22 minute read

Malfunctions

Fuses and relays

F120 50AFuse / air-conditionning F167 25AFuse / elevation pressure fan

F121 50AFuse / air-conditionning

F122 15AFuse/option.windshieldwiper

F123 50AFuse / supply A1020

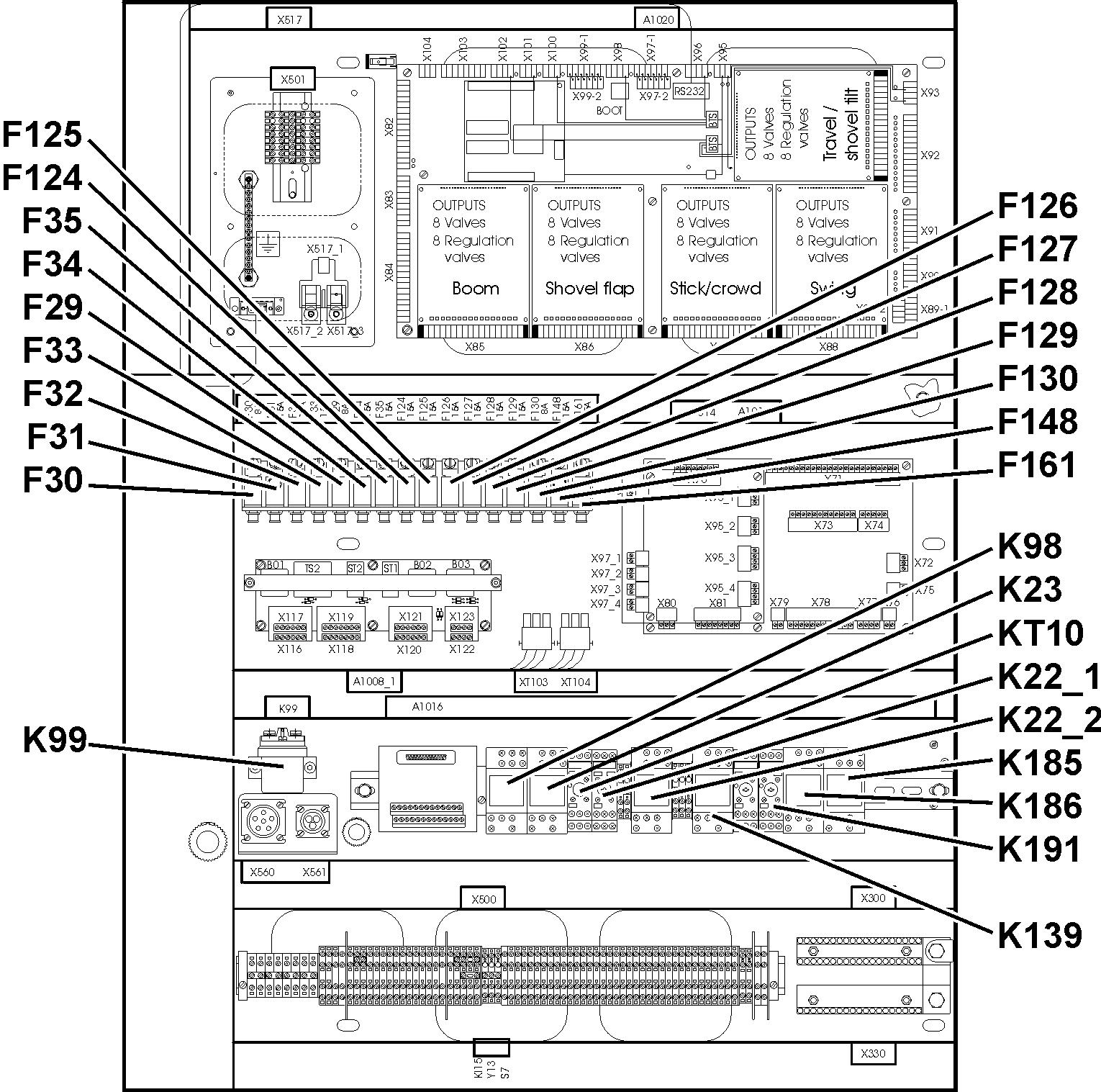

4.3.2Cabin electrical box E1005

The cabin electrical box E1005

15AFuse / charging

F29 8AFuse / reserve cameras K22_1 Relay / reserve

F30 8AFuse/ attenu. platesupply res.

F31 15AFuse/A1020 boom/shoveltilt

F32 15AFuse / A1020 stick / swing

F33 15AFuse / A1020 / trap door

F34 15AFuse / A1020

F124 15AFuse / S7, A1001

Relay / reserve

Relay second air conditionned

F127 15AFuse / greasing

F128 15AFuse / board

F129 15AFuse / cabin

F130 8AFuse / A1001

F148 15AFuse / A1019

F161 15AFuse / A1036

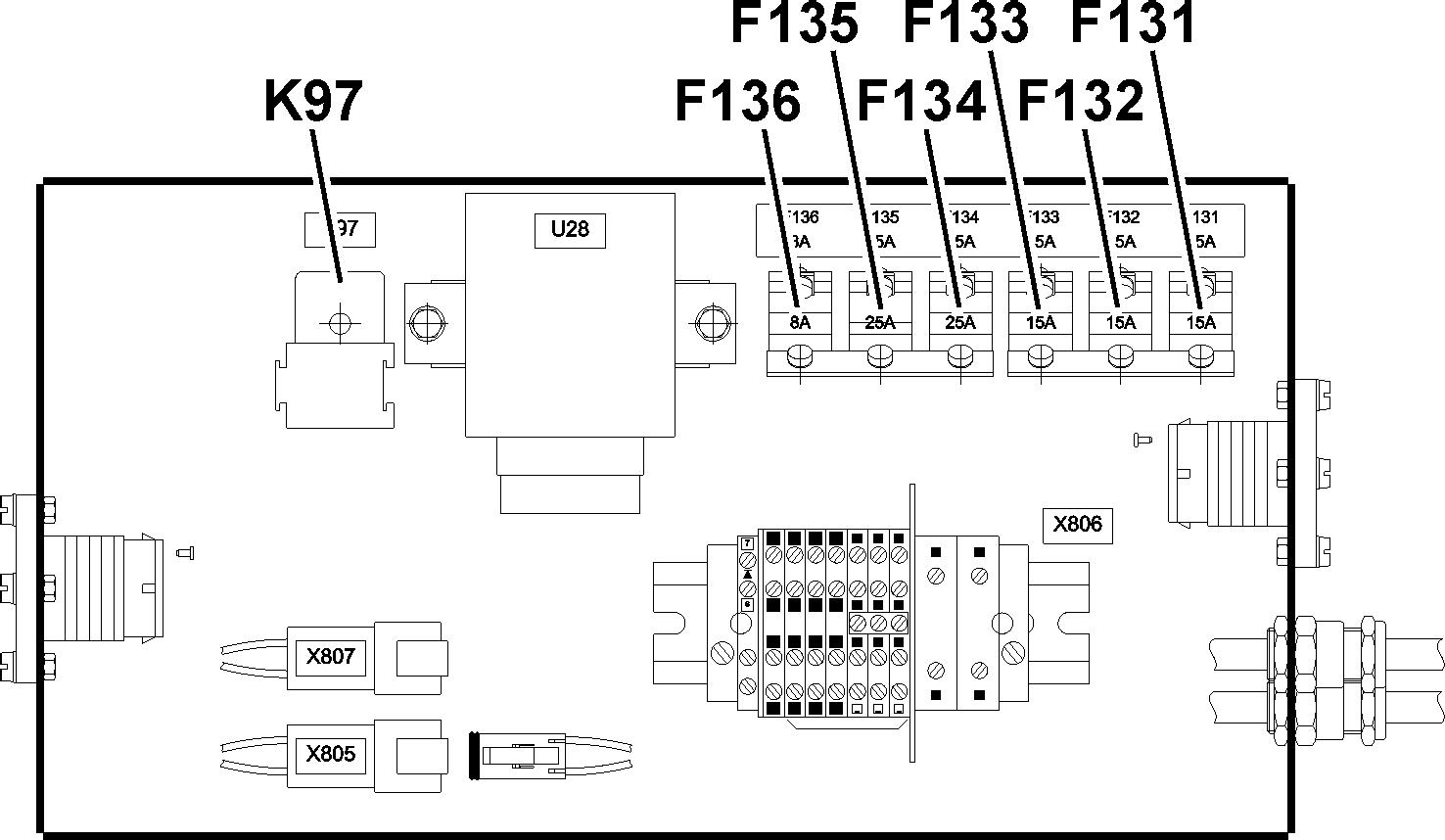

4.3.3Heating / air-conditioning electrical box E1006

Heating / air-conditioning electrical box E1006

F131 15AFuse / evaporator engine 1 K97 Relay / A/C compressor

F132 15AFuse / evaporator engine 2

F133 15AFuse / evaporator engine 3

F134 25AFuse / reserve

F135 25AFuse / reserve

F136 8AFuse / reserve

5.1Servicing the machine safely

General safety instructions

nel.

givenintheoperatinginstructionsforrepeattests/inspections.Itisimperativethatasuitablyequippedworkshopisavailable in order to carry out maintenance work.

venattheendoftheseoperatinginstructions defines precisely who is required / permitted to carry out what work. Jobs listed as daily / weekly work may be carried out by the machine's driver or maintenance personnel when they have received appropriate instruction. The remaining work may only be carried out by specialist personnel with appropriate training.

the manufacturer. Original replacement parts are always guaranteed to meet these criteria.

rrying out maintenance work. Avoid the wearing of rings, wrist watches, ties, scarves, open jackets, baggy clothing etc... There is a risk of injury from, for example, getting caught up or being drawn in. Protectivegoggles,safetyhelmets, safety shoes andgloves, reflectivevestsand ear protection etc. are required for specific jobs.

diesel engine while the diesel engine is running.

Personswithpacemakersshouldnotapproachwithin20cmoftherunningdiesel engine.

Do not touch voltage-carrying parts on the electrical connection of the individual solenoid injection pumps (Unit Pumps UP) while the diesel engine is running. nance work.

pair work. Designate persons in charge of supervision.

maintenance work on the machine on level, firm ground with the working equipment set aside and the engine switched off.

every maintenance locations on the uppercarriage, is when the uppercarriage is aligned with the undercarriage so that the sprockets locate at the back-end. The ladder situated on the undercarriage only corresponds with the uppercar- onsduringmaintenanceandrepairwork. ents, of the hydraulic hoses and of the counterweight must be replaced after every removal. work, they must be immediately reinstalled and checked at the end of the work. ularly when working under the machine, earlyvisiblepositiononthecontrolpanel. Pull out the start key and shut off the main battery switch. ated heaters only in well ventilated areas. Before operating these units, check ventilation. applicable local regulations.

Cleaning

hemachinebeforestartingmaintenanceorrepair work and pay particular attention to connections and screw fittings. Do not use aggressive cleaning products and use lint-free cleaning cloths.

chine for the first two months after initial set-up of the machine (or after repainting).

other cleaning materials: onsandtherimbearingtopreventwater or steam entering the bearing points. or steam may not be permitted to enter. Electric motors, electrical components,control boxes,plugconnections and air filters are particularly at risk. into contact with hot cleaning products during cleaning work. The fire extinguisher could start. observe following recommendations: er than 20 inches neutral cleaning agents such as customary car shampoos diluted to 2 or 3 percent maximum chafing and damage. onsandtherimbearingtodisplaceany water or cleaning products that may have entered.

Corrosion protection

ne must be inspected and renewed at regular intervals. For further information, refer to the Maintenance manual for corrosion protection.

Field of view

evitablyreinstalledandcorrectlyadjustedbeforetheinitialset-upofthemachine.

correctly adjusted.

ing operation or when travelling.

hange on the machine, the sight conditions must be maintained. These conditions must otherwise be checked according to ISO 5006. must always be clean.

e dangers due to a restricted field of view are minimized, particularly for machines with an operating weight which is superior to 40 tons.

Crack testing

fully, there is a possibility of individual cases of overloading occurring, which could lead to cracks or loose connections. Themachineshouldthereforebecheckedregularlyforcracks,looseconnections or other visible damage to maintain operational safety.

isessentialthatthemachineiskeptclean and cleaned regularly.

nance plan: supported, on firm, horizontal substrate, with the equipment in longitudinal and cross direction for variable loads. Current accident prevention regulations must be adhered to. axle andgearbox storage, support outriger, lower slewing ring support with tower and slewing ring. perslewingringsupport,cabsuspension,mountingforslewing gear andcounter weight. ttachments, e.g. boom, stick, quick change adapter, digging tool and grapple. ns and pinconnections, ascents, ladders and mounting elements. ally.Ifacrackissuspected,thedyepenetration test should be carried out as a crack test on areas which do not have goodvisibility,suchastheringbearingsupport,inordertoincreasetestingsafety. diately. Welding work on load-bearing parts of the earth-moving machinery, loading devices and transport devices may onlybecarriedoutbytrainedspecialistpersonnelandonlyinaccordancewiththe accepted rules of welding engineering. In case of doubt, contact the LIEBHERR customer support service to discuss suitable remedies.

Welding, drilling, firing and grinding work

undercarriage, uppercarriage, equipment this rule is neglected, the warranty is voided. d grinding work on the machine with expressauthorization.Cleandustandcombustiblematerialsoffthemachineandits surrounding areas before welding, drilling, firing or grinding. Ensure adequate ventilation. Risk of fire or explosion. move the negative terminal first and reconnect it last. pairshouldbedoneoncomponentswhichmaycontain inflammable gases (welded counterweight, components must be previously andsufficiently ventilated with pressurized air to avoid all fire or explosion hazard point, so the welding current will not run through parts like the swing ring, rotary connection, gears, bushings, bearings, hinges, joints, hydraulic hoses, sockets, rubber parts or seals.

Process materials

chemicalsubstances,observetheappropriate current safety regulations for the product.

ement parts are disposed of in a safe and environmentally acceptable manner.

(Risk of burning and scalding).

Repair work

parts.Usedeviceswhicharesuitablefor thispurpose and which have sufficient load capacity. When replacing single parts and larger subassemblies, carefully secure them on lifting devices so that they do not presentarisk.Onlyusesuitableandcorrectlyfunctioningliftingdevicesandloadtakeup devices with adequate load capacity. Do not stand or work under swinging loads.

rying capacity.

Wear work gloves when working with wire cables. him. forms which are appropriate for the job. Donotusemachinepartsasclimbingdevicesiftheyarenotdesignedforthispurpose.

When working at height, wear a harness to prevent falling.

Forfurther information, seesection"Maintenanceanchorpoints"or contactLiebherr customer service.

rmsandladders arefree ofdirt,snow and ice.

carefully, so that pneumatic cylinders do not hit their stops, because this could cause mechanical damages.

operate is securely supported before working (e.g. replacing teeth). Prevent metal touching metal when doing this.

ly totally released the pretension of the chain tensioning unit. securely supported with appropriate supports.

jeopardize stability and prevent metal touching metal while doing this. trained specialist personnel.

connect the upper structure to the chassis using stop bolts.

ment.

pressure can penetrate the skin.

ment, switched off the engine and depressurized the hydraulic system. After switching off the engine, with the start key in contact position and with the safety lever downinto its lowestposition,youmustoperateallpilotcontroldevices(joystick and pedals) in all directions in order to reduce the actuating and dynamic pressures in the work circuits. You must then reduce the internal tank pressure asdescribed in these operating instructions.

Electrical system

Have all faults, such as loose connections, blown fuses and lamps and clogged or abraded cables rectified by personnel.

the event of malfunctions in the power supply.

pment may only be carried out by skilled electrical personnel or by trained personnel under the supervision of an electrician in accordance with electrical regulations.

second person is available to operate the emergency-off or the main switch and overvoltage release. Cordon off the working area with a red and white safety chain and a warning sign. Only use insulated tools.

voltage, briefly disconnect the supply cable at earth and electronic devices such as capacitors using an earthing rod.

that they areoff circuit, earth them and then disconnect them briefly. Insulate adjacent live parts.

electric arc welding on the machine. Firstdisconnectthenegative,thenthepositivepole.Whenreconnecting,proceed in the reverse order.

Hydraulic accumulator

personnel.

licaccumulatorscancauseseriousaccidents.

hydraulic system (hydraulic system including hydraulic tank), as described in these operating instructions.

accumulator.

The hydraulic accumulator can be damaged by heat penetration and can be made to rupture by mechanical working. RISK OF EXPLOSION!

SION if oxygen or air is used.

purpose of use before installation.

on hydraulic accumulators. Ensure that this marking remains visible.

Hydraulic lines and hoses

work on hydraulic lines and hoses!

ibledamageandanypossibledamagemustbeimmediatelycheckedforleakage. else.

and burns.

natural aging process. This restricts their duration of use. common causes of failure.

ing to lines and hoses at place of use must be adhered to.

temperatures, frequent movement cycles, extremely high pulse frequencies, multiple shift usage).

the following arefound during inspection: cture formation in hose material); whether ina unpressurized orpressurized state or on bends e.g. sheath separation, blistering; ings which reduce the tightness of the fittings or thehose / fitting connection; tly. Do not mix up the connections. pressure hoses, the screws from the half-clamps or full flange must always be attached to both hose ends and should only be tightened afterwards. ssure lines and hoses with bent fittings, thesidewiththebentfittingmustalwaysbetightenedfirstandthenthesidewith the straight fitting tightened afterwards. attached and tightened subsequently. covers and protective devices are properly fastened. Doing this will prevent vibration and damage during operation. hoses or parts. prox.halftheexteriordiameterofthe hose is recommended. The distance should not, however, be less than 10 to 15mm. stick), check before initial start-up that there are no chafing areas in the entire area of movement.

Disposal

Disposal of the machine of the machine are disposed of correctly after the service life in accordance with all applicable national, regional or local regulations for waste disposal and environmental protection. uidsfromallcomponentsbeforedisposal.

Disposal of gas tanks and pressurized tanks ds disposed of in an applicable recycling point. technician. ts andoperating fluids manufacturer for disposal. of in an applicable recycling point.

Disposal of fuel, lubricants, operating fluids and consumables peratingfluids inapplicablecontainers before disposal.

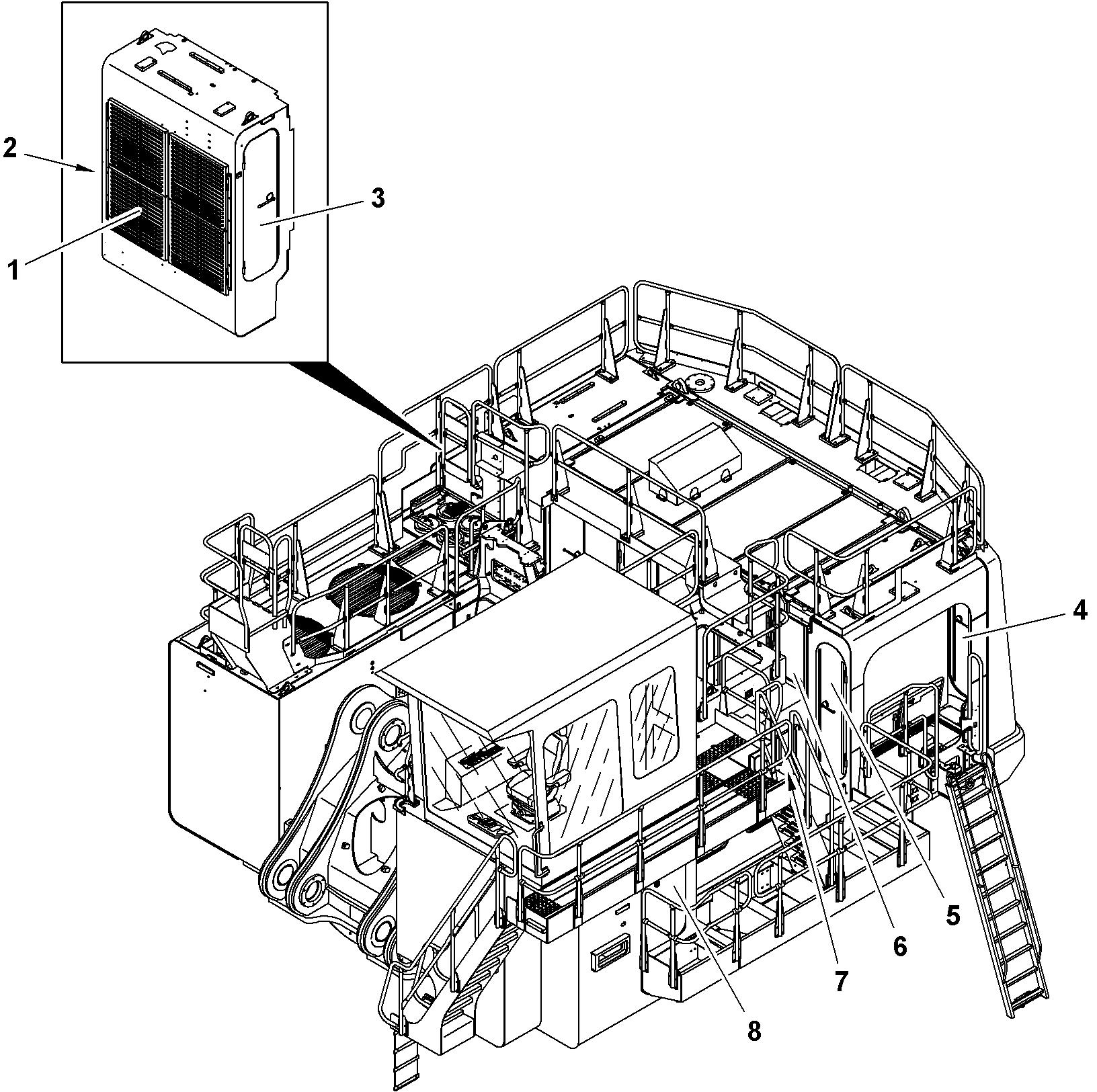

5.2Maintenance access doors

Themachinehasaccessdoorsformaintenance.Thelocksintegratedinthehandles must be unlocked before starting to drive.

Caution!

Access doors cancloseaccidentally andtraptheoperatoror maintenancepersonnel.

When you have opened the access doors, latch them using the retainer.

5.3Maintenance anchor points

You must always access to the machine through the access provided.

Forinstallation,maintenanceandrepairwork,itispossiblethattheservicepersonnel is obliged to removefall protectionelementssuchas handrails toget access toor to remove some parts of the machine.

Danger!

Risk of falling when fallprotection elements are removed.

The machine has anchor pointsfor safe installation, maintenance and repair work. Evenifappropriatefall-arrestequipmentisinstalledtotheanchorpoints,fall-arrest equipmentcannotpreventfalls.Commonsenseandfall hazardawarenessareimportant safety precautions for work that is done from above the ground.

5.3.1Approved anchor points

There are four types of approved anchor points on the machine:

The welded and the drilled anchor points have a specific label (see § "Signs on the machine"). To be easily identified, the welded and the drilled anchor points are also painted in blue (in white if the excavator is blue).

The lifting points given in the section "Transport drawings" can also be used as anchor points.

Thehorizontalmiddlebaronhandrailscanalsobeusedasanchorpoint(asillustrated below). The used handrail must have at least two vertical posts.

Welded anchor points

Drilled anchor points

5.3.2Use the anchor points

Before you use an anchor point, always do a check of its condition. If an anchor point has been used to arrest a fall, orif you are not sure about its safecondition,donotusethisanchorpointuntilithasbeeninspectedand,ifnecessary, tested by a competent person.

Always use the anchor points with applicable fall-arrest equipment. Use a harness with a maximum arrest force of 6kN. Only attach to approved anchor points.

Never attach more than three persons to a lifeline.

Never attach more than one person to another type of approved anchor point. If several persons must attachthemselves to the machine,they must usedifferent anchorpoints.

Never use an anchor point to attach parts or material.

Persons who must work with fall-arrest equipment must be specially trained. Alltheanchorpointsandthetighteningofthehandrailsmountingscrewsmustbe examinedbyauthorizedspecialistpersonnel.Formaintenanceintervals,referto the control and maintenance chart.

5.4Lubricants and operating fluids

5.4.1General information on changing lubricants and operating fluids

Note

Thequantitiesgiveninthelubricationandoperatingmaterialchartandonthelubrication chart in the cab are only guide values.

After each oil change or refill, check the level in the relevant unit.

Note!

Adheringtoregulationsforlubrication,levelchecksandoperatingmaterialchanges guarantees a high degree of reliability and a long service life for the machine. Itisparticularlyimportanttoadheretotheoilchangeintervalsandusethespecified type of lubricant.

Observe the followingwhenusing andcheckinglubricants and operating fluids:

All lubricants and operating materials are not miscible or compatible.

When you change the lubricant or the operating material for a component or a system,makesurethattheoldandthenewlubricantsoroperatingmaterialsare miscible and compatible with each other.

If not, flush the component or the system first with new approved lubricant or new approved operating material.

Note!

Cleanliness is of the utmost importance when changing oil.

Clean all filler plugs, filler covers and drainplugs andtheirsurroundings before opening.

For preference, drain off oil when it is at operating temperature.

Ensurethat oldoils arecollectedanddisposed of in anenvironmentallyacceptable manner using the removable oil filter cartridges.

Danger!

When checking and changing lubrication and operating materials, ensure that the following precautions are adhered to:

Unless otherwise indicated, carry out all work on the machine on level, solid ground and with the electric motor switched off.

Whenever you reach into the electric motor compartment, always secure the cover and side doors against accidentally falling back or closing.

Do not smoke and avoid naked flame.

Turn the main battery switch to position 0 (off) and remove the ignition key.

5.4.2Lubricating

SymbolDisplay

Hydraulic system

Swing gear

Travel gear

Splitterbox

Grease / Swing ring teeth

Grease

Cabin heater

Windshield washer

Check oil level

Oil change

First oil change

Oil analysis

(1)If filled with COB-2, COB-3 or COB-4 gear oil

(2)If filled with COB-1 gear oil

(3)Refer to the Operating Manual (section «Lubricating and operating material specifications»)

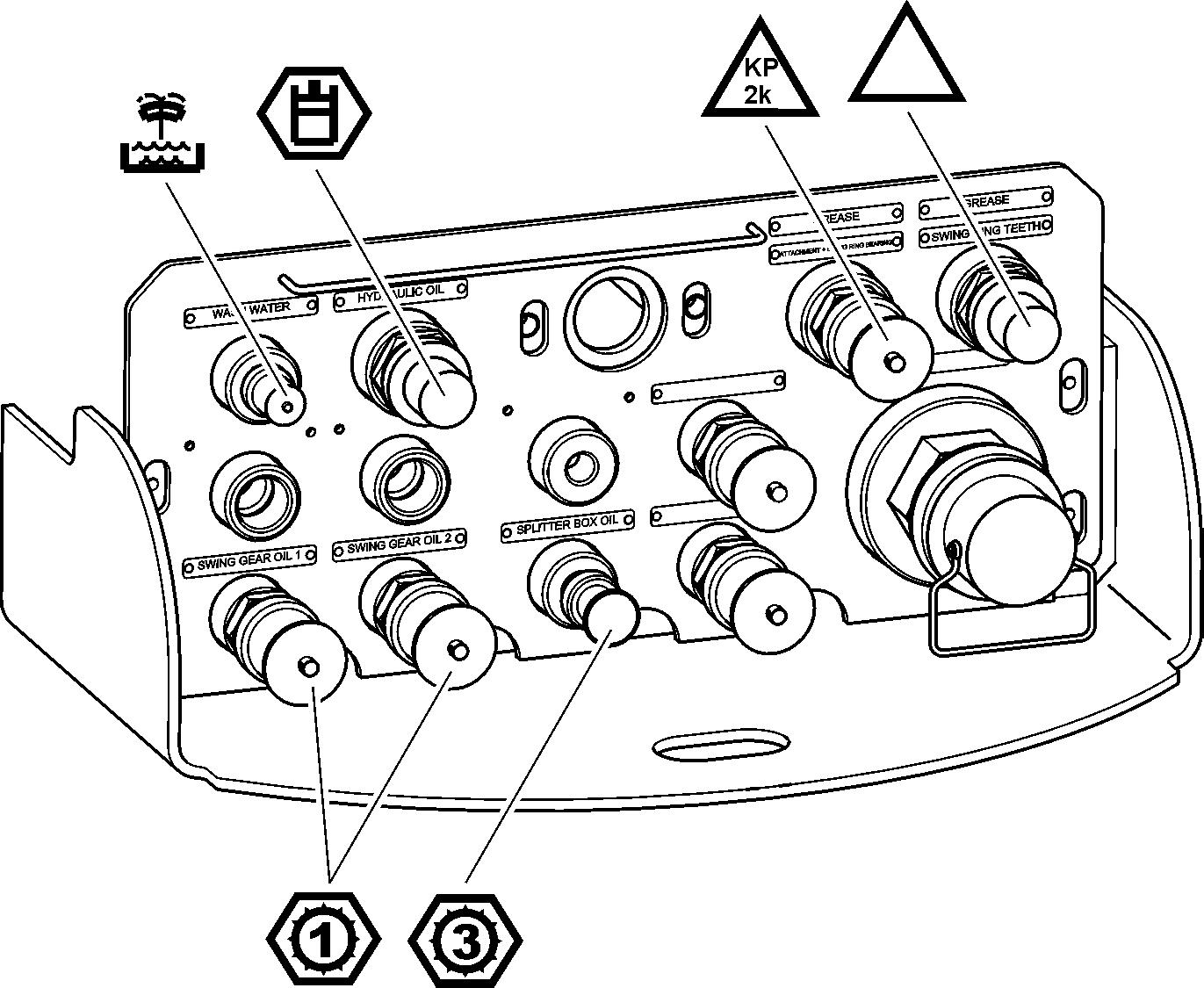

5.4.3Service trap

Tosimplifytheoilchangeandtherefillingprocedure,thedrainofthefollowingmajor components on the uppercarriage are centrally connected to a service trap:

ComponentAdapter

Swing gearOSP250

SplitterboxC-180750

Hydraulic oil6000B12100-200 l/min

WindshieldwasherEC280B825 l/min

DesignationMediumSymbolClassificationViscosityQuantity*

Electric motorLubricating grease RefertotheManualofsafety,installation and maintenance of the electric motor manufacturer.

Hydraulic tankRefertosection "Lubricatingandoperating material specifications". 2035 l. in hydraulic tank 4200 l. in whole system

Swing gearTransmission oilRefertosection"Lubricatingandoperating material specifications". 2 x 37 l.

5.4.5Operating material chart

DesignationMediumSymbolQuantity*

AirconditioningsystemRefrigerating agent: oil in a new compressor: oil to add in the system after a compressor replacement:

*The given quantities are onlyguidelines. Checkfluid level after each change or refilling.

5.4.6Service trap

For safety reasons and ease of maintenance, oil for the connected components shouldonlybedrainedandrefilledthroughthequick-changecouplingsintheservice trap.

However,thesecomponentsarealsoequippedwithoil drainvalves,seedescription for oil change procedure of these components.

To lower and raise the service trap copyright © Liebherr-Mining Equipment Colmar SAS 2021

Whentheservicetrapislowered,theserviceplateisaccessiblefromthegroundlevel.

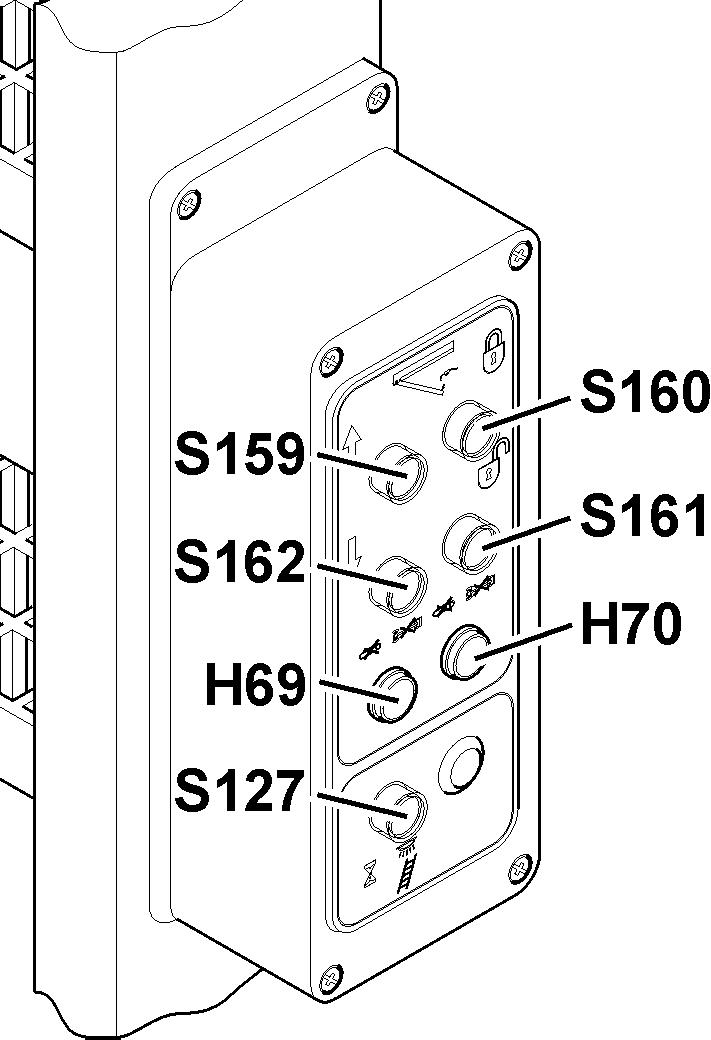

Theservicetrapcanbemovedupanddownvia thefourpushbuttons onthecontrol box E1022_2 mounted on the access ladder.

The service trap can also be actuated with the motor stopped. It should only be moved out if the uppercarriage and the undercarriage are aligned.

To lower the service trap from its uppermost position:

First push the switch S161 to unlock the trap.

Then push the switch S162 to move the trap downward.

To retract the trap:

First push the switch S159 until the red indicator light H69 goes out.

Thenpushtheswitch S160 tolockthetrapuntilthelockpinhasreacheditsstop position.

The lighting of the red indicator light H70 indicates that the locking pin of the trap is not in end (locked) position.

The lighting of the red indicator light H69 indicates that the trap is not in upper end position.

The locking of the trap via switch S160 is possible only when light H69 is out.

Caution!

Forsafetyreasons,theexcavatorcanonlybeoperatediftheservicetrapislocked in its uppermost position. Otherwise the red indicator light H70 comes on. This means that the swing and travel movements remain locked.

However,thissafetymeasurecanbebypassedforaslongasthebuttonS122onthe right front instrument panel is depressed.

5.5Lubricating and operating material specifications

Liebherr-Mining Equipment

Colmar SASonly gives approval for the Liebherr-branded lubricants and operating materials given in this manual.

Forotherlubricants,fluidsorgreases,Liebherr-MiningEquipmentColmarSASgives technical specifications for their related applications. It is the responsibility of the lubricant, fluid or grease supplier to check, justify and ensure to the owner of the machine that the lubricant, fluid or grease obeys these specifications sustainably.

5.5.1Lubrication forthe electric motor

RefertotheManualofsafety,installationandmaintenanceoftheelectricmotormanufacturer.

Lubricating and operating material specifications

5.5.2Hydraulic oil specifications for LIEBHERR Mining excavators

Hydraulicoilsmustmeettherequirementoutlinedbelow(dependingontemperature range).

Non-compliancewiththeserequirementsshallvoidallwarrantyandliabilitybyLIEBHERR.

LIEBHERR recommends maintaining the hydraulic oil to a cleanliness level that meets contaminant code 20/18/15 according to ISO 4406.

Maximum water content of hydraulic oil : <0,1%.

Caution!

According to the oiltype used for the hydraulic system, the fans speed regulation must be set specifically ("STANDARD", "COLD" or "EXTRA-COLD").

livered without arctic kit, it is set to "STANDARD"at delivery. an arctic kit, it is set to "COLD" at delivery.

Beforefirststartoftheexcavatororifanoiltypechangeisdoneafterwards,thefans speed regulation setting must be checked and corrected if necessary. Contact LIEBHERR Customer Service.

LIEBHERR oils forhydraulic system

Requirements

Fig. 5-8 LIEBHERR oils for hydraulic system

A Ambient air temperature

B Operating range

C Extra-cold start range if excavator fitted with operating Liebherr arctic kit (with warm-up instruction)

Fans speed regulation settings

LIEBHERR oilfans speed regulation setting

Liebherr Hydraulic Plus"STANDARD"

LIEBHERR oilfans speed regulation setting

LiebherrHydraulic Basic 68"STANDARD"

Liebherr Hydraulic Basic 100"STANDARD"

LiebherrHydraulic HVI"COLD"

Liebherr Hydraulic Plus Arctic"EXTRA-COLD"

Engineoils for hydraulic system

Requirements

A Ambient air temperature

B Operating range

C Extra-cold start range if excavator fitted with operating Liebherr arctic kit (with warm-up instruction)

Caution!

Minimumambientairtemperatureforextra-coldstartdependsonoiltypeandbrand and equals to oil pourpoint temperature +5 degrees K.

Recommended and approved are mineral engine oils, which conform to one of the following specifications:

CK-4E7228.1

CJ-4E5228.3

CI-4E3228.5

CH-4E2

CF-4

CF

Lubricating and operating material specifications

Fans speed regulation settings

Engine oilfans speed regulation setting

SAE10W30"STANDARD"

SAE10W40"STANDARD"

SAE20W-20 (ISO VG68)

"STANDARD"

SAE15W40"STANDARD"

SAE30 (ISO VG100)

SAE 10W (ISO VG46)

Hydraulic oils for hydraulicsystem

Requirements

"STANDARD"

"EXTRA-COLD" or "COLD"

A Ambient air temperature

B Operating range

C Extra-cold start range if excavator fitted with operating Liebherr arctic kit (with warm-up instruction)

Caution!

Minimumambientairtemperatureforextra-coldstartdependsonoiltypeandbrand and equals to oil pourpoint temperature +5 degrees K.

Hydraulic oils must contain dispersant and detergent additives and conform to one of the following specifications:

51524-2 (HLP, HLP-D)ISO 11158 (HM)

51524-3(HVLP,HVLP-D)ISO 11158 (HV)

Additional requirements:

Shear stabilityDIN 51350-6 CEC L 45-A-99

Fans speed regulation settings

KRL/C < 15%

Hydraulic oilfans speed regulation setting

ISO VG68"STANDARD"

ISO VG100"STANDARD"

ISO VG46"COLD"

ISO VG32"EXTRA-COLD"

Warm-up procedure

The black bar C indicates that the ambient temperatures are maximum 20 °C below the operating range B.

IntheeventofacoldstartatanambienttemperatureincludedinrangeC,thefollowing warm-up instruction applies to the hydraulic oil:

1. Starttheelectric motor. Carefully activatethe working hydraulic circuits. Operateahydrauliccylinder(Stickforexample)andmovethemtothestopquicklyand many times. After approx. 5 minutes, start the travel hydraulic circuits. Warm-up duration: approx 10 minutes

For temperature below the limits A :

2. Preheat hydraulic oil in the tank before starting the electric motor.

Biodegradable hydraulic oils

The use of biodegradable hydraulic oils must in any case be discussed with LIEBHER MINING EQUIPMENT COLMAR SAS.

Do not mix biodegradable hydraulic oils from different suppliers and never mix with mineral oils.

Donotusevegetableoilsastheydonotpossessthenecessarythermalstability. Depending on the temperature range, LIEBHERR recommends its poly-alpha-olefin (PAO, HEPR) oils, that are biodegradable according to CEC-L-103-12 (21 days, > 60%, primary decomposition):

Liebherr Hydraulic Plus or Liebherr Hydraulic Plus Arctic

If these oils are not available locally or if further specifications are required, use one of the following oils (before choosing an oil, contact our Customer Service):

Fully saturated synthetic ester-based oils, HEES

Depending on the temperature range, the viscosity grade of the HEES oil must conform to the above specifications for hydraulic oils.

Caution!

LIEBHERRrecommendstolimittheuseofHEESoilstoareaswhereHEESoilsare mandatory by local regulations.

Lifetimeofcomponentsmadeoutofrubbermaterialsuchashoses,seals,compensators might be reduced while using HEES oils!

When mixing ester-basedbiodegradable hydraulic oils with mineral oils, there is a riskofagressivechemicalreactions,whichmightdamagethehydraulicequipment.

Hydraulic oil selection forcold climate conditions

When a LIEBHERR Mining excavator works under cold climates conditions, in any case, the appropriate arctic kit must be installed.

Oil must match the above prescription for engine oils or hydraulic oils. ature must be at least 5 K below the minimal air ambient temperature.

mperature > 160°C (recommended > 200°C).

The operating range of the arctic oil depends on the ambient air temperature and must be checked as follow: stays below +20°C, the oil viscosity at +50°C (oil temperature) must be over 16 cst.

In this case, the fans speed regulation "EXTRA-COLD" must be selected. stays below +30°C, the oil viscosity at +60°C (oil temperature) mustbe over 16 cst.In this case, thefans speed regulation "EXTRA-COLD" or "COLD" must be selected. stays below +40°C, the oil viscosity at +70°C (oil temperature) mustbe over 16 cst.In this case, thefans speed regulation "COLD" must be selected.

ContactLIEBHERRCustomerServiceforadditionalquestionsaboutoilselection.

Oil mixing

In principle, oil mixing between two different oil types must be avoided. Mixing two different oil types leads to an unknown lubricant with resultant unknown physical properties (viscosity, pourpoint, flashpoint, ageingbehaviour,lubricity,reactionwith additives...).

However, if mixing is absolutely necessary, respect the following maximum mixing proportions: or LIEBHERR oils with mineral oils, or hydraulic oils withmineraloils,or twodifferentmineral oilstogether,ortwodifferent hydraulicoils together: max. 10% max. 2% or mineral oils or LIEBHERR oils:

Hydraulic oil change intervals

Oil changes at pre-set intervals (mineral oils and PAO oils only)

This procedure is applicable only for mineral oils and PAO oils. If you use HEES biodegradable oil, refer to the next section.

A Mineral oils and PAO oils hOperating hours

Liebherrrecommendsthatyousamplethehydraulicoilevery500operatinghours (refer to the section "Condition monitoring with oil analysis").

Change the hydraulic oil every 2000 operating hours.

Oil changes at optimized intervals

Thisprocedureisapplicableformineraloils,PAOoilsandHEESbiodegradableoils.

A

B h Operating hours

1 First oil sample

2 Second oil sample

3 Next oil samples at regular intervals

You can extend the oil change intervals (up to 6000 operating hours and possibly even more) as long as the properties of the oil are satisfactory. Get a sample of the new hydraulic oil.

Ifyouusemineral oilor PAO oil,youmustsamplethehydraulicoil every 500operating hours after the first 1500 operating hours.

If you use HEES biodegradable oil, you must sample the hydraulic oil every 250 operating hours.

Changethehydraulicoilimmediatelyiftheresultsoftheanalysisarenotsatisfactory (referto the section "Condition monitoring with oil analysis").

5.5.3Swing and travel gear oils

Note!

Foragivenmachineoperatingtemperaturerange,andifdifferentviscositygrades areapprovedaccordingtothefollowingspecifications,alwayschoosethelubricant with the highest viscosity grade.

Lubricating and operating material specifications

Caution!

Gears flushing is necessary when switching from mineral oil to synthetic oil. Use new oil to flush the gear when switching from mineral oil to synthetic oil. Flushing with cleaning fluid or Diesel fuel is not permitted.

Usegearoilmeetingfollowingviscosityclassesandspecifications(dependingonthe ambient temperature):

* COB-1: Gear oil according to DIN 51517, part 3, CLP-HC(1) (1) HC / Synthetic carbon hybrid (poly-alpha-olefin PAO)

TEST / REQUIREMENTSTANDARD / REFERENCE REQUIRED LEVEL / PERFORMANCE

Relative scuffing load-carrying capacity A/8.3/90DIN ISO 14635-1>14

Relative scuffing load-carrying capacity A/16.6/140DIN ISO 14635-1>12

FVA-FZG micro-pitting load capacity GT-C/8.3/90FVA Information sheet no. 54/I-IV GT-High

FE-8 roller bearing wear tests 7.5/80/80 and 7.5/100/80DIN 51819-3Pass (excellent)

FLENDER AG approval-Approved

Tab. 5-5

FVA = ForschungsvereinigungAntriebstechnik e.V. ("Research association for drive technologies")

FZG = Forschungsstelle für Zahnräder und Getriebebau der TU München ("Gear Research Center of the Technical University of Munich")

** COB-2: Gear oil according to DIN 51517, part 3, CLP

TEST / REQUIREMENTSTANDARD / REFERENCE REQUIRED LEVEL / PERFORMANCE

FVA-FZG micro-pitting load capacity GT-C/8.3/90FVA Information sheet no. 54/I-IV

GT-High

FE-8 roller bearing wear tests 7.5/80/80 and 7.5/100/80DIN 51819-3Pass (excellent)

FLENDER AG approval-Approved

Pour point temperatureISO 3016VG220: TPourpoint <-15°C

VG320:TPourpoint <-15°C

VG460:TPourpoint <-10°C

VG680: TPour point < -5°C

*** COB-3: Gear oil according to API classification GL5

TEST / REQUIREMENTSTANDARD / REFERENCE REQUIRED LEVEL / PERFORMANCE

API classificationGL 5-

Scuffing load capacity FZG test A/8.3/90DIN ISO 14635-1>12

MIL-L2105 B/C/DMAN342 type M1-

Mercedes Benz235.0-

ZF FriedrichshafenTE-ML 05A, 16C, 17B, 19B, 21A -

**** COB-4: Gear oil according to API classification GL5

TEST / REQUIREMENTSTANDARD / REFERENCE REQUIRED LEVEL / PERFORMANCE

API classificationGL 5-

Scuffing load capacity FZG test A/8.3/90DIN ISO 14635-1>12

MIL-L2105 D, PRF-2105EMAN342 type N-

ZF FriedrichshafenTE-ML 05A, 07A, 16D, 21A -

Tab. 5-8

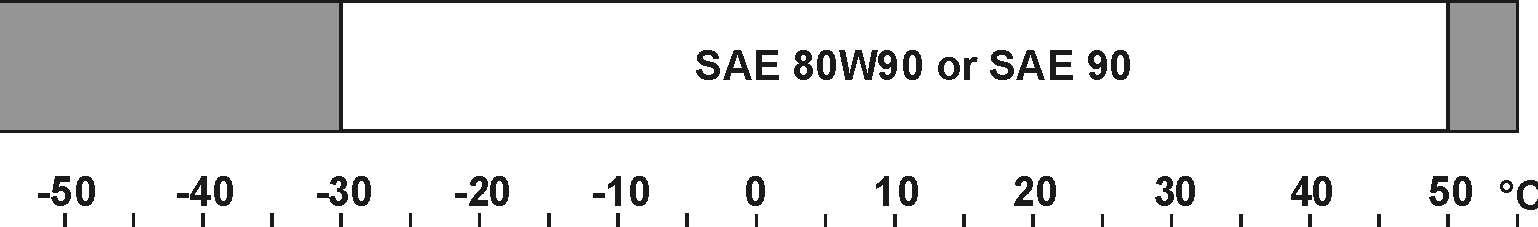

5.5.4Splitterbox oil

Use gear oil with viscosity classification SAE 90 or SAE 80W90 and meeting specifications API-GL-5 and MIL-L-2105 B, C or D.

Lubricating

5.5.5Lubricating grease

The machine has two lubrication systems: and the swing gear bearings e swing ring teeth. For each of these systems, use grease that meets the specifications that follow.

Specifications for standard applications (ambient temperature of more than -20°C) MethodUnit attachment gear

Swing

Specification

Flow pressure at -20°C1) Low temperature torque at -20°C Starting torque

1) One of the two methods.

2) Or equivalent test under responsibility of the lubricant manufacturer.

Lubricating solidsUnitSpecification

Maximum particle sizemicronGraphite <25

<15 Other solids <15

Mean particle sizemicronGraphite ~10-15 MoS2 ~5-10

Other solids ~5-10

Maximum content%Maximum 10 total for solids additives Graphite <8

Greases which use calcium simple soap as thickener are not permitted.

Grease selection for cold climate conditions

For application below -20°C: given in the specifications for standard applications. variation over the year, consistency grade must be adapted.

(below -20°C) and are mandatory for operations below -40°C. entralized lubrication system must be tested at minimum ambient temperature of the application.

Additional requirement:

Grease mixing

When the grease is changed from one type of grease to another, the basic recommendationistoremovealltheoldgreasefromthesystem.However,thefullremoval from the system is not possible especially in the swing ring and in the swing gear bearings.

Thecompatibilityoftwodifferentgreasesisnotgivenandcancausecatastrophiclubrication failures. Lubricating greases made of different thickener base must never bemixedtogether.Notonlythethickenertype,butalsothebasicoilandtheadditives treatmentshavetobeconsidered. Thecompatibility ofgreases shouldbe evaluated accordingtoASTMD6185.Furthermore,awrittenstatementofthelubricantsupplier must justify greases compatibility.

5.5.6Other lubricants

Refer to the table that follows for other lubricants.

LubricantDescription / manufacturer

Contact spray for slip ringsCramolin

Lubricant for pistons, piston nuts and piston bearing installations on the hydraulic cylinders

Special anti-corrosive material for installation areas of sealingelementsonhydraulic cylinders

Anti-corrosion grease for open piston rods (cylinders that do not move often or transportation)

Gleitmo 800

Castrol-Tarp

Liebherr Cylinder Protect

5.6Condition monitoring with oil analysis

5.6.1General information

Oil analysis helps to monitor the main components condition by observing oil chemical and physical properties which can show either the oil contamination by foreign or wear particles, or the degradation of its properties.

Component oil analysis in accordance with the recommended procedures, intervals and specifications and the records of a component oil analysis are strongly recommended because this will support any warranty claim raised upon LIEBHERR.

Bycomparingtheoilpropertiesandcontaminantstoreferencelevelsandevenmore byobservingtheirtrendsoveraperiodofoperation,itispossibletooptimizethecomponent lifetime, possibly to prevent further damage (preventive exchange) and potentially to reduce rebuild and maintenance costs.

An oil analysis will give an indication of the component condition. But the measured valuesandtheirtrendoveraperiodofoperationneedalwaystobeinterpretedinrelation to the machine operating conditions and to events such as services, top-up, component change-out, etc.

Theinterpretationoftheanalysisresultsneedalsotobecomparedtosamplesofthe new oil. Therefore, new oilneeds tobe analysedtwicea yearand when changing to another oil supplier.

This procedure is applicable for these components:

These parameters must be monitored:

5.6.2Oil sampling

Sampling intervals chart.

, Mg, B, Zn, P, Ba or S) the used oil immediately before draining it. plier.

Sampling instructions

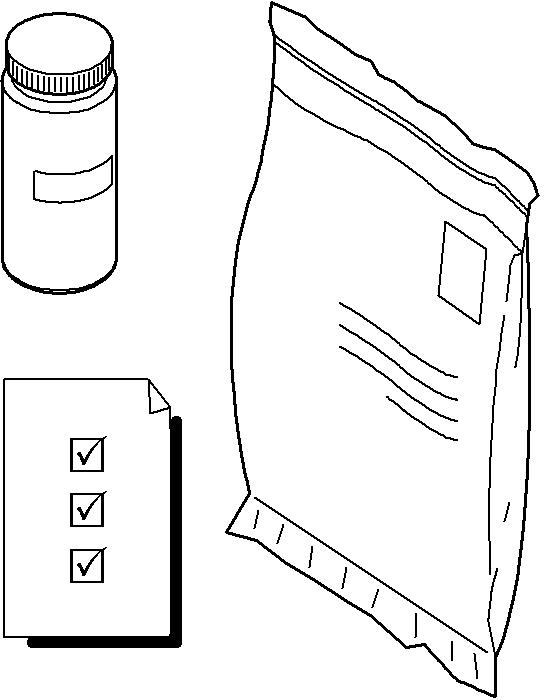

General sampling instructions: Wear personal protective equipment. Get the sample:

Clean the area around the sampling point before you get the sample. Use an appropriate sampling kit.

Keepthesamplingmaterialawayfromhumidityanddust.Taketheseprecautions to choose a storage area.

Make sure the sampling material is perfectly clean (without dust, water, fuel...). If different sampling procedures are applicable for a component, always use the same sampling point and the same sampling procedure for this component to make sure that the analysis records stay relevant.

Fill the sampling bottle with oil to 80% level. Do not fill the sampling bottle to the top.

Close the sampling bottle tightly to ensure the integrity of the sample. Identify the sample with a label.

Carefullyfillinasampleinformationsheet.Inanycase,itismandatorytogivethis information with the sample:

Send the sample in oil-proof adapted material. Check fortherequiredsampledelivery timeandforsample export licence(ifthe laboratory is located out of the country, make sure that the export of the sample is authorized from your location to the laboratory).

Do not wait before sending the sample to the laboratory. Record and save sampling operations and results.

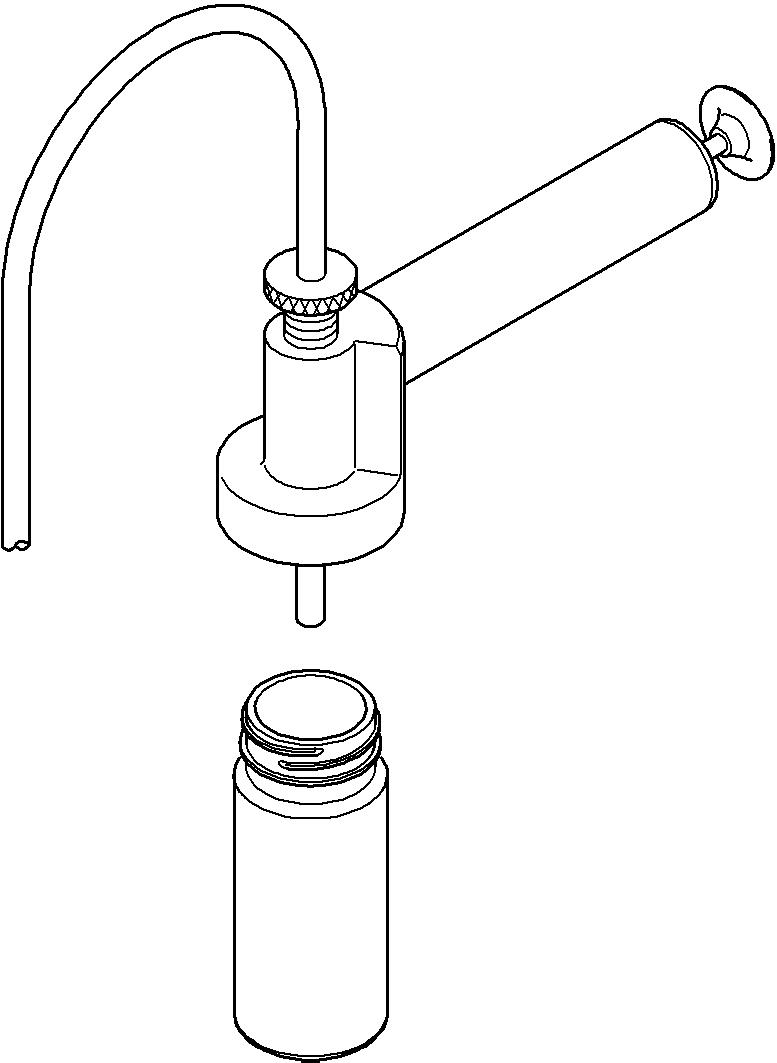

If you get the oil sample with a sampling pump:

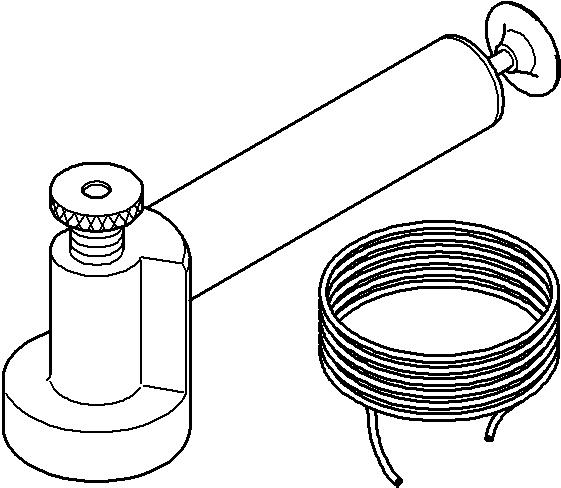

Sampling pump

Use a sampling pump if you get the sample directly in the tank or on the component (machine stopped).

Always use a new sampling hose.

Cut the sampling hose to the correct length (e.g. dipstick length plus 20 mm).

First, let sufficient oil flow to flush the sampling hose.

If you get the oil sample in the tank, take the sample in the middle of the tank.

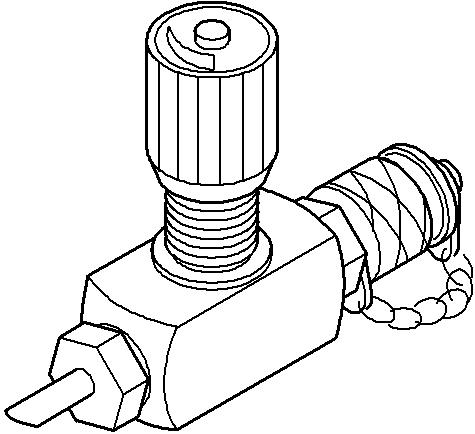

If you get the oil sample through a sampling valve:

Always use a new sampling hose.

First, let sufficient oil flow to flush the sampling hose. Gettheoilsampleinthemid-stream,i.e.firstletasmallamountofoilflowthrough the valve before sampling it.

Sampling material

You can order LIEBHERR approved sampling material to get the samples: Note!

These sampling kits are prepaid kits and include the cost of the analysis.

Before ordering these sampling kits, check for sample export licence: make sure that the export of the sample is authorized from your location to Europe.

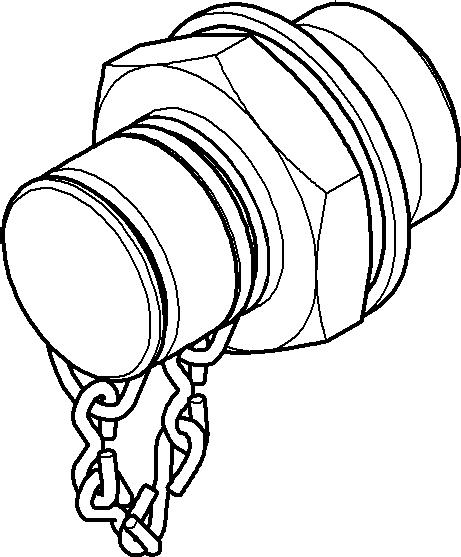

Oil sampling points Splitterbox

To get a sample of the splitterbox oil:

Note!

Two sampling procedures are applicable for this component. Always use the same sampling point and the same sampling procedure for this component to make sure that the analysis records stay relevant.

Use the sampling valve 1 which is installed next to the splitterbox. or

Useasamplingpumpandgettheoilsamplethroughthedipsticktubeofthesplitterbox.

Travel gear

To get a sample of the travel gear oil: Usea sampling pumpand gettheoilsamplethroughthe fillingandlevelplugs 1.

Hydraulic oil

To get a sample of the hydraulic oil: Use the sampling valve 1 which is installed next to the splitterbox.

Splitterbox

5.6.3Sample processing

Analysis standards

LIEBHERRrecommendstosubmittheoilsamplestoOELCHECKGmbHforoilanalysis.

Ifanotherlaboratoryisused,theoilanalysismustbedoneaccordingtothesestandards:

, contamination and additives by ICP)

Action level values

These tables give the action level values for the different monitored parameters for each component and the action to be taken if the action level value is reached. These values are applicable for mineral and synthetic oils.

Caution!

If three analyses one after the other give out-of-range results: Contact LIEBHERR Customer Service with the related analysis records.

Caution!

Comments and recommendations given by the laboratory on the analysis report must also be taken into account.

Splitterbox

Iron level100 ppmChange oil (get a sample again after 250hours).

Copper level10 ppmChange oil (get a sample again after 250hours).

Silicon level20 ppmCheck component for entrance of dust (sealing, breathers...).

Flush and change oil (get a sample again after 250hours).

Water content0,10%Change oil (get a sample again after 250hours).

Viscosity change (at 40°C and 100°C) <15%(*) Change oil (get a sample again after 250hours).

Additives change±20%(*) Change oil (get a sample again after 250hours).

(*) Difference compared to new oil value.

Swing gear

ComponentParameterAction level value

Action

Iron level400 ppmChange oil (get a sample again after 250hours).

Copper level150 ppmChange oil (get a sample again after 250hours).

Silicon level15 ppmCheck component for entrance of dust (sealing, breathers...).

Swing gear

Flush and change oil (get a sample again after 250hours).

Water content0,10%Change oil (get a sample again after 250hours).

Viscosity change (at 40°C and 100°C)

<15%(*) Change oil (get a sample again after 250hours).

Additives change±20%(*) Change oil (get a sample again after 250hours).

(*) Difference compared to new oil value.

Travel gear

ComponentParameterAction level value

Action

Iron level400 ppmChange oil (get a sample again after 250hours).

Copper level50 ppmChange oil (get a sample again after 250hours).

Silicon level30 ppmCheck component for entrance of dust (sealing, breathers...).

Travel gear

Flush and change oil (get a sample again after 250hours).

Water content0,10%Change oil (get a sample again after 250hours).

Viscosity change (at 40°C and 100°C)

<15%(*) Change oil (get a sample again after 250hours).

Additives change±20%(*) Change oil (get a sample again after 250hours).

(*) Difference compared to new oil value.

Hydraulic oil

ComponentParameterAction level value

Action

Silicon level15 ppmCheck for entrance of dust (cylinders, breathers...) (get a sample again after 250hours).

Viscosity change (at 40°C and 100°C)

<15%(*) Change oil (get a sample again after 250hours).

Water content0,10%1. If the machine has a bypass filter element with water separator installed, replace the filter. you get a satisfactory range.

2. Get a sample again after 250hours. If the results are still out-of-range: factory range.

Hydraulic oil

Particle Quantification (PQ Index)

501. Change the return filters, pilot oil filters, leak oil filters and replenishing filters.

2. Get a sample again after 250hours. If the results are still out-of-range: < 20 or less.

Cleanliness level (ISO 4406)

21/19/161. Change the return filters, pilot oil filters, leak oil filters and replenishing filters.

2. Get a sample again after 250hours. If the results are still out-of-range: inant code 20/18/15 or less.

(*) Difference compared to new oil value.

5.7Electric motor

Refer to the CONVERTEAM Manual for safety, installation and maintenance for detailed description of maintenance work to be performed.

In addition, accurately observe the following items and perform all maintenance work according to the intervals given in the control and maintenance chart.

5.7.1Mounting screws

Mounting screws

Check the mounting screws on the motor brackets and the motor gear mounts regularly for tightness, retorque if necessary.

For maintenance intervals, see control and maintenance chart. Any improperfasteningwouldgreatlyreducetheexpectedlifeof therubbermounts.

1 Hex. head screw M16280 Nm 3 Hex. head screw M16280 Nm

2 Hex. head screw M16280 Nm

Caution!

Loctite (Ident 8503598) must be applied on mounting screws 1, 2 and 3 when installing the screws in order to avoid possible damages on the parts.

Thescrews1,2and3shallonlybetightenedafterthemotorandthesplitterboxas acompleteunithasbeenpositionedonthePowerPackframe,sothatapretentioning of the rubber mounting can be avoided.

5.7.2Elastic bedding

Thetworubbercushions 4 atthefrontfaceofthemotormustbecheckedandreplaced at regular intervals. For maintenance intervals, see control and maintenance chart.

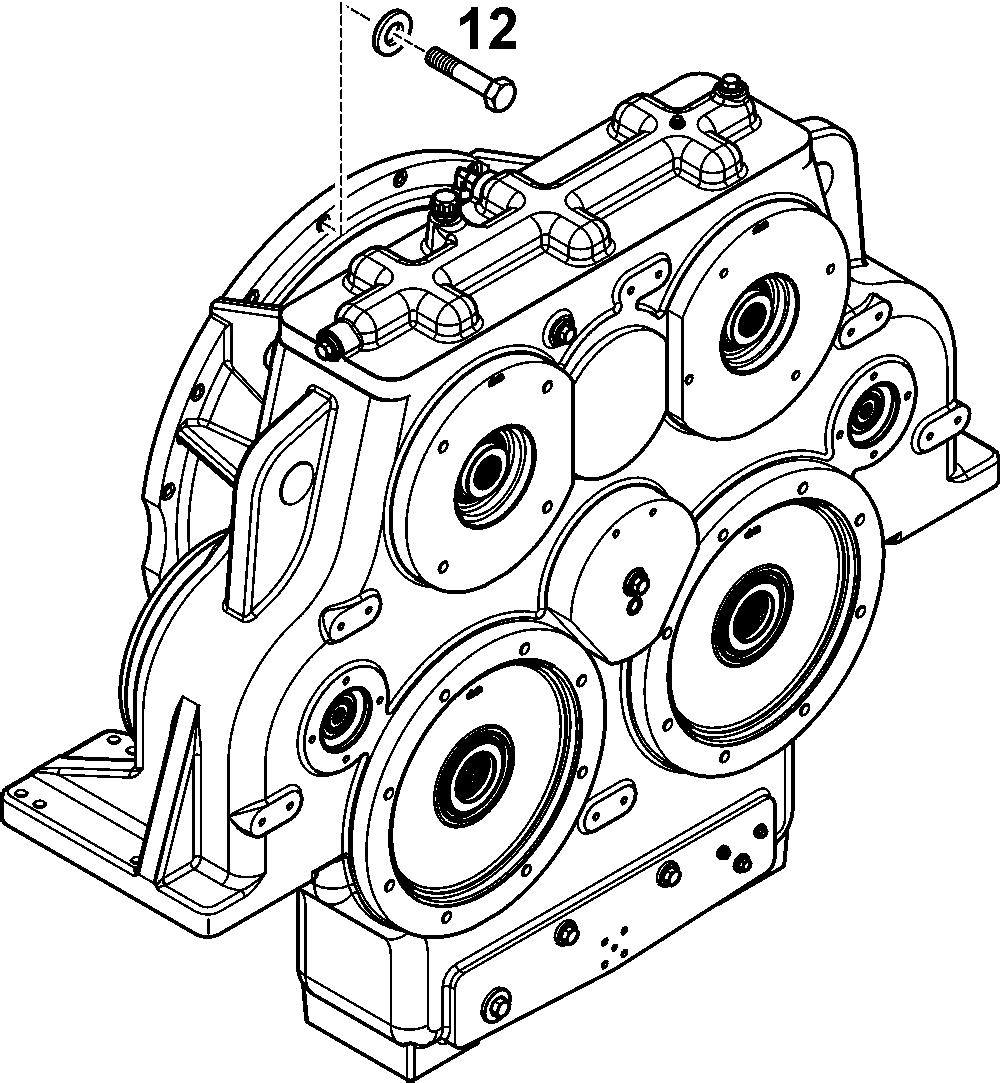

5.8Splitterbox

5.8.1Mounting screws

Mounting screws

Checkthemountingscrewsonthesplitterboxbracketsregularlyfortightness,retorque if necessary.

For maintenance intervals, see control and maintenance chart. Any improperfasteningwouldgreatlyreducetheexpectedlifeof therubbermounts.

Caution!

Loctite (Ident 8503598) must be applied on mounting screws 1 and 2 when installing the screws in orderto avoid possible damages on the parts.

Thescrews1and 2shallonlybetightenedafter themotorandthesplitterboxasa completeunithasbeenpositionedonthePowerPackframe,sothatapretentioning of the rubber mounting can be avoided.

5.8.2Elastic bedding

Thetworubberbuffers3 atthesplitterboxsidemustbecheckedandreplacedat regular intervals.

For maintenance intervals, see control and maintenance chart.

5.8.3Air filter

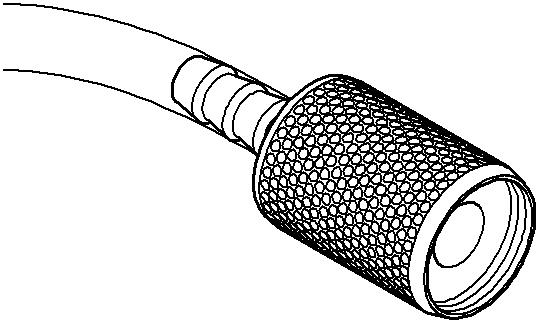

Fig. 5-24 Breather on splitterbox

Theairfilterinthesplitterboxbreather1mustbechecked,cleanedandchangedregularly.

To clean the air filter:

Open breather 1 by pushing it and turning it ¼ turn.

Remove filter from breather housing. Check filter condition and clean it with fuel.

Reinstall filter in breather housing.

Close breather 1

For check, clean and change intervals, see maintenance schedule.