AWARD WINNERS

Honouring Ontario’s top producers THE

CELEBRATING QUALITY

OF ONTARIO DAIRY PRODUCERS COMMITMENT TO EXCELLENCE MARCH 2024 40063866 Publications Mail Sales Agreement No

VOICE

Not all Vaccines are Created EQUAL

Hi, my name’s Jonathan Hess, DVM. My practice is Hess Veterinary Service West based in Hagerman, Idaho. I serve in the Magic Valley. We focus quite a bit on the efficiency of our young stock replacement operations. I always thought Endovac had a place in the young stock just because the amount of gramnegative exposure. We use Endovac Dairy in the first week of life. It’s very smooth. No matter how good your husbandry is, you’re still going to have a myriad of gram-negatives and those gram-negatives seem to be getting smarter and stronger. Salmonella is really everywhere. It’s not something you get rid of, it’s something you manage. What I like about Endovac is the management of salmonella and any gramnegative really, which is crazy. It’s really helped clients manage through that diarrhea period which usually shows up around 10 days to two weeks and continues into 20 to 30 days. It seems to work well for us.

As far as other uses, I do have other facilities that struggle with gram-negative pneumonia problems after the animal leaves the hutch. There’s been gram-negative vaccines in the past that are a little harder on the cow or the calf, especially ones related to respiratory. Endovac is employed there one to two weeks before they move to a different housing situation to address certain gram-negative pneumonias. You know, the ever-present, I say Pasteurella but there’s other things. There’s quite a bit of Salmonella pneumonia that people don’t even want to talk about, but it’s there. Places that use it younger, boost them if you will, to get them ready to go to the co-mingled housing. It has really helped with slowing down quite a bit of the treatment rates on these places.

As far as a consistent product that has a 40-year history, it’s smooth and safe. I definitely feel confident to stick with this for gram-negative control.

–Jonathan Hess,

–Hess Veterinary Service West For more information, please visit EndovacDairy.ca 1-800-944-7563 | 6080 Bass Lane | Columbia, MO 65201

DVM,

PUBLISHED BY

DAIRY FARMERS OF ONTARIO 6780 Campobello Road Mississauga, ON L5N 2L8

ADVERTISING

Pat Logan pat.logan@milk.org 519-788-1559

GRAPHIC DESIGN

Katrina Teimo

MANAGER, COMMUNICATIONS

Sharon Laidlaw sharon.laidlaw@milk.org

CONTRIBUTORS

ACER Consulting, Andrew Brooks, Ryan Dick, Katie Duncan, Essi Evans, Luke Heider, Rebecca Hannam, Chris McCullough Jeanine Moyer, Pedro Nogueira, Robert Price, Theresa Rogers, Javier Sanchez, Lilian Schaer, Brittany Wood

Canada Post Publications Mail Sales Product Agreement No.40063866.

Return postage guaranteed. Circulation: 8,000. ISSN 0030-3038. Printed in Canada.

SUBSCRIPTIONS

For subscription changes or to unsubscribe, contact:

MILK PRODUCER

6780 Campobello Road

Mississauga, ON L5N 2L8

Phone: (905) 821-8970

Fax: (905) 821-3160

Email: milkproducer@milk.org

Opinions expressed herein are those of the author and/or editor and do not necessarily reflect the opinion or policies of Dairy Farmers of Ontario. Publication of advertisements does not constitute endorsement or approval by Milk Producer or Dairy Farmers of Ontario of products or services advertised.

Milk Producer welcomes letters to the editor about magazine content.

*All marks owned by Dairy Farmers of Ontario.

WEBSITES & SOCIAL MEDIA

www.milkproducer.ca

www.milk.org

Facebook: /OntarioDairy

X: @OntarioDairy

Instagram: @OntarioDairy

LinkedIn: dairy-farmers-of-ontario

3 WWW.MILKPRODUCER.CA • JANUARY 2024 • March 2024 | Vol. 100 No. 3

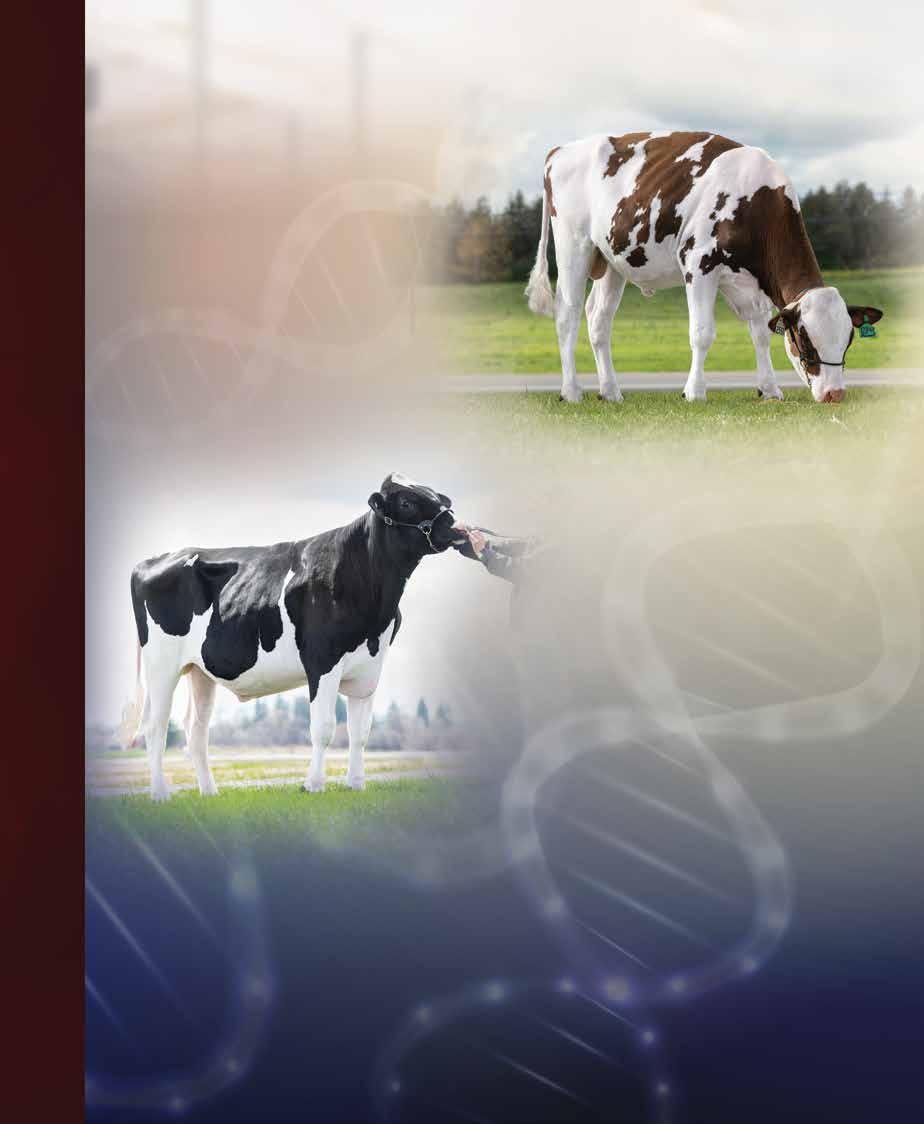

CON TENTS

11 Leadership and Commitment to quality Honouring Ontario’s top producers ON THE COVER CELEBRATING QUALITY 8 What makes high quality milk 20 ProAction celebrates 10 years of on-farm excellence 34 Farm Management – Bare Trusts and New Tax Filing Requirements RESEARCH 23 Combating Biofilms: Ensuring Quality Milk from Farm to Table 30 Enhancing Milk Quality with Fatty Acid Research 32 Calf Care: Maximizing the Value of Male Dairy Calves 38 Silage Inoculants WORLD DAIRY 43 Irishman Breeding Medium Sized Cows DEPARTMENTS 4 Board Editorial 6 Ask an FSR 25 Dairynomics 43

QUALITY IS IN A DAIRY PRODUCER’S DNA

By Vicky Morrison, BOARD MEMBER, REGION 9, DISTRICTS OF ELGIN, ESSEX, KENT, LAMBTON AND MIDDLESEX, DAIRY FARMERS OF ONTARIO

AND CHAIR OF DFO’S QUALITY ASSURANCE COMMITTEE

When you think of Canadian milk, it is synonymous with high quality.

Dairy producers are committed to producing high quality milk on farm—ultimately for Canadians to enjoy every day. As the regulator and sole delegated authority for the marketing of milk, DFO is accountable to the Ontario Farm Products Marketing Commission and the Ministry of Agriculture, Food and Rural Affairs, for the application and administration of quality programs. There is much support in place to help producers achieve and maintain the highquality standards expected.

DFO’s Field Service Representatives (FSRs) apply the provincial Raw Milk Quality program including Grade A inspections. Most recently, DFO increased its frequency of milk bacteria testing above and beyond regulatory requirements. Bacteria (bactoscan)

Farm and Family

is now tested for all milk pickups. Increased testing means producers can identify issues sooner and better manage their farms. Having access to more data points will also enhance DFO’s monitoring capabilities at the load and provincial levels. Ontario dairy farmers work hard to overachieve all quality targets and FSRs work as partners with each producer to provide support in maintaining the production of highquality milk. Many Ontario dairy farmers are recognized annually for their exceptional milk through DFO’s Raw Milk Quality Certificates.

Further, for the second year, the DFO board honoured five Ontario dairy producers across the province at the Annual General Meeting for the best quality scores and leading the industry by example. The winners, their families and their farms were publicly acknowledged as the best of the best and are now being featured in this issue. Consistency is an overarching theme

among award-winning dairy producers and in these pages, they offer perspectives on successful procedures they’ve put in place on their farms, which have worked well to help reach the highest standards of quality.

Dairy producers love what they do, and quality is part of their DNA. Congratulations to these producers, their families and the countless staff, team members and partners who share that commitment. Thank you, you are an inspiration to all producers striving for the highest quality milk possible each and every day.

Does your succession plan work for both? Don’t risk your legacy, take our simple self-assessment and find out where you stand.

• MARCH 2024 • WWW.MILKPRODUCER.CA 4

Vicky Morrison

Scan here to start MNP.ca BOARD EDITORIAL

DairyRotor T8900 Pushing performance at every turn.

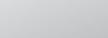

Janlaur Farm Ltd., Gowanstown, ON

Jan & Lauren Wilting are the 2nd generation farmers. They currently milk 350 cows with GEA DairyRotor T8900 - 40 Stalls.

‘‘ Milking in our new barn with the Rotary Parlour has been everything we hoped for. Speed, efficiency, and cow comfort come to mind every day we milk. It took our cows 4 days to get used to the rotary and now we very rarely use the crowd gate to encourage our cows to get on. Our milking time has been cut in half, down to two hours. We can milk 170 cows per hour. Another bonus, our Bactoscan and Somatic cell count dropped with the new barn and parlour. ’’

BRITISH COLUMBIA

Mountain View Electric Ltd.

Enderby — 250 838-6455

Pacific Dairy Centre Ltd.

Chilliwack — 604 852-9020

ALBERTA

Dairy Lane Systems

Leduc — 780 986-5600

Nobleford – 587-335-9742

Lethbridge Dairy Mart Ltd.

Lethbridge — 888 329-6202

Visit us online at:

GEA.com/canada

SASKATCHEWAN

Dairy Lane Systems

Warman — 306 242-5850

Emerald Park — 306 721-6844

MANITOBA

Tytech

Grande Pointe — 204 770-4898

ONTARIO

Conestogo Agri Systems Inc.

Drayton — 519 638.3022 1 800 461-3022

Dairy Lane Systems

Komoka — 519 666-1404

Lawrence’s Dairy Supply Inc.

Moose Creek — 613 538-2559

McCann Farm Automation Ltd.

Seeley’s Bay — 613 382-7411

Brockville — 613 926-2220

McLaren Systems

Cobden — 613 646-2062

Performance Dairy Centre Inc.

Embro — 519 423-9119

Wood’s Dairy Source

Keene — 705 295-3247

ATLANTIC PROVINCES

Atlantic Dairy Tech.

Charlottetown, PE — 902 368-1719

Sheehy Enterprises Ltd.

Shubenacadie, NS — 902 758-2002

Lower Queensbury, NB — 506-478-4878

QA &

QUESTION

DAIRY FARMERS OF ONTARIO’S (DFO) FIELD SERVICES REPRESENTATIVES (FSRS) are not only milk inspectors, they are also your source of support for everything from milk quality troubleshooting to quota questions and paperwork, questions about policies and regulation, and anything else related to DFO and how it applies to your farm. Our team of 13 field staff have seen and heard a lot. This column was created to use our collective expertise by sharing answers to some of the most commonly asked questions we receive. We are here to help you.

ARE QUALITY INVESTIGATIONS ONLY DONE ON FARMS WITH PENALTY RANGE QUALITY RESULTS?

ANSWER

Field Service Representatives (FSRs) play a vital role in maintaining milk quality standards within the dairy industry. FSRs are responsible for troubleshooting milk quality issues and receive daily emails identifying farms experiencing abnormal test results. These emails serve as a compass, guiding FSRs to farms in need of support.

FSRs utilize these insights to schedule visits and provide handson assistance to producers grappling with milk quality troubles.

Producers can also directly reach out to FSRs to arrange farm visits for investigating such issues before penalty level test results are achieved.

In an ideal scenario, producers would contact their FSRs at the onset of milk quality issues, allowing ample time for collaborative improvements. However, often FSRs are only brought in when producers are already facing penalties, which makes finding solutions and implementing changes more difficult.

The proactive engagement of FSRs underscores the importance of early intervention and collaboration in ensuring excellent milk quality.

“We stick with what works…Udder Comfort.”

STEMPFLE HOLSTEINS, Maynard, Iowa

Paul,

43

SCC

Family

“We have been using Udder Comfort™ for 10 years. We use it on all fresh animals after each milking for a week after calving,” says Scott Stemp e.

Scott and parents Paul and Jody have a 750-cow dairy near Maynard, Iowa. Many of their registered Holsteins go back to Butlerview Roy Glamorous. As herd manager, Scott enjoys seeing the progression from calf to milk cow.

“Transition at calving is the most important part of a cow’s lactation. Udder Comfort is an important tool to get her through that transition and into her milk faster,” says Scott.

“We stick with what works, and we have always had really good results with Udder Comfort. It softens udders to milk faster and easier so cows get a better start in their lactations.”

• MARCH 2024 • WWW.MILKPRODUCER.CA 6 ASK AN FSR

For external application to the udder only, after milking, as an essential component of udder management. Always wash and dry teats thoroughly before milking. 1.888.773.7153 1.613.652.9086 uddercomfort.com Call to locate a distributor near you.

— Scott Stemp e

Jody and Scott Stemp e 750 Reg. Holsteins

kgs/cow/day

3.2P (3x)

4.1F

avg. 160,000

reach their potential since 1998! ASK AN FSR

featured in Sept. 2021 Holstein America on RFD-TV 2021 IA-District 1 Young Holstein Breeder Award (Scott) Helping

11-866-267-6255 -866-267-6255 CALL TO ACCESS FREE, CALL TO ACCESS FREE, UNLIMITED COUNSELLING UNLIMITED COUNSELLING Stress on the farm Family or relationships Financial pressure Anxiety or depression Managing your workload Substance use Loneliness or isolation Supporting loved ones Processing traumatic events FREE MENTAL HEALTH SUPPORT FOR ONTARIO FARMERS, FARM WORKERS AND THEIR FAMILIES

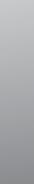

CANADIAN MILK IS SOME OF THE HIGHEST-QUALITY MILK IN THE WORLD and is produced to some of the highest standards.

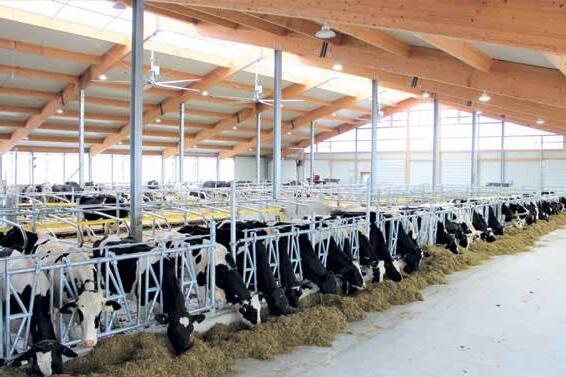

Making sure the milk Ontario farmers produce is of the highest quality is a big responsibility and it starts with high-quality farming practices and healthy, well-cared-for cows.

Dairy Farmers of Ontario staff members, Jeff Hyndman, Assistant Director, Raw Milk Quality and Quality Assurance Programs and Emily McDonald, Manager Field Service and Raw Milk Quality Programs answer some common questions about practices that produce highquality milk, including many farm and herd management processes that Quality Award winners follow on their farms.

Q. What makes high-quality milk?

A. Excellent standards, consistent operations and being proactive are the leading farm management strategies that produce the highest quality milk on Ontario dairy farms.

Establishing a detailed routine and sticking to it is important. Cows like consistency, and for those farms that hire labour, a consistent and documented routine can help maintain and improve milk quality. For example, a recommended routine should include cleaning stalls, regular milking schedules (for parlour and tie stall), scheduled maintenance and equipment cleaning. Following a routine also sets a standard everyone is required to follow, and setting excellent standards, like cleanliness of equipment and animals directly contributes to milk quality.

WHAT MAKES HIGHQUALITY MILK?

Ontario dairy farmers are surrounded by resources and tools they can leverage to help produce quality milk. Collecting and analyzing data to identify gaps or areas of improvement can be helpful. Many farmers have access to data from a variety of sources and can easily lean on their farm management advisory team to leverage and implement relevant information.

DFO recognizes how much farmers rely on data to make good management decisions. That’s one of the reasons our organization increased the frequency of milk bacteria testing from five to seven days a week. As of March 1, 2024, the testing frequency has increased, and Ontario dairy farmers will now receive BactoScan results on each milk pickup. Using this information, farmers can closely monitor their bacteria counts (a major contributor of milk quality) and be more proactive when it comes to addressing or solving any necessary concerns before they become larger problems.

The proAction program is another on-farm tool and resource farmers can rely on that contributes to quality assurance. Now in its tenth year, this on-farm food safety and milk quality program

• MARCH 2024 • WWW.MILKPRODUCER.CA 8 QUALITY

Jeff Hyndman, Assistant Director, Raw Milk Quality and Quality Assurance Programs

Emily McDonald, Manager, Field Service and Raw Milk Quality Programs

The freezing point of milk is an indicator of its quality and is determined by its composition. Since the freezing point of milk is fairly constant, the freezing point of bulk tank milk is measured and used to determine the addition of water to milk which can influence milk quality.

has proven to elevate the standards of milk production, and in turn, enable dairy farmers to produce the highest quality milk. Following the six modules – Food Safety, Milk Quality, Animal Care, Traceability, Biosecurity and Environment – farmers can use the program tools to literally take a proactive approach to farm management to enhance quality across every aspect of their farm.

Milk quality criteria is used to control somatic cell count (SCC), bacteria levels, freezing point and inhibitors. These criteria are regulated and used to assess farm milk quality. Farmers are responsible for monitoring and analyzing these test results to ensure the production of quality milk.

Q. How can Ontario dairy farmers consistently maintain an ideal BactoScan count?

A. The first step is to monitor and understand milk bacteria testing results that are provided by DFO. As noted above, the frequency of these results is increasing this year, providing farmers with more information to help make management decisions and address any concerns.

Working with an equipment dealer as part of a farm management team, farmers can take a proactive approach to managing BactoScan counts by completing a regular wash analysis to ensure the wash

system is functioning properly. This should include a slug analysis, temperature checks for each wash cycle, chemical measurements during each cycle and verification that the proper volume of water is being used. Dealers can also update wash carts with the correct chemical measurements and record water hardness and wash water volume.

Additional tips include ensuring adequate water temperature (starting between 70-75°C) and running all wash cycles for each milking (including a sanitary rinse, wash and acid rinse). Farmers should use a new wash filter for each wash and milking and regularly check the tank when it is empty for any build-up, and to verify a proper wash has occurred.

When it comes to milking and animal cleanliness, farmers should ensure teats are clean and dry and milkers have clean hands or wear clean gloves.

Q. Any tips for improving Freezing Point Estimate?

A. The freezing point of milk is an indicator of its quality and is determined by its composition. Since the freezing point of milk is fairly constant, the freezing point of bulk tank milk is measured and used to determine the addition of water to milk which can influence milk quality.

Follow these management tips to improve Freezing Point Estimate (FPE):

• Ensure milk does not freeze in the bulk tank during or after the cooling process.

• Make sure the bulk tank agitator works properly.

• There must be an adequate volume of milk on the first milking to properly cool and agitate milk.

• Check the Time Temperature Recorder for any cooling or agitator alarms.

9 WWW.MILKPRODUCER.CA • MARCH 2024 •

Milled our dair y barn floors in ars later we just had AGRI-TRAC

• Be sure the safety switch functions properly.

em again. It lasted 22 Years! We chose bothtimesinstead of grooving

• Reduce hoof and leg injuries

s and lasts. We have experience, NOT work! Thank you AGRI-TRAC.

AGRI-TRAC Milled our dair y barn floors in August of 2000.22 Years later we just had AGRI-TRAC backto do them again. It lasted 22 Years! We chose AGRI-TRAC bothtimesinstead of grooving because it works and lasts. We have experience, grooving does NOT work! Thank you AGRI-TRAC.

• Reduce cull rates

Providing Permanent Traction forfarmers thatlastsdecades!

Q. Do you have any management recommendations for maintaining healthy somatic cell counts?

A. Another important indicator of quality milk, a lower SCC means improved quality and a longer shelf life for milk.

The easiest way to keep SCC counts low is to keep high SCC cows out of the bulk tank. Here are a few more considerations for managing SCC counts to ensure quality milk production:

• Be sure to pre-strip cows and make this part of routine milking procedures.

AGRI-TRAC gives thecows the Traction they need without being too aggressive on their feet We also like how the floor is easy to scrape and clean.

Mario Vriens Friendly Farms

Over 25 Years Providing Permanent Traction for farmers that lasts decades!

877-966-3546

Arthur, ON

AGRI-TRAC gives the cows the traction they need without being too aggressive on their feet. We also like how the floor is easy to scrape and clean.

James Walker, Walkerbrae Farms Guelph, ON

like how the floor is easy to scrape and clean.

• Use approved iodine based pre and post dips and dry with individual cloth or paper towels.

Providing Permanent Traction forfarmers thatlastsdecades!

James Walker Walkerbrae Farms

• Follow veterinarian recommendations for milking procedures, treatments, culling and purchasing animals.

James Walker Walkerbrae Farms Guelph, ON

Mario Vriens Friendly Farms Arthur, ON

www.agritraction.com

AGRI-TRAC milled our dairy barn floors in August of 2000. 22 years later we just had AGRI-TRAC back to do them again. It lasted 22 Years! We chose AGRI-TRAC both times instead of grooving because it works and lasts. Thank you AGRI-TRAC

Mario Vriens, Friendly Farms, Arthur, ON

www.agritraction.com 1-877-966-3546

877-966-3546

Guelph, ON

www.agritraction.com

• Work with DHI to conduct regular cow sampling and collect individual SCC counts.

• Mark high SCC cows and keep detailed records – this can help identify chronic performers, types of mastitis, stage of lactation, time of year, treatment outcomes, etc.

Q. Can you identify farm management characteristics that produce high-quality milk?

A. Quality milk production relies on management and isn’t dependant on barn style or age. Farmers don’t have to do or know everything – the most successful farmers surround themselves with a team they can rely on and learn from.

Some of the highest quality milk producers invest in a trusted advisory team and utilize tools and resources available. A solid milk quality team can include farm staff, nutritionist, veterinarian, equipment dealer, service technician, accountant, financial lender, and of course a DFO Field Service Representative. Consulting with an advisory team that shares similar values and standards of excellence will also contribute to quality milk production.

Paying attention to every detail and taking a proactive approach to concerns as soon as they arise is also a key management characteristic for producing quality milk. This encompasses everything from animal health to barn and equipment maintenance and means addressing any concerns as soon as they arise. Delaying any issues like faulty equipment, alerts or BactoScan results will only compound problems.

Tidiness and cleanliness can never be overstated when it comes to quality. Farms with high quality milk incorporate equipment and barn cleaning into their daily routines. Their animals are also clean and well bedded.

The drive for continuous improvement is another quality we often see among top quality milk producing farms. This can include anything from being open to trying new practices and technology to adopting the latest research to improve animal welfare, cow comfort or nutrition. Once again, striving for improvement takes a team, and farmers can lean on their farm management advisory team for the latest information, improvements and recommendations.

• MARCH 2024 • WWW.MILKPRODUCER.CA 10 6918 Middlebrook Rd., RR1 West Montrose, ON N0B 2V0 519-669-5772 JEMBROOK WELDING INC. • General Welding • Tank Manufacturing • Repairs

LEADERSHIP AND COMMITMENT TO QUALITY

“Ontario dairy producers meet some of the most stringent milk quality requirements in the world. These Quality Award recipients have demonstrated what it takes to be a true leader in our industry. Congratulations to the winners for this incredible achievement.”

— Mark Hamel, Board Chair

"Congratulations to the winners for raising the bar and achieving the highest standards to become a recipient of this award. DFO is proud to recognize the hard work, persistence and attention to detail you have put into producing high-quality milk every day. Your dedication to your craft and to the industry is exemplary."

— Cheryl Smith, CEO

AT THE 2024 AGM IN JANUARY, the DFO board recognized producer commitment to the production of high-quality milk and industry leadership at the DFO Recognition Dinner.

Five Ontario dairy producers with the best quality scores were recognized for their outstanding commitment to quality, and the DFO Lifetime Achievement Award was presented to Don Johnston, (Cherry Crest Holsteins). Don’s Lifetime Achievement Award was recognized in the February issue of Milk Producer.

In this March issue, we are recognizing our Quality Award winners, who received Gold Quality Certificates for milk shipped in 2022:

• Oasis Acres Ltd. – Suzanna & Albert Westerhof, Jonathan & Jocelyn Westerhof

• Sunnyfield Holsteins – Brent, Susanne & Cal Snoddon

• Campbell Farms – Don & Laurie Campbell

• Slits Dairy Farms Ltd #2 – Maik & Bianca Schapendonk, Pedro & Jolanda Slits

• Zethill Farms Ltd. – Russell & Joyce Zettler, Joel & Alisha Zettler

Both Slits Dairy Farms Ltd. and Zethill Farms Ltd. are recognized for the second consecutive year.

11 WWW.MILKPRODUCER.CA • MARCH 2024 • AWARD WINNERS

ZETHILL FARMS LTD.

Russell and Joyce Zettler & Joel and Alisha Zettler

Q& A

What steps do you take to ensure consistent, high-quality milk production on your farm?

We like to stick to a routine. We’ve found a consistent routine helps to keep our cows clean and happy. Cleaning and maintaining stalls multiple times a day is part of our routine, along with regular equipment cleaning and maintenance.

What is the most important factor that influences milk quality onfarm?

After general cow care and bedding stall maintenance, I believe the next big factor that influences milk quality is teat end health.

What does this award mean to you?

It is an honour to be recognized for the work we put in every day to make high quality milk. Travelling to receive the award, surrounded by our industry and peers also makes it all worth it.

What does quality mean to you?

Milk quality means so much to us. We take pride in the high-quality milk we produce.

What are you most proud of?

We’re proud to have won this award two years in a row and for setting the bar on milk quality in Ontario.

2ND YEAR IN A ROW

Location Hanover, ON, Bruce County

Breed of Cow Milked Holstein

Number of milking cows 58

Farm established 1979 (tie stall) with new robot barn built in 2017

Barn and Parlour

1 Lely A4 Free stall sand bedded

• MARCH 2024 • WWW.MILKPRODUCER.CA 12

Representing Zethill Farms, Joel and Alisha Zettler receive their award from past board chair Murray Sherk and board chair Mark Hamel

WINNER

Visiting Zethill Farms Ltd. is always a pleasure and an “easy” Grade A. Their satisfaction with doing a great job is very evident in their care of the animals and their effort to ensure that their dairy facility appears like they just moved. The attention they give when completing daily tasks transfers easily into the awardwinning milk quality tests. Keeping the milking equipment clean, both inside and out and keeping their cows clean are top priorities. During my last visit when I complimented Russ on the conditions of the dairy facility, he was surprised that every other producer didn’t do the same. Wouldn’t that make an FSR’s job easy. Thank you, Zettler Family!

Betty-Anne Elliott, FSR

13 WWW.MILKPRODUCER.CA • MARCH 2024 •

AWARD WINNERS

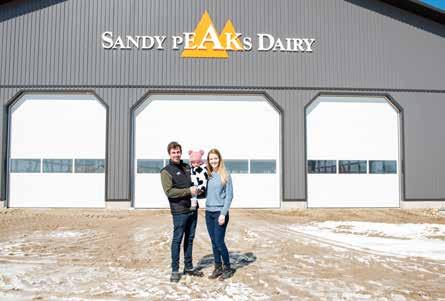

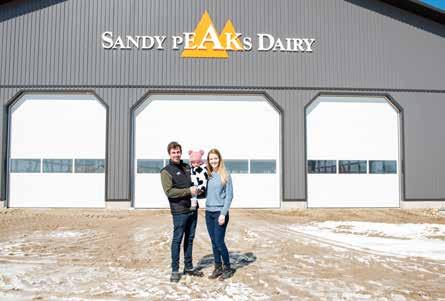

SANDY PEAKS DAIRY LTD.

(SLITS DAIRY FARM #2)

Q& A WINNER

2ND YEAR IN A ROW

Pedro and Jolanda Slits & Maik and Bianca Schapendonk

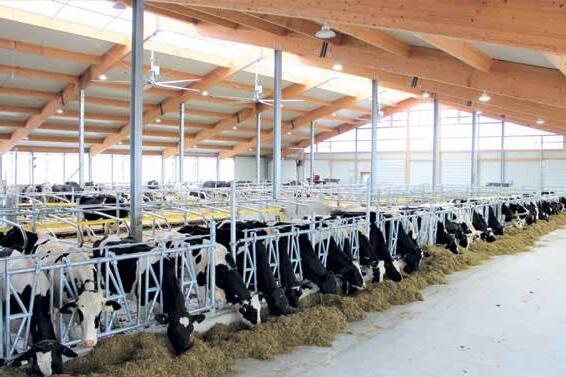

What steps do you take to ensure consistent, high-quality milk production on your farm?

On our farm, quality milk starts with good stall management and high-quality feed. Good stimulation before milking is important, making cow preparation a priority for us at milking. Data analysis also helps us identify the best times to scrape pens and clean stalls and helps us make the most out of our milking preparation and schedules. We also work closely with industry experts to maintain our parlour equipment and milking preparation.

What is the most important factor that influences milk quality on-farm?

We believe parlour set up and milk preparation are the two most important factors in producing quality milk on our farm.

What is your message to consumers about the quality of Canadian milk?

It’s important that as Canadian dairy farmers, we demonstrate how proud we are of our high quality dairy products and the nutrition they provide to everyone, including our own families, friends and local community.

What does this award mean to you?

We have such a passion and love for what we do and this award validates everything we do. This award is also a confirmation of how we set up our barn, proving our decisions have been a success for our cows and the quality milk they produce.

What else do you want people to know about your farm?

We love being a part of such an amazing and supportive industry. We are proud to be part of a community that produces quality milk products. We love what we do, and the opportunity to work with our animals, family and employees means it never feels like a job.

What does quality mean to you?

Quality is a confirmation of the work we put in every day and the standards and procedures we follow in order to provide a highly sought after nutritious product.

What are you most proud of?

Working as a team to build our farm and herd that produces quality products. We’re proud to continuously set standards and challenge ourselves to be better every day, setting an example for our children and sharing our passion for what we do.

• MARCH 2024 • WWW.MILKPRODUCER.CA 14

Location

Brunner, ON

Perth County

Breed of Cow Milked Holstein

Number of milking cows

96

Farm established

2018 as part of Slits Dairy Farms and the Slits family succession plan

Barn and Parlour

Double 12 Parallel

Parlour with Rapid Exit Free stall barn with natural ventilation

AWARD WINNERS

"The Slits family has done it again! What a demonstration of longterm commitment to milk quality in the dairy industry to achieve this award two years in a row. Maik & Bianca Schapendonk alongside Pedro & Jolanda Slits continue to put the daily work in to ensure their operation is clean and tidy and they are milking cows in great health and condition."

Heather McFarlane, FSR

15 WWW.MILKPRODUCER.CA • MARCH 2024 •

Representing Slits Dairy Farms Ltd. #2, Maik & Bianca Schapendonk accept their award from past board chair Murray Sherk and board member Roger Boersen.

OASIS ACRES LTD.

Suzanna and Albert Westerhof & Jonathan and Jocelyn Westerhof

Q& A

What steps do you take to ensure consistent, high-quality milk production on your farm?

Every part of the system must work properly to achieve good results. Producing high quality milk and keeping our cows healthy has always been our goal.

What is the most important factor that influences milk quality on-farm?

When producing high quality milk, consistency in milking times along with udder preparation are important. Properly maintaining milking equipment is important too. Grooming and cleaning the sand stalls (we rake twice a day) has resulted in low somatic cell counts and comfortable cows.

What is your message to consumers about the quality of Canadian milk?

High quality milk tastes great and Canadian consumers need to be able to expect that from Canadian dairy producers when they buy any type of dairy product.

What does this award mean to you?

We know that nothing we do on the farm would be possible without the blessing of God and we are very thankful to Him.

Location

Komoka, ON, Middlesex County

Breed of Cow Milked Holstein

Number of Milking Cows

55

Farm established

Established in 1958 by Albert’s parents and purchased by Albert and Suzanna in 1993. Currently managing a farm succession transition with son Jonathan and his wife Jocelyn

Barn and Parlour

Double 8 parallel parlour with sand stalls built in 2018

• MARCH 2024 • WWW.MILKPRODUCER.CA 16

Representing Oasis Acres Ltd, Albert and Suzanna Westerhof receive their award from past board chair Murray Sherk and board member Vicky Morrison

AWARD WINNERS

The Westerhof’s do an incredible job of managing their dairy operation. Attention to detail in all areas of the dairy operation is easily seen on farm visits going back many years.

The attentiveness they provide consistently from the milkhouse to equipment to animal housing and animal care is easily observed. In 2023 the farm shipped quality milk with an average bactoscan of 3,000 and average SCC of 36,000. They are very deserving of this award. It is evident that milk quality and providing a positive image to the dairy industry is a priority to them. It is a pleasure to work with this producer and observe the pride they take in their business.

Ross Crawford, FSR

CAMPBELL FARMS

Don & Laurie Campbell

Q& A

What steps do you take to ensure consistent, highquality milk production on your farm?

Keeping our cows healthy and comfortable is our top priority. To achieve this, we follow timely and consistent milking procedures, like a pre and post teat dip, pre-strip and use individual towels for each cow. Quality milk production also requires caring for our cows even when they aren’t producing, like dry treating each animal at dry off and maintaining a twomonth dry period.

What is the most important factor that influences milk quality on-farm?

Consistency is key. Especially when it come to the consistency of milking procedures and feeding practices. Being proactive is also important, like regular maintenance of all milking equipment, careful recordkeeping and anything else we can do to reduce routine and production interruptions.

What is your message to consumers about the quality of Canadian milk?

I believe Canadian milk is healthy and nutritious. Consumers should also know that every step of the dairy value chain – from the farmer to the bulk tank grader, right through to the processor – follows strict protocols to ensure consumers can also enjoy the safest milk available. Never cry over spilled milk, just go to the store and buy more!

What does this award mean to you?

I’m extremely surprised that a farm like ours could win this award. Quality is just something we do every day by following our practices and protocols and it’s nice to be recognized for the hard work we do every day.

What else do you want people to know about your farm?

I’m still relatively new to the dairy industry, but I know that nothing happens without the help and support of others. It takes a team and I’m especially grateful for the support of my wife, Laurie, son Ryan, Triple P Consulting and Paris Veterinary Clinic.

Location

Brantford, ON, Brant County

Breed of Cow Milked Holstein

Farm established 2015 – as a participant in the DFO New Entrant Quota Assistance Program

Barn and Parlour Tie stall

• MARCH 2024 • WWW.MILKPRODUCER.CA 18

AWARD WINNERS

The dedication to produce milk with high quality that the Campbell Family demonstrates is outstanding. It is no surprise that their farm ranks at the top of Ontario milk producers for milk quality as they have repeatedly been awarded Gold Seal Awards. Their farm can be found constantly ranked by Lactanet for having one of the lowest SCC averages each year. Congratulations Campbell’s on your recognition!

Wesley Emmott, FSR

19 WWW.MILKPRODUCER.CA • MARCH 2024 •

PROACTION® CELEBRATES 10 YEARS OF ON-FARM EXCELLENCE

A DECADE AGO, dairy farmers decided to proactively create a comprehensive verification program that demonstrates how our sector was meeting the expectations and values of Canadian society when producing high-quality milk. This new program would see Dairy Farmers of Canada (DFC), our partners and farmers build upon a long history of high standards to create the proAction program.

DECADES IN THE MAKING, CONTINUOUSLY IMPROVED

The beginnings of proAction date back to 1997 with a national program for Food Safety. Four years of further development and consultations with dairy farmers, industry specialists, experts and partners culminated with the first national on-farm quality assurance program for Canadian dairy farmers: Canadian Quality Milk (CQM).

CQM was a strong start, designed with checks and balances in place to confirm conformance, transparency and accountability. Over time, demonstrating to Canadian retailers and consumers how dairy farmers responsibly produce food beyond food safety became essential. Dairy farmers and sector experts collaborated with academics and government to develop resources that would encourage continuous improvement on farms beyond food safety – for animal health and welfare, health, biosecurity and the environment. Rules and best practices were also being developed to improve animal identification and traceability.

It became clear that our sector needed to address consumer demands related to knowing where food comes from, what’s in it, and how it impacts the environment before outside agencies imposed such standards on us. With the help of farmers and sector partners, DFC explored an expansion of CQM, broadening its focus to six essential areas: Food Safety, Milk Quality, Animal Care, Livestock Traceability, Biosecurity and Environment. The proAction program had begun.

“As dairy farmers, we are very proud to collectively demonstrate responsible stewardship of our animals and land, sustainably producing milk and meat that are high quality, safe, and nutritious,” said David Wiens, president of DFC and the former chair of the proAction committee. “Treating our animals well, and providing excellent care is one of the highest priorities of the Canadian dairy sector.”

Over the past decade, these six modules brought greater cohesiveness to the program, improving the Canadian dairy sector’s ability to respond to biosecurity threats while demonstrating to Canadians the industry’s place in a sustainable diet. For example, Livestock Traceability helped lead to DairyTrace, a program that saw reports of events like dairy cattle births, movements and tag retirements reach more than 1.3 million in 2023. These reports improve how our industry manages emergencies, ensuring we’ll be in the best position to respond to and manage health threats and food safety issues. The Environment module, the last part of the proAction program to be validated on all farms, included environmental management practices to contribute to long-term success of farms. The final validations were completed in August 2023, marking the implementation of the full proAction program on all dairy farms in Canada.

DFC explored an expansion of CQM, broadening its focus to six essential areas: Food Safety, Milk Quality, Animal Care, Livestock Traceability, Biosecurity and Environment. The proAction program had begun.

• MARCH 2024 • WWW.MILKPRODUCER.CA 20 QUALITY

Livestock Traceability helped lead to DairyTrace, a program that saw reports of events like dairy cattle births, movements and tag retirements reach more than 1.3 million in 2023.

PROACTION HELPS DAIRY FARMERS MEET THE EXPECTATIONS OF CANADIANS

Quality assurance programs are not unique to Canada. As consumer expectations continue to grow, dairy industries around the world are also unveiling programs to help manage those demands. The United States has the National Dairy Farmers Assuring Responsible Management (“FARM”) program, the United Kingdom uses the Assured Food Standards (“Red Tractor”) program for farms, Australia has its Dairy Sustainability Framework, and the International Dairy Federation (IDF) has released several versions of its “Guide to Good Dairy Farming Practice.” Other Canadian livestock sectors have programs or initiatives with a similar range of practices, too.

Most importantly, all these programs, including proAction, exist to assure people that the food they consume is safe and high-quality.

The Blue Cow logo, seen on over 8,700 products from close to 500 brands, stands for proAction and the robust practices of farmers, clearly showing Canadians that they can trust the people and processes behind their favourite dairy products. Food distributors, retailers and restaurants are also interested in seeing proof behind our sector’s claims of quality, safety, sustainability and animal welfare. proAction provides that proof.

“Lactalis Canada and the Blue Cow logo go hand-in-hand, as we both stand for high-quality dairy,” said Gilles Froment, Senior Vice President for Government and Industry Relations at Lactalis Canada. “Our brands benefit greatly from leveraging this iconic symbol underpinned by proAction, the industry’s robust quality assurance and continuous improvement program under which Canadian dairy farmers demonstrate the highest standards in areas such as food safety, environmental sustainability, and animal care.”

By meeting customer expectations in a unified way, proAction helps the dairy sector ensure that all milk produced in Canada, regardless of where it comes from, will be of the highest quality. Throughout all our years of progress, one thing remains the same: your steadfast work as dairy farmers continues to form the foundation of our industry and the high value of dairy for Canadians.

21 WWW.MILKPRODUCER.CA • MARCH 2024 • Product guide 2022 Silage Management Silage Covers Vapour Barrier Silage accessories Twine & Netting 5% EARLY ORDER DISCOUNT UNTIL MARCH 4TH 5259 Hwy 8, Mitchell, ON (519) 393-8290 www.zuidervaartagri.com Visit our website for a dealer near you Megaplast Power Low OTR oxygen barrier • Filled Pea Stone Bags • VH Megastretch 7-layer bale wrap • VH Net Wrap 2,600, 3,000 & 3,600 m/roll SUPPLYING ALL SILAGE NEEDS SIDEWALL TIRES 16 MAX PACK Silage compaction roller The MAX PACK has been specially designed to increase forage compaction to pack silage tighter, increasing storage capacity and silage quality Adjust the weight of MAX PACK by filling the drum with water Provides a raking action to help level the silage The 4 in. high fins help press in silage tight, while solid drum packs Side shift models available Pack better along walls Hydraulically shift the MAX PACK 3 ft left or right for better safety in drive over piles and when silage is high above bunker walls Bump wheels standard on outside of frame to prevent damage to walls and machine Model Side Shift Width Empty weight Filled weight MP 250 SS YES 8 ft 3600 lbs 6750 lbs MP 300 SS YES10 ft 4250 lbs8250 lbs MP 350 SS YES11.5 ft 4625 lbs9250 lbs MP 300NO 10 ft 4250 lbs8250 lbs MP 350NO 11.5 ft4400 lbs 9025 lbs MP 400 NO 13 ft 4750 lbs10000 lbs ExtraWeights56lbseach Equipment Zuidervaart Agri-Import Ltd 519-393-8290 MAX PACK SILAGE COMPACTION ROLLERS Available in 8, 10, 11.5, 13ft widths S ILO- K I NG S ILO- K I NG® Forage & Grain Treatment NEIL WIDEMAN (519) 577-6893 (800) 435-9560 AGRIKING.COM/CANADA 16 DIFFERENT ENZYMES TO PREDIGEST FIBRE MULTIPLE STRAINS OF LACTIC ACID BACTERIA USES ANTIOXIDANTS TO LIMIT RESPIRATION IMPROVE CELL WALL DIGESTIBILITY REDUCES pH FOR A MORE STABLE ENSILING PROCESS

Leading with traceability

For the team at Summitholm Holsteins, traceability is important to build public trust and ensure that our industry can thrive by providing protection, prosperity, and peace of mind. What does traceability mean to you?

Herd management software allows us to easily input our data in seconds, and then it sends the data directly to DairyTrace. ”

Ben Loewith, Summitholm Holsteins (Joe Loewith and Sons

Milking 480 cows in Lynden, Ontario

Meet dairy producers across Canada in our video series as they share why and how they implement traceability on their farm. Scan QR code

view the videos.

“ DairyTrace.ca • 1-866-55-TRACE (1-866-558-7223) • info@DairyTrace.ca

Ltd.)

to

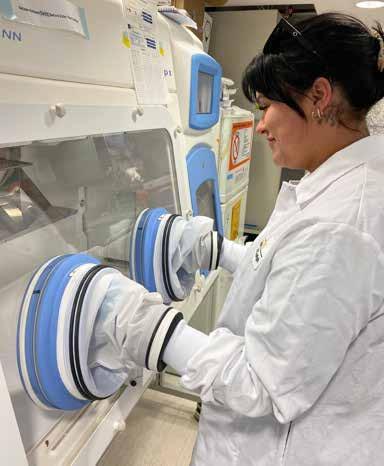

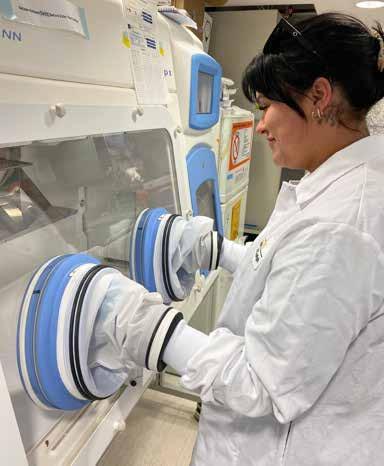

COMBATING BIOFILMS: ENSURING QUALITY MILK FROM FARM TO TABLE

RECENT STUDIES FROM DR. GISÈLE LAPOINTE and her research team at the University of Guelph’s Ontario Agricultural College (OAC) suggest that biofilms – microscopic bacteria that form a thin film inside milking and storage equipment – can be found throughout the milking system.

Biofilms are not always visible to the human eye, and it can be nearly impossible to predict where and when they will occur, especially given the high standards that farms and processors have for maintenance and cleaning procedures. However, the risk to milk quality can be important because of how biofilms can facilitate the growth of other bacteria that lead to spoilage and changes in taste, colour or texture during processing.

“When discovered in the milking system, the bacteria in the biofilm can continuously multiply and release other bacteria into the milk over time, reducing milk safety and quality,” LaPointe says. “Bacteria in the milking system can multiply and spread further into the transport truck and then into the processing facility, causing spoilage defects or general changes in taste and texture of fluid milk, cheese or yogurt.”

LaPointe’s team in the Department of Food Sciences, including Tara Wilson and Yueqi Xi, have been studying the on-farm and processing impacts of biofilms for the last three years.

Xi’s research for her Master’s degree in Food Science investigated the handling of milk at the farm, evaluating how biofilms and other aspects of the environment can influence the raw milk. At the same time, her counterpart Tara Wilson, as part of her PhD degree in Food Science, is studying an on-farm processing facility where milk is made into cheese the next day, allowing a complete study of the ecosystem from start to finish.

“When discovered in the milking system, the bacteria in the biofilm can continuously multiply and release other bacteria into the milk over time, reducing milk safety and quality.”

– Dr. Gisèle LaPointe

23 WWW.MILKPRODUCER.CA • MARCH 2024 •

RESEARCH

“One of the most important things we’re learning about biofilms is how they provide food and protection for bacteria, allowing them to multiply and transfer from water and cows to milking systems and raw milk,” LaPointe says. “Biofilms help create a shared microbial community within and between environments.”

The team’s findings on biofilms have impressed upon them just how important regular maintenance and cleaning are in preventing quality issues throughout the supply chain. Things as simple as water temperature or small deviations to maintenance can allow biofilm to form, quickly resulting in changes that can last until the original problem is identified and treated.

“Biofilms help bacteria survive in the environment, protecting them from harsh conditions where they may even become resistant to disinfectants,” LaPointe explains. “We see that initial higher bacterial load in one part of a milking system can build up, and within a few weeks, that accumulation can move further down the system.”

Because biofilms aren’t always visible to the naked eye until there is significant build up, identifying the problem early is difficult, however, there are things producers can watch out for in specific places to prevent biofilm buildup.

“When biofilms grow so large that they can be seen by the eye, they

The team’s findings on biofilms have impressed upon them just how important regular maintenance and cleaning are in preventing quality issues throughout the supply chain.

are even more difficult to remove,” LaPointe says. “Producers can look out for milk residue in hoses, on the inside surfaces of bulk tanks or receiver jars that are much easier to notice.”

LaPointe notes that the main priority for farmers to manage quality on farm should be to keep up with regular maintenance on equipment, like replacing liners, hoses and any other deteriorating material, and verify and track proper cleaning measures.

This, along with monitoring udder health and milking hygiene, good equipment maintenance, proper cooling, water quality, washing and sanitation practices, all help to maintain excellent milk quality.

This research was supported by a contribution from the Dairy Research Cluster 3 (Novalait, Dairy Farmers of Ontario and Agriculture and Agri-Food Canada) under the Canadian Agricultural Partnership AgriScience Program administered by the Dairy Farmers of Canada, and partly by the NSERC/DFO Industrial Research Chair in Dairy Microbiology held by Gisèle LaPointe.

• MARCH 2024 • WWW.MILKPRODUCER.CA 1-888-231-3575 • CALFHUTCH.COM A Breath of Fresh Air for your Calves Open Air Flex-Pens and DryZone Slatted Flooring Pens available in 5’, 6’, 7’ Depth Options and 36” or 48” Width Options High-grade galvanized front and rear steel panels facilitate excellent air circulation while providing convenient visual access to monitor your calves Pen’s side panel can be removed for paired calf housing • DryZone Slatted Flooring keeps calves dry, improves air flow and saves bedding AGRI-PLASTICS: AN OFFICIAL MILK BAR DISTRIBUTOR Now Carrying the Milk Bar’s Complete Product Range

P5 MESSAGE – MARCH INCENTIVE DAY AND 2024 FALL INCENTIVE DAYS - CONVENTIONAL

By Constantin Urtilescu • MANAGER, GOVERNMENT RELATIONS

Due to a continued higher than usual market demand since the beginning of 2024, the P5 Boards announce one incentive day for the month of March, for conventional producers.

In addition, the P5 Boards announce the following conventional incentive days to be issued on a non-cumulative basis for the fall of 2024: 1 day in August, 2 days in each of the months of September and October, and 1 day in November.

The following table summarizes the incentive days:

Conventional Organic

February 2024 1

March 2024 1

April 2024

May 2024

June 2024

July 2024

August 2024 1

September 2024 2

October 2024 2

November 2024 1

December 2024

The P5 provincial boards’ primary objective is to continuously monitor the milk market situation and meet demand in the most optimal way and will continue to adapt production signals to address market changes, as required.

“Raw milk orders from processors in the P5 continue to be unusually strong since the beginning of the calendar year” says Patrice Dubé, Dairy Farmers of Ontario’s chief economics and policy development officer.

“By putting the incentive days in February and March, we are trying to meet short-term processing needs while keeping an eye on the long-term that still indicates that the P5 production signal may be slightly too strong in relation to the market demand that has to be filled by P5 milk. The P5 Board’s hope is that, for the long-term, overall demand catches up to production in order to avoid any adjustments to the production signal.”

Provincial Boards continue to work with the CDC to try to get the best information possible

on all market segments, especially the hotel, restaurant and institution segments, in order to better understand the overall market trends. CDC is also currently reviewing their long-term forecast which would give the industry a better idea of where things are heading for the rest of the 2024 calendar year.

In January 2024, butter stocks reached 31,340 tonnes, up from December by 3,978 tonnes. January butter stock levels are higher than where they were in January 2023.

Cheese stock levels for the month of January 2024 were at 99,019 tonnes, up 2,259 tonnes from December and slightly lower than where they were in January 2023.

For the 52-weeks ending December 30, 2023, sales for fluid milk, fluid cream, yogurt, ice cream, cheese and butter increased/ decreased by -1.3, -2.3, 3.1, 1.7, 1.7 and -2.3 per cent, respectively, compared with December 31, 2022.

MARCH 2024 • MONTHLY RETAIL MARKETS AND PRODUCTION REPORT •A MARCH 2024

A monthly recap of markets and production trends in Canada and Ontario

CANADIAN REQUIREMENTS AND PRODUCTION

Canadian butterfat requirements in kilograms and actual butterfat production across the P10.

12-month production (in millions of kilograms)

12-month requirements

(in millions of kilograms)

Canadian production has increased by 2.7 per cent over the previous 12 months, and requirements have increased by 1.5 per cent over the previous 12 months.

SOLIDS NON-FAT TO BUTTERFAT (SNF-BF) RATIO

This graph shows Ontario’s SNF-BF ratio for the last 12 months.

January 2024: 2.1429

NATIONAL RETAIL SALES

Average increase in retail sales for dairy products sold in Ontario and the dairy product’s share of the total market sales, including at hotels, restaurants and institutions.

FEBRUARY

HIGHLIGHTS

• Due to a continued higher than usual market demand since the beginning of 2024, the P5 Boards announce one incentive day for the month of March, for conventional producers.

• In addition, the P5 Boards announce the following conventional incentive days to be issued on a non-cumulative basis for the fall of 2024: 1 day in August, 2 days in each of the months of September and October, and 1 day in November.

As of March 26, 2022

* Source: AC Nielsen & StatsCan NOTE: There is a two-month lag in the national retail sales data.

• In January 2024, butter stocks reached 31,340 tonnes, up from December by 3,978 tonnes. January butter stock levels are higher than where they were in January 2023.

• MARCH 2024 MONTHLY RETAIL MARKETS AND PRODUCTION REPORT B DAIRYNOMICS – MARKET UPDATE

950,000 1,000,000 1,050,000 1,100,000 1,150,000 1,200,000 1,250,000 1,300,000 1,350,000 Jan 2023 Feb 2023 March 2023 April 2023 May 2023 June 2023 July 2023 Aug 2023 Sept 2023 Oct 2023 Nov 2023 Dec 2023 Jan 2024

Butterfat (Daily kgs) Requirements Production

422.3 408.2

Ontario SNF:BF ratio

12 MONTHS ENDING FEB 3, 2024 RETAIL SHARE OF TOTAL MARKET Fluid milk -0.70% 81.50% Cream -1.40% 40.90% Cheese 2.80% 54.40% Butter -0.20% 57.60% Ice cream 2.00% 70.70%

3.40% 94.40%

Yogurt

SNF:BF Ratio 2.10 2.15 2.20 2.25 2.30 2.35 Feb 2023 March 2023 April 2023 May 2023 June 2023 July 2023 Aug 2023 Sept 2023 Oct 2023 Nov 2023 Dec 2023 Jan 2024

202401

ONTARIO UTILIZATION

Percentage of the total milk produced in Ontario that was used to produce dairy products.

Fluid Milk & Cream Yogurt and Ice Cream Cheese

Butter & Powders Skim Milk Disposal

January 2024

Fluid milk & cream

Yogurt & ice cream

Cheese

Butter & powders

Skimming

P10 UTILIZATION BY CLASS

For January 2024 (kg of butterfat/kg of solids non-fat)

*There is a two-month lag reporting these figures

Class 1a1 (includes Classes 1a2, 1a3, 1c and 1d for confidentiality reasons) Fluid milk and beverages

Class 1b Fluid creams Class 2a Yogurt, yogurt beverages, kefir and lassi

Class 2b4 (includes Classes 2b1, 2b2 and 2b3 for confidentiality reasons) Fresh dairy desserts, sour cream, milkshakes and sports nutrition drinks

Class 2b5 Ice cream and frozen yogurt

Class 3a1 Specialty cheese

Class 3a2 Cheese curds and fresh cheeses

Class 3b2 (includes Class 3b1 for confidentiality reasons) Cheddar cheese and aged cheddar

Class 3c1 Feta

Class 3c2 Asiago, Gouda, Havarti, Parmesan and Swiss

Class 3c4 (includes Classes 3c3 and 3c5 for confidentiality reasons) Brick, Colby, farmer’s, jack, Monterey jack, muenster, pizza cheese, pizza mozzarella and mozzarella other than what falls within 3d

Class 3c6 Paneer

Class 3d Mozzarella used strictly on fresh pizzas by establishments registered with the Canadian Dairy Commission

Class 4a Butter and powders

Class 4d (includes Classes 4b1, 4b2, 4c and 4m for confidentiality reasons) Concentrated milk for retail, losses and animal feed

Class 5a Cheese for further processing

Class 5b Non-cheese products for further processing

Class 5c Confectionery products

MARCH 2024 • MONTHLY RETAIL MARKETS AND PRODUCTION REPORT •C DAIRYNOMICS – UTILIZATION UPDATE 31% 7% 30% 32% 0%

DECEMBER 2023 JANUARY 2024 12-MONTH AVERAGE Fluid milk & cream 31.3% 31.0% 29.9% Yogurt & ice cream 5.8% 7.1% 7.4% Cheese 28.7% 29.4% 29.0% Butter & powders 29.9% 32.3% 30.8% Skimming 4.3% 0.2% 2.8%

% Butterfat % Solids non-fat

% Revenue 26.36% 8.02% 4.94% 2.33% 0.80% 0.93% 4.77% 14.55% 0.80% 2.53% 8.35% 0.46% 2.76% 15.96% 1.03% 1.66% 3.18% 0.57% -5% 0% 5% 10% 15% 20% 25% 30% 35% 5c 5b 5a 4d 4a 3d 3c6 3c4 3c2 3c1 3b2 3a2 3a1 2b5 2b4 2a 1b 1a1

ONTARIO MONTHLY PRODUCER AVERAGE GROSS BLEND PRICE

A total 3,200 producers sold milk to DFO in January compared with 3,255 a year earlier.

ONTARIO DEDUCTIONS, PER HL

For January 2024

January 2024: $ 97.87

Within quota Overquota

DFO administration $0.675 $0.675

DFO research $0.050 $0.050

CanWest DHI $0.060 $0.060

Transportation $3.940 $3.940

Market expansion $1.400 $1.400

Total deductions $6.125 $6.125

Average total net $86.849 -$6.125

* These figures are based on Ontario’s average composition for January 2024 of 4.3266 kg butterfat, 3.3212 kg protein and 5.9503 kg other solids, rounded to the nearest cent.

P5 AND WESTERN MILK POOL BLEND PRICES

The graph below shows the 12-month blend price for the P5 provinces and Western Milk Pool (WMP).

*There is a two-month lag reporting these figures

WMP: $89.66 P5: $90.05

U.S. CLASS PRICES

The February 2024 Class III Price, US$16.08 per hundredweight, is equivalent to C$49.31 per hectolitre. This equivalent is based on the exchange rate US$1 = C$ 1.35097 the exchange rate when the USDA announced the Class III Price.

The Class III Price is in $ US per hundredweight at 3.5 per cent butterfat. One hundredweight equals 0.44 hectolitres. Canadian Class 5a and Class 5b prices track U.S. prices set by the U.S. Department of Agriculture.

Source: USDA WMP blend price P5 blend price

MONTHLY QUOTA PRICES ($/KG)

* Newfoundland does not operate a monthly quota exchange. Quota is traded between producers.

** Quota cap price of $24,000 in effect in Prince Edward Island, New Brunswick, Ontario, Nova Scotia and Quebec.

Co-ordinated by Dairy Farmers of Ontario’s communications and economics divisions. Questions? Please email questions@milk.org.

STAY UP TO DATE!

Weekly Update email newsletter every Friday for Ontario dairy producers.

Milk Producer magazine is the voice of Ontario dairy producers. Subscribe for free or read online at www.milkproducer.ca.

Dairy Farmer Update provides updates with the monthly milk cheque.

Producer Dashboard , a secure platform behind your password on MMS that contains important news, updates and forms.

www.milk.org

Facebook: /OntarioDairy

Twitter: @OntarioDairy

Instagram: @OntarioDairy

LinkedIn: /company/Dairy-Farmers-of-Ontario

• MARCH 2024 MONTHLY RETAIL MARKETS AND PRODUCTION REPORT D DAIRYNOMICS – PRICES UPDATE $70 $75 $80 $85 $90 $95 $100 $105 Feb 2023 March 2023 April 2023 May 2023 June 2023 July 2023 Aug 2023 Sept 2023 Oct 2023 Nov 2023 Dec 2023 Jan 2024

Blend price in $/hL

*

PRICES PROVINCE PRICE/KG AMOUNT WANTED/KG AMOUNT FOR SALE/KG AMOUNT PURCHASED/ Alberta $ 55,600 457.29 302.52 238.29 Saskatchewan $ 39,000 20.00 63.90 17.00 Manitoba $ 41,000 112.21 124.00 71.00 British Columbia $ 35,500 481.19 79.27 79.27 Ontario $ 24,000 23,874.11 388.70 387.09 Quebec $ 24,000 17,829.50 552.21 552.23 New Brunswick $ 24,000 334.20 4.40 4.40 PEI Nova Scotia $ 24,000 1529.64 4.29 4.29 No Clearing Price Established

FEBRUARY

$76 $78 $80 $82 $84 $86 $88 $90 $92 Feb 2023 March 2023 April 2023 May 2023 June 2023 July 2023 Aug 2023 Sept 2023 Oct 2023 Nov 2023 Dec 2023 Jan 2024

Lochdal Alexandri a, ON Ti est al l F r iedRid Plattsville, ON 1 Rob ot S u n n y Point F Densmore Mills, NS F r e es t a l l Decisions today set pace for tomorrow. 1 800 549 4373 lactanet.ca The dairy farmer of the future holds their herd to a new standard with interconnected technology, consistent management practices, data-driven decision making, and a cow care culture. Contact us. We can help you find your path forward. #2 #3 #8 Future-Proof Your Herd *Based on Herd Performance Index from Lactanet Canada See the full list of Canada's Best Managed Dairy Herds at lactanet.ca Watch the highlights of our celebration on YouTube

Top25recipient 2021, 2022 ,and2023

*

Top 25 rec ipient 2023 *

Top25recipien t 2022 and2023 *

ENHANCING MILK QUALITY WITH FREE FATTY ACID RESEARCH

By Jeanine Moyer

WHAT STARTED AS AN ISSUE WITH MILK FROTHING (or lack of) has quickly developed into insights on how the Canadian dairy industry can improve milk quality.

“Our research started in 2018 when cafes in British Columbia were noticing that milk used to create beverages like lattes and cappuccinos wasn’t foaming properly,” explains doctoral candidate Hannah Woodhouse. “The culprit was high levels of free fatty acids (FFA) in the milk, which is also associated with milk rancidity, reduced shelf life, and inhibited fermentation. We wanted to uncover what farmers can do to prevent high FFA.”

The research to identify the on-farm risk factors was led by the University of Guelph team - Prof. David Kelton, Dairy Farmers of Ontario Dairy Cattle Health Research Chair in the Department of Population Medicine and Hannah Woodhouse.

DFO has already taken a proactive approach to managing FFA by testing levels on all bulk tank shipment samples since August 2018 and provided this information to producers for over a year now. Woodhouse explains that, generally, FFA levels are lower in parlormilked herds than in tie-stall or robotically milked herds.

“If we consider FFA as another milk quality measurement, Ontario producers have already raised the bar and should be recognized for their work in this area.”

• MARCH 2024 • WWW.MILKPRODUCER.CA 30 RESEARCH

To investigate why some herds have higher FFA levels than others, the research team set out to visit 300 farms throughout Ontario and British Columbia. Responses from farmer questionnaires and on-farm visit data were compared to each farm’s bulk tank FFA sample. “We found that multiple factors can contribute to higher FFA levels, which means that there are many ways to reduce FFA,” notes Woodhouse.

FREE FATTY ACID RISK FACTORS

“Many of the contributing factors we found can be addressed with simple management tweaks,” says Woodhouse.

Adding pre-cooling mechanisms like a plate cooler or tube chiller can reduce the need for longer bulk tank agitation periods, preventing FFA and reducing bacteria levels. Woodhouse suggests farmers pay attention to TTR alarms, especially if milk is freezing, a significant contributor to high FFA levels.

Additional risk factors include feeding high levels of supplemental fat, which can directly impact FFA levels. Feeding wet rations, that contain higher levels of butyric acid or are low in protein can also increase the risk of FFA.

Cows milked three or more times a day (especially those in late lactation) could be contributing to higher FFA levels. Woodhouse notes that shorter milking intervals can restrict milk fat globules from forming and strengthening membranes, leading them to be more susceptible to breaking down. “Managing milking permissions for late lactation cows could be a simple solution for farms with robotic milking systems,” says Woodhouse. Another easy fix that could reduce FFA levels is ensuring to always change the milk filter every milking, which is up to three times a day for robotically milked herds.

This project is the only one of its kind in North America, but most of the research results are consistent with findings reported in other areas of the world. However, some of the findings are unique to Canada’s supply-managed dairy system, including the observation of increased FFA levels in the fall during incentive days.

“If we consider FFA as another milk quality measurement, Ontario producers have already raised the bar and should be recognized for their work in this area,” says Woodhouse.

31 WWW.MILKPRODUCER.CA • MARCH 2024 • by Call 306-543-4777 Email ot@otfarms.ca Reducing methane / carbon neutral Land-based ingredient (sustainable) WE’RE AT CDN DAIRY EXPO HALL 2

Research by the University of Guelph shows adding Promix Dry Cow allows for: > Better rumen pH > Less sorting > Higher dry matter intake Adding Promix Dry Cow increases feed intake and rumen health in transition cows. WWW.LIQUIDFEEDS.COM Box #237, Innerkip, Ontario N0J 1M0 1.800.265.8335 For complete research information see: liquidfeeds.com/research/dry-cow-trial-december-2019

TMR SOLUTIONS

Promix Dry Cow

MAXIMIZING THE VALUE OF MALE DAIRY CALVES

By Veal Farmers of Ontario

DAIRY FARMERS PLAY AN IMPORTANT ROLE IN THE VEAL SUPPLY CHAIN. The veal sector continues to strive for responsible antimicrobial stewardship and reducing use, so we rely on dairy farmers to provide calves that are strong and healthy on arrival. Veal Farmers of Ontario has developed a pre-transport checklist to help producers decide if their young calves are ready to leave the farm. You can find it at https://calfcare.ca/is-this-calf-fit-to-ship and we’ll discuss it in more detail below.

Ensuring all calves on the farm receive four litres of high-quality colostrum within six hours of birth, and their first feeding as soon as possible, will improve passive transfer of immunity. Male dairy calves leaving the farm are commingled at a young age before their own immunity kicks in. Stress from transport can also reduce immunity and

Calves leaving the dairy farm should be over 90 lbs. and healthy—this means they are bright, alert, and well-hydrated, and have a normal temperature (38.5°C).

leave the calves more susceptible to disease, making excellent colostrum management essential for every calf on the farm.

Calves leaving the dairy farm should be over 90 lbs. and healthy—this means they are bright, alert, and well-hydrated, and have a normal temperature (38.5°C). Calves should be in good body condition and

• MARCH 2024 • WWW.MILKPRODUCER.CA 32

CALF CARE

have a full abdomen from a recent feeding. Consider the last time the calves will be fed before they reach the veal farm—there may be multiple stops before they reach their final destination, and they could be hungry and dehydrated at the time of sale.

Also consider the calves’ age prior to shipping. According to the Health of Animals Regulations Part XII (Transport of Animals), if the calf is nine days of age or older, it can go to a sale barn or assembly centre. Calves younger than that cannot. Be sure to send records, including birth date and time of last feeding. Calves must also be identified with an approved RFID tag, preferably with the button in the right ear. Many veal farms use automated feeders, which rely on proper tag placement.

The Health of Animals Regulations Part XII (Transport of Animals) have also identified conditions and symptoms that indicate that a calf is unfit and will be more likely to suffer during transport—this includes wet, unhealed navels. Find the full list of conditions at http://vealfarmers.ca/producer-information-2/transportation/. Don’t ship calves that have diarrhea, or wet, unhealed navel.

A University of Guelph study showed that 26 per cent of male calves had a significantly enlarged navel with heat, pain, moisture, or malodorous discharge when examined at arrival to a veal facility. Research

A University of Guelph study showed that

26 per cent of male calves had a significantly enlarged navel with heat, pain, moisture, or malodorous discharge when examined at arrival to a veal facility.

shows that calves with navel infections have a greater risk of dying and lower growth rate. It is imperative to have preventative measures in place, including a clean maternity pen area, excellent colostrum management, and clean and dry bedding for housing calves.

To maximize the returns from male dairy calves, interpret the market signals and focus on the quality of calves being shipped; if they need to stay on the farm longer, consider putting the infrastructure in place to give you the flexibility to do that. Find more information on calfcare.ca.

"Your Ultimate Dairy Handling S olutions" 519-788-3676 | www jakesweldinginc com | Norwich, Ontario

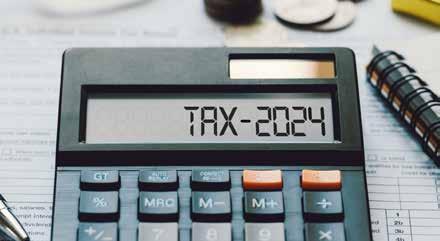

BARE TRUSTS: MANY ONTARIO FARMERS EXPECTED TO HAVE NEW TAX FILING REQUIREMENTS

NEW TAX FILING REQUIREMENTS will have a significant impact on farmers, particularly in Ontario. Many farmers will now find themselves with a new filing requirement based on the common use of bare trust agreements in their operation.

Why do you need to know about bare trusts? Significant changes to the trust filing requirements mean every farmer must now be able to identify their bare trust agreements and meet new T3 filing obligations. Have you added someone or been added by someone to a property such as land, a residence, bank account, or investment account?

Many farmers use this type of planning to facilitate farm operations, but they didn’t need to be too familiar with any bare trust agreements created, until now.

New federal trust reporting rules will come into effect for taxation years ending after December 30, 2023, and knowing how to meet the filing requirements can have lasting impacts on your operations.

The new trust filing and disclosure rules include bare trust agreements which were previously exempt from filing. A bare trust arrangement is a legal relationship where one person (individual/ corporation/ trust) legally owns a property or part of a property but does not have any rights or obligations with respect to the property; the rights and obligations of the property are held in trust for another person.

IMPACT WHEN NEW LEGISLATION TAKES EFFECT

The end of 2023 signals a change to existing reporting requirements for agriculture trusts. Here are a few key things to know for tax years ending December 31, 2023 and later:

• Bare trusts generally exist where the legal ownership (i.e. who is on the title for the asset, but has no rights or obligations) and the beneficial ownership (i.e. who has all the rights and obligations with respect to the asset) are separate. It is important to remember that whether a bare trust exists is a legal determination.

• A trust return must be filed 90 days after year end – usually March 31.

• Penalties for not filing the trust return are $25 per day for each day it’s late to a minimum of $100 and a maximum of $2,500.

EXAMPLES OF COMMON BARE TRUSTS FOR FARMERS THAT WILL NOW RESULT IN A TAX FILING REQUIREMENT

Based on experience with our clients, here are common planning arrangements that can result in bare trust arrangements, which would now be subject to a T3 tax filing requirement:

New federal trust reporting rules will come into effect for taxation years ending after December 30, 2023, and knowing how to meet the filing requirements can have lasting impacts on your operations.

MANAGING LAND TITLE MERGERS

• When two contiguous properties are owned by the same person, municipalities in Ontario will often merge the land titles. It is often inconvenient for estate, succession, and future sale planning when multiple land titles are merged into one. Therefore, a common solution is to ensure the legal ownership is not identical: Property 1 is owned by Farmco, and Property 2 is owned by Farmco (99 percent) and Mr. X (one percent). As the legal ownership is not identical, the two properties will not be merged by the municipality.

• In this scenario, it is still Farmco, the beneficial owner, who holds 100 percent of the rights and obligations with respect to both Property 1 and Property 2: Farmco paid the purchase price, Farmco is responsible for the upkeep, and Farmco is entitled to all proceeds in the event of a sale. Mr. X, the legal owner of a one percent interest in Property 2, can be viewed as a bare trustee with no rights and responsibilities to Property 2. In this case, Mr. X is now required to file a T3 trust return to disclose the bare trust arrangement.

DEFERRAL AND CANCELLATION OF LAND TRANSFER TAXES

• When a farm property is transferred from Corp A to Corp B, both

• MARCH 2024 • WWW.MILKPRODUCER.CA 34 FARM MANAGEMENT

of which are controlled by the same person, it may be possible to apply for a deferral and cancellation of land transfer taxes. If this planning is implemented, a bare trust arrangement can arise, as a bare trust company Corp C (the legal owner) holds title to a farm property for a period of at least three years, in trust for Corp B (the beneficial owner) which received the rights and obligations with respect to the farm property from Corp A. If this is the case, Corp C is now required to file a T3 trust return to disclose this bare trust arrangement.

ESTATE PLANNING

• A common estate planning strategy is to add another person to the title of an asset, whether it is land, a house, or a bank account. There is no desire to transfer the beneficial ownership of the asset to this person at this time, as the intention is to simply allow a smooth administration of an estate. As the additional person added to the title is not a beneficial owner, he or she can be viewed to act in the capacity of a bare trustee in a bare trustee arrangement and is subject to these new filing and disclosure rules.

• It's important to note that whether a bare trust exists is a legal determination. Most bare trust arrangements cannot be easily identified from financial statements or prior years’ income tax returns. It is best to discuss your situation with your financial advisor so that any identified bare trust arrangements and filing requirements can be addressed.

To learn more about how your operation may be impacted by the upcoming changes to filing requirements and the exemptions available, contact Joel Aalbers, Partner, CPA, CGA, Joel.Aalbers@mnp.ca

35 WWW.MILKPRODUCER.CA • MARCH 2024 •

“Farmers know how their farms run, but unexpected things happen. When they do, we can’t always rely on ourselves and our personal knowledge. Critical information needs to be written down.”

– Ryan Dick, Health and Safety Consultant, WSPS

ACCURATE PROCEDURES ARE THE FOUNDATION OF QUALITY WORK

TWO WORKERS ARE OUT IN THE FIELD when one slips and is pulled under the tractor. The other person calls 9-1-1, but when EMS arrive at the farm, they don’t know where on the vast property to find the injured worker.

An experienced farmer is being rushed to the hospital after a sudden heart attack. Surgery and a hospital stay are required, so the farming operation is left to the two new employees who just came on board. They have completed orientation training, but don’t have any experience running a dairy farm.

In both of these scenarios, having well-documented procedures would make a big difference. In the first, if emergency response procedures that outlined field locations and how to access them were in the tractor cab, the worker who called 9-1-1 would have known exactly what to tell EMS. In the second, an employee handbook with step-bystep instructions, along with information about hazards and how to control them, would help the two new workers keep things running safely until the owner returned.

“We often assume everyone on the farm knows as much as we do,” says Ryan Dick, Health and Safety Consultant with WSPS. “Farmers know how their farms run, but unexpected things happen. When they do, we can’t always rely on ourselves and our personal knowledge. Critical information needs to be written down.”

When you go through a task and document the best way to do it, you not only ensure that it will be done the same way each time, but

• MARCH 2024 • WWW.MILKPRODUCER.CA 36

FARM MANAGEMENT

Aeration Improves Composting

Aerated Static Pile Composting

you also reduce the risk of something being missed. “Procedures are key to standardizing the work,” says Ryan. “During the busier seasons when we’re working a lot of hours, it’s easy to forget something or skip a step because we’re rushing and fatigued. Having a procedure to follow helps ensure work is being done safely and with a high-standard of quality.”

Eliminates offensive odours, parasites, and pathogens

Reduces water runoff, Improve soil quality

Aeration Improves Composting

Recycles soil nutrients, balances pH levels

Aeration Improves Composting

Hosts beneficial microbes, retains soil moisture

Compost piles do not require frequent turning

Aerated Static Pile Composting

DEVELOP SAFE WORK AND EMERGENCY RESPONSE PROCEDURES

Easy and cost effective for your waste management

Eliminates offensive odours, parasites, and pathogens

Reduces water runoff, Improve soil quality

Recycles soil nutrients, balances pH levels

“Every farm should have safe work procedures,” says Ryan. He recommends starting with your hazard assessment. “The hazard assessment breaks down the steps involved in a task and indicates where there is risk of injury or illness. Use this information to develop your safe work procedure.”

Hosts beneficial microbes, retains soil moisture

Compost piles do not require frequent turning

Once completed, safe work and emergency response procedures will be useful material to review during orientation and training. As Ryan mentioned earlier, having these details written down ensures nothing is missed when you are bringing new hires up to speed. You could organize the work by season to make sure you are covering all the tasks and associated hazards a worker may encounter at each time of year. “Harvesting is very different work than starting up in the spring,” says Ryan. “When a worker hasn’t performed a task in several months — and when you haven’t trained someone on that task in several months—you don’t want to rely on your memory.”

Easy and cost effective for your waste management

COMMUNICATION IS ONGOING