West River Farm Ltd

Grant & Gene Sache and Families Rosedale, BC 182 Cows MilkingRobot

Emily & Braden Bertens Steve & Teresa MacKay Embro, ON 104 Cows MilkingRobot

Marten & Margriet Bylsma Alma, ON 344 Cows MilkingParlour

Congratulations to top herds who were recognized at the unveiling of Canada’s Best Managed Dairy Herds for 2024 and thank you to everyone who joined the celebration!

See the full list of Canada's Best Managed Dairy Herds at lactanet.ca

Watch the highlights of our celebration on YouTube

PUBLISHED BY

DAIRY FARMERS OF ONTARIO

6780 Campobello Road Mississauga, ON L5N 2L8

MANAGER, COMMUNICATIONS

Sharon Laidlaw sharon.laidlaw@milk.org

ADVERTISING

Pat Logan pat.logan@milk.org 519-788-1559

GRAPHIC DESIGN

Katrina Teimo

CONTRIBUTORS

Sharon Laidlaw, Jeanine Moyer, Hannah Woodhouse, Annik L’Espérance, Maria Kalergis, Sebastian Decap, Dr. Elouise Molgat, Dr. David Kelton, Ryan Dick, Veal Farmers of Ontario,

Canada Post Publications Mail Sales Product Agreement No.40063866.

Return postage guaranteed. Circulation: 8,000. ISSN 0030-3038. Printed in Canada.

SUBSCRIPTIONS

For subscription changes or to unsubscribe, contact: MILK PRODUCER

6780 Campobello Road Mississauga, ON L5N 2L8

Phone: (905) 821-8970

Fax: (905) 821-3160

Email: milkproducer@milk.org

Opinions expressed herein are those of the author and/ or editor and do not necessarily reflect the opinion or policies of Dairy Farmers of Ontario. Publication of advertisements does not constitute endorsement or approval by Milk Producer or Dairy Farmers of Ontario of products or services advertised.

Milk Producer welcomes letters to the editor about magazine content.

*All marks owned by Dairy Farmers of Ontario.

WEBSITES & SOCIAL MEDIA

www.milkproducer.ca

www.milk.org

Facebook: /OntarioDairy

X: @OntarioDairy

Instagram: @OntarioDairy

LinkedIn: dairy-farmers-of-ontario

Recognizing producers for their commitment to consistently produce high-quality

and demonstrate industry leadership.

By Vicky Morrison, Dairy Farmers of Ontario (DFO) Board Member, Region 9, Elgin, Essex, Kent, Lambton, and Middlesex, and Chair of DFO’s Quality Assurance Committee

As we mark Dairy Farmers of Ontario's (DFO) diamond anniversary, I am filled with pride and gratitude for the profound impact our industry has had on consumers, our communities, and the province.

For six decades, my fellow dairy farmers and I have been unwavering in our commitment to producing the highest quality milk, ensuring every Ontarian enjoys the best our farms have to offer. On my own farm, my family and I take great care in every step of the process, from using the latest technology to feeding our cows the best nutrition to maintaining the highest standards of cleanliness and safety.

Commitment to quality is the cornerstone of consumer trust and confidence in our milk supply. At DFO, we take our role as a regulator of milk quality and food safety seriously. From our field services team, raw milk testing, bulk milk tank graders (BTMGs) and tank truck inspections, every touchstone in our industry serves to deliver the highest standards of quality and safety in Ontario milk.

As the regulator and sole delegated authority for the marketing of milk in Ontario, DFO administers the raw milk quality program under the authority of the Ontario Ministry of Agriculture, Food and Agribusiness (OMAFA). This privilege enables our mission to provide leadership and excellence in the production of Canadian milk. It is foundational to DFO’s work, our commitment to maintaining the highest standards of milk quality and food safety, supporting farmers in meeting regulatory requirements and market demands, making sure the milk that consumers buy is safe and of the highest quality, and fostering a collaborative environment among all stakeholders to uphold quality standards.

Recent consultations on proposed amendments to the Ontario Milk Act highlight the importance of the rigorous process and policies that DFO applies in the production of cow’s milk in Ontario. DFO remains fully committed to ensuring our industry in Ontario continues to have the highest food safety standards, compliance and enforcement mechanisms and we will work

closely with OMAFA as they continue to consider amendments to align food safety regulations under a single statute and set of regulations.

Every day, producers work tirelessly to deliver quality milk on-farm. Our dedication is supported by industry stakeholders, OMAFA and the Ontario Farm Products Marketing Commission and, over the years, Canada has benefitted from this industry collaboration in support of an effective supply management system.

Our work continues, and our commitment remains unwavering. DFO and producers will continue to maintain high levels of quality and deliver exceptional milk for the benefit of consumers and Ontarians.

Don’t settle for generic advice. Our workshops provide your family with direct consultations with a team of advisors, including an accountant, lawyer, and financial advisor. Scan the QR code to find a workshop near you. Scan Here

By Emily McDonald, Manager Field Service and Raw Milk Quality, Dairy Farmers of Ontario

Dairy Farmers of Ontario’s (DFO) Field Services Representatives (FSRs) are not only milk inspectors, they are also your support for everything from milk quality troubleshooting to quota questions and paperwork, questions about policies and regulation, and anything else related to DFO and how it applies to your farm. Our 13 FSRs have seen and heard a lot. This column was created to use their collective expertise to share answers to some of the most common questions received.

DAIRY FARMERS OF ONTARIO’S (DFO) milk quality recognition program honors Ontario’s dedicated dairy producers who consistently demonstrate exceptional milk quality. This initiative acknowledges the hard work and commitment of farmers who meet rigorous standards set by DFO, ensuring consumers across the province enjoy fresh, high-quality milk.

Producers who achieve outstanding milk quality are eligible for special recognition through quality certificates. These certificates serve as a symbol of excellence in the dairy industry, reflecting a producer’s dedication to best practices in quality milk production. Farmers are assessed on several factors, such as somatic cell count (SCC), bacterial count, Grade A status, among others. Both the general and gold quality certificate criteria are listed in the table.

The top five dairy producers in the province are recognized every January at DFO’s annual general meeting in January in Toronto, Ont. These producers are celebrated for their exceptional milk quality results, which are the best in the province.

Congratulations to the producers who achieve these goals and collect certificates each year. Their dedication ensures the highest standards in milk quality, benefiting both the dairy industry and consumers.

Quality penalties None None

Bacteria count

Somatic cell count

Average of all tests less than or equal to 20,000 IBC/mL

Annual weighted average SCC less than or equal to 200,000 cells/mL

Average of all tests less than or equal to 10,000 IBC/mL

Annual weighted average SCC less than or equal to 150,000 cells/mL

Production Shipments in January and December Shipments in January and December

Milk rejection

Not responsible for a load rejection at a dairy plant; and No bulk tank rejections by an official grader (BTMG)

Not responsible for a load rejection at a dairy plant; and

No bulk tank rejections by an official grader (BTMG) Farm Premises Grade A at all times during the year Grade A at all times during the year

The T8900 is a compact rotary parlour featuring low-profile stall engineered for fast, smooth cow flow on and off the platform. The low profile cabinet and smooth, rounded stall corners favouring cow comfort and animal movement.

75° angle stall shown. Available also in 90° angle.

BRITISH COLUMBIA

Mountain View Electric Ltd.

Enderby — 250 838-6455

Pacific Dairy Centre Ltd.

Chilliwack — 604 852-9020

ALBERTA

Dairy Lane Systems

Leduc: 780 986-5600

Blackfalds: 587 797-4521

Lethbridge: 587 787-4145

Lethbridge Dairy Mart Ltd.

Lethbridge — 888 329-6202

Red Deer — 403 406-7344

SASKATCHEWAN

Dairy Lane Systems

Warman — 306 242-5850

Emerald Park — 306 721-6844

Swift Current — 306 203-3066

MANITOBA

Tytech

Grande Pointe — 204 770-4898

Scan the QR code and see GEA Next Generation Rotary Parlour at Sterkholm Farms.

ONTARIO

Conestogo Agri Systems Inc.

Drayton — 519 638.3022 1 800 461-3022

Dairy Lane Systems

Komoka — 519 666-1404

Lawrence’s Dairy Supply Inc.

Moose Creek — 613 538-2559

McCann Farm Automation Ltd.

Seeley’s Bay — 613 382-7411

Brockville — 613 926-2220

McLaren Works

Cobden — 613 646-2062

Performance Dairy Centre Inc.

Embro — 519 423-9119

Wood’s Dairy Source

Keene — 705 295-3247

ATLANTIC PROVINCES

Atlantic Dairy Tech.

Charlottetown, PE — 902 368-1719

Sheehy Enterprises Ltd.

Shubenacadie, NS — 902 758-2002

Lower Queensbury, NB — 506-478-4878

Cheryl Smith, CEO

Jeff Hyndman brings a quarter century of field experience, quality and regulatory oversight to the role of Director of Regulatory Compliance (DRC), ensuring continued high-quality milk in Ontario. He is a very welcome addition to DFO’s Executive Team.

FARMERS OF ONTARIO (DFO) is the regulator and sole delegated authority for the production, quality, and marketing of milk in Ontario. In this role, DFO is accountable to the Ministry of Agriculture, Food and Agribusiness and the Ontario Farm Products Marketing Commission.

For 60 years, DFO has ensured that the cow’s milk industry in Ontario has adhered to the highest food safety standards, compliance and enforcement mechanisms. As the designated Administrative Authority, DFO has managed the Provincial Raw Milk Quality Program on behalf of OMAFA since 1998 by implementing Regulations 761.

Ontario maintains high milk quality by enforcing standards at the farm level across the province. Overseeing and managing the safe production of milk in Ontario largely relies on the Director of Regulatory Compliance (DRC) and the ream of highly trained Field Services Representatives (FSRs) and Bulk Tank Milk Graders (BTMGs).

Jeff Hyndman is DFO’s newly appointed Executive Director, Regulatory Compliance & Quality Assurance. In this role, Jeff is responsible for the delivery of the provincial Raw Milk Quality Program. He also leads the entire Production Team.

Jeff’s journey with DFO has been a remarkable testament to his dedication and leadership. Since joining the organization in May 1999 as a

Field Services Representative, he has consistently embodied the values of DFO, demonstrating a strong commitment to the organization and industry. Over the last 25 years, Jeff’s knowledge and expertise has supported numerous initiatives in continuous improvement across production, raw milk quality and assurance while supporting the Field Services Team in the continuous, steadfast delivery of excellence in customer service with quality, testing and measurement programs on-farm, and through the pickup and delivery of milk processes.

Jeff replaces Alex Hamilton who recently retired after 37 years of dedicated and remarkable service for which DFO is extremely grateful.

DairyTrace is working with different partners along the dairy value chain to help everyone seamlessly report events on dairy animals.

Traceability events reported by all dairy value chain participants are vital to a complete traceability system. Our recent collaboration with AssistExpo now provides a great option for dairy shows/fairs to report traceability movements to DairyTrace.

Mackayla DeKwant, DairyTrace Program Manager, Lactanet to meeting with producers at the Canadian Dairy XPO April 2 & 3 at the Lactanet booth!

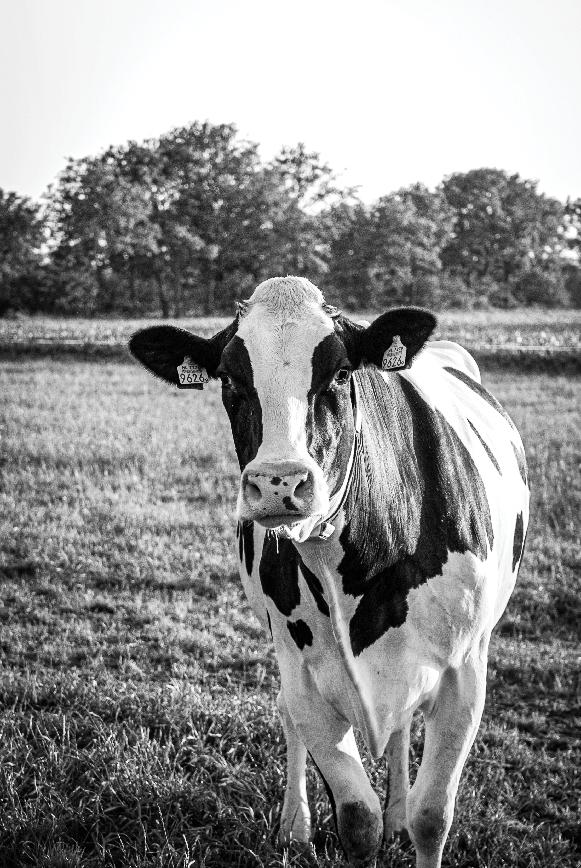

QCANADIAN MILK IS RENOWNED FOR ITS EXCEPTIONAL QUALITY, and Ontario producers are committed to continuous improvement. Achieving the highest standards in milk production starts with good management, consistent farming practices and the health and well-being of cows. Dairy Farmers of Ontario (DFO) staff members, Jeff Hyndman, executive director of regulatory compliance and quality assurance, and Emily McDonald, manager field service and raw milk quality programs, share insights on the practices that lead to high-quality milk, emphasizing the importance of rigorous standards in building consumer trust and ensuring the safety and nutritional value of dairy products.

How do milk quality standards impact consumer trust in dairy products?

Milk quality standards play a crucial role in shaping consumer trust in dairy products. These standards help ensure milk is safe, nutritious and free from harmful contaminants. If consumers trust milk is being consistently tested and meets these standards, they’re more likely to buy dairy products. Rigorous standards in milking practices, storage and transportation also reinforce consumer confidence in the cleanliness and hygiene of milk products. This includes regular inspections of dairy farms.

QWhat role do milk quality standards play in ensuring the safety of dairy products?

Milk quality standards are crucial in ensuring the safety of dairy products because they set guidelines for the quality and safety of milk from the farm to the final product. These standards help prevent contamination, ensure nutritional value and maintain product consistency.

QWhat two or three factors affect milk quality the most?

Hygiene and sanitation: the cleanliness of the milking environment is critical for milk quality. Any contamination from dirt, bacteria or foreign substances during the milking process can degrade milk quality and lead to spoilage. Proper cleaning of milking equipment, cows and the environment helps prevent microbial contamination and ensures milk remains safe for consumption.

Cow health and nutrition: the health of the cows plays a major role in the quality of milk. Sick cows or cows suffering from infections, such as mastitis (inflammation of the udder), can produce milk with lower quality, including higher bacterial counts, increased somatic cell counts or abnormal milk composition. Additionally, a cow’s diet directly affects milk quality. A well-balanced diet ensures the milk contains the right levels of nutrients, including fat, protein and vitamins.

Milk handling and storage: how milk is handled after milking significantly impacts its quality. Factors, such as the temperature at which milk is stored, the speed at which it is cooled and how it is transported, all affect its safety and freshness. Milk must be cooled rapidly (ideally one to four degrees Celsius to prevent bacterial growth). Any delays in cooling or improper storage conditions can lead to spoilage or contamination.

QIn what ways do milk quality standards contribute to the overall health of dairy cows?

Milk quality standards play a key role in promoting the overall health of dairy cows. These standards encompass several areas related to animal care, milking practices and environmental conditions.

Milk quality standards are benchmarks producers use to ensure consistent delivery of raw milk to processors. This results in high-quality and safe products for the growing consumer market, thereby returning economic viability to Ontario dairy farmers.

All milk is held accountable through quality thresholds. Milk is tested for bacteria, somatic cell count, freezing point, inhibitors and premises standards. The raw milk penalty program is designed to enforce quality standards for milk production. The program imposes penalties on producers who fail to meet the required standards. These penalties are intended to encourage producers to adopt better practices to ensure raw milk meets health and safety standards for consumption. In some cases, the penalties can range from fines to suspension of milk pick-ups from non-compliant producers.

How do milk quality standards help in maintaining the nutritional value of milk?

Milk quality standards help maintain the nutritional value of milk by setting limits on contaminants like bacteria, antibiotics and somatic cells. With proper handling, storage and processing practices, consumers receive a consistent and nutritionally balanced product. Regular testing and inspections throughout the production chain, from farm to processing plant, identify and address any issues that could compromise milk quality and nutritional value.

Tell us about the importance of DFO’s authority to set and enforce milk quality standards

The dairy industry’s reputation depends heavily on the quality of the product. By enforcing standards, DFO helps maintain a consistent and high-quality supply of milk, ensuring consumers have confidence in Ontario dairy products. This contributes to the sustainability and growth of the dairy industry.

What measures can dairy farmers take to consistently meet or exceed milk quality standards?

Many farmers follow these practices already and adhere to the code of practice. These standards are highly recommended to run an efficient farm with a healthy herd. Producers should always aim to:

• Maintain cleanliness and hygiene;

• Monitor and manage cow health;

• Implement proper milking techniques that are consistently followed;

• Test and monitor milk quality;

• Implement biosecurity measures and best management practices.

Milk quality standards are crucial in ensuring the safety of dairy products because they set guidelines for the quality and safety of milk from the farm to the final product. These standards help prevent contamination, ensure nutritional value and maintain product consistency.

Additionally, producers are encouraged to stay informed on best practices, new technologies and any changes to milk quality regulations or standards. Participating in industry workshops, seminars and consulting with experts can help improve practices.

And finally, keeping detailed records of milk quality testing, cow health, feed and equipment maintenance helps producers track performance and identify areas for improvement. Producers should consult with their dairy specialists, such as their veterinarians, field services representatives, nutritionists, etc., to identify and implement best practices specific to their farm to optimize milk quality.

#1 ACTIVE “PP” GPA-LPI BULL > +14 CONF (#2 Overall All Bulls) 12/24

Possibly the Most Complete Bull Ever Released! PP – A2A2 BB +14 CONF. +98 KG FAT

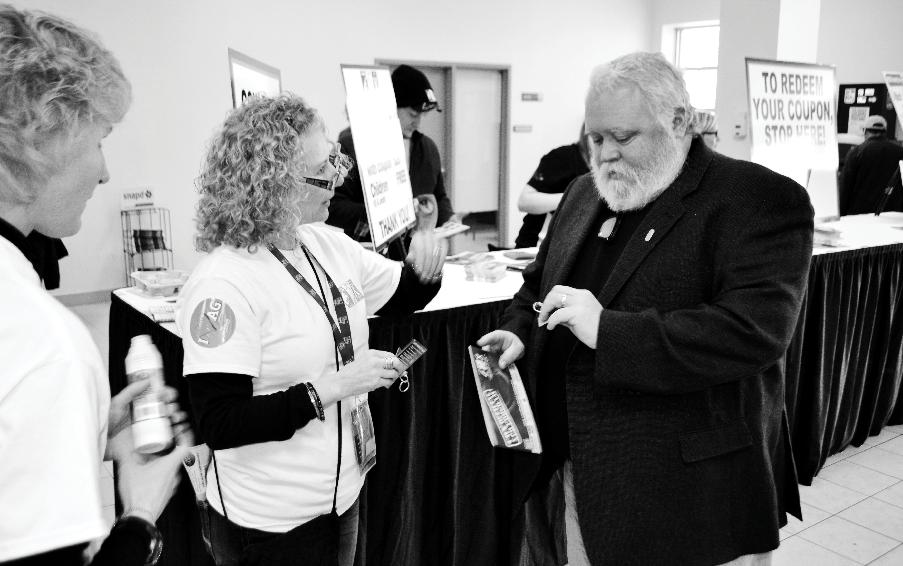

At the 2025 AGM in January, DFO’s board recognized several producers for their commitment to consistently produce high-quality milk and demonstrate industry leadership.

Five Ontario dairy farms with the best quality scores were recognized for their outstanding commitment to quality.

In this issue, we are recognizing our Quality Award winners, who all received Gold Quality Certificates for milk shipped in 2023:

Oasis Acres Ltd.

Albert & Suzanna Westerhof & Jonathan and Jocelyn Westerhof

Free Ridge Farms Ltd.

Brett and Blair Freeman

Tansymoss Farms

Paul & Shawna Chaddock

Zethill Farms Ltd.

Russell, Joyce & Joel Zettler

Midlee Farms

James, Connie, Dave & Trevor McDiarmid

“Ontario dairy producers adhere to some of the world's most rigorous milk quality standards. These Quality Award winners have exemplified what it means to be industry leaders, consistently working to achieve high standards in milk production. Congratulations to all the recipients for this remarkable accomplishment.”

— Mark Hamel, Board Chair

“Congratulations to the award winners for achieving the highest quality standards. Your relentless commitment to excellence and innovative practices is reflected in the high-quality milk your farm produces every day. DFO is proud to acknowledge your dedication, meticulous attention to detail and exceptional contribution to the industry.”

— Cheryl Smith, CEO

Komoka, Ont., Middlesex County 2023 and 2024

Established in 1958 by Albert’s parents and purchased by Albert and Suzanna in 1993. Currently managing a farm succession transition with son Jonathan and his wife Jocelyn.

and parlour

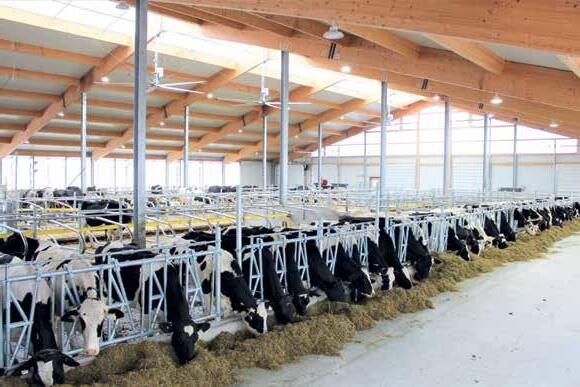

Double 8 parallel parlour with sand stalls built in 2018.

What steps do you take to ensure consistent, high-quality milk production on your farm?

Consistency is a priority for producing high-quality milk. For example, regularly cleaning our sand stalls, keeping consistent milking times and udder preparation are all important. Properly maintaining milking equipment also contributes to milk quality.

What is the most important factor that influences milk quality on-farm?

Our goal has always been to produce high-quality milk and keep our cows healthy. Keeping every part of our milking system working properly is also an important factor to achieving good results.

What is your message to consumers about the quality of Canadian milk?

High-quality milk tastes great, and consumers can consistently expect and rely on this from Canadian dairy farmers when they buy any type of dairy product.

What does this award mean to you?

We know nothing we do on the farm would be possible without the blessing of God and we are very thankful to Him.

What else do you want people to know about your farm?

We are a family-run farm. We hope our children and grandchildren will one day live and work on the farm, too. A farm is a great place for kids to grow up.

Working every day to produce quality milk gives us satisfaction in our work.

Consistency, hard work and God’s blessings on our work.

What do you love most about the dairy industry?

Working with our cows and producing a good, quality product.

“The Westerhofs continue to receive milk Quality Award certificates dating back to the 1990s. Whether they are shipping from their new freestall facility built in 2018 or from the older tiestall barn before that, they continue to concentrate on producing great quality milk. In 2025, their average bactoscan was 3,000 and average somatic cell count was 43,000. They are very humble and don’t think they do anything special. Their attention to detail is built into their daily protocols. For example, on a weekly basis, they check the automatic wash solution pumps confirming the proper amounts are being dispensed. Thank you again for providing a positive image for the dairy industry.”

Ross Crawford – FSR

Oasis Acres Ltd. milk

55 Holstein Cows

Lancaster, Ont., Glengarry County

Farm established In 1982.

and parlour

Double 10 parallel swing-over parlour. Currently renovating to retrofit barn to AMS with four GEA R9500 robots.

What steps do you take to ensure consistent, high-quality milk production on your farm?

Everything is cleaned and well serviced. That includes regularly cleaning stalls and emptying water bowls three times daily. We have a strict milking procedure that ensures everyone follows the same protocol, including an iodine pre-dip and a 4XLA post dip. Any problematic cows are identified with leg bands and the milking unit is sanitized before being attached to the next cow. We also dry treat all animals and use a teal sealant.

“The Chaddocks have consistently demonstrated their commitment to producing high-quality milk for many years, and their attention to detail is evident in every aspect of their farm. It is always a pleasure to visit, and I’m thrilled they’ve been formally recognized for their hard work in producing excellent quality milk. Congratulations to everyone at Tansymoss Farms!”

Karen Thomson – FSR

What is the most important factor that influences milk quality on-farm?

Keeping everything clean. Did we mention cleanliness?!

What is your message to consumers about the quality of Canadian milk?

We are proud of what we do. We also believe Canada produces some of the highest quality milk in the world. We adhere to strict protocols and are transparent about our production methods through programs like proAction. Canadian consumers can rest assured they are receiving a high-quality product.

What does this award mean to you?

This award means all the hard work, time and effort we put in every day has paid off with quality results. We truly appreciate the industry acknowledgement and recognition.

What else do you want people to know about your farm?

We’re grateful to be a family-run business. We farm with two of our six children, Wyatt and Dawson. We’re mindful that it takes our combined efforts to be successful.

What does quality mean to you?

Quality is the result achieved through good management, communication, attention to detail and consistently striving to do better.

What are you most proud of?

We are proud of everything we have achieved over the years. From milking 15 cows in a tiestall barn in 1982 to milking with robots in 2025. Our farm has come a long way over the years.

Tansymoss Farms milk

150 Holstein cows

What keeps you so successful?

We believe it’s our attention to detail and always knowing where the dollars are that contributes to our success as Ontario dairy farmers. We’re open minded, able to self-evaluate, willing to make changes and embrace technology.

What do you love most about the dairy industry?

We love the sense of community and knowing we are nourishing our fellow Canadians with a quality product.

Osgoode, Ont., Carleton County

Farm established In 1997.

Barn and parlour

Freestall, sand bedded barn with double 10 parlour.

Midlee Holsteins milk

125 Holstein cows

What steps do you take to ensure consistent, high-quality milk production on your farm?

Cleanliness and maintenance are key. Our sand-bedded system significantly contributes to the quality of milk we produce. The stalls are raked twice daily, and we bed every two weeks. This helps keep our animals clean and comfortable. Regular maintenance of our milking system is a priority, and our cows are tested on DHI, with higher SCC cows screened and treated as needed.

We believe keeping a closed herd is important and contributes to the health of our animals and the quality of milk produced. Ensuring the cows are naturally clean also influences quality. Our sand bedding helps keep the animals clean and reduces mastitis.

Quality is the most important aspect of the milk we produce. Quality also resonates with consumers more than anything else, and they buy Canadian milk because they know our milk is the highest quality in the world.

What is your message to consumers about the quality of Canadian milk?

“The McDiarmid family continuously strives to improve within the dairy industry through consistent, efficient and effective means. They prioritize cow comfort, animal health and keep a proactive approach working closely with their farm veterinarian. A visit to the McDiarmid’s farm regularly turns into a discussion concerning trending practices, industry news and questions about potential options to improve, demonstrating their dedication and commitment to quality milk and the industry. The family’s proactive and consistent approach to the dairy industry is immediately understood by simply observing their farm as you walk through it. Congratulations to the McDiarmid family on achieving this well-deserved award!”

Adam Lefebvre – FSR

As farmers, we are dedicated and extremely proud of the milk we produce.

It’s nice to be recognized for all our hard work as a family, but especially for our staff. We are all very proud. There aren’t many industries left that do what we do. As farmers, we are an economic driver, and we have the opportunity to produce a high-quality product Canadians are proud to consume.

We are successful because we work as a team and our strengths complement each other. We are also fortunate to work with some amazing employees who care about producing quality milk, too. As farmers, we are privileged to have the land base and resources to continue increasing our production efficiently – Ontario is a great province to milk cows in.

Farm established

In 1979 (tiestall) with new robot barn built in 2017.

Barn and parlour

One Lely A4.

Freestall and sand bedded.

What steps do you take to ensure consistent, high-quality milk production on your farm?

Good stall management is important for producing quality milk. Cleanliness, maintenance and keeping our milking equipment working properly also contributes. We know keeping our cows happy and healthy is key to producing quality milk.

“Thank you Zettler family for your commitment to producing high-quality milk. Successfully making the top five for the last three years shows that your daily routine rarely varies. Giving priority to clean milking equipment, clean and well cared for animals, and a clean dairy facility is the key to your success. It is always a pleasure visiting your farm and checking in with you.”

Betty-Anne Elliott –

FSR

What is the most important factor that influences milk quality on-farm?

The most important factor has to be consistency. Even with the robot, everything we do is based on a routine. Every task is conducted at the same time every day for consistency.

What are you most proud of?

We are proud of being quality award winners for three years in a row. Winning this award demonstrates we are consistently consistent in our efforts to produce high-quality milk.

Zethill Farms Ltd. milk

55 Holstein cows

By Sharon Laidlaw, Communications Manager, Dairy Farmers of Ontario

At the core of Ontario’s thriving dairy industry, bulk tank milk graders (BTMGs) play a pivotal role in maintaining the highest standards of milk quality. These dedicated professionals are essential partners in the dairy supply chain, working diligently to grade, sample and transport milk from farms to processors across the province, says Jeff Hyndman, Dairy Farmers of Ontario’s (DFO) executive director, regulatory compliance and quality assurance.

DFO has established a rigorous program for the vehicles and drivers within its transportation system. This program is a main reason Ontario milk and dairy products are recognized globally for their exceptional safety and quality.

The role of a BTMG is clearly defined in Regulation 761. Only certified BTMGs are authorized to accept, grade, reject, measure, sample and transfer milk from a farm bulk tank to a tank truck. This certification process is rigorous, requiring comprehensive training and examinations to ensure all BTMGs are well-equipped to perform their duties effectively.

The grading process carried out by BTMGs is a critical step in ensuring quality milk leaves the farm. They are important to the process and give legitimacy to the samples collected by following strict procedures. Their role and responsibilities are far reaching. This meticulous process begins the moment a BTMG arrives at a dairy farm, says Joanna Yalcinkaya, DFO’s program manager, raw milk quality. They start by grading milk through sight and smell, assessing its initial quality. This visual and

olfactory inspection is crucial in identifying any immediate issues that could compromise milk’s quality.

Next, the BTMG measures the volume of milk in the farm bulk tank and then agitates the tank for at least two minutes before collecting a sample. This agitation ensures milk is thoroughly mixed, providing a representative sample for testing. Milk’s temperature is also checked after agitation to ensure it meets the required standards. These steps are not just routine tasks; they are essential in assessing the quality of raw milk before it is transferred into the tank-truck, Yalcinkaya notes.

“BTMGs are the first step in the grading process. The plant milk grader at the plant will also grade the milk by sight and smell and has the authority to reject the milk,” she says. “We oversee approximately 650 BTMGs, some new to the industry and some who’ve been doing this important task for many years. What is consistent with all of them is the commitment to serve the industry well by ensuring quality service between the producers they represent and our customers—the dairy processors of Ontario.

Becoming a BTMG involves a detailed training process. Prospective BTMGs start as apprentices employed by milk transport companies. They undergo a comprehensive training course focusing on milk grading, sampling, measurement and related regulations. To earn their certification, apprentices must pass both written and practical examinations and every five years, BTMGs must complete a renewal course to maintain their certification.

As we celebrate the excellence of Ontario’s dairy producers in producing milk of the highest quality, we also recognize the invaluable contributions of BTMGs in helping maintain the highest standards in milk production.

— Jeff Hyndman

“BTMGs are the link between producers and processors. They are required to interact with both bodies and must do so in a professional and consistent manner,” Hyndman says. “DFO trains and licences BTMGs and processors rely on them to grade properly to ensure the milk they receive meets quality standards.”

This collaboration ensures any potential problems are identified and resolved promptly, maintaining the high standards expected in Ontario's dairy industry.

DFO’s mandate in maintaining high milk standards

Maintaining high-quality milk is an important component of DFO’s mandate as the regulator and sole delegated authority for marketing milk in Ontario. DFO’s mission is to provide leadership and excellence in the production of Canadian milk and is dedicated to maintaining rigorous raw milk quality and food safety standards. As such, DFO examines and certifies qualified BTMGs to conduct their duties with care and diligence and has the authority to ensure all BTMGs adhere to the policies and regulations set out with respect to carrying out their duties.

The work of BTMGs is vital in maintaining consumer trust in dairy products. Their efforts help sustain the economic viability of dairy farms and ensure consumers continue to enjoy fresh, high-quality milk, Hyndman says..

PACKED WITH A HIGHER CONCENTRATION OF IGG, IMMUNOLIFE | 200 IS THE ULTIMATE CHOICE FOR YOUR CALVES' HEALTH AND VITALITY

“As we celebrate the excellence of Ontario’s dairy producers in producing milk of the highest quality, we also recognize the invaluable contributions of BTMGs in helping maintain the highest standards in milk production,” Hyndman says.

Insights from the Future Performance Research Centre in Every Bag

Using Food Quality Casein Rich Skim Milk Powder to Improve Overall Health and Growth

100% Canadian Skim to Support the Canadian Dairy Industry

Prebiotics to Support Overall Health

Enhancing Absorption with Organic Minerals

Precision Feeding with Mapleview Agri

Improving Fat Mobilization with Emulvion

Balancing Medium Chain Fatty Acids for Better Health

DFO marketing tells our compelling “local” story to consumers through our farmer equity work. This work aims to highlight the dedication of Ontario farm families by showcasing their care and commitment to producing high-quality milk.

The majority of Canadian consumers trust the food and agriculture industry, with

82%

having a positive perception of the quality of food produced in Canada and

88%

finding it trustworthy.

86%

DFO's farmer equity marketing campaigns emphasize the care and quality behind Ontario milk, driving positive perceptions and a higher likelihood of dairy consumption among viewers. of Canadians seek locally produced food, and

68%

look for food produced using environmentally sustainable methods, showing strong support for local economies and sustainable practices.

Through our equity work, we focus on driving consumption by telling the story of hardworking local farm families and our standards of delivering high-quality milk

Over the past several years, DFO marketing has leveraged a variety of media tactics to tell this story ranging from TV, video, out of home, digital audio, PR, influencers and social media.

DFO aims to connect Ontario consumers with local Ontario dairy farmers through shared values and a love for milk. We are doing this by reminding Ontarians of the care and love our local dairy farmers put into producing high-quality milk for everybody. Our campaigns drive home the message Ontario milk is produced with care by more than 3,100 local dairy farming families across Ontario, who are connected to our communities through shared values and a universal love of milk.

Since 2019, DFO marketing has been, telling the story of our farmers through our “Farmer Equity campaigns”. These campaigns have highlighted various farm families to strengthen dairy industry perceptions of local, highquality and care, with the goal of increasing milk consumption. Through a variety of creative assets and content over the past years, the campaigns continue to build an emotional connection between Ontario dairy farmers, milk and consumers by reminding Ontarians of the love dairy farmers have for milk and everything that goes into making it.

our

After watching the ad:

85% of Ontarians agree Ontario dairy farmers take pride in what they do.

83% of Ontarians agree Ontario dairy farmers are passionate about what they do.

83% of Ontarians agree Ontario dairy farmers produce milk for everyone.

Recallers of the ad report a 17% increase in their perceptions of “quality” +14%

increase in their perceptions of “local” and +13% increase in their perceptions of “care”

Additionally, these recallers report a 13% increase in their likelihood to consume more dairy after watching the ad.

Based on these strong results, “Set the Table” will air again as part of the upcoming Spring Equity campaign (March 24 – June 1), alongside refreshed social and out-of-home assets that showcase local, highquality milk produced by Ontario dairy farmers for everybody.

The markets are still very strong and P5 quota for the last calendar year (2024) has been leaning toward the Canadian Dairy Commission’s (CDC) optimistic model, with a 2.3 per cent actual quota growth versus a 2.6 per cent forecast growth for 2025.

P5 butterfat production is also very strong and forecasted to continue to be 1.5 per cent higher in 2025 than in 2024. As a result, butter and cheese stocks are relatively high for this time of year, respectively reaching 36,300 and 101,400 tonnes in January 2025. It is worth noting the current January butter stocks level is already equivalent to the highest level that is

normally observed in the months of June or July.

P10 and P5 are currently facing a significant challenge with butter stocks continuously increasing while both Ontario and Quebec, but mostly Quebec, are having difficulties meeting all processors’ orders, especially during weekdays. This situation could be explained, at least in part, by the high butterfat level in farm raw milk. This significantly reduced the overall milk volume necessary to fill P5 quota, resulting in a gap between milk orders and milk available to satisfy solids nonfat needs, with the resulting butterfat surplus ending up in butter stocks.

“The CDC and provincial boards are further investigating the market dynamic to better understand where to go next,” says Patrice Dubé, Dairy Farmers of Ontario’s chief economics and policy development officer. “This investigation will hopefully help us understand if an adjustment to the production signal, one way or the other, is required. The main objective will always be to appropriately fill all of the P5 market.”

For the 52-weeks ending Dec. 30, 2024, sales for fluid milk, fluid cream, yogurt, ice cream, cheese and butter increased by 0.3, 2.0,4.1, 1.5, 2.5 and 4.5 per cent, respectively.

Canadian butterfat requirements in kilograms and actual butterfat production across the P10.

12-month production (in millions of kilograms)

12-month requirements (in millions of kilograms)

Canadian production has increased by 2.5 per cent over the previous 12 months, and requirements have increased by 2.9 per cent over the previous 12 months.

NATIONAL RETAIL SALES

Average increase in retail sales for dairy products sold in Ontario and the dairy product’s share of the total market sales, including at hotels, restaurants and institutions.

This graph shows Ontario’s SNF-BF ratio for the last 12 months.

As of March 26, 2022

* Source: AC Nielsen & StatsCan NOTE: There is a two-month lag in the national retail sales data.

• The markets are still very strong and P5 quota for the last calendar year (2024) has been leaning toward the Canadian Dairy Commission’s (CDC) optimistic model, with a 2.3 per cent actual quota growth;

• P5 butterfat production is also very strong and forecasted to continue to be 1.5 per cent higher in 2025 than in 2024;

• For the 52-weeks ending Dec. 30, 2024, sales for fluid milk, fluid cream, yogurt, ice cream, cheese and butter increased by 0.3, 2.0,4.1, 1.5, 2.5 and 4.5 per cent, respectively.

Percentage of the total milk produced in Ontario that was used to produce dairy products.

For January 2025 (kg of butterfat/kg of solids non-fat)

*There is a two-month lag reporting these figures

% Solids non-fat

Fluid Milk & Cream

Butter & Powders

Yogurt and Ice Cream Cheese

Skim Milk Non Marketed

January 2025

Class 1a1 (includes Classes 1a2, 1a3, 1c and 1d for confidentiality reasons) Fluid milk and beverages

Class 1b Fluid creams Class 2a Yogurt, yogurt beverages, kefir and lassi

Class 2b4 (includes Classes 2b1, 2b2 and 2b3 for confidentiality reasons) Fresh dairy desserts, sour cream, milkshakes and sports nutrition drinks

Class 2b5 Ice cream and frozen yogurt

Class 3a1 Specialty cheese

Class 3a2 Cheese curds and fresh cheeses

Class 3b2 (includes Class 3b1 for confidentiality reasons) Cheddar cheese and aged cheddar

Class 3c1 Feta

Class 3c2 Asiago, Gouda, Havarti, Parmesan and Swiss

Class 3c4 (includes Classes 3c3 and 3c5 for confidentiality reasons) Brick, Colby, farmer’s, jack, Monterey jack, muenster, pizza cheese, pizza mozzarella and mozzarella other than what falls within 3d

Class 3c6 Paneer

Class 3d Mozzarella used strictly on fresh pizzas by establishments registered with the Canadian Dairy Commission

Class 4a Butter and powders

Class 4d (includes Classes 4b1, 4b2, 4c and 4m for confidentiality reasons) Concentrated milk for retail, losses and animal feed

Class 5a Cheese for further processing

Class 5b Non-cheese products for further processing

Class 5c Confectionery products

ONTARIO MONTHLY PRODUCER AVERAGE GROSS BLEND PRICE

A total 3,157 producers sold milk to DFO in January compared with 3,200 a year earlier.

For January 2025

The graph below shows the 12-month blend price for the P5 provinces and Western Milk Pool (WMP).

*There is a two-month lag reporting these figures

$96

$94

$84 $86

$82

January 2025: $ 102.89 WMP: $92.42 P5: $92.26

* These

The February 2025 Class III Price, US$20.18 per hundredweight, is equivalent to C$66.28 per hectolitre. This equivalent is based on the exchange rate US $1 = C$ 1.44675 the exchange rate when the USDA announced the Class III Price.

The Class III Price is in $ US per hundredweight at 3.5 per cent butterfat. One hundredweight equals 0.44 hectolitres. Canadian Class 5a and Class 5b prices track U.S. prices set by the U.S. Department of Agriculture.

Source: USDA

Co-ordinated by Dairy Farmers of Ontario’s communications and economics divisions. Questions? Please email questions@milk.org.

STAY UP TO DATE!

Weekly Update email newsletter every Friday for Ontario dairy producers.

Milk Producer magazine is the voice of Ontario dairy producers. Subscribe for free or read online at www.milkproducer.ca.

Dairy Farmer Update provides updates with the monthly milk cheque.

Producer Dashboard , a secure platform behind your password on MMS that contains important news, updates and forms.

www.milk.org

Facebook: /OntarioDairy

Twitter: @OntarioDairy

Instagram: @OntarioDairy

/company/Dairy-Farmers-of-Ontario

Use the Goldilocks approach for milk temperature to reduce free fatty acids

By Hannah Woodhouse, PhD in Epidemiology at the University of Guelph

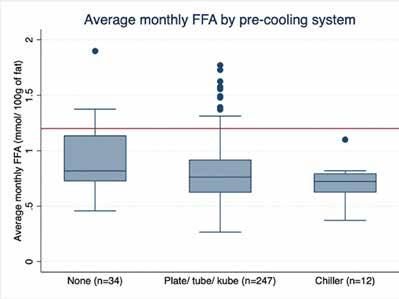

can play havoc on increasing free fatty acid (FFA) content. Free fatty acid concentrations above 1.20 millimole (mmol) per 100 grams of fat result in poor milk quality that directly impacts processors and consumers. A few of these quality concerns include impaired milk foam formation and stability (for specialty coffee), cheese coagulation issues, increased milk rancidity and reduced shelf life.

Free fatty acids are products of milk fat breakdown caused by stress on milk. That stress can be physical (excessive handling of milk) or enzymatic (coming from naturally occurring milk enzymes or bacteria). Mitigation begins at the farm level.

University of Guelph research has identified milk temperature to significantly impact the FFA content in bulk tank milk. Ensuring milk is neither too warm nor too cold is important.

Fresh, warm milk is the perfect environment for exponential bacteria growth. Bacterial enzymes can break down milk fat, resulting in FFA. Research detected an association between increased milk bactoscan levels and elevated FFA.

Some of the time temperature recorder (TTR) alarms that can indicate milk is too warm and at risk of high FFA levels include “slow cooling” and “high blend temperature.” A study looked at Ontario farms with TTR alarms and compared milk FFA levels between an alarm-associated pick up and a pick up without an associated TTR alarm. Higher FFA levels were observed when a “slow cooling” or “high blend temperature” TTR alarm occurred.

An efficient pre-cooling mechanism (such as a plate cooler, tube cooler or chiller that reduces milk temperature to below 20 degrees Celsius) can help prevent these TTR alarms and reduce elevated FFA risk. By cooling milk before it reaches the bulk tank, the tank cooler and agitator will work less. This can decrease the number of bacterial enzymes and reduce physical stress on milk to keep milk fat globules more intact.

On the other hand, milk that is too cold (<0.5°C) could be even more detrimental to FFA levels than milk that is too warm. Freezing milk expands the milk fat globules to the point of irreversible damage, resulting in the release of FFA.

Research observed the average FFA concentration for milk pick-ups associated with a “milk too cold” TTR alarm to be elevated (average of 1.31 mmol/100 g of fat). Seventy-four per cent of these observations came from farms without pre-cooling, and they were associated with 0.30 mmol/100 grams of fat higher FFA levels than farms with pre-cooling. Farms without pre-cooling may be more likely to turn on the bulk tank cooler right away to prevent a “slow cooling alarm.” However, milk may not have reached the agitation paddles, increasing freezing risk.

Farms with automated milking systems or smaller herds with a large bulk tank are also at increased risk of milk freezing. This is because sufficient milk volume can take a while to reach the agitation paddles.

Ultimately, monitoring milk temperature by paying attention to TTR alarms can be helpful in preventing elevated FFA. Waiting until milk reaches the agitation paddles before turning on the bulk tank cooler is important since freezing milk can increase FFA levels substantially. Consideration of a pre-cooling mechanism could be an impactful step to not only reduce FFA levels, but also bacteria levels and energy outputs on the farm.

Figure 2: A University of Guelph study on herds in Ontario and British Columbia observed lower FFA levels on farms with pre-cooling mechanisms (by an average of 0.16 mmol FFA/ 100g of fat).

The red line indicates the FFA sensory threshold of 1.20 mmol/100 grams of fat, and boxes represent each category’s observation range, with dots representing outliers. Note that farms with an average monthly FFA above 2.0 mmol/ 100 grams of fat (n=5) are not displayed.

— Nick Thurler

“We are using Udder Comfort™ since it rst came out. I think we were the very rst customers,” says Nick Thurler of Thurler Farms, Inc. Nick and his sons Robert and Michael operate the dairy, milking 480 to 500 cows. His sons are the third generation. Today, they are also involved in manure to biogas.

“Udder Comfort softens and soothes the udders. When we see a cow that needs it, we put it right on, right away, and things get better. We also like the blue color. Other milkers see it and pay more attention to that cow,” Nick explains.

“We tried other products, but they didn’t seem to work. Udder Comfort works,” Nick adds.

By Dairy Farmers of Canada

SINCE THE RELEASE of the new and updated Code of Practice for the Care and Handling of Dairy Cattle, Dairy Farmers of Canada (DFC) and the proAction committees have been working diligently to incorporate the new requirements into the proAction program.

The proAction animal care technical committee has invested many hours through both in-person and virtual meetings, and the food safety and biosecurity technical committees have also met to discuss changes to their respective module requirements. DFC combined the results of all the committee discussions and developed a draft farmer reference manual, validation protocol and other supporting documents.

Due to the large volume and complexity of changes, the proAction committee determined a full onfarm pilot was critical to ensure successful implementation, including clear requirements, consistent validation and buy-in from Canadian farmers. This decision impacted implementation timelines since a pilot takes time, so DFC is targeting implementing the package of new requirements in April 2027.

The pilot project will determine whether this specific calculator, called the Cool Farm (CFT), will provide accurate measurements within the Canadian dairy landscape, paint an accurate picture of our sector’s sustainability and assess its ease of use.

Together with provincial organizations, DFC launched the on-farm pilot in December 2024, and it will run until spring 2025. DFC will seek feedback from farmers, provincial staff, validators and veterinarians, and the proAction committees will evaluate results and consider revisions if needed.

DFC is confident the April 2027 implementation of the new Code of Practice for the Care and Handling of Dairy Cattle will provide the best chance for successful implementation of the new requirements that will benefit farmers, the Canadian dairy industry and consumers.

Many Canadian dairy farmers want to measure their carbon footprints to learn how they can take practical, individual action toward a more sustainable sector. To this end, DFC and provincial marketing boards are proud to announce the launch of a pilot project to test an on-farm greenhouse gas (GHG) emissions calculator.

The pilot project will determine whether this specific calculator, called the Cool Farm (CFT), will provide accurate measurements within the Canadian dairy landscape, paint an accurate picture of our sector’s sustainability and assess its ease of use. The CFT is designed to help measure a farm’s carbon footprint, provide farmers with data and help them customize environmental plans and increase efficiencies.

Forty farms across Canada have volunteered to test this tool over the next year. These participants will benefit from the knowledge of CFTcertified advisers for ongoing technical support, assessment completion and advice on how to turn results into an implementation plan that aligns with best management practices. Farmers will then evaluate their complete experience, including the CFT’s usefulness and ease of use.

The pilot project will determine if the CFT provides accurate insights for Canadian dairy farmers; for instance, understanding where energy and transport emissions are highest can help farmers improve efficiencies and lower costs. Data from the project will then be compared with DFC’s life cycle assessment results and used to identify the most significant areas of on-farm emissions contributions. While the pilot project’s focus is on carbon footprints, farmers can also use the CFT to voluntarily explore other desired sustainability projects, including identifying hotspots and mitigating risks beyond greenhouse gas emissions, such as water conservation and soil health.

Both pilot projects have been made possible through Agriculture and Agri-food Canada funding via the Sustainable Canadian Agricultural Partnership.

Where the science of nutrition meets accurate

a

By Jeanine Moyer, Annik L’Espérance, Maria Kalergis, Dairy Farmers of Canada

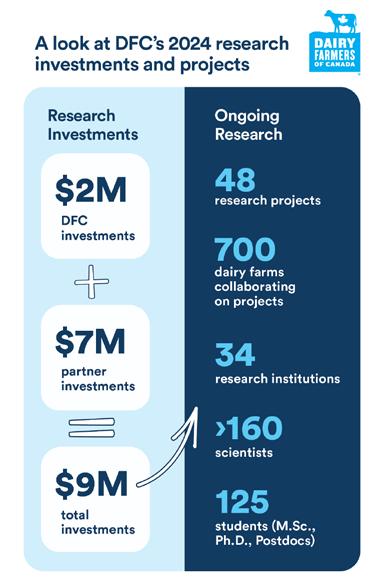

EVERY YEAR, Dairy Farmers of Canada (DFC) invests in scientific research to advance the future of the dairy industry.

In 2024, DFC invested $2 million in human nutrition and health, as well as dairy production research, along with an additional $7 million that was leveraged through grant opportunities and partnerships. DFC supports research programs targeting investment priority areas and outcomes of the National Dairy Research Strategy.

Each year, DFC publishes the Research Highlights report featuring information on research investments, progress and developments from ongoing projects. The 2024 report includes results and updates from a selection of human nutrition and health research projects. It contains information about the pursuit of evidence-based health claims for Canadian dairy products, validating the superiority of dairy as an optimal protein source, the public health benefits of adding dairy to the diet and dairy’s role in bone health.

Learn more about DFC’s commitment to research and innovation in the 2024 Dairy Farmers of Canada’s Research Highlights report by scanning the QR code on page 36.

Here’s a look at some of the ambitious, forward-thinking projects and ongoing studies featured in the 2024 report:

Validating dairy’s role as a complete and superior protein source:

Project Proteos is a major international research project led by renowned protein expert, Paul Moughan from Massey University in New Zealand and collaboratively funded by a consortium of food-based organizations and brands, including DFC. The project focuses on developing an advanced understanding of protein quality across various sources, including dairy, using the Food and Agriculture Organization of the United Nations (FAO) recommended method: digestible indispensable amino acid score (DIAAS). This method offers a more accurate assessment of the nutritional value of proteins in human diets than previous methods.

Currently, protein quality in the United States and many other countries is assessed using the protein digestibility corrected amino acid score (PDCAAS) method. The concern with this method is it underestimates the quality of animalbased protein foods and overestimates that of plant-based protein foods.

While the FAO recognizes the DIAAS method is ideal for assessing protein quality, more published data is required before adopting this as the main method for assessing protein quality. Project Proteos aims to address this research gap, which will help facilitate adoption by the FAO and other jurisdictions.

Dairy’s role in preventing bone fractures and falls in aged care: key findings from the fractures trial

A pivotal research study has shown increasing dairy intake in aged care settings can have a profound impact on reducing bone fractures and falls while improving nutritional intakes. The project, conducted by a research team at the University of Melbourne, found by incorporating more milk, cheese and yogurt into their daily diet, elderly individuals can strengthen their bones and muscles, ultimately improving their quality of life and reducing healthcare costs associated with fractures and falls.

The study was funded by Dairy Australia and members of the dairy research consortium, including DFC.

While the FAO recognizes the DIAAS method is ideal for assessing protein quality, more published data is required before adopting this as the main method for assessing protein quality.

In the Know is a training tailored to the agricultural community that increases understanding of mental health and wellness, normalizes conversations about mental health, and reduces stigma.

Estimated economic and health impact of low dairy consumption

University of Saskatchewan researchers are investigating how dairy consumption impacts the development of cardiovascular disease (CVD) and osteoporosis in Canada. Both conditions share common risk factors, including poor diet, particularly low dairy intake.

Recent changes in Canada’s Food Guide, which removed dairy as a food group, have raised concerns about potential health and economic consequences. This research project aims to address two critical gaps in Canadian public health knowledge:

1. What is the impact of low consumption of dairy products on CVD and osteoporosis from a health economics perspective in the Canadian context?

2. How does optimal intake of dairy influence the development of CVD and osteoporosis?

This study could play a pivotal role in shaping Canadian dietary guidelines and public health initiatives, particularly around dairy promotion. By providing evidence-based recommendations, the research team hopes to encourage healthier dietary habits that reduce the risk of chronic diseases like CVD and osteoporosis. In doing so, this research underscores the value of dairy as a key component of a diet that supports long-term health and economic sustainability.

• Reinforced pump head

• Gate valves all around

• Twin short agitation nozzle with position indicator

• Stainless steel nozzle ball joint

• Thicker sprocket and motor mount

• Inline cooling pump (no more belt)

• New oil cooling reservoir bolted on the housing

• Remote control

Trailer model features:

• Can reach up to 4’ in pit depth difference

• PTO stays connected on the trailer

• Transport mode locking mechanism on trailer

BRITISH COLUMBIA

Mountain View Electric Ltd.

Enderby — 250 838-6455

Pacific Dairy Centre Ltd.

Chilliwack — 604 852-9020

ALBERTA

Dairy Lane Systems

Leduc: 780 986-5600

Blackfalds: 587 797-4521

Lethbridge: 587 787-4145

Lethbridge Dairy Mart Ltd.

Lethbridge — 888 329-6202

Red Deer — 403 406-7344

SASKATCHEWAN

Dairy Lane Systems

Warman — 306 242-5850

Emerald Park — 306 721-6844

Swift Current — 306 203-3066

MANITOBA / NW ONTARIO

Penner Farm Services Ltd.

Blumenort — 204 326-3781

Thunder Bay ON – 800 461-9333

Tytech

Grande Pointe — 204 770-4898

Claire Snoddon Farm Machinery

Sunderland — 705 357-3579

Conestogo Agri Systems Inc.

Drayton — 519 638-3022 1 800 461-3022

County Automation

Ameliasburg — 613 962-7474

Dairy Lane Systems

Komoka — 519 666-1404

Keith Siemon Farm Systems Ltd.

Walton — 519 345-2734

Lamers Silos Ltd.

Ingersoll — 519 485-4578

Lawrence’s Dairy Supply Inc.

Moose Creek — 613 538-2559

McCann Farm Automation Ltd.

Seeley’s Bay — 613 382-7411

Brockville — 613 926-2220

McLaren Works

Cobden — 613 646-2062

Melbourne Farm Automation

Melbourne — 519 289-5256

Watford — 519-876-2420

Silver-Tech Systems Inc.

Aylmer — 519 773-2740

Dunnville — 905 981-2350

ATLANTIC PROVINCES

Atlantic Dairy Tech.

Charlottetown, PE — 902 368-1719

Mactaquac Farm Equip. Ltd.

Mactaquac, NB — 506 363-2340

Sheehy Enterprises Ltd.

Shubenacadie, NS — 902 758-2002

Sussex Farm Supplies

Sussex, NB — 506 433-1699

By Sebastian Decap, Director of Strategic Marketing and Technology, Trouw Nutrition Canada

MILK QUALITY IS AT THE HEART OF DAIRY FARMING, influencing both profitability and consumer trust. But what exactly defines high-quality milk? For some, it’s about fat and protein content, which impact processing efficiency and product yield. For others, it’s about hygiene, with somatic cell count (SCC) and bacterial levels determining safety and shelf life. While these factors directly affect the price farmers receive and are closely monitored, milk quality is more than just a number—it reflects a cow’s health, immune status, environmental conditions and nutrition. In many ways, milk serves as a window into the effectiveness of herd management and feeding strategies.

Milk quality goes beyond lab results—it reflects the cow’s environment, health, management and nutrition. Fat and protein levels depend on energy balance, amino acid supply and overall diet formulation. When a cow is in optimal metabolic condition, milk composition remains stable, indicating a healthy cow. Conversely, fluctuations in milk components can signal nutritional imbalances, stress, diseases or, more importantly, management challenges.

One key indicator of milk quality is SCC. A high SCC suggests an immune response to infection, often mastitis, which is primarily caused by bacterial infections. While nutrition plays a supportive role by strengthening immune defenses and reducing inflammation, the main factors influencing mastitis and SCC levels are hygiene, milk procedures and overall herd management. Adequate intake of essential trace minerals in highly bioavailable forms, like zinc, copper and manganese is key. These trace minerals enhance immune function, helping cows to better respond to infections and maintain lower SCC levels, thus improving milk quality.

Milk urea nitrogen (MUN) provides insight into nitrogen utilization. High or low MUN values indicate inefficient protein metabolism, often due to a variation between dietary protein and energy supply. Fine-tuning rations and bunk management optimizes protein use, reduces nitrogen waste and improves milk protein synthesis.

Milk quality is a multifactorial issue influenced by genetics, environment, management and nutrition. While some factors are beyond a farmer’s control, nutrition helps improve milk quality by supporting the immune system and metabolic stability. However, no nutritional strategy can replace best management practices.

A cow’s immune system plays a fundamental role in milk quality. When immunity is compromised, infection risks like mastitis increase, leading to elevated SCC and reduced milk quality. While proper nutrition strengthens immune resilience, reducing disease incidence and inflammatory responses, it cannot replace the need for good overall farm management. Hygiene, cow comfort and effective milking practices remain the primary defenses against mastitis and high SCC levels. A well-managed farm creates the best conditions for optimal milk quality.

The transition period is a critical window for immune function and overall health. During this time, cows undergo metabolic and physiological changes that challenge their immune defenses. A well-managed transition diet ensures adequate energy, protein and essential micronutrients to support immune resilience, reducing postpartum diseases that compromise milk quality.

Energy balance is key during transition. Negative energy balance, common in early lactation, weakens immune responses, increasing infection risk. Properly formulated transition diets with controlled energy intake before calving and rapid adaptation to higher-energy diets postpartum help minimize metabolic stress and support immune function.

Essential nutrients, such as vitamin E and selenium, directly strengthen immune function. Deficiencies impair white blood cell activity, reducing a cow’s ability to fight infections, increasing SCC and lowering milk quality. A well-supplemented transition diet ensures cows enter lactation with a robust immune system, improving udder health and milk composition.

Despite the best nutrition, additives and immune support, milk quality will never reach its full potential without proper hygiene and management. Nutrition is a valuable tool, but it works best when combined with strong management practices that prioritize cow health and welfare.

At the 2025 Dairy Farmers of Canada (DFC) Annual Dairy Policy Conference, market intelligence analysts presented data showing how Canada’s dairy sector has remained resilient, supported by supply management and consistent demand through fluctuations in food prices and evolving consumer preferences.

DFC Policy & Trade Analyst Julia Trottier presented recent Consumer Price Index data indicating a 1.8 per cent increase in overall inflation from December 2023 to December 2024. Dairy product prices rose by 3.0% in December 2024, while overall food prices increased by 0.6%. The modest rise in the food price was largely offset by declines in the cost of food purchased from restaurants and alcoholic beverages from stores, driven by the temporary GST/HST break in December. On a 12-month average basis, however, dairy prices increased by 2.0%, while overall food prices rose 2.7%.

Price comparisons using government data suggest that the average Canadian price per liter is $1.60, compared to $1.43 in the U.S., though this is not uniform across either country. “The more north you get in the U.S., the price goes up — there’s about a 10-cent difference,” Trottier explained. While there is consensus between data sources that butter and yogurt are more expensive in the U.S., cheese prices are similar across both markets.

“It’s also important to note, of course, that the price of milk at the farm and what consumers pay are not part of the same pricing scheme,” Trottier added. “These are distinct markets, and pricing dynamics differ significantly along the supply chain.”

In the past five years, American dairy farms have suffered significant losses equivalent to the entire Canadian dairy market, underscoring the relative stability of Canada’s dairy industry.

Despite higher food costs, she noted that consumption in all food categories is rising, driven by population growth. However, purchasing habits are shifting as disposable income fails to keep up with rising prices, while the trend of plant-based beverages gaining market share appears to be reversing.

DFC’s Lead, Policy Analysis, Maxime Collette noted that consumption patterns vary among demographic groups.

“Asian Canadians have higher per capita consumption of plant-based beverages, eggs, tofu, and meat/dairy substitutes,” he said. “French speakers, who make up 20 per cent of Canada’s population, have higher per capita consumption of milk, yogurt, ice cream, natural cheese and processed cheese.”

Age also influences dairy consumption, with younger adults favouring plant-based beverages, tofu, and dairy substitutes, while older consumers have a higher intake of cream, cheese, butter and eggs. However, young consumers do not consume dairy in a strictly linear or declining pattern; their choices fluctuate based on trends, health perceptions, and lifestyle factors. They may incorporate traditional dairy products in specific contexts, such as high-protein diets, indulgence, or cultural influences, even as they explore alternative options.

Collette spoke about the opportunity for dairy farmers to reverse the per capita decline. “There is a trend towards higher-fat dairy products over the last decade,” he said, indicating this could be seen as an opportunity to stimulate further growth in total consumption of dairy products in Canada.

As Canadian dairy prices remain competitive with international markets and shifting consumer preferences offer new opportunities, the industry continues to adapt to ensure its long-term growth and stability.

July 13 to 16, 2025, Toronto, Ontario

Westin Harbour Castle

By Dr. Elouise Molgat, DVM, Veterinary Advisor – Lactanet, Dr. David Kelton, DVM, PhD, FCAHS, Professor Emeritus – University of Guelph

MILK QUALITY AND MASTITIS MANAGEMENT are areas that present continuous improvement opportunities for the dairy sector. These are areas where we can always strive to be more efficient and innovative and to do our part as an industry in reducing antimicrobial use.

Selective dry cow therapy (sDCT) is one such innovative approach that can be adopted to make judicious use of antibiotics without compromising udder health and performance. This is particularly important since mastitis is the main cause for antibiotic use in dairy herds. sDCT represents a progressive and sustainable strategy in the dairy industry that balances animal health and welfare with public health concerns.

Blanket dry cow therapy (treating all cows with antibiotics at dry-off) used to be the recommended practice by the National Mastitis Council (NMC) under the 10-point mastitis control program. It still remains the recommended practice for herds with mastitis challenges. However, with the overall improvement in udder health in recent years and the adoption of antimicrobial stewardship, sDCT is now considered a best management practice for farms with good udder health and milk quality control.

sDCT targets only cows with subclinical mastitis at dry-off and cows at increased risk of infection during the dry period to receive intramammary antibiotics. Healthy and low-risk cows do not receive antibiotic treatment, only an internal teat sealant to prevent new infections during the dry period. It is the administration of antibiotic treatments that is selective, not the internal teat sealants.

There are many benefits to this practice. The most striking is the reduction in use of dry cow intramammary antibiotic tubes. Based on several field studies, around a 20 to 60 per cent reduction in antibiotic use at dry-off can be expected (Rowe et al., 2023). From another point of view, dry-off practices on the farm are also influenced by the cost-benefit balance between the use of intramammary products at dry-off and udder health impacts. A sDCT cost-calculator tool from the University of Minnesota's college of veterinary medicine is available online (Selective Dry Cow Therapy Cost Calculator - Dairy Know) and allows you to simulate and compare the cost of sDCT strategies for a specific farm. A review of the literature on dry cow therapy practices was conducted by de Jong et al (2023) and concluded the overall economic impacts of switching to sDCT is difficult to estimate. The benefits vary among herds due to differences in pathogen profiles, sDCT protocols and level of antibiotic reduction achieved.

If a herd is already enrolled in Lactanet milk recording and has access to routine somatic cell count (SCC), an SCC-based algorithm approach such as the one proposed by Lactanet (see below) will be the most costeffective. Finally, acknowledging the value of working time on a dairy farm, it is reassuring to know sDCT generally is a time-saver or has little effect on working time compared with blanket dry cow therapy, depending on the protocol (Le Page et al., 2024).

There are a few additional herd-specific considerations when deciding to move to sDCT. For example, given the herd seasonality in SCC in some herds, sDCT could be implemented only during the low-risk period (often winter and spring), with a switch back to blanket dry cow therapy during the high-risk period (often summer and early fall). Additionally, overall transition management and facilities are key for sDCT success. A decision tree and risk assessment is available on the SCC200 website, along with factsheets, videos, podcasts and other resources.

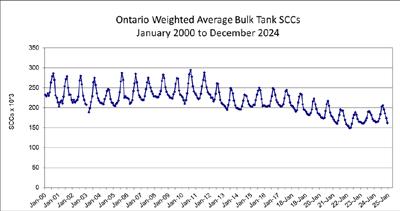

Evolution of SCC in Ontario for the period 2000 to 2024.

National SCC standard lowered at 400,000 scc/mL. Data courtesy of Dairy Farmers of Ontario.

Herd Level*

Cow Level* (once herd level is met)

Are your cows good candidates for sDCT?

• minimum 8 herd tests with SCC results (in past 12 months)

annual herd average SCC < 250,000 no more than 2 herd tests with SCC average >= 250,000

cow SCC average <= 200,000 (last 3 tests) no clinical mastitis event in 3 months prior to dry-off less than a 99 days estimated dry period

According to Lactanet 2024 data, nationally, just over half of the herds enrolled in milk recording would qualify as good candidates (herd-level criteria) for sDCT. Within these herds, just over half of the cows would be good candidates to not receive intramammary antibiotics at dry-off. This has the potential to save on half the intramammary products on eligible farms, amounting to nearly half a million (480,076) dry cow intramammary antibiotic tubes being saved at the national level.

SCC Herd Summary Report

SCC Cow Summary Report

SCC Management List Report

Udder Health Report

Advisor Favourite

Producers who decide to move to sDCT can choose from two approaches depending on what is most beneficial and practical for their farm. The first and most commonly used is the algorithm-guided method based on routine SCC data and clinical mastitis records. The figure above illustrates the algorithm proposed by Lactanet, which generates the sDCT report. For herds that do not have access to reliable data, the culture-guided method is an alternative option, which is to determine which cows require antibiotic treatment at dry-off based on milk culture results taken a few days before drying off. Both approaches are equally effective.

It is essential herds that do move to sDCT are closely monitored to determine the program’s success. The health status and SCC dynamics in fresh animals should be tracked using dry-off and fresh SCC data, such as the Lactanet dry off and fresh monitoring report, along with meticulous record-keeping. As with any changes made to your herd health program, it is crucial to work with your herd veterinarian so you’re equipped with the right tools and have access to reliable data to measure and monitor the impacts of these changes.

References

1. de Jong, E., McCubbin, K. D., Speksnijder, D., Dufour, S., Middleton, J. R., Ruegg, P. L., Lam, T., Kelton, D. F., McDougall, S., Godden, S. M., Lago, A., Rajala-Schultz, P. J., Orsel, K., De Vliegher, S., Krömker, V., Nobrega, D. B., Kastelic, J. P., & Barkema, H. W. (2023). Invited review: Selective treatment of clinical mastitis in dairy cattle. Journal of Dairy Science, 106(6), 3761-3778. https://doi.org/10.3168/jds.2022-22826

2. Le Page, T., Ferchiou, A., Dufour, S., Kabera, F., Dubuc, J., Lhermie, G., Raboisson, D., & Roy, J. P. (2024). Dairy farmer income, working time, and antimicrobial use under different dry cow therapy protocols. Journal of Dairy Science, 107(10), 8115-8129. https://doi. org/10.3168/jds.2023-24407

3. Rowe, S., Kabera, F., Dufour, S., Godden, S., Roy, J. P., & Nydam, D. (2023). Selective dry-cow therapy can be implemented successfully in cows of all milk production levels. Journal of Dairy Science, 106(3), 1953-1967. https://doi.org/10.3168/jds.2022-22547

Adjust the weight of MAX PACK by filling the drum with water

Side

Hydraulically

By Ryan Dick, Health and Safety Consultant with Workplace Safety & Prevention Services

Follow these five tips to keep you and your farm workers safe

SOME SAFETY HAZARDS ARE EASIER TO SPOT THAN OTHERS, such as a moving tractor, a robotic milker or a large animal. Most dairy farmers know how to work safely around these things. But what about hazardous gases?

“Much of what you find on the farm is organic. And organic products break down and decompose, animals produce manure, all of which can create gases,” explains Ryan Dick, health and safety consultant with Workplace Safety & Prevention Services. “So, it’s not only the chemical pesticides and herbicides you need to be aware of. Silo gas and manure gas are invisible, odourless and can be just as deadly.”

Silage—made up of grass, corn, maize and other plants—is often stored in a silo to ferment. Silo gas, which contains carbon dioxide and nitrogen dioxide, is produced during the fermentation process, depending on the silo style. “The gas displaces oxygen within the silo. So, if a farm worker goes into that silo for any reason, they won’t be able to breathe for long,” says Ryan.

Milk parlours are often connected to the silo, which means there’s a risk of silo gas seeping in. “Workers need to be aware of this potential hazard and understand that if someone collapses after going in, they can’t run in after them,” says Ryan. “Not without the proper personal protective equipment, such as a self-contained breathing apparatus.”

Manure lagoons will produce fumes and odours, but out in open air they are not likely to pose a risk to workers. “However, some dairy farms have digesters, so there’s a covered container. Farm workers need to be aware of the potential gas exposure before working with digesters,” says Ryan. Workers also need to be careful when using liquid manure tankers around the farm, particularly if they bring the tanker into a shop, garage or other enclosed space.

Methane or ammonia buildups are other situations dairy farmers need to avoid. Barns usually have adequate ventilation to dilute the methane and ammonia produced by the animals. However, before a storm when the animals are corralled inside and the windows and doors are closed tightly, ventilation may no longer be adequate.