04 19 www.bakingbiscuit.com IBIE A marketplace of innovation AIBI The Congress in Manchester JADI ABADI Indonesia’s Number 1

up to 20% less fossil fuel-based resin than the standard closure, uses up to 20% fewer greenhouse gas emissions to produce, and advances industry sustainability levels.

But that’s just the beginning. Eco-Lok delivers that same reliability and rigidity you’ve come to expect from plastic bag closures. It also has the same print-on capability, is compatible with all existing machinery, and has the global market leader in bag closures standing strong behind it… Kwik Lok.

So we invite you to join us in our efforts to make the world a more sustainable place and check into Eco-Lok. Because it’s the little things that make a big difference.

TO LEARN MORE, VISIT: KWIKLOK.COM

THE FUTURE HAS ARRIVED. AND IT’S SUSTAINABLE.

KWIK LOK and ECO-LOK are trademarks of KWIK Lok Corporation.

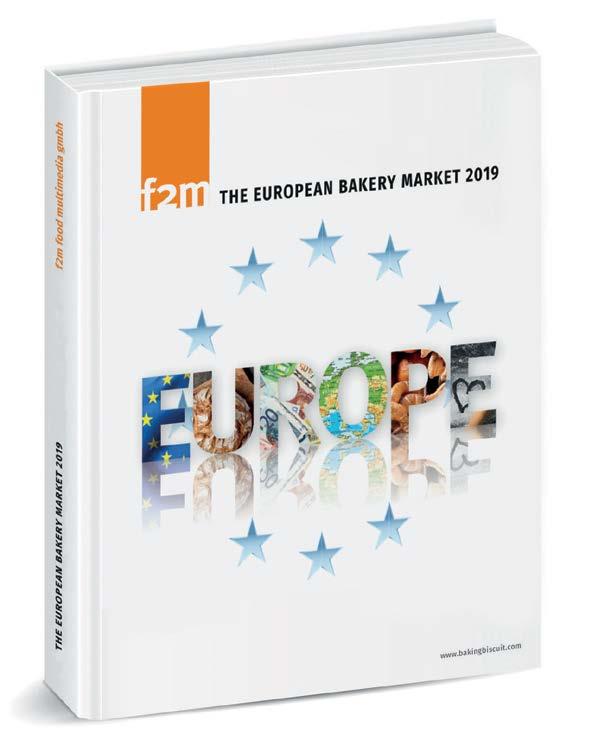

A view of Europa

As a specialist European publishing house, we have focused on the baking sector for many years. We put our whole heart and dedication into our research and inform our readers about technical innovations, and show profiles of bakeries, markets and concepts. Of course, we are also on site at trade fairs all over the world in search of trends and new products. That’s also why we are represented again with our own stand at the IBIE (International Baking Industry Expo ™ ) trade fair in Las Vegas. The editorial team has again brought something special for the trade fair in its baggage on this occasion: firstly, hot off the press, the current issue of baking+biscuit which you are now holding, and secondly the equally new first edition of the 2019 Yearbook.

The emphasis of the book is on the European baked products market with all its diversity. We already presented various countries with their different baking traditions and markets four years ago. Big political differences already existed within Europe at that time, and today Europe and the European Union face challenges; Brexit, climate change and migration, to name but a few topics.

The editorial staff have experienced great optimism during their travels in Europe. In the main, it is young people who are getting involved and want to shape their future. So these are still politically turbulent times, but developments in baked products markets remain interesting.

Retail chains and discounters, especially Western European protagonists, are playing an ever-bigger role in the baked goods market. As far as the subjects of consumer trends, purchasing and dietary trends are concerned, differences between countries, whether East vis-à-vis West or from North to South, are becoming increasingly blurred. The out-of-house market is also recording growth, and bakeries play a prominent role in all the countries of Europe when it’s a question of a quick bite to eat outside one’s own four walls.

Moreover, the scarcity of skilled labor is forcing further automation in baked goods production, and brings profit to suppliers of frozen baked products. Excellent artisan bakery work, premium quality and customer-oriented service are finding ever more customers at the same time. On the one hand consumers are demanding, but on the other they are also willing to pay a suitable price for higher quality. The European baked products markets are and remain fascinating, but markets in North and South America and Asia are still exciting, and offer variety and ideas. Being part of this sector of the industry fills us with pride and joy, and if you are interested in the new specialist book and want to take a look at Europe, simply contact us at: info@foodmultimedia.de or visit: www.bakingbiscuit.com, where you can order the book as an e-paper (pdf file) or in printed form.

I hope you will greatly enjoy reading them!

Best Regards,

How much does your software know about bread?

Ours knows a good deal. Industry-specific processes, integration of machines and systems, monitoring and reporting, traceability, quality management and much more.

The CSB-System is the business software for the bread and bakery goods industry. The end-to-end solution encompasses ERP, FACTORY ERP and MES. And best-practice standards come as part of the package.

Bastian Borchfeld

Bastian Borchfeld

Would you like to know exactly why industry leaders count on CSB?

EDITORIAL

Your commments or suggestions are always appreciated: phone: +49

borchfeld@foodmultimedia.de ADVERTISEMENT www.csb.com

++ Bastian Borchfeld, Editor-in-Chief

40 39 90 12 28

Visit us! Hall 7.1 Booth B090 - C093

Control

06 Rademaker: Performance and flexibility

AIBI

12 Manchester : A successful AIBI Congress

Production

10 Haton: “We play in the Champions’ League”

16 Zeppelin Systems: “The ideal bun line”

BVT: Industrial Vacuum Cooling

“It`s important to understand the African market”

PUBLISHING COMPANY

f2m food multimedia gmbh Ehrenbergstr. 33

22767 Hamburg, Germany +49 40 39 90 12 27 www.foodmultimedia.de

PUBLISHER

Hildegard M. Keil +49 40 380 94 82 keil@foodmultimedia.de

EDITOR-IN-CHIEF

Bastian Borchfeld +49 40 39 90 12 28 borchfeld@foodmultimedia.de

EDITORIAL STAFF

Helga Baumfalk +49 40 39 60 30 61 baumfalk@foodmultimedia.de

ADVERTISING DEPT.

International sales director Dirk Dixon +44 14 35 87 20 09 dixon@foodmultimedia.de

Advertisement administration

Susanne Carstens +49 40 38 61 67 94 carstens@foodmultimedia.de

DISTRIBUTION +49 40 39 90 12 27 vertrieb@foodmultimedia.de

TRANSLATION

Skript Fachübersetzungen Gerd Röser info@skript-translations.de

TYPESETTING

LANDMAGD in der Heide

Linda Langhagen; design@landmagd.de

PRINTED BY

Leinebergland Druck GmbH & Co. KG Industriestr. 2a, 31061 Alfeld (Leine), Germany

BAKING+BISCUIT INTERNATIONAL

is published six times a year. Single copies may be purchased for EUR 15.– per copy. Subscription rates are EUR 75.– for one year. Students (with valid certification of student status) will pay EUR 40.– (all rates including postage and handling, but without VAT).

Cancellation of subscription must be presented three month prior to the end of the subscription period in writing to the publishing company. Address subscriptions to the above stated distribution department. No claims will be accepted for not received or lost copies due to reasons being outside the responsibility of the publishing company. This magazine, including all articles and illustrations, is copyright protected. Any utilization beyond the tight limit set by the copyright act is subject to the publisher’s approval.

Online dispute resolution in accordance with Article 14 Para. 1 of the ODR-VO (European Online Dispute Resolution Regulation): The European Commission provides a platform for Online Dispute Resolution (OS), which you can find at http://ec.europa.eu/consumers/odr

Valid advertising price list: 2019

www.bakingbiscuit.com 04/2019 CONTENT 04 IMPRINT

cover photo: © Kwik Lok © f2m © Wasin Pummarin –123rf.com 20 44

26

38 Dimassaba:

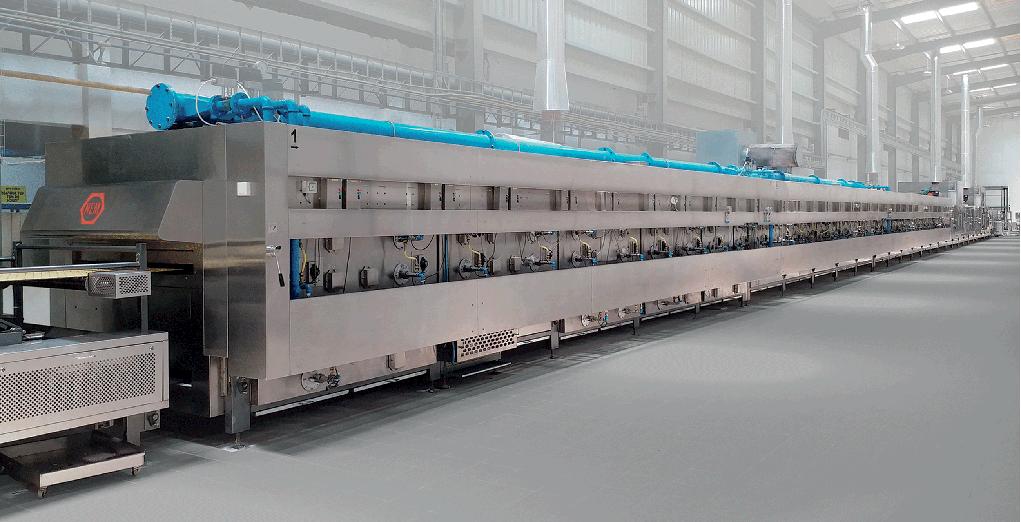

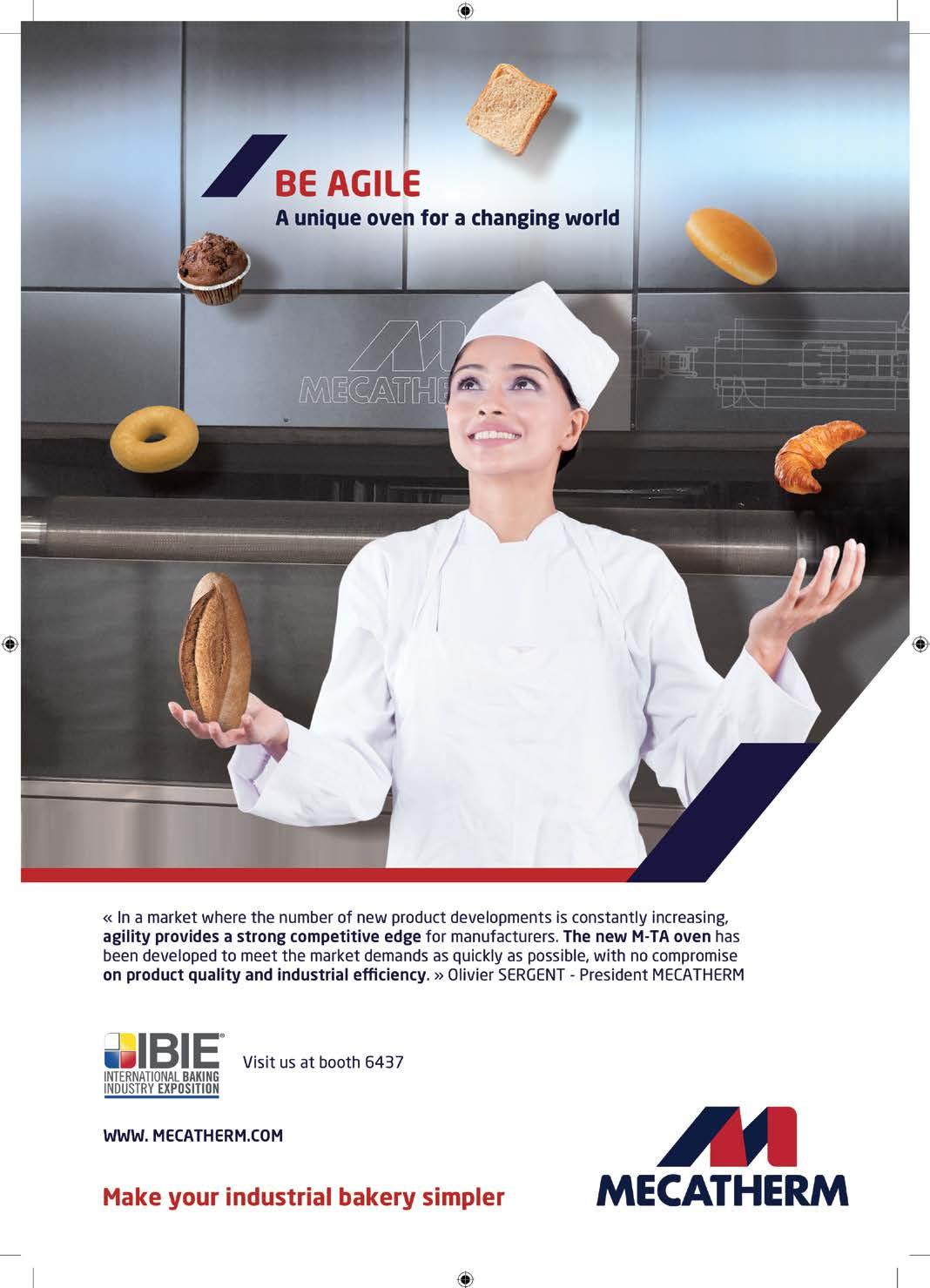

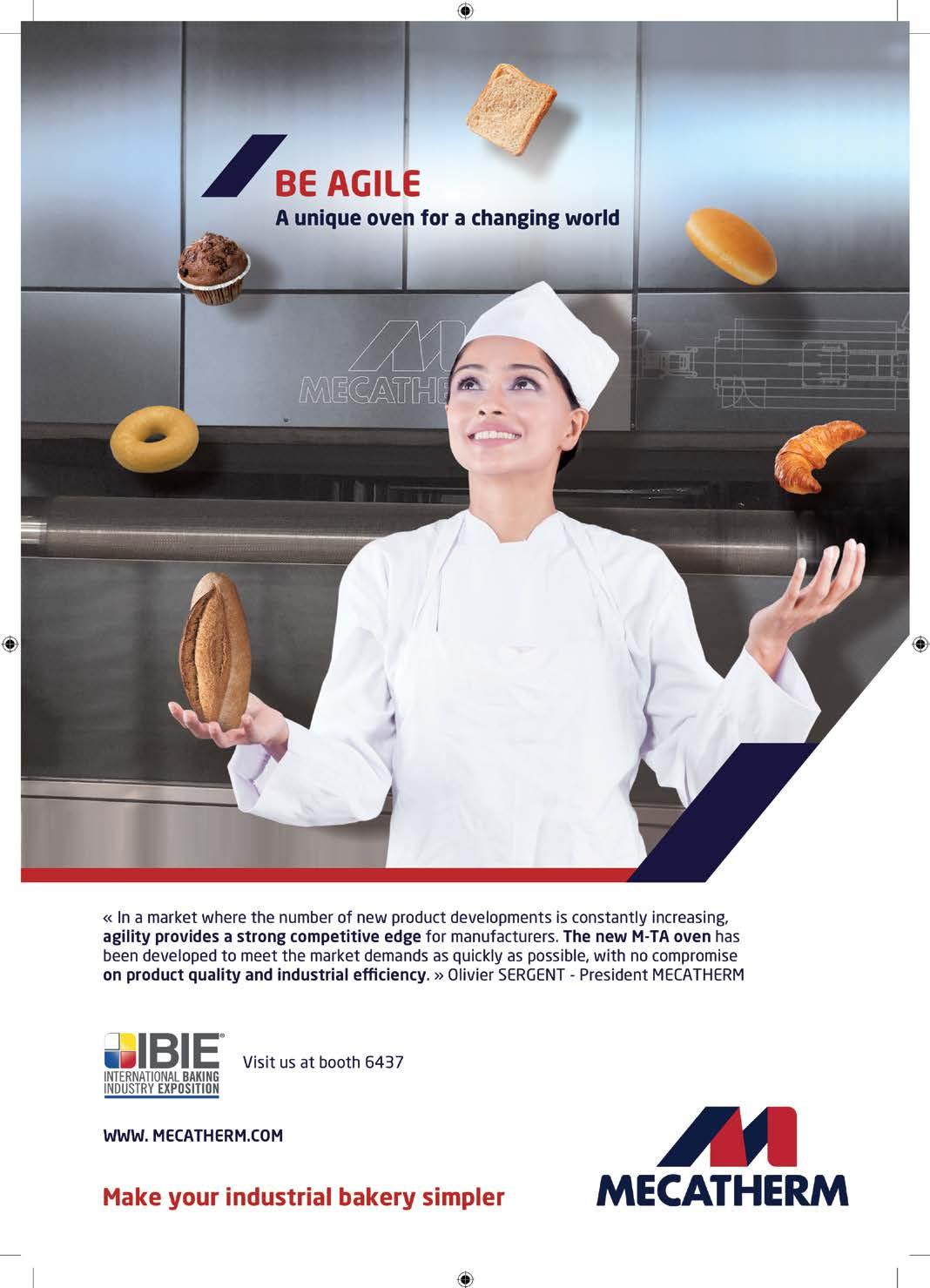

40 MECATHERM:

42 König: One for all doughs 44 JADI ABADI: The Number 1

and Exhibitions

IBIE:

and Trays

Lhotellier R2A : All

35 Anneliese :

36 Precisma :

36 Kempf : A new coating Robotics 50 Schubert : Intelligent packaging Food Law 54 Meyer-Kretschmer: Acrylamide in bakery wares Regulars 03 Editorial 28 News 59 Trade fair calendar Insert König Maschinen Gesellschaft m.b.H., 8045 Graz/Austria © AIBI 12

The Baguette Factory

Fairs

20

A marketplace of innovation Pans

30 Bundy : Unrivaled Value, Quality and Innovation 32

about coatings 34 acs Coating Systems : Absolutely flat and warp-free

The most unusual shapes are possible

Compact, efficient, universally usable

Bake better product and improve oven throughput

with the New

2 Digital Humidity Sensor

®

The new SCORPION 2 Digital Humidity Sensor provides a better way to measure humidity in your oven, proofer, dryer and cooling tunnel. This breakthrough design provides a more accurate and reliable way to measure the absolute moisture content of the thermal environment. The sensor contains a proprietary humidity sampling system with patent pending Anti-Saturation Technology™ that allows measurements in high temperature and very high dew point processes.

SCORPION®

For details,

us at info@readingthermal.com

ext. 2. Visit us at Booth 5521

visit readingthermal.com, e-mail

or call 610-678-5890

Performance and flexibility

Rademaker has developed a new pastry production line. The Universal Pastry Line with its newly-developed controller can produce a wide variety of dough pieces highly flexibly. Its construction is modular, and a well-thought-out tool concept ensures fast product changeover.

+Ability to perform meets quality – that’s the motto of the new generation of production lines from the bakery equipment manufacturer Rademaker. Specifically, it involves a newly-designed production line (Universal Pastry Line). The Netherlands-based company sees potential for the new line, which is designed for industrial operators and medium-sized companies, especially in the European and North American markets. That’s also why Rademaker is showing the machines at the IBIE trade fair in Las Vegas and the südback trade fair in Stuttgart.

Operation 24/7

Explaining the design concept of the new generation of production lines, Paul Groenewegen, Managing Director of Rademaker Germany (which also serves the Austrian and Swiss markets) says: “In their design, we took special care to ensure the production lines have very good accessibility to make cleaning and maintenance as simple and easy as possible, and we maintain the highest hygiene standards.” Stainless steel, smooth surfaces, a rounded frame and the use of materials approved by the FDA (U. S. Food & Drug Administration/ the US foodstuffs and medicines authority) guarantee that the machines are easy to clean. Paul Groenwegen goes on to explain that “The Universal Pastry Line has no recesses, cavities or dead zones, and it goes without saying that this new Rademaker production line is entirely designed and

approved for wet cleaning.” The belts are also equipped with quick-release devices, the belt tensioning rollers are massive, and all of the machine’s bearings are located externally. The machines are designed to operate 24/7. Moreover, due to the high in-house production ratio of around 94%, Rademaker also ensures that the customer’s high quality demands and a problem-free spare parts supply are guaranteed.

A new tool concept

When developing the production line, the designers considered it important to enable tool-free component and tool exchange. In the tool design concept for the latest generation of machines, each tool and every part of the machine has an individual identification number. According to Paul Groenewegen: “The tool assistant developed by Rademaker, which we call Tool Assistant, simplifies operating and retooling plants.” Tool Assistant stores individual tool and line configurations. Thus line settings are reproducible, e.g. when there is a product changeover, and users can understand and access them easily. All the line and tool data can be exported to the control panel or a tablet, or as a printout. Pop-up windows in the control panel explain to the plant operator which settings and process steps must be carried out. The control system is displayed on a 22-inch adjustable-height touch-panel. Access is password-protected, e.g. for recipe management, and there is also an option to access by chip.

www.bakingbiscuit.com 04/2019 CONTROL 06

++ Low maintenance costs, energy-efficient drives, an Eco mode, robust plant construction compliant with an industry standard, long operating lives if maintenance is good, and a new, flexible tool system – these are the characteristic features of the new plants

© Rademaker

The new machine has fewer drives compared to other plants. Nowadays, instead of up to 20 motors/drives, only seven or eight per plant are needed. This is noticeable in the form of lower maintenance costs, for example. Users need to stock correspondingly fewer spare parts. As Groenewegen explains: “The subject of preventive maintenance plays an important role for Rademaker, so we prepare an individual kit of spare parts for each new plant, which the customer can keep in stock.”

Rademaker’s consistent emphasis on the “identical parts concept” in relation to spare parts also reduces the user’s stock-holding costs. Rademaker BV’s R&D Manager Jan van de Grift adds “We use standard components if it is possible for us to do so, but of course we add specific tools and designs to our machines in accordance with customers’ wishes. For us, this is a challenge we gladly accept.” Van de Grift played a key role in developing the new line concept, including implementation of the new controller. “We know how important an intuitive controller is in practical terms. It must be easily understandable, safe and secure. This is ensured by the novel cascade controller we have developed, e.g. with dough output (loop control) and dough input (DDIC) monitoring, together with a dough presence monitor,” explains Jan van de Grift. “This leads to improved product quality and greater operational reliability,” adds Paul Groenewegen because, for example, the new controller specifies which dough the operator must prepare and/or process next to make optimum use of the line, so the production facility will have the best possible capacity utilization.

Flexibility

As Groenewegen explains: “Simplified operation, improved process control and lower maintenance costs compared to other models lead to a considerable reduction in operating costs, and support the efficient use of personnel.” Moreover, the cascade controller allows the production line to operate in sectional mode, or even automated modular operation, to increase the production facility’s flexibility. Thus the controller provides an increase in the machine’s capacity utilization, while simplifying operation at the same time.

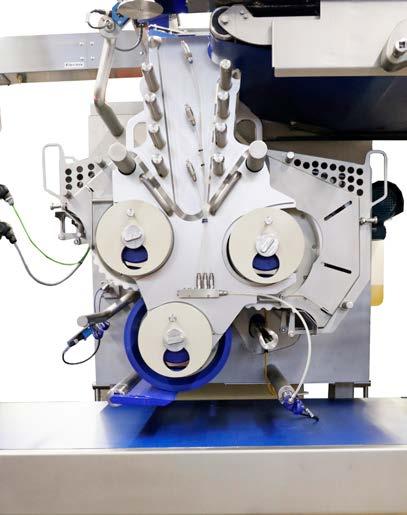

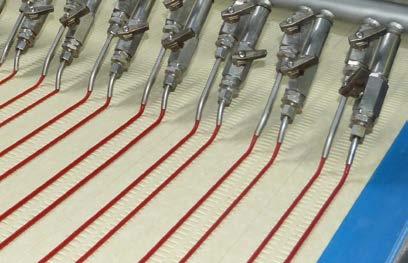

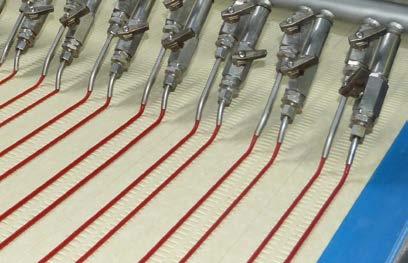

The fact that the new Universal Pastry Line’s modules are interchangeable also makes this possible. Components such as the fat pump were also re-engineered. This enables different fats such as butter, margarine or clarified butterfats to be processed as needed. Horizontal and vertical screws with a molding function in the new, reengineered fat pump ensure a continuous flow of fat is applied to the dough sheet. Sensors supervise the process and ensure constant pressure

www.bakingbiscuit.com 04/2019 CONTROL ADVERTISEMENT

© f2m PosiDrive Spiral™ • High Tension

Heavy Loads

Greasy Products

Product Movement Proven Solution For: Call for System Audit +31 20 581 3220 www.ashworth.com Booth 5753

++ R&D Manager Jan van de Grift (l.) and Managing Director Paul Groenewegen

•

•

•

++ Each tool and machine component is given a name and a unique identification number. These allow a user to know which tool he/ she should use when there is a product changeover

monitoring. The fat pump is also mobile and can be removed from the production unit, e.g. for cleaning. The designers also took care to ensure that the fat pump can be dismantled and cleaned easily. According to R&D Manager Jan van de Grift “We are also confident we have the most accurate fat pump on the market, and errors are less than 1%.”.

Fat pump data

+ Fat pressurizing is monitored by a sensor, thus preventing unwanted heat input, and lamination takes place more cleanly

+ The fat layer is applied across the entire working width without any dead corners (hygienic design) across a 270 mm width

+ Options to adjust the fat layer thickness of the applied fat layer (dough/butter ratio)

+ Accurate weights through minimal tolerances of below 1% – depending on fat type and temperature

+ Friendly cleaning opportunities through good accessibility to the entire fat pump

With the new production line, Rakemaker offers a choice between various different lamination methods to cater for customers’ requirements and requests. As Paul Groenewegen explains: “This is how we support customers to find the best lamination method, which depends on the required capacity and type of dough being used.” For example, the overlapping method is suitable for stable doughs (lamination width 600 mm). The horizontal lamination method is also an option for softer doughs (lamination width 600 to 1,600 mm), while the “cut-and-stack” method is the most flexible system with regard to the number of fat-dough layers, and can be used to laminate both rather firm and rather soft doughs. The lamination width when using these methods is between 600 and 1,600 mm.

++ Intuitive cascade control design allows the plant to operate sectionally, while an intelligent controller gives support during production, retooling and cleaning

Rademaker laminators also allow a dough cooling and resting section to be installed. With the Universal Pastry Line, dough resting times up to 2.5 hours are achievable in this way. “The engineering and technology for this system were developed by Rademaker, and it builds them itself. A very large volume of experience and know-how in this area has been accumulated during the past approx. 30 years. The cooling process ensures that the dough and fat layers remain intact in laminated doughs. This leads to a considerable improvement during the downstream processing of the dough sheet,” according to Jan van de Grift. To which Paul Groenewegen adds “But even for products that are not laminated, the rest time ensures dough relaxation and thus the best possible flavor and a trend to larger baked product volumes.” In relation to the cooling and resting section, the new controller also calculates that the timing, i.e. time and belt speed, are optimally coordinated to one another in order to guarantee high capacity utilization.

Rademaker’s new Universal Pastry Line now enables (semi-) industrial and in-store bakeries to manufacture all kinds of baked and laminated products in any size and shape, filled or unfilled. Hourly capacity is from 350 to 1,500 kg of dough. The company says a significant reduction in operating cost is also possible. This is achieved by improvements such as efficient, error-free tool change, a low level of maintenance and simplified, intuitive operation. Moreover, Rademaker is confident that hygienic machine design has been raised to a new level. Modular construction also ensures flexibility, and single plant components, e.g. a mono-pump metering machine with an individual single-series controller is possible at the customer’s request. Furthermore, the new plant’s controller is undergoing further optimization, for example the flour dusters, which can be cleaned in a dishwasher, allow synchronization of the new pastry line plant to achieve a high output capacity and great production flexibility. +++

www.bakingbiscuit.com 04/2019 CONTROL 08

© f2m © Rademaker

Right hand model 9840 shown with optional water spray, stacked water splitter, conveyor and MPA auto fill system. SMART SEEDER CALL US TODAY +44 1638 668563 THE TOPPING EXPERTS P.O. Box 748 • Maysville, OK 73057• Telephone (405) 867-4467 • Fax (405) 867-4219 • e-mail: sales@burford.com www.burford.com Unit 4 Sam Alper Court, Depot Road, Newmarket, Suffolk CB8 0GS UK • +44 1638 668563 • e-mail: sales@burford.com Booth 4803/4603

“We play in the Champions’ League”

WP-Haton concentrates on making up doughs by classical methods using dough dividers, rounders, long rollers and proofers. The focus is on excellence and flexibility.

The classical bread make-up method is called classical because it translates the advantages of traditional artisan work into modern technology. These include dough structure retention, shape stability up to the end product even with very soft doughs, and last but not least great flexibility regarding the doughs and weights that can be processed, and the baked products formed from them. Panningen thereby satisfies a global trend in the baked goods market that focuses increasingly on artisan quality and product diversity. The Crustica bread line, which on its own processes doughs with a water content of up to 80% of the flour used and a 12-hour dough resting time, yields more than 20 different products.

Hygiene and materials research are currently among Haton’s major lines of development. This has turned the basic dough divider solution into a wash-down solution in which individual components such as pistons, drums or conveyor belts etc. can be moved out of the machine and washed, and even the entire plant can be run and cleaned with water. It fulfills international protection standards for protection against water jets, and to some extent even against temporary immersion. For plants on which rye doughs containing sourdough are processed, the surfaces can additionally be designed to be significantly more acid-resistant than in the past. For example, Haton’s materials researchers are seeking a durable replacement for the Teflon coating in cones to eliminate the need for recoating processes.

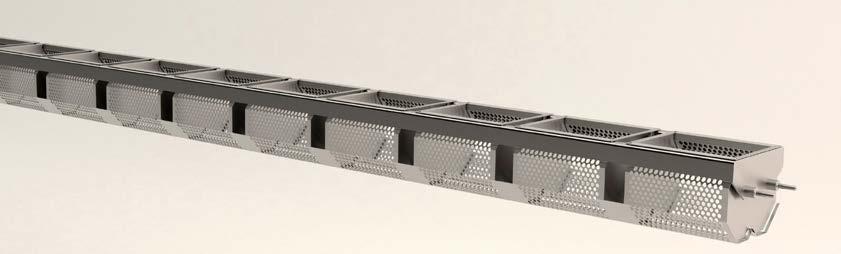

Hygiene and new materials were also the headline for the Clean Proofers development that uses proofing baskets made from a novel plastic in large industrial intermediate proofers. The first of these plants are currently proving themselves in practical use, while the developers work on an automatic cleaning system. The current developments of long roller systems that allow the least possible pressure to act on the dough are aimed more at improving quality and efficiency.

The V 700 Industrial Dough Divider

Weight accuracy: 99.5%

The V 700 is an example of the way Haton’s materials research developments have made their mark in the design of its machines. The V 700 is a dough-friendly volumetric dough divider. Dough piece weight accuracies of 99.5% are achievable. Thanks to new materials developments, it is now available both as a wash-down version and with acid-resistant units.

e V 700 is a dough-friendly volumetric dough divider with dough curacies of 99.5%

Panningen now earns 65% of its sales revenues outside Europe, and research & development suggestions originate correspondingly more often from other continents. For example, they include a decoseeder, initially requested by the American market, which strews toast-breads weighing up to 800 g all over with seeds, and does so at hourly rates of 4,000 to 5,000 pieces, depending on the proportion of grains. The idea has floated over to the Old Continent in the meantime, where it is being used for tinned breads made from rye mixed dough with a TA (dough hydration) of 175.

On the other hand, the Doughtwister has Asian roots. From the old 4-pieces method for toast-breads, it has created a

PRODUCTION 10

+

© Haton www.bakingbiscuit.com 04/2019 ++ C-Proof

© Haton

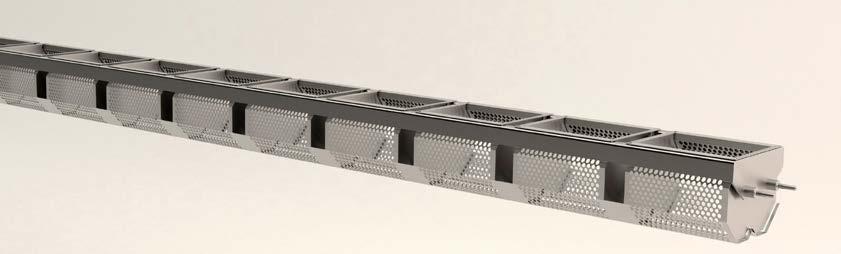

perforated stainless steel swing-trays

6-pieces version for small weights made from sweet doughs. Digitalization and automation are a third key development focus at Haton, although basically the cost-benefit question is in the foreground. Sales Director Rabi Williams says the meaningful aspect is “the communication between the dough divider and the checkweigher, but when it’s a question of controlling an entire line, we make sure trained operators are standing alongside the lines and have a technically qualified overview.” According to the expert: “We offer appropriate training courses where these are requested and

WP-Haton

Location: Panningen, The Netherlands

Production program:

Dividers: Rounders, Proofers, Molders

Even before the new millennium started, WP-Haton was one of the first bakery machine producers to organize their manufacture based on the Kaizen philosophy. Haton’s management has a flat structure. Divided up into regions, the Key Accounters, Project Accounters and Service Managers rank equally and work alongside and with one another under the CEO Henk Snellink.

in demand, and we also do so repeatedly in the event of staff turnover.”

Equally clearly and distinctly, Williams draws a clear line compared to other dough make-up systems such as dough sheet or extruder technologies. “We play in the Champions’ League and we concentrate on making further developments in our systems, e.g. by offering dough dividers with a 99.5% weight accuracy. That provides our customers with efficiency and flexibility.” +++

Around 700 exhibitors from 20 countries in six halls. Discover all the facets of the six main trade fair themes, find out about the diversity of topics and enjoy the atmosphere of a genuine trend and specialised trade fair for handcrafts. We look forward to seeing you!

südback – The trade fair for bakers and confectioners.

ADVERTISEMENT 11 PRODUCTION

++ Left: Axel Wagner, Key Account Manager, right: Rabi Williams, Marketing and Sales, Director Sales and Operations

the love of handcrafts. Fine. Finer. südback. 21. –

Messe Stuttgart www.suedback.com

© Haton © Haton

For

24.09.2019 |

A successful AIBI Congress

Approx. 200 baking sector representatives met together for the 36th AIBI Congress in Manchester. High-caliber speakers provided information about how experts envisage the bakery sector in the future, and what challenges will need to be overcome.

+A round 200 baking sector representatives from the whole of Europe and the USA met together for the 36th AIBI Congress in Manchester, England, from May 30 to June 2. High-caliber speakers, e.g. Ross Warburton, Executive Director of Warburtons, provided information about how bakery experts envisage the bakery sector in the future. There was also a discussion of the challenges facing the bakery sector, and how these can be overcome.

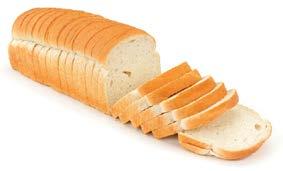

Ross Warburton explained that Warburtons Bakery is a private family company being actively managed by the fifth generation. According to the speaker, with around 4,500 employees in twelve production facilities and 14 depots throughout the whole of Great Britain, Warburtons is the country’s biggest family-managed bakery business. Its headquarters is in Bolton, and the bakery uses its own fleet of around 900 trucks to deliver its fresh products daily from depots and production units to approx. 18,500 customers. The baked goods are then sold in supermarkets. According to the speaker, Warburtons is considered to be Britain’s most popular bakery brand. The company generates annual sales revenues of around GBP 550 million. Ross Warburton dealt in detail with changes in the market.

For example, turnover with packaged, sliced sandwich bread has declined by 4% in the past four years. The turnover of bagels, for example, increased by 73% in the same period (compared to four years ago). Turnover grew with wraps (+67%) and bread rolls/buns (+7%). Warburton explained that “We must constantly adjust to changing consumption habits.” New players in the market, such as discounters and the growing offering of frozen baked products are changing the market. The responses available to bakeries could be to offer sandwich alternatives, for example, instead of “only” toast-bread. Ross Warburton also sees growth potential in the areas of “snacking” and “healthy baked products”. Warburton stressed that product life cycles are becoming altogether shorter. Therefore he says innovations and new products are important. That’s also why the company constantly invests in production facilities and in new plants.

Employee management

Another highlight was the presentation by Sir John Timpson, Chairman of Timpson, the British shoe repair chain, which has more than 2,000 shops throughout the country. The British businessman has a weekly management column in the

www.bakingbiscuit.com 04/2019 AIBI 12

++ Joseph Street, President of the AIBI from 2017 to 2019 (l.), Susanne Döring, General Secretary, and the new AIBI President Janez Bojc from Slovenia

++ The Lord Mayor of Manchester, Councilor Abid Latif Chohan

++ Sir John Timpson, Chairman of the shoe repair chain, gives a talk about “Magnificent service from magnificent staff”

++ Traveling from the USA especially for the occasion: Robb MacKie, CEO and President of the American Bakers Association. The expert supplied information about the North American bakery market

++ Ross Warburton, Executive Director, Warburtons, gives infor- mation about the bakery sector’s positioning in the market

© f2m ©

© f2m © f2m © f2m © f2m

++ Anne Fremaux, Bakery Director, Gira, presents new figures about the European baked goods market and highlights new trends in the baking sector

f2m

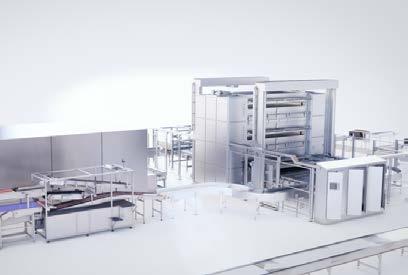

100 years of combined passion and know-how

With combined experience we enable you to produce the finest baked products

At IBIE in September, GEA Comas and GEA Imaforni will present durable solutions for the bakery industry built on 100 years of combined engineering knowhow coupled with fine craftsmanship. Our know-how extends to the development of new recipes by working together with our customers.

Meet with our experts to discuss your exact processing needs and explore how our GEA Bakery Experience Centers can bring your product ideas to life.

We look forward to meeting you at IBIE, booth 7547, in Las Vegas from September 8-11, 2019.

++ A historic double-decker bus took us to an evening event with live music to bring to a close the successful AIBI Congress in Manchester

newspaper “The Daily Telegraph”. Sir John has also written several books about his management style. For example, the employees in the shops should assume local responsibility and should take decisions themselves, e.g. about pricing. He says the price list for the various services is more like a guideline in this respect. What is important, however, is that money comes into the checkout. The task of management is to support the staff in the shops, including with private problems, for example. According to Sir John, employees should enjoy their work and should feel they are part of a family.

Trends

Anne Fremaux, Gira’s Bakery Director, presented new figures for the baked products market, and gave participants information about new trends in the European baking. For example, there is a rise in the consumption of baked products in the patisserie and Viennoiserie areas. But there is also growth in the areas of flatbreads, hamburger buns and donuts. On the other hand, according to the speaker, the trend in bread consumption is downwards. In the bread area, Anne Fremaux sees growth for premium baked goods, e.g. baked in a stone oven, and for “artisan-style” breads, i.e. baked goods that look as though they were “made by hand”. However,

“healthier” baked products with more dietary fiber or proteins, or breads enriched with spices or vegetables also offer opportunities for growth. The subjects of “Clean Label”, “Avoiding Refuse”, “Vegan” and “From the Region” are highly important to consumers.

New elections

In addition to the specialist presentations, new elections were also held. The members elected Janez Bojc, President of the Slovenian Federation, to be the new AIBI President. The new President thanked his predecessor Joseph Street for the latter’s activities and initiatives in the interests of European Industrial Bakers during his time in office. Bojc issued an invitation to Slovenia for the next AIBI Congress. The 37th AIBI Congress will take place in Bled from May 27 to 30, 2021.

Georg Heberer from Frankfurt was confirmed in his office as the President’s First Deputy. Armin Juncker, CEO of the Federation of German Industrial Bakeries, remains as Treasurer of the AIBI. The AIBI (International Association of Plant Bakers) represents the interests of large bakeries and supplies information for its members. More information at: www.aibi.eu +++

++ There was time between the specialist lectures to discuss the presentations

www.bakingbiscuit.com 04/2019 AIBI 14

© AIBI

© AIBI

© AIBI

© AIBI

© AIBI

© AIBI

© AIBI

Versatility Reliability Quality

VMI offers state-of-the-art mixing technologies to meet the varied requirements of the baking industry.

VMI is THE mixing company.

70 rue Anne de Bretagne, Saint-Hilaire-de-Loulay, 85600 Montaigu Vendée - France Tel. +33 (0)2 51 45 35 35 - contact@vmi.fr - vmimixing.com

MIXING SOLUTIONS for bread, pastries, cakes and snacking industries

ULTIMIX Planetary mixer

VISIT US BOOTH

ROBOTIZED MIXING SYSTEM with suspended shuttle

#6779

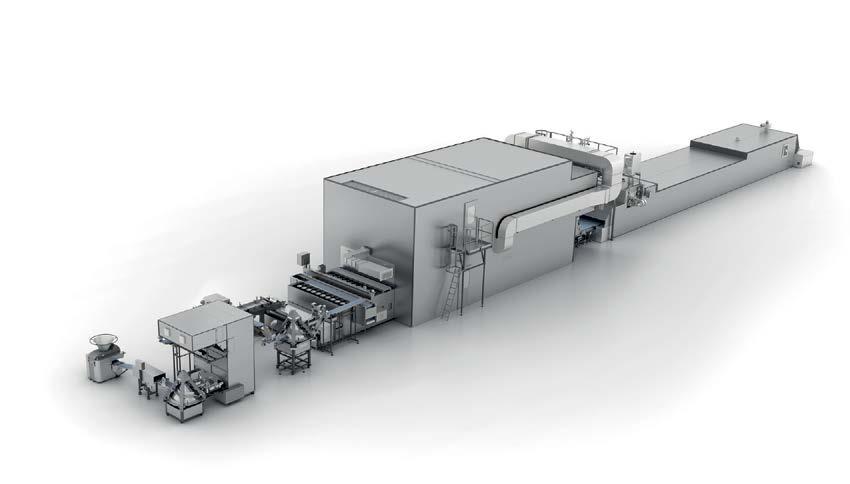

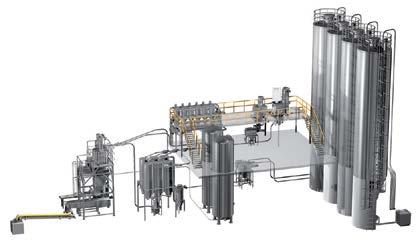

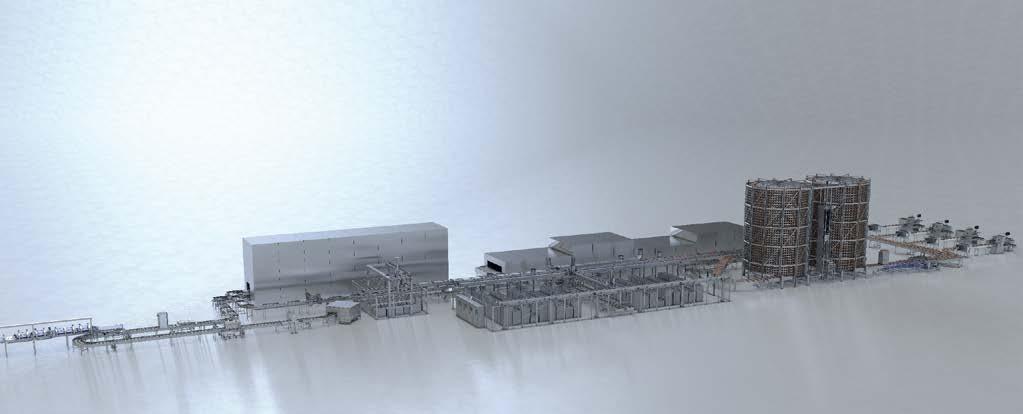

“The ideal bun line”

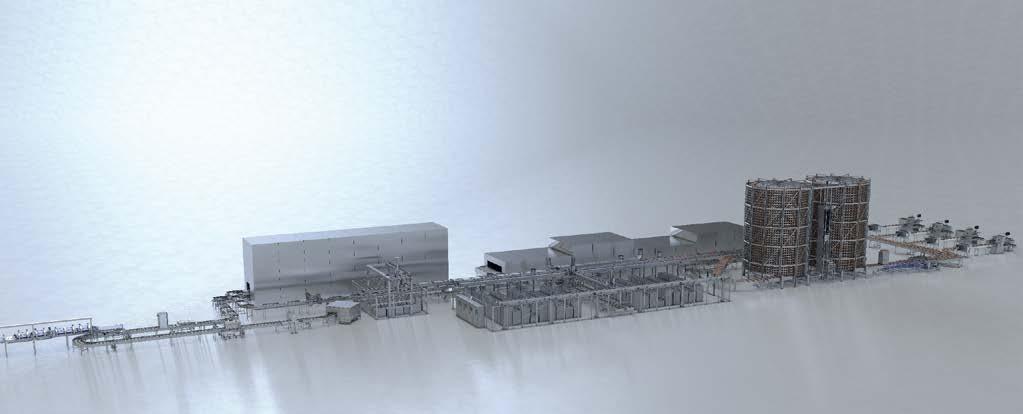

Consultant Thomas Ismar of Zeppelin Systems GmbH says: “We haven’t re-invented bun production, but we have made it more efficient and more flexible at the same time.”

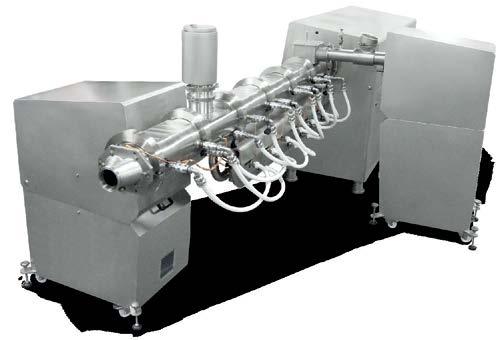

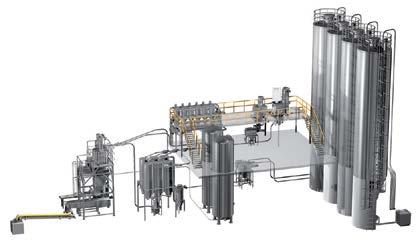

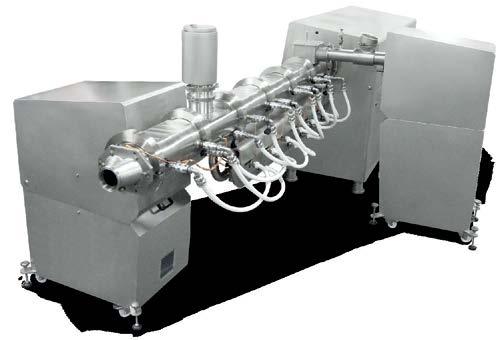

+Flexibility already begins at the dough preparation stage. The line evolves around with a continuous mixing system from the CODOS ® series that can either supply straight dough or can also operate on the sponge& dough principle.

The CODOS ® , following more than 100 plants now in service in baked goods production worldwide, got an all-round makeover last year with new drive technology, new cooling, Washing in Place, and also a new controller that communicates with Zeppelin’s higher-level automation and digitization software. So Zeppelin created the new CODOS ® NT.

The previous asynchronous geared motor has been swapped for a water-cooled servo drive with a single reduction gear, which means not only a 40% weight saving but also a reduced installed length, i.e. space is saved, and on top of that energy consumption is reduced.

The cooling system of the CODOS ® NT has also been fully redesigned. The efficiency level of the trough cooling has been improved considerably, which ensures better heat transfer. All the trough cooling assemblies will be positioned outside of the new continuous mixer in future.

Moreover, with assistance from research work at the Cereals Research Institute IGV Foodtech in Rehbrücke, Germany, the geometry and spacing distances of the mixing tools themselves have been optimized again. According to Michael Piepenbrock, Zeppelin’s Business Unit Manager,

www.bakingbiscuit.com 04/2019 PRODUCTION 16

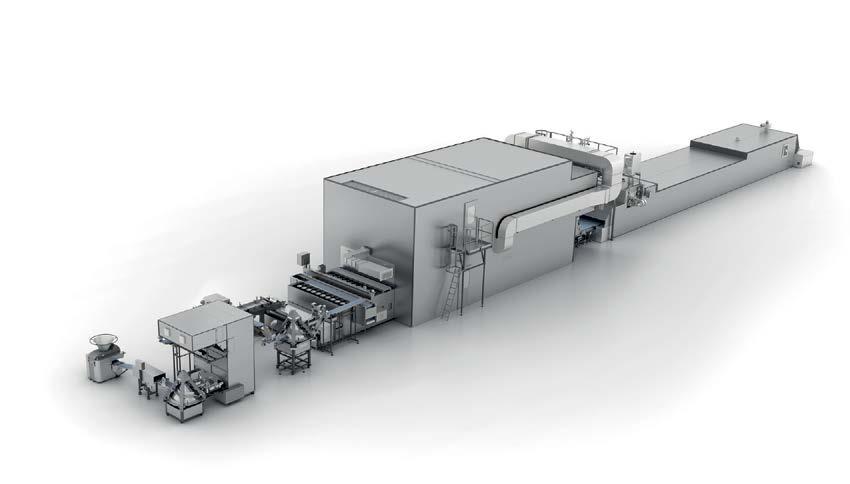

++ Zeppelin presented its version of the ideal toast-bread line at the iba 2018 trade fair. At the IBIE 2019 in Las Vegas, the talk is now all about the “ideal bun line”

© Zeppelin Systems

© Zeppelin Systems

The European Bakery Market 2019

Please contact: Viktoria Usanova via E-mail: usanova@foodmultimedia.de

COnTENT

++ 7 Country portraits: Hungary, Poland, Romania, Slovakia, Sweden, Switzerland, United Kingdom

++ Expert Interviews: The European out-of-home market

++ Market Research: Trends and market dynamics

++ Company reports: Profiles of major suppliers to the bakery market

f2m food multimedia gmbh Ehrenbergstr. 33 · 22767 Hamburg · Germany · info@foodmultimedia.de Phone: +49 40 39 90 12 27 · Fax: +49 40 39 90 12 29 · www.foodmultimedia.de fotolia.com © lukiv007 Hard copy • 272 pages • EUR 49 incl. VAT + delivery costs For more information, please visit

Subscribe now to baking+biscuit international and you will get a digital copy of

book for free

our website: www.bakingbiscuit.com

the

new!

Food Processing Plants: “That provides more power and performance with less energy consumption, and makes the CODOS ® scalable.” There will be a CODOS ® NT 160 with a dough production capacity of approx. 3 tons/hour, the CODOS ® NT 200 at 4 - 5 tons/hour and the CODOS ® NT 230 with up to 8 tons/hour of dough. In 80% of all cases, a CODOS ® stage will be combined with a DymoMix that supplies pre-mixed, uniformly wetted raw materials to the CODOS ® . A two-stage CODOS® solution is usually used when processing flours containing extremely high gluten levels.

The sponge&dough principle involves installing conveyor belts between the sponge dough preparation stage and the final mixer, on which the sponge dough can rest and ferment while being conveyed, for up to 24 hours if required. The

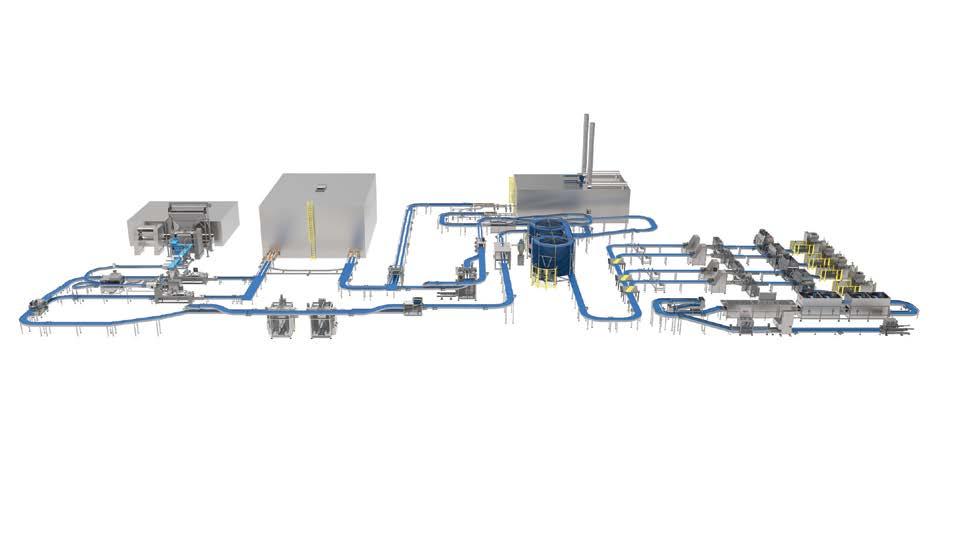

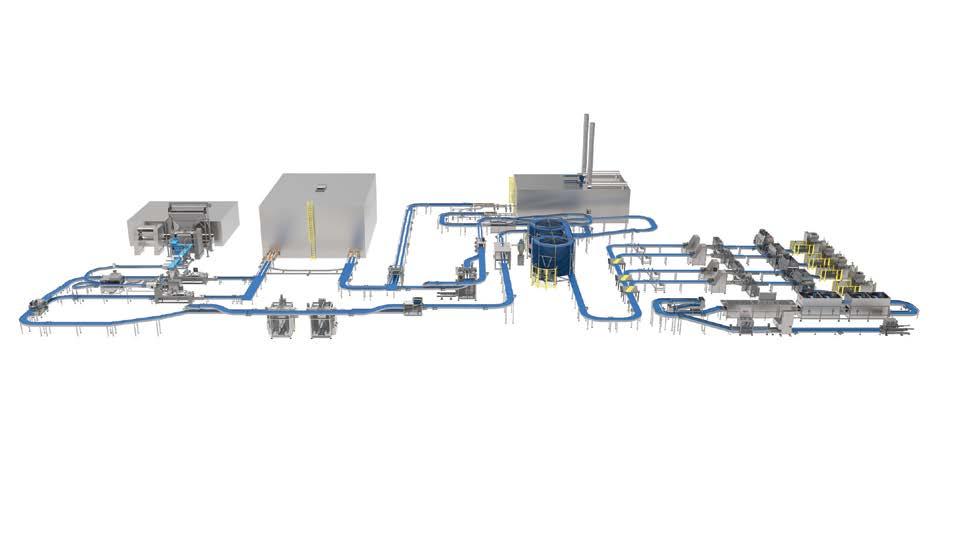

section can also be encased and air-conditioned if necessary. The layout being presented by Zeppelin in Las Vegas is based on a project in cooperation with well-known European manufacturers such as Handtmann, which is supplying the dough divider, and the Tecnopool Group, which is responsible

conveyor belt adjusts to the required resting time, and can accommodate up to 9 tons of dough. According to Ismar, four hours of fermentation are normally suggested for buns. A mixing capacity of 4 tons/hour of sponge&dough would need a transport unit 20 m long, 6 m high and 4 m wide. However, not only does the space requirement turn out to be modest, the investment budget for the fermentation stage also remains very manageable at EUR 0.5 million. Ismar says: “It’s probably the best value for money sponge&doughsolution of all.” Of course, the mixer and fermentation

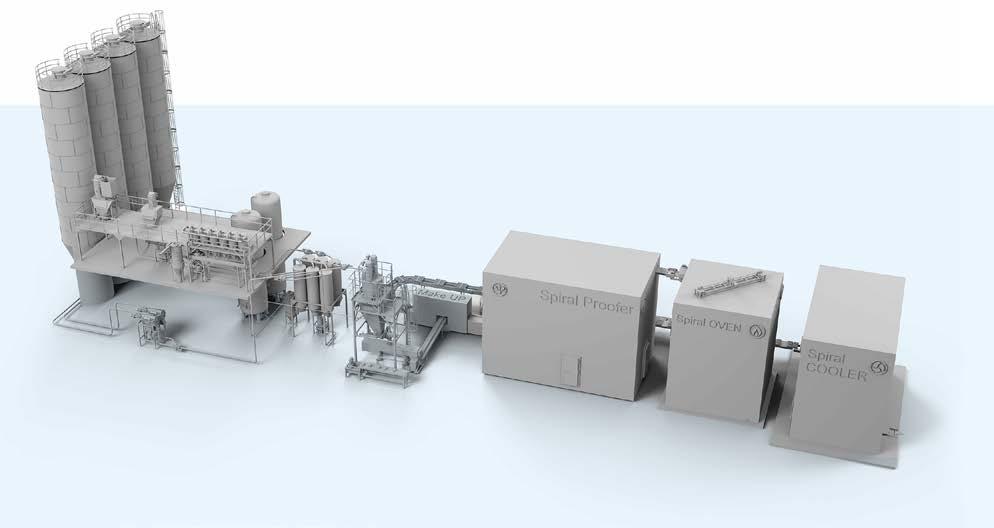

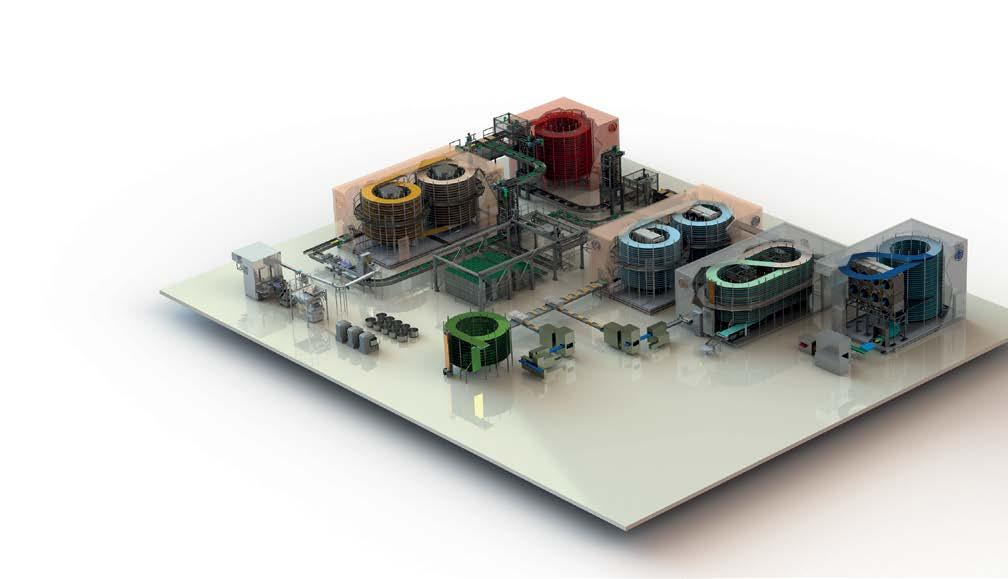

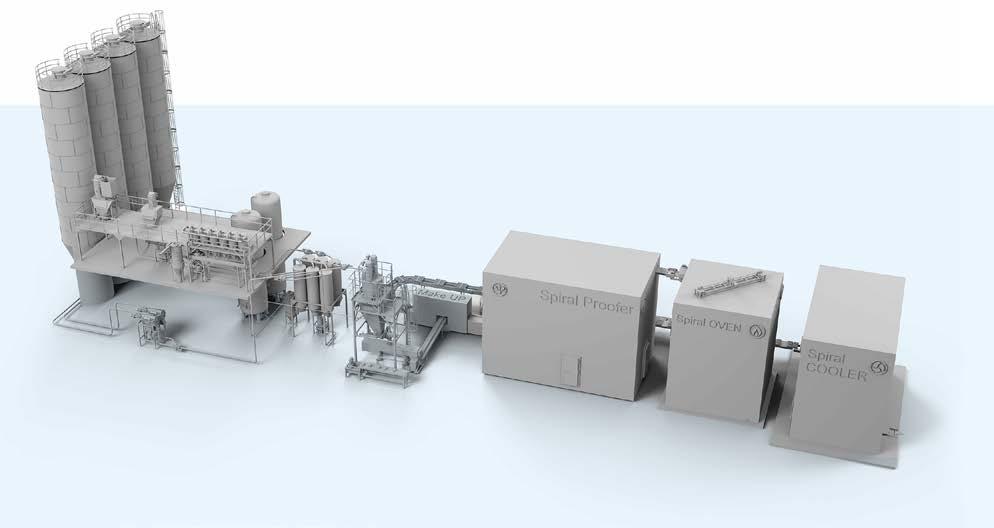

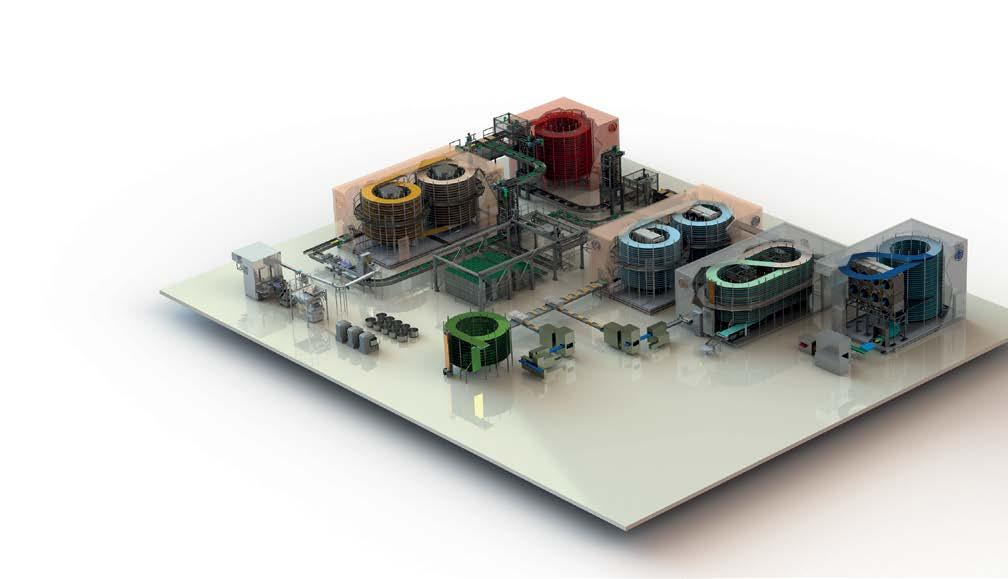

for tray handling, the proofer, oven, cooling system and, if necessary, the freezer. Tecnopool specializes in spiral systems for all temperature ranges, and its developments include a novel thermo-oil-heated spiral oven in which hot oil circulates in pipes underneath the levels of the spiral. The construction of the spirals allows the pipes to run under one level and above the next, thus exposing the products being baked to radiant heat from both directions. The customer and/or the required production program decide whether the construction of the oven is circular or oval and whether the conveyor belt entry and exit are located at the top or bottom, as well as the oven’s height and thus the number of levels of spiral. The oven can be subdivided into temperature zones with separate oil circulations, to achieve a specific heat/time profile for a particular product. A heat exchanger positioned in the center of the oven and supplied from the hot oil system, together with a blower, provide convection heat if needed. A selection of various different steel rod belts is available to transport the baked goods, depending on whether baking is to take place directly on the belt, on trays or in pan clusters. According to Tecnopool, a combination of a spiral proofer, spiral oven and spiral cooler needs up to 600 m 2 less space than tunnel oven lines. +++

www.bakingbiscuit.com 04/2019 PRODUCTION 18

++ Layout for a bun line with an hourly capacity of 3,000 pieces per hour. The biggest line designed up to now delivers up to 60,000 buns/hr

© Zeppelin Systems

© Zeppelin Systems

© Zeppelin Systems

contact@americanpan.com | americanpancom For more than 30 years, American Pan has led the way in baking tin and tray innovation; from energy-saving designs to industry-leading coatings. We don’t believe in “one size fits all.” By engineering trays, applying exclusive coatings and providing economic refurbishment programs to fit your exact product and facility needs, we help you save money, increase quality, and outpace the competition. Bundy Baking Solutions: American Pan | Chicago Metallic | DuraShield | Pan Glo | RTB | Shaffer SKELMERSDALE, UK | +44 (0) 1695 50500 IRLAM, UK | +44 (0) 161 504 0771 THE PERFECT PAN from the first bake to the last. Contact our sales team to get started on your custom pan or cleaning program today. BARCELONA, SPAIN | +34 93 781 46 00 ALEXANDRIA, ROMANIA | +40 247 306170

Booth #5460

A marketplace of innovation

The IBIE 2019, International Baking Industry Exposition, will take place in Las Vegas from 8 to 11 September. On an area of approximately 65,032 m 2 more than 1,000 exhibitors will display products and services that pertain to the baking industry.

+According to the organizer, the IBIE is the largest trade show held in North America that showcases the industry’s latest technologies, equipment and new product introductions. Some companies have informed us in advance which innovations they will be presenting in Las Vegas.

All divisions of Bundy Baking Solutions will be present at IBIE 2019. Booth 5460 will showcase the latest products and technology from all of the companies. American Pan will feature a full range of custom baking pans including the newest large format bun pans, ePANs, TabLock trays, and trays for Mecatherm systems. The booth will also exhibit cake and bread pans in a variety of designs and the company’s proprietary coatings, including non-stick coating and silicone glaze. Information about the pan cleaning and recoating services will also be available. A full array of stock bakeware will be on display. These pans are shipped daily from Humboldt, Tennessee, USA to bakeries and foodservice operations throughout North America (for further information see page 30).

Shaffer will showcase multiple mixers and dough handling equipment, including the new Select Series Mixer line. Shaffer’s new Select Series Mixers are precisely engineered to offer maximum value and durability. The all stainless-steel construction combined with watertight enclosures and an open frame feature under the bowl, provides the ultimate mix of simple yet sanitary design. The mixer’s single end belt drive system and simple operator controls are comprised of well-known, commonly stocked components that make the

IBIE 2019 will take place

September 8-11, 2019 with a full day of IBIEducate on September 7 at the Las Vegas Convention Center. The trade show takes place every three years. It will span nearly 700,000 square feet (about 65,032 m 2) of space more than 1,000 exhibitors displaying products and services that pertain to the baking industry. The show is expected to draw more than 23,000 baking professionals.

Website: www.ibie2019.com +++

mixer easy to operate and maintain. The tilt system can be configured for forward only or forward and reverse tilting of the bowl. Select Series Mixers are available in triple roller bar or single sigma arm models to produce breads, buns, rolls, cookies, granola, and other baked goods. The Shaffer ® VerTech ® refrigeration jacket provides bakeries peak performance and efficiency, with the most effective, durable, and energy efficient bowl cooling available. The VerTech ® jacket is specifically designed for triple roller bar mixers that demand mixing durability; it easily holds up to stiff doughs and high horsepower machines without increasing mix time. In accelerated fatigue testing on a full-scale model, using over twice the force of a low absorption dough, the VerTech ® jacket showed no damage, even at over 40 times more cycles than other conventional jacket designs.

Shaffer continues to provide new, simple options for the sanitation of mixers. Schaffer’s agitator shaft seal design has progressed to include fewer parts leading to faster cleaning and superior leak prevention. The shaft seal design achieves superior sealing by applying exact pressure on the inner seal. This pressure forces the inner seal to expand and seal tightly to the agitator shaft preventing dough from leaking.

Shaffer’s new removable flour gate assembly is designed to be easily removed from the canopy to provide access for thorough cleaning of the assembly and area around the flour

www.bakingbiscuit.com 04/2019 FAIRS AND EXHIBITIONS 20

About IBIE

© Wasin Pummarin –123rf.com

++ Shaffer’s new Select Series Mixers are precisely engineered

© Bundy

gate. The assembly uses retained hand knobs that are integrated into the housing to provide tool-free removal in less than one minute and prevent the loss of hardware. Thorough sanitation of the flour gate assembly and surrounding area eliminates sources of allergen contamination and provides a clear check at a critical control point in sanitation evaluations. The assembly can even be retrofitted to existing mixers.

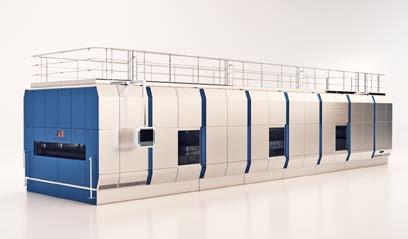

MECATHERM , Barembach/France, a world leader in automatic production lines for industrial bakeries, will be unveiling a brand-new flexible line concept. Raymond Nogael, VP Marketing, explains: "MECATHERM'S flexible line solution adapts to a new economic model with flexibility and agility, to replace the previous mass consumption reference model. Today, industrial bakery manufacturers need to be able to produce multiple products involving varied customized processes and need to launch products on the market quickly, without compromising on quality or performance". The new flexible production line, which will be launched during the IBIE 2019 trade show is the solution highlighted by MECATHERM to respond to this new demand. Smart and responsive, this new line provides the opportunity to supply a large range of products, produced using different process combinations with trays of varied types and formats. The latest MECATHERM technology and equipment, such

++ The new M-TA Oven fully redesigned allows a variety of heattransfer options from above and below

as the M-TA oven and the M-UB handling system unveiled during IBA 2018, will play a part in providing an innovative solution for industrial bakers. IBIE visitors can also attend demonstrations of the new M-NS divider at MECATHERM`s booth. This new make-up line has numerous advantages: its innovative technology produces authentic bread with a taste and shelf life adapted to current market demand.

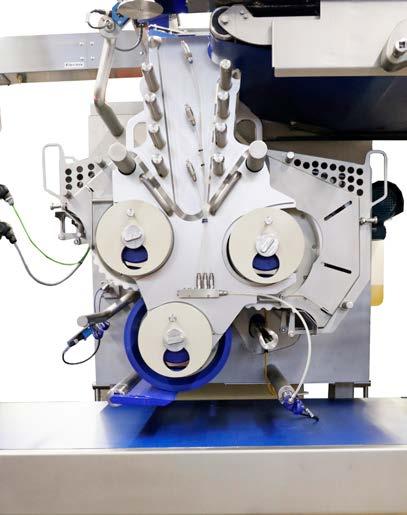

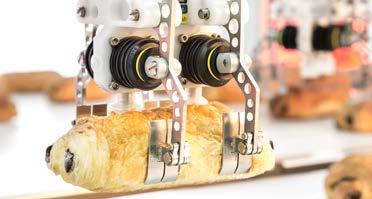

Koenig Bakery Systems , Ashland/USA, will showcase its baking equipment at IBIE 2019. The very compact Mini Rex Multi dough divider and rounder features a new forming

TOTAL DOUGH HANDLING

© MECATHERM

21 FAIRS AND EXHIBITIONS ADVERTISEMENT

BVT Bakery Services BV The Netherlands www.bvtbs.com

BOOTH 7189

station – it can now also produce Teleras & Bolillos. Bakers can easily insert various tools for producing the traditional Latin American breads, additional to products such as hot dog and hamburger buns and rolls with a plaited look, etc. The compact line has a capacity of up to 1,200 pieces per row/per hour and can also operate as a stand-alone machine with 1, 2, 3 or 4 rows.

The Combiline plus EC is a modular roll line in “Easy Clean” design. Apart from its high versatility for producing various types of buns, the line provides easier cleaning, maintenance and access to all modules for minimized downtimes. The “plus” stands for an increased capacity of 33 strokes/min. for 11,880 pieces per hour with a 6-row operation. The line can produce various products such as hamburger and hot dog buns, decoratively stamped buns such as Kaiser, hoagies and half baguettes.

unparalleled performance combined with modern hygiene properties. The Starline adapts perfectly to baker’s needs and preferences and to the space requirements and work processes on-site in the bakery. It can be equipped with the advanced RONDO Control Concept, which makes operation simpler, faster and above all safer, even for non-skilled operators. The visualization includes the entire production line, so operation is intuitive and streamlined.

New developed system for bend croissants: Cromaster is a compact croissant system for an hourly output of between 4,000 (2-row production) and 24,000 croissants (8-row production) per hour. In addition to its compact and space-saving design, the Cromaster is characterized by high process reliability. The adjustable curling unit (patent pending) allows the production of both tightly and loosely curled croissants.

Under the motto, “100 years of combined passion and knowhow,” GEA will be exhibiting advanced bakery technology from its leading brands, GEA Comas and GEA Imaforni. Both processing and freezing technology will be represented at booth 7547.

Combiline plus EC

Easy cleaning and short changeover times are becoming increasingly important for bakeries of all sizes. Thus, the Combiline plus in “Easy Clean design” is comprehensively designed for easy and open access to all components. The “Easy Clean” concept features easily removable conveyor belts and flour dusters for cleaning purposes, and no tools are needed. In addition, all electric drive components are completely sealed off from the dough area. The proofing cabinet of the Combiline plus EC has been completely redesigned at a 45° angle, so that there is no soiling due to the sloping surfaces. The forming tools, e.g. for decorative stamping of dough pieces, are easily extracted and changed with quick-releasing methods and can be stored separately on their own accessory trolley. The line offers open design and has large service doors for easy accessibility to all modules. Furthermore, sensor systems ensure operator safety.

RONDO , the Swiss manufacturer of dough processing machines and systems, will be exhibiting many innovations and enhancements for artisanal, semi-industrial and industrial production at IBIE booth 5837. The company will show three different types of make-up lines, Starline, Polyline and Ecoline. The top model is the Starline, a user-friendly, robust make-up line boasting

Exhibits will include the high capacity GEA Rotary Molder for making soft dough cookies and shortbreads with different shapes and dough consistencies. Also on display, the GEA Multi-piston Depositor, which works with ovens up to three meters wide and boasts a host of innovative features that result in better products and higher productivity. As well in the spotlight, the GEA Paper Cup Denester, which places paper cups, aluminum foils and plastic containers for production of cupcakes, muffins, pies and layer cakes and operates at up to 50 cycles/minute. And throwing a little light on things will be the GEA TecLight, the new LED light option

www.bakingbiscuit.com 04/2019 FAIRS AND EXHIBITIONS 22

++ Easy cleaning and short changeover times:

© Koenig

© Rondo

++ The high-end make-up line Starline combines high performance with ease of use and ample space for accessories

© GEA

++ High capacity GEA Rotary Molder for making soft dough cookies and shortbreads with different shapes and dough consistencies

AMFBAKERY.COM | sales@amfbakery.com USA | Netherlands | UK | China | Singapore | Canada | Mexico | UAE MIXING | MAKEUP | BAKING | PACKAGING | POST-PACKAGING overall energy e ciency, or take your first step into automation, AMF’s Den Boer, Vesta, and BakeTech Baking Systems o er best-in-class equipment solutions with unparalleled support for the life of your bakery. Booth 5436/5420

from GEA, specifically developed for use under freezing conditions reaching -40 degrees Fahrenheit.

GEA experts will also present CALLIFREEZE®, a new freezer control system for GEA spiral freezers that continuously monitors the product’s level of frozenness to ensure that products are perfectly frozen without wasting energy; GEA A-Tec spiral freezers, which have been designed specifically for the North American market and featuring hygienic design, high product yield, fewer defrosts and low energy consumption; and GEA Packaging Solutions, including vertical form, fill seal and thermoforming systems that maintain food quality throughout the supply chain.

At booth 7469, Aasted , Farum/Denmark, will present a wide range of process technologies ranging from dough forming to adding value to products with chocolate decorations or enrobing. The exhibits also include the new Alice ™ II, the next generation of extruder as well as the Alice ™ High-speed wire cutter, which is even more refined, faster and easier to use.

Middleby Bakery will display some new developed technologies at IBIE this year.

Auto-Bake Serpentine: Auto-Bake’s Dream Line can produce up to 1 million mini-bites per day in less than 20 meters with one line operator. According to the company it is the highest throughput in the smallest floor space in the industry.

Baker Thermal Solutions: The Templex Gen II Proofer offers a space-saving automatic proofing solution with the benefit of reduced maintenance based on the simplified new design. Burford is introducing three redesigned machines this year; The new Smart Pattern Splitter, the new 824 Spray Applicator and the new Enrober, with many added features to maximize accuracy and improve efficiency.

Glimek: Exclusively at IBIE, the Bread Line 450 produces up to 4500 pieces per hour. According to the company the IPP 1270 Intermediate Pocket Proofer is one of the most flexible pocket proofers on the market today.

Hinds-Bock: With the ever-increasing price of production floor space, Hinds-Bock develops equipment solutions that utilize minimal production space, while increasing and optimizing production throughput.

Scanico ’s Spiral Solution has been redesigned with direct drive and a hybrid plastic belt as integrated part of Middleby Bakery. The Controlled Air Cooling improves shelf life by filtering and controlling the cooling air.

Spooner Vicars will showcase the latest generation Rotary Moulder – the A-PEX Sport – and the new A-PEX Wirecutter. Both high speed applications, the A-PEX Sport is built to run at 40m/min, while the new Wirecutter is designed to run up to 300 cuts/min.

Features:

+ Easy to access the cutting mechanism

+ Fast changeover of wire cutter frame

+ Off-line function of complete extruder head gives easy access for cleaning and service

+ Fully adjustable cutting performance

+ Repeatable/adjustable parameters

+ Gentle dough extrusion with accurate weight control

+ Automatic clutch connection between head and drives

Stewart Systems will bring an 8-pocket Bun Make-Up Line with a fully updated Bun Divider, featuring individual pumpsand many other updates. The result is better weight accuracy and product consistency. Stewart’s Pillo-Pak will demonstrate new sealing technology in conjunction with MAP (Modified Atmosphere Packaging) Technology which will provide extended shelf life in a bulk format for QSR buns.

Sveba Dahlen will launch the new F500 F-Series Proofer –the proofing cabinet of the future – and Sveba Dahlen Connect that uses modern technology and connected ovens to increase your profitability and ensure the quality and consistency of your bread.

© Aasted ++ Aasted`s new Alice ™ High-speed wire cutter

FAIRS AND EXHIBITIONS 24

©

++ Stewart Systems’ High Speed Bun Make-up Line

Stewart Systems

www.neweramachines.com sales@nem.co.in

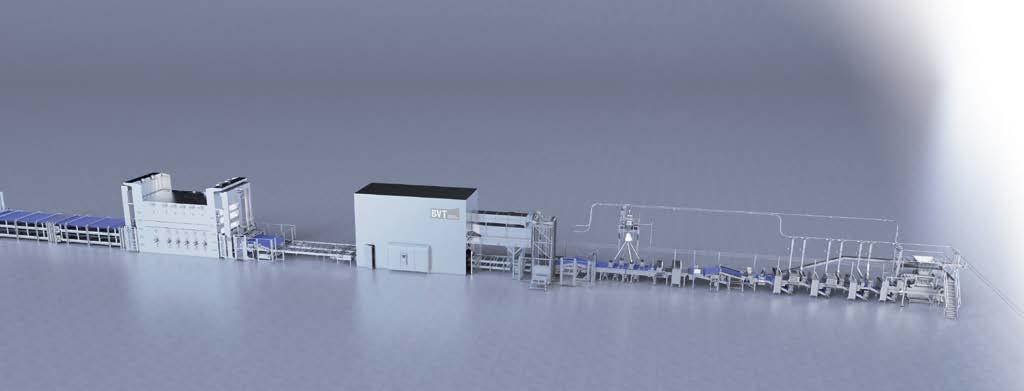

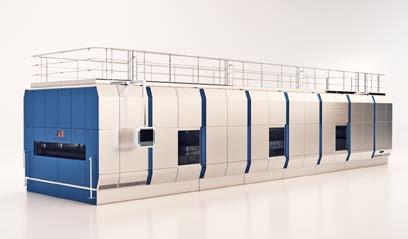

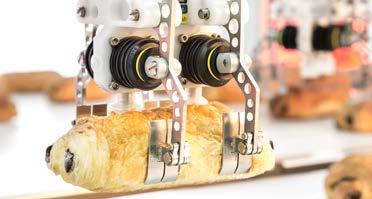

Industrial Vacuum Cooling

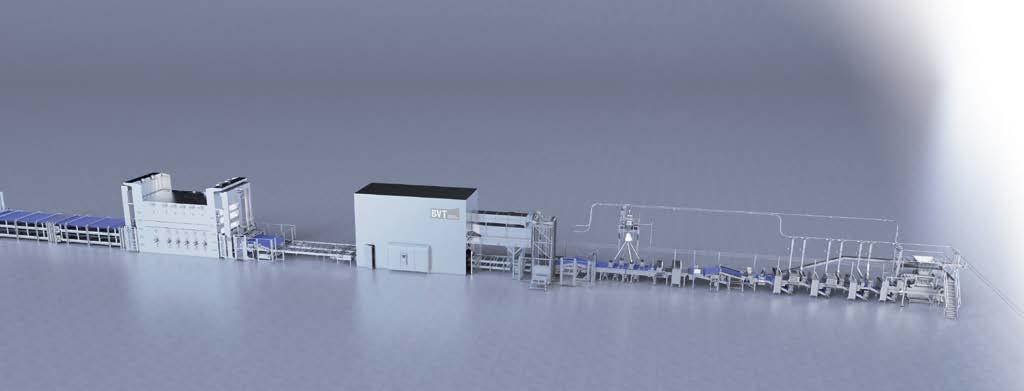

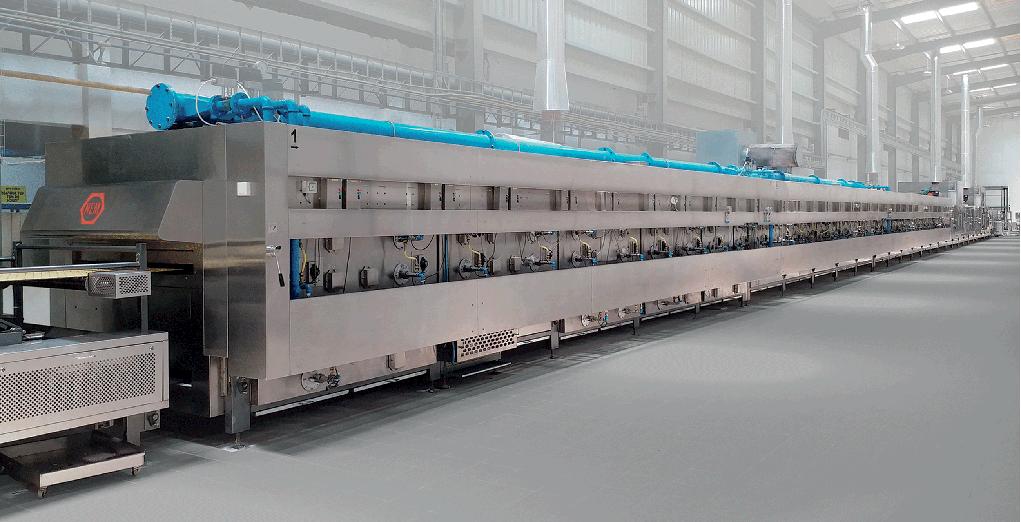

Industrial Vacuum Cooling has been introduced to the market some years ago. One of the suppliers is the Dutch Verhoeven Bakery Equipment Family (BVT/NewCap/Vacuum Cooling & Baking Company). In the meantime this game-changing application has been appreciated on a worldwide scale.

The continuous -fully automated- system to cool baked products such as bread, toast, croissants, muffins, buns and rolls is part of the product range from the Dutch Verhoeven Bakery Equipment Family (BVT/NewCap/Vacuum Cooling & Baking Company).

The development of processes like Vacuum Cooling opens up a whole new perspective for the market of food production. Although technically incorrect, the term ‘vacuum baking’ is often used in the bakery industry, implying the fact that the Vacuum process has great influence on the baking process. While the baking process can significantly be shortened, a different baking profile and baking curve arises.

The first continuous Vacuum Cooling systems have been installed at major Industrial bakeries over the world. By integration of this technique in the bakery production environment the average production capacity could be raised by 30-50%, because of the substantial reduction of the production time. Industrial Vacuum Cooling has now been applied for the production of standard baked products such as toast, biscuits and apple pies, but also for special products such as Gluten free. The implementation has resulted in substantial cost reduction and quality improvements.

Most of these customers are continuously looking for a better quality of their product. But the investment is based on more than quality improvement alone. The scale of economics can be obtained by saving on space (the system is substantially smaller than a conventional cooling system) and on ingredients (the volume of the product is increased by Vacuum Cooling). Furthermore the reduction of the ecological footprint is supported by a massive decrease of the huge energy consumption

++ A vacuum cooling system is shown. This 25 m2 system could replace a traditional 250 m2 spiral cooler. Nevertheless the size of the vacuum cooling system is product dependent.

which is an important characteristic and one of the future challenges for the bakery industry.

The continuous Vacuum Cooling Process is much less time consuming than the conventional one. The modular designed installation is compact. The cells are stackable and can swiftly be loaded and unloaded. The ingenious operating system allows a rapid, partly pulsing increase and a controlled decrease of the vacuum. The Vacuum Cooling process enables a high capacity of production. The room capacity is customised and modified to the conventional oven production requirements. The system can be scaled up to quantities of 45.000 cakes, 54.000 croissants or 12.000 toast breads per hour, depending on the capacity of the preceding production line, the recipes and baking processes.

Author

Patrick Duss is an expert in vacuum cooling. The trained baker and confectione is also a studied business economist. He comes from a family of four generations of bakers. He has been involved in vacuum cooling technology for over 15 years. Duss is part of the V-team within the Vacuum Cooling & Baking Company. This team, within the Verhoeven Bakery Equipment Family, consisting of specialists within vacuum technology which focus on development, manufacture and implementation of vacuum systems in the baking industry

Vacuum Cooling & Baking Company

Parallelweg 13, 5349 AD, Oss, The Netherlands info@vacuumcooling.com, www.vacuumcooling.com

PRODUCTION 26

+

©

www.bakingbiscuit.com 04/2019

++ When the products come out of the oven it is important that they are placed in the vacuum cooling system as soon as possible. There is need for a quick supply.

BVT © BVT

The average cooling time for the products is reduced to 2-3 minutes instead of 60-90 minutes. At the production of Zwieback Toast, the maturing time of up to 24 hours can even completely be abolished.

Next to the production of batch chambers for bakery products the Dutch company offers tailor made Vacuum Cooling solutions for the production of other product like sauces, soups and fillings, tailored to the recipes and production requirements. The systems are wanted because they are suitable for versatile applications which allows the use for a variety of products.

The operating system forms the heart of the process and system. The product quality can be maximised and an increase of the volume can be realised due to a substantial reduction of the baking time. While the product is still dynamic the product quality is influenced and the capacity of the oven can be increased with 25-40%.

The Vacuum cells are closed and therefor the heat loss which occurs in the conventional cooling process, can be efficiently regained through heat exchangers. The existing temperature and condition of the production rooms is much less influenced by the baking process.

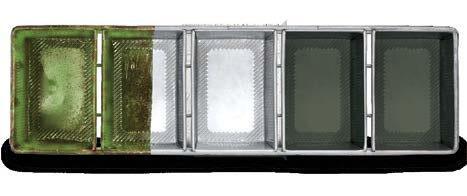

TINSETS

+ the right shape for everybody

+ for all trolleys and industrial lines

+ coatings for any type of dough

ZTROLLEYS

Make the most of your bakery

+ super stable

+ safe up to 66% of space

+ available for any tray size

TRAYS

Our trays can be used anywhere, both in the bakery and showroom. Any dimension and functional coating is possible.

++ On the left a bread loaf is shown that was baked and cooled with the vacuum cooling system. On the right a bread loaf is shown that was baked and cooled the traditional way.

The baked product is stabilised due to the vacuum cooling process, and will lose practically no moisture (less than 4% sometimes down to 2,5%) compared to the conventional products.

Vacuum Cooling influences the distribution of the moisture, which leads to energy saving. On freezing time for instance a 30% saving can be realised. At the same time the physical characteristics like the crust can be improved and controlled. The baker steers the process in a detailed way, resulting in a better product with less Acrylamide and other unwanted compounds. +++

HIGH QUALITY THAT MATCHES YOURS

We are a well-known German producer of bakery equipment

+ Baguette and mould trays

+ Racks and baking trays

+ Tin-sets

+ Coating and Recoating

ADVERTISEMENT 27 PRODUCTION

© BVT Visit us at Südback Hall 5 Booth D58 or at www.anneliese.com MADE IN GERMANY In der Krause 67, 52249 Eschweiler +49 (2403) 7001 0

@

uksales@anneliese.com

++ Ashworth’s New Website

Ashworth Bros., Inc., headquartered in Winchester, Virginia/ USA, has launched a new, mobile-friendly website. Customers and prospects can readily access comprehensive product information to help them select the right belt for their specific requirements. The easy to navigate design offers seamless browsing for users and provides enhanced visibility of new products and services. By simply clicking on product photos, users can find information on features, benefits, and specifications for a wide range of processing applications.

++ Sale of Bosch Packaging Technology

at Koelnmesse, who in turn will be developing the leading international trade fair for photography, video and imaging as a global platform for the industry. +++

++ Vincent Langelaar is the new General Manager for AMF Tromp

AMF Bakery Systems, Gorinchem, The Netherlands, announced that Vincent Langelaar has joined the Company as General Manager for AMF Tromp. “We are proud to have Vincent on board,” mentioned Fabiano Malara, Vice President and General Manager for AMF Europe. “With his proven industry experience developed over years of consultancy, business ownership, and senior positions with other equipment suppliers, he will guide the organization to a higher level of customer service and best-in-class technology.” +++

++ Tremaine Hartranft Named Director of Technical Sales at Reading Bakery Systems

Bosch plans to sell its packaging machinery business, based in Waiblingen, to a newly incorporated entity managed by CVC Capital Partners (CVC). The company and its Pharma and Food units will remain intact. Based in Luxemburg, CVC is a leading private equity and investment advisory firm with 24 offices in Europe, Asia, and the United States. It currently manages more than US$75 billion of assets. The parties signed an agreement on July 11, 2019 effecting the transfer of the entire packaging technology business and its 6,100 associates in 15 countries. +++

++ Spooner Vicars appointed David Hamilton as new Sales Director

Spooner Vicars announced the appointment of David Hamilton as Sales Director. David Hamilton is well known within the industry and has held numerous appointments, most recently as General Manager/Director of Silcoms, an Industrial Chain Manufacturer and supplier to the Bakery Industry. According to the company he has an in depth knowledge of the products having spent the majority of his working life at Spooner Vicars where he spent his career in sales, project management and engineering, eventually ending his tenure with the company as Operations Director. David will be based out of the companies premises in Golborne, Wigan, UK. +++

++ New Director of yummex Middle East

Koelnmesse has named Jan Philipp Hartmann (35) as the new Director of yummex Middle East (29 to 31 October 2019 in Dubai). His responsibilities include further strengthening the confectionery trade fair as a platform for innovation in the entire Middle East & North Africa region. Hartmann is replacing Fabian Ströter, the new Director of photokina

Tremaine Hartranft of Reading Bakery Systems (RBS), one of the world’s leading manufacturers of snack production systems, has been promoted to Director of Technical Sales, effective immediately. “We are very excited to welcome Tremaine and the wealth of technical expertise that he brings to our sales team,” said Shawn Moye, Vice President of Sales at RBS. Hartranft started with RBS in May of 2005 and held positions of increasing responsibility including Applications Designer, Project Engineer and Director of Engineering. In his new role, Hartranft will be responsible for the technical sales group, project management group and applications group. Along with these responsibilities, he will assist the growing RBS worldwide sales team, and support customer visits to the states. Working at RBS headquarters, he will also be the liaison between the sales and engineering departments, assuring a smooth transition for all projects. +++

++ Reading Bakery Systems Selects Meng Yeong Chong as Sales Manager for China

As part of its continuing expansion into South East Asia and China, Reading Bakery Systems (RBS) announced that Meng Yeong Chong has joined the company as sales manager for China. Meng will report to David Kuipers, Senior Vice President of Sales and Marketing for RBS. Before joining RBS, Meng worked in sales engineering and sales with Andritz, a large Austrian company with businesses covering hydropower equipment, pulp and paper processing, metal processing and separation technologies. He also worked for Heinkel, a privately held company based in Germany looking to expand their footprint in Asia. +++

www.bakingbiscuit.com 04/2019 NEWS ++ NEWS ++ NEWS 28

+++

++ Vincent Langelaar

© AMF Bakery Systems

++ David Hamilton

© Spooner Vicars

++ Meng Yeong Chong

© RBS

++ Tremaine Hartranft

© RBS

© Bosch

Specialists in food processing equipment www.rademaker.com Consistent Quality, Efficiency, Profitability Customers demand the highest quality bakery products delivered on time and at the right price. Rademaker understands these challenges. We provide efficient bakery equipment for every possible production environment, based on your specific dough processes and product requirements. Resulting in the lowest cost of ownership in the market yielding maximal results in terms of product quality and return on investment. Meet us at: Booth 5861 Booth 5C42

Unrivaled Value, Quality and Innovation

The Bundy Baking Solutions family of companies has been providing the baking industry with quality, innovative solutions for over 50 years ranging from custom baking pans and recoating services to state-of-the-art mixing technology.

+American Pan continues to make investments in equipment, tooling, and talent on a global level to ensure that the highest quality standards are met. The company has five manufacturing plants including one in Romania, one in South America, and three in the United States. These operations provide customers with options to meet their specific product, timeline, and budget needs while providing the consistent quality and service that they need and deserve.

Energy Efficiency with ePAN Designs

Available in any size or configuration, ePANs are made from aluminized steel with a specially designed framework called an e-band. The ePAN is around 50 % lighter than a traditional pan and offers numerous advantages to the baking industry. It requires less power to move it around a baking operation, less energy to heat up, and less time to cool down. Stronger than standard pans, ePANs can be stacked higher and therefore require less storage space.

Economical Screen Replacement Design

Another pan made with groundbreaking technology from American Pan is the TabLock Baking Screen. This pan features a fastening system for the baking screen that does not use rivets and does not require a drill for removal and replacement. The fastening system uses an engineered tab on the screen that locks into the tray frame using a proprietary hand tool.

Another feature is the quick and easy removal of the screen using another specially designed hand tool; this means that screens can be replaced in the bakery rather than having to be shipped to a service center, saving bakeries time and money.

Best-in-Class Pan Coatings

American Pan offers a full range of proprietary pan coatings including both silicone-based and fluoropolymer coatings which have all been specifically formulated for baking to provide the most effective release of baked products. Available on new and refurbished pans, these coatings consistently

www.bakingbiscuit.com 04/2019 PANS AND TRAYS 30

© Bundy

++ The ePAN is around 50 % lighter than traditional pans and requires less energy

© Bundy

deliver more releases, sometimes twice the number of releases, than all other competitors worldwide. With their extensive recoating facilities and life cycle programs, they provide bakeries with a cost-effective solution to baking pan management.

AMERICOAT ® , the clear silicone glaze from American Pan has been proven to provide up to 30% more releases than all other silicone glazes. The coating reduces staining, minimizes labor costs, and cuts pan oil usage by up to 50%.

FlexiCoat is a rubberized silicone coating that is a popular choice for coating baguette pans, baking screens, and other perforated trays to provide specific baking characteristics and consistent quality.

American Pan’s DuraShield® fluoropolymer coatings provide bakers with a long-lasting coating that provides an excellent release of baked goods. With a minimum of 3,000 releases guaranteed on most products and over 5,000 releases documented at some of the world’s leading bun bakeries, Dura Shield ® provides the world’s longest release life. DuraShield ® is certified to be PFOA-free and offers improved sanitation with complete elimination of oil usage.

OptiShield ® fluoropolymer coatings have been developed to provide a durable solution for conditions where a standard coating will not perform. Whether it is an extremely sticky dough or extreme temperatures, American Pan has a formulation that will work for your operation.

The Value of Pan Refurbishment

Pan refurbishment services from American Pan increase the life of pans at a fraction of the cost when compared with those associated with purchasing new pans and help to keep pans in optimal condition during their use.

American Pan currently has four pan refurbishment locations throughout Europe, including one in Romania, one in Spain, and two in the UK.

All pan refurbishment operations use the same proprietary method of cleaning and recoating, which has been refined and perfected over five decades of hands-on experience. The system has been designed to quickly and efficiently remove old coatings, carbon, and greases from baking pans following which the pans are coated with DuraShield, OptiShield, AMERICOAT, or FlexiCoat. After being recoated, the pans are delivered back to the bakery ready for use in production. This process has been proven to significantly extend pan life and decrease or eliminate the use of release agents.

Providing Better Pan and Bakery Management

In today’s competitive manufacturing environment, bakeries rely on technology that allows them to visualize every aspect of the production process and eliminate inefficiencies. Analytics received using American Pan’s SMART Pan

Tracking® system provides bakeries with data to monitor pan coating life and line efficiency.

The SMART Pan Tracking system begins with American Pan’s uniquely encoded pans that are laser etched with a 2D code and pan number. The code and number are linked to a database specific to each bakery that includes information such as pan type, dimensions, mould size, coating life expectancy, and the number of bake cycles on the pan. Sensing technology is incorporated into the bakery’s production line to scan each pan and feed data to a secure website.

The system can even identify ways to improve a bakery’s line efficiency, such as monitoring and reducing the number and duration of gaps between pans – thus identifying “missed opportunities” for maximizing throughput on high-speed baking operations. +++

31 PANS AND TRAYS www.bakingbiscuit.com 04/2019

KOENIG BACKMITTELGMBH & CO. KG • Postfach 1453 • D-59444 Werl Tel. 02922/9753-0 • Fax 02922/9753-99 E-Mail: info@koenig-backmittel.de Internet: www.koenig-backmittel.de The Nut specialists Quality-brand and freshness with long tradition

Hazelnut- and Peanut-Products, roasted, sliced, diced and slivered. Hazelnutfilling and Multi-Crunch.

ask for products meeting your specifications. KOENIG Motiv4 NTS 91x53.qxd 12.02.2007 11:10 Uhr Seite 1 Machines for bakery engineering www.precisma.at Baking tray cleaning machines • Release agent applicators • Predusters • Conveyors and handling plants Precisma GmbH, Leombach 10, 4621 Sipbachzell, Austria Phone: +43 (0) 7240 / 20 919, E-mail: office@precisma.at

Almond-

Please

++ TabLock Baking Screen © Bundy

All about coatings

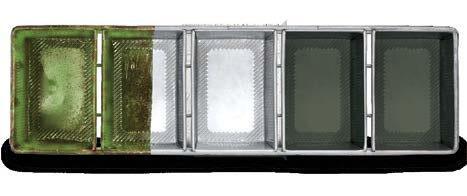

Lhotellier R2A, a subsidiary of the Kaak Group in the Netherlands, has developed and marketed non-stick coatings for the baking sector since 1963. Experts provide support when choosing optimum non-stick and de-panning coatings.

+L hotellier R2A is considered to be a specialist for tray and pan cluster cleaning and (re )coating, since this Kaak Group company has developed and marketed non-stick coa tings since 1963. In this respect, Lhotellier R2A offers a wide selection of different coatings to guarantee optimum de-pan ning with any product and every kind of pan. The company promises that greasing becomes wholly or partly superfluous, depending on the coating and product. These coatings are suitable for all types of materials, and satisfy the European Directives for products that come into contact with foodstuffs.

A multi-layer system

The coating for pan clusters or trays is applied by means of a multi-layer system. The surface texture is of the greatest importance to ensure a strong bond with the coating. There fore the first step in the coating process is thorough cleaning of the surface. After this first step, a primer coat is applied to maximize the bond between the pan and the non-stick coating. Depending on the specification, this is followed by the application of one or more coats with specific de-panning properties. Finally, the coating is sealed, creating a uniform, hard-wearing coating with corresponding proofing, baking and de-panning properties. As a rule, the outer surface of the pan is given a black enamel coating to ensure optimum heat transfer.

The company offers the following coatings: Multi-Flon ® : According to information from the company, a Multi-Flon ® fluoropolymer coating provides a high degree of resistance against abrasive wear, chemicals and rusting.

Multi-Sil R ® : According to Lhotellier R2A, the Multi-Sil R ® rubber-silicone coating is suitable for baguette baking trays and for applications involving sweet dough.

Multi-Sil G® : The Multi-Sil G® coating is said to be especially suitable for very viscous doughs or batters such as cake dough, but is also frequently used in the production of bread and confectionery.

The company constantly carries out research on new coatings, and as Bruno Servant, R&D Manager for Lhotellier R2A, explains: “Optimizing our coating is a continuous process. That’s logical, since our customers increasingly seek perfection.”

As well as consultancy and cleaning & (re-)coating trays and pan clusters, the company also offers the das iBakeware ® detector system. This system uses an ID (identification) code located on the product carriers, i.e. on trays or pans. The Kaak ID system scans this ID code and can thus recognize which product carriers need to be recoated or replaced

www.bakingbiscuit.com 04/2019 PANS AND TRAYS 32

+++

++ Lhotellier R2A constantly researches and develops novel coatings for a wide variety of applications in the baking sector

© Kaak

++ The iBakeware® detector system reads the ID (identification) code on trays or pans, thereby recognizing which product carriers need recoating or replacement

©Kaak

Absolutely flat and warp-free

The experts at acs Coating Systems GmbH, Wilhelmshaven/Germany, have developed new coatings and trays.

+The name says it all: Hifficiency® stands for High Efficiency. Explaining the new developments, Dr. Christoph Stecher, Managing Director of acs Coating Systems GmbH, Wilhelmshaven, says: “For baking that means: avoiding even baking paper, greatly reduced use of separating agent, or none at all, shorter baking times, easy cleaning, e.g. in a tray washer, and longer lifetimes for the coating and for the complete baking ancillaries.” Moreover, this is made possible by the latest DURAPEK ® nonstick, multislide ® coatings, which are robust, lye-resistant and tray-washer-proof, as well as showing only a fraction of the wear compared to conventional PTFE-/ PFA-/Teflon coatings, not to mention silicones. Dr. Stecher goes on to explain that “You have another benefit, especially for instore baking: they contain no solvents, or resins that are not particularly temperature-resistant. Even at high temperatures, there are no out-gassings of pollutants, i.e. no fluorine, no PFOA, no PFO, no benzene, no (bis-)phenols, no sulphones etc., and the coatings are suitable up to more than 300°C.” He says that is also unique. These coatings, for which multiple patents have been issued and which are manufactured on special plants at acs without the use of s olvents and paint chemistry, is the high-performance plastic polyaryletherketone. According to the expert, this is naturally much harder and more resistant than any fluoropolymer/Teflon or the plastic resins that are normally used. The Managing Director goes on to stress that “acs produces the lacquer powders itself, and these coatings are not available anywhere else.”

Non-stick effect

Since the non-stick effect functions very well in the great majority of applications, Hifficiency ® accessories can be used quite universally. However, Dr. Stecher points out that specially modified recipes are needed for some applications, e.g. bread pan clusters.

Furthermore, he also says acs has developed a new generation of baking trays that do not warp in the oven, and are also altogether much more robust than all the trays that are