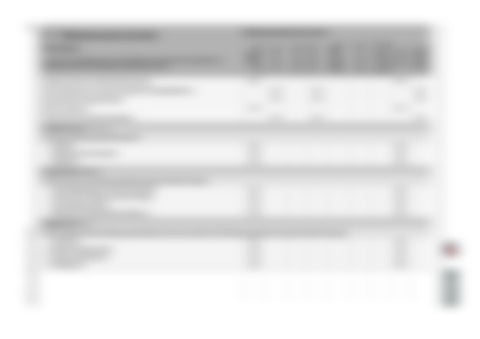

3-7

3.3

Maintenance plan (overview)

●

Check insulating mats in the engine compartment for damage/attachment

●

●

●

Adhesive labels and Operator's Manual

●

●

●

Engine cover gas strut

●

Pressure check of work and drive hydraulics Lubrication service (

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

):

Check the function of the following assemblies/components. Rectify if necessary: • Lights, signalling system, acoustic warning system • Check function of safety bars, check for damage • Check emergency lowering • Safety device: maintenance strut of loader unit Leakage check (

●

):

Lubricate the following assemblies/components: • Quickhitch • Mobile parts of lock mechanism • Attachments Functional check (

●

):

SERV-HB 1101c cp EN – Edition 1.0 *1101c_cp311.fm

Check for tightness, leaks and chafing: pipes, flexible lines and screw connections of the following assemblies and components. Rectify if necessary: ● • Visual check ☞ Engine and hydraulic system ● ☞ Cooling and heating circuit ● ☞ Travelling drive ●

● ● ● ●

Authorised

workshop

Customer

Every 3000 s/h

or 5 years max.

●

Every 1500 s/h

Every 1000 s/h once a year

Every 500 s/h

Every 250 s/h

Couplings, dirt pile-up on hydraulic system dust caps

Every 50 s/h

For service and maintenance work on the attachment, please refer to the operation and maintenance manual of the attachment manufacturer as well.

Service work (daily)

Work description

Maintenance plan/service hours (s/h)