Stay Connected Stay Supported

Dive into the data. Discover the progress.

Our annual Progress Reports are now available online. Explore key achievements, insights, and milestones.

Visit us online: lactanet.ca/annual-reports

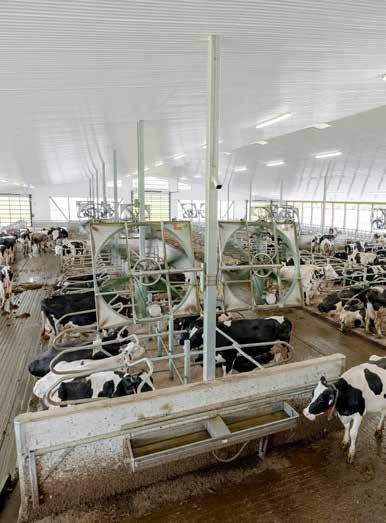

Photo: Schenkels Farms

PUBLISHED BY

DAIRY FARMERS OF ONTARIO

6780 Campobello Road Mississauga, ON L5N 2L8

COMMUNICATIONS

Sandra Da Silva sandra.da-silva@milk.org 905-817-2178

ADVERTISING

Pat Logan pat.logan@milk.org 519-788-1559

GRAPHIC DESIGN

Katrina Teimo

CONTRIBUTORS

Jeanine Moyer, Jaxon Desautels, Eugene Ng, Matt McIntosh, Annik L’Espérance, Émie Désilets, Melinda Kovacs, Débora Santschi, Chantal Fleury, Shelby Duggan, Gabriella Condello, Emily Leishman, Hannah Sweett, Chris Bartels, Colin Lynch, Fillipo Miglior, Christine Baes, Ricarda Jahnel, Workplace Safety & Prevention Services, Veal Farmers of Ontario.

Canada Post Publications Mail Sales Product Agreement No.40063866.

Return postage guaranteed. Circulation: 8,000. ISSN 0030-3038. Printed in Canada.

SUBSCRIPTIONS

For subscription changes or to unsubscribe, contact: MILK PRODUCER

6780 Campobello Road

Mississauga, ON L5N 2L8

Phone: (905) 821-8970

Fax: (905) 821-3160

Email: milkproducer@milk.org

Opinions expressed herein are those of the author and/ or editor and do not necessarily reflect the opinion or policies of Dairy Farmers of Ontario. Publication of advertisements does not constitute endorsement or approval by Milk Producer or Dairy Farmers of Ontario of products or services advertised.

Milk Producer welcomes letters to the editor about magazine content.

*All marks owned by Dairy Farmers of Ontario.

WEBSITES & SOCIAL MEDIA

www.milkproducer.ca

www.milk.org

Facebook: /OntarioDairy

X: @OntarioDairy

Instagram: @OntarioDairy

LinkedIn: dairy-farmers-of-ontario

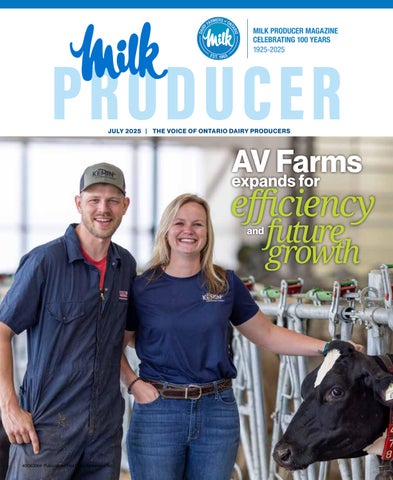

FARMS EXPANDS FOR EFFICIENCY AND FUTURE GROWTH

From inspiration to execution, AV Farms transformed a relocation into a chance to reimagine their dairy farm.

Shaping the future of dairy-beef calf rearing

cows' "burps" from a

Committed to excellence through strong farm management

By Steve Runnalls, Dairy Farmers of Ontario (DFO) Board Member, Region 12, Northern Ontario and Haliburton. Steve chairs the DFO Transportation Committee, and serves on the Audit and Quality Assurance committees.

For close to 50 years, my family and I have been managing a vibrant dairy farm in Thornloe, Ont. However, owning and managing a dairy farm today isn’t the same as it was when my family first started.

It’s about producing high-quality milk, balancing finances and investing in growth, keeping up with the latest industry news and research, and fostering a deep commitment to animal welfare and the land we work and live on – all while navigating industry uncertainties and preserving supply management.

This month’s edition of Milk Producer is dedicated to farm management, featuring articles about advances in technology, the latest research and tools to help dairy producers manage a profitable business, while continuing our commitment to producing high-quality, safe milk for Canadians.

Advances in technology and research are improving productivity and data-driven decisionmaking on the farm, while reducing labor demands and minimizing stress on cows. It has really transformed how we farm today!

On our farm, milking, feeding and cleaning are all automated. The automated milking system allows cows to be milked whenever they choose, while

automated feeding ensures they always have access to fresh feed. Deep-bedded stalls, robotic cleaning and controlled tunnel ventilation work together to maintain a clean, comfortable and stress-free environment for the herd.

The health and well-being of cows are at the heart of our industry. Healthy, comfortable cows produce high-quality milk, which is our commitment to Canadian families.

Sustainability is also a top priority. From improving pasture rotation to investing in energy-efficient equipment, dairy producers ensure the land and animals will thrive for generations without sacrificing output.

We have embraced the use of cover crops, which play a vital role in sustainable farming by protecting and enriching the soil, preventing erosion, improving water retention and reducing the need for intensive tillage.

To continue to thrive in dairy, it’s important to support the sector. Investing in the dairy industry and on-farm operations is critical for building a sustainable and secure future. Strategic investment, whether in technology, animal care or the environment, ensures long-term viability of an industry that feeds thousands of Ontarians.

We have made significant investments on our farm, which includes enlisting experts and having a collaborative team approach. With the right people on board — such as veterinarians, feed advisors and crop scouts, to name a few — we gain valuable knowledge and perspectives that help us make better-informed decisions.

Vicky Morrison

While not all advice will be the perfect fit for your operation, keeping an open mind and considering different viewpoints strengthens decision-making and ultimately supports the long-term success of our farm.

Dairy farming is a full-time commitment to quality, care and continuous improvement. With the right tools, training and support, dairy farmers can continue to feed our communities while protecting the land and animals they depend on. Because in dairy farming, smart management isn’t just good practice — it’s the foundation of long-term success.

Steve Runnalls

The critical role of milk cooling on the farm

Why quick cooling is key to milk quality

Dairy Farmers of Ontario’s (DFO) Field Services Representatives (FSRs) are not only milk inspectors, they are also your support for everything from milk quality troubleshooting to quota questions and paperwork, questions about policies and regulation, and anything else related to DFO and how it applies to your farm. Our 13 FSRs have seen and heard a lot. This column was created to use their collective expertise to share answers to some of the most common questions received.

MILK COOLING ON THE FARM serves two essential purposes: it prevents bacterial spoilage and extends on-farm storage time, helping to reduce transportation costs. While refrigeration may seem simple, its impact on milk quality is anything but simple.

Bacteria are always present in milk — even with excellent hygiene — and can multiply rapidly under the right conditions. Even a low initial bacteria count can explode if milk isn’t cooled quickly, leading to spoilage long before pickup.

That’s why simply switching on the cooler a few hours late or even after lunch, isn’t good enough.

Milk produced under hygienic conditions can maintain its quality for 15 to 20 hours. However, both the storage temperature and the speed of cooling are critical. In Canada, bulk tanks are designed to lower milk temperature to 4°C within one hour after the end of milking. Delays in reaching this temperature allow bacteria to multiply exponentially, compromising milk quality even before transport.

The range of bacteria in bulk tanks can vary widely — from a few thousand CFU (colony forming units) per mL on well-managed farms, to several million where hygiene or cooling are lacking. Daily cleaning and proper disinfection of all milking equipment remain the most decisive factors in keeping bacterial counts low.

While rapid cooling significantly slows bacterial growth and extends shelf life, it’s not a substitute for rigorous hygiene — the two work hand-in-hand. Producers who prioritize both are rewarded with excellent quality milk.

In the end, cooling isn’t just a mechanical process — it’s an investment in product quality, customer trust and farm profitability. For today’s dairy producer, rapid cooling is not a luxury. It’s a necessity.

1From Hoyle, 1979, Machine Milking, p.355, Technical Bulletin 1, NIRD

gea tuff built

When nothing beats sand, GEA Tuff can.

Increase the longevity of your electric pump in sand-intensive environments by choosing a GEA Tuff built pump. It will help reduce downtime and maintenance costs, thus enhancing overall operational efficiency and profitability.

BRITISH COLUMBIA

Mountain View Electric Ltd.

Enderby — 250 838-6455

Pacific Dairy Centre Ltd.

Chilliwack — 604 852-9020

ALBERTA

Dairy Lane Systems

Leduc: 780 986-5600

Blackfalds: 587 797-4521

Lethbridge: 587 787-4145

Lethbridge Dairy Mart Ltd.

Lethbridge — 888 329-6202

Red Deer — 403 406-7344

SASKATCHEWAN

Dairy Lane Systems

Warman — 306 242-5850

Emerald Park — 306 721-6844

Swift Current — 306 203-3066

MANITOBA / NW ONTARIO

Penner Farm Services Ltd.

Blumenort — 204 326-3781

Thunder Bay ON – 800 461-9333

Tytech

Grande Pointe — 204 770-4898

ONTARIO

Claire Snoddon Farm Machinery

Sunderland — 705 357-3579

Conestogo Agri Systems Inc.

Drayton — 519 638-3022

1 800 461-3022

County Automation

Ameliasburg — 613 962-7474

Dairy Lane Systems

Komoka — 519 666-1404

Keith Siemon Farm Systems Ltd.

Walton — 519 345-2734

Lamers Silos Ltd.

Ingersoll — 519 485-4578

Lawrence’s Dairy Supply Inc.

Moose Creek — 613 538-2559

McCann Farm Automation Ltd.

Seeley’s Bay — 613 382-7411

Brockville — 613 926-2220

McLaren Works

Cobden — 613 646-2062

Melbourne Farm Automation

Melbourne — 519 289-5256

Watford — 519-876-2420

Silver-Tech Systems Inc.

Aylmer — 519 773-2740

Dunnville — 905 981-2350

ATLANTIC PROVINCES

Atlantic Dairy Tech.

Charlottetown, PE — 902 368-1719

Mactaquac Farm Equip. Ltd.

Mactaquac, NB — 506 363-2340

Sheehy Enterprises Ltd.

Shubenacadie, NS — 902 758-2002

Sussex Farm Supplies

Sussex, NB — 506 433-1699

Strengthening

cyber defenses

Protecting Canada’s farms in the digital age

By Jaxon Desautels, CPA, CMA, MNP, Digital Ag Specialist & Eugene Ng, Partner, MNP Digital, Cyber Security Leader

CANADIAN AGRICULTURE IS REVOLUTIONIZING through digital advancements. Precision farming, automation and data-driven decisionmaking are increasing efficiency and profitability for producers. However, these advancements come with growing cyber risks. Farms today are not just fields and barns — they are interconnected networks of smart devices, sensors and cloud-based management systems. Unfortunately, increased connectivity has made farms a prime target for cyber criminals. This issue has become so significant that it has even been highlighted by the Federal Bureau of Investigation (FBI) south of the border.

Despite the rising threat, cyber security awareness in the agricultural sector remains low. According to the MNP Digital Cyber Security on the Farm 2025 Report, developed in conjunction with RealAgristudies, four out of five Canadian producers believe they have never experienced a cyberattack — a stark contrast to reports from nearly half their suppliers, who indicate otherwise. This disconnect underscores the urgent need for greater cyber security education and preparedness across the industry.

A new reality: The growing threat of cyber attacks on agriculture

Agriculture is crucial to Canada’s economy and food security, and any disruption to farm operations — from supply chain interruptions to compromised data — can have significant ripple effects on consumers, retailers and global markets. This is precisely why cyber criminals have turned their attention to the industry. The threat landscape is evolving, with attackers using increasingly sophisticated techniques. Ransomware, phishing and AI-driven scams are among the most prevalent threats facing farmers today. Criminals are leveraging artificial intelligence to create deepfake videos, voice phishing (vishing) and fraudulent supplier communications that trick farm operations into divulging sensitive information or making unauthorized payments. In fact, MNP’s Digital team found 68 per cent of cyber incidents involve human error, whether it’s an employee clicking a fraudulent link or

using weak passwords. Even more concerning, 62 per cent of cyber attacks involve ransomware or extortion, meaning criminals lock farm data and demand payment for its release.

Operational technology (OT) on farms is another major vulnerability. Systems that control irrigation, automated feeding and GPS-guided machinery are often not built with security in mind. A cyberattack targeting these technologies could halt planting, disrupt harvests or even endanger livestock.

The disconnect: Farmers underestimating the risk

Canadian producers are facing a hidden danger they don’t even realize exists. With 82 per cent believing they’ve never been targeted by a cyberattack, yet nearly half of their suppliers report they have. The reality? Many cyber threats operate in silence. Phishing emails, malware and unauthorized access often go unnoticed — until it’s too late.

This false sense of security is further complicated by generational knowledge gaps. MNP’s Cyber Security Ag report found that only seven per cent of farmers feel very knowledgeable about cyber security. Though younger farmers being more familiar with digital risks, and older generations often assuming they’re safe because they use less technology, both groups tend to be overconfident in their preparedness for a cyberattack. This overconfidence leaves their farms vulnerable, making cyber security not just a necessity, but an urgent priority.

The cost of inaction: What’s at stake

The financial impact of cyberattacks can be devastating. Ransomware incidents, in particular, have crippled agribusinesses worldwide. In these attacks, hackers encrypt a farm’s data and demand payment in exchange for restoring access. For farms reliant on digital management systems, an attack can mean losing critical data on crop yields, livestock health and financial records. Beyond financial losses, cyber security breaches can erode trust. Producers operate within tightly knit supply chains, and an attack on one operation can have cascading effects. These cyberattacks are not unique to agriculture but are part of a growing trend across all industries. According to Statistics Canada, one in six businesses was impacted by a cyber security incident in 2023, with the frequency increasing with the size of the business. This aligns with the data unearthed in MNP’s Cyber Security on the Farm 2025 Report, which shows that cyber threats increase with the size of a farm based on income levels.

The real-world impact

In one case, a small hog farm in Ontario fell victim to a ransomware attack orchestrated by activists. The attackers infiltrated the farm’s computer systems, encrypting vital data and threatening to release fabricated evidence of animal abuse unless a ransom was paid. This incident not only jeopardized the farm’s operations but also posed a significant reputational risk. Cyber security experts warn that such tactics are likely to become more common, emphasizing the need for heightened awareness and robust security measures within the agricultural community.

Another significant event involved one of the world’s largest meat processing companies. They experienced a ransomware attack that disrupted their operations across multiple countries, including Canada. The company ultimately paid several million dollars to the attackers to regain access to its systems and prevent further disruption. This attack highlighted the susceptibility of even large agribusinesses to cyber threats and underscored the potential for widespread impact on the food supply chain.

These incidents illustrate the evolving tactics of cyber criminals targeting the agricultural sector. From direct financial extortion to threats of reputational damage, the methods employed are becoming more sophisticated and damaging. As farming operations continue to integrate advanced technologies, it's imperative for producers to implement comprehensive cyber security strategies to safeguard their businesses against these emerging threats.

How do these attacks happen?

Cyber criminals use a variety of tactics to infiltrate farm systems, including:

• Phishing Attacks: Deceptive communications trick producers into revealing passwords or installing malware. These attacks are most successful during busy seasons, when vigilance is low.

• Ransomware: Hackers encrypt critical farm data and demand payment for its release. Without proper backups, a single attack can wipe out years of financial records and operational data.

• Exploiting known vulnerabilities: 14 per cent of cyberattacks gain access through outdated or unpatched software, allowing criminals to bypass security measures.

• QR code scams (Quishing): Fraudulent QR codes redirect users to malicious sites designed to steal login credentials.

• AI-driven fraud: Cyber criminals use artificial intelligence to create highly convincing scams, such as another form of phishing known as vishing (voice phishing), that mimic trusted communications — exploiting human trust, as they’re often difficult to detect, even for tech-savvy individuals.

Cyber criminals cast a wide net, targeting businesses that lack proper cyber defences. Small and mid-sized farms are particularly vulnerable, as they often assume they aren’t big enough to be a target — but the reality is quite the opposite. Here’s a look at how some of the most common methods have compared over the years, with most seeing a rise year after year, based on Statistics Canada:

to attacks, many farms remain vulnerable to disruptions that could have been prevented.

Here are four key steps you can take to improve your cyber security:

1. Increased awareness and training

Cyber security is not just an IT issue — it’s a business necessity. Producers and their employees must understand how to recognize phishing attempts, secure sensitive information and report suspicious activity. Implementing basic cyber security training can significantly reduce the likelihood of falling victim to scams.

Cyber security planning: Bridging the preparedness gap

Cyber security preparedness remains low among Canadian producers. The study revealed that nearly 80 per cent of farms lack a formal cyber security plan. Without a structured approach to identifying threats and responding

PACKED WITH A HIGHER CONCENTRATION OF IGG, IMMUNOLIFE | 200 IS THE ULTIMATE CHOICE FOR YOUR CALVES' HEALTH AND VITALITY

W W W . T R U V I T A L . C A

FUTURE PERFORMANCE IS: USING FOOD QUALITY CASEIN RICH SKIM MILK POWDER TO IMPROVE OVERALL HEALTH AND GROWTH

2. Develop an incident response plan

An incident response plan outlines the steps to take when a cyberattack occurs, minimizing damage and ensuring a quick recovery. This includes:

Identifying who is responsible for cyber security

Creating a communication plan to notify key stakeholders in the event of a breach.

Establishing backup and recovery procedures to

3. Secure farm equipment and operational

Many cyberattacks exploit vulnerabilities in OT. By implementing basic security measures, you can better

Regularly updating software to patch unknown

Using multi-factor authentication (MFA) for all critical

Ensuring that devices — such as GPS systems, automated feeders and irrigation controls — are not connected to public networks.

Mapleview milk replacer includes high-quality skim and casein, rich in essential amino acids and designed to better mimic whole milk. Unlike lower-cost alternatives, skim is slower to digest, allowing calves to maximize nutrient absorption. This enhanced digestion strengthens the immune system, helping calves combat diseases more effectively and thrive in their early stages of development. W W W .

4. Work with experienced cyber security partners

Cyber security isn’t just about installing software — it’s about a holistic strategy that includes people, processes and technology.

Engage with professionals to assess risks and

Leverage managed security services for proactive monitoring and protection if you have a small or nonexistent in-house team.

Turning risk into opportunity

While the cyber security landscape may seem overwhelming, proactive planning can turn these challenges into opportunities. Producers who invest in cyber security today will be better positioned to protect their operations, maintain trust with suppliers and leverage technology safely for long-term growth.

The Canadian government and industry organizations, such as Cybersecure Canada, provide free resources and training programs to help farms strengthen their cyber security defences. Collaborating with experienced partners, like MNP, can also provide tailored solutions that fit the unique needs of agricultural operations.

Want to boost your farm’s cybersecurity? Start by figuring out where your risks are. If you’re not sure how to do that or need help building a plan to mitigate them, an advisor can assist you through the process.

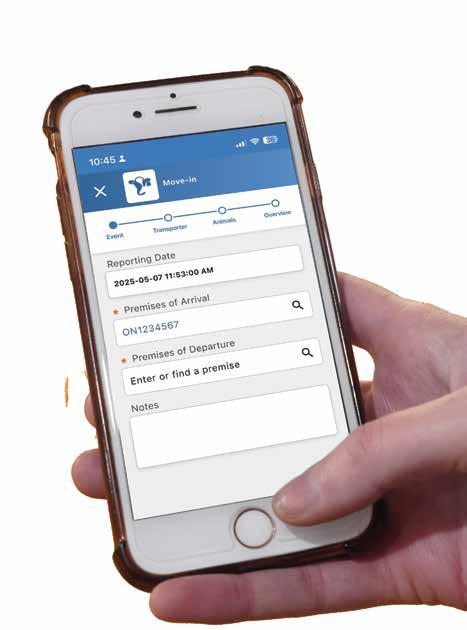

Report traceability events on-the-go with the DairyTrace app. No internet connection? No problem! Enter event reports and the app will automatically sync them when you have a connection.

Reporting movements? The app even links to your address book in the DairyTrace Portal, making reporting easier when you save premises identification numbers (PID) for future movement reporting.

Gerrit Damsteegt, Boundary Lane Farms, Shubenacadie, Nova Scotia

The thing that works very well for us is reporting traceability events using the DairyTrace app...you can report anywhere, anytime you want.

Introducing kids to the financial side of farming

By Matt McIntosh

This article is reprinted by permission of the author and Farm Credit Canada. It was originally published in the March 2019 issue of FCC's magazine, AgriSuccess. For subscription information about AgriSuccess, see www.fcc.ca/agrisuccess.

TAKING TIME TO INTRODUCE KIDS TO THE BASICS OF FINANCIAL MANAGEMENT helps prepare them to manage the farm business from the office, as well as the tractor.

Small tasks bring learning opportunities

For Tannis Axten, a grain farmer from Minton, Sask., broaching financial management with her children starts by having them help match receipts to credit card statements. Doing so gives them an idea of what it costs to operate the farm.

“It opens up the conversation on farm expenses, and for questions,” Axten says.

With a daughter interested in marketing, expense management has helped show her grain marketing is “not easy or cheap.”

4-H programs centered on field crop management have been beneficial, too. Kids involved in these clubs rent (either literally or in name only) a small parcel of land from their parents and keep track of production costs throughout the year.

“It’s been a huge eye-opener. Some years they don’t make any money, so it really helps them understand,” Axten says, noting the opportunity for life lessons.

“It doesn’t matter what you do, there’s always going to be the business side. You can figure it out. It’s just easier when you’re younger and not in it already.”

Reinforcing the basics

A basic understanding of personal finance is also critical, according to Patti Durand, agriculture transition specialist.

“Do they know what income tax is? Insurance? Credit rating? We underestimate how soon it’s helpful to have these conversations,” Durand says. “Frequently within farms, personal and business is the same. Starting with a good personal acumen creates a good foundation.”

“Discussing personal finance in a piecemeal fashion,” says Durand, “can be informative for children and young adults.” Even explaining the purpose of a tool can be useful, such as how credit can be used, and how it can use you.

“Those are really great life skills we tend to leave off the table but expect them to figure it out,” she says.

Impart real business experience

Like Axten, Durand also says allowing junior partners to gain real business experience is critical. That means not skewing the partnership by, for example, providing free equipment.

“Money doesn’t have to change hands but put a value on it. Explain what the value is,” Durand says.

A basic understanding of personal finance is critical. The world of finance, though, is complex. With this in mind, Durand reiterates resources such as financial management courses, expertise from trusted advisors or the local chamber of commerce can help impart more in-depth knowledge.

The world of finance, though, is complex. With this in mind, Durand reiterates resources such as financial management courses, expertise from trusted advisors or the local chamber of commerce can help impart more in-depth knowledge.

“Identify where you can reach out. You don’t have to know everything, but know where to find it,” says Durand.

Regardless, she says not to forget high-level conversations.

“Pull out farm financial statements and talk about them. Contextualize them. Plant seeds of interest so they can get a better understanding.”

Bottom line

Discussing the basics of personal finance and providing real learning opportunities on the farm can help farm kids understand – and get involved in – the business side of farm management.

Start them young, with jobs like matching receipts to credit card statements to give them an idea of monthly farm costs. Over time, explain terms such as income tax, insurance and credit rating to help them expand their financial knowledge.

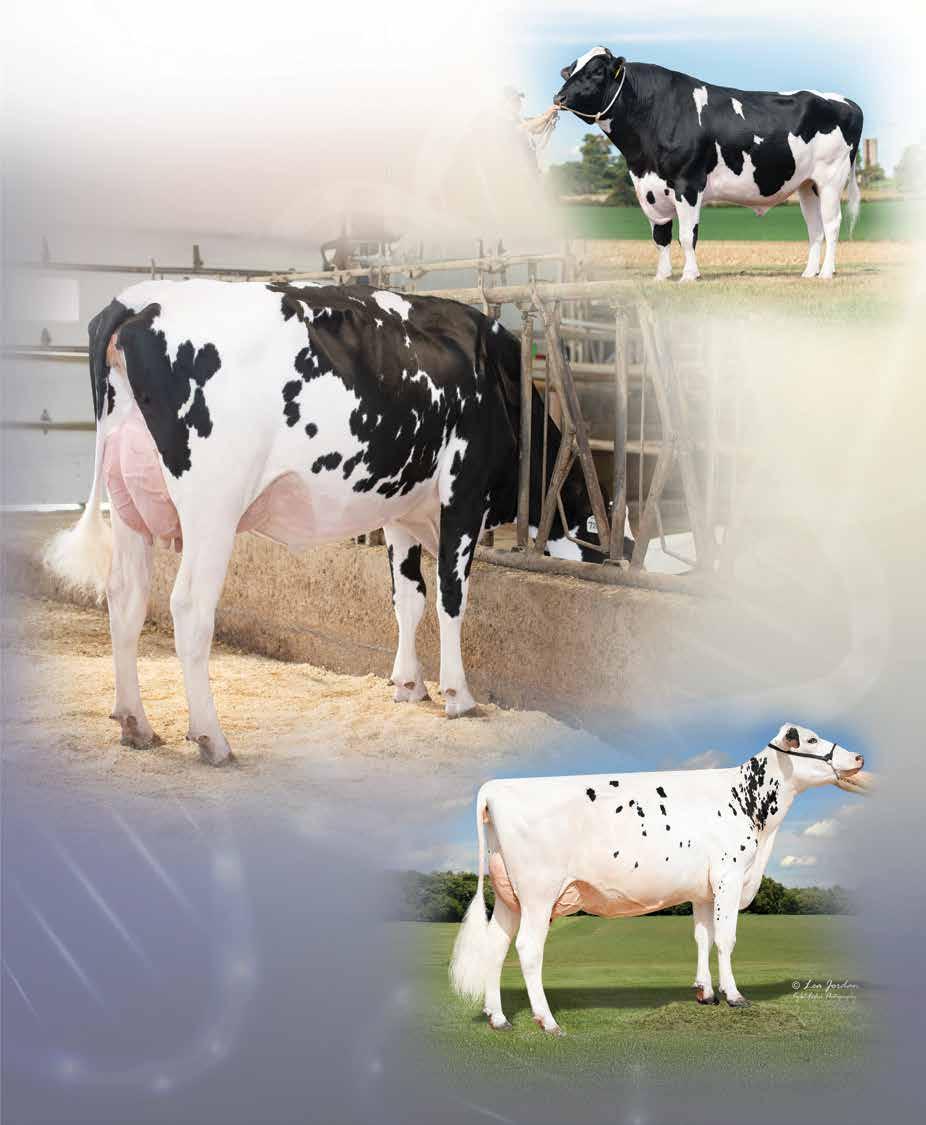

At Holstein Canada, three key services work together to support better herd health and long-term success.

REGISTRATION

Monitor inbreeding, recessives and haplotypes to make informed mating decisions. Scan

GENOMICS

Get more reliable trait evaluations to make accurate breeding and management decisions.

CLASSIFICATION

Evaluate key conformation traits linked to production and longevity.

Registration, Genomics and Classification are tools we use to make informed breeding decisions towards our goals. We believe that well balanced/functional cows that can produce lots of milk/kg fat, but also with longevity is the key to a productive dairy operation. As a bonus it brings more enjoyment to dairy farming to work with high genetics and to do Classification.

– Rolf van Benthem, van Benthem Dairy Ltd., Red Deer County, AB

Handling chemicals on dairy farms

Five tips to do it safely

By Workplace Safety & Prevention Services

FROM FUELS TO FERTILIZERS, CHEMICALS PLAY A VITAL ROLE IN MODERN FARMING OPERATIONS. However, understanding their potential impact on human health is crucial for maintaining safety and well-being. “The instances of occupational illness among farmers are significantly higher than the instances of injury. In my experience, it seems like most farmers do not think about the long-term health effects of chemical exposure until it is too late. We can be too complacent,” says Ryan Dick, Health and Safety Consultant with Workplace Safety & Prevention Services (WSPS).

For example, Ryan sees dairy farmers working with fertilizers without gloves or a dust mask. “A lot of fertilizers contain nitrogen stabilizers and other additives. When they get wet or when used in hot, humid conditions, these additives start to burn off, which releases dust and vapours into the air,” explains Ryan. “You need to prevent exposure from inhalation and from skin contact, which is why gloves and a dust mask or respirator should be used,” he says.

Another common exposure Ryan sees when visiting dairy farms is from bleach and other cleaning products. “Farm workers disinfect milk parlours after every milking, often using bleach or peracetic acid products in combination with a pressure washer,” says Ryan. “It’s very important to make sure the dilution ratio is correct. If not, the worker could be inhaling dangerous vapours or risk having splash back onto exposed skin, allowing chemicals to be absorbed through skin contact.”

Oils, solvents and fuels, which are commonly used for farming equipment, also pose health risks if they are inhaled or ingested. “But I still see dairy farmers drinking a coffee or eating lunch after using these products without wearing gloves or washing their hands,” says Ryan. Symptoms of exposure to chemicals can range from headache, coughing and shortness of breath to dizziness, vomiting and unconsciousness. Over time, repeated exposure can lead to cancer and other diseases.

Training, awareness and due diligence

Whether you work directly with a certain chemical or not, awareness is very important. Farm workers must be able to recognize a hazardous chemical if they come across it. This is why training, along with proper labelling and storage matters. “Do not store chemicals in an empty drink bottle or unlabelled plastic container,” warns Ryan.

Ontario Regulation 860 – Workplace Hazardous Materials Information System (WHMIS) does not apply to farming operations. However, employers need to ensure they are taking every precaution reasonable in the circumstances to protect the worker, as outlined in the Occupational Health and Safety Act 25(2)(h). Taking every reasonable precaution includes notifying the worker of actual or potential hazards onsite, such as chemicals, even if the worker is not normally handling them.

This is why Ryan recommends that farm operators provide their workers with WHMIS training. Doing so will help ensure farm workers know how to recognize, use, handle and store chemicals, as well as how to respond in an emergency if exposure occurs. “Every dairy farm I have ever visited has chemicals onsite,” says Ryan. “Providing WHMIS training protects your workers and supports your due diligence.”

Reduce your exposure to chemicals

In addition to providing chemical training to all those working with or near chemicals on your farm, Ryan offers these tips to help reduce everyone’s risk of exposure to hazardous chemicals.

1. Site-specific chemical training: In addition to general WHMIS training, complete site-specific chemical training that focuses on the specific chemicals used at your farm, where they are stored, how to use them safely and how to respond in an emergency.

2. STOP – THINK – ACT: Use this approach to assess the hazards associated with certain chemicals and develop procedures that will reduce the risk of exposure. Stop before starting a task that uses a specific chemical. Think about how you can reduce your risk of exposure and read the Safety Data Sheet to learn the best way to protect yourself. Act on what you have learned and take the necessary steps to perform your task safely.

3. Labelling and storage: Always store chemicals in proper containers with clear labels. “Chemicals can easily end up in the hands of children when proper precautions are not taken,” says Ryan. “Do not leave them around the farm.” Make sure they are securely stored in the proper location.

4. Inspection, training and maintenance: Ensure all workers have received in-depth training on the proper use of personal protective equipment (PPE) and when it is required. Training should include regular inspection and maintenance of PPE, which will help ensure you always have the right equipment on hand and in good condition when you need it. PPE should always be inspected before use.

5. Good ventilation: Ensure storage areas are well-ventilated to avoid an unexpected build-up of fumes or gases. Ventilation fans should be run for an adequate amount of time to dissipate any fumes before entering a chemical storage facility. The amount of time required to dissipate fumes will vary depending on the size of the facility, with larger areas needing longer pre-entry ventilation.

Find out more: Visit the Agriculture Safety Centre at WSPS.ca for valuable information to help you keep safe.

focuses on

AV Farms farm management cow-centered, future-ready

From inspiration to execution, AV Farms transformed a relocation into a chance to reimagine their dairy farm that’s been built with a cow-focused approach to efficiency and future growth.

By Jeanine Moyer

“We focused on optimizing and levelling up. The new location opened opportunities to optimize our feed environment, equipment, facilities, herd health, animal comfort and production. The sky was the limit for any new idea, and we embraced the design process.”

– Andrew Eisses

FOR DECADES, the Eisses family of Hewitt Creek Farms, in Simcoe county, followed the ‘work with what you have’ mentality of most farmers – retrofitting the barn when needed, adjusting feeding systems to accommodate new rations and reconfiguring stabling to allow new technology installations. But, when increasing urban pressure pushed them out of the Innisfil, Ont. location the family had farmed in since the 1960s, Andrew and Victoria Eisses of AV Farms embraced the opportunity to design their ideal barn to meet their needs and priorities today, and for the future.

The Eisses’ broke ground for their barn in July 2023 and moved their herd into the new facility in July 2024. Today, they milk 130 cows with three Lely A5 robots in their new barn that has the capacity to milk 220 cows. They use sexed semen as part of their breeding program and breed beef on dairy, raising angus cross and Speckle Park beef cattle to utilize the additional space and leverage an extra revenue stream.

With the help of family, it took the young couple four years to plan, build and move the herd into their new location in Oro-Medonte, Ont. The process began by meeting with their builder, HFH Inc. to design a facility that would meet their current needs and leave plenty of room for expansion.

“Every choice we made was centered around our cows,” says Andrew, explaining that the needs of the herd drove every decision the couple made. “We didn’t want the new facility to impose any restrictions or compromises for our cows. The new barn structure and farm management needed to support everything from cow comfort and health to milk production and animal reproduction. And leave plenty of room for improvement and growth.”

The couple knew that by focusing on creating the best environment for their cows and streamlining their new facility they could also find management efficiencies, especially in labour and feeding systems.

Design with purpose

The building process began long before the Eisses’ made the decision to move their herd. Both Andrew and Victoria are graduates of the Ontario Agricultural College at the University of Guelph where they had opportunities to tour plenty of dairy barns. When it was time to design their new facility, they took inspiration from a few specific barn setups that had stood out to them.

“We focused on optimizing and levelling up,” says Victoria. “The new location opened opportunities to optimize our feed environment, equipment, facilities, herd health, animal comfort and production. The sky was the limit for any new idea, and we embraced the design process.”

The couple knew that by focusing on creating the best environment for their cows and streamlining their new facility, they could also find management efficiencies, especially in labour and feeding systems.

The Eisses Family is a shining example of resilience, dedication, and forward thinking in the dairy community. Known for their tireless work ethic, and thoughtful planning, they made the decision to relocate from their original farm location, turning an obstacle into a great success story. Throughout the transition and the move, they remained committed to their dedication to quality and animal care. Cow comfort has always been a top priority for the Eisses, and it shows in every aspect of their operation. Their animals and facilities are always kept at the highest standards, a true reflection of pride in their work and passion for the dairy industry. It is a pleasure to work with such a hardworking and forward-thinking family.

– Blythe Mackie, FSR

Andrew explains they opted for a selfpropelled TMR mixer over a fully automated feeding system because they wanted wider alleys and versatility. The overall design of the barn and animal flow was created to reduce time and stress on the animals. “Our cows literally grow through the facility, moving from one pen to the next as they mature,” says Andrew, explaining that the calf group pen is positioned beside the heifer pen, and milking and dry cows are positioned side-by-side too, so the animals never have to move too far, and are always beside familiar pen mates. Andrew also notes the installation of locking head gates is a significant improvement for safer, timely and less invasive animal handling.

Sorting gates were also installed to their robot milking set up, allowing them to automatically sort the animals into a separate holding pen via the robot. The holding pen, or cow treatment area, is designed with a locking head gate and handling chute to limit livestock handling and interactions and ultimately reduce animal stress and labour. This area was created to easily sort animals that need attention or treatment, like hoof trimming or health checks. “A separate, easily accessible cow treatment area was a priority for us,” says Victoria. “This is an example of a cow-driven decision that prioritizes animal health, while also providing a quiet area for the animals to just eat, drink and rest.”

Overall animal health is key for AV Farms, including healthy feet. That’s why the couple chose to install foot baths outside every robot milker and in the heifer pens. Andrew explains his proactive management to foot health is a preventative approach when used in conjunction with hoof trimming, saving time and reducing animal stress. He also notes that by “improving and staying on top of foot health, we are promoting the longevity of our cows and overall herd.”

Year of transition

Now, after nearly a year on their new farm and adjusting as needed, everyone and everything is finally settling in. “It really takes

We’re beginning to realize the labour efficiencies, improvements in reproduction and milk production, and we can’t wait to see how far we’ll go.

– Victoria Eisses

a full year to transition to a new barn,” says Victoria. “We also had to experience all four seasons to work out all the kinks.”

While managing their herd in their new barn was exciting, moving their home and herd to the new location was a challenge, especially during haying season. The cows also needed their own adjustment period, including adapting to different forages and a new feeding system. Andrew says they haven’t seen a significant increase in production yet but expects to see their return on investment

come through after the first year. His takeaway from this first year of adjustments was to hold off on making any major management decisions, because he knew and experienced firsthand that the transition would take time.

“We’re just starting to get dialed in to where we want to be after one year,” says Andrew. “We’re beginning to realize the labour efficiencies, improvements in reproduction and milk production, and we can’t wait to see how far we’ll go.”

Building their new dairy facility supports the farm’s mission statement – Pursing Excellence in Faith, Family and Farming.

Looking back at their entire planning, building and transition process, Andrew and Victoria feel grateful for the partnerships they developed, especially with their builder. Andrew points out just how important it is to trust your builder. He believes one of the key success factors during the building process was the trust he had in HFH Inc. and his ability to be decisive.

“If the builder had a question that needed an answer from me, I either provided an answer or asked them to provide more information to help me decide. I didn’t want to hold up any part of the process and I think this approach helped to make the build as smooth as possible for everyone,” he says

Victoria says that while there weren’t too many surprises along the way, she was happy to rely on their builder to manage logistics, especially when it came to dealing with the local municipality and building delays. Victoria also advises fellow farmers who are considering new barn builds to explore grant opportunities. She says they were able to leverage grant funding that helped them maximize their resources to implement some of the new health-focused features, like the foot baths.

Future-focused farming

As young and passionate farmers, Andrew, Victoria and their family are invested in the future of their herd, farm and the dairy industry.

“Our plans and decisions are focused on growth,” says Victoria, noting the new barn is only at half capacity now, but they have the ability and farm management systems in place to expand. “We’re proud of what we’ve built for our cows and for our future.”

Building their new dairy facility supports the farm’s mission statement – Pursing Excellence in Faith, Family and Farming. Andrew believes that pursing excellence means there’s always work to do and room for improvement, and he’s optimistic that together, they will continue to realize new levels of excellence and success. Andrew and Victoria have much appreciation and thank the older generation who over their decades of dairy farming and hard work made this opportunity possible to Pursue Excellence in Faith, Family and Farming.

Supporting innovation in processing

Equipping new dairy entrepreneurs (including on-farm processors) with tools to innovate

Program information:

Dairy Farmers of Ontario's (DFO) Start Up Scale Up Innovation Program aims to equip new dairy entrepreneurs, including onfarm processors, with knowledge, mentorship and grants as they innovate in the dairy processing industry.

The Start Up Stream is for new dairy processors who require support setting up their business with focus on helping participants complete a business plan, navigating through the dairy industry and moving towards product launch.

The Scale Up Stream, on the other hand, is for dairy processors who are either in-market or close to processing their intended products. With a completed business plan, participants enter the Scale Up Stream and are eligible to submit expenses towards a matching grant from DFO and receive further mentoring support.

Recently, there has been a heightened interest in the program from producers to become an on-farm processor. There are 24 on-farm processors across Ontario, with several more in the initial and developmental stages.

The programs successfully support both on-farm processors and new entrants into the sector as they innovate in a complex category.

Supports both on-farm processors and new entrants into the dairy sector through two streams, based on the stage of the business:

START UP: New Ideas and concepts, business is not yet operational

SCALE UP: Business is operating and in need of support for further growth

The program offers entrepreneurs:

• Mentorship services

• Business knowledge

• Three matching grants of $10,000 awarded over a 3- to 5-year (max) period

The Start Up and Scale Up program has supported the introduction of some innovative products all made with high-quality Ontario dairy, including:

GoodPud

A thick, rich and indulgent creamy chocolate dessert pot in a selection of flavours, such as salted caramel and Belgian dark. All are made using local, Ontario cream. This small but mighty dessert is a perfect single serving portion and comes in resealable, recyclable and reusable glass jars. Sisters, Sarah and Polly Senior, longed for this style of dessert that they enjoyed growing up in England and knew they needed to make their own in Ontario, using high-quality cream. Learn more about GoodPud at www.goodpud.ca.

Crowdie Cheese by Golspie Dairy

Crowdie is a fresh cheese that they make using the whole milk from their herd of Holstein cows. It is based on a Scottish farmhouse cheese, and is similar to a cream cheese, spreadable with a very smooth texture. This product is produced by Golspie Dairy, an onfarm dairy processing facility located on Glen Atholl Farm. It is made by the Marshalls, a fifth-generation dairy farming family that just celebrated 150 years on their farm last July. Located just outside of Woodstock, this on-farm processing plant specializes in fresh dairy products and small-batch cheeses based on iconic and well-loved British staples. Learn more about Golspie Dairy at www.golspiedairy.ca.

Quark by Markhoeve Dairy

Queso Fresco by Sabana Cheese

This award-winning Latin cheese combines a rich history, exceptional quality and truly fresh taste. In 1997, a Venezuelan couple came to Canada and decided to make it their new home, but they longed for the tastes and flavors from their childhood. Antonieta, one of the owners, was inspired to share the decadent cheese recipes of her great grandparents and began shaping the idea of a Canadian-made Latin cheese. Sabana has expanded their product line of cheese and is now selling in major retailers like Sobeys and Longos. Learn more about Sabana Cheese at www.sabana.ca.

Quark is a European-style fresh cheese, similar to a creamy yogurt. Perfect for desserts, breakfast or as a versatile ingredient in baking and dips. This product is produced by the Backx family’s dairy farm Markhoeve dairy, in their processing facility, located on-farm in Waterford. They have a passion for providing Norfolk County with fresh onfarm dairy products, including quark. Learn more about Marhoeve Dairy at www.markhoevedairy.com.

Mapleton’s Organic Ice Cream

Mapleton's Organic is a family owned and operated farm, located in picturesque Wellington County. They specialize in ice cream that is made in their on-farm ice cream processing facility. They offer a variety of flavours, from classics like vanilla and mint chocolate chip, to seasonal flavours like lavender, maple chunk and pumpkin pie. Mapleton’s welcomes the public on-farm to see their herd and how they produce the delicious milk for their ice cream. Learn more about Mapleton’s Organic at mapletonsorganic.ca.

To discover more Dairy Processors making delicious products right here in Ontario, please refer to the Ontario Dairy Guide found on our website: https://new.milk.org/discover-dairy/ontario-dairy-guide/.

P5 Message – Additional 2025 Fall Incentive Days –Conventional and Organic

To continue to meet the stronger demand for fresh dairy products in the fall, specifically yogurt and fresh cheese, the P5 Boards announce one additional conventional incentive day to be issued on a non-cumulative basis in each of the months of July to November for conventional producers. Organic producers are issued one additional incentive day on a non-cumulative basis in each of the months of August to November. This adjustment aims to continue to maintain the production level forecasted for the period.

The P5 provincial boards’ primary objective is to continuously monitor the milk market situation and meet demand in the most optimal way and

will continue to adapt production signals to address market changes, as required.

P5 production is currently lagging behind in relation to the P5 forecast, but the P5 demand is increasing at a rate higher than the CDC’s optimistic model. For the last 12 months, the quota allocated to P5 has increased by 2.7 per cent, which is above the 2.6 per cent forecast under the CDC’s optimistic model. The strength in the overall demand and the anticipated strong demand for the fall period has led to the recent decisions on fall incentive days to fill the short-term fall market. The P5 quota committee will continue to keep an eye on the medium- to long-term market to ensure the right production signal will be sent.

In May 2025, butter stocks reached 39,442 tonnes, down from April by 1,520 tonnes. May butter stock levels are at their highest level for the same month over the last five years.

Cheese stock levels for the month of May 2025 were at 106,013 tonnes, up 812 tonnes from April and higher than the last five-year average.

For the 52-weeks ending May 31, 2025, sales for fluid milk, fluid cream, yogurt, ice cream, cheese and butter increased/decreased by 0.4, 1.2, 5.8, 3.3, 2.8 and 2.7 per cent, respectively.

A monthly recap of markets and production trends in Canada and Ontario

CANADIAN REQUIREMENTS AND PRODUCTION

Canadian butterfat requirements in kilograms and actual butterfat production across the P10.

950,000 1,000,000 1,050,000 1,100,000 1,150,000 1,200,000 1,250,000 1,300,000 1,350,000

12-month production (in millions of kilograms)

12-month requirements (in millions of kilograms)

Canadian production has increased by 2.6 per cent over the previous 12 months, and requirements have increased by 2.9 per cent over the previous 12 months.

This graph shows Ontario’s SNF-BF ratio for the last 12 months.

NATIONAL RETAIL SALES

Average increase in retail sales for dairy products sold in Ontario and the dairy product’s share of the total market sales, including at hotels, restaurants and institutions.

MAY HIGHLIGHTS

• To continue to meet the stronger demand for fresh dairy products in the fall, specifically yogurt and fresh cheese, the P5 Boards announce one additional conventional incentive day to be issued on a non-cumulative basis in each of the months of July to November for conventional producers;

• For the last 12 months, the quota allocated to P5 has increased by 2.7 per cent, which is above the 2.6 per cent forecast under the CDC’s optimistic model;

• In May 2025, butter stocks reached 39,442 tonnes, down from April by 1,520 tonnes. May butter stock levels are at their highest level for the same month over the last five years.

As of March 26, 2022

* Source: AC Nielsen & StatsCan

NOTE: There is a two-month lag in the national retail sales data.

ONTARIO UTILIZATION

Percentage of the total milk produced in Ontario that was used to produce dairy products.

Fluid Milk & Cream Yogurt and Ice Cream Cheese Butter & Powders

Milk Non Marketed

P10 UTILIZATION BY CLASS

For May 2025 (kg of butterfat/kg of solids non-fat)

*There is a two-month lag reporting these figures

% Solids non-fat

Class 1a1 (includes Classes 1a2, 1a3, 1c and 1d for confidentiality reasons) Fluid milk and beverages

Class 1b Fluid creams Class 2a Yogurt, yogurt beverages, kefir and lassi

Class 2b4 (includes Classes 2b1, 2b2 and 2b3 for confidentiality reasons) Fresh dairy desserts, sour cream, milkshakes and sports nutrition drinks

Class 2b5 Ice cream and frozen yogurt

Class 3a1 Specialty cheese

Class 3a2 Cheese curds and fresh cheeses

Class 3b2 (includes Class 3b1 for confidentiality reasons) Cheddar cheese and aged cheddar

Class 3c1 Feta

Class 3c2 Asiago, Gouda, Havarti, Parmesan and Swiss

Class 3c4 (includes Classes 3c3 and 3c5 for confidentiality reasons) Brick, Colby, farmer’s, jack, Monterey jack, muenster, pizza cheese, pizza mozzarella and mozzarella other than what falls within 3d

Class 3c6 Paneer

Class 3d Mozzarella used strictly on fresh pizzas by establishments registered with the Canadian Dairy Commission

Class 4a Butter and powders

Class 4d (includes Classes 4b1, 4b2, 4c and 4m for confidentiality reasons) Concentrated milk for retail, losses and animal feed

Class 5a Cheese for further processing

Class 5b Non-cheese products for further processing

Class 5c Confectionery products

Fluid milk & cream

Yogurt & ice cream Butter & powders

ONTARIO MONTHLY PRODUCER AVERAGE GROSS BLEND PRICE

A total 3,153 producers sold milk to DFO in May compared with 3,189 a year earlier.

ONTARIO DEDUCTIONS, PER HL

For May 2025

* These figures are based on Ontario’s average composition for May 2025 of 4.2639 kg butterfat, 3.2622 kg protein and 5.9548 kg other solids, rounded to the nearest cent.

P5 AND WESTERN MILK POOL BLEND PRICES *

The graph below shows the 12-month blend price for the P5 provinces and Western Milk Pool (WMP).

*There is a two-month lag reporting these figures

U.S. CLASS PRICES

The June 2025 Class III Price, US$18.82 per hundredweight, is equivalent to C$58.21 per hectolitre. This equivalent is based on the exchange rate US $1 = C$ 1.36251 the exchange rate when the USDA announced the Class III Price.

The Class III Price is in US$ per hundredweight at 3.5 per cent butterfat. One hundredweight equals 0.44 hectolitres. Canadian Class 5a and Class 5b prices track U.S. prices set by the U.S. Department of Agriculture.

Source: USDA

MONTHLY QUOTA PRICES ($/KG)

Co-ordinated by Dairy Farmers of Ontario’s communications and economics divisions. Questions? Please email questions@milk.org.

STAY UP TO DATE!

Weekly Update email newsletter every Friday for Ontario dairy producers.

Milk Producer magazine is the voice of Ontario dairy producers. Subscribe for free or read online at www.milkproducer.ca.

Dairy Farmer Update provides updates with the monthly milk cheque.

Producer Dashboard , a secure platform behind your password on MMS that contains important news, updates and forms.

www.milk.org

Facebook: /OntarioDairy

Twitter: @OntarioDairy

Instagram: @OntarioDairy

LinkedIn: /company/Dairy-Farmers-of-Ontario

Shaping the future of dairy-beef calf rearing

Insights into health and growth traits of Holstein and Holstein-Angus calves

By Melinda Kovacs, MSc in the Department of Animal Biosciences at the University of Guelph

A RESEARCH GROUP AT THE UNIVERSITY OF GUELPH, led by Drs. Michael Steele and Dave Renaud, have been involved in a five-year research initiative aimed at filling the knowledge gap around managing dairy x beef calves. As crossbreeding becomes more common in the industry, understanding how these calves perform compared to purebred Holsteins is critical.

In a recent study, the group compared health and growth records of over 600 calves, and the results suggest that raising crossbred calves may offer real advantages to farmers. Crossbred calves had less diarrhea, required fewer antibiotics treatments and weighed over 7 kg more than Holsteins by 3 months of age.

What are dairy x beef calves

With the widespread use of sexed semen in the dairy industry, producers can now breed replacement heifers more efficiently, while incorporating beef semen into their breeding program. This strategy has led to a rise in dairy x beef crossbred calves on farms. A May market report indicated that crossbred calves sold for $1,300 to $2,450 CAD, whereas good-quality Holstein bull calves ranged from $1,000 and $1,650 CAD, highlighting the potential economic benefits to dairy farmers.

Crossbred calves are typically raised much like non-replacement Holsteins but ultimately enter the beef supply chain after weaning. They are often transported within the first 10 days of life to a rearing facility, mixed with calves from other farms, and weaned at a young age. While these management practices are standard, they can be stressful, increasing the risk of illness during the rearing period and affecting both short- and longterm health and growth performance. Gaining a better understanding of how these crossbred calves handle early-life stress and how they compare to Holsteins could help improve calf care and farm profitability.

What the research shows

In a study conducted at a calf-rearing facility in Ontario, Holstein and Holstein x Angus calves were raised under the same conditions for three

IN A RECENT STUDY, THE GROUP COMPARED HEALTH AND GROWTH RECORDS OF OVER

600 calves

CROSSBRED CALVES HAD LESS DIARRHEA

required fewer antibiotics treatments weighed over 7 kg more than Holsteins by 3 months of age

months. Health was monitored daily by evaluating both fecal consistency and clinical signs of bovine respiratory disease, while intakes and body weights were recorded on a weekly basis to evaluate growth performance.

The crossbred calves arrived at the rearing facility smaller than Holsteins but quickly caught up, and by four weeks after arrival, the crossbred calves were significantly heavier. The crossbred calves were also more feed efficient, meaning they required less energy from feed to gain the same weight compared to Holsteins. The researchers also found that crossbred calves had fewer days with diarrhea and required fewer antibiotic treatments to recover from diseases.

What this means for farmers

Healthier calves and fewer antibiotic treatments mean lower cost, less labour and better growth, all of which translate into economic gains.

Additionally, reducing antimicrobial use can improve consumer trust, especially as public attention to antibiotic use in food production continues to grow. It also plays a key role in slowing the development of antimicrobial resistance, a growing challenge for human, animal and environmental health.

However, these research findings do not mean that crossbred calves require less care and attention than Holsteins. To reach their full potential, crossbred calves still need to receive adequate quantities of colostrum after birth, proper nutrition during rearing and careful monitoring for signs of illness.

Future research

This study is just one part of the broader research initiative. Researchers have also followed 40 Holstein and Holstein x Angus steers from birth to 14 months of age to study growth across all production stages and to compare carcass quality. In addition, several nutrition trials are underway to learn how diet affects immunity, growth and meat quality of dairy x beef calves.

One of the biggest challenges in the dairy x beef world is the lack of communication and coordination between industry partners, from the dairy farm to the feedlot. The goal of this research program is to identify best practices that improve health, growth, sustainability, and ultimately the value of these crossbred animals throughout the production chain.

“I am absolutely a fan of Udder Comfort!

“I am absolutely a huge fan of Udder Comfort!™ It gives the feeling of freshness and comfort. We have used it 12 years, rubbing it on for better texture or to soften a quarter. We use Udder Comfort for fresh cows, especially good for rst calf cows. We also use it before, during, and after a show to give the best udder texture possible. We see more of the udder’s veins, and the cows are more comfortable,” says Bianca Foley. The Foley family has a rich history of honors in Ayrshire breeding. They milk 50 Ayrshires at Vieux Village, Piopolis, Quebec. Their 5-year-old Vieux Village Gentleman Joy EX97 stood grand with 4-year-old Vieux Village G Montana EX94 reserve at the 2024 World Dairy Expo and Royal Agricultural Winter Fair.

— Bianca Foley

Estimating cows' "burps" from a milk sample

Does it really work?

By Débora Santschi, Innovation and Development Director, Lactanet & Chantal Fleury, Assistant Director of Economic Research, Les Producteurs de lait du Québec

JUST LIKE HUMANS, COW’S

BURP. But did you know that researchers can estimate the number of cows’ burps based on one milk sample?

Findings from this research, based out of Quebec, will help drive industry sustainability efforts and reduce greenhouse gas emissions.

Why measure methane?

Enteric methane emissions account for about half of the greenhouse gas (GHG) emissions in the carbon footprint of Canadian milk. This emission source is a key focus in the national commitment to reduce GHGs and in the dairy industry's desire to offer consumers milk with a lower carbon footprint.

However, estimating enteric methane emissions would require a significant amount of time for each producer to collect the necessary data. To avoid increasing the administrative burden on producers, while still allowing them to understand the profile of their herd, milk sample analysis was prioritized in Quebec.

How is methane measured on farm?

Since June 2024, 14 farms in Quebec have been equipped with methane “sniffers” in the feeder bins of 24 milking robots. A methane sniffer is a white box attached to the wall near the robot, with a whole system of pumps and electronics inside. There is also a thin tube that goes to the robot's feeder, where the cow breathes while eating its concentrate. Robot farms were selected to facilitate the linking of individual methane measurements with cow production data. This project is being carried out with financial support from the Quebec government as part of the 2030 Plan for a Green Economy.

The sniffer works like a small vacuum cleaner: it continuously sucks in air through its tube, which is protected by a filter at the end. On farms, there is always some methane in the ambient air and in circulating gases. It's like a baseline, a background noise. However, when a cow enters the robot and its nose is in the feeder, the carbon dioxide (CO2) and methane (CH4) it exhales can be detected, which are both significantly higher than in the ambient air. By difference, we obtain the CO2 and CH4 emitted by the cow.

How do you go from an exhalation in the robot to an estimate of whole-day methane emission?

Other countries are also working with these methane sniffers. There are equations that can be used to convert the concentration of methane detected during milking in the robot into the cow's total daily emissions. By using some data on the cow (weight, milk production and composition, days in gestation, etc.) and a ratio between CO2 and CH4 to obtain grams of methane per day, plus adding up the values for all the cows, we obtain the enteric methane emitted by the lactating herd.

How is it possible to estimate the methane produced by cows from a milk sample?

There is no methane in milk. Methane emissions are linked to ruminal fermentation, which is very closely connected to the composition of milk. We all know that a change in feed ration can change the fat or protein content of milk. This change in feed also affects minor compounds in milk, such as urea and fatty acid profile, and many other small molecules. These changes in ruminal fermentation result in small changes in milk composition. When we put all this together in a mathematical model, we produce an algorithm that estimates methane based on the information contained in the milk sample.

Enteric methane emissions account for about half of the greenhouse gas (GHG) emissions in the carbon footprint of Canadian milk.

Once the algorithm has been developed using data from the 14 farms equipped with sniffers, it can be applied to all farms in Quebec.

Do cows in Quebec produce a lot of methane?

According to the first results from this project, cows in Quebec produce on average emissions that are very similar to what the scientific literature reports, between 500 and 600 g CH4 /day. High-yielding cows naturally emit more methane than low-yielding cows because they have a more active metabolism. By converting the units to grams of CH4 /kg of components-corrected milk, we put everyone on a level ground for comparison. We can then compare farms and cows based on the unit of production, i.e., one litre of components-corrected milk. The provincial average is currently between 14.5 and 15.5 g CH4 /kg of corrected milk.

To learn more about this project, visit https://lait.org/en/our-future/ investments-research/lactanet-methane-estimation-project/.

Dairy Farmers of Ontario (DFO) has an annual scholarship program that offers up to six $5,000 scholarships to high school students entering a post-secondary degree or diploma program in agriculture.

To be eligible for these scholarships, an applicant must:

• be the son or daughter of a DFO licensed producer;

• Parabone • Herringbone

• Parallel • Rapid Exit

• Tandem style

• Also custom orders

• Self lock head gates

• Pro free stalls

• Slant stalls and gates

• Calf pens

• Tie stalls • Tip tanks

• be entering semester one of an agricultural degree program or a diploma program with a demonstrated tie back to agriculture (up to one scholarship will be available from a non-traditional degree or diploma program);

• have achieved an average of 80 per cent or greater in Grade 12 credits (best six to be averaged).

Selection criteria will be based on:

• academic achievement;

• future career plans;

• demonstrated leadership in secondary school and community activities.

How to Apply:

• Application forms are available on DFO’s website at new.milk.org under Industry Login. On the left-hand side, go to Documents > Forms > Application for DFO Scholarships.

• Dairy Farmers of Ontario must receive complete application forms by Aug. 30, 2025, to be considered.

For details: contact Robert Matson at robert.matson@milk.org or 905-208-7981

Developing a national reporting system for pregnancy and developmental conditions in dairy cows

By Shelby Duggan, Gabriella Condello, Emily Leishman, Hannah Sweett, Chris Bartels, Colin Lynch, Fillipo Miglior, Christine Baes & Ricarda Jahnel

PREGNANCY LOSS AND CALF

DEVELOPMENTAL CONDITIONS are being reported more frequently in Canada’s dairy population, raising concerns for animal welfare, herd productivity and farm profitability. While some of these cases are due to environmental stressors, others may be the result of inherited genetic traits that affect calf development or pregnancy success.

Background

The introduction of genomic selection and improvement in reproductive technology has driven significant gains in productivity and efficiency across the dairy industry. Yet, early breeding strategies prioritized production traits over health and fertility, with potential effects on reproductive performance and calf viability. At the same time, the rapid adoption genomic selection and advancement in reproductive technology has increased the possibility of undesirable gene variants being inherited when carriers are unknowingly mated. As these gene combinations become more widespread in the population, the frequency of genetic conditions

has also grown, specifically those affecting pregnancy and calf development. Recognizing these unintended consequences of selection, greater emphasis is being placed on traits related to health and fitness of livestock to promote more balanced genetic progress.

Increased awareness and improved diagnostic capabilities have played a role in bringing more of these cases to light. As a result, producers today are more equipped than ever to recognize and report genetic conditions, and the role of genetics is becoming more apparent. This growing awareness has created the need to better understand what these conditions are and how they can be managed.

What are “pregnancy and developmental conditions”?

Pregnancy and developmental conditions refer to issues that affect calf health and survival, including pregnancy loss, birth defects, unexplained illness and early death. Pregnancy loss can occur at any stage before birth and is categorized by timing: embryonic loss happens within the first 41 days of gestation,

while fetal loss occurs afterward and includes abortions and stillbirths. Abortions involve the loss of a fetus between days 42 and 260, and stillbirth refers to a full-term calf (after day 260) born dead. Malformed calves may have defects affecting limbs, joints or organs. Early calf mortality describes death within the first year of life when no nutritional, management or infectious cause is found. Similarly, youngstock (under three years of age) may develop unexplained illness with no identifiable environmental or infectious origin.

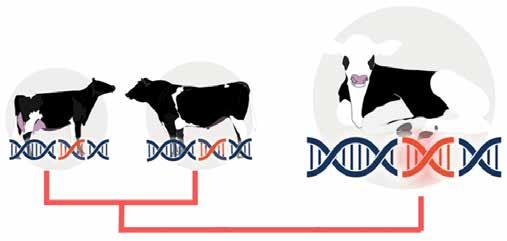

How do undesirable genetic conditions occur?

Every calf will inherit half of its genetic material from its dam, and the other half from its sire. For each gene, it will receive one version from each parent.

An individual animal can carry a single copy of an undesirable gene without displaying any clinical or subclinical signs. Without clear indications, carriers of one undesirable gene copy may not be detectable without genetic testing. However, when an animal inherits two

copies of this undesirable gene, detrimental effects can occur, affecting pregnancy success and/or the calf’s ability to survive. Certain gene pairs can be lethal, resulting in pregnancy loss or early mortality in calves, while others may impede normal calf development, leading to deformities and reduced survival rates.

With modern breeding programs and advancements in reproductive technology, undesirable genes can spread rapidly if not identified and managed early, posing not only a national, but a global concern.

To date, the dairy industry has made great strides in identifying and managing genetic conditions. But, as the frequency of new genetic variants grows, we must remain diligent with reporting to allow researchers to investigate associated genes.

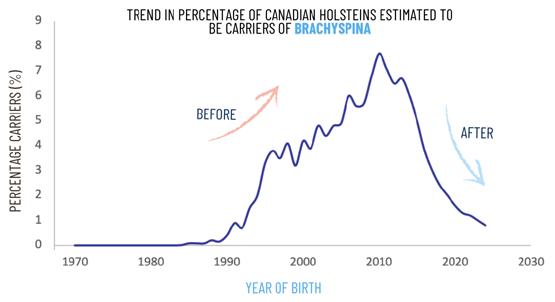

As an example, Brachyspina, a lethal defect marked by low birth weight (~10 kg), shortened spine and elongated limbs, was first documented in 2007. Through farmer-reported cases and genetic testing, Brachyspina was identified as a hereditary disease resulting from the inheritance of two copies of an undesirable gene. Once a gene test was developed, breeders could manage its presence in breeding programs by avoiding mating potential or known carrier animals, limiting its spread to future generations.

TREND IN PERCENTAGE OF CANADIAN HOLSTEINS ESTIMATED TO BE CARRIERS OF BRACHYSPINA

BEFORE AFTER

YEARS OF BIRTH

Figure 1. Trend in the percentage of Canadian Holsteins estimated to be carriers of Brachyspina. Graph recreated and restyled by the author using original data and structure from Lactanet.

Figure 1. Trend in the percentage of Canadian Holsteins estimated to be carriers of Brachyspina. Graph recreated and restyled by the author using original data and structure from Lactanet.

Important: Not all pregnancy and developmental conditions are genetic!

Current reporting in Canada

Identifying the root cause of a pregnancy or developmental condition can be challenging. More commonly, these conditions are linked to environmental factors such as nutritional imbalances, stress, temperature extremes, toxins and disease and infection prevalence within the herd. However, genetic testing is important for uncovering genetic links to these conditions and developing practices to prevent them in the future.

Many countries have established national surveillance systems that allow veterinarians and producers to report suspected genetic conditions and manage their occurrence. In contrast, Canada has not yet implemented a national system for documenting these cases. Instead, reporting is limited to company-specific platforms or tools integrated into existing herd management software, such as DairyComp or Holstein Canada’s “Calf Abnormality Report”.

Poor use of these tools has resulted in limited reporting and a gap in valuable data that could help address and mitigate undesirable genetic conditions in livestock. To date, no research has been conducted to understand the barriers that may prevent producers from reporting or how to improve

How can reporting and genetic selection help?

Reporting and subsequent genetic testing is important for identifying and managing undesirable genetic conditions in the dairy population.

As an example, Brachyspina, a lethal defect marked by low birth weight (~10 kg), shortened spine and elongated limbs, was first documented in 2007. Through farmer-reported cases and genetic testing, Brachyspina was identified as a hereditary disease resulting from the inheritance of two copies of an undesirable gene. Once a gene test was developed, breeders could manage its presence in breeding programs by avoiding mating potential or known carrier animals, limiting its spread to future generations.

Current reporting in Canada

Many countries have established national surveillance systems that allow veterinarians and producers to report suspected genetic conditions and manage their occurrence. In contrast, Canada has not yet implemented a national system for documenting these cases. Instead, reporting is limited to company-specific platforms or tools integrated into existing herd management software, such as DairyComp or Holstein Canada’s “Calf Abnormality Report”.

Poor use of these tools has resulted in limited reporting and a gap in valuable data that could help address and mitigate undesirable genetic conditions in livestock. To date, no research has been conducted to understand the barriers that may prevent producers from reporting or how to improve access to existing platforms. Identifying these factors is essential for enhancing both herd health and broader industry practices.

Important: Not all pregnancy and developmental

conditions are genetic!

Identifying the root cause of a pregnancy or developmental condition can be challenging. More commonly, these conditions are linked to environmental factors such as nutritional imbalances, stress, temperature extremes, toxins and disease and infection prevalence within the herd. However, genetic testing is important for uncovering genetic links to these conditions and developing practices to prevent them in the future.

What can you do?

Producer participation is essential for building a system that can strengthen herd health, support informed breeding decisions and safeguard the long-term sustainability of the Canadian dairy industry.

To address challenges surrounding pregnancy and developmental conditions, and the lack of reporting, the Centre for Genetic Improvement of Livestock (CGIL) at the University of Guelph has partnered with Dairy Farmers of Canada, Holstein Canada, Lactanet and Semex to develop an improved reporting system tailored for Canadian dairy producers to document these incidences in their herds (with additional funding from DairyGen Research Council and Dairy Farmers of Canada).

Producer participation is essential for building a system that can strengthen herd health, support informed breeding decisions and safeguard the longterm sustainability of the Canadian dairy industry.

To ensure this system meets the needs of ALL Canadian dairy producers and maximizes future use, we need your help! By scanning the QR code below, you can anonymously participate in our research project (REB #64) where you can share:

• Preferences for the reporting platform

• Outlook and knowledge of genetic testing

• Experiences with pregnancy loss and calf conditions in your herd

• Experience with reporting health-related events

Your input is vital in helping us build a practical, producer-informed reporting system for the Canadian dairy industry.

Research Project: Survey (REB #64)

Many countries have established national surveillance systems that allow veterinarians and producers to report suspected genetic conditions and manage their occurrence.

If you have any questions about this project, you may contact Gabriella Condello (gcondello@ uoguelph.ca), Dr. Shannon Cartwright (scartwright@holstein.ca) or Dr. Hannah Sweett (hsweett@lactanet.ca).

LIsten to farmers talk about the cool farm tool on the canadian podcow

In January, Dairy Farmers of Canada and the provincial dairy associations implemented a pilot project testing an onfarm greenhouse gas (GHG) emissions calculator called the Cool Farm Tool.

On The Canadian Podcow, hosts Sarah Sache and Andrew Campbell talked to two dairy farmers, and self-professed data geeks, about their experiences participating in the project.

In the interview, Josh Dillman and Janet Harrop go all-in on their specific on-farm sustainability journeys. They talk about farming in their respective provinces, how they found using the Cool Farm Tool, and how they see the future of it and other GHG calculator tools in the Canadian dairy sector.

“I'm a measurable person, and I like to be able to know measurables,” said Dillman. “We've talked about greenhouse gas emissions around the industry for a while, and when the opportunity was presented to know what that number actually may be, even though I’m still learning what that means, obviously I had an interest in going through with the exercise.”

You can hear more about their thoughts on using the Cool Farm Tool, as well as a full catalogue of great episodes, by following the QR code below or searching for “The Canadian Podcow” wherever you listen to podcasts.

You can also watch the interview on YouTube by going to Y YouTube.com/@CanadianPodcow.

Listen to a back catalogue of great episodes at canadianpodcow.ca and e entredeuxtraites.ca

Sarah Sache

Andrew Campbell

New DFC Student Program: Bridging dairy research and practice to empower future experts

By Annik L’Espérance & Émie Désilets, Dairy Farmers of Canada

IN A DYNAMIC AND CONSTANTLY EVOLVING SECTOR LIKE DAIRY, the future depends not only on producing high-quality milk today but also on ensuring a strong foundation of knowledge and expertise for tomorrow.

In line with this commitment, Dairy Farmers of Canada (DFC) is proud to announce the launch of the new DFC Student Program, a dedicated initiative for students and postdoctoral researchers involved in DFCfunded research projects. The program aims to strengthen the connection between scientific research and the realities of the Canadian dairy sector.

Through this initiative, students will deepen their knowledge of the sector, access networking and training opportunities, actively participate in knowledge translation and transfer (KTT) activities, and be recognized for their valuable contributions to the future of the sector. By bridging the gap between research and real-world application, DFC is cultivating a dynamic community poised to drive innovation and progress across the dairy sector.

Connecting research to practice