International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

1, 2Student, Dept. of Instrumentation Engineering, Padm. Vasantraodada Patil Institute of Technology, Sangli, Maharashtra, India

3. 4 Student, Dept. of Mechanical Engineering, Padm. Vasantraodada Patil Institute of Technology, Sangli, Maharashtra, India ***

Abstract - Agriculture plays a crucial role in the life of an economy. It is the foundation of our economy system. Food and raw materials are provided by agriculture, but it also provides jobs to a significant portion of the population. In agriculture, many machines and equipments are developed and research is carried out. There are many machines andtypes ofequipment that are operatedmanually to save money. Fertilizers ameliorate the growth of plants. This can be met intwo ways, theorthodox one being additives that provide nutrients. The second mode by which some fertilizers act is to ameliorate the effectiveness of the soil by modifying its water retention and aeration. This article, like many on fertilizers, emphasizes the nutritional aspect. Fertilizers typically provide, in varying proportions. We have decidedto focus on themultipurpose agricultural machine, in which we will concentrate on the spraying process and try to solve the spraying problem. The efficiency of spraying can be improved by using an engine or prime mover.

Key Words: Agriculture, Fertilizers, Food, Spraying, Growth,Machines,Equipments,Farmer.

FarmersinIndiaprefersprayingmethodsthatareeasyto useand require theleastamount of work.Becausedueto miscellaneous labor problems itis very difficult to do allactivitiesrelatedtofarminginthestipulatedtime.Still, thesprayermachinesavailableforthefarminthecountry areimported.Engine-drivensprayersarefastbutthecostis high.Existingmanuallyoperatedsprayersareinefficientso modification is required. Themainreasonfor the poor acceptance was the law capacity of the machine. A simple manually operated sprayer having an average capacity of onehectareperdaywouldbeabettersolution. Asasafety measure,therobotsprayspotentiallydangerouschemicals withinrestrictedareasofafarm.Somechanismisrequired to develop to solve all the problems related to the agriculturalsprayer.Inthisproject,wehaveconcentratedon a wheel-operated agriculturalsprayer.Inwhichweare trying to develop a machine which will run on remote operated.Onfarms,Insectsarelargelyresponsibleforcrop destruction. Insecticides orpesticides, a man-made or

natural preparation are used to kill insects or otherwise controltheirreproduction.Theseherbicides,pesticides,and fertilizersareappliedtoagriculturalcropswiththehelpofa special device known as a "Sprayer," sprayer provides optimumperformancewithminimumefforts.Theinvention of a sprayer,pesticides,andfertilizers,bringrevolution to the agriculture or horticulture sector, especially by the invention of sprayers,enabling farmers to obtain the maximum agricultural output. They are used for garden spraying,weed,andpestcontrol,liquidfertilizing,andplant leafpolishing.Therearemanyadvantagesofusingsprayers suchaseasytooperate,maintainandhandle,facilitatingthe uniform spread of the chemicals at the desired level precision-madenozzletipfortheadjustablestream, and capable of throwing foggy spray, light or heavy spray, depending on the requirement. The agricultural sector is facing problems with capacity issues, shrinking revenues, andlaborshortagesandincreasingconsumerdemands.The prevalenceoftraditionalagricultureequipmentintensifies these issues. In addition, most farmers aredesperately seeking different ways to improve the equipment quality whilereducingthedirectoverheadcosts(labor)andcapital. Thusasignificantopportunityrestswithunderstandingthe impact of a pesticide sprayer in an agriculture field. A pesticidesprayerhastobeportableandwithanincreased tank capacity as well as should result in cost reduction, labor,andsprayingtime.Inordertoreducetheseproblems, thereisanumberofsprayersintroducedinthemarketbut thesedevicesdonotmeettheaboveproblemsordemandsof thefarmers.Theconventionalsprayerhasdifficultiessuchas itneedsalotofefforttopushtheliverupanddowninorder tocreatethepressuretospray.Anotherdifficultyofpetrol sprayers is to need to purchase fuel which increases the running costof the sprayer. In order to overcome these difficulties,Ihaveproposedawheel-drivensprayer,itisa portabledeviceandnoneedforanyfueltooperate,whichis easytomoveandspraysthepesticidebymovingthewheel. Themechanisminvolvedinthissprayeristhereciprocating pumpandnozzleswhichwereconnectedatthefrontendof the sprayingequipment. Indian farmers now employ outdated pasties and spraying techniques, which wastes pesticidesandcouldhavenegativehealtheffects

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

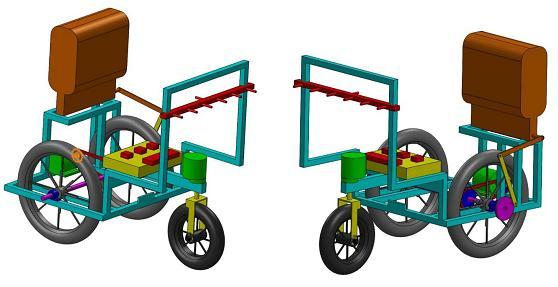

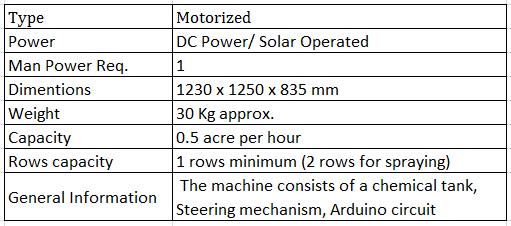

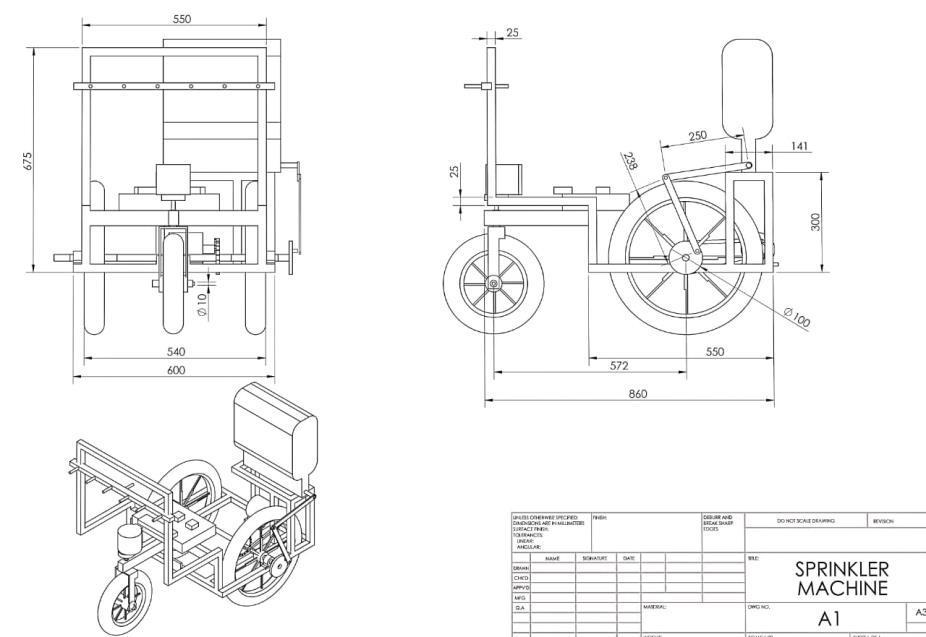

India is a global agricultural powerhouse. Approximately 70% of our population is dependent on agriculture. Agriculture accounts for one-third of our national income.Our economy is based on agriculture. The development of agriculture has much to do with the economic welfare of our country. Although we are a developing country, we do not use technology to improve our agriculture. So we have to fabricate some machines whichcanbehelpfultofarmerssoastoincreasetheirprofit, productionandtosavetheirtime.Pesticidesprayingisone ofthechallengesafarmerusuallyfaces.Presently,farmers havetocarrypesticidesontheirshoulders,andsprayersare operated manually. To overcome this problem, we have designedasmallfourwheelmachinewhichhasthecapacity to carry up to fifty liters of pesticides. This machine is electronicallyoperatedthroughwirelessremotecontrol.The entire machine is powered by a DC battery. The machine consists of the main body frame, battery, DC Motor, Gear Motor,Wipermotor,Wheels,TankandminiatureCentrifugal Pump. It consists of four wheels. The back wheels of the machineareoperatedbytheDCwipermotor.Frameismade up of mild steel. Blowers are attached at a certain height fromtheframe.Theblowerheightcanbeadjustablesothat itcanbeusedfordifferentcrops.Theblowerisoperatedby ahighspeedDCmotorthatdrawsthewaterfromthetank and sprays it out. This gear motor rotates the blower through 180 degrees so that the pesticide can be evenly sprayedonbothsidesofthefield.Thetankislocatedonthe frontoftheframe.Thetransmitterandbatteryiskeptnext tothebattery.Thesupplytoallthemotorsandtransmitter isprovidedbyabya7ADCbattery.Initially,thereceiveris turnedonwhenthebatterysupplyisturnedon.Here,weare usingafour-channelRFreceivermodule(i.e.,wecancontrol fourmotorssimultaneously).Relaysand12vDCsuppliesare used to connect each channel to the motors. Receiving a signalfromthetransmitter,thereceiversendsacommandto therelay,whichoperatesthemotor,andthemotorswitches on.Inthisproject,channelAisconnectedtothewipermotor WhenchannelAisselectedinthetransmitter(asshownin theblockdiagram),thewipermotorispoweredON.Itdrives thebackwheelsofthemachineandthemachineproceeds tomoveforward.ByselectingchannelB,thegearmotoris turnedonanditstartsrotating.Bysimultaneouslyturning onallthreenozzlechannels,themachinestartsmovingand sprayingfrombothsides.

Fig -1:Blockdiagramofproposedmechanism

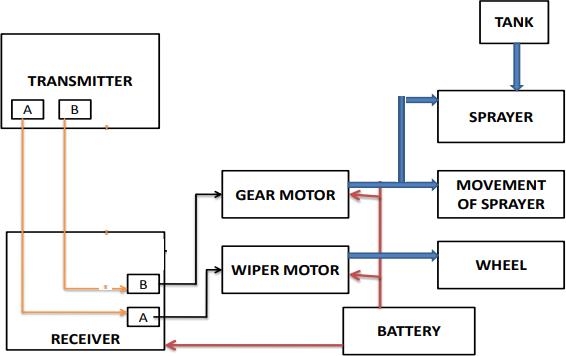

2.1 SPECIFICATIONS OF PROPOSED MACHINE

Table -1: Specifications

3.1 Capacity of the machine

Totaltravelofmachinein1acre

Traveldistance=40x500=20000ft=6153m

Totaltimerequired=6153x5=30765sec=512min

WehaveconsideredApproximately8hours54min. So,roughlywecansaythattheplantationmachinecapacity is1acre/perday.

Wheelshaftrpm ��=πDN/60 ��=π

SinceV=31.84≈30rpm

The distance covered by wheel in 1 revolution πD=π*0.4=1.256m

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

Totalestimatedapproximateweightifmachine=15kg

Totalsoildragisconsidered=10kg

DesignFactor=1.2considered

Totaldesignload=1.2*25=30kg

P=300N

Torquerequired=P*Radiusofwheel =P*0.2=60Nm

Weknow, ��=2πNT/60

P=2x3.14x40x60/(60x1000)=251watt

Byconsideringfriction&extrajerkintheagriculturalfield motor/engine/enginepowerconsidered

P=0.5hp=367.5watt

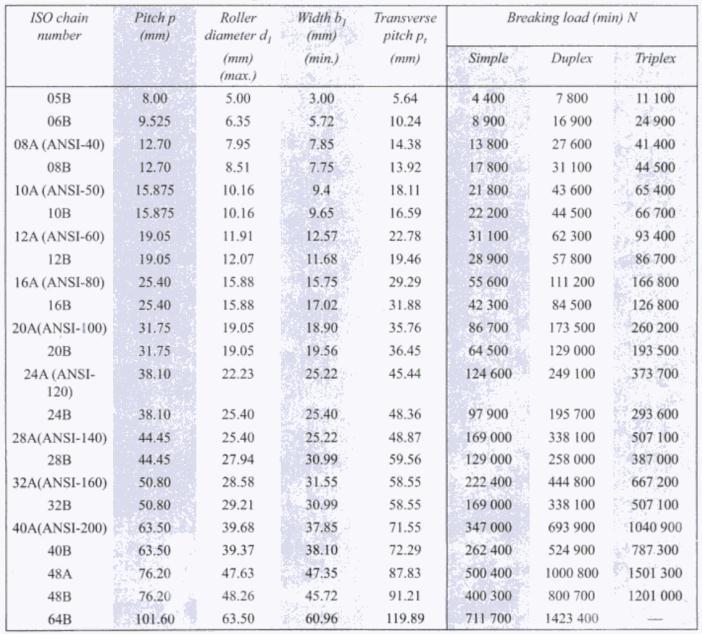

Frombelowtablewehavedeterminedwhichchaintypeis applicable for drive By considering the agricultural application we are going to design chain drive for 1hp application.Fromthetableasperapplicationandspeedwe haveselectedtheservicefactor=1.3

Designpowerrequired=735x1.3=955watt

By considering application and extra jerk and safe design primemoverpowerconsidered=955watt

Fromselecteddimensionsasperapplication:-

C=450mm;P=25.4mm;F=t=24teeth’s

From above table we have to select factor but there is no speed reduction so K = 1 assumed. L=1100mmisconsidered To calculatetensioninthechaindrivewehaveusedherePulley driveformulas:- P=motor Power0.5hp=367.5watt. ��=��(��1 ��2)

V=1m/5sec V=0.2m/sec

T1 -T2 =3675________________________________________________(1)

Also, T1/T2=eπθ T1/T2=e0.2∗(π/180)∗120

θ=Angleofwrap=1200 ��0.418=1.52

T1/T2=1.52____________________________________________________(2)

FromEquations(1)&(2) P=V(T1 -T2)

3675=(T1 -T2) 3675=0.52T2 T2=7067.61N T1=10742N

3.4 Design of Drive Shaft ∈����=0 T1 +T2-RA -RB =0 RA+RB =17809

TakingthemomentaboutpointA (T1 +T2)*100=500RB 17809*100=500RB RB =3561N RA =14247N

MaterialofshaftconsideredC40

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

Sut =580��/����2 &Syt =380��/����2

Tensilestress(σ)=250��.��.

F.S.=FactorofSafety=4 σ=145��/����2

ShearStress(τ):AsperASMEcode

τ=0.18*Sut Orτ=0.3*Syt (Whicheverisminimum)

τ=104��/����2Orτ=99��/����2 So,τ=99��/����2 Considered.

Consideringkeywayeffect τ=0.75*99=74��/����2

Considering the following conditions for design of shaft:Designofshaftagainstbending:MA =14247x500=7123569N-mm

Designofshaftconsideringbending:Mc =��32*d3 *σ d=24.25mm__________________________________________________3

Designofshaftagainsttorsion. Te =��/16*d3*τ 126*103=��/16*d3 *74 d=20.54mm.____________ __________4

DesignofshaftconsideringcombinedeffectAspermaximum shearstresstheory, Mc =12⌊��+(√��2+��2)⌋

Te=√��2+��2

Fromaboveequation

Mc =��/32*d3*σ

Sodesignissafe. Te =��/16*d3*τ

Fromaboveequation,hencecheckingtheallowablestress value, from equation 3 & 4 the shaft diameter considered 25mm.HenceDesignissafe.

3.5 Design of bearing

Totalradialload

Fr =T1+T2 Fr =1914N

Totaldynamicload P=X*Fr +YFa X=1 V=1(Innerraceisrotating) Fa =0 Y=1

Hence, P=1*1*Fr =1914N.

Totallifeinhoursforagriculturalapplicationconsidered L10 =10,000Hr

Lifeinmillionsofrevolution (60∗��∗��ℎ)/106 =(60∗30∗10000)/106 L10 =18millionsofrevolution. Sototaldynamiccapacity

C=P(L10)1/3=1914*(18)1/3 =5016.09N

FromSKFtablefrom20mmshaftdiameterDeepGroveBall Bearingchart,bearingselectedis61904

We choose single fluid full cone nozzle, Discharge of pump= mass flow rate (ṁ) 5lit/min = 8.33*10-5 m3/sec ṁ= density*area*velocity ṁ= Density*A*V ṁ= Density*π/4*d²* V1 Therefore, From this relation A1V1=A2V2 V2= 0.0117m3/sec&V1=0.00106m3/sec

Practicallybatterychargetimeshouldbegivenasthe40%of batterylosses.Batterychargetime(theoretically)

Wipermotor=40watt;Pumpmotor=60watt

Totalload=40+60=100watts

Currentcalculation

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

P-Powerofmotor;I-current;V-Voltage

a)Wipermotor

P=I*V 36=I*12=3A b)Pumpmotor

P=I*V 60=I*12=5A

Sototalcurrentis=3+5=8A

Batterybackuptime

Totalload=100w

Back uptime= (Battery current *voltage of battery *no. of batteries*efficiencyofbattery)/Loadinwatts

Here,weconsider12AHBattery ‘N’meansno.ofbatteries ղ =efficiencyis80% =AH*V*N*ղ /w

Batterybackuptime=1.15hrs

Generallyspeaking,awheelisacircularpartthatrevolves aroundanaxle.Wheelsandaxlesareoneofthesixsimple machines, and the wheel is one of their key components. Whenwheelsarecombinedwithaxles,heavyobjectsmaybe movedeasily,facilitatingmovementortransportationwhile supporting a load, or performing labor within a machine. Wheels are also used for other purposes, such as a ship's wheel,steeringwheel,potter'swheelandflywheel.

Selecting the correct type and size of spray nozzle is essential for each application. The nozzle determines the amount of spray applied to an area, the uniformity of the application, the coverage of the sprayed surface, and the amountofdrift.Cropprotectionproductsareappliedwith onlyafewtypesofnozzles,includingextendedrangeflatfans,singlefluidfullconenozzles,etc.Thisisbecausethere are a wide variety of spray applications that can be done withnozzles.Usingnozzles,youcandisperseliquidsoveran area,increaseliquidsurfacearea,andcreateimpactforceon solidsurfaces.Therearethreepurposesforusingnozzles:to distributeliquidsoveranarea,increaseliquidsurfacearea,

and create impact force. Spray nozzles can be described according to a number of spray characteristics in a wide variety of applications. In order to cause atomization, the breakup of the fluid into drops, spray nozzles can be classifiedaccordingtotheamountofenergyrequired.Spray nozzles can have one or more outlets; a multiple outlet nozzleisknownasacompoundnozzle.Multipleoutletson nozzlesarepresentonsprayballs,whichhavebeenusedin thebrewingindustryformanyyearsforcleaningcasksand kegs.Spraynozzlesrangefromheavydutyindustrialusesto lightdutyspraycansorspraybottles

Usually mounted beneath the cowl (the area outside the windshield'sbase)oronthefirewall,windshieldwipersare poweredbylargeelectricmotors.Withthehelpofthemotor, thewiperarmsaremovedbackandforthbythelinkage.A separatemotorpowerstherearwindowwiperonvehicles with rear window wipers. When the wiper motor doesn't function properly, it can be difficult to see it. The wiper motorisabouttofailifitoperatesslowlyorintermittently, runs at one speed, or stops mid-seal. There may also be a problem with other parts of your wiper system if your wipersaren'tworking.Amotorfuseorcircuitbreakercanbe blown if the wiper blades are stuck to the windshield becauseoficeorsnowinthewinter.Theinteriorswitchthat controls the wipers may also fail, as well as wires or the linkage connecting the wiper arms that pushes and pulls them.Lubricationmayalsoberequiredformovingpartsin thelinkagethathavebecomestuckduetocorrosionand/or gunk.

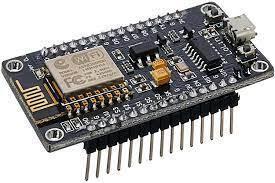

WiFimodulesliketheESP8266provideaccesstoyourWiFi network for microcontrollers equipped with integrated TCP/IPprotocolstacks.AWi-Finetworkingapplicationcan be hosted on the ESP8266 or offloaded to another application processor. ESP8266 modules come preprogrammedwithATcommandsetfirmware,meaning youcanconnectthemdirectlytoyourArduinodevicetoget WiFi capabilities similar to those in WiFi shields. The ESP8266moduleisanextremelycosteffectiveboardwitha huge, and ever growing, community The ESP8266 uses a

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

32bit processor with 16 bit instructions. As well as WIFI communication,itcanalsobeusedforconnectingtoWiFi networks, accessing the Internet, hosting a web server, connectingtoSmartphone’setc.Furthermore,theESP8266 can be programmed like any other microcontroller and especiallyanArduino.

Whileithasahighpower-to-weightratiodespitehavinga very small power-to-volume ratio and an extremely low energy-to-volume ratio, it is able to deliver high surge contents despite a very small energy-to-volume ratio Secondary batteries include lead-acid batteries. There is reversibility in chemical reactions occurring in secondary cells. When current is passed through these batteries (recharging),thereactantsthatgenerateanelectriccurrent canberegenerated.Itiscalleddischargingwhencurrentis extractedfromasecondarybattery(forwardreaction).

Thereisnoproblemwiththemachineanditisworkingas expected. Sprinkling activities in the farm could be streamlinedbyusingthismethod,whichwillsavetimeand effort. Most senior citizens and ladies will find the set up very easy to handle. The development of a robot for agriculturalpurposesisunderway.Oncerobotshavebeen optimized for performance andcost,agricultural spraying operations can be improved. As a result, if this concept is presentedappropriatelyfortheIndianmarket,itwillassist in reducing the 15% modality rate observed in Indian formers, which is related to pollution. As for the 15% modality rate related to agricultural spraying operations seeninIndianformers,itwillhelpinreducingit.

[1] S.R.Kulkarni,HarishNayak,MohanFutane,“Fabrication of portable foot operated Agricultural Fertilizer and pesticides spraying pump”, “International journal of Engineering Research and technology”, ISSN:22780181,volume4,Issue07(July-2015)MitulRaval,Aniket Dhandhukia, Supath Mohile, “Development and Automation of Robot with Spraying Mechanism for Agriculture Application”, “International journal for Research in Emerging science and technology”, EISSN:2349-7610,volume2,ISSUE8,(Aug-2015)

[2] Prof. Swati D.Kale, Swati V. Khandagale, Shweta S. Gaikwad,“AgricultureDroneforSprayingfertilizerand pesticides”,“Internationaljournalofadvanceresearchin computer scienceand softwareEngineering”, volume 5,Issue 12,(Dec-2015)Designing a Small-Scale Grain Harvester:AToolforUrbanandPeri-urbanGrowers

[3] SandipH.Poratkar,DhanrajR.Raut,“Developmentof multi-nozzle pesticide sprayer pump”, “International journalofModernEngineeringResearch”,ISSN:22496645,volume3,Issue2,pp-864-868,(April-2013)

[4] SarveshKulkarni,KaranHasurkar,RamdasKumbhar, Amol Gonde, Raut A.S “Review of Solar Powered PesticideSprayer”,“InternationalJournalofResearchin Advent Technology”, Vol.3, No.4, E-ISSN: 2321-9637 (April2015)

[5] https://www.researchgate.net/publication/314200288 _Automatic_Adjustable_Spraying_Device_for_SiteSpecific_Agricultural_Application