MILK PRODUCER MAGAZINE CELEBRATING 100 YEARS 19 25-2025

MAY 2025 | THE VOICE OF ONTARIO DAIRY PRODUCERS

MILK PRODUCER MAGAZINE CELEBRATING 100 YEARS 19 25-2025

MAY 2025 | THE VOICE OF ONTARIO DAIRY PRODUCERS

PUBLISHED BY

DAIRY FARMERS OF ONTARIO

6780 Campobello Road

Mississauga, ON L5N 2L8

ADVERTISING

Pat Logan pat.logan@milk.org 519-788-1559

GRAPHIC DESIGN

Katrina Teimo

CONTRIBUTORS

Jeanine Moyer, Bruna Mion, Andrew Brooks, Sean Tarry, Navdeep Saini , Angie Wilson, Lilian Schaer, Canadian Mental Health Association, Veal Farmers of Ontario

COVER PHOTOGRAPHER

Nelson Zandbergen, Assistant Editor, Farmers Forum

Canada Post Publications Mail Sales Product Agreement No.40063866.

Return postage guaranteed. Circulation: 7,200. ISSN 0030-3038. Printed in Canada.

SUBSCRIPTIONS

For subscription changes or to unsubscribe, contact:

MILK PRODUCER

6780 Campobello Road

Mississauga, ON L5N 2L8

Phone: (905) 821-8970

Fax: (905) 821-3160

Email: milkproducer@milk.org

Opinions expressed herein are those of the author and/ or editor and do not necessarily reflect the opinion or policies of Dairy Farmers of Ontario. Publication of advertisements does not constitute endorsement or approval by Milk Producer or Dairy Farmers of Ontario of products or services advertised.

Milk Producer welcomes letters to the editor about magazine content.

*All marks owned by Dairy Farmers of Ontario.

WEBSITES & SOCIAL MEDIA

www.milkproducer.ca

www.milk.org

Facebook: /OntarioDairy

X: @OntarioDairy

Instagram: @OntarioDairy

LinkedIn: dairy-farmers-of-ontario

www.milkproducer.ca

By Roger Boersen, Dairy Farmers of Ontario (DFO) Board Member, Region 10, Huron and Perth. Roger chairs the DFO Markets and Allocation Committee and serves on the Organic Producer Advisory SubCommittee, Audit, Quality Assurance, and Research and Development committees.

At Boern View Farms Ltd., we are a family operation supported by a team of local employees, milking 425 cows and caring for 1000-head on the farm premises. Managing our farm requires teamwork, dedication, and a focus on delivering results for herd health and comfort while improving farmer quality of life. That is where technology and good data play a key role in day-to-day farm management. From our family farm experience, the practical application of technologies has demonstrated the importance of quality data, and more to the point, no data is better than bad data.

In thinking about the role that technology plays on dairy farms, I turned to my children – Krista and Adam, for input and validation on the most important benefits that technology has provided on our farm in recent years. Here is our family farm perspective on technology and the role it plays in helping us to operate a well-managed farm as third and fourth generation dairy farmers.

Data-driven Standardization of Treatment Practices. Our robotics collect a massive amount of data, and using this data allows us to add a quantitative component to assessing animal health, rather than relying on subjective measures. For example, if a cow's rumination falls below a certain threshold, a cow quarter somatic cell count or temperature rises, the cow is sorted for individual observation quicker than usually human eyes can observe. This enables us to

begin early treatment, starting with therapeutic care rather than antibiotic intervention.

Deploying technology. We also monitor calf milk intakes and intervene with non-antibiotic treatment before the animal shows observable signs of sickness. This allows us to ensure that all animals receive the same quality of care and makes training new employees much easier as they do not need to exclusively look at an animal for subjective symptoms but can also use a datadriven approach for early detection.

Reduction of Manual Labour. Robotics and other technological advancement in agricultural equipment has drastically reduced the requirement of manual labour. Tedious and repetitive physical tasks have been replaced by more intellectually demanding tasks. This has allowed us to employ higher skilled employees to our team, while reducing the physical burnout that is associated with physical labour. We believe that this has contributed to a more pleasant place to work for both employees and farm owners.

Increased Time Flexibility. Most of our new machines and robots run 24 hours a day and require a certain amount of management daily. This service can be done at any time, which increases the flexibility that we have with our time. While there is still a considerable amount of work, this increased flexibility allows us to

prioritize urgent tasks when they arise or reorganize our day if other projects require our attention. This has not only increased our quality of life as a family, but also allows employees a lower stress job, as their time is also flexible.

Individual Targeting of Animals. Advancements in technology have allowed us to track and address animals on an individual basis, rather than just as a herd. We can target feed our highest producing cows, providing them with the exact nutrition their body needs. It also helps us identify and treat animals who may require intervention. Technology is a valuable tool in early detection, enabling us to focus on the cows that need more attention, enhancing our experience by enabling us to be attuned to subtle changes in the herd. The individualization allows us to get the most out of our animals, while providing them the best quality of life while we are at it.

In short, at Boern View Farms, technology has reduced workload and improved quality of life for farmers, employees, and animals alike.

From ever-evolving regulations to dietary trends and global producers penetrating Canada’s dairy market, you face a myriad of challenges. Let MNP help you capitalize on new opportunities, streamline operations, and improve your bottom line. Ian Murphy, CPA,

Dairy Farmers of Ontario’s (DFO) Field Services Representatives (FSRs) are not only milk inspectors, they are also your support for everything from milk quality troubleshooting to questions on quota and paperwork, policies and regulation, and anything else related to DFO and how it applies to your farm. Our 13 FSRs have seen and heard a lot. This column was created to use their collective expertise to share answers to some of the most common questions received.

that may cause a dairy farm to be unable to ship milk from its dairy facility. When that happens, producers can take advantage of the DFO board policy known as Shared Facilities. Shared Facilities will allow producers to keep generating an income during a time of need.

Production catastrophes that may disrupt operations can vary from facility damage due to extreme weather events, renovation or construction, medical conditions or a producer death. In each of these circumstances, producers are required to provide supporting documentation to qualify for the use of Shared Facilities.

The policy allows a producer experiencing a catastrophe to temporarily relocate their cows (if applicable) to another dairy operation, enabling them to continue meeting their quota when they are unable to produce or ship milk from their own facility for a period of time.

So how does it work? Producers who have suffered a production catastrophe may be permitted to share facilities with up to five existing producers for a period of up to six months, provided DFO is notified and approves the request within 72 hours of the production catastrophe. Through shared facilities, the appropriate milk shipments can be moved back to the licence of the producer who suffered the production catastrophe.

A production catastrophe is defined as a situation that physically prevents the marketing of milk from a licenced facility and only includes herd health problems or the loss of the milk production facility. Herd health problems include death of a significant portion of the herd or the occurrence of a disease or condition that prohibits the sale of milk from that herd. (i.e. reportable disease).

Producers who are rebuilding and are unable to milk in their current facility following a production catastrophe may be approved to share facilities for an additional six months immediately following their initial six month period, subject to providing documentary evidence that the rebuilding is planned or there is actual physical evidence (confirmed by their Field Services Representative) that the rebuilding has started. The period of one year can be extended to 18 months (the maximum permitted by policy) if the producer makes a written request and DFO is satisfied there has been significant progress in the building of the facility.

When planning renovations or construction of new facilities, producers who are applying to use shared facilities are required to submit documentation prior to the start of their project. Producers must provide a signed contract with a contractor, and show proof that a minimum 10 percent deposit has been made, or if a producer is doing the renovation themselves, they must show proof of ordering the material and proof of the shipping date as well as a project timeline. Producers are granted the use

of shared facilities for a maximum of six months provided that at the threemonth mark, they provide proof of significant progress such as proof of framing or poured concrete. The period of six months can be extended to one year and then again to the 18 month maximum if the producer makes a written request and DFO is satisfied there has been significant progress in the renovations of the facility. Producers who have renovated or newly constructed facilities must have a Grade A inspection of the facility and be classified as Grade A before milk can be offered and marketed for sale,

If there is a producer death or a producer with a medical condition (with a medical diagnosis) that prevents them from producing milk, they may be permitted to use shared facilities with up to five existing producers for a period of up to six months, provided DFO is notified and approves the request. The intent of the shared facilities policy for medical reasons is to provide producers six months to explore their options moving forward regarding their farm operation, and not intended to cover the period of medical recovery. At the end of the six-month period, producers must resume shipments, or they may request permission to have their quota held in abeyance (a quota hold) for one year. Abeyance allows producers to decide on the future of the quota without the pressures of immediately selling.

1. Producers using shared facilities and producers providing shared facilities services are not eligible for twice-a-month payment.

2. Producers shut off from the milk market as a result of the application of Ontario Regulation 761 or as a result of not meeting assurance programs requirements are not eligible to use shared facilities during the month(s) in which they are shut off.

3. Shared facilities is not a quota leasing program; rather, it is a specialized support option available only to producers who meet specific qualifying circumstances.

Shared facilities policy permits producer-to-producer assistance in producing milk for specific reasons, such as catastrophe, new build or renovation, for a maximum of 18 months, and medical or death for a maximum of 6 months. In Ontario, there are approximately 30 producers per month that use this policy and approximately 45 producers per month assisting them. If you are looking for more information, all DFO board policies can be found online.

Shared Facilities is a specialized support option available only to producers who meet specific qualifying circumstances.

PP

ILLUSTRATOR-P *RC

VOGUE A2P2-PP (EX-97)

724HO02004 A2A2 / AB

#1 Type in Top 100 LPI +15 Conf

VOGUE ILLUSTRATOR-P *RC (EX-93)

724HO02008 A2A2 / AB

#1 Type Red /RC Proven Sire +13 Conf

STANTONS OVERHAUL-P

724HO02037 A2A2 / BB #1 GPA-LPI Polled +4016 GLPI +11 Conf

VECTOR FRA APOLLO-PP

724HO02040 A2A2 / BB

#1 GPA-LPI “PP” A2A2 +3950 GLPI +14 Conf

#1 Mammary #2 Conf. & #3 Rump in Top 100 Genomic Bulls

Available in Canada from

Contact for International

By Bruna Mion, PhD, Dairy Production Expert –Nutrition and Management, Lactanet

THE TRANSITION PERIOD IS ONE OF THE MOST CRITICAL PHASES IN A DAIRY COW’S LIFE. During this time, cows face numerous challenges that can impact their health, fertility and milk production. However, tools and strategies, such as feed additives, activity monitors and data management software, provide producers the edge they need to manage it better than ever.

In February and March, the Canadian Dairy Hub, a project developed by Lactanet and funded by the Dairy Farmers of Canada through the national dairy knowledge project, organized two webinars. They featured both experts and dairy producers, who combined real-world experience and research insights to explore how management practices are helping reduce transition challenges, boost cow health and improve reproductive performance.

The first webinar focused on the dry period, with contributions from Dr. Trevor DeVries from the University of Guelph, Audrey Villeneuve of Ferme 3V (Ontario), and Tyler Howard of Howardvale Holsteins (Prince Edward Island). The second webinar explored the journey from calving to conception, featuring Dr. Stephen LeBlanc from the University of Guelph, Anton Borst of Halarda Farms (Manitoba) and Bruno Blouin of Ferme Belhorizon (Quebec). Recordings are available on the Canadian Dairy Hub website.

Before exploring how producers and experts are tackling transition challenges, it’s important to understand why this period is so critical – and so difficult to manage.

The transition period presents complex challenges since cows undergo significant metabolic and hormonal changes to prepare for lactation. This shift requires major adaptations in energy metabolism, yet it often coincides with a drop in feed intake – just when nutritional needs are peaking. These challenges can increase the risk of health problems, with consequences that can affect the entire lactation. Cows that struggle during the transition period may produce less milk, have lower fertility and face a higher risk of culling. Detecting problems early is key, but not always easy without proper tools, space and consistent monitoring. Although the webinars did not focus entirely on the technologies available, several innovative solutions were discussed, highlighting their role in helping producers manage these challenges more effectively.

Feeding transition cows effectively is crucial to ensuring the success of this period. The essentials of feeding management for transition cows involve high-quality feed, 24-hour feed availability, a diet that meets nutritional requirements and consistent management to maximize feed intake. Minimizing sorting and providing a balanced diet are essential.

Technologies, such as feed additives, including anionic salts and mineral binders, are frequently applied to the close-up diet to support calcium metabolism, reducing the risk of milk fever and

subclinical hypocalcemia. Dr. Trevor DeVries emphasized the importance of maintaining consistency in both feed and intake levels. If the farm deviates from the target nutritional values, the likelihood of negative outcomes increases. In addition, the inclusion of certain feed additives with low inclusion rates, demands consistent intake to ensure their effectiveness.

While feeding strategies form the foundation, monitoring how cows are responding adds another layer of control and early detection. Feed intake is one of the most important factors that determine the success of the transition period. Maintaining high feed intake during the dry and fresh period is essential to maintain nutrient intake, supporting rumen functionality, and ensuring proper fermentation.

Technologies like rumination collars, used by Howardvale Holsteins, Halarda Farms and Ferme Belhorizon, provide valuable insight into how cows are coping during the transition period. Bruno Blouin explained that at his farm, he ensures cows have good rumination before moving them from the fresh pen to the main lactating group. Dr. Stephen LeBlanc noted that while the use of rumination collars is wellsupported by research, there is no universal threshold for “normal” rumination that applies to every farm. Instead, what matters most is observing the trends – specifically, whether rumination is increasing after calving. A drop in rumination is often an early warning sign since it typically occurs before a decline in milk production.

If you are using this technology, it’s essential to follow up on any cows showing reduced rumination since it may signal health issues.

Technologies, such as feed additives, including anionic salts and mineral binders, are frequently applied to the close-up diet to support calcium metabolism, reducing the risk of milk fever and subclinical hypocalcemia.

Data-driven decision-making is becoming increasingly crucial in managing transition cows. By utilizing herd management software, producers can track key indicators of cow health and performance, providing valuable insights into the effectiveness of their management strategies.

Anton Borst noted that while data from various technologies can inform decisions, the quality of the data entered into the management software is essential. As he stated, “If you have bad data, you make wrong decisions with confidence. And when you have good data, you can make good decisions with confidence”. This highlights the importance of accurate record-keeping as the effectiveness of the technology is only as good as the data it relies on.

Don’t forget the basics: comfort, stocking density, water and environment

No matter how advanced the tools, the success of the transition period still depends on providing the basic needs for the cows: clean and dry bedding, proper stocking density, access to high quality water, access to excellent feed and avoiding other stressors (ie. heat stress), are fundamental for cow wellbeing

Audrey Villeneuve shared how their farm’s recent changes in the housing facilities for the dry cows allowed for reduced cow movement and minimized stress. These changes, combined with other management practices, have resulted in positive outcomes.

Integration is the key

No single tool solves all transition challenges — but when data, sensors, diet, and management come together, the results are powerful. What today’s producers are showing is that a more connected approach leads to healthier cows, better reproduction and a smoother transition period.

EFFECTIVE 200 IgG BOVINE DRIED COLOSTRUM

PACKED WITH A HIGHER CONCENTRATION OF IGG, IMMUNOLIFE | 200 IS THE ULTIMATE CHOICE FOR YOUR CALVES' HEALTH AND VITALITY

FUTURE PERFORMANCE IS: INSIGHTS FROM THE FUTURE PERFORMANCE RESEARCH CENTRE IN EVERY BAG OF MILK REPLACER

Mapleview milk replacer is backed by over a decade of research and trials involving more than 10,000 calves. The insights gained are integrated into our products, combining cutting-edge science with practical solutions that work on your farm.

By Andrew Brooks

WHEN MILK PRODUCER SPOKE WITH ICLASSIFIER co-founder and chief innovation officer Dr. Ghader Manafiazar last year (see “More than meets the eye” in the June 2024 issue), the Alberta-based developer of AI-powered livestock classification technology was making strides in bringing its AI-based linear body type traits classification technologies and services to market.

iClassifier’s main product is an automated assessment machine (AAM) which includes a physical stall or pathway for image capture combined with AI-based image analysis that provides body type trait classification following the imaging, and a user interface (via a mobile app). This technology provides the ability to capture images on an iOS or Android device and upload them to iClassifier’s cloud server for analysis. The company has also introduced JRun, a standalone 3D/2D imaging device that supports accurate imaging.

Among the significant developments since last year, iClassifier recently signed a memorandum of understanding with the Canadian Angus Association and Holstein Canada, which iClassifier hopes will result in a long-term business relationship.

“It’s an exciting development,” Manafiazar says. “We’re working closely to understand each other — for them to understand the technology better, and for us to get their members' perspective and consider those points in adapting the technology we have in place.”

iClassifier has also embarked on field tests of its systems. The first step involves taking live measurements of beef and dairy livestock using the AAM or JRun.

Ultimately, Manafiazar believes seeing the AAM at work in field conditions will help promote adoption by end users. At this stage, iClassifier has its eye on adoption for farms with a herd size of 50-plus. However, as the AAM is picked up by larger operators, its mobile app will gain traction with smaller farms.

iClassifier has also been developing its global reach, filing patents for its hardware and software not only in Canada, but also in the United States, Australia, New Zealand, the European Union and Brazil. These patent pushes reflect the increasing interest iClassifier has attracted from around the world. There has been strong interest from New Zealand in particular.

“They’re interested to see how we can get the technology to work there,” Manafiazar says. “For example, if I'm a producer in New Zealand with a heifer that I want to sell to the Canadian market, the Canadian buyer will need to know how she scores in their system.”

Rather than investing the time and expense of sending an assessor to New Zealand to do the scoring, iClassifier’s system will enable the hopeful New Zealand seller to capture the required data and send it to Canada for conversion to the Canadian scoring system. Of course, Manafiazar says, it can work the other way around too, enabling Canadian farmers to sell livestock to New Zealand — or anywhere.

“This is a great opportunity for collaboration between different dairy and beef breed associations in different countries. And it’s also an opportunity for the associations to provide another service for their members.”

iClassifier also demonstrated its JRun 3D/2D imaging system at the CSAS-ASAS (Canadian Society of Animal Science and American Society of Animal Science) annual meeting in Calgary last July. There, the device attracted the attention of two producers from South America, and iClassifier has been in contact with them for testing. However, Manafiazar says, JRun has potential applications in all kinds of other industries that want to use 3D imaging in their domain.

“CSAS-ASAS is mainly attended by academia and policy makers –plus some progressive producers. With our demonstration, we were introducing JRun to the research community to brainstorm and to find other applications of our standalone device.”

iClassifier is looking at industry research as a basis for developing a new algorithm to measure anogenital distance, a body trait that correlates closely with reproductive performance.

More developments are underway. “We started with Canada,” Manafiazar says. “We’re securing our position in other countries through our patent applications, but we’re looking to do more in the Canadian market and diversify the application of our product.”

wants yOur Beef / dairy CrOss Calves

• Oxford Cattle Company is working with genetic companies to select sires for use in our guaranteed calf buy back program.

• We are now pleased to announce that we are interested in buying your holstein bull calves and can include them in your regular pick up. We will take calves that are over 92 lbs and 10 days old. The price will be negotiated on a weekly basis.

• Presently serving southwestern Ontario region and Ottawa region.

• For a Calf Pick Up Request text (519) 788-1399 by 1:00 pm Mondays

Get more insights into your dairy operation with the SenseHub® Dairy monitoring ecosystem

Gain the freedom and confidence to make informed decisions with data and insights collected from individual animals on reproduction, health and milk quality monitoring.

With SenseHub® Dairy, farmers can now incorporate a variety of features in their application plan:

SenseHub® Dairy Youngstock Help improve dairy calf performance by monitoring indicators of well-being, health and nutrition for the first 12 months of life.

SenseHub® Dairy In-Line MilkPlus Sensor* Monitor milk yield, fat, protein, lactose, blood and conductivity in real time to make informed management decisions for each individual cow.

SenseHub® Dairy In-Line Somatic Cell Count Sensor* Help improve milk quality and herd well-being with real-time somatic cell counts for individual cows at the milking point.

hardware required

diagnose,

or

The integration of drone technology in dairy has game-changing potential

By Sean Tarry

look to explore precision farming solutions, farmers, scientists and researchers across the country have been exploring, innovating and testing. Many of today’s dairy farms employ a range of technologies throughout their operations, from automation and robotics to artificial intelligence and machine learning. Although numerous technologies are available today, few seem to present the same gamechanging opportunities as unmanned aerial vehicles (UAV), otherwise known as drones.

UAVs are still in the early stages of adoption amongst farmers. However, the technology seems to be gaining traction, as the potential benefits of their integration is tremendous, presenting the opportunity for the industry to enhance efficiencies, ensure improved animal welfare and increase farm profitability.

“There’s a lot of different pieces of tech that have been introduced over the past 10 or 15 years that have really helped to improve farming operations,” says Markus Weber, Owner of Landview – a provider of UAV hardware and software to farmers. “Drones are one of the more recent technologies that are all connected and working together to help farmers improve their operations.”

Some of the more common applications for UAVs on farms includes those seen in field crop applications. UAVs popularity in field crop applications includes yield predictions, determination of crop deficiencies and incorporation with other integrated pest management practices. Although those within the field crop sector have embraced UAV technology, the use of drones is not limited to crop applications.

Existing tasks for these UAVs within the livestock sector include assessment of fences, water troughs, irrigation systems and feed storage areas. These time intensive tasks can be sped up with the aid of UAVs

allowing for producers to get snapshots of troublesome areas to address. Those sectors with extensive and widespread grazing systems have seen adoption of UAVs for herd and flock monitoring and management, allowing farmers to remotely track animals over expansive pasture areas and receive an accurate and time-efficient headcount. By pairing these data with imagery, environmental conditions (including weather) and other farm management software, farmers can gain insights about bottlenecks they may be facing.

If that wasn’t enough, UAVs equipped with high-resolution cameras can also be used to identify abnormalities in the behaviour of individual livestock within the herd, helping in some cases to spot lameness and other health issues that might need to be addressed. It’s an impressive list of applications that Weber says could go a long way toward the creation of more precise and efficient farming operations. However, he suggests that perhaps the greatest benefit that dairy farmers have yet to fully realize is the UAV’s ability to see into the future.

“One of the biggest forward-looking applications for the use of drones on dairy farms that use pastures, is their ability to direct optimal grazing for the herd,” he explains. “Using drone imagery, farmers will be better able to assess pasture conditions, aiding in decisions related to grazing patterns and feed management. Essentially, drones can help farmers identify quickly which parts of the pasture need fertilizer next as well as the parts where their herd should feed, cutting down the hours that would be required to manually inspect the pasture’s condition, and eliminating a lot of the guesswork that’s traditionally gone into decisions like those.” This technology is just one of the ways that existing UAV technology used in field crop settings may start to see increased application in the livestock sector.

Weber also mentions that some are starting to hone another UAV application where they are used to monitor for and detect approaching predators (such as bears and wolves) and even chase them away from the livestock. It’s just another notch on the growing list of benefits that UAVs can offer dairy farmers and their operations. As Weber points out, that list is likely to continue expanding for some time as the use of UAVs becomes more widespread and additional applications are explored.

“I think we’re going to see a lot more farmers integrating the use of drones and other forms of advanced technology to continuously improve their farming operations going forward. We still haven’t seen anywhere near the full potential of drones and their use. So, it will be interesting to see how farmers and partners of the industry innovate to get the most out of the technology.”

By Sean Tarry

THE PRACTICE OF DAIRY FARMING HAS EVOLVED SIGNIFICANTLY THROUGHOUT THE YEARS. From its earliest origins that trace back to approximately 7,000 BC with the domestication of cattle and yielding of dairy products, to the introduction of contemporary large scale operations and the many advances in technology that helps support them, dairy farming has changed quite a bit. Despite these changes, one thing that’s remained constant for those operating within the industry is the need to meet the sustained demand for dairy products. It’s a need that requires a great deal of hard work, attentiveness, intuition and at times, guesswork. It’s a need that, according to a recent report, can be addressed in part by the power of artificial intelligence (AI) and machine learning.

Authored by Diego Nobrega, Assistant Professor within the Faculty of Veterinary Medicine at the University of Calgary, the report titled ‘Dairy Farming 2.0: Milking the Potential of Artificial Intelligence’ explores some of the most promising applications and many potential benefits of the use of AI within dairy farming operations. In fact, within the report Nobrega suggests that continued advancement, widespread adoption and implementation of the technology could prove to revolutionize the industry, creating greater efficiencies and facilitating improvements across the entire sector.

“AI tools are becoming more popular among farmers because they behave like high-tech helpers that assist with daily activities on farms,” reads an excerpt from the report. “In theory, these tools use technology to monitor how animals behave and detect diseases before they even start. They also help farmers make smart choices for their operations. Imagine having a farm assistant or veterinarian that tells us when animals are getting sick or which cows to breed and when. This assistant, powered by AI and machine learning, is like a digital farm manager making sure everything runs smoothly.”

The daily farming activities and smart choices which can be aided and improved by the use of AI technology, according to the report, are numerous, including the facilitation and management of more accurate feeding, the optimization of insemination and animal reproduction processes and enhancements in milk yields through the use of AIpowered autonomous milking robots. However, in his estimation, Nobrega believes that the most impactful benefit that current AI technology presents for dairy farmers and the continued success of their operations is reflected in its ability to ensure improved cattle health and safety.

“The most promising uses of AI in dairy farming have been in the realm of disease detection,” he says. “Tapping in data generated from sensors or milking robots, AI is promising to facilitate detection of sick or underperforming animals, including those with mastitis, digital dermatitis and lameness. AI in dairy can also help farmers with heat and dystocia detection.”

For instance, Nobrega’s report highlights a handful of impressive case studies which demonstrate the profound potential of AI in detecting disease and protecting the overall health of a herd. In an Irish Veterinary Journal release titled ‘Prediction of lameness using automatically recorded activity, behavior and production data in post-parturient Irish dairy cows’, it was noted that scientists leveraging innovative approaches involving AI and machine learning analysis tools had achieved an 85 per cent success rate in correctly identifying both lame and normal cows.

Another study titled ‘Hot topic: Detecting digital dermatitis with computer vision,’ conducted by Preston Cernek of the Northern Illinois Veterinarian Services cites that AI systems were able to demonstrate an accuracy of 88 per cent in the early detection of digital dermatitis.

What’s more, Nobrega’s report references a UK-based research group that used data from 1,000 farms in order to construct an automated mastitis classifier tool. Analyzing individual cow and herd data, the classifier managed to discern with 98 per cent accuracy contagious mastitis from its environmental variety, providing the potential for farmers to effectively manage and even prevent the spread of mastitis among herds.

Though this type of technology is still in its infancy with respect to its true capabilities, the results that are being generated through trials and testing are incredibly promising. And, combined with the speed of advancement, a steady decrease in the cost of the associated tools and their availability, Nobrega suggests that the implementation and use of AI in agriculture is only going to become more common as we move forward, but with some caveats.

“AI tools are coming in different formats and shapes, and feasibility will pretty much depend on the farm set up,” he says. “Most of the time, you have one or more precision farming tools, such as accelerometers, boluses, sensors, or cameras, working together with software, usually through a computer or phone app. Given the wide range of tools out there,

In the long run, the success of these tools will really depend on whether suppliers can prove they bring solid economic value to farmers. However, any process that increases efficiency will inevitably be adopted and become mainstream.

buying and installing them is likely doable for most farms in Canada. The real challenge, though, is getting the most out of these tools. That depends a lot on whether farm staff can actually see, understand, and act on the data. It also hinges on how much training support is available and whether suppliers are around to help troubleshoot. From my perspective, these are the biggest gaps when it comes to making AI tools truly feasible right now.”

Despite the remarkable potential that AI-powered tools currently present, Nobrega points out that in addition to proper implementation and use, there are also some aspects of the technology that require special attention and focus.

“The Canadian dairy industry is well known for being quick to adopt new technology, which is awesome,” he asserts. “But there are a few key questions we should be asking before making a long-term financial commitment to any AI tool for the farm.”

Among the questions that dairy farmers looking to implement and use AI technologies within their operations, the report calls out concerns over the ease of integration with existing technologies, the learning curve and training that would be necessary, data privacy and security, scalability, future-proofing and the regular support and maintenance that will be required to run the system. Fundamentally, however, the report suggests that questions specific to functionality and purpose, including ‘What specific tasks or challenges on my farm can this AI tool address?’ and ‘Does this tool align with the goals and needs of my dairy operation.’ must be addressed by farmers in order to properly understand its use and potential effectiveness within their operations.

These questions and concerns aside, the report casts an optimistic light over the growing use of AI-enabled technologies and the continued development of the industry toward the age of precision farming. It provides a glimpse into the labour, operational and cost efficiencies that a not-too-distant future holds for dairy farmers across the country. In fact, according to Nobrega, the continued move of the industry toward AI and machine learning is not only gaining momentum, but is quickly becoming an inevitability.

The Canadian dairy industry is well known for being quick to adopt new technology, which is awesome. But there are a few key questions we should be asking before making a long-term financial commitment to any AI tool for the farm.

– Diego Nobrega

“The number of AI tools out there is only going to grow, and we will keep seeing more farms adopting them. But honestly, I think we are still a long way from tapping into the full potential of AI in livestock. In the long run, the success of these tools will really depend on whether suppliers can prove they bring solid economic value to farmers. However, any process that increases efficiency will inevitably be adopted and become mainstream. I believe precision farming and AI will continue to grow and eventually become indispensable tools in the way we raise animals in Canada, as they are becoming in other sectors such as healthcare and business.”

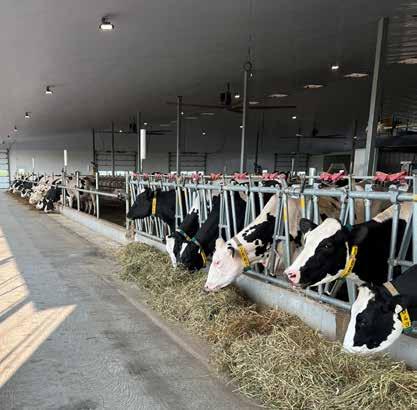

Cecilbay Farm

After a devastating windstorm, the McFadden family rebuilt their barn – and their way of life – embracing cutting-edge dairy automation that’s boosting production, cow comfort and family time.

By Jeanine Moyer

THE MCFADDEN FAMILY OF NAVAN, ONT. were in the early stages of planning a new barn build, with their sights set on upgrading milking technology, when a natural disaster in 2022 literally forced them to embrace the latest dairy systems technology.

Looking back, Travis McFadden, co-owner of Cecilbay Farm expresses gratitude for making the best out of what was easily one of the worst situations any dairy farmer could face. He explains that in the span of two years, his family went from milking 70 cows in a tie-stall barn to a new, stateof-the-art facility with plenty of lighting, fresh air and some of the most advanced technology in North America.

“It wasn’t by choice,” admits McFadden. “But today, we have a new barn with robotic and automated systems that operate just about everything.”

As fifth generation dairy farmers, McFadden farms with his brother, Devyn. Their parents, Gord and Lucy McFadden are also actively involved in the farm and are upgrading their technology management skills alongside the younger generation.

The new automated systems include ventilation, feed management, two GEA milking robots and a feeding robot. The GEA dairy feed F4500 is the

first North American GEA dairy feed system and has provided autonomous feeding in the McFadden's new barn since early 2025. Not only has the robot transformed their feeding routine, but it has proven to improve their flexibility, reduce labour requirements, increase milk production and enhance the health and wellbeing of the farm’s dairy herd.

Like most farmers, the McFadden’s wanted to see just how these new systems worked for themselves. Throughout the planning phase they visited farms, consulting with farmers and equipment manufacturers to determine the best design for their new barn. Their research even took them to Germany to see the GEA robotic feeder in action, and that’s where the unanimous decision to bring the robot feeding system to their farm was made.

The GEA dairy feed F4500 works simultaneously with McFadden’s feed kitchen, automatically measuring and mixing rations directly from the farm’s upright feed storage silos. The systems ‘talk’ to each other via wi-fi and are programed to mix and distribute fresh feed six times a day for the milking cows, and once a day for the heifers and dry cows. The daily milking cow feeding schedule begins at 2 am with regular intervals through to 9 pm.

It wasn’t by choice. But today, we have a new barn with robotic and automated systems that operate just about everything.

– Travis McFadden

The McFadden family has, since before my time, operated a well-kept and simple tie-stall facility. Visits are always positive and enjoyable as you walk through their obviously well cared for farm. The construction of a new automated facility following an unfortunate storm led to an opportunity to involve all family members in new ways to improve their dairy operation. Through innovative technology, the McFaddens can be seen excitedly making new plans, setting new goals and continuously improving in ways they never expected. The positive application of new and innovative technologies implemented on the McFadden farm has been greatly welcomed. The family continues to learn about the benefits to their system and continues to work towards great milk quality.

Congratulations and good luck to the McFadden family!

— Adam Lefebvre, FSR

“We are feeding more volume than ever before, but the cows love the consistently fresh feed and I’ve never seen animals more content,” says McFadden, explaining that the bunks are regularly cleaned up, but that the feed volume can be easily adjusted to manage or reduce leftover feed.

Data collection is another of the many benefits of the technology upgrades. Not only can McFadden see the difference the automated systems are having on the herd for himself, but he’s got the numbers to back it up. “We’re still in the early stages,” he admits, noting that the herd is still adjusting to the barn, milking robots and feeding routine. “But since we’ve started using the robotic feeder, we’ve seen the number of visits to the milking robot rise, our milk production is steadily increasing, animal body conditions and activity are ideal, and our numbers are showing our cost per cow is even going down.”

McFadden acknowledges that adapting to the new systems –particularly the robot feeder – has come with a learning curve. As the only one of its kind on the continent, there are few people with relevant experience he can turn to for guidance. He emphasizes the “huge level of trust” placed not only in the feeding robot but in every automated system in the barn, all of which are essential to keeping operations running smoothly. To support this transition, the family relies on a dedicated team that includes their nutritionist, veterinarian, GEA service representatives, and their local equipment supplier, Lawrence’s Dairy Supply.

“Every day I notice our milk production is up over the day before,” says McFadden. “Production, herd health and animal comfort are our top priorities, but the leading reason we took the leap to implement the milking and feeding robots is the flexibility they provide for our family and our lifestyles.”

The investments, especially in the robot feeder were significant. Not just the economics, but the trust required to allow a robot to manage one of the most important components of herd health and productivity – feed rations. McFadden says the decision was made together as a family, weighing the pros and cons of the robot feeder with a traditional tractor and feed mixer system. In the end, the flexibility the robot offered was the deciding factor. “While the robot meant flexibility and a reduction in labour, we knew the system would require constant supervision and maintenance,” he says, explaining that before they made their final decision, he and Devyn agreed that one of them would always be available and on call to manage the barn and the robots.

“This was a lifestyle decision for ourselves, and our families and we haven’t looked back,” he explains. As a result, the barn has become a new gathering place for the family to spend time together. McFadden says his kids regularly ride their bikes and play hockey in the barn while the family is working, and he’s even caught his dad joining in and taking advantage of the opportunity to spend time with his grandchildren.

The robot feeder has been successfully operating for nearly five months now. McFadden and his family are navigating the expected hiccups with the support of their GEA service team while they appreciate watching their herd adjust and enjoy their new surroundings.

In March 2025, the family hosted an open house that attracted more than 1,400 visitors. Many of them flocked to the eastern Ontario farm to see the robot feeding system, including some from the U.S. One of the highlights of the day for McFadden was the reaction of his herd to the huge number of visitors. He says the cows were calm, quiet and the crowd didn’t interrupt their routine at all. “Their reaction, or lack of, tells me they have adjusted to our new facility, and it is providing them with the most comfortable and productive surroundings possible.”

It's been a busy few years for the McFadden family, and while the outcome has been everything they could have hoped for, they will never forget that the progress they’ve made was rooted in a disastrous situation. That’s why McFadden reminds fellow farmers about the importance of farm safety, risk management and investing in appropriate insurance coverage.

“Farming is a lifestyle, and it means so much more for our family thanks to experiences we’ve shared together – good and bad – and the opportunities this new barn and the robots are providing us.”

Farming is a lifestyle, and it means so much more for our family thanks to experiences we’ve shared together – good and bad –and the opportunities this new barn and the robots are providing us.

– Travis McFadden

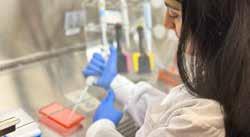

By Navdeep Saini, PhD Candidate, University

of

Guelph’s

School of Environmental Sciences, under the supervision of Dr. Kari Dunfield (University of Guelph) and Dr. Andrew VanderZaag (Agriculture and Agri-Food Canada)

METHANE FROM STORED MANURE IS A CHALLENGE FOR DAIRY FARMS — but the fix might be easier than expected.

Our research team at the University of Guelph, in collaboration with Agriculture and Agri- Food Canada, Ottawa, tested whether adding sulphur-based compounds — like sulphuric acid or calcium sulphate — to stored liquid dairy manure could help lower methane emissions. The results were promising, with emissions reduced by as much as 81 per cent.

Why this matters

Manure storage, particularly liquid systems used on dairy and swine farms, is a major source of methane — a powerful greenhouse gas. With increasing pressure on producers to reduce emissions, simple and affordable solutions like this could offer real value on the farm.

Manure storage, particularly liquid systems used on dairy and swine farms, is a major source of methane — a powerful greenhouse gas. With increasing pressure on producers to reduce emissions, simple and affordable solutions like this could offer real value on the farm.

Methane is produced when tiny microbes called methanogens break down organic matter in oxygen-free environments, like those found in manure storage pits or tanks. These microbes naturally convert manure components into methane during the decomposition process.

This study looked at whether changing manure storage conditions could reduce methane by affecting which microbes were active.

In a controlled lab study, dairy manure was stored in sealed containers for 170 days and treated with three different rates of sulphuric acid and calcium sulphate. Methane emissions were measured over the storage period, and microbial communities were analyzed to understand the impact of each treatment.

These treatments reduced methane emissions by shifting the microbial community in the manure. With sulphur-based additives, there were fewer methane-producing microbes and more microbes that use sulphur instead. This microbial shift helped lower methane emissions using simple products that many farms already have access to.

Good news — the additives aren’t killing the bacteria. There were still plenty of microbes left to help breakdown manure and release nutrients that benefit your crops.

Where the science of nutrition meets accurate feeding for a sustainable

Methanogens belong to a group of microorganisms called archaea – they’re not bacteria, but they play a similar role in breaking things down. A single litre can contain billions of them. In our study, untreated manure at 23°C had about 6 to 7 million methanogens per mL of manure. That’s a big reason why stored manure produces so much methane — even small shifts in these microbes can make a major difference.

Know What You're Adding – And Why It Matters

There’s no shortage of companies selling manure additives these days. In fact, many are showing up on farms weekly with new products, promising better results. But here’s the catch – do you actually know what’s in those additives?

If you don’t know what’s in the product, how can you trust it works? And more importantly, how do you know it’s actually improving the fertilizer value of your manure?

That’s where things need to change. Instead of relying on mystery blends, we’re testing well-known, farm-ready additives like sulphuric acid and calcium sulphate. These aren’t new to the industry – they’re proven to cut methane emissions and boost the nutrient value of manure. And the best part? Most farms already have the equipment needed to apply them.

Even better – you don’t have to take anyone’s word for it. You can test your own manure. Try adding these additives to a portion of your manure, then take a sample and get it tested for nutrient value. You’ll be able to see for yourself whether it’s making a difference.

It’s a practical, transparent way to get more out of your manure, support climate goals, and make informed decisions – without relying on unknowns.

What’s the next step we’re looking at in our research? We are working with cooperative farmers involved in the Living - Lab Ontario to see how this works in open outdoor storage tanks. We are also interested in the soil. Future work will be looking into any effects treated and acidified manure has on soil. Does it release nutrients more efficiently? Does it change how soil microbes work? Does it impact long-term soil health?

We’re tracking those changes – from short-term boosts in fertilizer value to how the soil responds over time. The goal is to understand if these additives can improve manure management not just in the tank, but also in the field.

Because for farmers, it's not just about reducing emissions. It's about making every part of the system – from storage to spreading – work smarter. And if we can do that with simple, tested tools already available on the farm, even better.

• The distribution is managed with our internal belt conveyor, ensuring the feed mixture remains consistent and properly distributed.

• The TMR has been effectively evaluated using the Penn State particle separator.

• A high precision feed waste sensor* helps minimize feed waste and enhances feeding efficiency.

• GEA’s mix quality sensor* ensures a consistent mix each time a ration is made.

* Currently under development. Availability based on farm evaluation and country.

BRITISH COLOMBIA

Pacific Dairy Centre Ltd.

Chilliwack — 604 852-9020

ALBERTA

Dairy Lane Systems Alberta

Leduc: 780 986-5600

Blackfalds: 587 797-4521

Lethbridge: 587 787-4145

Lethbridge Dairy Mart Ltd.

Lethbridge — 888 329-6202

Red Deer — 403 406-7344

Scan the QR code and see the GEA DairyFeed F4500 in action at Cecilbay Farms in Navan, Ontario.

SASKATCHEWAN

Dairy Lane Systems Saskatchewan

Warman — 306 242-5850

Emerald Park — 306 721-6844

Swift Current — 306 203-3066

MANITOBA

Tytech

Grand Pointe — 204 770-4898

ONTARIO

Conestogo Agri Systems Inc.

Alma — 519 638-3022

Dairy Lane Systems Komoka — 519 666-1404

Lawrence’s Dairy Supply Inc.

Moose Creek — 6 13 538-2559

McCann Farm Automation Ltd.

Seeley’s Bay — 613 382-7411

McLaren Works Cobden — 613 646-2062

Performance Dairy Centre Inc. Embro — 519 423-9119

Wood’s Dairy Source Keene 705 295-3247

ATLANTIC PROVINCES

Atlantic Dairy Tech, Inc.

AMS Sub-dealer for Sheehy Entreprises Ltd.

Charlottetown, PE — 902 368-1719

Sheehy Entreprises Ltd.

Shubenacadie, NS — 902 758-2002

Lower Queensbury, NB — 506 478-4878

By Angie Wilson, PhD, Dairy Specialist, Ontario Ministry of Agriculture, Food and Agribusiness

SUCKLING IS A

CALVES, but cross-sucking is a common concern when housing them in pairs or groups. It can be frustrating to see calves suck on each other’s udders, ears, navels and other areas. However, social housing has benefits in terms of growth and social development, and the updated Dairy Code of Practice for the Care and Handling of Dairy Cattle requires that by April 1, 2031, healthy, thriving and compatible calves kept indoors must be housed in pairs or groups by four weeks of age. Fortunately, there are researchbased solutions that can help reduce cross-sucking behaviour.

Cross-sucking is when a calf sucks on the body part of another calf, such as the head, navel, udder or tail. This unwanted behaviour was thought to be associated with navel infections, udder deformations, mastitis and lower milk production. However, recent studies have not consistently linked these issues to cross-sucking.

Understanding natural calf behaviour can help us reduce cross-sucking. Although suckling behaviour can occur at any time of the day, it is most often seen after a meal, rather than before. Calves instinctively suckle when they start drinking milk (or milk replacer), and they want to keep suckling for at least 20 minutes after they finish their meal. Calves may suckle on objects in the pen or hutch and the body parts of other calves. This is a natural behaviour that occurs in response to ingesting lactose and serves an important role: activating digestive hormones that help calves with digestion and feeling full after a meal.

Because calves are strongly motivated to suckle, it is important to give them outlets for this behaviour to minimize cross-sucking and sucking on other objects. There are ways to reduce or redirect this behaviour.

Dairy researchers at the University of Wisconsin-Madison looked at milk and starter feeding strategies to reduce cross-sucking in pair-raised calves. The research team had 32 pairs of Holstein calves they followed from birth until after weaning. Pairs of calves were assigned to one of four treatments:

1. milk and starter in an open bucket;

2. milk in an open bucket and starter offered in both an open bucket and a specialized bottle with a teat allowing grain to pass through (grain bottle);

3. milk in a slow flow teat bucket and starter in an open bucket;

4. milk in a slow flow teat bucket and starter offered in both an open bucket and a grain bottle. Providing starter early is important for rumen development and the grain bottle was considered a potential option to reduce cross-sucking.

Calves were bottle-fed 2.8 litres of pasteurized whole milk twice per day until milk treatments began at 14 days (3.8 L twice daily) and were completely weaned at about seven and a half weeks of age. Starter (in either the bucket or grain bottle) was first offered at six days of age and was fed unlimited. The researchers measured how long it took for calves to investigate the starter within 90 minutes of putting it out. They also monitored calves’ behaviour during and right after milk feeding from week three to weaning using real-time observers and video recording to identify cross-sucking. They watched for grain bottle use, cross-sucking and sucking on objects.

Calves approached the grain bottle 20 minutes faster than grain in an open bucket, and 73 per cent of the calves chose the grain bottle first. However, there appeared to be no difference in starter intake between treatments. Calves fed milk from teat buckets drank slower than those fed from open buckets, overall spending about five minutes longer drinking before weaning and about two and a half minutes longer drinking during weaning. Also, calves provided with both a teat for milk and for starter preferred the milk teat. They directed their suckling behaviour toward the milk teat of the empty bucket rather than the grain bottle teat.

Both before and during weaning, calves with open buckets for milk and starter spent the most time cross-sucking. Before weaning, providing grain bottles cut time spent cross-sucking in half for calves fed milk with an open bucket and feeding milk from slow-flow teat buckets further decreased cross-sucking by two-thirds, regardless of grain bottle access. Even though the grain bottle was a potential option to redirect suckling behaviour, it was not as effective before weaning as using a slow-flow teat. However, during weaning, where cross-sucking increased overall, the grain bottle and slowflow teat had a similar effect in reducing the behaviour.

The researchers concluded that providing milk via slow-flow teats effectively reduces cross-sucking in calves paired in outdoor hutches. They suggest that the slow-flow teats extend the drinking time and provide an outlet for suckling, which in turn decreases crosssucking. The grain bottle is another practical option that provides a continuously available suckling outlet for calves.

Other feeding strategies to reduce cross-sucking include feeding high-quality milk or milk replacer and ensuring calves receive enough milk. This helps them get the necessary nutrients to grow and avoid chronic hunger. Restricted milk feeding is considered an outdated practice, with a minimum of 9 L per day recommended for calves and even more during cold weather. Allow calves to exhibit natural suckling behaviour by leaving the bottle after the calf has finished drinking or by providing standalone nipples. To reduce competition among calves, ensure there is at least one nipple per calf. Limit competition among calves fed by an automatic milk feeder by decreasing the number of calves per teat and giving them enough time to drink. This is especially important during weaning when calves are hungry. Another approach commonly used is nose flaps, but these are only a physical barrier and do not stop calves’ strong motivation to suckle. Understanding that suckling is a natural and essential behaviour, and providing calves with opportunities to perform it, can reduce cross-sucking among pair- and group-housed dairy calves.

• Feed calves with nipples instead of buckets;

• Use slow-flow nipples so calves drink slower and spend longer drinking;

• Provide starter in a grain bottle to encourage suckling;

• Let calves access the feeding nipple for at least 20 minutes after finishing their meal;

• Provide artificial nipples for calves to suck on;

• Increase daily milk allowance and provide high-quality milk/milk replacer.

References

National Farm Animal Care Council (2023). Code of Practice for the Care and Handling of Dairy Cattle. (pp. 13-14). NFACC, Ottawa, ON, Canada.

Salter, R. S., Reuscher, K. J., Van Os, J. M. (2021). Milk- and starter-feeding strategies to reduce cross sucking in pair-housed calves in outdoor hutches. Journal of Dairy Science, 104(5), 6096-6112.

Van Os, J. M. (2022). 6. Feeding practices and reducing cross sucking. In Two Heads Are Better Than One: A Starter Guide to Pairing Dairy Calves. Available at: https:// animalwelfare.cals.wisc.edu/wp-content/uploads/sites/243/2022/06/06-feeding.pdf. Accessed March 6, 2025.

Break the fly reproduction cycle with regular introductions of fly parasites. These natural enemies attack and kill flies where they feed and breed: in the manure!

Effective: Control flies before they mature and breed. Safe: For humans and other animals. Deadly for flies.

Natural: Unlike pesticides, no harmful side effects. Economical: Comparable or less cost than pesticides.

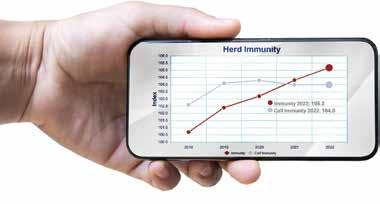

The media landscape is constantly changing and as marketers, we keep our pulse on that landscape as we plan each marketing campaign.

The right mix of media is integral to the success of any campaign as it allows us to reach the right consumers, with the right messaging, at the right moment when they are open to receiving our messages.

Our research shows that consumers are spending on average, 11.5 hours consuming media each day. This time is spent on Linear TV, Radio, Print, Desktop/Laptop, Mobile, and Connected TV.

And 1/3 of this time (approx. 4 hrs per day) is spent on a mobile device.

Leveraging Social Media is one way we reach our consumers. We know that consumers are spending on average 1 hour and 42 minutes with social media each day across various platforms.

We leverage these platforms to reach our consumers across various touch points reaching a hyper targeted audience with our message.

We then layer in the demographics of each social platform to ensure we are connecting with consumers across various age groups to deliver our messaging.

Integration across our various social/digital platforms allows for personalized content automation. One way this integration can be achieved is through our email marketing program, web and social ecosystems.

We can track those who view specific recipes on our website and they will be sent similar recipes via email. Additionally, while on social, consumers can direct message for full recipes. Shortly thereafter, they will be automatically sent similar recipes driving engagement across our ecosystem.

One specific example of how we leveraged new media to reach our audience is Dairycraft. Recognizing the rising popularity of gaming among younger demographics and the value of gamification in learning, DFO’s education team created a custom built digital dairy world in Microsoft’s Minecraft: Education Edition. Dairycraft offers students a fun, immersive way to learn about dairy farming right inside the world’s most popular educational game.

Research shows that 87% of Canadian children aged 7-11 play video games, and half of them use computers weekly to do so - a frequency comparable to game consoles. Given that, it’s no surprise that Dairycraft has been downloaded seven million times around the world!

This educational game allows students to learn about dairy farming in a fun and accessible way. There are 3 key lessons which teachers can also implement into their classrooms: First, in States of Matter, students discover how milk is processed, making connections

Go to Dairycraft.ca to try it out yourself!

between scientific concepts and real-world applications. Next, the Nutrition module teaches students about the nutrients found in milk and how they contribute to a healthy diet. Finally, students learn about the key people and roles on a dairy farm in the Dairy Careers module gaining insight into the teamwork and expertise that support the industry. The combination of gameplay, learning, and classroom-ready activities, creates a dynamic educational experience that teachers and students love.

Source: https://mediaincanada.com/2023/01/30/how-many-kids-in-canada-are-connecting-withvideo-games/>

IN THE LAST 12 MONTHS , the market has continued to be strong and tracking with CDC’s optimistic model. The P5 butterfat production has also tracked with the P5 forecast for the last three months. The P5 butterfat production forecast is expected to be 1.5 per cent higher than the actual 2024 P5 BF production. Butterfat level in P5 milk has dropped in March in comparison to February but is still at a higher level compared to the same month in the last two previous years. A drop in butterfat level in milk is normally observed in March due to feed conditions and warmer weather.

“Continuous quota calculation indicates that P10 could be in an over quota situation for March 2025 and that it would be solely the responsibility of P5” says Patrice Dubé, Dairy Farmers of Ontario’s chief economics and policy development officer.

“If P5 does not realign production with P5 Quota within the next six months, P5 could be required to transfer dollars to the Western Milk Pool at that point in time. However, there is currently an understanding at the national level not to change the production signal until more

analysis is done to better understand what is happening in the marketplace. This analysis will try to shed some lights as to why butter and cheese stock levels are high while an important gap between milk ordered by processors and milk available is observed week after week at the P5 level. Stakeholders will have to decide on a way forward at the national meeting in June.”

In March 2025, butter stocks reached 40,052 tonnes, up from February by 932 tonnes. March butter stock levels are at their highest level for the same month over the last five-years. Butter stocks are also already above our July target level, which is around 35 000 tonnes.

Cheese stock levels for the month of March 2025 were at 106,115 tonnes, up 4,311 tonnes from February and higher than the last fiveyear average.

For the 52-weeks ending March 29, 2025, sales for fluid milk, fluid cream, yogurt, ice cream, cheese and butter increased/decreased by 0.4, 1.2, 5.2, 1.7, 2.1 and 0.6 per cent, respectively, compared with March 2024.

Canadian butterfat requirements in kilograms and actual butterfat production across the P10.

12-month requirements (in millions of kilograms) 12-month production (in millions of kilograms)

441.2 420.5

Canadian production has increased by 2.7 per cent over the previous 12 months, and requirements have increased by 2.7 per cent over the previous 12 months.

This graph shows Ontario’s SNF-BF ratio for the last 12 months.

March 2025: 2.1174

NATIONAL RETAIL SALES

Average increase in retail sales for dairy products sold in Ontario and the dairy product’s share of the total market sales, including at hotels, restaurants and institutions.

• In the last 12 months, the market has continued to be strong and tracking with CDC’s optimistic model;

• In March 2025, butter stocks reached 40,052 tonnes, up from February by 932 tonnes. March butter stock levels are at their highest level for the same month over the last five-years;

• For the 52-weeks ending March 29, 2025, sales for fluid milk, fluid cream, yogurt, ice cream, cheese and butter increased/decreased by 0.4, 1.2, 5.2, 1.7, 2.1 and 0.6 per cent, respectively, compared with March 2024.

As of March 26, 2022

* Source: AC Nielsen & StatsCan NOTE: There is a two-month lag in the national retail sales data.

Percentage of the total milk produced in Ontario that was used to produce dairy products.

2025

For March 2025 (kg of butterfat/kg of solids non-fat)

*There is a two-month lag reporting these figures

Class 1a1 (includes Classes 1a2, 1a3, 1c and 1d for confidentiality reasons) Fluid milk and beverages

Class 1b Fluid creams Class 2a Yogurt, yogurt beverages, kefir and lassi

Class 2b4 (includes Classes 2b1, 2b2 and 2b3 for confidentiality reasons) Fresh dairy desserts, sour cream, milkshakes and sports nutrition drinks

Class 2b5 Ice cream and frozen yogurt

Class 3a1 Specialty cheese

Class 3a2 Cheese curds and fresh cheeses

Class 3b2 (includes Class 3b1 for confidentiality reasons) Cheddar cheese and aged cheddar

Class 3c1 Feta

Class 3c2 Asiago, Gouda, Havarti, Parmesan and Swiss

Class 3c4 (includes Classes 3c3 and 3c5 for confidentiality reasons) Brick, Colby, farmer’s, jack, Monterey jack, muenster, pizza cheese, pizza mozzarella and mozzarella other than what falls within 3d

Class 3c6 Paneer

Class 3d Mozzarella used strictly on fresh pizzas by establishments registered with the Canadian Dairy Commission

Class 4a Butter and powders

Class 4d (includes Classes 4b1, 4b2, 4c and 4m for confidentiality reasons) Concentrated milk for retail, losses and animal feed

Class 5a Cheese for further processing

Class 5b Non-cheese products for further processing

Class 5c Confectionery products

ONTARIO MONTHLY PRODUCER AVERAGE GROSS BLEND PRICE

A total 3,157 producers sold milk to DFO in March compared with 3,191 a year earlier.

March 2025: $ 102.53

The graph below shows the 12-month blend price for the P5 provinces and Western Milk Pool (WMP).

*There is a two-month lag reporting these figures

$96

$94

MONTHLY QUOTA PRICES ($/KG)

WMP: $91.27 P5: $91.66

Newfoundland does not operate a monthly quota exchange. Quota is traded between producers.

* Quota cap price of $24,000 in effect in Prince Edward Island, New Brunswick, Ontario, Nova Scotia and Quebec.

ONTARIO DEDUCTIONS, PER HL

For March 2025

* These figures are based on Ontario’s average composition for March 2025 of 4.3938 kg butterfat, 3.3459 kg protein and 5.9577 kg other solids, rounded to the nearest cent.

The April 2025 Class III Price, US$17.92 per hundredweight, is equivalent to C$56.31 per hectolitre. This equivalent is based on the exchange rate US $1 = C$ 1.38414 the exchange rate when the USDA announced the Class III Price.

The Class III Price is in $ US per hundredweight at 3.5 per cent butterfat. One hundredweight equals 0.44 hectolitres. Canadian Class 5a and Class 5b prices track U.S. prices set by the U.S. Department of Agriculture.

Source: USDA

Co-ordinated by Dairy Farmers of Ontario’s communications and economics divisions. Questions? Please email questions@milk.org.

STAY UP TO DATE!

Weekly Update email newsletter every Friday for Ontario dairy producers.

Milk Producer magazine is the voice of Ontario dairy producers. Subscribe for free or read online at www.milkproducer.ca.

Dairy Farmer Update provides updates with the monthly milk cheque.

Producer Dashboard , a secure platform behind your password on MMS that contains important news, updates and forms.

www.milk.org

Facebook: /OntarioDairy

Twitter: @OntarioDairy

Instagram: @OntarioDairy

LinkedIn: /company/Dairy-Farmers-of-Ontario

By Veal Farmers of Ontario

DEVELOPMENT USUALLY OCCURS during the first four to eight weeks of a calf’s life. This process is driven primarily through the intake of dry feed. If the calf is offered starter from an early age, then the rumen will begin to develop within two weeks of birth. Rumens also need bacteria, liquid, outflow, and absorptive ability to develop. Calf starter quality plays a key role in helping the rumen thrive and prepare for weaning.

Different types of bacteria begin to establish in the rumen shortly after birth through the ingestion of air, milk, and surrounding materials, like straw.

Bacteria in the rumen need water to ferment dry feed. Without adequate amounts of water, bacteria will not grow, which hinders ruminal development. Calves should be provided water at birth, not only when calf starter is being offered. Water does not cause the esophageal groove to close, so any water consumed will enter the rumen, unlike milk and milk replacers that enter the abomasum. Offering free choice water will promote starter intake and can increase average daily gain.

Rumen pressure, contractions, and regurgitation (cud chewing) are measurements of ruminal outflow activity. This activity is very slow at first but should increase proportionally with dry feed intake.

Papillae are the small finger-like projections providing an absorptive surface for the rumen. Research shows that papillae development is determined in large part by dry feed intake and rumen development depends largely on when dry feed is made available to the calf. Providing calf starter and water is the best way to promote early dry feed intake. As with all types of feeds, however, the quality of calf starter plays a major role in its effectiveness, feed efficiency, and consumption rates.

All good starters require sufficient nutritional content. Without good palatability, however, the nutritional content will never be utilized. Palatability is generally highest with textured feed, followed by complete pellets.

Molasses, at about four to five per cent of the ration, is often used to increase the palatability of a calf starter. It also helps to control dust in the feed.

However, starters with considerable amounts of molasses may freeze during winter or clump in hot, humid weather. Molasses is also a potential source for fly contamination.

As calves transition from a milk-based to a grain-based diet, it is important to have a proper weaning process in place to help prevent stalling of growth. Reduce the volume of milk being fed incrementally, and in at least two stages, to promote consumption of calf starter. Do not fill the grain bucket with more calf starter than what will be consumed between feedings. This will help keep the feed fresh. Remember, calves are ready to be weaned when they eat at least one kilogram of starter per day for three consecutive days.

Tip: Calf starter should be offered in a shallow bucket. Start off with a handful and gradually increase that amount as the calf begins to consume all the feed that is in the bucket. They will eat more if they can feel the bottom of the bucket.

A note about weaning

It is important to also ensure that calves are not moved, and painful procedures such as disbudding, dehorning, and castration are not performed in the weeks surrounding weaning, as these events can be stressful. When calves experience stress, they do not put their energy toward growth and maintaining their immune system, making them susceptible to developing disease. Ensuring a high intake of starter will minimize the impacts of weaning and help maintain growth and immunity for calves.

Calf Care Corner, brought to you by Veal Farmers of Ontario, delivers the latest information to help you improve the way calves are raised on your farm. Follow @CalfCareCorner on Facebook and sign-up for monthly e-newsletters on calfcare.ca.

By Lilian Schaer

IN FEBRUARY 2025, Alltech hosted the first-ever Canadian screening of its documentary A World Without Cows. The film provides an unbiased, global perspective on the relationship between cows and the environment.

In a film full of compelling statistics and powerful imagery, one quote stood out for Livestock Research and Innovation Corporation (LRIC) CEO Kelly Somerville: “Farmers are the world’s worst communicators.”

“We hear it all the time—agriculture needs to do a better job of telling its story and this film is one way to push the conversation beyond the usual echo chambers and foster an important dialogue about livestock’s role in our world,” says Somerville.

Ontario is home to some world-class research on the environmental impacts of livestock as well as cutting-edge facilities at the Agricultural Research and Innovation Ontario (ARIO) research stations. LRIC,

although not directly public facing, plays a critical role in supporting the organizations shaping agriculture’s narrative, ensuring that sound science is available and accessible to inform public discussions about livestock and the environment. This includes research benchmarking environmental performance and the continual improvements made by Canadian livestock producers.

“I jumped at the chance to moderate a panel featuring our members and partners. It was a great opportunity to address an audience of agricultural stakeholders and dive into some of the key points raised by the documentary – from the environmental, social, and economic impact of cattle globally to the ongoing efforts of producers the world over to increase efficiencies,” Somerville adds.

Panelists included Dr. Michael Lohuis, Vice President of Research and Innovation at Semex Alliance; Martha Baker, Global Director Carbon Markets at Alltech; Craig McLaughlin, president of Beef Farmers of Ontario; and Laurie Stanton, dairy farmer and owner of Stanton Dairy near London.

Alltech, an LRIC member, is currently taking requests and proposals for private and industry event screenings. The long-term goal is to share the documentary on a major streaming service. This panel interview has been edited for length and clarity,

When we’re challenging misconceptions, what do you think is one of the most misunderstood aspects of cattle?

Laurie Stanton: The balance with methane. When you look at the whole picture and how methane is recycled through (nature), we should stress that more.

Craig McLaughlin: The people telling the story aren’t part of the industry. We are doing good things, and that story is not being told.

Martha Baker: The example in the film, two thirds of business card is the world’s non-usable land; the remaining third is land suitable for growing crops. It’s an easy way to have a conversation about land use and the importance of grazing animals.

Michael Lohuis: Methane isn’t the same as carbon dioxide (CO2). Methane leaves the atmosphere after 10 years, so as long as we keep it constant, we aren’t contributing to warming but CO2 is fundamentally different.

What is the role of breeding and genetic improvement to help mitigate environmental impacts?

Lohuis: It takes many small solutions in the tool box, like methane mitigation supplements in the feed, or genetics. It’s now possible through genomic selection to select for feed efficiency, immunity, and methane reduction. Genetics is a permanent solution and cumulative over generations so over time, it can really help us raise the level of the animals and how sustainable they are.

How do we feed the growing population with farmers asked to do so much more and how do we balance sustainability with this?