3 minute read

Control and operation

stone, concrete and other breakable materials.

draulic ripper in the longitudinal direction of the machine and with the windshield closed or with a front protective grid.

retracted and that the stick is not in the vertical position.

performing retraction and extension motions of the hydraulic hammer. rupted for more than 15 seconds at a time to the same place. Change the breaking point. Too long uninterrupted operationofthehydraulichammerleadstoanunnecessaryoverheatingofthehydraulic oil.

lic hammer or of the hydraulic ripper to breakstoneorothermaterials.Donotmoveobstacleswiththehydraulichammer. Misuse of this nature would damage both the hammer and the machine.

thehydraulic ripper must beadjusted dependingon thenatureofthe ground and the excavator model.

Safe use of a ripper

cienttobreakoutrocks.Thus,theseapplications aremoreseverethaninnormal use.

theuseofarippercanresultinvibrations, shocks or stresses which are higher than in normal use. It may reduce the expected lifetime of structures and/or components.

vice.

ted by Liebherr, warranty for steel structures and machine components will be ceased.

Safe use when loading and unloading (particularly when loading and unloading wood)

attachment raised and the load lifted up; this applies, for example, when loading and unloading wood.

ewillbedisplacedupwardsinthevertical direction. The driving characteristics of the machine will thus be influenced persistently, e.g. through reduction of the dynamic stability. The following instructions are therefore to be observed at all times: red machinecharacteristics and environmental conditions.

noeuvres.

aking, accelerating and changing direction.

ed the upper structure to the driving position. nging movement and dropping of the load when the attachment is raised. cab.

there is a risk of objects falling from above.

s, such as logs, is dependent on length, diameterandspecific weight.Theinfluencingvariables present inanaturalproduct, such as moisture, must be noted.

ator to receive special instruction and training. processisonlypermittedwhenthemachineoperatorhas sufficient training and practical experience.

Safe useof machines with tower elevation

gravity of the machine will be displaced upwards in the vertical direction. The driving and work characteristics of the machine will thus be influenced persistently, e.g. through reduction of the dynamic stability.

themachinemustbealignedhorizontally before use. In horizontal alignment, the centre of gravity of the uppercarriage is over the centre of the undercarriage, which reduces the risk of tilting. nd tilt despite being aligned!

The following instructions are therefore to be observed at all times: When moving the machine: e undercarriage (transport position). holes and uneven surfaces jeopardize the stability of the machine. red machine characteristics (high centre of gravity) and environmental conditions.

noeuvres. rection.

direction in order to prevent unacceptable banking of the machine. slowly!

When loading and unloading: the uppercarriage out of the transport position. act surface of the support (load carrying capacity of the substrate). A support subsiding would have disastrous consequences!

as close as possible to the machine (Caution! swinging grab) and hold the load close to the undercarriage and above the substrate.

Protection from vibration

andmethodofuse.Thefollowingparametersinparticulararedecisiveinfluences: selects the speed, gearbox ratio, working method and route himself. This means that there is a wide range of different vibrational loads for the same machine type.

Speed, steering, brakes, control elements when driving and working.

Whole-bodyvibrationalloadforthemachineoperatorcanbereducedifthefollowing recommendations are observed: s andauxiliary devices for eachpart of the job. and height of the operator. structions. chine, particularly with respect to: tyre pressure, brakes, steering, mechanical connections etc. ment jerkily. chinespeedtosuittherouteasfollows: calculate in sufficient time to carry out any work required. able) which reduce vibration for machines that are driven frequently. If such auxiliary systems are not available, regulate speed to avoid "oscillating" the machine.

(i.e. for earth-moving machinery such as hydraulic excavators, this should be a seat which corresponds with EN ISO 7096).

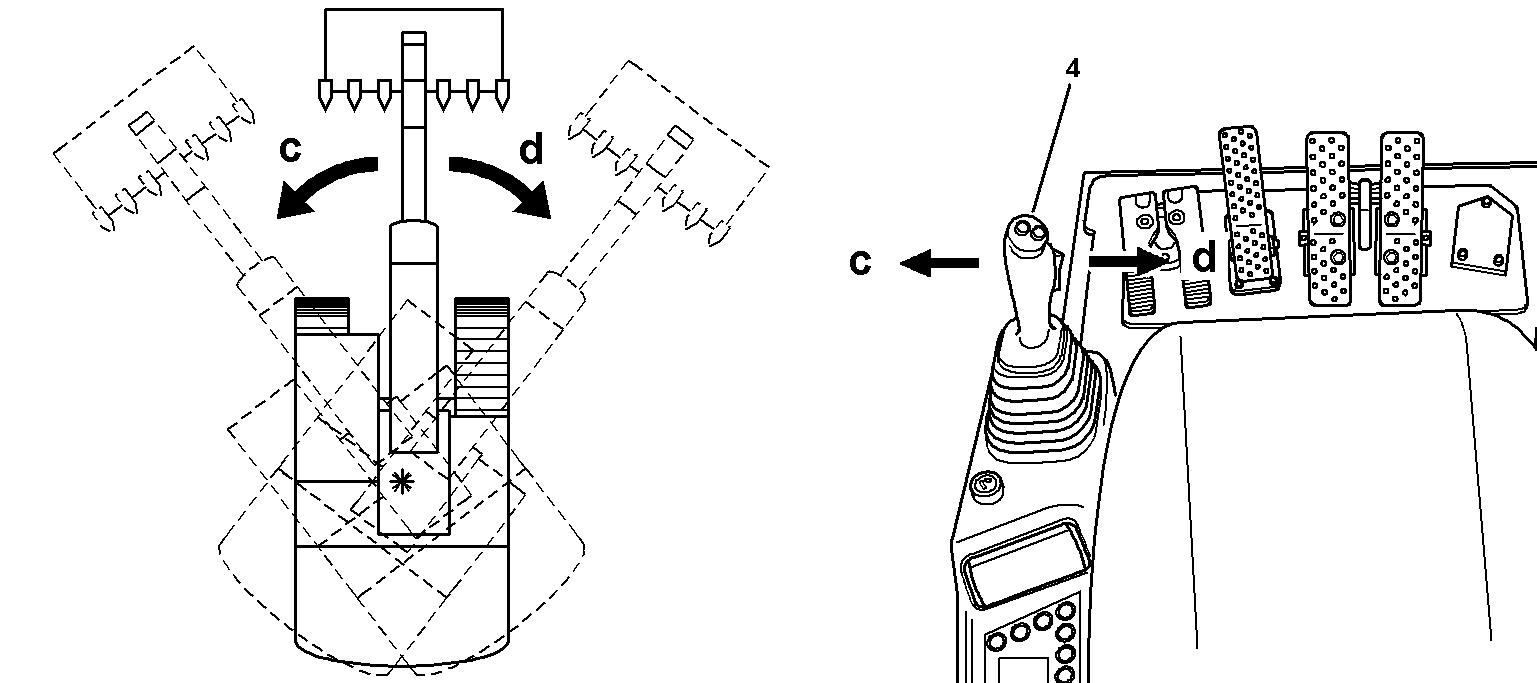

3.4.1Uppercarriage swing movements

The swing movements of the uppercarriage are controlled by the left joystick.

Fig. 3-64 Rotating the uppercarriage

Push the left joystick to the left c: The uppercarriage rotates to the left. Push the joystick to the right d: The uppercarriage rotates to the right.

Braking the uppercarriage

Themachineisequippedaswellwithanhydraulicaswithamechanicalswingbrake.

The hydraulic swing brake

Let the left joystick move back to neutral position. The hydraulically swing braking of the uppercarriage takes place. In normal working conditions, the braking efficiency is sufficient to bring the uppercarriage to a standstill rapidly.

Move the left joystick in the opposite direction. The maximum hydraulic braking action of the uppercarriage is achieved.

The mechanical swing brake

Themechanicalbrakeisanegativelyactingmultidiscbrakewhichisintegratedinthe swing gear. It allows to stop the uppercarriage in any desired position (for parking, when working on a slope, ...)

Press "Swing brake" button S17 Swing brake is applied. LED in the button illuminates.

Press button again. Swing brake is released. LED in the button goes out.

Caution!

Thebrakeonlyapplieswhentheuppercarriageisnearstandstillandifnoswingmotion is actuated with the joystick.

To stop the uppercarriage when working on a slope:

Use the joystick to reduce the uppercarriage speed. Press button S17 to operate the swing brake.

Move the joystick back to "0" position only after the brake operates.