1 minute read

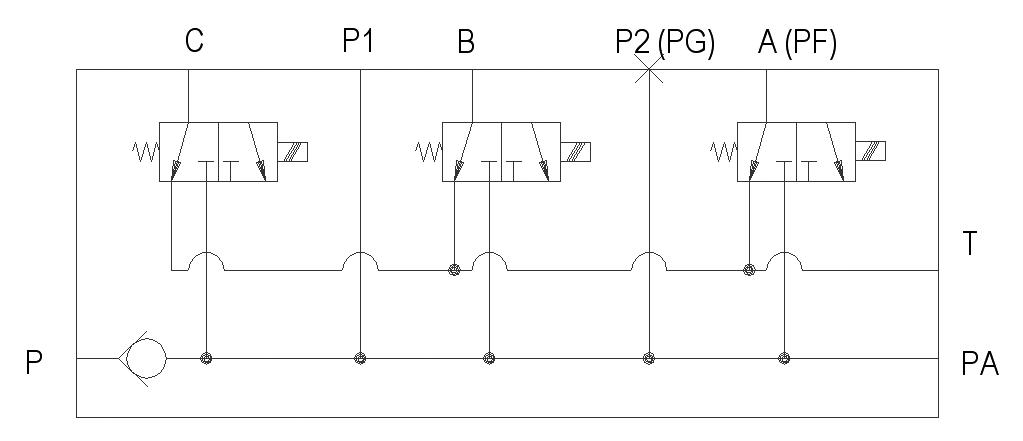

HYDRAULICSYSTEMME12002

27.Apply adhesive (Loctite #241 or equivalent) to the surfaces of hexagon socket screws (472) as shown. See Figure 3-258.

30.Install the top of bellows (501) into block (420). See Figure 3-261.

28.Tighten hexagon socket screw (472) to the specified torque. See Figure 3-259.

31.Apply anticorrosion oil (WD-40 or equivalent) inside of bellows (501). See Figure 3-262.

32.Install the bottom of bellows (501) into the groove in cover (201). See Figure 3-261.

IMPORTANT:If the bellows are not tightly installed into the groove (and are loose), bellows resistance to dust and water decreases.

29.Tilt block (420), apply grease to the top of push rod (214) and inject grease into grease cap (203) of plug (202) as shown. See Figure 3-260.

IMPORTANT:Apply and inject grease using a spatula made of soft material. Do not damage the push rod and plug surfaces.

HydraulicSystemComponents

TTank line

PPump supply hose <- gear pump

P1 Port drive counter balancing -> main valve block

P2Swing unit - park brake

A 2nd drive speed - drive unit

BMicroswitch/safety valve/joysticks

COil flow limitation switch P1 u. P2

HydraulicDiagram