International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

1,2,3 Asst. professor, Dept of Mech Engg, C.B.I.T, Gadipet hyd 4Asso.professor,Dept of Mech Engg, C.B.I.T,Gadipet, hyd ***

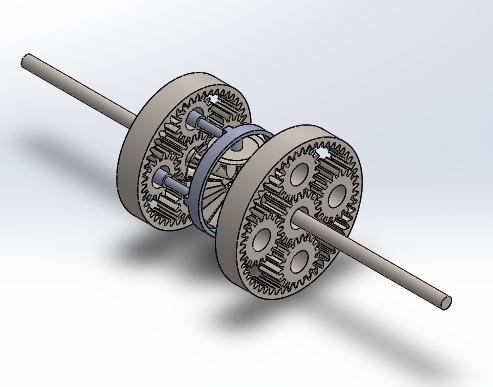

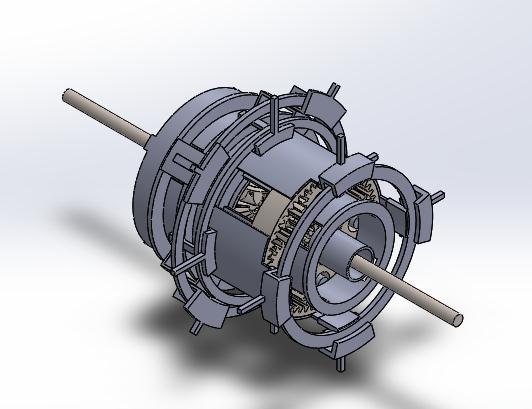

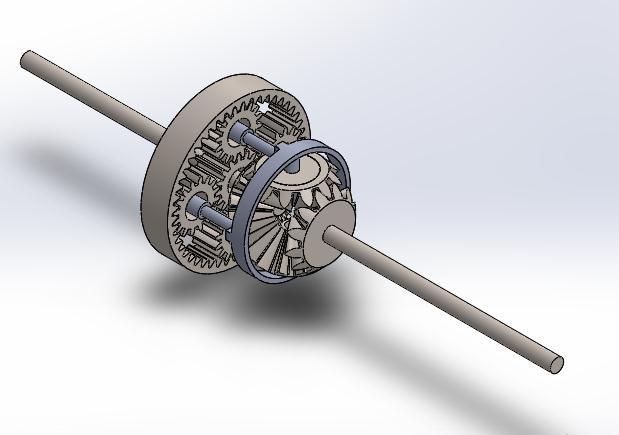

Abstract Planetary gearboxes are most commonly used in automatic transmission of automobiles and have significant advantage over spur gear transmissions due to their compactness andsignificantspeedreductionwithsametorque output. Present automobiles use 3 sets of planetary gear sets attached with a torque converter in their transmission. In general the gearbox and differential are present as separate units. In this a novel planetary transmission integrated with an open differential is designed. The gearbox contains two planetary gear sets to achieve 5 forwardand1reversestageof transmission with inputs given at sun and ring gears of planetary gear sets. The transmission will be tested for transmitting 75 BHP and 100 BHP at 2500 RPM, 5000 RPM, 7500 RPM and particular torque equivalent speeds. The 3D model is drafted using Solid Works and analysis is done using Ansys software

Key Words: Differential ,Planetary gear box

Transmissions are used in automobiles running using internal combustion (IC) engines as the engines produce optimal power delivery at particular torque range. High torqueisneededforquicklystartingfromrestandhighspeed is required for maximum power delivery, which can be achievedusingagearbox.Adifferentialsplitsasingleinputof powerdeliveryintotwoseparateoutputsgiventoeachwheel to have different speeds while turning. Combining both gearboxanddifferentialwillmakethespaceaccompaniedby thecomponentslow.Thegearsetsthatweareusinghereis planetary gear set which can be adjusted to multiple gear ratios per gear set with good load bearing capacity and mechanicalefficiencywhencomparedwithconventionalspur geartrains.Andthemainrootsofatransmissionaregears. Mr. G. Balbayev [1] has worked on design of two degree planetary gear box from aspects of mechanical design and kinematicmodeling.Andproposedadesignforthegearbox whichworkswithaproperspeedwithoutjamminggears Dr. A.Srinath[2]andhisteamhaveworkedonestimatingthe efficiencyofplanetarygeartrainsbasedonnumberofteeth ongearsandstructuralarrangement.Andconcludedthatif thegearsareplacedparalleltoeachotherthentheefficiency is more. Mr. Wen Miln Hwang [3] along with Mr. Yu Lien Huang proposed a configuration design of six speed

automatic transmissions using two degree planetary gear trainswiththreeplanetarygearsets.Mr.OliverK.Kelley[4] has worked on the design of planetary gear trains. And proposedthataminimumangleof88.57oandacorrectionof 1.43oshouldbepresentbetweentwoplanetgearsforsmooth powertransmission.Mr.A.Kahraman[5]andhisteamhas worked on kinematics and power flow methodology for automatic planetary gear transmissions and proposed all possible kinematic configurations satisfying design constraints.Mr.QingtaoLi[6]andhisteamhaveworkedon designofanewplanetarytransmissionwhichsplitsoneinput totwooutputsusingbothcontinuouslyvariabletransmission andplanetarygearswithsixconfigurations.Mr.NitinKapoor [7]andhisteamhaveusedglassfilledpolyamidecomposite material in a differential gearbox as an alternative for a gearboxwithmetallicgears.Withthehelpofcomputeraided engineeringandCATIAtheydevelopedvariousparametric modelsandanalyzedusingAnsysforequivalent(Von Mises) stressunderstaticconditions.Mr.C.Veeranjaneyulu[8]has conducted structural analysis on differential gears using aluminum alloy, alloy steel and cast steel for speeds 2400RPM,5000RPM,7500RPMandobservedthataluminum alloystressvalueswerewithinpermissiblestressvalues.

Themainaimistodesignanovelplanetarytransmission system integrated with a differential by using only 2 planetary gear sets and a differential. The transmission systeminputisgivenonlytogearset1andisconnectedto gearset2whichisconnectedtothedifferential.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

progressed with solid connections between the gears and thenfinallymodifiedusingbrakeclutches.

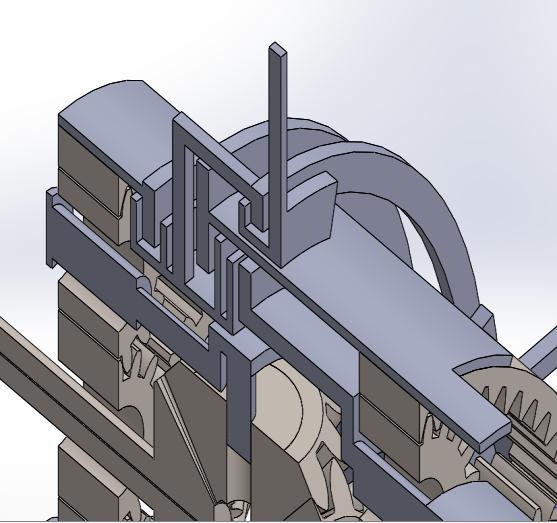

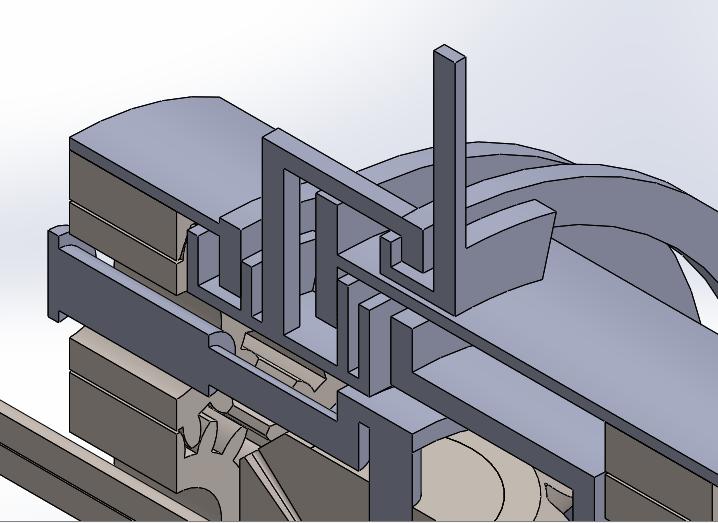

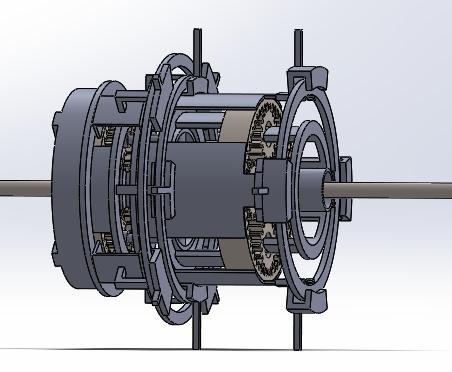

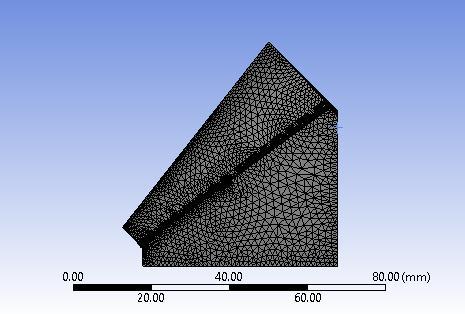

Fig 1:Gearssetswithdifferentialinisometricview

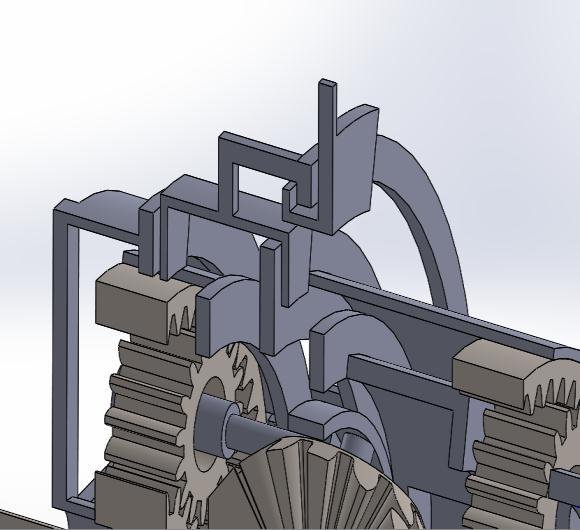

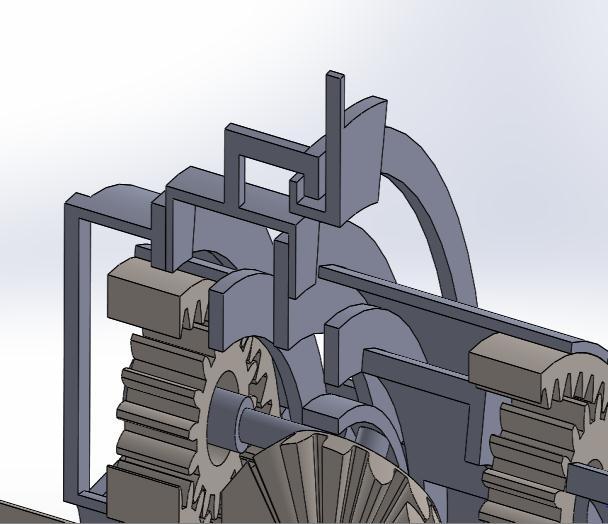

Themainelementsinworkingofthetransmissionsystem are the two brake clutches and the ring actuator clutch. Brakeclutch1isusedtoconnecttheringgearofgearset2 withringandplanetarycarrierofgearset1,similarlybrake clutch2isusedtoconnectsungearofgearset2withring gearofgearset1.

Brake Clutch 1 working: The clutch has three modes dependingonthegearselected Mode 1: In this mode the brake clutch won’t be in contact withtheringgearofgearset2andeitherofplanetarycarrier andringgearofgearset1.

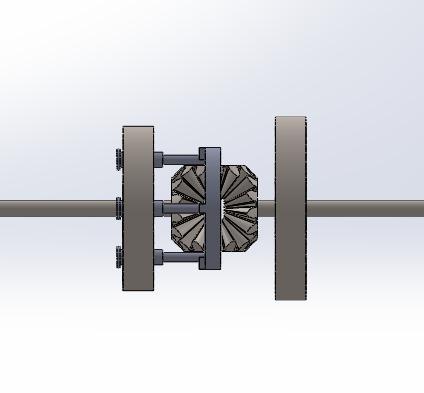

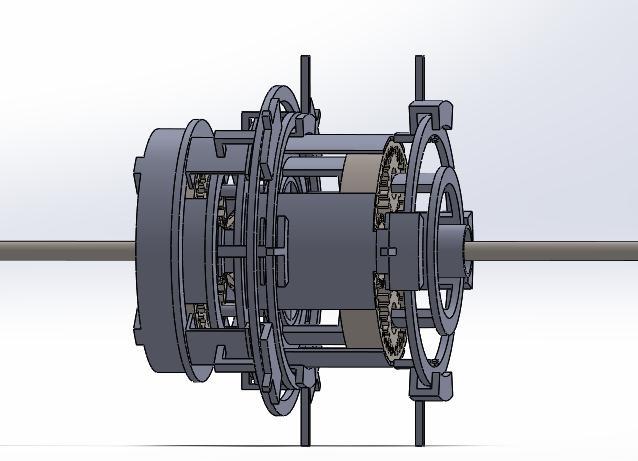

Fig 2:Gearsetswithdifferentialinfrontview

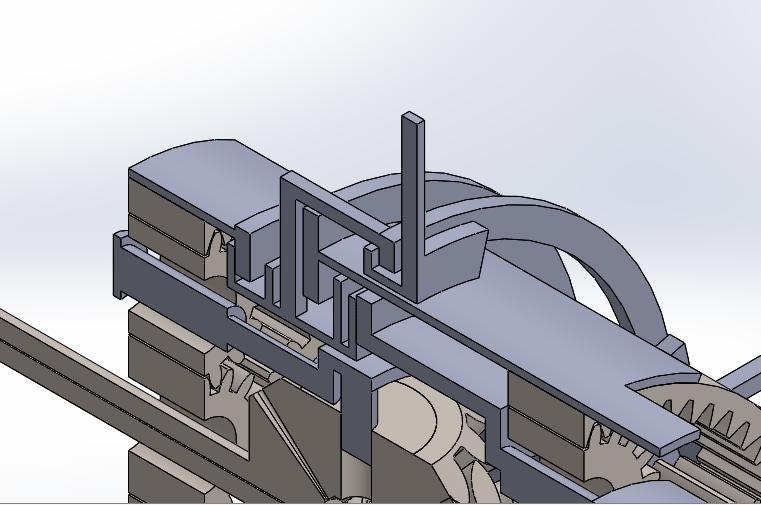

Fig 3:Gearset2connectionwithdifferentialin isometricview

As in the above figures the final model transmission is designedusingonlytwoplanetarygearsetsandadifferential. Theinitialdesignismadeusingonlyoneplanetarygearset withdifferentialattachedtothesungearandinputsaregive toeitherringgearorplanetarycarrier.Inthenextdesigntwo planetarygearsetsareusedwithdifferentialandaspecific reverseassemblyisusedforachievingreverse.Thedesign

Fig 5 BrakeClutch1mode1

Mode2:Inthismodethebrakeclutchwillbeincontactwith theringgearofgearset2andplanetarycarrierofgearset1.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

Mode2:Inthismodethebrakeclutchwillbeincontactwith thesungearofgearset2andringgearofgearset1.

Fig 6 BrakeClutch1mode2

Mode3:Inthismodethebrakeclutchwillbeincontactwith theringgearofgearset2andringgearofgearset1

Fig 8 BrakeClutch2mode2

Ring actuator clutch: Thisclutchisusedtohelpinlocking of planetary carrier on gear set 1. This is clutch has two modesdependingonthegear

Mode 1: In this mode the ring clutch will be ahead of planetarycarrierofgearset1,thishappenswhentheinputis giventosungearofgearset1.

Fig 7 BrakeClutch1mode3

Brake Clutch 2 working: Thisclutchhastwomodesbased onthegearselected

Mode1:Inthismodethebrakeclutchwillnotbeincontact withthesungearofgearset2andringgearofgearset1

Fig 9 Ringactuatorclutchmode1

Mode 2: In this mode the ring clutch will be behind the planetarycarrierofgearset1.

Fig 7 BrakeClutch2mode1

Fig 10 Ringactuatorclutchmode2

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

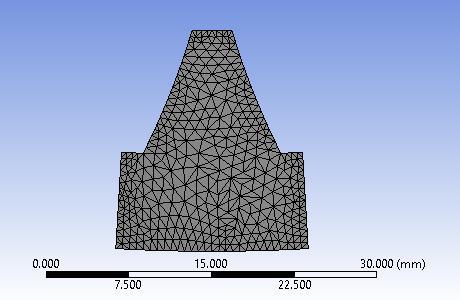

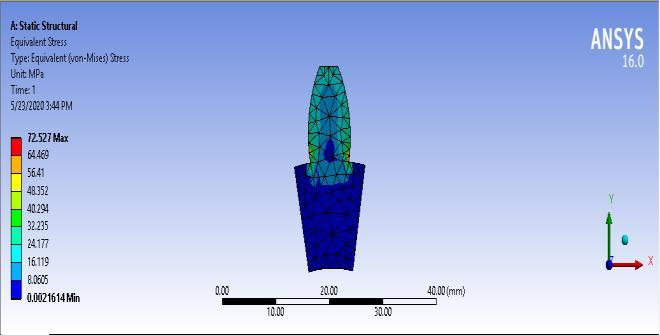

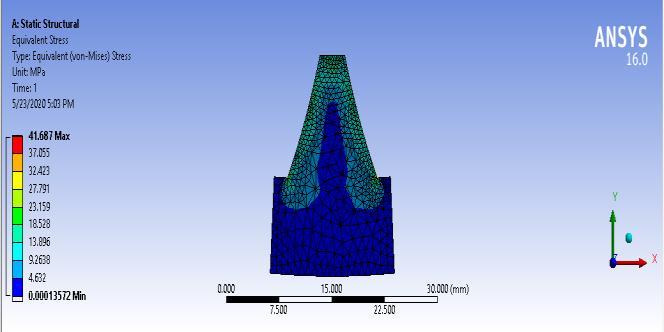

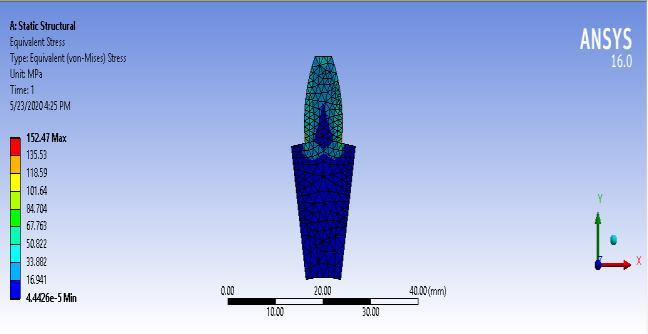

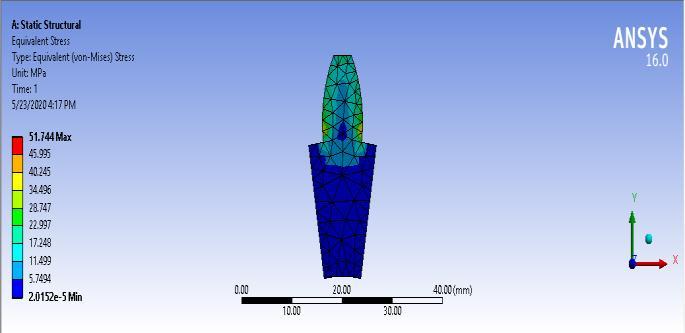

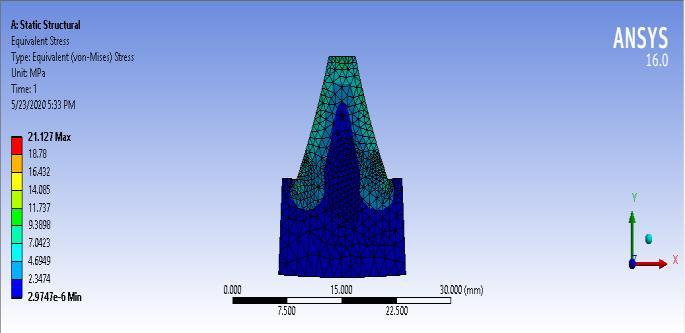

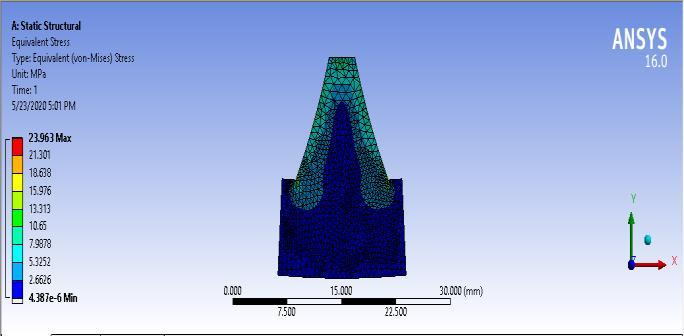

The analysis is done in static structural module of Ansys R16.0withappropriateboundaryconditionsappliedonthe geartoothprofiles

Theboundaryconditionsare Thebaseofthetoothisfixed

Thetangentialloadisactingonthetipofthetooth

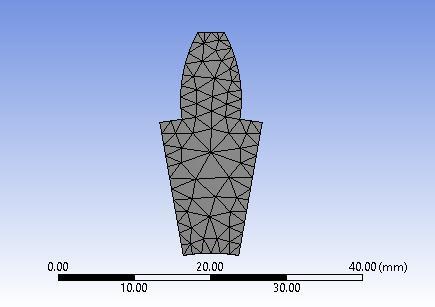

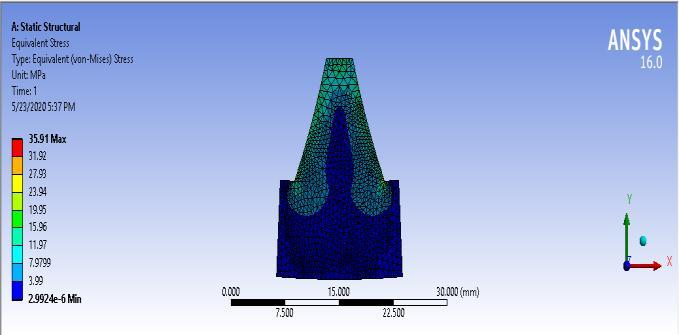

Fig 11

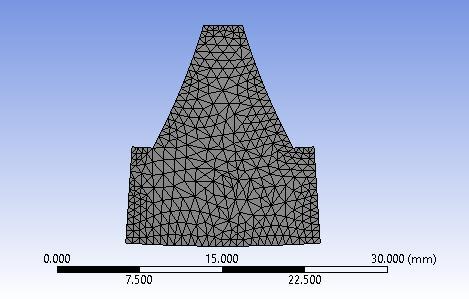

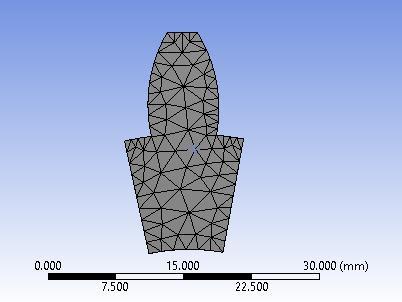

Fig 12 Meshedmodelofgeartoothforsunandplanetgear ofgearset1

Fig 14 Meshedmodelofgeartoothforringgearofgear set2

Fig 13 Meshedmodelofgeartoothforringgearofgearset 2

Fig 15 Meshedmodelofgeartoothforbevelgearof differential

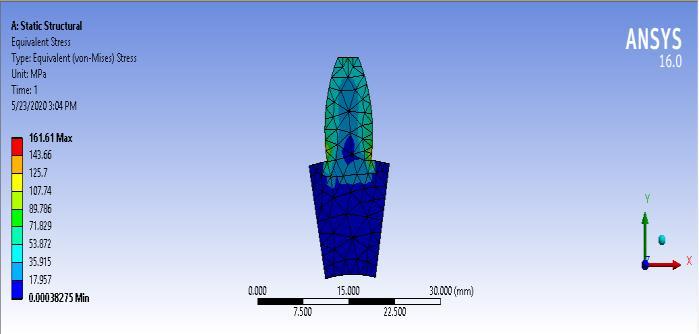

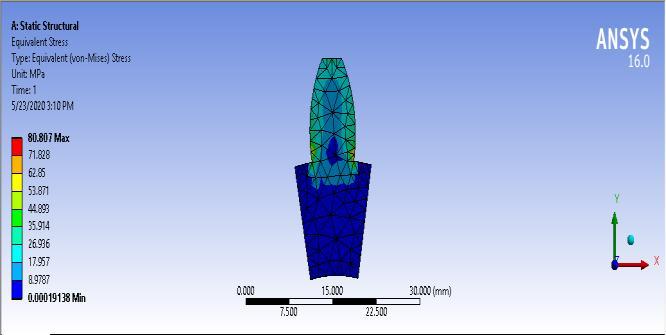

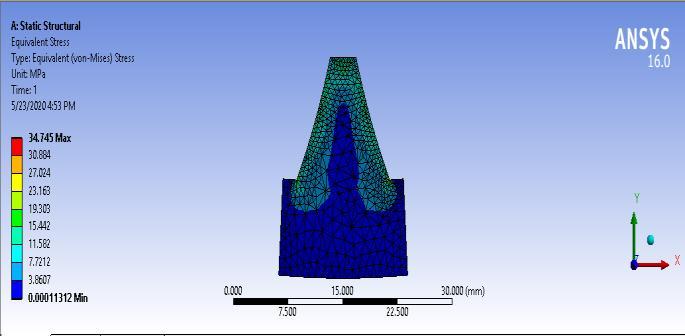

2.3.1. Stress distribution for 75 BHP at 2500 RPM

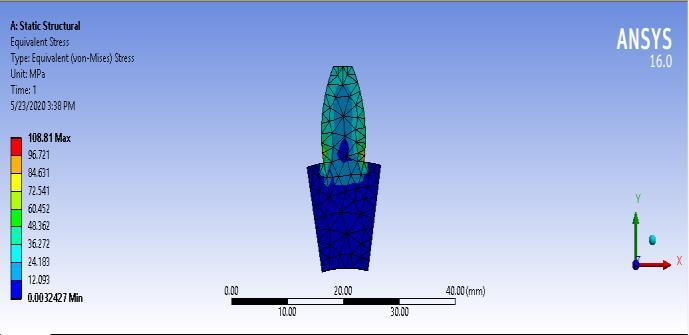

Fig 16 Stressdistributionforgeartoothofsunand planetgearofgearset2

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

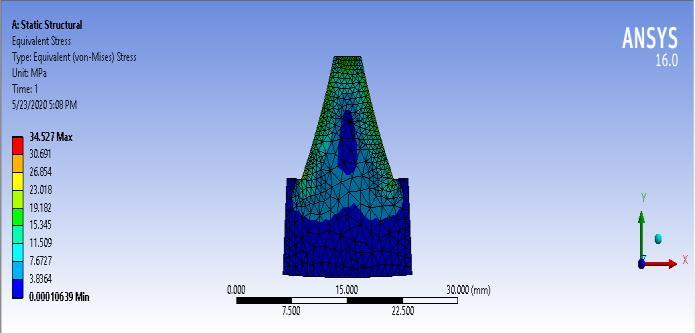

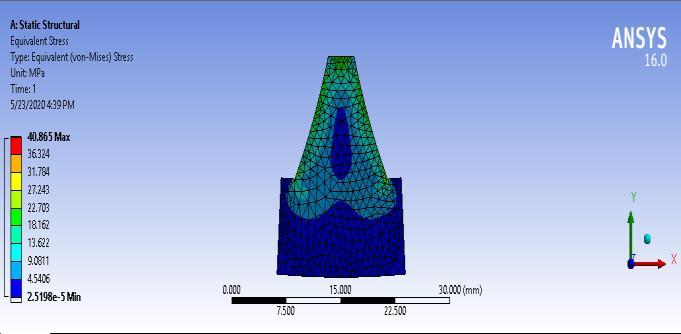

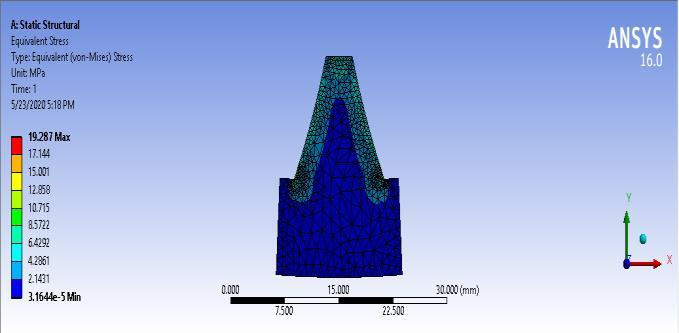

2.3.2. Stress distribution for 75 BHP at 5000 RPM

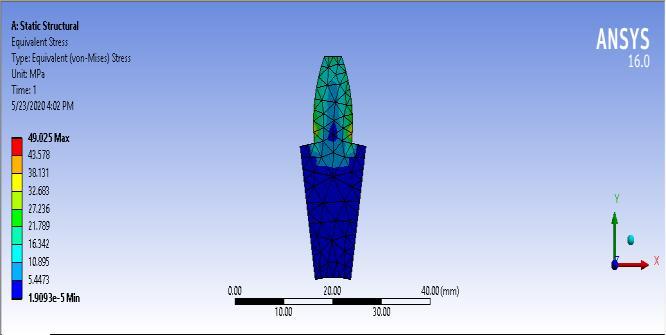

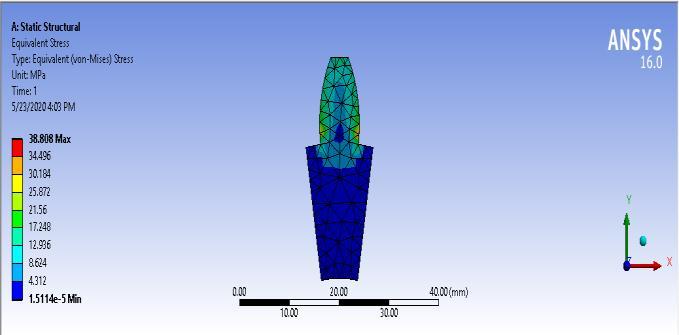

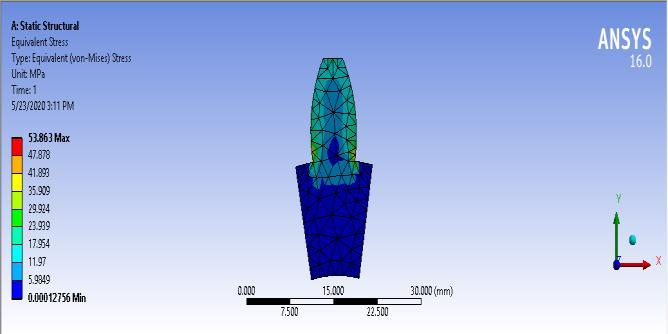

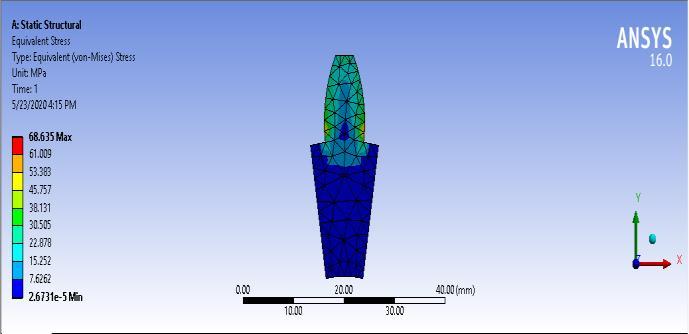

Fig 17 Stressdistributionforgeartoothofsunand planet gearofgearset1

Fig 20 Stressdistributionforgeartoothofsunand planetgearofgearset2

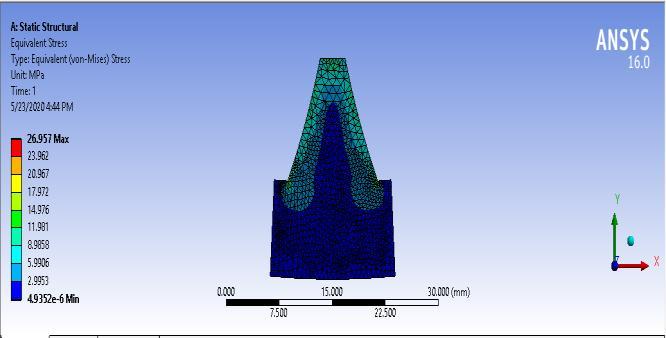

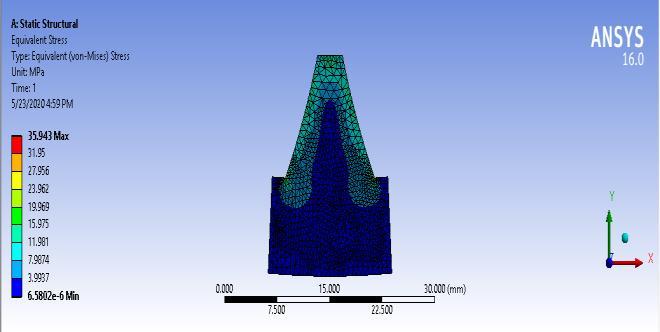

Fig 18 Stressdistributionforgeartoothofringgearof gearset2

Fig 21 Stressdistributionforgeartoothofsunand planetgearofgearset1

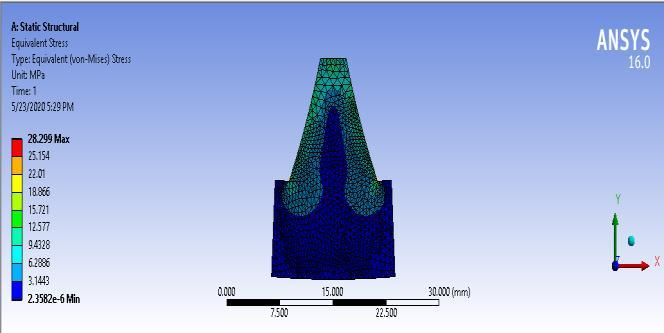

Fig 19 Stressdistributionforgeartoothofringgearof gearset2

Fig 22 Stressdistributionforgeartoothofringgearof gearset2

Fig

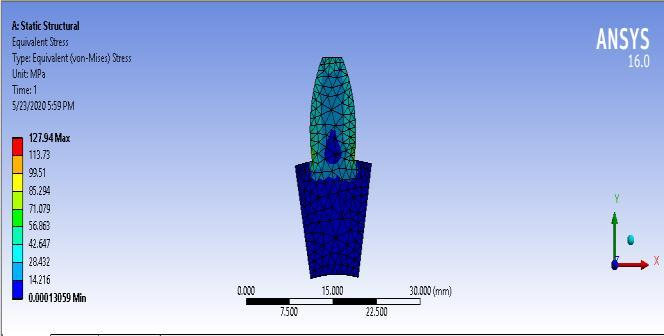

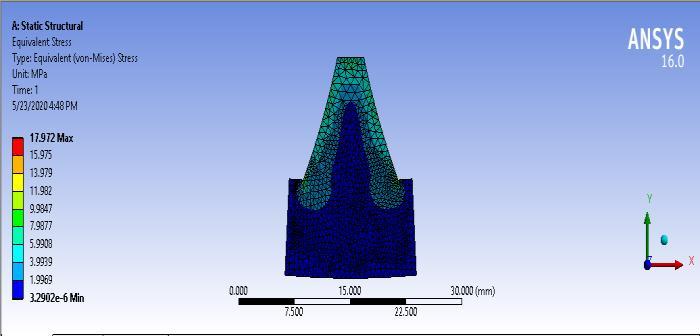

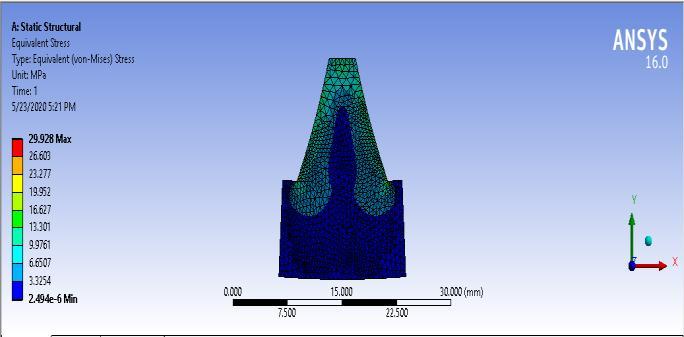

Fig 27 Stressdistributionforgeartoothofringgearof gearset1 2.3.4 Stress distribution for 75 BHP at 150N m Torque

Fig

Fig 25Stressdistributionforgeartoothofsunand planetgearofgearset1

Fig 28 Stressdistributionforgeartoothofsunand planetgearofgearset2

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

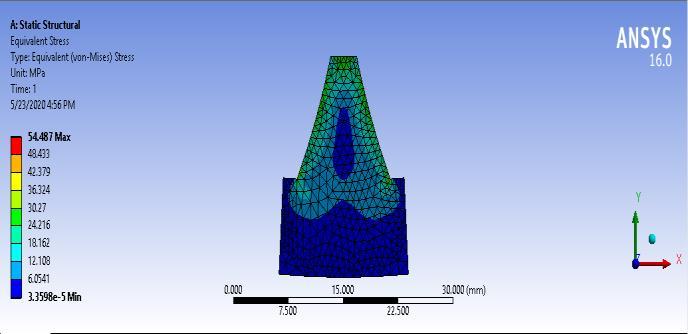

2.3..5. Stress distribution for 100BHP at 2500RPM

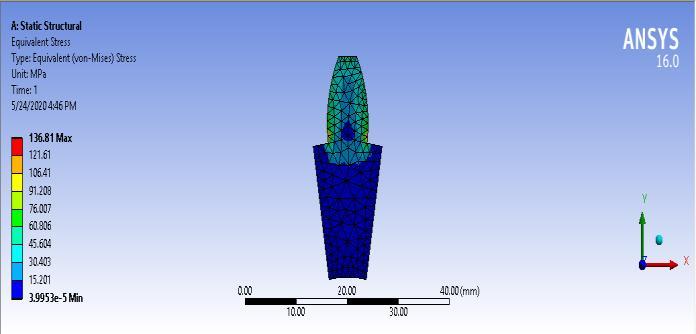

Fig 29 Stressdistributionforgeartoothofsunand planetgearofgearset1

Fig 32 Stressdistributionforgeartoothofsunand planetgearofgearset2

Fig 30 Stressdistributionforgeartoothofringgearof gearset2

Fig 33 Stressdistributionforgeartoothofsunand planetgearofgearset1

Fig 31 Stressdistributionforgeartoothofringgearof gearset1

Fig 34 Stressdistributionforgeartoothofringgearof gearset2

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

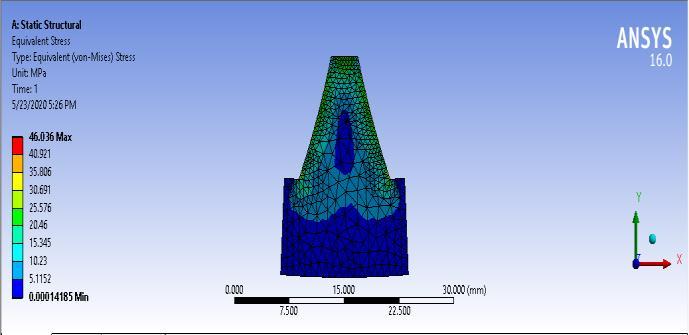

2.3.8. Stress distribution for 100BHP at 180N m Torque

Fig 41 Stressdistributionforgeartoothofsunand planetgearofgearset1

Fig 44 Stressdistributionforgeartoothofsunand planetgearofgearset2

Fig 42 Stressdistributionforgeartoothofringgearof gearset2

Fig 45 Stressdistributionforgeartoothofsunand planetgearofgearset1

Fig 43 Stressdistributionforgeartoothofringgearof gearset1

Fig 46 Stressdistributionforgeartoothofringgearof gearset2

International

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

Fig 47 Stressdistributionforgeartoothofringgearof gearset1

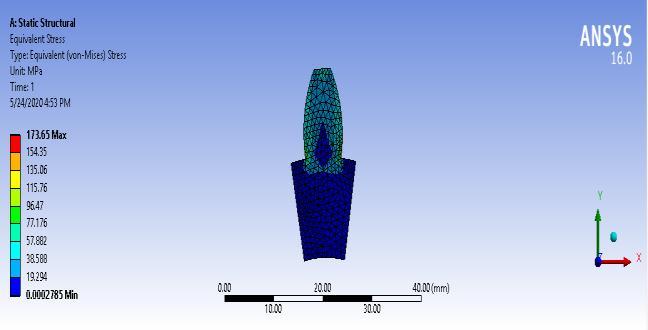

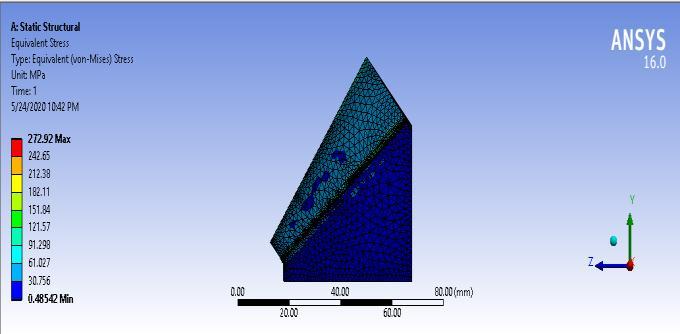

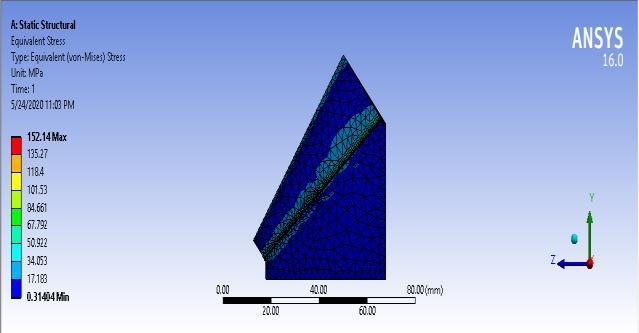

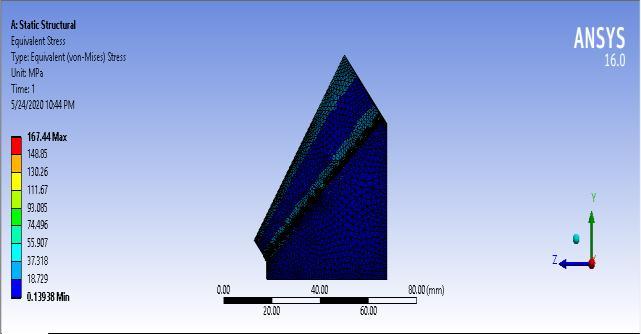

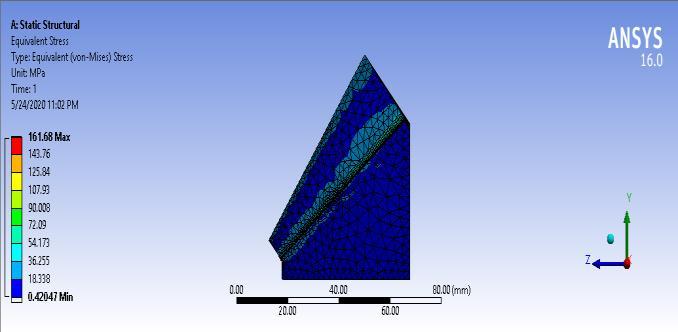

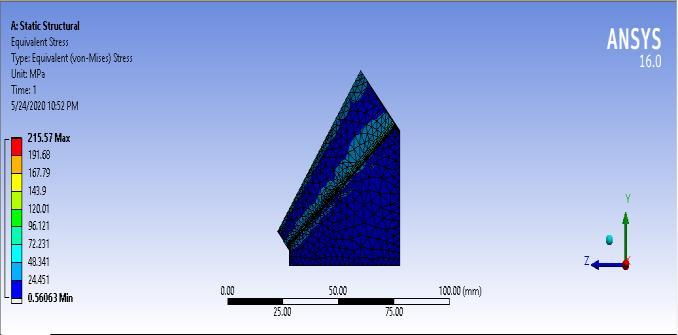

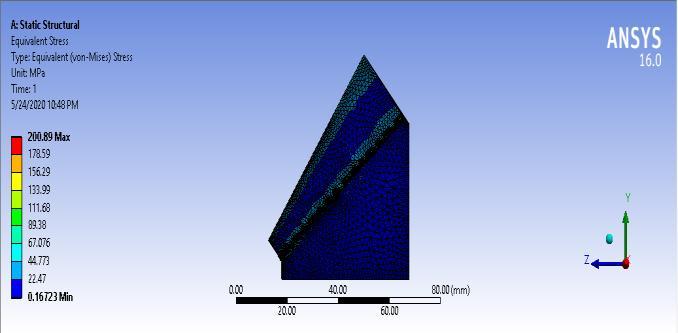

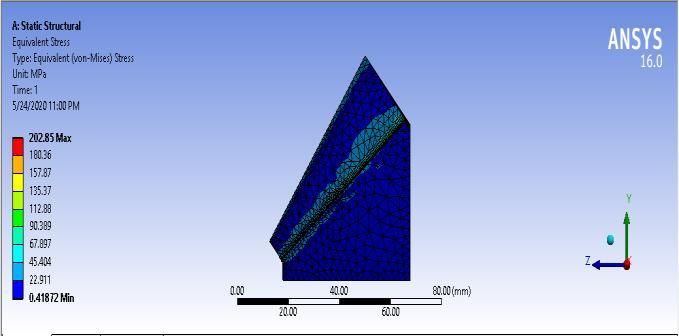

2.3.9. Stress distribution for bevel gears at 75BHP power transmission

Fig 50 Stressdistributionforgeartoothofbevelgearat 7500RPM

Fig 48 Stressdistributionforgeartoothofbevelgear at2500RPM

Fig 51 Stressdistributionforgeartoothofbevelgearat 150N mTorque

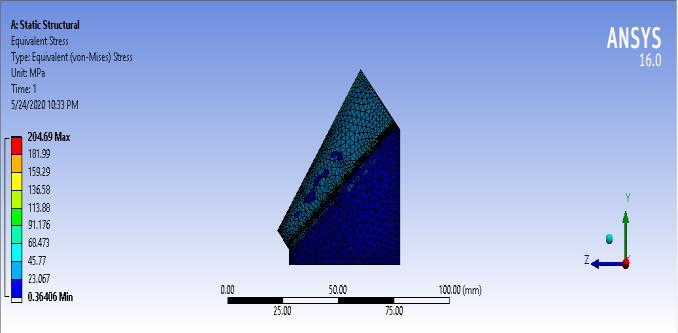

2.3.10. Stress distribution for bevel gears at 100BHP power transmission

Fig 49 Stressdistributionforgeartoothofbevelgearat 5000RPM

Fig 52 Stressdistributionforgeartoothofbevelgearat 2500RPM

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

Resultsaretabulatedbelow

Geardia(mm) Ft (N) σ(MPa) 80 5343.83 161.07 90 4749.57 136.81 240 1781.27 40.86 270 1583.19 34.52

Table 1 Stressdistributionfor75BHPat2500RPM

Fig 53 Stressdistributionforgeartoothofbevelgearat 5000RPM

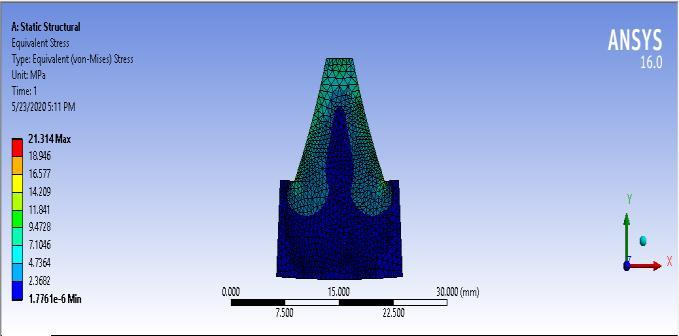

Geardia(mm) Ft (N) σ(MPa) 80 2671.91 80.807 90 2374.98 49.025 240 890.49 26.957 270 791.53 21.314

Table 2 Stressdistributionfor75BHPat5000RPM

Geardia(mm) Ft (N) σ(MPa) 80 1780.99 55.863 90 1583.19 38.808 240 593.69 19.972 270 527.7 17.28

Table 3 Stressdistributionfor75BHPat7500RPM

Fig 54 Stressdistributionforgeartoothofbevelgearat 7500RPM

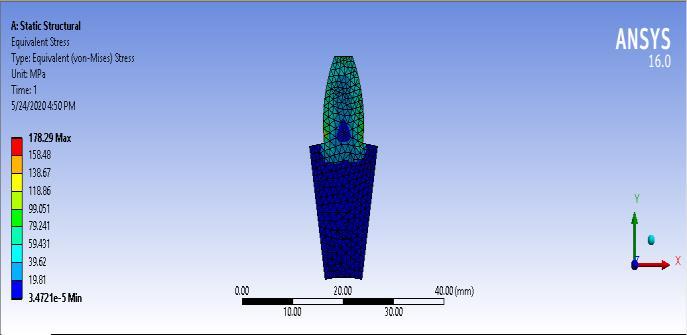

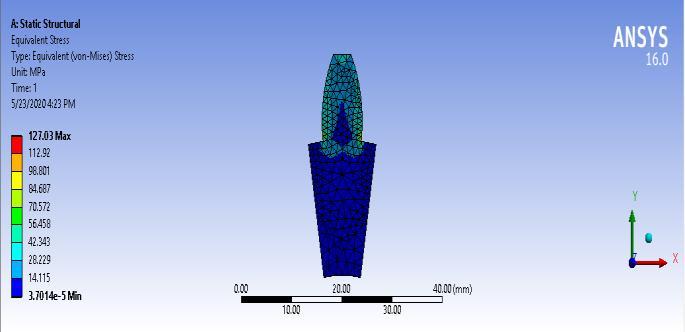

Geardia(mm) Ft (N) σ (MPa) 80 3752.51 127.94 90 3334.32 127.03 240 1250.55 34.745 270 1111.44 29.92

Table 4.Stressdistributionfor75BHPat150N mTorque

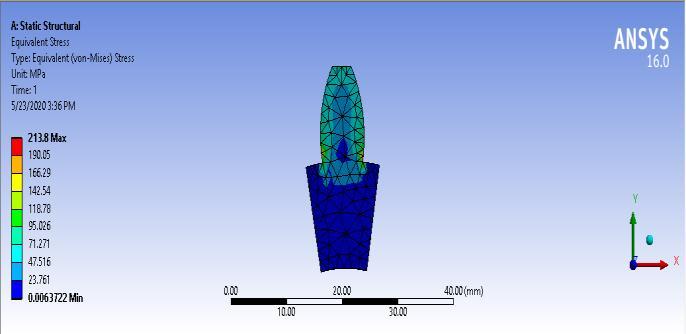

Geardia(mm) Ft (N) σ (MPa) 80 7125.11 213.80 90 6332.70 178.29 240 2375.03 54.486 270 2110.92 46.03

Fig 55 Stressdistributionforgeartoothofbevelgearat 80N mTorque

Table 5 Stressdistributionfor100BHPat2500RPM

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Geardia(mm) Ft (N) σ (MPa) 80 3562.55 108.81 90 3166.38 68.635 240 1187.33 35.943 270 1050.92 28.299

Table 6 Stressdistributionfor100BHPat5000RPM

Geardia(mm) Ft (N) σ (MPa) 80 2374.60 72.527 90 2110.92 51.744 240 791.59 23.96 270 703.64 21.127

Table 7 Stressdistributionfor100BHPat7500RPM

Geardia(mm) Ft (N) σ(Ansys)(MPa) 80 4502.11 173.65 90 4002.14 152.47 240 1500.4 41.687 270 1333.57 35.91

Table 8 Stressdistributionfor100BHPat180N mTorque

Speed(RPM) Ft (N) σ (MPa) 2500 3563.69 204.69 5000 1781.27 161.68 7500 1187.27 152.14 3561 2501.11 167.44

Table 9 Stressdistributionfordifferentialat75BHP Powerdelivery

Speed(RPM) Ft (N) σ (MPa) 2500 4751.59 272.92 5000 2375.039 215.57 7500 1583.191 202.85 3957 3000.8 200.89

Table 10 Stressdistributionfordifferentialat100BHP Powerdelivery

Completeoptimizeddesignofanovelplanetarytransmission integratedwithdifferentialforautomatictransmissionofthe vehicle. The gearbox should be easy to install, repair and maintain.Thegearboxwilloccupylessspaceandalsohave lessweightreducingtheoverallweightofthecar.Comparing withothergearboxeshelpedusoptimizingthedesignand generatingrequiredspeedratios.

1. G.Balbayevetal,DesignandCharacterizationofa New Planetary Gear Box, New Advances in Mechanisms, Transmissions and Applications, Mechanisms and Machine Science 17, DOI: 10.1007/978 94 007 7485 8_12, © Springer ScienceBusinessMediaDordrecht2014.

2. Dr. A. Srinath et al, Mechanical Efficiency of Planetary Gear Trains: An Estimate, Mechanical EngineeringResearch,1,No.1;December2011.

3. Mr.Wen MilnHwangetal,Configurationdesignof six speed automatic transmissions with two degree of freedom planetary gear trains, TransactionsoftheCSME/delaSCGM,Vol.29,No.1. 2005.

4. Mr. Oliver K. Kelley et al, The design of Planetary GearTrains,SAEAnnualMeeting,January1959.

5. Mr. A. Kahraman et al, A Kinematics and Power Flow Analysis Methodology for Automatic Transmission Planetary Gear Trains, Journal of MechanicalDesign,November2004.

6. Qingtao Li et al, Power split transmission with continuously variable planetary ratio, MechanismandMachineTheory140(2019)765 780.

7. NitinKapooretal,designandstressstrainanalysis of composite differential gear box, International Journal of Science, Engineering and Technology Research(IJSETR),Volume3,Issue7,July2014.

8. C.Veeranjaneyulu et al, design and structural analysisofdifferentialgearboxatdifferentloads, International Journal of Advanced Engineering Research and Studies, IJAERS/Vol. I/ Issue II/January March,2012/65 69.

9. Mr. Surya Prabhakaran et al, Bending Stress Analysis of a Spur Gear for Material Steel 15NI2CR1MO28.

10. Mr.TawandaMushiri,Analysisofageartrainusing finiteelementmodeling.

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page2757