MILK PRODUCER MAGAZINE CELEBRATING 100 YEARS 19 25-2025

OCTOBER 2025 | THE VOICE OF ONTARIO DAIRY PRODUCERS

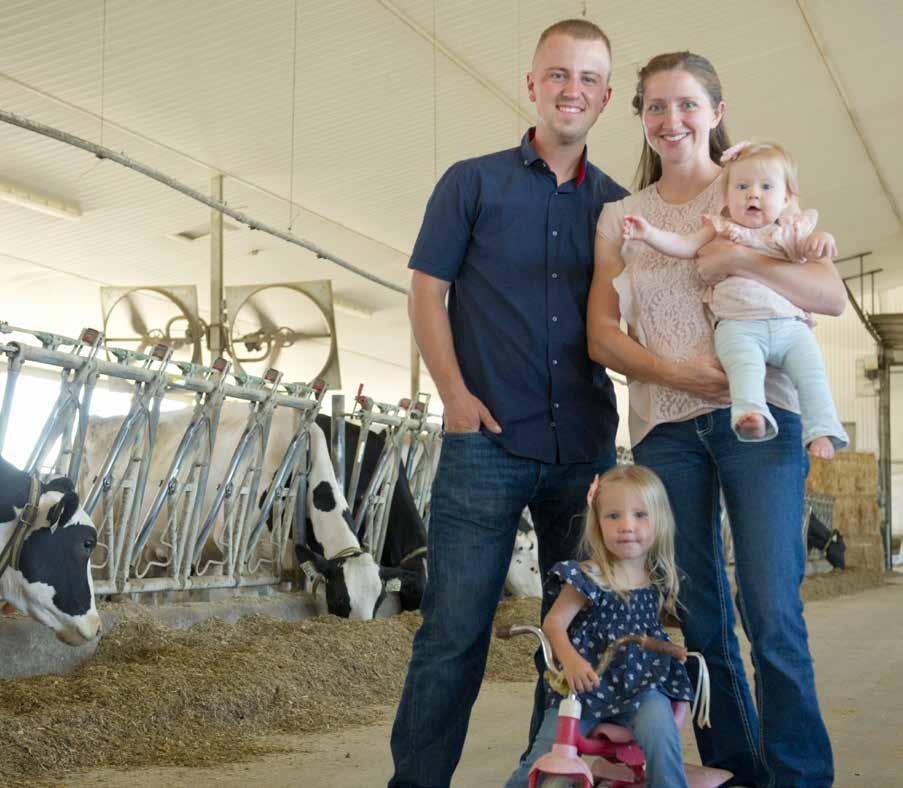

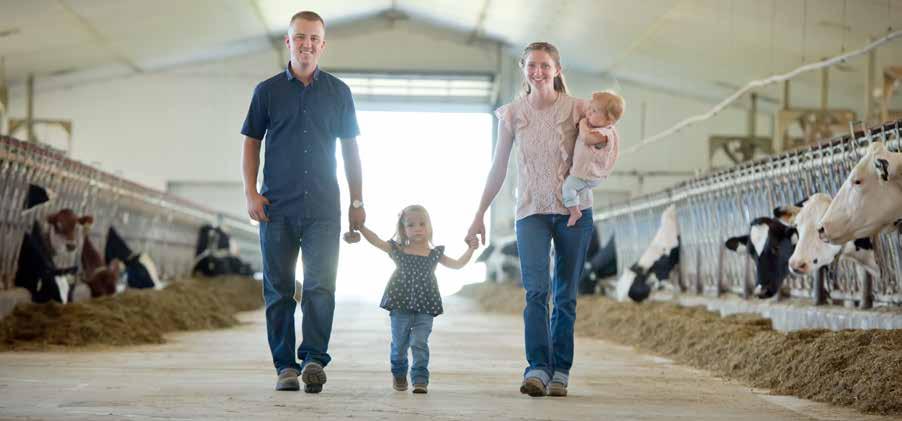

For the Slits family, dairy farming is both a calling and a business - guided by clear goals and financial know-how

MILK PRODUCER MAGAZINE CELEBRATING 100 YEARS 19 25-2025

OCTOBER 2025 | THE VOICE OF ONTARIO DAIRY PRODUCERS

For the Slits family, dairy farming is both a calling and a business - guided by clear goals and financial know-how

When it comes to dairy farming, it’s essential to squeeze the most out of every day. Purina can help. We understand the challenges and we’ve got the tools and know-how to maximize your farm’s productivity and long-term profitability. Talk to us about our custom nutrition solutions, data synthesis and performance forecasting.

We’re ready and waiting to move your farm forward. Contact your local Purina Dairy Advisor today.

PUBLISHED BY

DAIRY FARMERS OF ONTARIO

6780 Campobello Road Mississauga, ON L5N 2L8

COMMUNICATIONS

Sandra Da Silva sandra.da-silva@milk.org 905-817-2178

ADVERTISING

Pat Logan pat.logan@milk.org 519-788-1559

GRAPHIC DESIGN

Katrina Teimo

COVER STORY PHOTOGRAPHY

Martin Schwable

CONTRIBUTORS

Andrew Leach, Omar Sandoval, Georgina Knitel, Amanda Hammell, Jeanine Moyer, Titouan Chapelain, ACER Consulting & Dairy Farmers of Canada, Cynthia Miltenburg, Hannah Sweett, Rodrigo Molano, Veal Farmers of Ontario, Workplace Safety & Prevention Services.

Canada Post Publications Mail Sales Product Agreement No.40063866.

Return postage guaranteed. Circulation: 8,000. ISSN 0030-3038. Printed in Canada.

SUBSCRIPTIONS

For subscription changes or to unsubscribe, contact:

MILK PRODUCER

6780 Campobello Road Mississauga, ON L5N 2L8

Phone: (905) 821-8970

Fax: (905) 821-3160

Email: milkproducer@milk.org

Opinions expressed herein are those of the author and/ or editor and do not necessarily reflect the opinion or policies of Dairy Farmers of Ontario. Publication of advertisements does not constitute endorsement or approval by Milk Producer or Dairy Farmers of Ontario of products or services advertised.

Milk Producer welcomes letters to the editor about magazine content.

*All marks owned by Dairy Farmers of Ontario.

WEBSITES & SOCIAL MEDIA

www.milkproducer.ca

www.milk.org

X: @OntarioDairy

Instagram: @OntarioDairy

LinkedIn: /company/Dairy-Farmers-of-Ontario

Facebook: /OntarioDairy

Ontario

Vice-Chair and Board Member, Region 3,

Leeds and Renfrew. John chairs the DFO Audit Committee and serves on the Governance, and Markets and Allocation Committees, the Ontario Advisory Committee for Milk, P5 Quota Committee, and the P5 Supervisory Body and P5 Markets Committee.

As a second-generation dairy producer, I’ve witnessed how the industry has evolved and how important it is to adapt. The dairy industry faces constant change – market volatility, rising costs and shifting consumer preferences.

Today, diversification and sound financial planning aren’t just smart strategies, they’re a means to stay competitive and resilient.

Diversification is about exploring new opportunities that complement the success of your farm. Whether it’s investing in crops, energy or on-farm processing, these ventures can generate additional income and make better use of our land, labor and infrastructure.

But diversifying a farm isn’t a one-size-fits-all approach. It requires thoughtful consideration of how well the farm is managed, the potential risks involved, the capacity to take on new ventures and the expertise to execute.

On our farm, we scaled up, invested in our equipment to cover more acres and diversified into cash crops. While my focus is in producing high-quality milk, my son’s expertise in equipment and cropping made him a natural fit to lead this growth opportunity.

Still, diversification is only part of the equation. To sustain a profitable, thriving farm, financial and strategic planning are essential. That means understanding cash flow, managing debt, investing wisely, tracking expenses, forecasting revenue and partnering with financial advisors to navigate market shifts and plan for long-term success. Simply put, financial acumen and diversification go hand-in-hand.

Equally important is succession planning. For many of us, the farm isn’t just a business, it’s a legacy built over generations. Succession planning, much like diversification, requires a customized approach, not all farms and farm families are the same.

Vicky Morrison

Ensuring a smooth transition to the next generation requires open communication and preparation as early on as possible, and a solid business base to build upon by the next generation. Whether passing the reins to a family member or training a new manager, succession planning protects the farm’s future and honours the hard work of those who built it.

In today’s dairy industry, resilience comes from diversification, financial strength and a clear vision for the future. These strategies empower us to adapt, grow and preserve what matters most. As dairy farmers, we’re not just producing milk – we’re building businesses, nurturing communities and preparing the next generation to carry our legacy forward.

80% of farms aren’t ready for a cyberattack

Our latest report shows that only 20 percent of Canadian farms have a cyber incident response plan — leaving many farms vulnerable.

This Cyber Security Awareness Month, discover how cyber threats are evolving in the agriculture sector and learn practical steps to build resilience and protect your dairy operation.

When we fired up the robots 2 years ago DairyComp support made the transition so smooth. We reached out with a simple text and would have been lost without them.

Tyce Kootstra Stradow Farms, Ponoka, AB 160 cows milkingRobots

We’ve been using DairyComp for the past 3 years and it’s become an invaluable cow management tool that has contributed to our success.

David Bekkers

Bekkers Farm, Antigonish, NS 150 cows milkingParlour

Contact us to learn more about software options.

1 800 549 4373

I have been using DairyComp since the ‘90s. I find it easy, intuitive, and the insight it provides is useful to help us stay at the top of our game.

John Schenkels Schenkels Farms, Whitney, NB 550 cows milkingParlour & Robots

DFO Board Members serve in key roles on national committees

Bart Rijke

Second Vice-President, DFC Executive

Chair, DFC Sustainability Committee

Member, DFC Governance Committee

Adam Petherick

Chair, DFC Audit and Risk Committee

Chair, DFC Biosecurity Technical Committee

DFC representative, Animal Health Canada Board of Directors

Vicky Morrison

Chair, proAction Committee

Chair, DFC Food Safety Technical Committee

Ontario representative, Canadian Dairy Research Council

DFC representative, National Farm Animal Care Council

Steve Runnalls

Ontario representative, proAction Committee

Ontario representative, Animal Care Technical Committee

Brian Burnett

Ontario representative, DFC Sustainability Committee

Dairy Farmers of Ontario (DFO) congratulates Bart Rijke on his recent election by the Dairy Farmers of Canada (DFC) Board to the new position of Second Vice-President. He joins President David Wiens (Manitoba) and Vice-President Daniel Gobeil (Quebec) on the DFC Executive.

In addition to their DFO Board duties and responsibilities, board members are regularly called upon to share Ontario’s expertise, counsel and time to the advancement of national objectives and activities in support of sustainable, thriving Canadian dairy farms.

DFO representatives continue to step up, playing leadership roles on national committees and working groups coordinated by DFC. The DFO team supports our board members in their national contributions, with staff supporting on many technical working groups and expert advisory committees, providing counsel on production, research, markets, nutrition and communications. Dairy Farmers of Ontario appreciates the dedication and time commitment that our board members devote to supporting the development and implementation of policy and programs for the benefit of all Canadian dairy farmers and our industry stakeholders.

DFO is committed to working collaboratively with our provincial colleagues to strengthen and grow the Canadian dairy farming industry through the coordination of innovative and sustainable production and advocate for the benefits of Canadian dairy and supply management. As a member of Dairy Farmers of Canada, DFO is committed to sharing our farm knowledge and dairy expertise to inform the national technical and policy work for the benefit of Canadian dairy farmers.

Dairy Farmers of Ontario has a long-standing history of sharing dairy knowledge, best practices and tangibles such as the Milk Calendar with our colleagues across the country. Collaborating on the development of on-farm programs, as well as research, marketing and advocacy on behalf of dairy farmers has never been more critical to the future of a dynamic, growing dairy industry in Canada. As a member of DFC, we are fully engaged in national programs that advance Ontario dairy farmers’ interests.

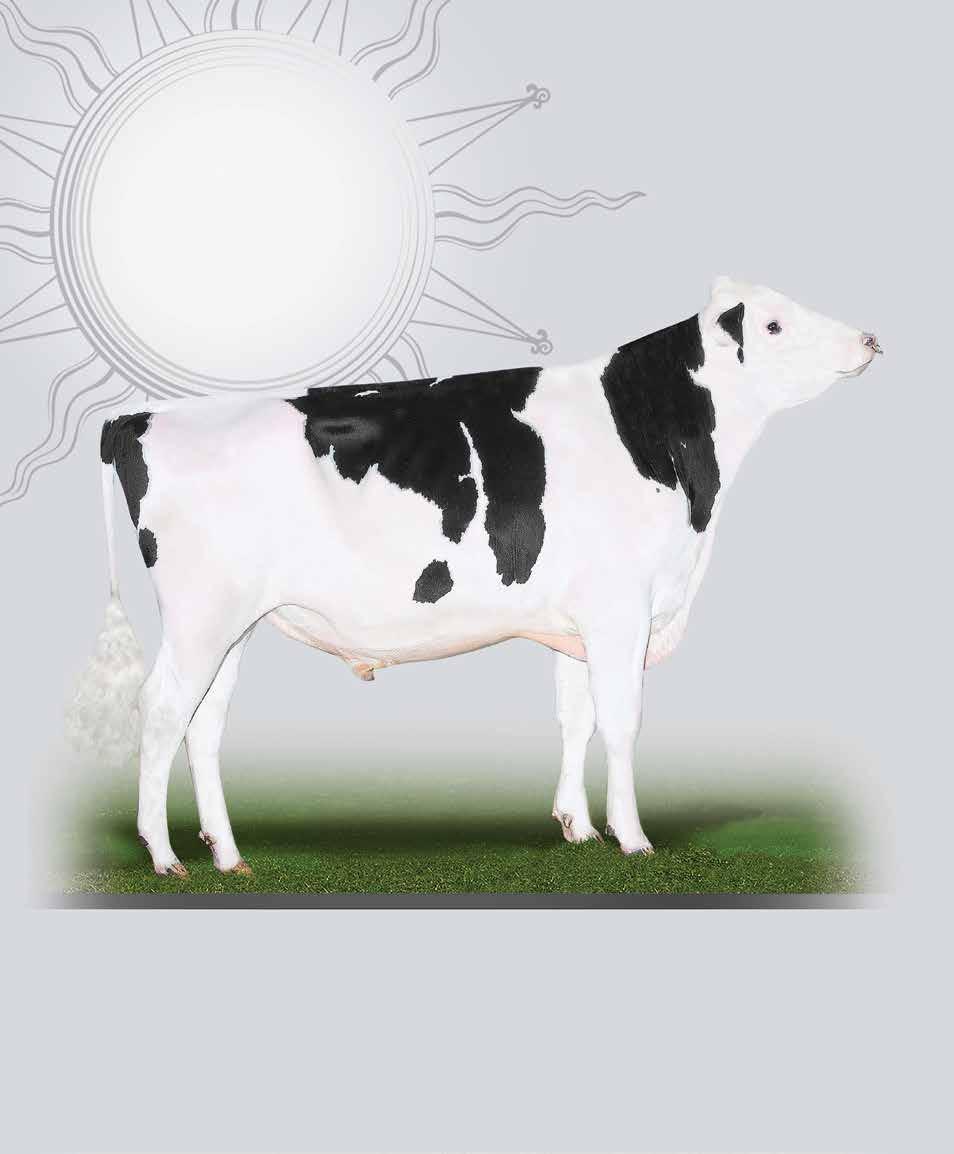

The closest bull to perfection we have seen in the breed to date.

By Andrew Leach, Advisor, Farm Life Financial

SUCCESSION PLANNING IS ONE OF THE

AND EMOTIONALLY COMPLEX — processes a farm family will ever undertake. It’s not just about transferring assets or naming successors. It’s about protecting something deeply personal: your legacy. But, before you can build a plan that truly reflects your values, you need to ask a critical question: what legacy are we trying to protect?

For Canadian farm families, legacy can take many forms. Some are rooted in the land itself, others in business success and quality standards, or the spirit of farming passed down through generations. Understanding which legacy matters most to your family can be the foundation of a meaningful succession plan.

For some, the legacy begins with the land. It’s the soil that’s been tilled for generations, the barns built by grandparents and the fields that hold decades of memories. This legacy of the land is about preserving the physical assets of the farm — not just for their economic value, but for their emotional and historical significance.

If this is the legacy you wish to protect, your succession plan should prioritize land stewardship, continuity of ownership and strategies to keep the farm intact. This would rule out the possibility of relocating the farming operation in the future, selling certain farming assets to pursue opportunities. This is an important piece of information for successors to understand as it directly impacts their business operations for the remainder of their farming lives.

Some families are driven by a commitment to excellence. The legacy of quality is about doing things right — maintaining high standards in production, animal care, environmental practices and customer relationships. It’s a legacy built on reputation and pride.

To protect this legacy, succession planning must include cultural continuity. How will you ensure that the next generation upholds the same standards? This might involve training programs, quality benchmarks or even branding strategies that reinforce your farm’s identity. Families who value this legacy over others are typically more willing to sacrifice contrasting legacy components. An example of this could be selling certain sentimental parcels of land to allocate financial resources to areas of operations that can improve operations and outputs.

For Canadian

farm families,

legacy can take many forms. Some are rooted in the land itself, others

in business

success and quality standards, or the spirit of farming passed down through generations.

Finally, there are families whose legacy is rooted in the spirit of farming itself. The legacy of the family is about keeping agriculture alive within the family — not necessarily through a specific farm or business model, but through shared values, traditions and a love for the land.

If this is your legacy, succession planning may involve creating opportunities for younger family members to explore different roles in agriculture, preserving family stories and traditions, or ensuring the farm remains a place of connection and belonging.

Each of these legacies is valid — and powerful. But they require different strategies, conversations and tools to achieve. That’s why the first step in succession planning isn’t legal or financial — it’s reflective. Families must take time to discuss what legacy they truly want to protect. What matters most? What do you want your children and grandchildren to inherit — not just in assets, but in values? How did we get to where things are today? What would we change if given the chance?

These conversations can be emotional, and they may reveal differing perspectives — and that’s okay. The goal isn’t to agree on everything, but to understand what’s at stake. Once you’ve defined your legacy, you can build a succession plan that protects it — one that’s not just practical, but deeply personal.

‘‘ I really like how fast the attachment is. The GEA DairyRobot R9500 is very cow friendly, the cows are comfortable in the box. It milks a quarter at the time which help us keeping only the good milk in the tank. ’’

Michael Flaman

Chris Adie Holsteins, Vibank, SK

Scan the QR code to watch the complete story of Chris Adie Holsteins of Vibank, Saskatchewan.

BRITISH COLOMBIA

Pacific Dairy Centre Ltd.

Chilliwack — 604 852-9020

ALBERTA

Dairy Lane Systems Alberta

Leduc: 780 986-5600

Blackfalds: 587 797-4521

Lethbridge: 587 787-4145

Lethbridge Dairy Mart Ltd.

Lethbridge — 888 329-6202

Red Deer — 403 406-7344

SASKATCHEWAN

Dairy Lane Systems Saskatchewan Warman — 306 242-5850

Emerald Park — 306 721-6844

Swift Current — 306 203-3066

MANITOBA

Tytech Grand Pointe — 204 770-4898

ONTARIO

Conestogo Agri Systems Inc. Alma — 519 638-3022

Dairy Lane Systems Komoka — 519 666-1404

Lawrence’s Dairy Supply Inc. Moose Creek — 6 13 538-2559

McCann Farm Automation Ltd.

Seeley’s Bay — 613 382-7411

McLaren Works Cobden — 613 646-2062

Performance Dairy Centre Inc. Embro — 519 423-9119

ATLANTIC PROVINCES

Atlantic Dairy Tech, Inc.

AMS Sub-dealer for Sheehy Entreprises Ltd.

Charlottetown, PE — 902 368-1719

Sheehy Entreprises Ltd.

Shubenacadie, NS — 902 758-2002

Lower Queensbury, NB — 506 478-4878

By Larry Batte, Southwestern Ontario Ag TransitionSmart Leader, MNP

EVERY FARM FAMILY FACES CRITICAL DECISIONS AT SOME POINT — who will take over, how the business will evolve and how to keep relationships strong through change. Some families navigate these transitions with confidence, while others find themselves unprepared, leading to conflicts or uncertainty.

What sets successful families apart? Their mindset and approach. They communicate openly, make informed financial decisions and create a plan that benefits both the farm and their family. We explore the seven traits that define farm families to sustain success for generations to come.

1. Planning starts early, not at the last minute

Many successful farm families make planning a priority — they make transition part of their ongoing farm discussions, ensuring alignment of the farm’s vision and goals while its management and leadership evolve. Instead of reacting to circumstances, they control what they can for their future.

Here are some tips to start the planning process and lay down a foundation:

• Start transition/succession conversations early, even before they seem necessary.

• Establish a long-term vision that guides decision-making for growth and stability.

• Introduce leadership transitions gradually to build experience and confidence.

• Identify potential challenges in advance and develop contingency plans.

• Regularly review and update transition plans to adapt to changing circumstances.

Proactive planning provides both stability and flexibility. It allows families to make well-informed decisions rather than being forced into rushed reactions during a crisis.

2. Communication stays open and transparent

Farm transitions rarely fail due to financial problems alone — miscommunication or lack of communication often causes the real damage. Assumptions, unspoken expectations and unclear roles and responsibilities create tension, leading to disputes that could have been avoided.

Strong farming families keep communication transparent and open. They regularly ensure all family members — both farming and non-farming — understand their vision and expectations. Transparency fosters trust, reduces misunderstandings and prevents conflicts before they escalate.

Here’s how you can strengthen communications:

• Hold structured family meetings that include all family stakeholders.

• Hold separate structured business meetings that include all the farming operations’ stakeholders.

• Define roles and responsibilities to ensure clarity.

• Establish an open-door policy where family members can voice ideas and concerns.

• Encourage honest discussions about financial expectations and inheritance.

• Document agreements to prevent misunderstandings.

Families that communicate well can make transitions smoother and more collaborative. Avoiding discussions only increases uncertainty and resentment.

A lack of defined leadership often leads to reactive or emotionally driven decision-making. Without structure, disputes arise and progress slows.

Success in this area lies in the ability to set up a governance framework that removes ambiguity. Outline leadership responsibilities, financial decisionmaking processes and structure the way you resolve conflicts. This approach ensures fairness, stability and long-term sustainability, and success of both the farming business and the farm family.

Here’s how you can create a structure for decision-making:

• Define the roles, responsibilities and accountabilities in writing.

• Establish a decision-making process for financial, operational and transition/succession-related matters.

• Develop a clear protocol for resolving disputes before they arise.

• Use advisory boards or outside consultants for objective perspectives.

• Separate business decisions from personal family dynamics.

A clear governance structure keeps farm operations running smoothly and keeps all decisions aligned with the farm’s long-term goals while enhancing family harmony.

Many families focus on minimizing taxes first when planning a transition. While tax considerations play an important role, they shouldn’t come before assessing whether the farm can remain viable while financially supporting the next generation.

Success comes in taking a step back before jumping into planning around tax considerations. Consider whether the farm generates enough income, how financial obligations — such as debt, expansion or retirement funding — will be managed, and how non-farming heirs will be compensated. Only once these core financial elements are understood does tax structuring come into play.

Prioritize financial viability by:

• Assessing whether that farm can generate enough income to sustain all involved generations.

• Exploring the financial structures that can allow for long-term farm security, as well as personal security (retirement planning).

• Considering how different transition scenarios impact the farm’s stability.

• Developing fair and practical compensation plans for non-farming heirs.

• Working with financial advisors to align tax efficiencies with the overall transition plan.

By addressing financial viability, farm families create a strong foundation for transition — one that protects both the business and family relationships. Without this step, tax efficiencies alone cannot ensure long-term success.

Agriculture constantly evolves. Farms that refuse to change often struggle, while those that embrace innovation stay competitive.

Prosperity comes from recognizing the need to modernize through the adoption of new technology, diverse revenue streams, risk mitigation strategies and openness to new ideas from all generations. See innovation as an opportunity — and an investment into your farm's future.

Here’s how you can implement a strategic plan for adaptability:

• Explore new revenue streams, such as direct-to-consumer sales or value-added products.

• Invest in technology to improve information, efficiency and sustainability.

• Encourage all generations to collaborate to introduce innovative ideas while respecting tradition.

• Network — attend industry conferences and stay informed about market trends.

• Diversify operations to reduce reliance on a single income source.

• Embracing change keeps your farm profitable and ensures it remains viable for your family-owned farming business.

6. Manage misunderstandings before they escalate

Disagreements happen in every family business. The difference lies in how these conflicts are handled. Successful conflict management happens when families acknowledge the intricate dynamics and address them early and head-on. Yet, conflict resolution still requires a little more structure than just having a conversation.

Many conflicts stem from uncertainty about the farm’s direction, leadership, financial expectations or ownership issues. Proactive families address these concerns before they escalate. They provide clarity by establishing fair processes, setting clear expectations and bringing in outside advisors when needed.

Effective strategies to build a structure for conflict prevention:

• Approach concerns immediately instead of avoiding difficult conversations.

• Involve neutral third parties or mediators when necessary.

• Implement a fair dispute-resolution process to manage conflicts objectively rather than personally.

• Outline goals, and expectations, and use written agreements to prevent misunderstandings.

• Separate business discussions from personal family issues.

• Managing conflict effectively strengthens family relationships while ensuring long-term business stability.

7. A shared vision keeps the farm moving forward

A farm’s long-term success is more than its financial performance. Families that align on values and goals create stronger businesses and smoother transitions.

A clear vision gives the next generation a sense of purpose. It guides deliberation, strengthens unity and helps ensure that the farm continues to

operate successfully. When all family members understand and support the farm’s direction, transitions become less stressful and more effective.

Here are practical approaches to align your family-run farm's vision:

• Define core values, long-term goals and a vision together.

• Ensure all family members understand and agree on the farm's purpose/ mission.

• Coordinate financial and operational decisions with the farm’s long-term vision.

• Regularly revisit and update the family’s goals and vision as the business evolves.

• Document the vision in writing to keep all generations aligned.

• A shared vision fortifies unity and ensures the farm continues to grow successfully.

A strong farm transition takes foresight, honest conversations and a willingness to make tough decisions before they become urgent. The families that thrive across generations plan with intention, and purpose, adapt when needed and make sure everyone knows their role in the farm’s future. Those who wait too long often find themselves scrambling, forced into decisions they’re not ready to make. The best time to start is now.

Contact a member of MNP's Agriculture team for more information about developing a plan for your family’s transition or succession.

By Omar Sandoval, Lactanet

IN THE DAIRY SECTOR, the demand for workers is only increasing and according to Canadian Agricultural Human Resource Council’s (CAHRC) forecasts1, the labour shortage problems in the industry are expected to persist or even increase in the coming years. Training and onboarding of new employees is crucial to their success and to reduce stress and possibilities of failure for employers and employees.

The structure of dairy farms is changing, and the challenge of managing employees is becoming a reality and a source of anxiety for many. Recent research conducted in Western Canada and Ontario has revealed a notable trend: farmers' anxiety seems to increase with the number of employees and the presence of non-family employees (Tambadou, 2024)2. This resonates with the growing concern for the wellbeing of Canada’s dairy farmers.

Source: Tambadou, 2024

Are the training programs cost-effective and do they improve herd health and milk quality? A recent American study3 suggests that it does. The study involved 112 farm workers on 16 dairy farms in Michigan and Ohio. The authors visited each farm three times to assess the impact of the trainings on workers' understanding of milking routines, milking behaviours, and subsequent effects on milk quality and udder health. One of the visits served to provide training on milk quality and milking protocols.

The dairy farms chosen for the study had to have a conventional milking system and the farm workers had to have no recent training on milk quality or milking protocols. Most participants were foreign workers (61.1 per cent), 70 per cent of whom had less than one year of experience. In addition, 74.7 per cent of the participants spoke Spanish, allowing language barriers to be considered in training programs as the diversity of educational pathways among workers also presents a challenge for educators when creating training content for all participants.

Following the training, the knowledge of the milking routine increased from 49.3 per cent to 67.6 per cent. Based on parlor evaluations, the contact time of the disinfectant in pre-milking routine increased by nine seconds per cow. The percentage of milkings with inadequate preparation time decreased from 69 per cent (pre-training) to 48 per cent (post-training). The proportion of insufficient coverage with the post-milking teat dip decreased from 9.8 per cent (77 of 782) pre-training to 5.9 per cent (34 of 572) post-training. And the somatic cell count (SCC) at the bulk tank stopped increasing. Overall, the results suggest that there was an improvement in milking routine, mastitis identification and milk quality.

Source: Zelmar et al. 2025.

Finally, in terms of the atmosphere within the teams, the training promoted greater satisfaction and stimulated productive discussions and behavioural changes.

Challenges faced by producers, such as stress and financial management, highlight the need to provide them with tailored support and resources to maintain their wellbeing and overall quality of life. (Tambadou, 2024).

On-farm practical training provides a good foundation for mastitis prevention, increase operational performance and engagement, build confidence and help your staff develop their independence and take responsibility.

Studies, the most recent of which was presented above, highlight the positive impact of training programs on various aspects of dairy farm operations, and the cost-effectiveness of these programs for producers (Stup et al., 2006; Sischo et al., 2019, Zelmar et al. 2024).

The main objective of training programs is to acquire knowledge and skills to prevent or reduce the risk of mastitis and associated economic losses before they occur; let us remember that in Canada, the cost of mastitis, taking into account the cost of treatment, the impact of the disease on milk production, the reduction in fertility and the risk of culling the animal, is in the range of $735 to $1,130 CAD less in profit per case of mastitis4.

Research also highlights the importance of training to foster teamwork, communication and worker satisfaction that will ultimately lead to improved decision-making and overall farm management (Rovai et al., 2016).

Given the central role of farm workers in maintaining optimal levels of food safety, milk quality and animal health, the success and profitability of dairy farms is highly dependent on their knowledge, skills and attitudes (Stup et al., 2006).

References

1Labour Market Information and Forecast 2023-2030 CAHRC Canadian Agricultural Human Resource Council; the national labour shortage is the difference between the total number of workers required and the number of domestic workers employed, which is equal to the employment of foreign workers plus the number of job vacancies. Peak Estimate to Reflect Maximum Demand During Seasonal Peaks in Agriculture.

2Using quantitative methods to understand how dairy farmer wellbeing connects to farm management, barn design, technology and animal welfare. *Author: Halimatou Tambadou. University of Manitoba.

3Zelmar et al. 2025, Impact of training dairy farm personnel on milking routine compliance, udder health, and milk quality, Journal of Dairy Science, Volume 108, Issue 2, p. 1615-1624.

4Economic impact of postpartum clinical disease on cow profitability. N. Antonacci*1, F. C. Ferreira2, F. S. Lima2, A. De Vries3, and E. S. Ribeiro.

FOR MANY, DAIRY FARMING IS MORE THAN JUST A JOB, it's a passion rooted in tradition and pride. Producing high-quality milk for Canadian families is a privilege that dairy farmers take seriously. But beyond the passion, dairy farming is also a business. As Perth County dairy farmer, Jeroen Slits, explains, there’s no single formula for running a farm, every operation is different. Still, when it comes to measuring performance, the numbers – both financial and production – ultimately tell the story of success.

Owners of Resolution Dairy Ltd., (Slits Dairy) in Brunner, ON, Jeroen and his wife, Caleigh, milk 130 cows in a Westfalia double-10 parlour. They manage their herd in a sand-bedded free stall barn and crop 700 acres, with half of the acres dedicated to livestock feed and half for cash crop. The family recently completed a multi-generation and multi-family farm succession, paving the way for Slits to return home and join the operation full-time after spending seven years in agricultural lending with a national financial institution.

“I’ve always been a numbers guy, but my off-farm experience in ag lending influences how I approach everything on our farm today,” says Slits. “I look at every situation with a financial lens and evaluate the financial impact of every decision.”

By Jeanine Moyer

The Slits family keep close tabs on the big picture by regularly monitoring interest rates, commodity prices, fertilizer (liquid and dry) and reviewing quarterly profit and loss statements, but not a day goes by on the farm without Jeroen or Caleigh reviewing their bank account to track transactions and stay on top of their cash flow. While Caleigh, who also had an off-farm career in farm finance before returning to the farm full-time herself, is responsible for the farm’s bookkeeping, the couple review their finances together weekly, studying accounts and tracking financial and overall farm management progress.

Slits firmly believes that a clear understanding of farm financials is the key to effective farm management. He’s also quick to highlight that these numbers are directly connected to production, reproduction and animal health that are also critical components of effective farm management. That’s why he diligently keeps track of key performance metrics like feed intake, pregnancy rate, feed efficiency ratio and kilograms of milk solids per cow. “These metrics, in turn, directly impact our financial statements,” he says, noting the importance of understanding financial statements because they can also read as a report card of a farm’s performance. The Slits’ also closely monitor and review key financial metrics, including EBITDA/kg, feed cost/litre, debt service coverage and year-over-year changes.

the

is both a calling and a business –guided by clear goals and financial know-how.

“Its important farmers be able to read financial statements and understand what they mean,” he says, noting that some of the most progressive farmers he worked with in his former banking career couldn't explain what the numbers on statements meant and why they were higher or lower than expected. “As a farmer, we also need to understand where the numbers are coming from, like what is driving feed costs, how our day-to-day expenses impact yearly profits and losses, and where we can find efficiencies.”

When it comes to managing debt, Slits says he doesn’t lose sleep because he understands that debt is necessary for business management and farm expansion. “Debt is a reality in farming, but farmers still need to be balanced. Too much debt isn’t good,” he says. His advice to fellow farmers is to stagger maturity dates to prevent all loans or debts from maturing at the same time. Slits says this approach is an effective tool to help farmers manage and hedge risk. He also believes risk management extends beyond debt load and interest rates. “Many farmers do a great job of hedging risks because they know it’s an important driver of financial success,” he says.

Effective debt management also depends on farmers maintaining a strong working relationship with their lender. Slits views this collaboration as the second most important factor in successfully managing farm finances. He cites open communication, a solid understanding of financial ratios and adherence to financial reporting as three key components of an effective relationship.

“During my time at the bank, I saw varying ranges of debt levels – some as low as $20,000 of debt per kg of quota and some as high as $65,000 of debt per kg of quota,” he says. “While the farms with higher levels had likely just completed an acquisition or a major expansion project, they were also typically diversified or had multiple revenue streams to make such high levels of debt manageable. No matter your debt load, I’ve learned you have to be comfortable with your own level of debt because you’re the one taking the risk.”

Slits advises farmers to meet with their lender at least once a year to review financial statements and share any future plans for the farm. “Lenders can help you manage your debt, provide strategic advice on interest rates, review financial ratios and even assist in planning future projects,” says Slits. “Consider your lender part of your farm management advisory team, especially if you’re looking for help with managing the financial side of the business.”

Its important farmers be able to read financial statements and understand what they mean. As a farmer, we also need to understand where the numbers are coming from, like what is driving feed costs, how our day-to-day expenses impact yearly profits and losses, and where we can find efficiencies.

– Jeroen Slits

Establishing a management team and a system for managing farm finances round out the list of items Slits believes are most important to farm financial management. “Surround yourself with people you trust for advice and keep in touch with them regularly,” says Slits, who relies on a robust farm management advisory team. Not only does he consult with his accountant and lender on farm finances, but conversations with his feed nutritionist, veterinarian, crop advisor and genetics company representative also include cost analysis to help him make the most informed decisions. In addition to their daily routine of reviewing bank transactions and weekly financial meetings, the Slits schedule weekly, quarterly and annual meetings with their advisory team that includes a review of financial ratios, cost of production, profit and loss statements, and cash flow related to each segment of the operation.

“The impact to our bottom-line factors into every decision we make on the farm,” says Slits, who shares two farm management changes he’s made over the years and the resulting impact on his balance sheet.

“There’s an old saying about being so focused on pennies that you trip over dollars,” Slits says. “And that’s the situation I found myself in a few years ago when it came to our breeding program.” He explains that the conception rates of his cows weren’t where he wanted them to be when he was breeding the animals himself. Even though he was trained and felt he was saving money on breeding costs, the value of reproduction and pregnancies outweighed the cost savings. Slits notes that the cost of breeding the animal became irrelevant when he wasn’t getting the conception rates and the long-term payoffs of the number of calves he needed.

“One of the biggest drivers of profitability on a dairy farm is reproduction,” says Slits. “We had to look at the big picture and the investments required to achieve our reproduction and financial goals to help us make the farm management decision to outsource our breeding, and we haven’t looked back.”

Another change in farm management was controlling feed costs. Slits continuously makes adjustments to balance feed costs with productivity.

One of the biggest drivers of profitability on a dairy farm is reproduction. We had to look at the big picture and the investments required to achieve our reproduction and financial goals to help us make the farm management decision to outsource our breeding, and we haven’t looked back.

– Jeroen Slits

He recommends farmers review their feed costs regularly, know what’s driving the costs and always be on the lookout for areas where they can save. “Feed costs can be complex, but the financial impact of this line item should always be top of mind,” he says. “Farmers need to find a balance between costs and production goals. The cheapest option isn’t likely the best, but neither is the most expensive.”

Setting clear goals is also a key part of the Slits’ farm management approach. The couple break down their goals into three areas: production, reproduction and financial. Each goal stands on its own, yet they’re all interconnected, with success ultimately measured through financial statements.

The Slits schedule weekly, quarterly and annual meetings with their advisory team that includes a review of financial ratios, cost of production, profit and loss statements, and cash flow related to each segment of the operation.

Financial foundations

Transitioning to full time on the farm this year has been a welcome change for Slits, but he’s grateful for the experience he gained in agricultural banking and the appreciation he has now for crunching numbers.

“Managing a dairy farm requires a lot of skill, and its hard to be an expert in everything,” says Slits. “Understanding the financial side of the business is so important, so never be afraid to ask questions if you don’t understand.”

Are you in the market

Whether you buy or lease could make a big difference in your farm’s success

By Amanda Hammell, Senior Manager, Farm Management Consulting, MNP

that can shape the efficiency and profitability of your farm. Whether you need to upgrade outdated equipment or you’re expanding your farming operations, making an informed decision requires careful consideration.

The first step in the purchasing process is to assess your farm’s operational needs. Is this purchase required for your farm’s success or is it just because your neighbour has one? Being honest with yourself in this step is critical to maintain and increase your farm’s profitability.

The second step is to decide how you are going to pay for the equipment. The main options are purchasing or leasing:

The most commonly used method to pay for farm equipment is through cash or financing. What are the benefits of purchasing?

1. Certainty of ownership: Title of equipment in your name, so ownership is secure.

2. Available tax deductions: You can deduct the cost of farm equipment at Canada Revenue Agency’s (CRA) prescribed Capital Cost Allowance (CCA) rates.

With the ever-increasing demand for equipment for your farm, leasing gives you other options to fund your farm’s purchases. What are the benefits of leasing?

1. Increased flexibility: As your farm grows, you might find that your needs change. Leasing agreements often come with options to upgrade or exchange equipment, ensuring you always have access to the latest technology and tools without the hassle of buying and selling.

2. Potential for faster tax benefits: Lease payments are typically considered operating expenses and can be deducted from your taxable income, potentially reducing your tax liability.

3. Preserving capital: By not tying up large amounts of money in assets, you can keep more funds available for other critical areas of your farm.

4. Predictable maintenance and repair costs: These costs are often included in lease agreements. This can save you from unexpected expenses and downtime, allowing you to focus on running your farm smoothly.

There are two types of leases that serve very different purposes:

• Operating: Operating leases are used to conserve cash with lower payments that represent only your direct use of the equipment. An operating lease functions like a rental agreement where the leasing company retains ownership, and you may have the option to purchase the equipment at the end of the lease term at market value or give it back to the leasing company. These kinds of leases are ideal for shorter term use and to conserve cash.

• Capital: Capital leases are structured similarly to operating leases where you lease the equipment from the leasing company and have the option to purchase it at the end of the term at a bargain purchase option. The main difference between an operating and a capital lease is the timing of lease payments. Capital leases have higher payments and a high bargain purchase option at the end of the term. By having higher lease payments and shorter terms, you may get tax deductions faster than CRA’s prescribed CCA rates. Capital leases are mainly used for tax planning purposes where tax minimization if your highest priority.

Every farm is unique, and every farmer will have different needs depending on the age of their equipment, what they’re farming, their financial goals and more.

Building a thoughtful and thorough plan can help ensure you’re getting the right equipment for your needs, and that it won’t break the bank.

Here are some questions you should answer when putting together an as asset purchase plan:

• What level of machinery is needed for my farm and the crops that I grow?

• How much equipment do I need to ensure I get timely activities like seeding, spraying and harvesting done at the optimal time?

• How can I best optimize tax deductions and cash flow?

• Will this equipment increase the profitability of my farm?

• What is working for other farms in my area?

• What industry benchmarks can help me make better decisions?

• Do opportunities exist to reduce the cost of this equipment by working with neighbours, family, joint ventures or partnerships?

It may seem daunting but carefully considering your needs and your financials will ensure you’re getting the most out of your investment. Speaking with an MNP advisor can help you determine the best course of action, so you feel confident in your farm’s future.

Whatever your equipment needs are, taking the time to put together a plan before making a purchase can help you make an informed decision that will best suit your farm’s needs for years to come.

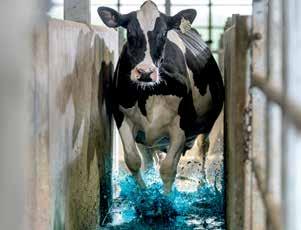

Redefining hoof health, herd performance and handler safety.

Put your herd at the forefront of hoof health — with BlueStride. Its innovative formula raises the bar for animal well-being, drives herd performance, and contributes to a safer barn environment for you and your crew. Make blue your new standard. Choose BlueStride today.

By ACER Consulting & Dairy Farmers of Canada

proAction’s evolution: How and why has proAction changed?

Societal and supply chain demands for more stringent food safety and quality assurance expectations have spurred the need for quality assurance in the Canadian dairy industry. Over time, we have seen the development of the Canadian Quality Milk (CQM) Program, its evolution into proAction, and the roll out of proAction modules for all things from food safety to animal care and the environment. When thinking about proAction’s evolution over time, it’s important to consider how it was initially developed and why the need for on-farm dairy quality assurance has continued to influence proAction’s evolution over the past decade.

Today, proAction consists of six modules: milk quality, food safety, animal care, traceability, biosecurity and environment. But what does the module development process actually look like? When a topic is identified as a priority for a proAction module, Dairy Farmers of Canada (DFC) establishes a Technical Committee of farmers, subject matter experts, key industry partners and provincial producer association staff, who work through the process of building requirements within that module. Requirements are typically built from an existing framework, legislation or regulation that farmers are already familiar with. For example, the proAction biosecurity module was based on the Canadian Food Inspection Agency (CFIA) Biosecurity for Canadian Dairy Farms National Standard that was developed with DFC in 2013. From there, the requirements go to the proAction Committee for review and deliberation.

• We are now pleased to announce that we are interested in buying your holstein bull calves and can include them i n your regular pick up. We will take calves that are over 9 2 lbs and 10 days old. The price will be negotiated on a w eekly basis.

Presently serving southwestern Ontario region and Ottawa region.

When considering updates or revisions to proAction, farmer participation and feedback are incorporated at every stage. Farmers sit on the Technical Committees and consist of about 93 per cent of proAction Committee members. proAction Committee chairs are also farmers. Once a module has been reviewed and approved by the proAction Committee, it often goes through a pilot process, where a selection of farmers in different provinces test out the module to see how it works, what the validation process is like, what is missing and what can be improved. Feedback from farmers, validators and provincial staff is taken into account and used to finalize the module. Final approval rests with the DFC Board of Directors.

To date, all modules that have been identified have been rolled out within proAction, but how are these modules revised over time? As per proAction’s CFIA recognition, each module has to be reviewed every two years. Through this review, Technical Committees look at any new regulations, standards, technology, best practices and research to determine if changes are needed to align with that information. Farmer involvement is important here too, with proAction Technical Committees being chaired and staffed by farmers (making up roughly 29 per cent). The proAction Committee then reviews any suggested module updates and depending on the scope of those changes, they may be piloted on farms and also approved by the DFC Board of Directors, prior to release.

How does DFC ensure that proAction aligns with evolving expectations?

A challenge with quality assurance programs in all agriculture industries, not just the dairy industry, is to ensure that national programs align with other regulations, legislation, science, best practices and supply chain expectations. As proAction continues to evolve, new updates or program revisions need to be consistent with expectations of the industry. In the initial inception of proAction, provincial organizations were heavily involved in the development process. Consultation with committees, board members, and provincial organizations was key to ensure that the program would have support in its roll-out. Today, provincial and national collaboration is still a priority at all levels. To continue maintaining CFIA recognition, proAction must demonstrate that any new regulations or legislation have been addressed within the program. By using this process of collaboration, proAction maintains its level of accountability, credibility and recognition within and outside of Canada.

proAction has CFIA recognition at two levels: recognition of the Food Safety module, as well as recognition of the proAction management system. Achieving both of these recognitions wasn’t easy. It involved a long checklist of requirements, a third-party audit and a follow-up every 20 months to verify that the requirements are still being met. This recognition is part of supporting Canada’s ability to export dairy products to the E.U., so all of this work and effort to keep proAction’s CFIA recognition is critical. CFIA is able to certify the milk products that are exported from Canada to the E.U. without any involvement from the farmer because of proAction’s CFIA recognition. This demonstrates the value that proAction requirements have for farmers directly, but it also highlights the other elements of the program that come together to give it credibility and rigor in national and international marketplaces.

Why is continuous improvement so vital to the longevity and success of the sector?

proAction’s core commitment to continuous improvement is not limited to farms but applies to the program itself. Over time, the program has to adapt to incorporate changes to regulations, updated scientific evidence, best practices and new supply chain expectations. If the program remained static from when it was first implemented, it would quickly lose its value as a vehicle for industry advancement and promotion. proAction must continue to evolve to maintain that value and credibility, but it also has to find balance. The program needs to remain applicable and achievable for farmers, while improving efficiency through removal of areas of duplication or overlap. The ultimate goal is to ensure the credibility of the program is maintained, while bringing value to the entire supply chain. proAction will continue to evolve and improve over time, highlighting the strength, credibility and value of the program for all industry partners.

“I believe proAction is the root of any continuous improvement process. And, you know, it's like any business model. If you stay immobile, you actually lose ground because the world is not waiting for you. It is of tremendous importance, I think, that Canadian dairy farmers and the industry as a whole, continue to demonstrate the benefits and added value of dairy products, while meeting the expectations that are evolving from both the consumer and customers,” says Giles Froment, senior VP of government and industry relations, Lactalis Canada.

Check out the Value of proAction Podcast, Episode 2 on soundcloud.com/ dfc-plc, to hear from David Wiens, Cheryl Schroeder and Gilles Froment.

Total requirements in July saw strong growth compared to July last year with an 8.7 per cent increase. On a 12-month basis, growth continues to be strong at 3.3 per cent. The same trend was seen in quota requirements for July.

P5 had been trending below forecast production and additional incentives days were issued to increase production through the fall. Looking at August, the incentive days have increased production, and production is back in line with the forecast on a cumulative basis. The two incentive days in August were filled at 41.6 per cent for Ontario and 37 per cent for P5. With the additional incentives issued, it is expected that production could trend higher than the forecast for the remainder of 2025.

The Western Milk Pool has removed one incentive day in each of the fall months, which resulted in production being below their previous forecast. There has been additional demand for

milk protein but not necessarily the same increase in demand for butterfat in P5. The P5 Quota Committee is considering further adjustments to the payment policy to ensure market demand for protein is supplied.

In August 2025, butter stocks reached 40,293 tonnes, down from July by 770 tonnes but have very strong numbers for this year. Butter stock forecast is close to the optimistic scenario at this time, and levels continue to be at the highest seen in the last five years.

Cheese stock levels for the month of August 2025 were at 109,381 tonnes, up 1,343 tonnes from July, higher than the last five-year average.

For the 52 weeks ending August 30, 2025, sales for fluid milk, fluid cream, yogurt, ice cream, cheese and butter increased by 0.0, 0.9, 6.6, 5.0, 3.6 and 3.7 per cent, respectively.

A monthly recap of markets and production trends in Canada and Ontario

Canadian butterfat requirements in kilograms and actual butterfat production across the P10.

950,000 1,000,000 1,050,000 1,100,000 1,150,000 1,200,000 1,250,000 1,300,000 1,350,000

12-month production (in millions of kilograms)

12-month requirements (in millions of kilograms)

Canadian production has increased by 3.4 per cent over the previous 12 months, and requirements have increased by 3.3 per cent over the previous 12 months.

This graph shows Ontario’s SNF-BF ratio for the last 12 months.

Average increase in retail sales for dairy products sold in Ontario and the dairy product’s share of the total market sales, including at hotels, restaurants and institutions.

As of March 26, 2022 NATIONAL RETAIL SALES

* Source: AC Nielsen & StatsCan NOTE: There is a two-month lag in the national retail sales data.

• Total requirements in July saw strong growth compared to July last year with an 8.7 per cent increase. On a 12-month basis, growth continues to be strong at 3.3 per cent;

• P5 had been trending below forecast production and additional incentives days were issued to increase production through the fall. Looking at August, the incentive days have increased production, and production is back in line with the forecast on a cumulative basis

• Cheese stock levels for the month of August 2025 were at 109,381 tonnes, up 1,343 tonnes from July, higher than the last five-year average.

Percentage of the total milk produced in Ontario that was used to produce dairy products.

Fluid Milk & Cream

and Ice Cream Cheese Butter & Powders Skim Milk Non Marketed

For August 2025 (kg of butterfat/kg of solids non-fat)

*There is a two-month lag reporting these figures.

% Solids non-fat

Class 1a1 (includes Classes 1a2, 1a3, 1c and 1d for confidentiality reasons) Fluid milk and beverages

Class 1b Fluid creams Class 2a Yogurt, yogurt beverages, kefir and lassi

Class 2b4 (includes Classes 2b1, 2b2 and 2b3 for confidentiality reasons) Fresh dairy desserts, sour cream, milkshakes and sports nutrition drinks

Class 2b5 Ice cream and frozen yogurt

Class 3a1 Specialty cheese

Class 3a2 Cheese curds and fresh cheeses

Class 3b2 (includes Class 3b1 for confidentiality reasons) Cheddar cheese and aged cheddar

Class 3c1 Feta

Class 3c2 Asiago, Gouda, Havarti, Parmesan and Swiss

Class 3c4 (includes Classes 3c3 and 3c5 for confidentiality reasons) Brick, Colby, farmer’s, jack, Monterey jack, muenster, pizza cheese, pizza mozzarella and mozzarella other than what falls within 3d

Class 3c6 Paneer

Class 3d Mozzarella used strictly on fresh pizzas by establishments registered with the Canadian Dairy Commission

Class 4a Butter and powders

Class 4d (includes Classes 4b1, 4b2, 4c and 4m for confidentiality reasons) Concentrated milk for retail, losses and animal feed

Class 5a Cheese for further processing

Class 5b Non-cheese products for further processing

Class 5c Confectionery products

A total 3,149 producers sold milk to DFO in August compared with 3,177 a year earlier.

DEDUCTIONS,

For August 2025

* These figures are based on Ontario’s average composition for August 2025 of 4.1601 kg butterfat, 3.2004 kg protein and 5.9401 kg other solids, rounded to the nearest cent.

The graph below shows the 12-month blend price for the P5 provinces and Western Milk Pool (WMP).

*There is a two-month lag reporting these figures.

The September 2025 Class III Price, US$17.59 per hundredweight, is equivalent to C$55.57 per hectolitre. This equivalent is based on the exchange rate US $1 = C$1.39167 the exchange rate when the USDA announced the Class III Price.

The Class III Price is in US$ per hundredweight at 3.5 per cent butterfat. One hundredweight equals 0.44 hectolitres. Canadian Class 5a and Class 5b prices track U.S. prices set by the U.S. Department of Agriculture.

Source: USDA

Co-ordinated by Dairy Farmers of Ontario’s communications and economics divisions. Questions? Please email questions@milk.org.

STAY UP TO DATE!

Weekly Update email newsletter every Friday for Ontario dairy producers.

Milk Producer magazine is the voice of Ontario dairy producers. Subscribe for free or read online at www.milkproducer.ca.

Dairy Farmer Update provides updates with the monthly milk cheque.

Producer Dashboard , a secure platform behind your password on MMS that contains important news, updates and forms.

www.milk.org

Facebook: /OntarioDairy

X: @OntarioDairy

Instagram: @OntarioDairy

/company/Dairy-Farmers-of-Ontario

By Titouan Chapelain, PhD candidate, University of Guelph

Titouan Chapelain is a PhD candidate at University of Guelph under the supervision of Professor Michael Steele. The objective of his thesis is to investigate how early life nutrition can impact feedlot performance and carcass traits at slaughter in beef-on-dairy calves.

IN EARLY LIFE MANAGEMENT IN THE DAIRY INDUSTRY, heifers tend to receive more optimum care and nutrition than male calves. As more calves of dairy origin enter the beef production chain, there is a need to consider whether dairy farmers would be rewarded for improved early-life management at the dairy farm in order to enhance feedlot performance and/or carcass traits at slaughter.

Stephanie Warner Dairy Specialist

Margaret Edwards

Dairy

Business Consultant

This question comes from the concept of developmental programming, where the environment (e.g., nutrition, stress, pathogens, etc.) calves are exposed to at a young age affects their future production later in life. For instance, researchers at the University of Cornell (NY, USA) found a relationship between pre-weaning growth rate and milk production from the first to the third lactation. For every kg of preweaning gain, heifers would have an increased milk production ranging from 850 to 1,113 kg during their first lactation.

A research group in the Netherlands followed the performance of heifers fed either an elevated plane of nutrition (8L of milk replacer / d) or a restricted plane of nutrition (4L of MR / d) up to weaning at 50 d of life. Heifers fed more milk not only doubled their growth rate during the preweaning phase compared to the restricted heifers but also produced 13,436 kg of FPCM (vs 11,089 kg of FPCM for restricted heifers) within the first 280 d of lactation. Interestingly, cows fed less milk earlier in life were 50 per cent more at risk of being culled before the third, fourth or fifth calving compared to cows fed more milk. It seems that the moderate investment in the preweaning phase can pay off in the long-term. Can this also apply to beef-on-dairy calves born on dairy farms and finished in feedlot operations?

This question has been the focus of a research team led by Professor Michael Steele at the University of Guelph (ON, Canada). So far, the research group has completed two studies involving beef-on-dairy calves: one supplementing high and low volume of colostrum at birth, the other one feeding two different types of milk replacer to calves. A third trial is currently ongoing, evaluating the effects of feeding high and low volume of milk throughout the milk feeding phase. All these experiments share a common objective: to assess the long-term effects of early-life nutrition on growth, health and feed efficiency throughout life and carcass traits at

Interestingly, cows fed less milk earlier in life were 50 per cent more at risk of being culled before the third, fourth or fifth calving compared to cows fed more milk. It seems that the moderate investment in the preweaning phase can pay off in the long-term.

In areas where farm expansion is limited by policy or environmental constraints, raising beefon-dairy calves offers a new approach for onfarm diversification and value creation.

slaughter. Preliminary results showed that feeding higher quantity of colostrum at birth may increase body fat deposition, and impact muscle metabolism. Also, feeding milk replacer rich in lactose (and low in fat) seemed to increase marbling deposition at slaughter. Given these findings, dairy farmers could likely be compensated for enhanced early-life practices that allow better feedlot performance or carcass quality.

This is where the different stakeholders of the beef-on-dairy supply chain need to work collaboratively to bridge the gaps that exist between them. Dairy farmers must be adequately compensated for delivering better calves – those with higher birth weights, improved immunity and health, and superior growth potential.

Similarly, feedlots that receive calves raised on enhanced nutritional programs must recognize and reward these practices from calf raisers through premium pricing. Moving toward vertically integrated models or long-term supplier relationships that incentivize early-life investment is already occurring in some regions and should be further explored in Canada.

In areas where farm expansion is limited by policy or environmental constraints, raising beef-on-dairy calves offers a new approach for on-farm diversification and value creation. The development of branded products that emphasize origin, animal welfare and sustainability could further unlock market opportunities.

By Hannah Sweett, Genetics Extension Expert, Lactanet & Rodrigo Molano, Dairy Production Expert, Rearing and Nutrition, Lactanet

Producing successful and profitable dairy replacements not only relies on an effective selection program, but also on the conditions provided during rearing that will ensure the heifer’s capacity to express her full genetic potential. In this process, the occurrence of diseases at calfhood is a major detractor of dairy producers return on their rearing investment. Diarrhea and respiratory diseases, the most common illnesses, affect 21 per cent and 19 per cent of dairy calves in Canada, respectively, according to farm records analysed by Lactanet. These occurrences represent a considerable burden, taking a motivational toll on caregivers and increasing rearing costs by $60 to $140 per treatment depending on the case1,2. However, the most considerable impact of these diseases on herd profitability is the increased risk of involuntary culling and mortality before

as calves3,4,5. We summarize current and novel strategies that dairy farms could use to keep dairy replacements disease-free right from the start.

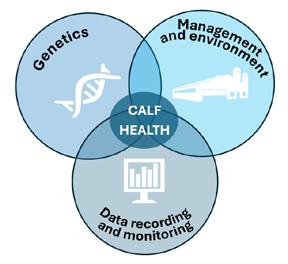

Genetics has always been a fundamental component of the rearing strategy allowing for selection of superior animals which leads to permanent and cumulative improvements in traits of interest. However, until recently, genetic evaluations for health traits have focused mainly on traits expressed in cows (ex. mastitis resistance, metabolic disease resistance, hoof health and fertility disorders), leaving early-life health in heifers overlooked. With the launch of Calf Health (CH) genetic evaluations for the Holstein breed in August 2025, producers now have a tool to select animals with superior resistance to calf diarrhea and respiratory problems.

AGRI-TRAC Milled our dair y barn floors in August of 2000.22 Years later we just had AGRI-TRAC backto do them again. It lasted 22 Years! We chose AGRI-TRAC bothtimesinstead of grooving because it works and lasts. We have experience, grooving does NOT work! Thank you AGRI-TRAC.

Mario Vriens Friendly Farms Arthur, ON

being too aggressive on their feet. We also like how the floor is easy to scrape and clean.

James Walker, Walkerbrae Farms Guelph, ON

The CH evaluation is a two-trait genomic evaluation system that combines diarrhea and respiratory problems. A moderate genetic correlation of 53 per cent exists between the two traits, reflecting the reality that calves who experience one illness are more likely to suffer from the other. Like other health traits, the heritability of diarrhea and respiratory problems is relatively low (5.4 per cent and 4.4 per cent, respectively). Nevertheless, such heritability levels still indicate that genetic selection can contribute to permanent and cumulative improvements in calf health.

The Calf Health index is expressed as a Relative Breeding Value (RBV), where the average is set to 100 and a standard deviation of five is used, with most animals therefore falling within a range of 85 to 115. Sires with higher RBVs are expected to produce daughters with greater resistance to calf diseases. For example, a five-point increase in a sire’s RBV for CH equates to 5.4 per cent more healthy daughters without a case of either diarrhea or respiratory problems. Calf Health RBVs can be viewed on LactanetGen.ca in the functional trait section of an animal’s Genetic Evaluation Summary page, as well as RBVs for both diarrhea and respiratory problems in the health tab. The CH index is largely independent of other evaluated traits in Canada indicating that direct selection is important to achieve meaningful genetic progress. Moreover, CH is expected to be included in the Health & Welfare subindex of the Lifetime Performance Index (LPI) by April 2026, further supporting your selection decisions.

AGRI-TRAC gives thecows the Traction they need without being too aggressive on their feet. We also like how the floor is easy to scrape and clean.

James Walker Walkerbrae Farms Guelph, ON

Although the new CH genetic evaluation will lead to more robust animals, the management and environment provided should still be focused on maximizing the calf’s capacity to fight infection while minimizing pathogen charge and exposure. Many efforts could be made in a myriad of areas, and at least one article could be written about each of them. Here are general considerations for a few:

• Herd health plan: it should be part of a comprehensive program designed with the herds veterinarian to define basic personnel training, biosecurity, vaccination and treatment protocols relevant to calf care.

• In-utero environment: adverse conditions during late gestation, like heat stress and nutrient imbalance, not only impact the cow but also her calf’s capacity to absorb the immunoglobulins from colostrum and to stay healthy6,7

• Colostrum and transition milk: feeding these two resources is essential for the calf’s health and development and is probably the most important practice to maintain calves’ health.

• Nutrition: calves need sufficient feed and water to support immune function. Feeding level should be adjusted according to the growing stage and environmental conditions to ensure adequate growth and health. This could be done by increasing feeding rate or the nutrient density during the pre-weaning phase, and by promoting solid feed and water intake around weaning. It is recommended to work with nutritionists and calf professionals to design effective feeding programs.

• Pathogen charge: the calving and housing environments, as well as feeding equipment, should be cleaned and disinfected between uses. An adequate stocking density and ventilation should prevent the accumulation of humidity, noxious gasses and air-borne pathogens. In addition, clean bedding should be added frequently.

• Calf comfort: housing and handling should minimize stress on calves.

• Team approach: coordinating efforts between farm owners, calf care givers and service providers.

Resources on these areas and practices are available on the Canadian Dairy Hub (dairyhub.ca) and Lactanet’s website.

“I am absolutely a fan of

“I am absolutely a huge fan of Udder Comfort!™ It gives the feeling of freshness and comfort. We have used it 12 years, rubbing it on for better texture or to soften a quarter. We use Udder Comfort for fresh cows, especially good for rst calf cows. We also use it before, during, and after a show to give the best udder texture possible. We see more of the udder’s veins, and the cows are more comfortable,” says Bianca Foley. The Foley family has a rich history of honors in Ayrshire breeding. They milk 50 Ayrshires at Vieux Village, Piopolis, Quebec. Their 5-year-old Vieux Village Gentleman Joy EX97 stood grand with 4-year-old Vieux Village G Montana EX94 reserve at the 2024 World Dairy Expo and Royal Agricultural Winter Fair.

The third key element towards a disease-free calf scenario is effective record keeping and monitoring. The most immediate and obvious benefit from this practice is the ability to evaluate mortality and morbidity outcomes while identifying opportunities for improvement. In addition, these data are valuable to assist management decisions and to increase accuracy of genetic evaluations, including for CH. Integrating and monitoring health, growth and genetic records will allow superior management and ensure future results.

A recent study in Ontario revealed that calf health data recording could be improved by keeping records close to the calf facility and by using a digital system that facilitates data entry and analytics8

By combining effective management, strategic genetic selection and consistent monitoring, lasting improvements in calf health can be made, reducing costs and supporting long-term herd success.

2Roche, S. M. M. Von Massow, D. Renaud, D. A. Shock, A. Jones-Bitton, and D. F. Kelton. 2020. Cost-benefit of implementing a participatory extension model for improving onfarm adoption of Johne’s disease control recommendations. J. Dairy Sci. 103:451–472. https://doi.org/10.3168/jds.2019-16708.

3Dunn, T. R., T. L. Ollivett, D. L. Renaud, K. E. Leslie, S. J. LeBlanc, T. F. Duffield, and D. F. Kelton. 2018. The effect of lung consolidation, as determined by ultrasonography, on first-lactation milk production in Holstein dairy calves. J. Dairy Sci. 101:5404–5410. https://doi.org/10.3168/jds.2017-13870.

4Abuelo, A., F. Cullens, and J. L. Brester. 2021b. Effect of preweaning disease on the reproductive performance and first-lactation milk production of heifers in a large dairy herd. J. Dairy Sci. 104:7008– 7017. https://doi.org/10.3168/jds.2020-19791

5Buczinski, S., D. Achard, E. Timsit, S. Cliniques, F.D.M. Vétérinaire, M.U. De, C. Js. 2021. Effects of calfhood respiratory disease on health and performance of dairy cattle : a systematic review and meta-analysis. J. Dairy Sci. 104: 8214-8227. https://doi.org/10.3168/ jds.2020-19941.

6Tao, S., Monteiro AP, Thompson IM, Hayen MJ, Dahl GE. 2012. Effect of late-gestation maternal heat stress on growth and immune function of dairy calves. J Dairy Sci. 95(12):7128-7136. https://doi.org/10.3168/jds.2012-5697

References

1Dubrovsky, S. A., A. L. Van Eenennaam, S. S. Aly, B. M. Karle, Paul V. Rossitto, M. W. Overton, T. W. Lehenbauer, and J. G. Fadel. 2020. Preweaning cost of bovine respiratory disease (BRD) and cost-benefit of implementation of preventative measures in calves on California dairies: The BRD 10K study. J. Dairy Sci. 103:1583–1597. https://doi. org/10.3168/jds.2018-15501.

7Sohrabi, H. R., Farahani, T. A., Karimi-Dehkordi, S., & Farsuni, N. E. 2024. Association of different classifications of hypocalcemia with quantity and quality of colostrum, milk production, and health of Holstein dams and their calves. The Veterinary Journal, 307, 106205. https://doi.org/10.1016/j.tvjl.2024.106205

8Edwards, K. Y., S. J. LeBlanc, T. J. DeVries, M. A. Steele, J. H. C. Costa, and D. L. Renaud. 2024. Barriers to recording calf health data on dairy farms in Ontario. JDS Commun. 5:42–46. https://doi.org/10.3168/jdsc.2023-0398.

Increase the longevity of your electric pump in sand-intensive environments by choosing a GEA Tuff built pump. It will help reduce downtime and maintenance costs, thus enhancing overall operational efficiency and profitability.

BRITISH COLUMBIA

Mountain View Electric Ltd.

Enderby — 250 838-6455

Pacific Dairy Centre Ltd.

Chilliwack — 604 852-9020

ALBERTA

Dairy Lane Systems

Leduc: 780 986-5600

Blackfalds: 587 797-4521

Lethbridge: 587 787-4145

Lethbridge Dairy Mart Ltd.

Lethbridge — 888 329-6202

Red Deer — 403 406-7344

Dairy Lane Systems

Warman — 306 242-5850

Emerald Park — 306 721-6844

Swift Current — 306 203-3066

MANITOBA / NW ONTARIO

Penner Farm Services Ltd.

Blumenort — 204 326-3781

Thunder Bay ON – 800 461-9333

Tytech

Grande Pointe — 204 770-4898

Claire Snoddon Farm Machinery

Sunderland — 705 357-3579

Conestogo Agri Systems Inc.

Drayton — 519 638-3022

1 800 461-3022

County Automation

Ameliasburg — 613 962-7474

Dairy Lane Systems

Komoka — 519 666-1404

Keith Siemon Farm Systems Ltd.

Walton — 519 345-2734

Lamers Silos Ltd.

Ingersoll — 519 485-4578

Lawrence’s Dairy Supply Inc.

Moose Creek — 613 538-2559

McCann Farm Automation Ltd.

Seeley’s Bay — 613 382-7411

Brockville — 613 926-2220

McLaren Works Cobden — 613 646-2062

Melbourne Farm Automation

Melbourne — 519 289-5256

Watford — 519-876-2420

Silver-Tech Systems Inc.

Aylmer — 519 773-2740

Dunnville — 905 981-2350

ATLANTIC PROVINCES

Atlantic Dairy Tech.

Charlottetown, PE — 902 368-1719

Mactaquac Farm Equip. Ltd.

Mactaquac, NB — 506 363-2340

Sheehy Enterprises Ltd.

Shubenacadie, NS — 902 758-2002

Sussex Farm Supplies

Sussex, NB — 506 433-1699

By Cynthia Miltenburg, Lead Veterinarian Animal Health and Welfare, Ontario Ministry of Agriculture, Food and Agribusiness (OMAFA)

DAIRY CATTLE LIVE IN SOCIAL GROUPS. Research has shown these groups contain complex social relationships and hierarchies that influence cattle behaviour. Typically, cattle benefit from familiarity with each other –their associations are not random, and they prefer to associate with certain individuals. In addition to preferred friendships, dairy cattle have a social rank within their larger group. Researchers studying social dominance measure the number of times dairy cows receive or initiate combative interactions. Low ranking cows are identified by observing how often they are physically displaced from the feeding area by another cow, typically through actions like head butting or pushing, that result in the cow relinquishing her position. Dominance can be influenced by many factors, age, lactation number, weight and size, health, milk production and potentially having horns or not.

A cow may be subordinate to one individual but dominant over another, even if both are also subordinate to the same higher-ranking cow. This creates a web of relationships rather than a simple chain of command. Ranking can shift over time as factors about the cows change, such as size, age and pregnancy status, and animals are added or removed from the group. Primiparous cows typically have lower social rankings than multiparous cows. As the dominance order becomes established, aggressive behaviours tend to be reduced.

Social dominance has practical importance – certain animals may consistently miss out or have reduced access to resources. Cows with higher competitive abilities tend to rest and feed at more preferred times and have priority access to space. A recent study published in Brazil found that herd dominance also influenced how cows were able to access heat abatement resources.

One might assume low-ranking cows can simply wait their turn to access feed or other resources once dominant cows are finished. However, dairy cows exhibit what is called allelomimetic behaviour – the tendency to imitate the behaviour of nearby animals. This means that when feed is delivered, the entire group is motivated to eat at the same time, and similarly when it’s time to rest, they prefer to do so together. As a result, synchronized behaviour can make it difficult for subordinate cows to access resources without conflict.

Prolonged waiting can negatively impact the daily time budget of a cow, resulting in reduced feeding or lying times. Research consistently demonstrates the benefits of providing adequate lying space and feeding space for dairy cows to benefit low ranking cows. Increasing feed space per cow reduces competition and allows simultaneous access. Similarly, lying times improve when there are more stalls available. These findings are reflected in the Code of Practice for the Care and Handling of Dairy Cattle and its requirements for space, which aim to minimize competition and ensure equitable access to essential resources.

With increasing adoption of automatic milking systems (AMS), access to the milking robot is another resource to be considered. AMS farms allow cows to establish their own milking, feeding and resting schedules. In an ideal scenario, these systems are inviting and stress-free, with flexible milking schedules encouraging regular cow access, supporting both animal welfare and optimal udder health. In practice, however, cow motivation can vary: some cows may be overly eager to visit the robot, while others may be reluctant or unable to compete for access. This imbalance can disrupt cow flow and require producer intervention. Barn design must accommodate the social structures of dairy cows, while also recognizing the practical reality that many cows must share access to the milking robot.