The new AZM150 electromechanical interlock boasts a slimline design and a holding force of 1,500 N. The AZM150 can be combined with a range of different actuators to suit different mounting situations, including a straight or angled actuator for sliding guards and a flexible actuator for small hinged guards.

A plus point of the interlock is the 360 degree rotating actuator head which is locked by simply putting on the cover. The actuator head with its two insert slits allows for a range of mounting and approach options for highly versatile use. o

SCHMERSAL | Enigma Business Park

Malvern, Worcestershire, WR14 1GL

www.schmersal.co.uk

uksupport@schmersal.com

Innovation in motion: Bespoke Engineering that deliver results.

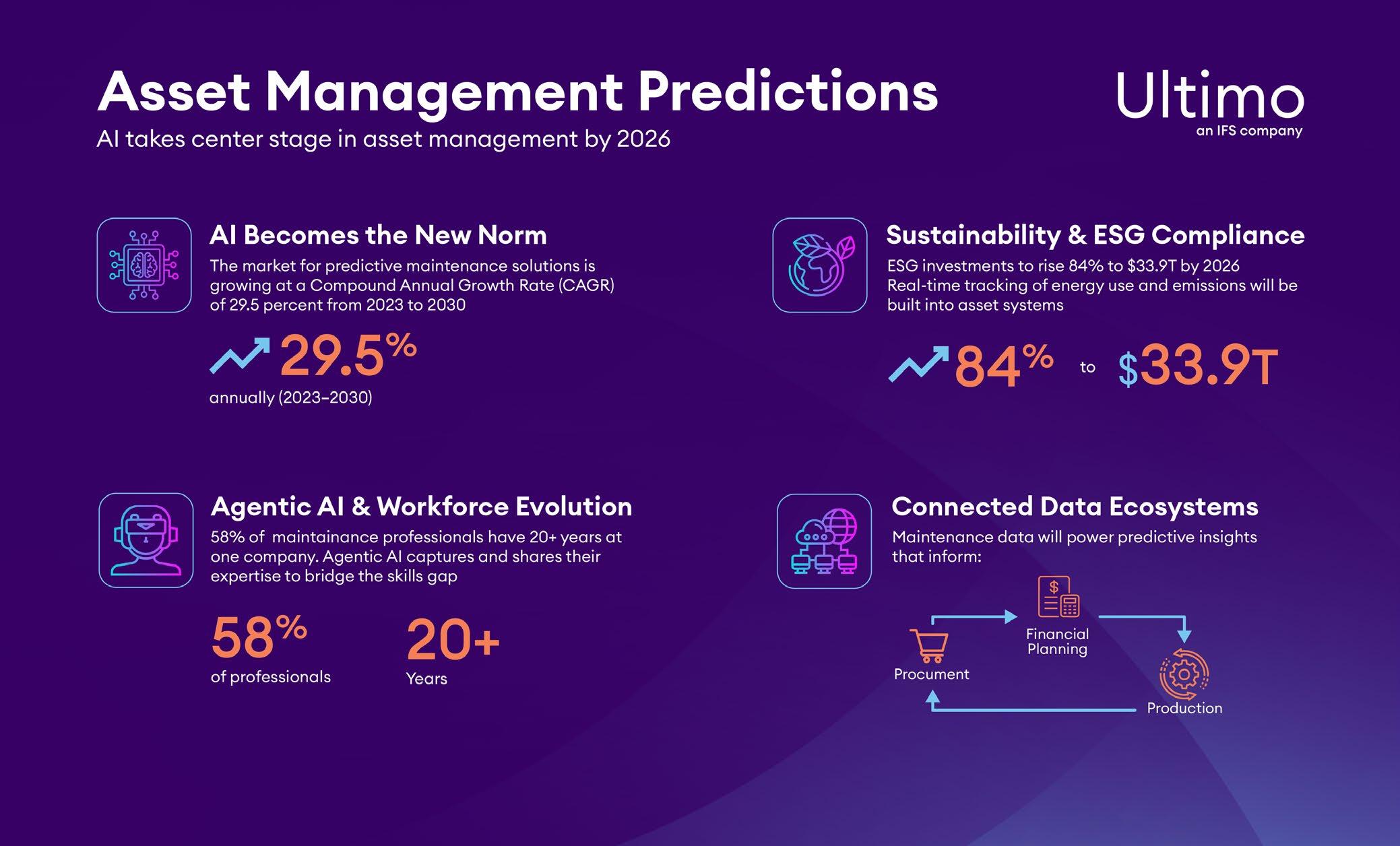

Four predictions for asset management in 2026.

Snap-On Industrial unveils new product range.

Midlands electric motor specialist celebrates 35 years of success.

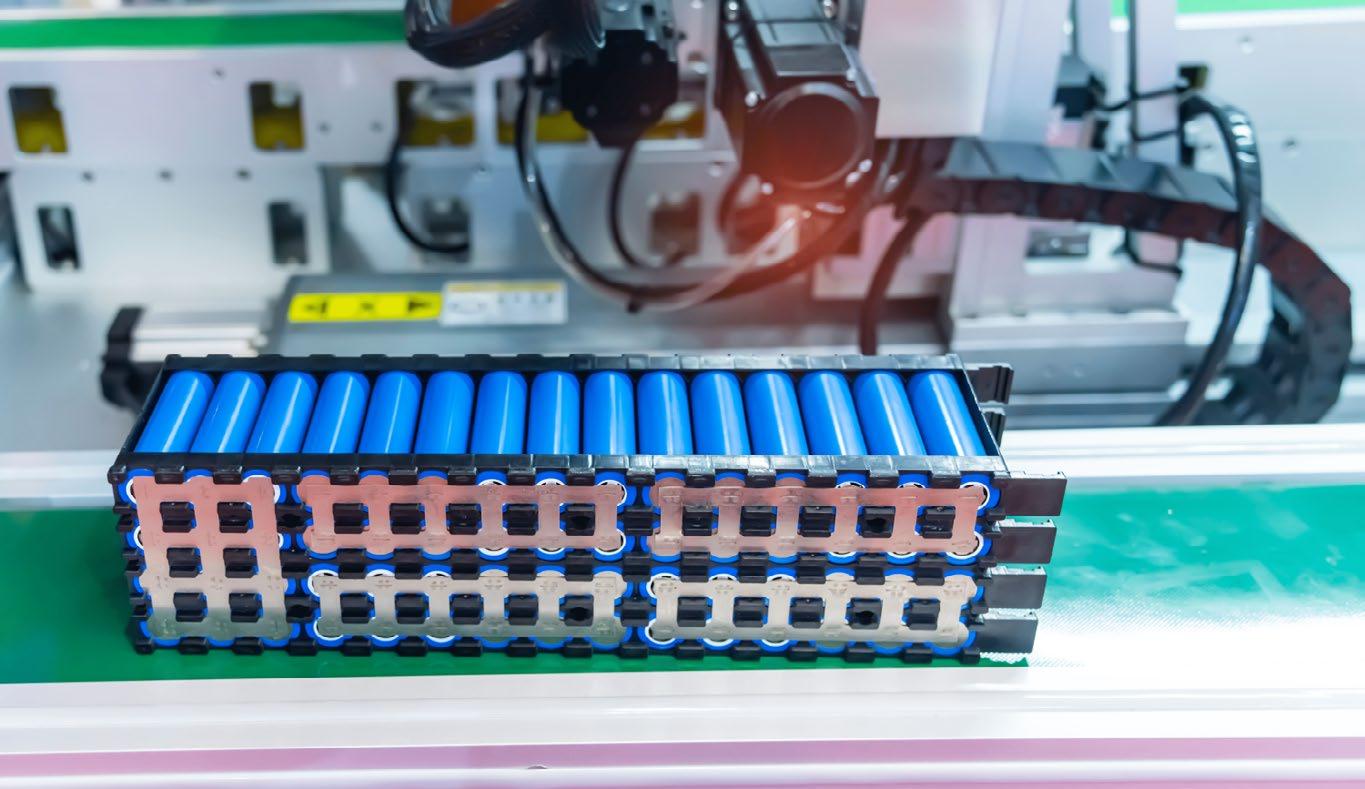

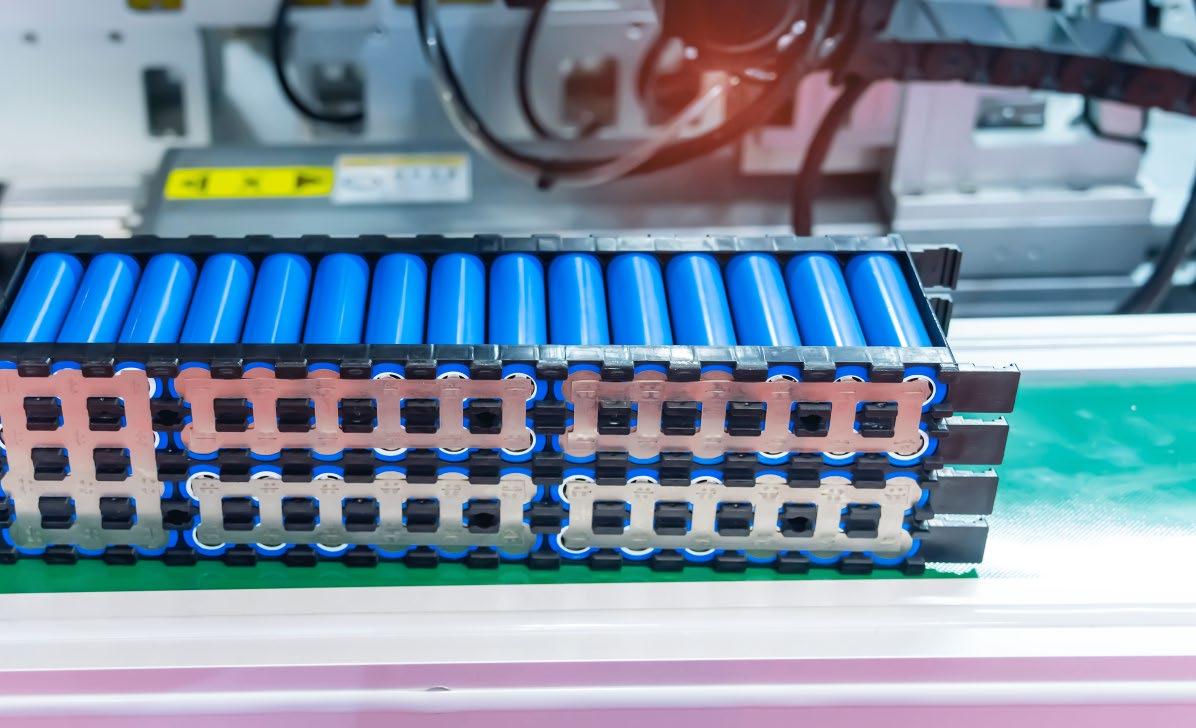

Getting battery design right in robotoics

The hidden cost of tolerance: Why manufacturing excellence requires uncomfortable decisions.

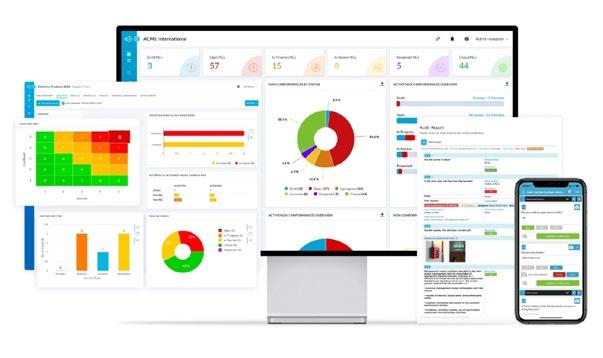

Nulogy powers smarter manufacturing compliance with auditcomply acquisition.

Editor in Chief

Antony Holter antony@designbuybuild.co.uk 01304 806039

Sales Director Harriet Bennett director@mhmagazine.co.uk 0203 907 9161

Sales Manager Jamie Bullock jamie@mhmagazine.co.uk 01227 936971

Business Manager Josh Holmes josh@mhmagazine.co.uk

Studio Designer Leila Schmitz leila@mhmagazine.co.uk

Accounts Manager Lauren Holmes Lauren@mhmagazine.co.uk 01304 806039

Publishing Director Martin Holmes martin@mhmagazine.co.uk Published by:

Media Global Ltd 18/20 Newington Road Ramsgate Kent CT12 6EE Tel: 01304 806039

Velocity Composites plc (AIM: VEL), a leading supplier of advanced composite material kits to the aerospace and high-performance manufacturing sectors, has secured a landmark contract renewal and expansion with a long-standing Tier One customer.

The newly signed long term agreement extends Velocity’s supply of structural composite material kits for the Airbus A350 programme, covering the A350900 and, for the first time, expanding into the A3501000 variant. The scope also includes additional new material kits across both aircraft types. The contract runs through to 2035 further cementing Velocity’s role as a trusted partner in one of the world’s most significant wide-body aircraft programmes.

Based on current Airbus build rate projections, the contract has an estimated potential value of up to $54 million. Revenue is expected to reach approximately $2.5 million in FY2026, with $1.0 million of that representing new business. This new work will replace

contracts with other customers that are naturally concluding, ensuring Velocity’s overall revenue trajectory remains aligned with its existing growth expectations.

All kits will be produced at Velocity’s advanced Burnley facility, where the company has been manufacturing A350-900 kits since 2017. Supply of the expanded packages is scheduled to begin in early 2026 following completion of the standard qualification and transfer process. Velocity already has approvals in place and a proven transfer track record, giving customers confidence in a seamless transition.

Jon Bridges, Chief Executive Officer of Velocity Composites, commented; “This renewal and expansion represents a major milestone for Velocity. It reflects the strength of our relationship with our customer and the confidence they have in our people, technology, and operational excellence. We

are delighted to expand into the A350-1000 for the first time and to be supplying all remaining kitted material for both variants. With build rates expected to rise, this long-term contract secures a substantial revenue stream and positions us to support one of the aerospace industry’s most important programmes.”

James Eastbury, Chief Customer Officer at Velocity Composites, added: “This award is a clear demonstration of the trust we’ve built with our customer over many years. Our integrated approach to material kitting—combining engineering expertise, digital traceability, and lean supply chain management—enables customers to reduce waste, improve efficiency, and increase throughput. These are critical drivers in the high-precision world of

aerospace manufacturing, and we’re proud to be delivering measurable value.”

The announcement reinforces Velocity’s reputation as a strategic partner capable of combining deep technical integration with long-term reliability. As aerospace manufacturers continue to focus on operational efficiency, sustainability, and supply chain resilience, Velocity’s advanced service model offers customers a proven solution to reduce cost, complexity, and risk.

With this agreement, Velocity strengthens its customer partnership and reaffirms its role as a key enabler of the global aerospace industry’s most ambitious programmes.

For more information, please visit: www.velocity-composites.com

RICHARD ASPINALL, SENIOR VICE PRESIDENT - ENTERPRISE EUROPE

Manufacturers continue to press ahead with digital transformation, continuing to invest heavily in the internet of things, whilst implementing and integrating newer technologies such as cloud services and artificial intelligence.

The promise of more efficient production is alluring, sharpened by broader market pressures, from increased regulation to fragile supply chains. Yet beneath the surface lies a less visible obstacle that threatens to undermine progress: a bandwidth bottleneck in network infrastructure.

The future of smart manufacturing won’t be determined by who has the most robots or AI algorithms. It will be determined by who builds a secure, unified and resilient network fabric capable of enabling those innovations at scale.

Manufacturers can’t rely on siloed solutions. They need one global, secure networking platform that

can keep plants running, protect against disruption and bridge edge, cloud and core environments –let’s discuss why this is the case, and how network infrastructure is key to competitiveness.

The factory floors of today have completely transformed as compared to those of the previous generation. No longer made up solely of heavy machinery and manual labour, they are now complex digital environments where smart sensors, robotics, digital twins and remote operations operate side by side. Each of these tools generate vast quantities of data, all of which must be collected and transmitted reliably and securely across sites and systems for monitoring and analysis.

Röchling Automotive’s 40 globally distributed sites required a high performance, secure, and highly reliable network to ensure consistent operation,

where downtime could cost millions per day. This is just one example of the critical nature of connectivity. Industrial machines can produce gigabytes of data daily, with a modern smart factory potentially relying on hundreds of such systems. For manufacturers, having network systems that can scale and adapt to meet these requirements is necessary.

If data cannot move quickly enough to support predictive maintenance, real-time analytics or safety monitoring, operations grind to a halt. The ability to sustain these capabilities ultimately depends on the resilience of the underlying network.

The cloud is evolving and so are its demands

As with many sectors, the initial wave of cloud adoption saw mass enthusiasm for offloading as much as possible to public providers. However, this approach has since matured, with manufacturers adopting multi cloud and hybrid strategies, weighing up which workloads belong in the cloud and which should remain closer to operations.

According to a recent Cloud Trends report, organisations are shifting away from public cloud, often due to cost, performance or sovereignty issues. In Europe, GDPR and initiatives like GAIA-X amplify the need for sovereignty-aware strategies.

A growing trend is the rise of so-called “AI factories” at the edge. Siemens and NVIDIA, for example, expanded their partnership recently to build “industrial metaverse” digital twin factories, including a FREYR Gigafactory project. These efforts demand deterministic, low-latency networking; if synchronisation lags, the digital twin loses predictive value.

This is driving repatriation of certain workloads back into private or on-premise environments, mainly citing their reasons as cost, control or security. All these factors create a more complex IT ecosystem that demands seamless connectivity between onpremises systems, edge deployments and the cloud environment chosen by the manufacturer. Many legacy networks weren’t initially designed to handle this level of interoperability.

Incompatibility, latency, and bandwidth limitations all present risks that could undermine even the most carefully laid out plans.

The infrastructure gap is a competitive risk

While discussions around manufacturing innovation often focus on robotics or AI, the less visible

infrastructure challenge carries just as much weight. Without the right digital backbone, the potential of these technologies cannot be realised.

In 2025 alone, UK and European manufacturers are projected to lose more than £80 billion due to downtime, according to research from IDS-INDATA. In an environment where margins are squeezed by energy volatility and supply chain risk, every minute of downtime is EBITDA at risk.

AI-driven processes, automated quality control, and robotics-enabled production lines all share a common dependency: a reliable and secure network. If the network falters individual processes or even entire operations are jeopardised. It is not tools which pose the biggest challenge, but the invisible fabric that supports them.

This is why the gap between infrastructure and capability is more than a technical issue, but a competitive risk. Manufacturers that are unable to modernise their connectivity will inevitably find themselves at a disadvantage compared to those that can. They may face longer downtime and missed opportunities, losing any competitive advantage despite large scale initiatives to gain one.

The key to modern manufacturing transformation is connectivity. Manufacturers must think beyond applications and cloud strategies and address the fundamental role of network infrastructure in enabling any transformation initiative. Investment in low-latency, high-bandwidth connectivity is the foundation of performance.

Manufacturers and Managed Service Providers (MSPs) can work together to design systems that can meet the ever-increasing demands of smart factories. System requirements, levels of security and scalability must all be considered from the outset, rather than treated as afterthoughts.

The next phase of digital transformation in manufacturing will not simply be about adopting more AI or shifting more workloads to the cloud. It will be about creating an infrastructure that can sustain these advances by removing the bandwidth bottlenecks that hold progress back. Those who recognise this reality and act accordingly will be best placed to harness the full potential of digital technologies, while those who ignore it risk being left behind.

www.gtt.net

Offer consistent product quality at the point of use for a wide range of applications, guide rails position the IBC and the mixer is raise and lowered into the IBC with a push button operated electrical actuator.

Fixed or mobile mixing stations are supplied complete with a control panel and safety interlocks.

Standard IBC mixing stations can be adapted to integrate with systems on site including pumps, valves, weighing and measuring instrumentation and controls to meet specific site requirements.

Offer consistent product quality at the point of use for a wide range of applications, guide rails position the IBC and the mixer is raise and lowered into the IBC with a push button operated electrical actuator.

Fixed or mobile mixing stations are supplied complete with a control panel and safety interlocks.

Standard IBC mixing stations can be adapted to integrate with systems on site including pumps, valves, weighing and measuring instrumentation and controls to meet specific site requirements.

Offer consistent product quality at the point of use for a wide range of applications, guide rails position the IBC and the mixer is raise and lowered into the IBC with a

actuator.

Fixed or mobile mixing stations are supplied complete with a control panel and safety interlocks.

Standard IBC mixing stations can be adapted to integrate with systems on site including pumps, valves, weighing and measuring instrumentation and controls to meet specific site requirements.

BY JAKOB ÁSMUNDSSON, CEO, DTE

Aluminium is a critical metal for the industries changing the world, from electric vehicles to solar energy. The aluminium sector is also battling a number of headwinds, ranging from high energy costs and thinner margins to scrap utilisation and pressures to reduce carbon emissions. To secure its future, the industry needs to embrace innovations and measurement is an area ripe for change.

Previously, metal samples needed to be handled by human operators and cooled before being analysed. This exposed operators to hazards and was less than ideal from an operations standpoint, prone to contamination and errors. Now, Laser-Induced Breakdown Spectroscopy (LIBS) is fuelling an industry transformation by revolutionising how metals are analysed. LIBS fires a high-energy laser pulse at the sample surface of liquid aluminium. The pulse vaporises a microscopic quantity of metal, creating a high-temperature plasma plume from which a unique emission spectrum is generated for every element present.

LIBS makes it possible for molten metal to be rapidly analysed, with data being collected in real time to inform process operations. Data from LIBS can

be used to prevent overprocessing and associated wasted energy, along with detecting critical safety incidents such as tap-outs. Laser measurement tools have benefits reaching beyond measurement to overall operations and finished products, as DTE’s partnership with Ramboll demonstrates.

By partnering with global leaders in engineering and consulting, DTE is enhancing process control for aluminium producers by combining its Molten Metal Analysers with world-class expertise in industrial automation and equipment integration. The industry now has a complete solution for real-time chemical composition analysis, allowing aluminium producers to optimise their processes with precise, in-situ data. Industrial 4.0 is all about the convergence of data, systems integration and automation, and DTE is helping aluminium producers to achieve just that and stay at the forefront of innovation.

LIBS is far more than just a measurement tool, and when integrated with wider systems and processes, it acts as part of a nervous system for aluminium operations. At a time when aluminium producers are battling headwinds, using the insights gained from a melt to optimise processes, save energy, and lower emissions is a real competitive advantage in a volatile world. The new era of aluminium production is here, and measurement is taking centre stage as an innovation transforming the industry for the better.

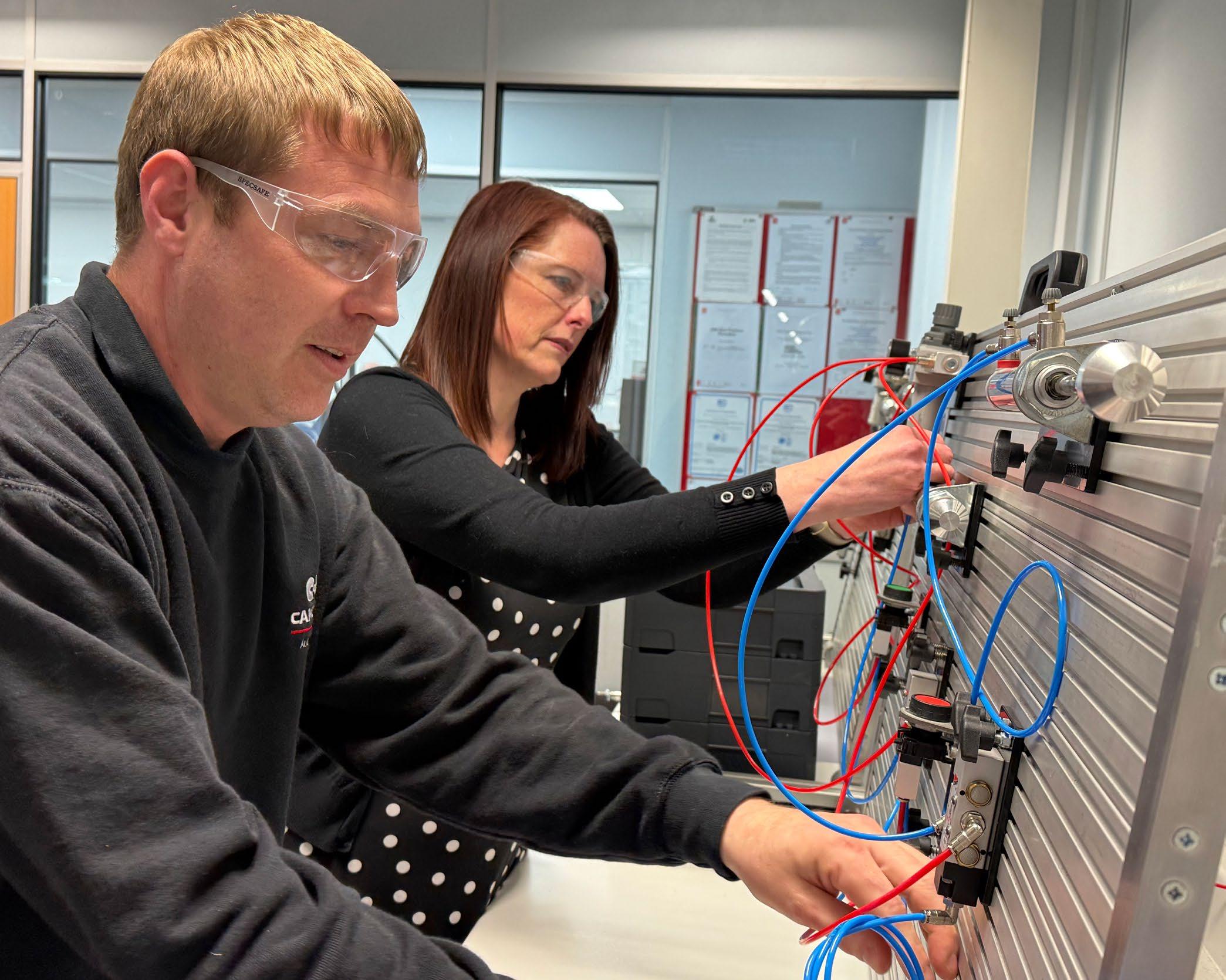

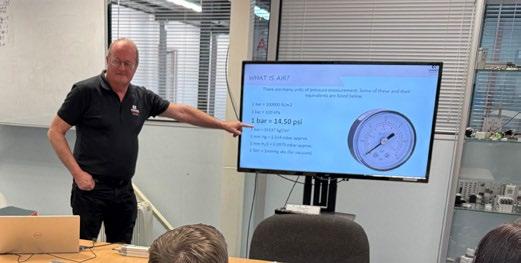

Camozzi Automation Ltd, a leading name in fluid power and automation technologies, has announced the expansion of its industry-recognised training portfolio with the introduction of two new specialist courses: Advanced Pneumatics/Electro-Pneumatics and Safety in Pneumatics/Energy Saving.

Launching in 2026, these new courses build on the success of the company’s long-running Introduction to Pneumatics programme — already a favourite among engineers, technicians, and maintenance professionals across multiple industries.

Designed to equip delegates with both theoretical understanding and hands-on experience, the new courses aim to support companies striving for improved efficiency, reliability, and workplace safety in their pneumatic systems.

Delivered at Camozzi Automation’s UK headquarters in Nuneaton, the enhanced training portfolio offers:

1. Introduction to Pneumatics – £525 per delegate (two-day course)

2. Advanced Pneumatics/Electro-Pneumatics – £595 per delegate (two-day course)

3. Safety in Pneumatics/Energy Saving – £450 per delegate (one-day course)

A £150 deposit per delegate secures a place, and discounts are available for multiple or multi-course bookings.

Advanced Pneumatics/Electro-Pneumatics: NextLevel Expertise

This comprehensive two-day course integrates mechanical and electrical principles, helping delegates gain a deeper understanding of modern pneumatic systems. Topics include:

• Circuit sequencing and cascade design

• Logic valves and time delay circuits

• Basic electrical theory and solenoid valve control

• Introduction to PLCs, ladder logic, and Fieldbus technology

Safety in Pneumatics/Energy Saving: Protecting People and Systems

Focusing on the twin goals of safety and sustainability, this one-day course highlights how safe design and energy-conscious operation can deliver rapid ROI. Topics include:

• Guard interlocking and emergency stop circuits

• Risk assessment best practice

• Pneumatic safety products and safe working procedures

• Air system optimisation and energy-saving techniques

Delegates will learn how implementing the course’s recommended techniques can help systems operate more safely and efficiently — often allowing the course to pay for itself within weeks.

Delivered by Industry Expert Steve Partington

All courses are led by Steve Partington, a respected figure in the pneumatics industry with more than 45 years of experience spanning R&D, applications engineering, and technical leadership.

“It’s incredibly rewarding to share the lessons I’ve learned over decades in pneumatics,” says Steve. “These courses give delegates practical, usable skills that deliver real value to their organisations.”

Spaces for the 2026 courses are limited. To register interest or enquire about group discounts, contact training@camozzi.co.uk or visit www.camozzi.co.uk/camozzi-pneumatics-training

Camozzi Automation Ltd 024 7637 4114 training@camozzi.co.uk www.camozzi.co.uk store.camozzi.co.uk DEVELOP SKILLS. SAVE ENERGY. IMPROVE SAFETY.

Hands-on learning in a dedicated training facility

Blend of theory and practical application

Learn techniques that save time, money, and energy

Certification awarded upon successful course completion

Dexory, the leading provider of real-time warehouse intelligence, visibility and autonomous solutions, today announced it has raised $165 million. This milestone reflects the value customers derive from the solution, resulting in strong growth since the company’s Series B in 2024. Eurazeo, through its Growth team, led the $100M Series C round, with participation from LTS Growth and Endeavor Catalyst, alongside existing investors DTCP, Atomico, Lakestar, Elaia, Latitude Ventures, Wave-X and others. In addition, Bootstrap Europe expanded the existing growth debt facility.

Since its Series B, Dexory has expanded the reach of its AI-enabled data-intelligence platform, DexoryView, across Europe, North America, and APAC, and established its North American headquarters in Nashville, Tennessee. This global footprint enables the company’s autonomous robots to capture and deliver the largest pool of live warehouse data and insights, driving significant improvements in efficiency, visibility, and scalability for its customers. Today, the platform is used by logistics leaders such as GXO, Maersk and DHL; manufacturers including Stellantis and GE Appliances; and by customers across pharmaceuticals, retail and eCommerce.

The new funding will accelerate Dexory’s product roadmap and expand access to its technology, removing key bottlenecks in warehouse transformation. In a market often stuck in pilots

and overpromises, Dexory delivers immediate value. Customers gain live visibility and dependable, scalable insights without long lead times or operational disruption.

“This new round allows us to bring forward transformational capabilities that our customers are asking for,” said Andrei Danescu, CEO and Co-Founder of Dexory. “By combining full-stack engineering with zero customer complexity, we are building advanced agentic systems powered by the industry’s richest set of real-world logistics data. This will help warehouses and supply chains shift from systems of record to true systems of action.”

As the industry looks for partners who can deliver innovative and reliable systems, this funding will enable Dexory to help warehouses self-optimise, anticipate challenges, and coordinate tasks seamlessly between people, machinery, and systems. It will also support new approaches to deploying large-scale distributed intelligence for legacy industries, opening the door to the next generation of resilient and adaptive supply chains.

Dexory will also strengthen its commercial teams and expand across multiple international markets as well as serving new sectors. This growth is underpinned by intelligence grounded in real operational data, including more than half a billion warehouse location scans. As a result, Dexory’s AI is reliable and immediately impactful for smarter decision-making across customer operations.

“We are excited to back Dexory as they continue to scale the impact of their platform and grow their global footprint,” said Raluca Ragab, Partner at Eurazeo. “Dexory’s extraordinary combination of robotic and software engineering strength bridges the constraints of the physical supply chain with the power of AI-optimised intelligence, harnessing operational data at scale and turning it into actionable insights. We see a vast global market ahead, and Dexory is uniquely positioned to help the industry leap into the future.”

Electro-technical accessories, such as connectors or heat-shrink tubes, determine the life cycle of numerous installations. They are particularly important when installed in vehicle, industrial automation or heavy machinery cabling systems. It is good to check, then, what distinguishes TE Connectivity products among other solutions.

This article presents the range of products supplied by TE Connectivity, a manufacturer that specialises in producing connectors, installation accessories and electro-mechanical components. Selected products from this range can be used in numerous applications, and they are featured in several sections of our catalogue. Obviously, we are not presenting the full assortment of this supplier here, but only its relatively small part.

This article covers the following issues:

• Types and applications of heat-shrink components

• Creating installations using rail-mounted connectorsand blocks

• Most popular types of connectors

• Power relays included in the TE Connectivity product range

Heat-shrink tubes and profiles

The range of heat-shrink tubes and profiles offered by TE Connectivity includes a few hundred items. It results from the variations concerning several parameters. One of those is the tube diameter that can range from 1.2 mm to 101.6 mm (before shrinking at a ratio of 1:2, 1:3 or even 1:4). This diverse range alone suggests that these products are designed for numerous electro-technical applications, i.e. in the field of electronic engineering, commercial electric engineering, and also industry and power generation, such as creating power supply lines for buildings. For the latter, i.e. high-current installations with largediameter cables, profiles with enhanced mechanical strength that is ensured, in the case of TE Connectivity products, by cross-linked elastomers, are the most common choice. Such components are divided into two main product categories: profiles and breakout boots. Profiles come with several functions, as they stiffen and reinforce the areas of straight or angular wire routing, and seal any reduction points, e.g. where a cable is inserted into a connector, pipe or conduit without a gland. Break-out boots ensure the continuity of the outer sheath in locations where a power or control cable is opened and separated into individual conductors (from 2 to 4), so that they eliminate the risk of contaminants and moisture

penetrating the cable, which in turn could lead, for example, to the hydrolysis of the inner insulation layers.

202K163-25_86-0

A profile coated with adhesive may become a sealing gland.

RNF3000-12_4-2-STK

Tubes

202K232-25/225-0

Profiles

462W023-25_225-0

Break-out boots

Note that the products presented here include heat-shrink elements that are additionally coated with adhesive (on the inside), which melts under the influence of the shrinking temperature to ensure tight and firm adhesion to the surface covered. It is particularly important when securing not only electric cables, but also pipes and hoses used to transport various liquids. The majority of TE Connectivity heat-shrink accessories is made of polyolefine that is resistant to exposure to numerous substances, such as oil, petrol or grease. Note also that small-diameter heat-shrink tubes are available in numerous colour versions to facilitate consistent labelling of power supply and signal lines, not only in three-phase systems.

Glands and other accessories

1SNG601190R0000

Polyamide gland ensuring IP68 degree of protection.

The TE Connectivity product range encompasses various mechanical installation components. These include glands made of plastic (polyamide), (nickelplated) brass or stainless steel. Their sizes are adjusted to lines and pipes with diameters ranging from 2 mm to 55 mm. They ensure a high degree of protection (IP68), i.e. full dust tightness and water resistance, also to pressurised water jets. Gland seals and nuts are available in sets or individually, which facilitates the selection of optimum solutions for each typical application. Additional products for those cabling accessories include caps with diameters ranging from 4 mm to 44.2 mm, as well as thread adapters. Moreover, TE Connectivity offers multi-circuit cable conduits.

DIN rail-mounted connectors

Connectors and distribution blocks mounted on DIN rails (TS32 or TS35) ensure optimum organisation of

distribution cabinets (and fuse boxes) and enhance all system retrofitting operations. They are used in power supply, signal and control circuits, mostly in industrial conditions. The TE Connectivity products related to this field of application are gathered in the Entrelec (SNK) family of solutions.

1SNK712021R0000

Rail-mounted connectors (2 and 3 terminals)

1SNK506214R0000

Rail-mounted connectors (4 and 6 terminals)

1SNL317510R0000

Distribution blocks

The majority of products included in this range are single-circuit components. Their enclosures are made of polyamide with the UL94V-0 flammability class. It is a diverse product range that comprises connectors with screwed and spring-loaded terminals designed to ensure minimum resistance and necessary mechanical strength (vibrations, shocks, jerking) when connecting conductors in the form of solid and stranded wires. TE Connectivity has strived to ensure the highest possible level of installation convenience, as the company estimates that using their products enables installers to save even 90% of installation time in comparison with solutions offered by competitive brands. Their symmetrical shape greatly reduces the likelihood of mistake during fixing and connecting operations. As the majority of connectors are 5.2 mm–8 mm wide, they facilitate creating complex systems even in relatively small enclosures. The TE Connectivity product range also includes distribution blocks mounted on rails or panels, as well as housings with built-in terminals for power line distribution. A high-current cable entry is located in the upper part of the enclosure, while the lower section comes with minor circuit leads (up to 24 in total), e.g. to be mounted in flats or rooms. The distribution blocks come in single or triple versions.

Connectors

Another extensive range of electric installation accessories offered by TE Connectivity includes common-use connectors and cable terminals. It encompasses all popular product types, i.e. mostly insulated flat connectors (width from 2.8 mm to 6.3 mm) and ring terminals. The former are used in almost every field related to electric system installation, in particular for creating connections in machinery, as they are characterised by very low resistance, resistance to vibrations and, simultaneously, short mounting time. The company offers products crimped on conductors with crosssections from 0.3 mm2 to 6 mm2, which makes them suitable both for making both signal and power supply connections. Therefore this product range is addressed not only to technicians working in machinery parks, but also to manufacturers of

electronic equipment, radio and TV devices and white goods. These products are also suitable for applications in such fields as the automotive industry, for servicing and retrofitting circuits in passenger and cargo vehicles.

9-160463-2

Less typical connector model with leads.

342145-1

Ring terminals

2-520409-2

Flat connectors

165085

Other terminals

Another popular product type includes ring terminals designed to be fastened on cables with cross-sections from 0.1 mm2 to 10.5 mm2. Here, too, a wide range of applications can be mentioned in which power supply connections predominate. These connectors are commonly used in renewable energy installations, primarily to create energy storage facilities, i.e. to connect batteries into high-capacity and highcurrent-efficiency power banks. They are also used in a similar manner in automotive applications to short various components to ground. They are universally applied to connect protective wires to enclosures and other metal components in network installations, as well as earthing fences, boxes, etc. Obviously, TE Connectivity also offers other models of terminals and connectors, such as spade, pin or angular variants, as well as components with leads, etc. These products are also available in a form of sets.

High-current relays

ECK200AAAPA

Coil leads are designed in a form of wires.

Note again that the products presented in this article constitute only a part of the TE Connectivity assortment. The company also offers a wide range of connectors and passive elements. Another range of solutions offered by this manufacturer includes the ECK series of power relays. They are designed for such application areas as renewable energy systems (inverter switching, energy storage), electric vehicle charging stations and even electric forklifts. They contain hermetically sealed SPST-NO contacts closed by applying voltage from 9 V to 36 V DC. As these components can withstand currents up to 150 A, 200 A or even 250 A (depending on the model), their leads are designed as screwed connections. Their nominal voltage reaches 1 kV DC. The manufacturer has also provided for a relatively wide tolerance for instantaneous currents, which may reach up to 1000 A, thus making these elements suitable for motor operation control applications.

www.tme.eu

Bicker Elektronik GmbH, Donauwoerth/Germany, presents a robust and fail-safe DIN rail bundle designed for control and automation tasks in industrial environments. The flexible DIN rail solution combines three perfectly matched components: the Delta DRL-24V120W1EN AC/DC power supply, the Bicker UPSI-2406DP1 DC UPS with integrated Li-ion battery pack, and the GIGAIPC QBiX-DREHLA6412H-A1 DIN rail industrial PC. Together, these components ensure a reliable and uninterrupted 24V DC power supply as well as high computing performance for continuous operation in harsh industrial conditions.

The space-saving DRL-24V120W1EN DIN rail power supply from Delta Electronics delivers 120 W nominal output (24V / 5A) with an efficiency of up to 91%. With a compact width of just 30 mm, it saves valuable space

on the DIN rail and simplifies integration into control cabinets. The wide input range of 90–264 VAC enables global use, while the operating temperature range of –40°C to +70°C ensures high reliability. Comprehensive protection features against short circuit, overvoltage and overtemperature guarantee safe operation. The power supply is certified according to IEC/EN/ UL 62368-1 and IEC/EN/UL 61010-1. Electromagnetic compatibility meets the industrial standards EN 61000-6-4 Class B (emission) and EN 61000-6-2 (immunity).

The Bicker UPSI-2406DP1 protects critical systems against power failures, voltage dips and transients. Delivering 24V / 4A (96W), the UPS automatically switches to battery operation in the event of a mains failure. Certified to IEC/UL/CSA 61010-1 / -2-201, the compact DC UPS is designed for operation from 0°C

to +50°C. The intelligent power-sharing function dynamically distributes input power between load and battery charging, while the battery management system with Smart Battery Lock prevents unwanted discharge and enhances operational safety. With the freely available cross-platform UPS management software „UPScom“, all parameters can be configured, system status monitored, and controlled system shutdowns or automatic reboots of connected IPCs initiated during power outages.

The GIGAIPC QBiX-DR-EHLA6412H-A1 is a powerful DIN rail industrial PC for 24/7 continuous operation in demanding industrial environments. Based on the Intel® Celeron® J6412 processor (4 cores, up to 2.6 GHz, 10 W TDP), it supports up to 32 GB DDR4 RAM. The system provides 2× Intel® Gigabit LAN, 4× USB, 4× COM, HDMI 2.0 and VGA, GPIO (8 bit) and three M.2 slots as well as a SIM slot for 4G/5G. With fanless passive cooling, 9–36 V DC wide-range input, DIN rail mounting and a rugged aluminum chassis, the IPC ensures reliable, maintenance-free operation from 0°C to +50°C. The QBiX-DR-EHLA6412H-A1 is ideal for control, monitoring and edge-computing tasks in modern Industry 4.0 applications. Bicker Elektronik also offers matching DDR4 SO-DIMM modules and M.2 SSDs with extended temperature ranges.

Integrated complete solution with system advantage

The Bicker DIN rail IPC bundle combines power supply, UPS protection, and an industrial PC into a single integrated solution. It ensures safe AC/DC power supply, protects critical systems from power outages, and simultaneously provides high-performance computing capacity:

• Reliable 24V DC power supply with UPS buffering

High reliability during voltage fluctuations and blackouts

Powerful IPC computing performance for DIN-rail mounting

Fanless and energy-efficient operation

Compact designs for space-saving control cabinet layouts

Minimized wiring and integration effort

• Compliance with industrial standards

The bundle offers a practical, ready-to-use complete solution for modern production and process automation.

www.bicker.de

DESIGNED SPECIFICALLY FOR DRIED FRUIT PROCESSING, OUR TAILORED AGITATOR SYSTEM

INCREASED EFFICIENCY, IMPROVED WORKFLOW AND DELIVERED MEASURABLE OPERATIONAL SAVINGS.

At Concept Engineering our wealth of knowledge and understanding of processes enables us to design, build and install bespoke, innovative and effective solutions.

We handle projects for companies across an array of industry sectors and have experience and expertise in the food, fish, manufacturing, medical and pharmaceutical sectors.

We pride ourselves in delivering first class service and maintain clear lines of communication with clients through conception, manufacture and post installation.

Formed in 2008 our operating has expanded continuously since then to a team 20 strong staff headed up by Managing Director Steve Larkin. Our manufacturing capability is supported by an in-house team of Design Engineers and CNC Programmers using CAD and Solid Works.

The business recently moved into new premises in Hull and major investment has been made in technology including CNC machines to deliver the finest precision close limit sheet metal work.

In March 2021 we achieved BS EN 1090 accreditation covering the fabricated structural steelwork products and assures the appropriate controls are in place at every stage of the manufacturing process from procurement of raw materials to final inspection and testing.

Our customer for this project is one of the UK’s leading suppliers of speciality nuts, dried fruit and confectionery to independent retailers, manufacturers and multiples.

The company needed a system which would break up 25kg blocks of raisins and feed them into the production line. They were unable to source a readymade solution and had to rely on using staff to manually break up the blocks.

Concept Engineering was approached to see if a solution was possible.

After analysing the production system Concept’s engineers designed and built a robust solution which met the standards and specification required. It was designed to provide a range of flexibility in product sizes and improve efficiency.

Concept Engineering were able to provide a full solution including agitator and conveyor system designed specifically for the client’s dried fruit process.

The Concept agitator system allowed the client to process a 25kg block of raisins every seven seconds. The new system has speed up production and produced significant savings in labour costs.

www.conceptengineering.co.uk

The Concept agitator system processes a 25kg block of raisins every seven seconds and can feed them into any production line

The new machine was developed after one of the UK’s leading suppliers of speciality nuts, dried fruit and confectionery required a bespoke solution to improve e ciency.

Concept Engineering of Hull were approached and they designed what is believed to be the only machine of its kind capable of breaking blocks of dried fruit without causing damage.

The Concept Fruit Breaker features an agitator to break up solid blocks of dried fruit, a task that previously had to be carried out manually.

2-6 GB Business Park, Wiltshire Road, Hull, HU4 6PA. 01482 351267

Generation. Each and Every Gas,” the range provides dedicated, portable solutions for traditional SF6, new alternatives like C4-FN and C5-FK fluoronitriles, and Clean Air. Most notably, the comprehensive ‘QU4D’ analyser can handle all insulating gases in a single, field-ready device. This empowers operators and engineers to maintain compliance, detect leaks, and ensure performance across their entire fleet, seamlessly bridging the gap between old and new technologies.

For any company in the technology sector, a 25-year anniversary is a significant milestone. It represents not only longevity and resilience but also a deep-seated expertise forged through decades of partnership with industry. As Cambridge Sensotec celebrates a quartercentury of advancing excellence in gas analysis, this milestone is not just a reflection on a successful past, but a launchpad for a future defined by innovation and responsiveness to the evolving needs of engineers and operations leaders. Today, this commitment is demonstrated by its solutions to the industry’s most pressing needs, from the market-leading Rapidox 6100 range to the launch of the pioneering Rapidox 1100-OPT-MAX analyser.

First, in the electrical power industry, the transition away from the potent greenhouse gas SF6 is no longer a future prospect but an urgent reality. Regulatory pressures are mounting, and utilities must navigate a complex shift whilst maintaining grid stability and operational performance. This requires versatile tools that can manage both legacy SF6-filled assets and the new generation of greener alternatives. Answering this call, Cambridge Sensotec’s versatile Rapidox 6100 range of zero-emission analysers is engineered for precisely this challenge. Under the principle of “Every

Simultaneously, the company is redefining the standards of precision process control with the introduction of the Rapidox 1100-OPT-MAX, the world’s first truly full-scale optical oxygen analyser. This breakthrough instrument uses dual optical sensors working in tandem to deliver unprecedented accuracy and stability across the entire measurement spectrum, from trace levels of 0.1ppm right up to 100% oxygen. By eliminating the sensor drift and limited lifespan associated with traditional electrochemical sensors, this technology offers a dramatically lower lifetime cost of ownership and enhanced reliability in critical applications, from inert gas blanketing to advanced manufacturing and laboratory environments.

As Cambridge Sensotec marks its 25th year, these innovations are more than just new products; they are a testament to a legacy of listening to industry and a future dedicated to engineering the solutions that drive it forward.

www.cambridge-sensotec.co.uk

Twenty five years on, Cambridge Sensotec has become the trusted name in gas analysis worldwide.

Our Rapidox analysers – along with a comprehensive range of accessories, calibration and servicing – deliver the precision and durability engineers demand across multiple gases, including Oxygen, C02, Helium, SF6, clean-air alternatives, and more.

With bespoke OEM solutions and global support, we keep operations safe, efficient and emission-aware.

Rapidox

SF6 6100

Multi-gas

Pumpback Analyser

Rapidox 6100

C4-FN & C5-FK

Pumpback Analyser

Rapidox 6100 CLEAN AIR Pumpback Analyser

Analyser

Oxygen analysis at its most precise.

l Two cutting-edge optical gas sensors.

l Fast response.

l Industrial-grade reliability.

Rapidox 6100 QU D

Multi-gas

Pumpback Analyser

cambridge-sensotec.co.uk

In the packaging and process industries, drive systems must operate reliably despite abrasive media, dust, corrosion, fluctuating loads and unpredictable disturbances. To ensure safe operation of conveying systems, dosing equipment and machinery for processing powders, granulates and liquids, robust solutions for power transmission and overload protection are essential. Stainless steel torque limiters (safety couplings) and shaft couplings fulfil these requirements by combining reliable torque transmission with high mechanical durability.

Conveyors, mixers, pumps and agitators form the backbone of production lines—from beverage filling systems to powder and granulate handling. These machines require continuous operation while being protected from overload, misalignment and abrasive wear. CIP/SIP processes and chemical exposure demand corrosion-resistant, hygienic and lowmaintenance components. Stainless steel provides these benefits thanks to its resistance to chemicals, moisture and temperature variations.

Couplings in these environments must compensate axial, radial and angular misalignment while withstanding shock loads, vibrations and frequent load changes. They also support safety functions such as overload release and emergency shutdowns. ENEMAC stainless steel couplings combine long-term mechanical stability with hygiene compliance, making

them suitable for food, pharmaceutical and cosmetic production.

Torque limiters disconnect the drive when a defined torque is exceeded, protecting against damage from blockages or foreign objects in screw conveyors, mixers or dosing systems. Typical uses include discharge screws beneath silos or filling systems experiencing torque spikes. ENEMAC torque limiters feature backlash-free design and 360° synchronous re-engagement for fast restart after faults.

Shaft couplings ensure precise and reliable power transmission between motors, gearboxes and driven components, even under misalignment. Elastomer couplings provide damping for dynamic equipment, while metal bellows couplings offer hygienic, backlash-free precision for filling and dosing systems. Stainless steel designs withstand aggressive cleaning agents and harsh environments.

www.enemac.de | www.enemac.eu info@enemac.de

BY BEREND BOOMS, HEAD OF EAM INSIGHTS, ULTIMO

The asset maintenance landscape is undergoing its most significant transformation in decades. As I speak with operations leaders, facility managers, and maintenance professionals across industries, one thing becomes crystal clear: we are standing at the threshold of a new era. The convergence of artificial intelligence (AI), sustainability imperatives, workforce evolution, and enterprisewide data integration is reshaping how organizations manage their most critical assets.

Based on my conversations with industry leaders and analysis of emerging trends, here are four predictions that will define asset maintenance in 2026 and beyond.

1. AI Becomes the New Norm

The predictive maintenance market is experiencing explosive growth. Valued at $7.85 billion in 2022, the global predictive maintenance market is expected to grow at a Compound Annual Growth Rate of 29.5

percent from 2023 to 2030. But 2026 will mark a critical inflection point where AI shifts from a futurefacing ambition to a standard operating procedure.

Advanced machine learning algorithms will soon predict equipment failures 6 to 12 months in advance with accuracy rates exceeding 85 percent. When implemented properly, IoT-powered predictive maintenance can achieve prediction accuracies above 90 percent, and this precision will only improve as more data becomes available.

The integration of IoT sensors, digital twins, and AI will create a comprehensive asset health monitoring ecosystem. This shift from time-based to conditionbased maintenance strategies will reduce costs by 20 to 30 percent, while real-time optimization adjusts schedules based on actual usage patterns rather than arbitrary calendar intervals.

What distinguishes 2026 is that AI will extend far beyond predictive maintenance. It will influence procurement decisions, optimize spare parts management, recommend replacement versus repair strategies, and even predict the financial impact of maintenance decisions on overall business performance.

The maintenance workforce is evolving rapidly, and technology is augmenting human capabilities. The global augmented reality market size was estimated at $83.65 billion in 2024 and is expected to grow at a CAGR of 37.9 percent from 2025 to 2030.

Augmented reality (AR) will guide technicians through complex repairs and inspections. A junior technician wearing AR glasses will have access to the same expertise as a 20-year veteran, with step-by-step visual instructions, real-time remote expert guidance, and instant access to technical documentation.

As experienced maintenance professionals retire, they take decades of institutional knowledge that cannot be easily replaced. Agentic AI systems offer a pathway to democratize this expertise before it disappears. By capturing the diagnostic patterns and troubleshooting logic of retiring professionals, these systems create a baseline understanding accessible to all technicians regardless of experience level.

This addresses the fundamental inequity of knowledge distribution. Junior technicians gain immediate access to expert-level guidance, while mid-career professionals can handle situations that previously required decades of experience. The result is a more resilient maintenance organization where capability is embedded in systems that ensure every technician can perform at a consistently high level.

Hybrid human-AI teams will become the norm, with AI handling routine data analysis, anomaly detection, and pattern recognition while human expertise focuses on strategic decisions, complex problem-solving, and relationship management.

3. Sustainability and ESG Compliance Integration

Environmental, social, and governance (ESG) considerations are now central to operational strategy and asset management decisions. ESG-focused institutional investment is seen soaring 84 percent to $33.9 trillion in 2026, representing 21.5 percent of assets under management.

In 2026, leading enterprise asset management (EAM) platforms will track carbon footprint and energy efficiency metrics in real-time at the asset level. By 2026, all ESG data will need to be digitally tagged, enhancing data comparability and accessibility.

Circular economy principles will guide asset lifecycle decisions. Environmental impact, carbon emissions, and the availability of sustainable replacement parts will play a major role in repair-or-replace decisions. Green maintenance practices will transform from niceto-have differentiators into competitive necessities.

Forward-thinking organizations will use their asset management systems to generate automated sustainability reports that demonstrate compliance with regulatory requirements while showcasing environmental stewardship to investors and customers.

The era of siloed systems is ending. In 2026, EAM platforms will connect seamlessly with enterprise resource planning (ERP), supply chain, and financial systems to enable enterprise-wide intelligence.

Real-time asset performance data will inform procurement strategies, determining optimal reorder points for critical spare parts. Production scheduling will adjust automatically based on equipment availability and condition. Financial planning will incorporate predictive maintenance forecasts to model capital expenditure requirements with unprecedented accuracy.

Self-service analytics will empower non-technical users to generate insights from maintenance data without requiring specialized training. Operations managers, financial analysts, and executive leaders will all access the same underlying data, each viewing it through lenses relevant to their responsibilities.

This data democratization represents a fundamental shift in how organizations approach asset management. Maintenance data will become a core component of enterprise-wide business intelligence.

These predictions paint a picture of an asset maintenance landscape that is more intelligent, sustainable, integrated, and human-centered than ever before. But transformation requires strategic planning, the right technology foundation, and a clear understanding of where your organization stands today.

www.ultimo.com

Snap-on Industrial held its third annual INSIGHT event at the Red Bull Technology Campus, an opportunity for the world-leading productivity solutions company to connect with its customers and preview new products that have been developed in direct response to feedback gathered at previous Insight events.

Snap-on Industrial has been in partnership with Red Bull Powertrains for the last four years, making the prestigious MK-7 event space a natural choice for this day-long event. Invited guests from the military, rail, aviation, and energy industries came together to take part in interactive product demonstrations, tour the Red Bull factory, and hear from their cross-industry peers during two in-depth panel discussions.

Celebrating its 105th anniversary this year, Snapon Industrial has earned a reputation for relentless innovation. The company now has more than 4,300

live patents and is passionate about forging close relationships with its customers, gathering valuable insights from these interactions so it can continue to create new tools and industrial solutions that meet the needs of engineers today and tomorrow.

Richard Packham, Director - UK & Europe for Snapon Industrial, said: “Now in its third year, our annual INSIGHT Event has become a highlight of our calendar, providing a unique opportunity to spend time with our customers, showcase our current and upcoming product range, and gather feedback that will shape our products and solutions as we move forward. There’s nothing more rewarding than being able to share our new prototypes with the people who inspired their creation; several of the products being previewed today have been developed on the back of questions and comments we received at last year’s event.”

Launched on 1st October 2025, the Control Tech+™ Electronic Torque Wrenches represent the next generation of digital torque wrenches. Reflecting the shift towards digital being seen across the torque industry, Snap-on Industrial’s expanded product range means there’s now a solution for every client, no matter their scope or scale.

Engineered with the aerospace and natural resources industries in mind, the Control Tech+™ Electronic Torque Wrenches are Bluetooth enabled for easy monitoring and reporting; runs on rechargeable batteries; and has earned an IP64 rating thanks to being virtually waterproof as well as dust and gas resistant.

Making their debut at INSIGHT 2025, two power tool prototypes and two new drills were previewed at the event, with guests encouraged to get hands-on and try the new technology for themselves.

The industrial drill has been crafted based on customer feedback. It is robust; is designed so that engineers can reduce repetitive strain injuries by keeping their wrist and arm in-line; and can achieve speeds of up to 6000 rpm. Accuracy is enhanced by limiting the drill to 10% speed at start while the higher rpm available means users can work more efficiently, drilling more holes per battery charge.

The upgraded 14V angle or collet drill is ideal for use in tight spaces, especially for those working in aviation, thanks to the flexible angles that can be achieved. It can now also reach higher speeds, be adapted with

interchangeable heads, and has a larger battery size that takes just one hour to fully charge.

Early prototypes still in development included a new rivet shaver and temporary fastener tool. Both were tested by the guests and the feedback provided will shape their continued development ahead of next year’s event.

Ever since Snap-on Industrial pioneered the idea of taking five handles of different configurations and ten sockets of varying dimensions and fashioning them to “Snap-on” to one another interchangeably, it has been known for its inventive and practical approach to hand tool development.

Intelligently designed to be in tune with an engineer’s instincts, each tool has a distinctive ridging to improve grip, provide a consistent user experience, and limit the amount of force required. Its pliers are the perfect example with a serration talon grip that offers 57% more pulling power when clamping compared to its closest competitors.

Empowering organisations to have complete visibility of their tool inventory, Automated Tool Control, a subset of the Level5 program of Tool Control, has empowered organisations to have complete visibility of their tool inventory for the past 15 years. Subject to continuous development and improvements, this dynamic system allows users to unlock the power of data and move at the speed of work.

The L5 Connect customisable software is secure, intuitive, and built to address everyday issues, using cameras, RFID tags, and barcodes to track when tools are removed and returned and when they require repair or calibration.

These insights flow into downloadable reports that can help organisations ensure their tool inventory is fit for purpose, have a full audit trail of each tool if they go missing or are damaged, and restrict access to authorised users.

L5 Connect is compatible with the Level5 Tool Control series; ATC Box, ATC Locker, ATC Portal, and the ATC FlexHub, an asset management storage solution for items in varied sizes developed based on feedback received at the first INSIGHT event in 2023.

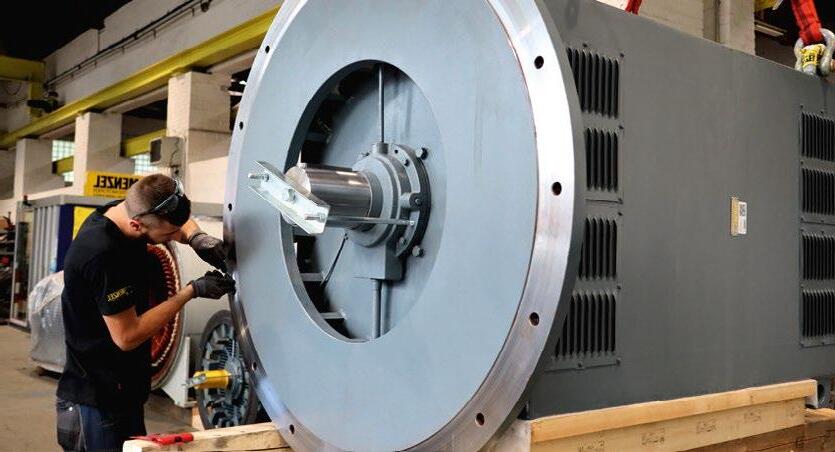

Menzel Great Britain has completed its biggest project to date, providing 10 seven-ton electric motors to the UK water utility company Thames Water, which serves 16 million customers across London and the Thames Valley.

This strategic motor replacement is crucial to extend the lifespan of a key water treatment plant by 10 years and secure the water supply to the Greater London area. Menzel won the contract for its economic, wellthought-out concept. The high-lift pump station at the Coppermills Water Treatment Works had experienced repeated failures, mainly due to the age of the existing equipment.

As Thames Water is planning to build a new station in about 10 years, the utility company put out a tender for an economic drive solution to ensure reliable operation of the existing pumps in the interim. Other OEMs suggested costly variable-frequency drives (VFDs), which would have required major building reconstruction to accommodate control systems and transformers. Menzel proposed slip ring motors that are compatible with the existing installation and use the electric infrastructure and starting equipment already in place. The state-of-the-art motors are superior to the original motors with nearly 5 % increased efficiency, greater ease of maintenance and an expected lifespan of at least 25 years.

The motor engineers worked closely with the project team of Thames Water’s contractor MWH Treatment.

Menzel Elektromotoren is uniquely qualified in customizing large slip ring motors and always considers the customer and the application needs in its designs. The company established a British subsidiary in 2009.

Their design also takes account of anticipated future extreme outdoor summer temperatures. The project came in under budget and was completed on schedule. Compared to the proposed VFDs, Menzel’s concept saved Thames Water hundreds of thousands of pounds, took much less time and is more environmentally friendly.

The German manufacturer Menzel Elektromotoren has great expertise in building and customizing large-scale slip ring motors. These particular 10 slip ring motors utilized the existing pump pedestals, ensuring minimal site work and disruption. Menzel even tailored the terminal boxes to match the existing installation to make the cabling as easy and cost-efficient as possible. Menzel’s modular motor families accommodate various mounting types, cooling types and accessories. The 10 new motors have a shaft height of 500 mm and are designed for vertical mounting on the pumps. Six of the motors feature the cooling type IC 81W (air-to-water heat exchanger) and four IC 611 (air-to-air heat exchanger). They provide IP55 ingress protection, operate at 3300 V and, between the different models, provide outputs of 746 kW or 343 kW and rated torques of 12075 Nm or 5551 Nm.

This project earned Menzel a place in the finals for the 2025 AEMT Awards of the Association of Electrical and Mechanical Trades.

More information: www.menzel-motors.com/reference/ ten-3300-kv-replacement-motors/

History and operating philosophy:

Tower Aerospace Inc. began operations in Canada 48 years ago; servicing National, International Markets, providing Private, Commercial , Corporate, Government , Military Aircraft Support; based on Commercial and National Emergency Response to provide a best-in-class hassle free direct delivery service to the customer. Success in 1986 being the only heavy jet approved support operator in Canada and providing National Military approved support as well the Company grew into manufacturing of our own airborne products. The goal for this day: to provide the best researched, verified quality assurance support operation , to offer an elevated level of secured, mission specific service to various National and International customers. Aircraft on the Ground cost incredible amounts of stagnant debt, immediate cash flow impact and become a dead weight to the operator. The only answer is solid proven support. Failure to deliver certified components to immediately go on the aircraft to ensure immediate certified flight authorization, failure to achieve that critical search, find, inspect and delivery process along with “critical approved documentation” failure is not an option. Operators must fly; stagnant operations are a financial failure and are not an option.

Today the Company has reached equivalency to world senior levels of quality assurance meeting FAA, Transport Canada, EASA , other International local state , provincial airborne rules, and regulations. Quality Assurance is a main rail in the operations of the Company. always safety-first policy. The privilege has been ours at keeping an ongoing progressive level of safety qualification at the highest world standards of airworthiness.

In 1987 Tower Aerospace advanced into Auxiliary Fuel Systems, Emergency Response Support , Advanced Wildfire Technology , Advanced Water- Fluid Delivery systems for Helicopters and Fixed Wing Aircraft.

In addition, the Tower engineering division manufactured and extensively test flew certified advanced wildfire airborne water bombing equipment for the Bell and MD line of Helicopters.

After 38 years of creative manufacturing airborne certified equipment including extensive research , development and intensive long term flight testing of our advanced products, our systems have been sold and distributed to many Countries proving long term operations with limited down time.

With certified modifications they are multipurpose capable , can relate to several world Helicopter types and large “specific service providing” operations such as World Hydro Support Operations in the wild. Notwithstanding Wildfire Initial Attack Support. Today wildfires are a proven disastrous threat across the world. Tower Aerospace has over forty years of experience in first hand advanced materials product design on wildfire advanced products including stress testing, testing new material manufacturing and certification of installed airborne equipment. Failure is not an option.

World Distribution - Emergency Response:

Over the 48 years Tower Aerospace has made its mark across Canada and Internationally in Emergency Response Distribution with our products , Support Services, serving Military, Commercial, Government, State, Provincial Airborne Operators with Emergency Response research and delivery of urgently required support certified products. Tower specializes in research , delivery of engineering with full quality control traceability , verification of all products , services sold and successfully delivered. We go to extensive lengths with no barriers to verify and trace to OEM and to prove authenticity of every shipment passing through our doors. Our database , research libraries are extensive, and traceability is as precise as possible, each time addressing each shipment. Delays and inappropriate or missing documents are not an option.

Constantly our staff Confirm Mandatory Product Safety processing to ensure the safety of the Aircraft, Crew, Passengers, and Valuable Cargo. Since the beginning of the Company, traceability and confirmation of product truly have been our hallmark. The same philosophy applies to our company support products and services. Technical, precise engineering reports, including various provable product test reports and in some isolated cases, confirming “claimed authentic scientific test reports.” Availability of the above scientific verification is subject to security issues surrounding product development, regulatory certified documentation, and proprietary ownership “classified or restricted category information.”

Company Ownership: Working Policy:

Tower Aerospace is privately owned and run, always paying strict attention to the future of the industry. Every airborne environment has its own specific methods of operations. Tower staff are trained to respect, always respond, support, blend with the individual and unique environment in total harmony. The total working environment brought forward by our customers is paramount to success. We blend our

support as a working arm of the customer. The future for Tower Aerospace and its affiliates is harbored in the mutual and agreed relations with our customers. Ethical behavior, honesty in open discussion and intent is paramount. The Company has earned the respect and security clearances in several Countries. Tower Aerospace is a Male/Female, Veteran owned and operated Company. Most of our staff and Principles were chosen for their ability and understanding of “flight” as Certified, qualified Pilots and Engineering history. Wherever , whenever possible we do what we say and mean. Failure is not an option. Staff are articulate and precise in daily operations. What goes up must safely come down.

Company growth and expansion: secured communication:

The Company is open to investor enquiries regarding partnering, possible ongoing ownership and eventual takeover:

Further information can be requested from Senior Owners. Contact Tower Aerospace: direct all communication to the President - S.G. McLeod –Founder. You will receive a secure response as soon as possible. Please mark all enquiries “Confidential.” With total respect, all response will be in “Private Confidential Mode”, and Tower staff will respect it as our own privacy,

Tower Aerospace and its affiliates have a long , respected, firsthand business case and international mindset supporting all aspects of the Aviation and Aerospace Industries. Over the past forty-five years all the groundwork has been laid and paid for to prove the Tower Name worldwide. Notwithstanding learning all the hard lessons in creating and building a multipurpose organization in one of the most difficult and advanced lead industries in the world; the science and geophysical advanced technology Aerospace Industry. Our future is creative, constantly challenging, productive, and open for anyone interested in the future of Air Travel and Space. The Company is poised , has the history to support advancing to Space Technology; the dedicated international direction of the Human Journey in Space to begin Human Habitation.

Finally, the business we chose 48 years ago includes offering advanced problem-solving processing and research activities, on every level of flight support. The gateway to Space.

All interested parties are invited to contact Tower Aerospace directly in a confidential manner.

www.toweraerospace.com

Using a well-engineered industrial chain, is of paramount importance in industrial processes. These chains play a crucial role in various sectors of manufacturing. In this article, we look at the significance of well-engineered chains, their functions, benefits, and the consequences of neglecting them.

1. **Efficiency and Productivity**: Industrial chains are the backbone of production lines. Well-engineered chains, as supplied by Köbo UK Ltd, ensure the movement of materials, products, and equipment. They minimize downtime, enhance production efficiency, and boost productivity.

2. **Safety**: Safety is a paramount concern in any industrial setting. Well-designed industrial chains, like the ISO9001 Chains supplied by Köbo UK Ltd, are less likely to fail unexpectedly, reducing the risk of accidents and injuries. Properly engineered chains also mitigate the chances of chain-related accidents, such as chain derailing or snapping, which can have severe consequences.

3. **Durability**: Industrial chains are exposed to extreme conditions, including high temperatures, heavy loads, and corrosive environments. A wellengineered chain is constructed to withstand these conditions, ensuring a longer lifespan. This durability translates into cost savings as it reduces the frequency of chain replacement and maintenance.

4. **Cost Savings**: While investing in high-quality industrial chains may seem expensive initially, it pays off in the long run. The reduced need for repairs and replacements, as well as increased operational efficiency, results in significant cost savings over time. In contrast, using inferior chains can lead to frequent breakdowns, expensive repairs, and higher operational costs.

5. **Precision and Accuracy**: Industrial processes often require precision and accuracy. Well-engineered chains provide the required consistency in movement and positioning, ensuring that products meet the desired specifications.

6. **Customization**: Industrial chains can be tailored to specific requirements. Well-engineered chains can be designed to accommodate various load capacities, speeds, and operating conditions.

7. **Environmental Impact**: Sustainable manufacturing practices are becoming increasingly important. Well-engineered chains can be designed to minimize energy consumption and reduce emissions. They contribute to greener operations by running more efficiently which aligns with environmental regulations and corporate social responsibility goals.

8. **Reduced Downtime**: Downtime can be a significant cost factor in industrial processes. Wellengineered chains are less prone to unexpected failures, reducing the frequency and duration of downtime. This, in turn, improves overall production continuity and customer satisfaction.

9. **Global Supply Chain Reliability**: In today’s interconnected world, supply chains often span across countries and continents. Well-engineered industrial chains ensure the reliability of these global supply chains.

10. **Quality Control**: Quality control is a critical aspect of industrial processes, particularly in sectors like automotive and aerospace. A wellengineered chain contributes to consistent quality by maintaining precise movement and positioning, crucial for the assembly of intricate components.

In conclusion, the importance of using industrial chains, in processes cannot be overstated. These chains serve as the lifeline of various industries, contributing to efficiency, safety, cost savings, and environmental responsibility. Neglecting the quality of industrial chains can lead to catastrophic consequences, including accidents, downtime, and financial losses. Therefore, investing in wellengineered industrial chains is not just a matter of choice but a strategic imperative for any organization aiming for long-term success.

FINANCIAL

For further information, please visit www.kobo.co.uk

BY OLIVER SELBY, HEAD OF SALES, FANUC UK

World military expenditure has increased by almost 10% from 2023 to 2024, reaching $2,718 billion . And the UK is no exception, having committed to increase defence spending to 3.5% of GDP by 2035 as part of a NATO agreement. With multiple countries striving to shore up sovereign defence capabilities, prices are likely to increase. How can the UK ensure it doesn’t get left behind?

Automation remains the fastest and most efficient route to increasing production capacity. And as a leading robot manufacturer, with a longstanding British presence, FANUC is perfectly placed to provide domestic automation capabilities. By supporting not only prime and tier defence companies, but also increasing automation capacity within wider manufacturing facilities, we can bolster the full UK sovereign supply chain.

Cyber resilience as standard

It must be acknowledged that FANUC is a Japaneseowned company. However, there are defence programmes of work currently underway that involve both the British and Japanese governments, underlining the mutual trust and support between the two nations.

Linked to this issue of mutual international trust is cybersecurity. Setting mandatory cybersecurity requirements for hardware and software products with a digital element, the EU’s new Cyber Resilience Act (CRA) comes into effect from September 2026. All UK machine providers will be affected and it will alter how equipment is risk assessed and CE marked.

The new FANUC R50iA controller – based on the latest CNC hardware, FS500 – is already fully CRA compliant, making it easier for our customers to complete their risk assessment. Going forward, all our robots will feature this new controller as standard, while our oIder controllers are currently undergoing validation to ensure they also meet the new standards.

Reliability meets innovation

Equipment longevity and avoiding obsolescence are also key drivers in defence and aerospace projects, not least because they often involve multiple stakeholders

and layers of complex engineering and compliance requirements. FANUC provides lifetime support on our products, assuring spare parts availability and local service support worldwide.

Yet innovation is equally crucial. We work closely with manufacturers, as well as organisations at the cutting edge of R&D (including universities, R&D/training institutes and High Value Manufacturing Catapults), to ensure we can respond swiftly to changing customer demands.

A prime example of this is Project Compass (Composites at Speed and Scale), an £80m investment which includes an aerospace manufacturing R&D project delivered by a consortium of companies including our system integrator partner Loop Technology, Boeing, Spirit AeroSystems and the Advanced Manufacturing Research Centre (AMRC).

Three FANUC M-2000iA/1700L six-axis industrial robots are being employed as part of the project, as well as an M-2000iA 1200L and a 900L model.

We also supported Airbus with its in-house robotics strategy, developing an industrial drilling robot (the M-800iA/60) to meet the company’s specific requirement.

Reducing project risk

Engaging regularly with prime manufacturers and their first tier suppliers is crucial to success in the defence and aerospace sectors. Keeping the supply chain tight helps to reduce financial risks, technical risks and security risks, as well as speed up project delivery. We look forward to seeing the results of our increased focus on bolstering the UK’s defence capabilities with domestic automation solutions, and the security benefits this can deliver for all.

Witness the future of precision engineering at FANUC’s brand-new machinery event, taking place 2729 January 2026 at FANUC UK, Ansty Park, Coventry. To register your interest in attending ‘The Future of Precision Engineering’, go to https://ukopenhouse. fanuc.eu/#whats-on

www.fanuc-academy.uk

Automation has a name.

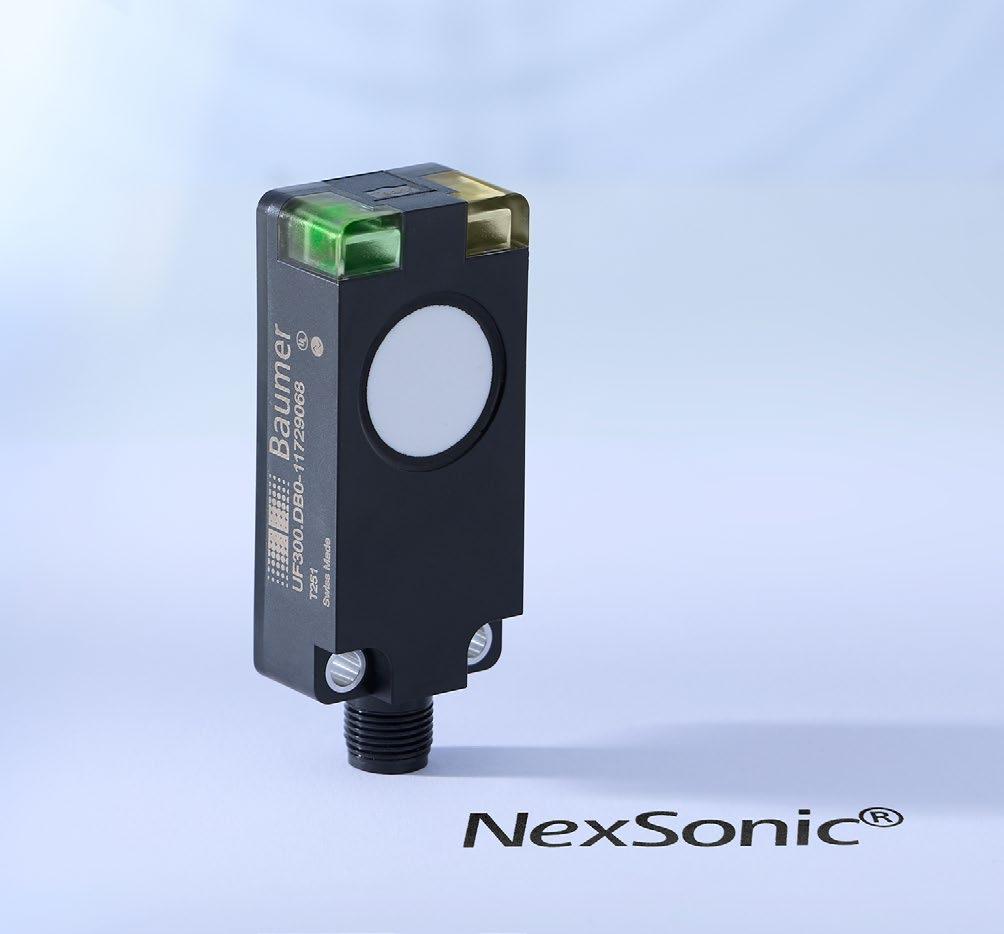

18 mm flat NexSonic UF300 ultrasonic sensor from Baumer 3-meter sensing range is ideal for applica-tions in intralogistics. Image: Baumer

At SPS 2025, Baumer is premiering further evidence of technological leadership as a sensor expert. In Nuremberg, Baumer presents the first compact ultrasonic sensor featuring a sensing range of 3 meters. But there is even more to that: new UF300 sets more standards that are best-in-class. With the shortest blind range of a mere 50 mm and only 18 mm installation depth there is maximum design freedom. An-other outstanding characteristic is the unrivalled short response time up to 56 ms.

Behind those top values is the NexSonic technology developed by Baumer for maximized ultrasonic sensor performance. NexSonic is based on an ultrasonic processor (ASIC) developed by Baumer and own patented sensor element. In NexSonic ultrasonic sensors, the piezo element with ASIC directly connects to the membrane. The result: shorter signal path and improved electromagnetic compatibility. The compact evaluation electronics boosts signal processing time and reliability. More benefits of the NexSonic technology are the adaptive sonic cone, ideal for detecting objects through narrow openings, and smart filter functions. These can suppress interfering objects.

UF300 with NexSonic technology is the latest member to the next generation of Baumer ultrasonic sensors. Available as both measuring and switching variant, UF300 adds on the Toolbox as a product family with maximum range. Extremely versatile in use, the sensor cuts down on the number of product variants in production and warehousing. The Toolbox of ultrasonic sensors comprises the six sensor families UF200, UF300, U300, U500, UR12 and UR18 in different designs and sizes. UF300 and UF200 are ideal for front mount. Particularly compact U300 (cubic) and UR12 (cylindrical) fit even tightest installation space. U500 (cubic) and UR18 (cylindrical) are extremely robust.

Intralogistics is a preferred application field for new UF300. Here, the sensors play to their strength by the unique combination of form factor and long sensing range of up to 3 m, even on irregular objects or materials that are difficult to detect. UF300 ultrasonic sensor is ideal for tasks like pallet detection - particularly on long fork arms - and for monitoring pallet stacks and gates in cold stores. Another application field are the packaging and electronics industries.

UF300 will be available in December 2025.

The Baumer Group is one of the world’s leading experts for high performing sensors and sensor systems in industrial automation. The unrivalled broad product portfolio, measuring precision and smart sensor functionalities provide intelligent solutions for digitalized production. With around 2,800 employees and 39 development centers, production sites and sales units in 19 countries, the Swiss family-owned Group is always close to the customers. As an innovation leader for more than 70 years, Baumer has been creating decisive market advantages and measurable added value with consistently high quality standards. For more information, visit www.baumer.com

Developed and verified ‘for industry, by industry’, EEMUA 231 Mechanical Integrity courses are for i n dustrial engineers at every career stage – with reality built - in to aid efficient hands-on work with primary containment and prevent loss of hazardous substances, including with pressure systems

• Satisfy industry requirements at each competency level – Awareness, Basic application, Practitioner, Leader

• Covering: *Legislative environment *Industry good practice *WSE *Equipment design *Operational considerations *Audit

*Asset condition *Test techniques *Inspection roles, process & reports *Postponement *Responses to findings

*ALARP *Record keeping *Feedback *User responsibilities & competencies *Operating Limits *Decision Making

• Certificated up to 5 years – CPD-approved.

• Flexible delivery to suit Learners and companies – Blended, Live online, Classroom, E-learning, or In-house.

• Courses throughout each year available to all – free or discounted to EEMUA Members and Associates