking systems

UNIT CODE COMPETENCY DESCRIPTION

AURETR009 Install vehicle lighting and wiring systems

AURETR010 Repair wiring harnesses and looms

AURETR027 Install ancillary electronic systems and components

AURTTA118 Develop and carry out diagnostic test strategies

AURTTC103 Diagnose and repair cooling systems

AURKTB101 Diagnose and repair mobile plant braking systems

AURKTA111 Diagnose and repair mobile plant hydraulic systems

AURKTD102 Diagnose and repair mobile plant steering systems

AURACA101 Respond to customer needs and enquiries in an automotive workplace

AURHTE102 Diagnose and repair heavy vehicle compression ignition engines

UNIT CODE COMPETENCY DESCRIPTION

AURTTF102 Inspect and service diesel fuel injection systems

AURHTF102 Diagnose and repair heavy vehicle diesel fuel injection systems

AURKTQ101 Diagnose and repair mobile plant final drive assemblies

AURHTQ103 Diagnose and repair heavy vehicle drive shafts

AURETR129 Diagnose and repair charging systems

AURETR130 Diagnose and repair starting systems

AURETR131 Diagnose and repair ignition systems

AURETR132 Diagnose and repair automotive electrical systems

UNIT CODE COMPETENCY DESCRIPTION

AURETR123 Diagnose and repair spark ignition engine management systems

AURETR124 Diagnose and repair compression ignition engine management systems

AURTTF105 Diagnose and repair engine forced induction systems

AURHTZ101 Diagnose and repair heavy vehicle emission control systems

AURKTX101 Diagnose and repair powershift transmissions

AURTTA104 Carry out servicing operations

AURETR143 Diagnose and repair electronic body management systems

AURETR122 Diagnose and repair vehicle dynamic control systems

UNIT CODE COMPETENCY DESCRIPTION

AURETR120 Diagnose and repair network electronic control systems

AURETR128 Diagnose and repair instruments and warning systems

AURETR144 Diagnose and repair integrated engine and transmission management systems

AURETU103 Service air-conditioning and HVAC systems

AURETU104 Diagnose and repair air-conditioning and HVAC systems

TLILILIC0003 Licence to operate a forklift truck

Ensure your business and team is equipped to be more efficient, boosting your bottom line and profitability, by expanding on their skills with MTA Training and Employment’s wide-range of upskilling training courses. MTA Training and Employment delivers training using the latest technology and practices available in the marketplace, and our trainers have extensive and current industry experience.

This course will give you the underpinning skills and knowledge you need to prepare for an apprenticeship as an automotive technician. As South Australia’s only dedicated automotive industry training provider, MTA Training and Employment (MTA) will give you the skills, training and access to industry employers to prepare you for your automotive future.

You’ll learn about workplace safety, basic automotive fault finding, troubleshooting techniques, batteries, wheel balancing, braking systems, cooling systems, steering systems, suspension systems, and the use of automotive tools and equipment.

MTA Training and Employment require you to complete work experience as part of this course. Whilst not mandatory for completion of the qualification, work experience will prepare you for a job in the industry and put you ahead of the game. Work experience for one week at one of our host employers is provided to all students.

MTA deliver the following units:

AURAEA002 Follow environmental and sustainability best practices in an automotive workplace

AURASA102 Follow safe working practices in an automotive workplace

AURATA001 Identify basic automotive faults using troubleshooting processes

AURETR115 Inspect, test and service batteries

AURTTA104 Carry out servicing operations

AURTTB101 Inspect and service braking systems

AURTTC001 Inspect and service cooling systems

AURTTD002 Inspect and service steering systems

AURTTD004 Inspect and service suspension systems

AURTTE104 Inspect and service engines

AURTTK102 Use and maintain tools and equipment in an automotive workplace

AURTTQ001 Inspect and service final drive assemblies

(continued):

AURTTQ103 Inspect and service drive shafts

AURETR103 Identify automotive electrical systems and components

AURLTA101 Identify automotive mechanical systems and components

AURLTJ102 Remove, inspect, repair and re-fit light vehicle tyres and tubes

AURTTF101 Inspect and service petrol fuel systems

AURTTF102 Inspect and service diesel fuel injection systems

AURTTK001 Use and maintain measuring equipment in an automotive workplace

AURTTJ011 Balance wheels and tyres

You will need practical hands-on aptitude, good communication and interpersonal skills, basic literacy and numeracy skills and a basic understanding of concepts including measurements, volumes, levels, ratios, pressure, temperature and chemicals.

To access funding through the South Australian Government, you must meet the eligibility criteria below.

You might be eligible for subsidised training if you live or work in South Australia, and are:

an Australian or New Zealand citizen

a permanent Australian resident or

an eligible visa holder.

You also need to be:

16 years or over and not enrolled at school

Check your eligibility here: https://mytraining.skills.sa.gov.au/training/get-started/check-eligibility

On successful completion, you will be awarded AUR20520 Certificate II in Automotive Servicing Technology. If you do not complete, you will be awarded a Statement of Attainment for the units of competency you have completed.

This is a 10-week full-time course delivered at MTA Training and Employment’s Royal Park Training Centre. Course times: 8:30 am to 4:00 pm (Monday to Thursday).

This course has been developed for qualified automotive technicians, or suitably skilled candidates and is designed to fast track an AAC02 – Refrigerant handling licence if participants have recent qualifications or meet the qualification criteria as set by ARCtick. RTA No. AU02967.

This course is essential for technicians working on air-conditioning systems in the automotive industry. An Automotive Air Conditioning Licence is required for any work on air conditioning equipment fitted to the cabin of a motor vehicle that involves a risk of a controlled refrigerant being emitted.

This course delivers the units of competencies that form part of the process for applying for a Refrigerant handling licence. Once the units of competencies have been completed and you have been awarded your statement of attainment, you must then present this to ARCtick to determine if you are eligible for your licence.

Environmental requirements relating to the servicing and repairing of air conditioning and HVAC systems

Identification and function of major air conditioning and HVAC system components

Principles of operation of air conditioning and HVAC systems

Types of air conditioning and HVAC systems

Service, repair and adjustment procedures of air conditioning and HVAC systems

Workplace health and safety (WHS) requirements relating to servicing, diagnosing and repairing air conditioning and HVAC systems

Handling, storing and transporting refrigerant cylinders and recovery cylinders

Diagnostic testing procedures for air conditioning and HVAC systems

There are no prerequisites for this training; however, to gain a refrigerant handling licence, you must hold one of the recognised qualifications listed on the arctick.org/refrigerant-handling-licence/licence-types/ The MTA do not guarantee or provide advice around licencing. You must contact ACRtick directly for advice. If unsure about eligibility, contact the Australian Refrigeration Council on 1300 88 44 83

The two-day course is delivered at MTA Training and Employment’s Royal Park Training Centre. Prior to attending the course, all participants are required to complete an online learning module, designed to provide them with the knowledge to be able to complete the practical component.

Course times: 8:30 am to 4:00 pm each day.

On successful completion, a statement of attainment will be issued for:

AURETU103 Service air conditioning and HVAC systems

AURETU104 Diagnose and repair air conditioning and HVAC systems

This course is designed to provide Students with the skills and knowledge to undertake activities related to Forklift Operation. Training is conducted in accordance with the Work Health and Safety Regulations (SA) 2012 and Safe Work Australia’s National Assessment Instruments for Licensing Persons Performing High Risk Work.

Through this course, participants will gain the knowledge in:

Understanding and identifying legislation requirements under the current Act and regulations

Forklift truck-types, including basic maintenance and checks

Operation of Forklift truck-steering, parking, approaching and lifting, loads and stability

Material handling-packaging, pallets, drums, attachments and hazardous substances

The environment-floor stability, obstacles, pedestrians, confined spaces and slopes

Operating a forklift is classed as a “high risk ” operation and requires a Licence to Perform High Risk Work from SafeWork SA.

Upon successful completion, the participant is eligible to apply for a forklift licence through SafeWork SA at their own cost.

*Note: Candidates who fail this assessment must re-enrol in a future course for additional instruction and reassessment. A $200 reassessment fee applies.

This course is recommended for Students with some operational experience on a Forklift or other plant. Students suited to this course would have a good understanding of and preferably exposure to Workplace Health and Safety requirements and risk management in a workplace. If you have no forklift exposure or experience, this course is not recommended. You may be required to undertake LLN testing depending on your previous qualifications.

The two-day course is delivered at MTA Training and Employment’s Royal Park Training Centre. Prior to attending the course, all participants are required to complete an online learning module, designed to provide them with the knowledge to be able to successfully complete the practical component.

Course times: 8:30 am to 4.30 pm each day.

Day 1: Training and Assessment to TLILIC0003 Licence to Operate a Forklift Truck

Day 2: SafeWork SA High Risk Work Licence (HRWL) Assessment

On successful completion, a statement of attainment will be issued for:

TLILIC0003 Licence to operate a forklift truck

This course has been developed to equip industry professionals with the skills to carry out light vehicle wheel alignment operations, including operating principles of steering geometry and wheel alignment, use of equipment and more.

During the course, you will learn how to conduct a pre-alignment inspection, carry out the wheel alignment process, and complete necessary workplace documentation and procedures.

The course focuses on light vehicles, providing hands-on experience of the key techniques involved in wheel alignment.

This course is ideal for individuals looking to advance their skills in the automotive industry.

By completing this course, you will be able to:

Identify, obtain and interpret information to perform a wheel alignment, and select the tools and equipment needed for the job.

Complete a wheel alignment pre-check according to workplace guidelines and identify and report any faults.

Perform the alignment and record readings, make necessary adjustments, re-check the alignment for accuracy, and record the final readings.

Conduct a final inspection to ensure the vehicle is ready for use.

Participants should be working in the automotive industry.

The half-day course is delivered at MTA Training and Employment’s Royal Park Training Centre.

Prior to attending the course, all participants are required to complete an online learning module, designed to provide them with the knowledge to be able to successfully complete the practical component.

Course times: 8:30 am to 12.30 pm, or 5:00pm – 9:00pm (night course).

This course is designed for automotive service and repair professionals who need to understand, diagnose, and repair networked control systems. Specifically, it applies to those working with embedded CAN Bus control systems found in:

Agricultural machinery

Heavy commercial vehicles

Light vehicles

Mobile plant machinery

Foundational understanding of automotive electrical principles is highly recommended.

This course is essential for Technicians working on modern vehicles and machinery that heavily rely on (CAN Bus) networked control systems. This course covers diagnosing and repairing of faults in these systems, which require specialised skills. Automotive technicians must understand CAN Bus and LIN Bus networks to ensure reliable communication between vehicle components like engine control units, infotainment systems, and safety features.

By taking this course, technicians will:

Gain practical hands-on experience in diagnosing and repairing network faults.

Learn to use diagnostic tools effectively, like scan tools and oscilloscopes.

Understand real-world failure scenarios and how to troubleshoot them efficiently.

With networked systems controlling everything from engine performance to climate control, mastering fault diagnosis and repair is critical for technicians in the automotive service industry.

This course is ideal for:

Light Vehicle Technicians

Heavy Vehicle Technicians

Mobile Plant Technicians

Agricultural Technicians

Participants should be working in the automotive industry and have an understanding of CAN bus technology.

Identification of common CAN Bus components in late-model light vehicles.

Gain an understanding of the operation and purpose of various CAN Bus systems.

Explore the interdependencies between CAN Bus and LIN Bus systems.

Understanding how and why the systems communicate.

Reduce the risk of post-repair system failure through understanding the system.

Build confidence in discussing CAN Bus-related repairs with colleagues and customers.

Improve repair accuracy and reduce liability.

Participants should be working in the automotive industry and have a good understanding of CAN Bus diagnostics and vehicle technology.

The two-day course is delivered at MTA Training and Employment’s Royal Park Training Centre.

Prior to attending the course, all participants are required to complete an online learning module designed to provide them with the knowledge necessary to successfully complete the practical component.

Course times: 8:30 am to 4:00 pm each day.

On successful completion, a statement of attainment will be issued for:

AURETR120 Diagnose and repair network electronic control systems

For more information:

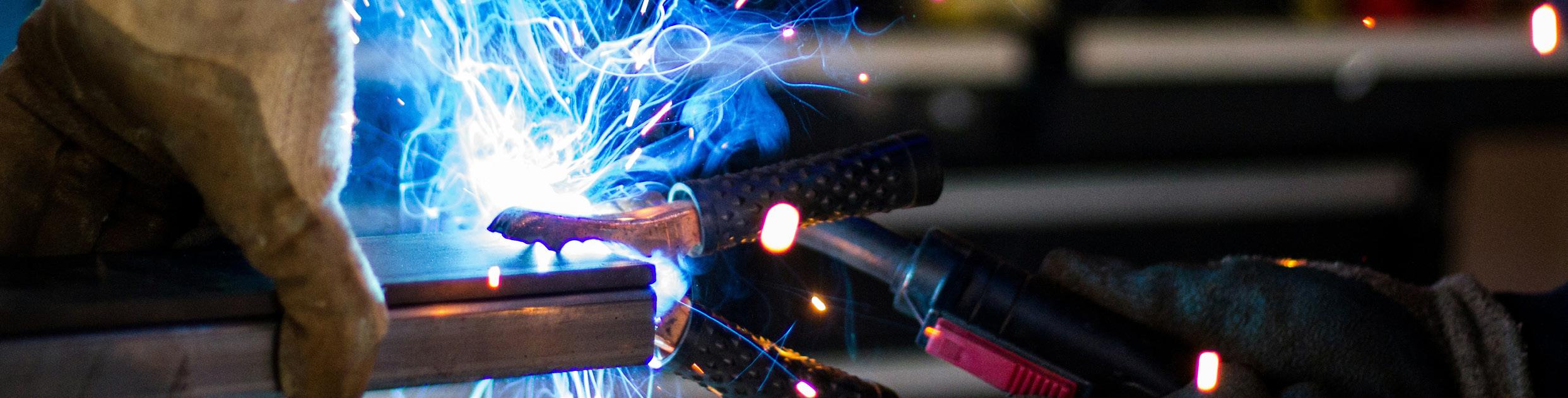

This course is designed for automotive technicians, especially in the heavy vehicle and agricultural fields, looking to expand on or develop advanced gas metal arc welding skills. This course is not suitable for panel beaters; our Mig Welding course is better suited.

This course covers the skills required to carry out gas metal arc welding in the automotive industry, commonly found in heavy vehicle suspension modifications or agricultural repairs.

By taking this course, students will:

Develop and enhance their skills in gas metal arc welding

Get hands-on welding experience focused on developing technical skills

Develop skills in butt, fillet and exhaust pipe butt welds

Course Outline

Identify and select appropriate welding techniques based on the material type and repair requirements.

Safely set up and operate welding equipment

Perform high-quality welds

Conduct final inspections to ensure components are ready for use

Participants should be working in the automotive industry.

The two-day course is delivered at MTA Training and Employment’s Royal Park Training Centre.

Course times: 8:30 am to 4:00 pm each day.

On successful completion, a statement of attainment will be issued for:

AURVTW109 Carry out basic gas metal arc welding

This course is designed for automotive workers and tyre fitters to develop and enhance their skills in tyre balancing and fitting.

This course covers the skills required to remove, inspect, repair and refit light vehicle tyres and tubes from wheels and balance tyres and wheels. By taking this course, students will:

Develop and enhance their skills in tyre fitting

Get hands-on experience

Understand the safety hazards and environmental issues

Course Outline

Safely set up wheel balancing machines

Conduct pre-balance inspection of tyres

Balance wheel and tyres

Removing and inspecting tyres, tubes and wheels

Repairing and refitting tyres and tubes

Participants should be working or seeking employment in the automotive industry.

Delivery Mode

The two-day course is delivered at MTA Training and Employment’s Royal Park Training Centre. Prior to attending the course, all participants are required to complete an online learning module, designed to provide them with the knowledge to be able to successfully complete the practical component.

Course times: 8:30 am to 4:00 pm each day.

On successful completion, a statement of attainment will be issued for:

AURLTJ102 Remove, inspect, repair and refit light vehicle tyres and tubes

AURTTJ011 Balance wheels and tyres

This course is designed for automotive panel beaters looking to expand on or develop advanced gas metal arc welding skills. Students will gain hands-on experience with a variety of welding processes used in modern shops, with an emphasis on quality, precision, and safety.

This course covers the skills required to weld various depths of automotive steel and metal, ranging from 0.8mm to 1.2mm.

By taking this course, panel beaters will:

Develop and enhance their skills in advanced gas metal arc welding

Get hands-on welding experience focused on developing technical skills

Set up and make adjustments to welding equipment

Select and use the most appropriate personal protective equipment (PPE)

Be able to identify and rectify weld defects

Identify and select appropriate welding techniques based on the material type and repair requirements.

Safely set up and operate welding equipment, including adjusting settings for varied materials and thicknesses.

Perform high-quality welds on a range of metals.

Prepare surfaces and components correctly for welding, including cleaning, clamping, and aligning metals.

Conduct post-weld inspections to identify and correct weld defects such as porosity, cracking, and lack of fusion.

Understand and follow manufacturer specifications and industry repair standards for non-structural repairs.

Recognise the impact of heat on materials, including warping and metallurgical changes, and adjust techniques accordingly.

Participants should be working in the automotive industry as a panel beater or have appropriate experience.

The five-day course is delivered at MTA Training and Employment’s Royal Park Training Centre. Course times: 8:30 am to 4:00 pm each day.

On successful completion, a statement of attainment will be issued for: AURVTW103 Carry out advanced gas metal arc welding on vehicle body sections

This course provides automotive repair professionals with a comprehensive introduction to Paintless Dent Removal (PDR) – an advanced repair method that eliminates dents without the need for fillers or repainting.

Designed specifically for panel beaters, damage assessors, and body shop managers, the course offers a strong foundation in Paintless Dent Removal (PDR) application.

Participants will gain hands-on experience using industry-leading tools and glue-pulling systems, developing the confidence to integrate PDR techniques into everyday repair processes.

Deliver faster, more efficient, and higher-quality repairs

Integrate PDR practices into workshop workflows to improve productivity

Increase profit by lowering costs and increasing efficiency

Exposure to cutting-edge PDR technology

Practical hands-on experience performing a range of repairs with PDR equipment

Learn skills to reduce reliance on fillers and paint in dent repair

Learn best practices for PDR in the modern workshop

Participants should be working in the automotive industry.

This is non-accredited training. A statement of attendance will be issued on completion of training.

This course is tailored for technicians currently working in the automotive industry who need to identify and understand Advanced Driver Assistance System (ADAS) components, as well as the operational characteristics of the systems commonly found in today’s modern light vehicles