International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

1PG Student, Industrial Safety Engineering, Department of Mechanical Engineering, BIT, Sathyamangalam

2PG Student, Industrial Safety Engineering, Department of Mechanical Engineering, BIT, Sathyamangalam

3Professor, Industrial Safety Engineering, Department of Mechanical Engineering, BIT, Sathyamangalam ***

Abstract Thegarmentsewingandpackingunitconducted hazard identification and risk analysis. The severity, probability, and frequency of recurrence have all been factored into the risk rating. Three risk categories have been established.Dependingontheseverity,alow,medium,orhigh risk level was assigned.1 to 7, 8 to 14, and 15 to 20, correspondingly, arethelevels ofincidence. This researchhas discovered that the risk of running a garment sewing and packing unit is moderate. Various control procedures were used. Found and recommended to ensure the plant workers' safety.

Keywords: Low, Severity, Probability, Hazard.

Hazardidentificationisoneofthemostimportantaspects ofahealthandsafetymanagementsystem.Itservesasthe foundationfordefiningsafeworkprocesses,implementing preventionprograms,andtakingothermeasurestoremove orcontroldangers.Anysourceofpossibledamage,harm,or adverse health effects on something or someone is consideredadanger.Ahazard'sriskistheprobabilitythatit willcauseharm.Identifyingexistingandpotentialworkplace dangers, assessing risks, selecting and implementing controls, and reviewing hazards are all part of the hazard identificationprocess.

Thehazardsofseveralactionsinagarmentunithavebeen identified.Activitiesweredividedintomanycategories,and risk assessments were conducted based on the severity, likelihood,andfrequencyofoccurrence.Thefollowingare themajoractivitiesandsubcategories.Thisresearchisbeing conducted,andariskreductionstrategyisbeingproposed.

Theaimofthisanalysisonhazardsandhazardassessment is to identify and examine dangers, risk sequences, and hazardsassociatedwithdangerousactivities.Tohelpidentify andanalyzerisks,avarietyoftacticsareavailable,ranging fromsimplequalitativeprocedurestoadvancedquantitative strategies. Because each has its own cause, strengths, and weaknesses,usingvarioushazardanalysismethodologiesis suggested. As a result of implementing the new improved

HIRA,workerproductivity,safety(physicalandmental),and jobsatisfactionwillallimprove.

Hazard Identification and Risk Assessment is a process that includes a number of sequential steps such as risk identification, result & frequency evaluation, hazard estimationbasedonexistingcontrols,andrecommendations toreducethoserisksthataren'twithinacceptablelimits.To beeffective,employermethodsforHIRAmustconsiderthe threat,danger,controls,anddocumentation.

Fig -1:HIRAProcess

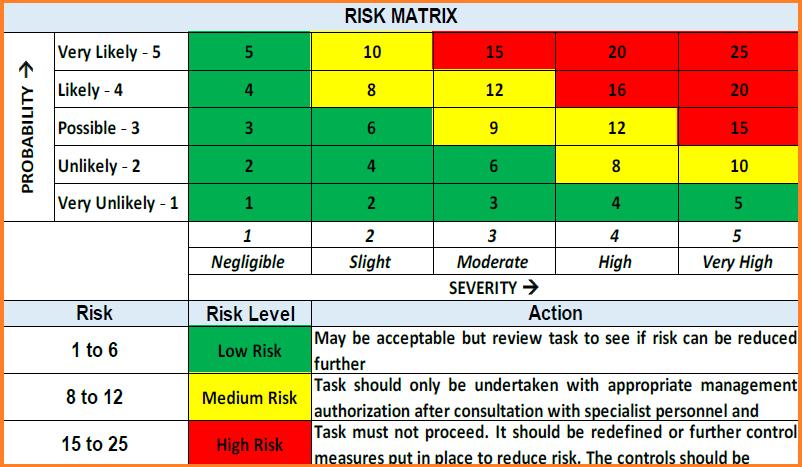

Theriskassessmentismostlydependentonthehazard's tolerance.Thedegreeofriskisassessedbycalculatingthe potentialseverityofinjuryandthechanceofdamage.When scoring threats and dangers, the effectiveness of existing threatcontrolmechanismsshouldbeassessed.Factorssuch asthecomponent(s)oftheframeaffectedandthenumberof personnelatriskmustbeconsideredwhendeterminingthe degreeoftheharm.

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page2043

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056 Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

damage. The chancedegree isdetermined by multiplying the severity and the probability of occurrence. (Score = SeverityxProbabilityofincidence).Beforeconsideringthe current controls, the base risk is determined using the severityandlikelihoodscores.Afterconsideringtheexisting restrictions,thetolerablethreatisestimated.Afterapplying thecontrolmethods,theratingofperfectdangerdetermines themajorhazards.Theseverityandlikelihoodofoccurrence of recognized hazards are appraised for their tiers of significancethroughthreatevaluationforbasicdangers,and residualhazardtiersaredeterminedbasedonthereduction in rating in chance of prevalence due to the presence of presentcontrols.

Matrix Fig 2:Riskmatrix

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

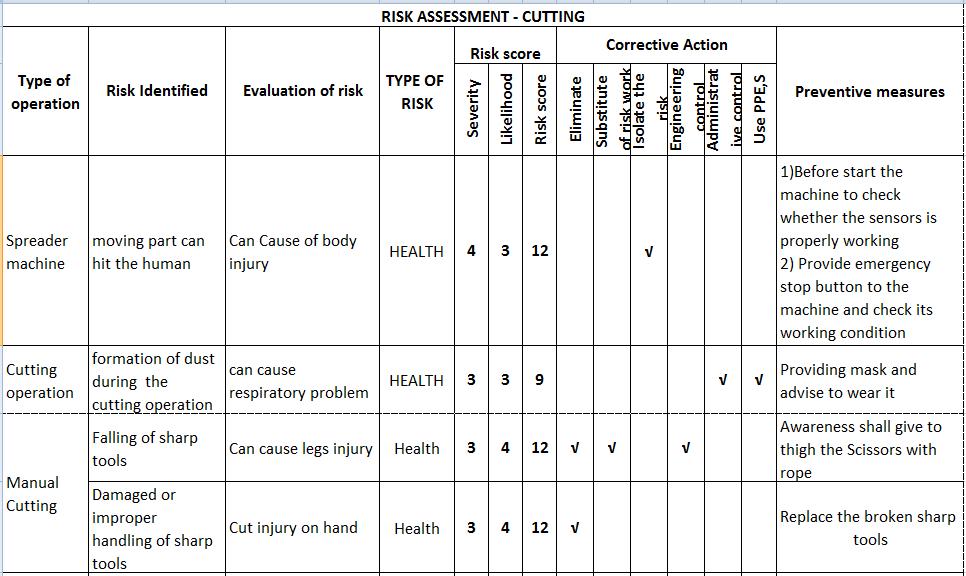

Table 3: Riskassessment Cuttingdepartment

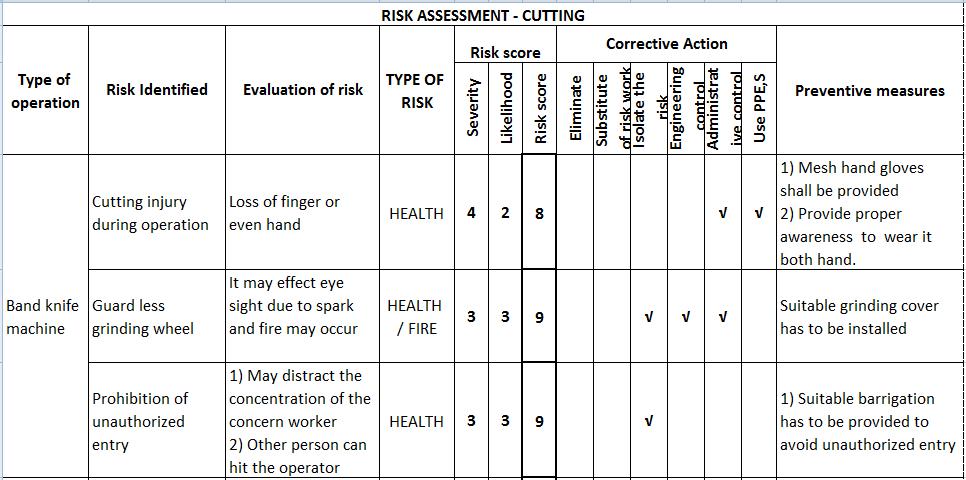

Table 4: Riskassessment Cuttingdepartment

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page2045

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

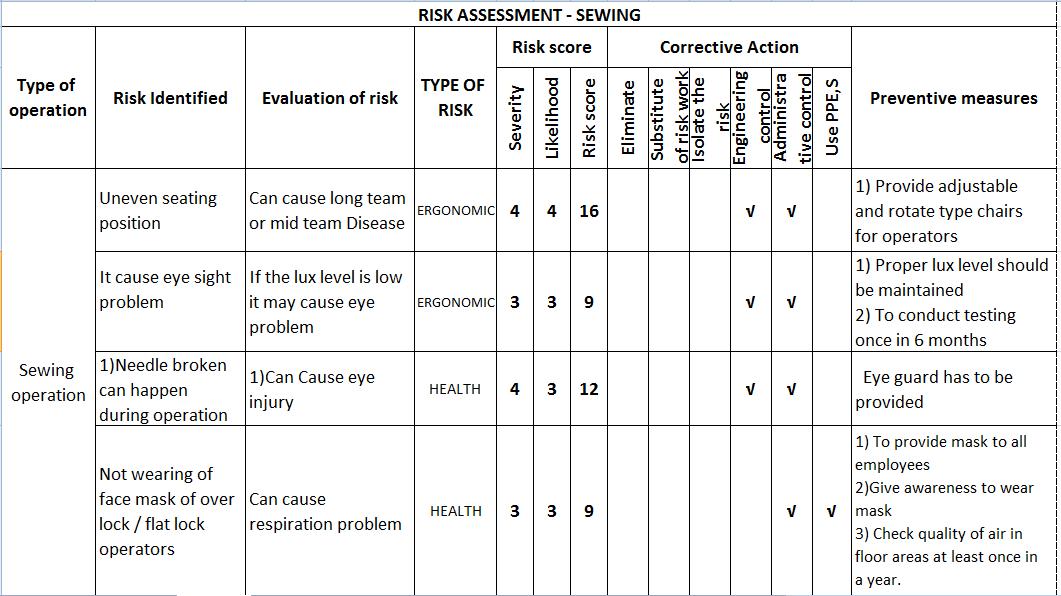

Table 5: Riskassessment Sewingdepartment

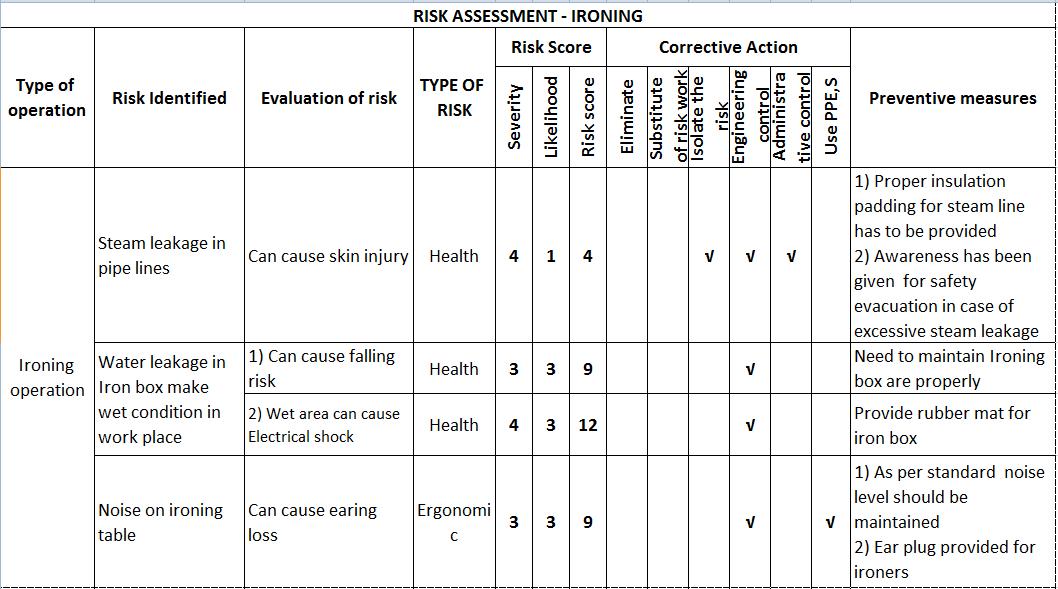

Table -6: Riskassessment Ironingdepartment

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page2046

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

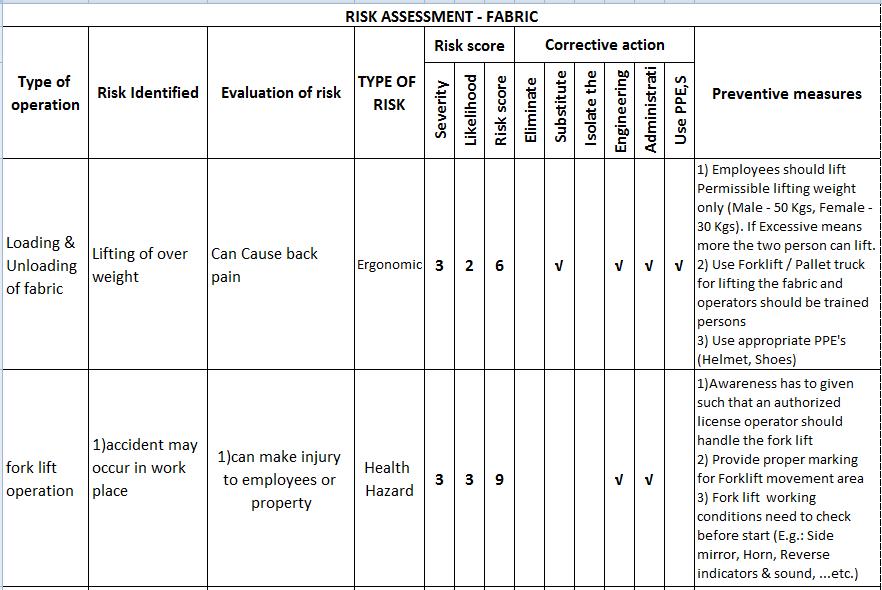

Table 7: Riskassessment fabricsection

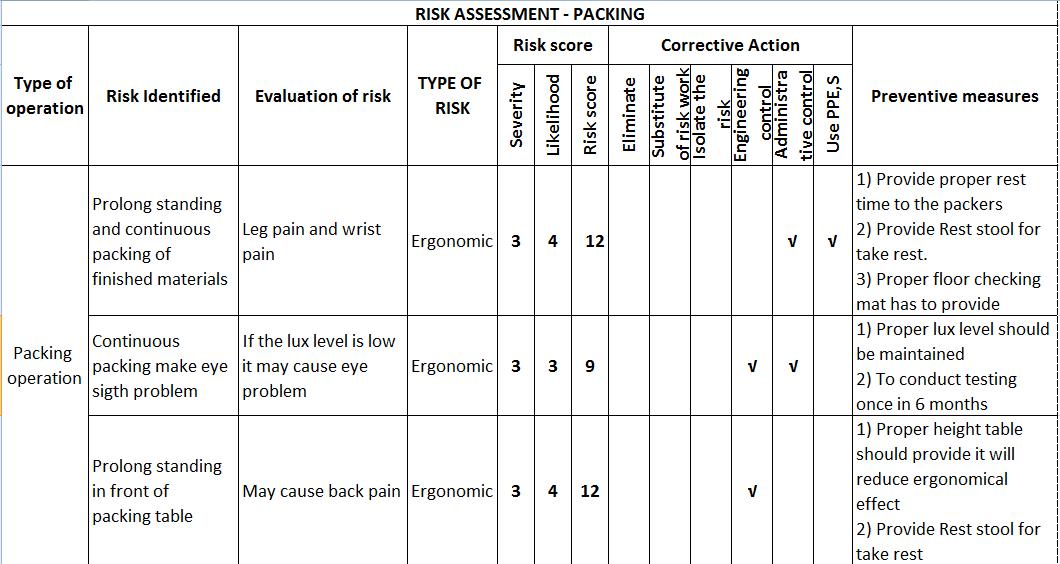

Table -8: Riskassessment Packingsection

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page2047

Riskanalysisfordifferentactivitieswasundertakeninthe Garmentunit.Itisfoundthattherisklevelwasrangingfrom 3to12fortheFabricprocess,6to16forthecuttingprocess, 9 to 16 for the sewing process, 4 to 12 for the ironing process,9to12forthepackingprocessand4to10forthe environmentalsignificant.Asaresultofthisstudy,various hazardswereidentifiedandthepracticalcontrolmeasures weredeveloped.

Thisresearchhasidentifiedseveraldangersintheareasof mechanical, electrical, material handling, chemical, ergonomics,andtemperatureextremes,aswell ascontrol strategiesbasedonthehierarchyofeliminationsubstitute engineering administration and personal protective equipment (PPE). Several procedures in the garment unit have been identified as having a very high level of risk, necessitating quick control actions. This research also demonstrates that a medium risk rating is linked to a number of activities for which control measures are indicated.

1. Md. Morshadul Hasan, Appel Mahmud. “Risks ManagementofReady MadeGarmentsIndustryin Bangladesh”, international research journal of businessstudies,ISSN:2089 6271

2. AshokkumarTC,Dr.MuthukumarK,ManojkumarR M “Hazard Identification and Risk Assessment (HIRA)inTextileIndustry”Vol:07issue:03,March 2020.

3. Razieh Janizadeh,”Textile Industry Hazard IdentificationandRiskAssessmentbyUsingHAZAN Method”ArchivesofOccupationalHealth,Volume3 ,Issue4,October2019,438 42.

4. Bedi, R. (2006). Evaluation of occupational environmentintwotextileplantsinNorthernIndia with specific reference to noise. Industrial health, 44(1),112 116.

5. Yhdego,M.(1991).Assessmentofnoisepollutionin friendship textile mill limited, Ubongo Dar es Salaam.Environmentinternational,17(5),479 485.

6. Ahmed, A. A. & Awadalkarim, M. A. (2015). Noise inducedhearinglossattwotextileplantsinSudan. Europeanacademicresearch,II(11),13995 14006.

7. SubrataTalapatra,NourinMohsin“AnAssessment ofHazardsandRisksin the Sewing Section ofthe ReadymadeGarmentIndustryinBangladesh”

8. Nazia Malik, Ashfaq Ahmed Maan, Tariq Sultan Pasha,SairaAkhtarandTanvirAli“RoleofHazard ControlMeasuresinOccupationalHealthandSafety in the Textile Industry of Pakistan”Vol. 47(1), 72 76;2010http://www.pakjas.com.pk.

9. Rajat Das Gupta, Subrata Nag ,Debashis Datta “Occupational Health Hazards among Workers in GarmentFactoriesinBangladesh”Vol.5,No.5,2015

10. Subashk,DrSubrataDas“OccupationalHealthand SafetyinTextileIndustries”Volume:06Issue:10| Oct2019.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056 Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page2048