62 minute read

system

5.14.1Low and high voltage circuit

Danger!

For any maintenance or repairnearthe LOW andHIGH VOLTAGE circuit,personnelhavetobecertifiedandqualifiedaccordingtotheircompetencesandauthorized bytheir employer to work on anelectrical installation. Current practices have to respect local safety regulations for electrical installations (wear of adapted PPE, works on electrical installation, lockout procedures, etc...).

Always use adapted tools for the voltage.

Any work or maintenance on the LOW and HIGH VOLTAGE circuit or boxes must be done with power totally disconnected and the concerned electrical circuit must be locked out according to local regulations by the electrician.

For any repair for a fault with HIGH VOLTAGE > 1000V, the excavator must be completelydisconnectedfromthenetwork.Onlyelectricalpersonnelareallowedto operate according to local regulations.

ForanyrepairforafaultwithLOWVOLTAGE<1000Vtill24V,minimumapproach distanceforanyconductiveobjectmustbeobserved.Forlowtensionelectricalcabinetandrepairwithpowerswitchedon,electricalpersonnelareunderobligationto disconnect any accessible conductive object and to border the working area with banner, safety nets, fences, etc...

5.14.2Standby heating supply

By pushing the button S184 («Control OFF») inside the cabin or any emergency switch, main breaker Q2A in high voltage electrical box S1 will open. High voltage stillsuppliesS1transformerT5Mforanti-condensationheatersandfor-40°Cheating system (optional).

Danger!

Standbysupplypresenceonmachine.Beforeanymaintenanceorworkonelectric HV/LV installation, the electric supply of the machine must be totally locked out at field switch.

Standard lockout procedure to disconnect totally the excavator: Locate power station supply and distribution. Stop excavator, disconnect excavator from the network at field switch. Check voltage presence on excavator supply line. Earth and short-cut the supply line. Lockout and tag out at field switch. Identify (i.e. check that ignition of Open S1. Open Q1A manual switchand use red lever to earth the uppercarriage. Close S1 and keep key in a safe place.

5.14.324V circuit

To ensure trouble free operation of the excavator, the electrical system must be in good condition. The gauges, indicators and components of the electrical system should be checked regularly for proper function (refer to «Control and maintenance chart»).

Always replace burnt out fuses and bulbs. Do not repair fuses. Check for bare and damaged wires, whichcould cause damage to the electrical system or a fire. Check for loose, dirty or corroded connections.

5.14.4Notes on the electrical system

Danger!

Risk of injury due to formation of sparks. Avoidsparksandnakedflamewhenchargingbatteriesorworkingonthebatteries.

Always wear protective goggles and gloves.

Burnt-outfusesandbulbsshouldbereplacedimmediatelywhenthecauseofthe defect has been corrected.

Correct defects such as loose connections, abraded cables or badly fastened clamps immediately.

Disconnectthebatterieswhen workingontheelectricalsystem orwhencarrying out electric arc welding on the machine.

Danger!

Risk of injury due to formation of sparks. Disconnect the negative terminal (-) first and connect it last.

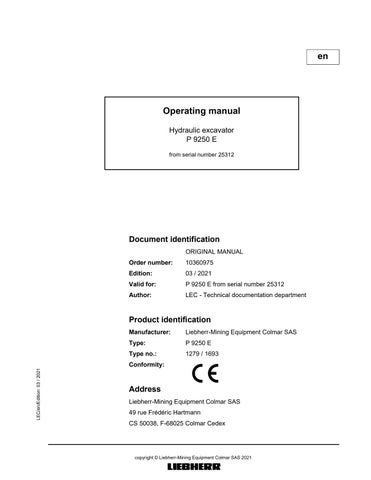

5.14.5Main battery switch

Caution!

Take particular care with machines with built-in independent heating. Only switch off the main battery switch is over.

5-51 Main battery switch

Before starting any work on the electrical system, including welding work on the machine, switch the main battery switch to position 0

Whenwashingthemachine,covertheelectricalunits(particularlythegenerator, cabling, electronic components and measured value sensor) to prevent water penetrating.

Note!

Batteries can become flat if the machine is out of service for longer periods. Beforelayingupthemachine forlongerperiods,switchthemainbattery switch to position 0 (off).

5.14.6Battery care

Thebatteriesmustalways bekeptcleantoensurethattheyareabletofunction perfectly.

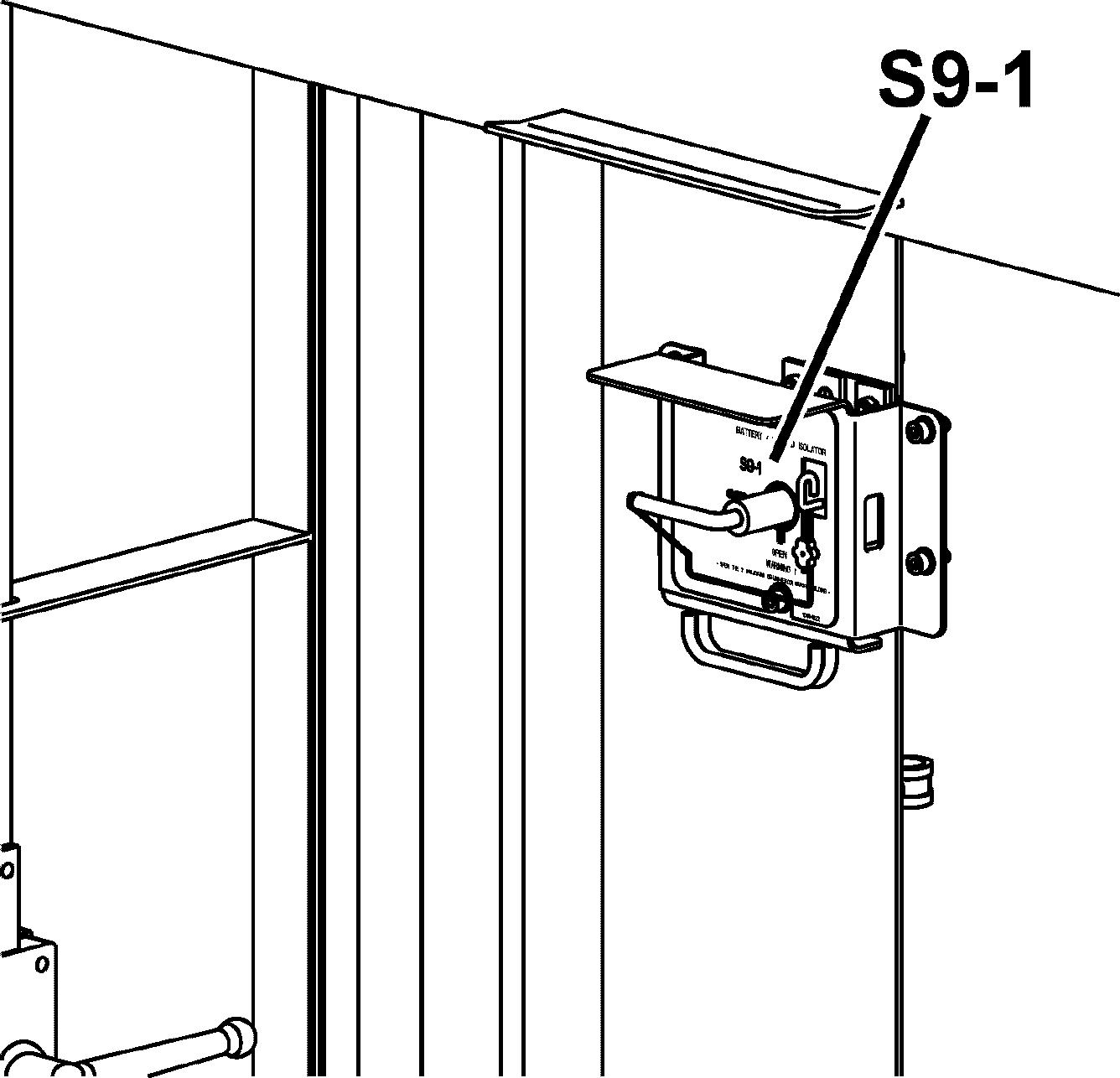

Particularcareshouldbetakentocleanthepoleendsandcableterminals A regularlyandtothencoverthemwithathicklayerofacidproofgrease(seeFig.5-52).

Danger!

Bent rubber hoses on the central gas outlet increasethe risk of explosion! Thehydrogencontainedinthebatteriesshouldnotbeallowedtobuildupintheaccumulator box and must be able to escape via the rubber hoses. The central gas outlet hoses must be routed without kinks.

Check the condition of the hoses regularly, particularly after installing a battery (see Fig. 5-52).

The fluid level in the cells should be 10 to 15 mm above the top of the plate. Only distilled water must be used for any refilling.

5-52 Battery care

From time to time, measure the acid concentration C using an acid tester. When the battery is fully charged, the unit weight is 1.28 kg/l (31.5°Bé).

Ifthe acid tester displaysa lower value,thebatteries arevirtually flat and should be charged if necessary.

5.14.7Electrical components location

5.14.8Electrical boxes and cab pressurization

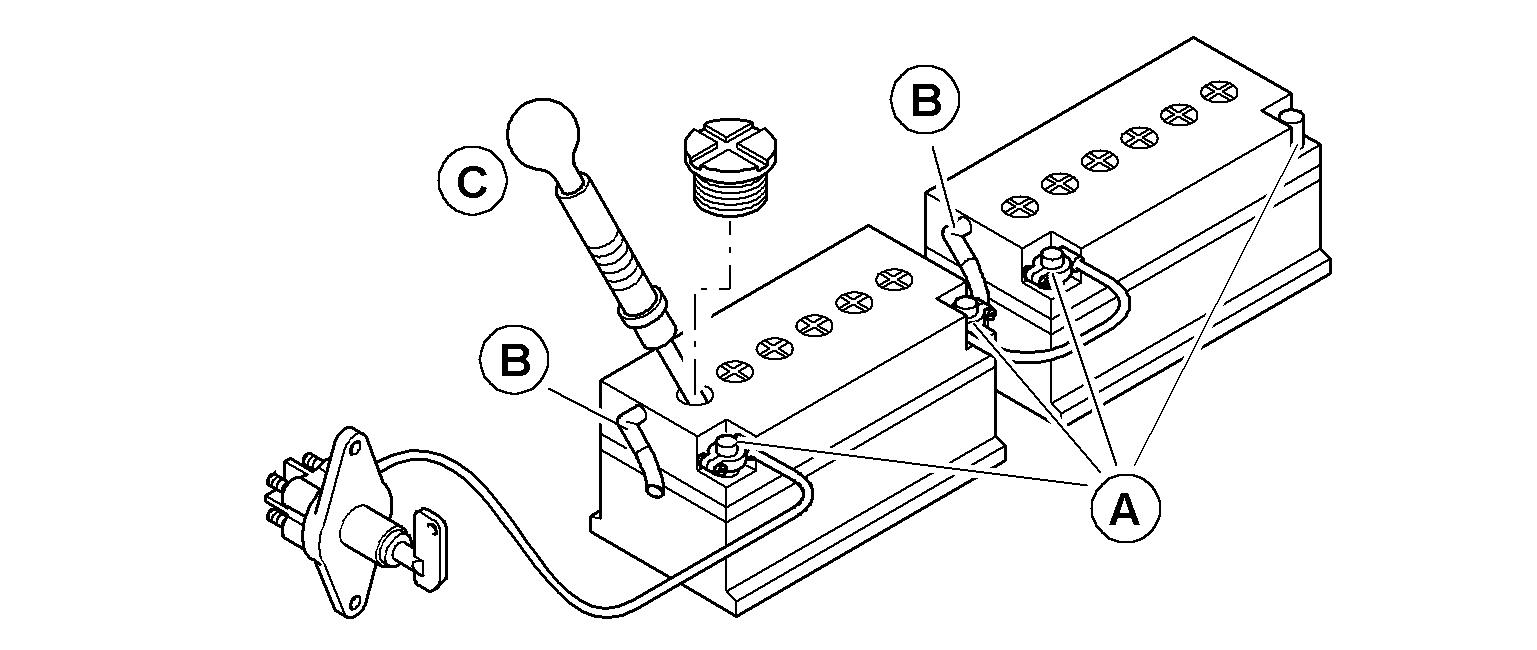

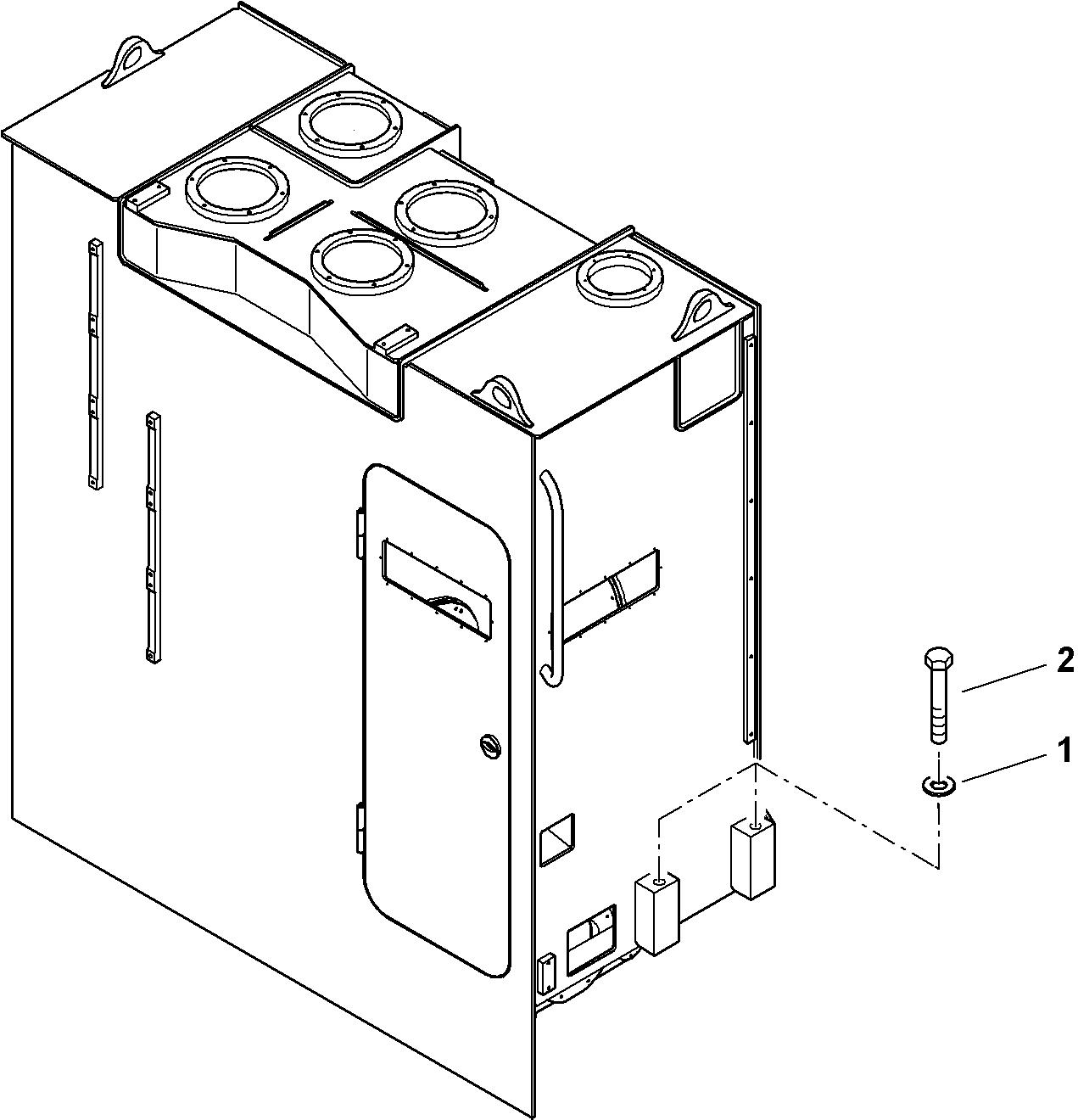

The aeration devices are installed as follows:

The air filters for electrical boxes and cab pressurization must be cleaned regularly. Clean the air filters: Press to open the dust discharge valve 5. Replace the main element and the safety element of the air filter system. For maintenance intervals, refer to the «Control and maintenance chart».

5.15Heating/air-conditioning system

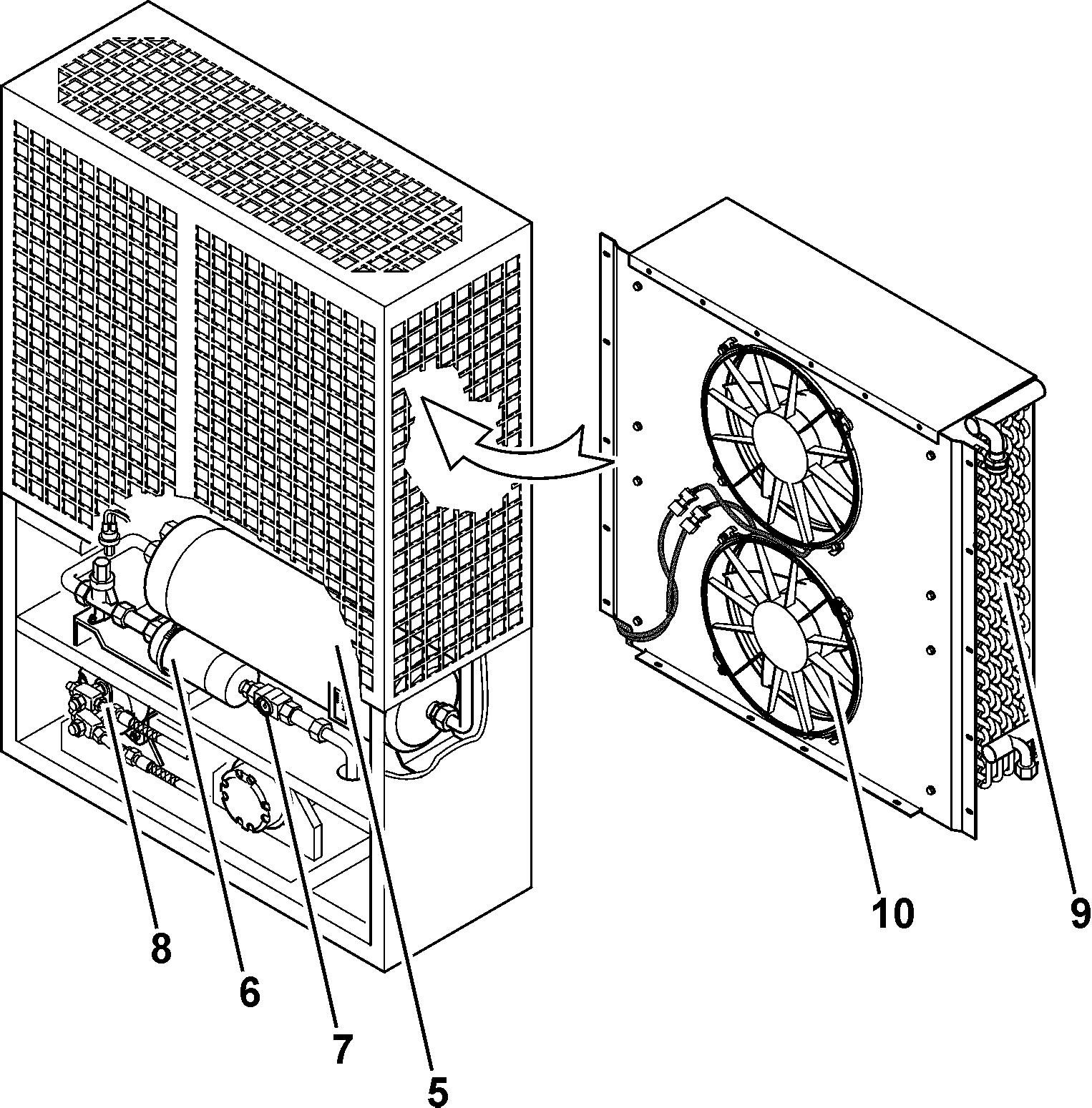

The excavator has a heating and an air conditioning system as standard. The heating system operates with a heater under the cab floor. The air conditioning system has the elements that follow:

Note!

Incaseofrepairatcondenserorreceiver,therefrigerantmustberemovedandcollected in an applicable tank The collectedrefrigerant can be cleaned and re-prepared by refrigerant manufacturers.

For maintenance intervals, refer to the «Control and maintenance chart».

5.15.1Heating system

Iffiltersaredirty,theairflowinbothheatingandairconditioningsystemsisreduced. This results in the forming of frost and system shut-off.

Removeandcleantheheatexchanger2andthefreshairfilter3atintervalsspecified in the «Control and maintenance chart».

Do not operate the machine, even briefly, without the filters 3 because, in this case, the heat exchanger 2 will quickly become blocked.

Clean and change the fresh air filter: Remove the fresh air filter 3

Note!

Never wash the filter elements with hot water or a steam jet. Never wash the filter elements with acids or aggressive solvents. If damaged or in a bad condition, replace the filter elements.

Clean the filter elements.

The container which is filled with the coolantmixturefor theheater is installed in the cab elevation.

Fill the container with coolant mixture: Remove the filler cap 1 to add coolant mixture. Forcoolantmixturespecificationsandquantity,refertosection«Operatingmaterial chart».

The heating system has also a preheating unit installed in the cab elevation which makes the coolant mixture warm.

No maintenance is necessary for the preheating unit. Butiftheheatingsystemisstoppedforalongtime,makesurethatthepreheating unit (with pump) stays always filled with coolant mixture or preservative fluid.

5.15.2Air-conditioning system

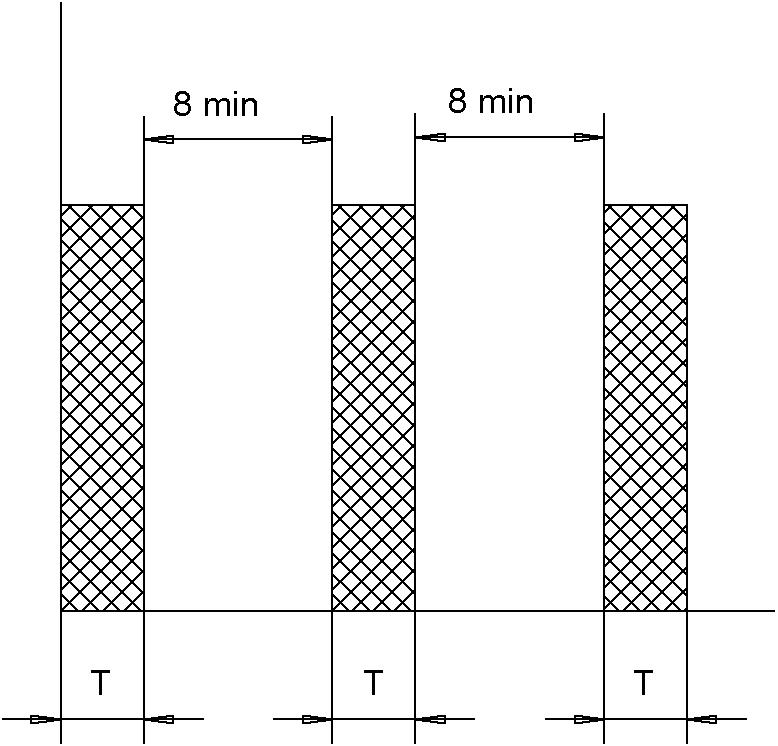

Switch on the air conditioning system for approximately 10 minutes every 2 or 3 weeks, regardless of the season.

During the warm season, perform checks or maintenance works that follow:

Filter check:

Check and clean the recirculated air filter 2 located in the roof of the cab.

Air conditioning unit check:

Check condition of receiver 5 and filter/dryer 6

If there is corrosion, rust or mechanical damage formation on the receiver 5 (on mountingconsoles,connectingparts,...),itmustbereplacedimmediatelybyreasonsofexplosions.Whilereplacing,takecareofthemountingdirection.Theexit is marked with an "A" and the top side is marked with "OBEN".

Replacethefilter/dryer6atregularintervals,atleastonceayear.Itmustbealso replaced after each opening of the refrigerant circuit. The arrow symbols on the filter/dryer must be in the direction of the expansion valve.

Inaddition,therefrigerantchargeofthesystemmustbecheckedatregularintervals,byobservingthesightglass7whiletheairconditionerisoperating.Bubbles or foam in the sight glass 7 indicate an insufficient refrigerant charge.

In this case, the system must be checked and refilled by a trained specialist. Checkthecolouroftheindicatorinthesightglass7.Iftheindicatorbecomesyellow,itmeansthatthereistoomuchhumidityinthesystem.Replacethefilter/dryer 6 immediately by a trained specialist.

Checkmounting bolts fortightness

Check condition of fans 10 and replace if necessary (defective fan). The fans must be free of dirt and damages.

Check the condenser battery 9. If necessary blow it out with pressurised air or steam, from the inner side (fan side) to the outside.

Check for possible damages on the compressor 8

Check compressor fastening.

Check condition, alignment and tension of V-belt.

5.15.3Additional maintenance operations

Check operation of evaporator blowers and condenser fans. All blowers have to be in working order in order to avoid air short circuit.

Check electric installation.

Check all hose fittings and couplings for leakage.

Check setting and function of defrosting thermostat at the evaporator coil. Checkcompressorpressureswitch.Ifthepressureatthecompressoronthelow pressure side is too high, the compressor pressure switch lights up an indicator lamps. This means that the compressor is not working well.

5.16Check mounting bolts for tightness

The mounting bolts listed below must be regularly checked and re-tightened if necessary.

Refer to «Control and maintenance chart» for checks intervals.

Note!

WheninstallingboltsofsizebiggerthanM40thethreadofthescrewmustbeslightlycoatedwithaMoS2basedgrease.Alsogreasetheboltheadsupportingsurface, unless hereafter otherwise specified.

Danger!

Due to their size, most of the below listed mounting bolts require, to be tensioned totheprescribedtorque,theuseofaspecial,hydraulicorelectricactuatedtensioning device.

Thesehightorquetensioningdevices are power tools,whichmust beoperatedby trainedmechanics,knowingthesafetyprecautionsedictedbythetoolmanufacturer and that must be observed to avoid accidents or personal injury.

Inparticular,payattentiontochoseasolidandsecurereactionpointforthetooland position the reaction arm during operation. Keep clear of the reaction arm during operation; if it must be held or steadedduring operation, use alternative means of securing the tool during operation.

Caution!

The mounting bolts of the main components (especially the bolts listed below), of thehydraulichosesandofthecounterweightmustbereplacedaftereveryremoval.

Checkmountingbolts for tightness

5.16.1Mounting bolts of the counterweight

The eight mounting bolts 5 (M42) must be torqued to 4810 Nm.

Note!

Greasetheheadandthreadof thescrew andthetwosidesof the washerwithMo-

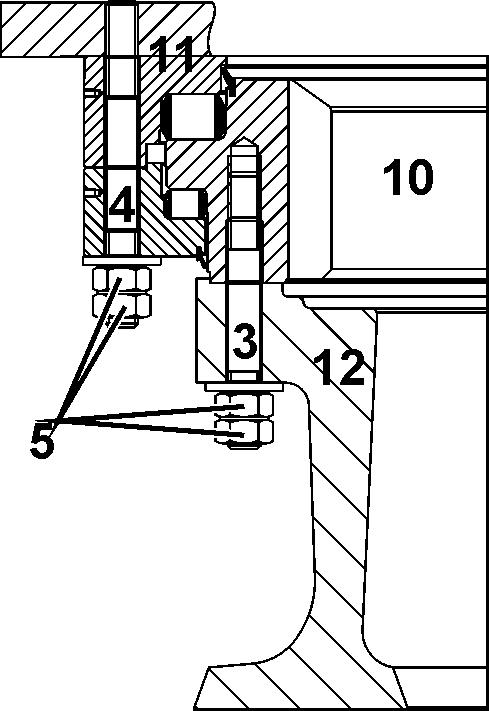

5.16.2Threaded studs of the swing ring

The threaded studs 4 (M36) for the mounting of the swing ring 10 to the uppercarriage 11 must be tensioned to 707,5 kN.

The threaded studs 3 (M36) for the mounting of the swing ring 10 to the undercarriage 12 must be tensioned to 707,5 kN.

Torque the lock nuts 5 on the studs 3 and 4 to 600 ± 100 Nm.

To get the correct stud tension, you must use the special tensioning procedure and tool (LIEBHERR recommends that you use the special tensioning cylinder ID. 5617448 at the required hydraulic pressure of 1350 bar, or that you use the tool ID. 10444128 at the required pressure of 1500 bar).

Danger!

Thespecialtoolmustonlybeoperatedbyqualifiedpersonnel,especiallytrainedfor the use of this high pressure tensioning device and aware of the operating instructionsaswelloftherecommendationsforaccidentanddamagepreventionconcerning this tool.

Useappropriateworkingplatformsandliftingdevicesto install andhold inposition the special tool while tensioning the studs.

5.16.3Mounting boltsof hydraulic tank

5.16.4Mounting bolts of Powerpack

Refer to section «Electric motor», in this chapter.

Checkmountingbolts for tightness

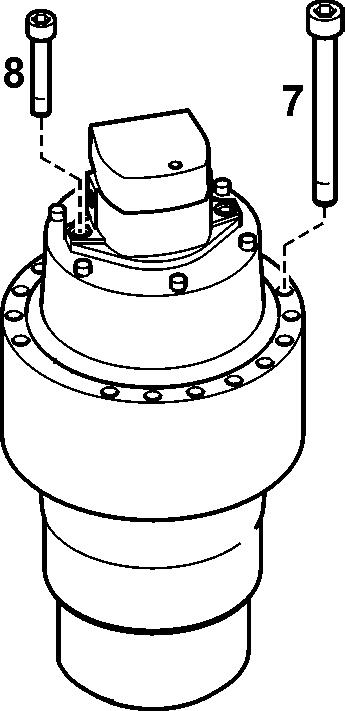

5.16.5Mounting bolts of the swing gear and motor

The mounting bolts 7 (M30) of the swing gear must be torqued to 1900 Nm. The mounting bolts 8 (M24) of the swing motor must be torqued to 960 Nm.

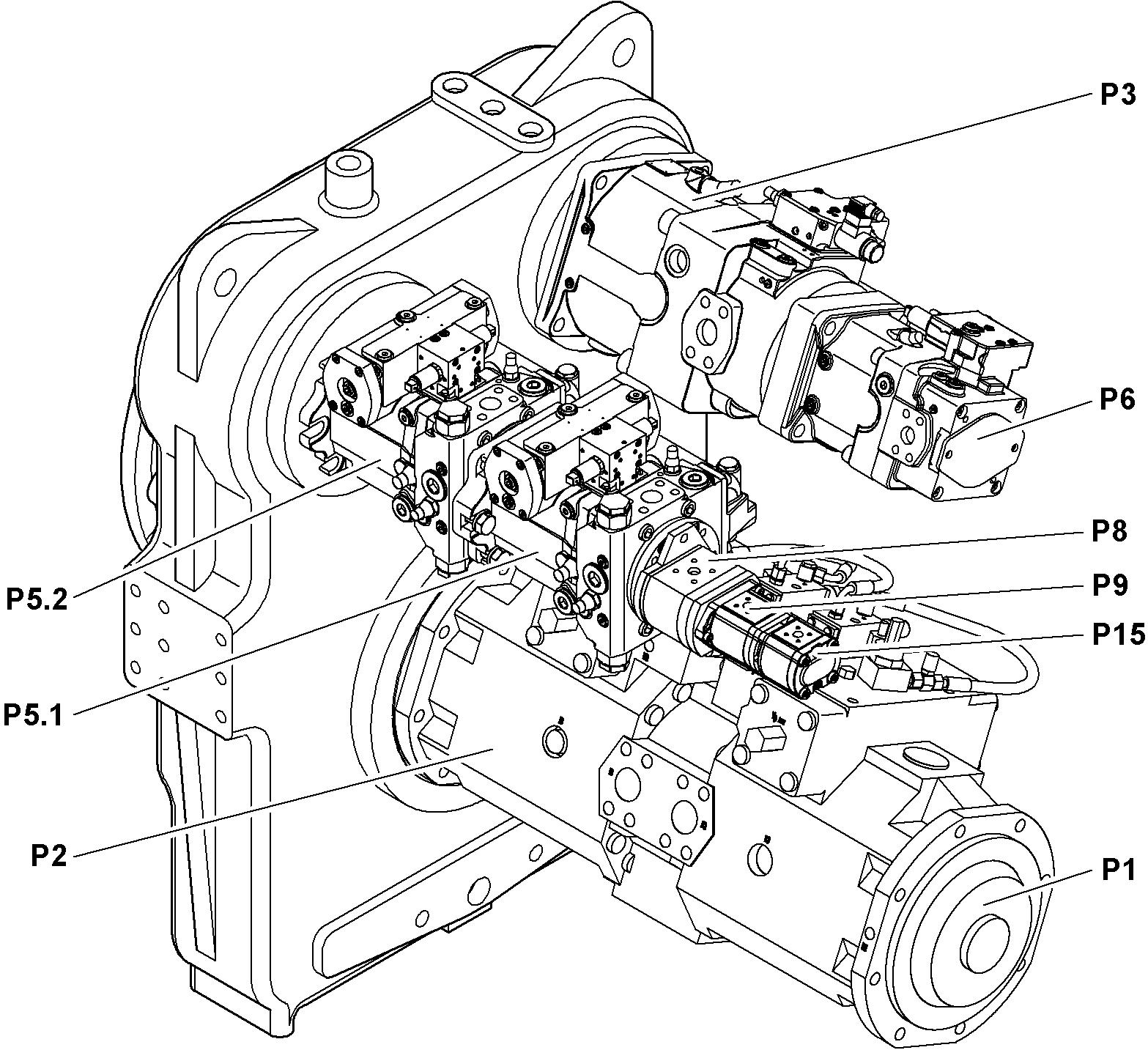

5.16.6Mounting bolts of hydraulic pumps

Checkmounting bolts fortightness

ThemountingboltsM20ofthemainworkingpumps (P1and P2)mustbe torquedto 425 Nm.

ThemountingboltsM20ofthemainworkingpump(P3)mustbetorquedto425Nm. ThemountingboltsM20oftheswingpumps(P5.1andP5.2)mustbetorquedto425 Nm.

ThemountingboltsM20oftheoilcoolerfanpump(P6)mustbetorquedto425Nm. The mounting bolts M20 of the lubrication, pilot oil and filtration pumps (P8 and P9 and P15) must be torqued to 85 Nm.

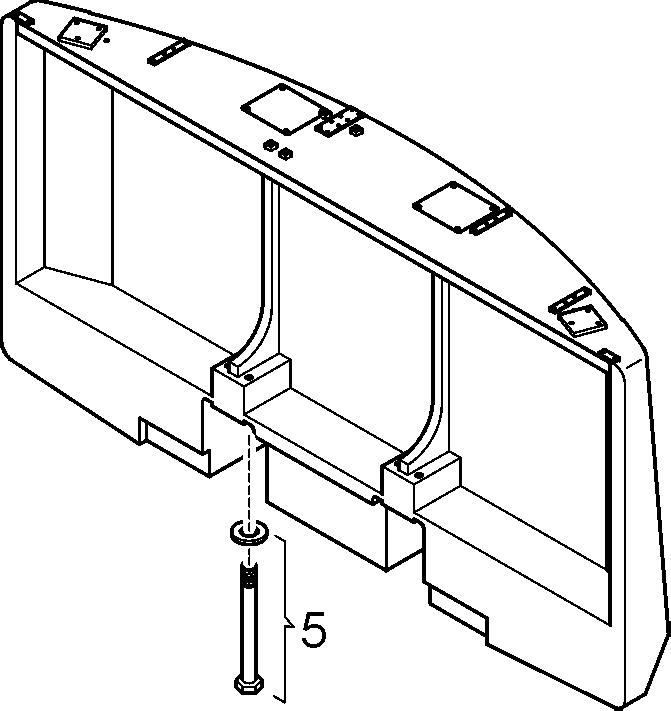

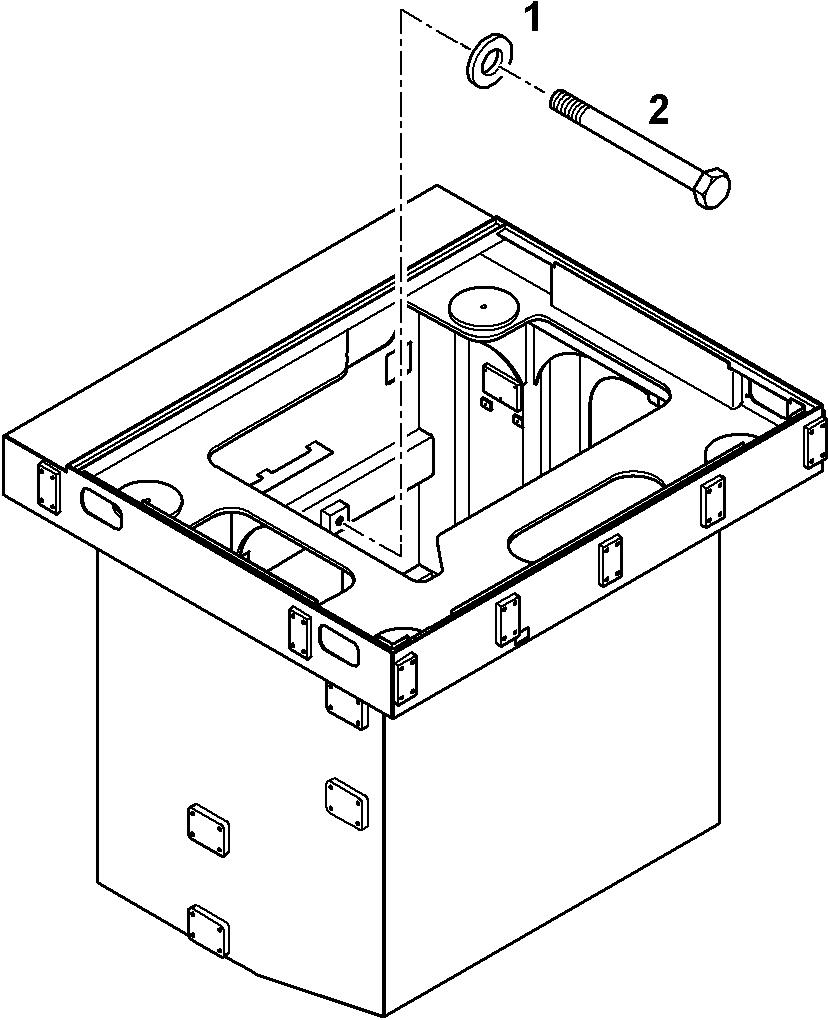

5.16.7Mounting bolts of the cab

cab

Note!

Torqueforscrew21isgivenforinformationonly,becauseitisnotaccessiblewhen the cab is mounted.

TorqueQuantity

1 Cab mount4

12 Screw M16x70270 Nm12

21 Screw M16x45270 Nm12

26 Screw M16x70270 Nm16

A Test distance

Also measure distance A, that is the total height of cab mounts 1

If distance A is smaller than the minimum permitted distance of 134,5mm:

Checkmountingbolts for tightness

Replace the mount. The tool you use must have a minimum precision of ±0,25mm. For maintenance intervals, see control and maintenance chart.

5.16.10High voltage electrical box S1

5.16.11Elastic elements mounting bolts

1 Stud M48 x 1126457 kN2700 Nm45

The studs 1 can be tightened using the tension or the torque tightening method. In both cases, obey the related prescribed value given in the table above.

5.17Swing gear brakes

The swing gear brakes are spring-applied, pressure-released multi-plate brakes. Theyareventilatedhydraulicallyandarefullysealedandintegratedintheswinggear transmission.

Their usage purely as parking brakes makes them wear-free and therefore maintenance free.

5.18General maintenance points

5.18.1Replacing working parts

Inadditiontothenormalmaintenanceandrepairworkthatistobecarriedoutatthe givenintervals,themachineoperatorandmaintenancepersonnelcanalsocarryout the repairs referred to below: draulic unit connections (not, however, on pressure relief valves which are lead sealed at the works). lic lines and bolt connections on the hydraulic system can be replaced.

It should be noted that only original Liebherr replacement parts are to be used. This is particularly relevant for hoses and hydraulic lines, which must be preassembled at the works. For all other repairs, particularly when dismounting the counterweight, works and dealership fitters are to be consulted.

5.18.2Welding work on the machine

Welding work on all main components serving the power transmission (such as the chassisframe,rotatingplatform,equipmentpartsetc.)mayonlybecarriedoutbythe manufacturer or by an authorized workshop.

Disconnect the batteries before starting any electric arc welding work on the machine.

Always disconnect the negative terminal (-) first and reconnect it last. Switch off the main battery switch!

Neverthelessifweldingrepair shouldbedoneoncomponentswhichmaycontaininflammablegases (welded counterweight,hydraulictank, fuel tank, ...) these components must be previously and sufficiently ventilated with pressurized air to avoid all fire or explosion hazard.

Caution!

Ifhighcurrentsflowthroughthebearingsorsealingelements,thesecouldbeburnt. Move the earthing cableof the welding tool as close as possibleto thewelding surfacesothattheweldingcurrentcannotflowoverpartsliketheswingring,rotary connection, gears, bushings, bearings, hinges, joints, hydraulic hoses, sockets, rubber parts or seals.

5.19Control and maintenance chart

Caution!

Careful maintenance can only be carried out when the machine is clean. Visual checks such as crack testing are only applicable on a clean machine. Clean the machine before you start maintenance work (see also the chapter

Caution!

You must do the weekly additional maintenance tasks. Liebherr recommends that you schedule this maintenance interval carefully.

Note!

If you find damage(s) on structural components (boom, stick, bucket, central part, side frames, rotating deck, hydraulic tank, fuel tank or cabin) please fill out the «Structural Inspection» form in Service Manual - Chapter 4 In addition:

- a visual inspection is required every 500 hours, - a detailed inspection is required every year or at least every 7500 hours.

5.19.1General information

The following maintenance chart will help you to do the adequate maintenance on your excavator.

It is mandatory to follow these maintenancecharts, to keep your excavator into best and safe condition.

The pre-requisite to any claim to Liebherr for operation issues or warranty, is that these maintenance charts are strictly followed and recorded.

Itismandatorytofollowtheserequirementsinordertokeepyourexcavatorsafe,efficient andalsoforwarranty reason.Liebherris not responsibleincase ofdamage if the maintenance requirements are not correctly followed. Moreover, your machine may not be running as efficiently and productively as it could be.

For lubricants and operating fluids, refer to the Operating Manual chapter 5.3.

Two types of inspection

Visual Check riorarea,installationorassemblytodetect obvious damage, failure or irregularity. This level of inspection is made from within touching distance unless otherwise specified. A mirror may be necessary toensurevisualaccesstoallsurfacesintheinspectionarea.Thislevelofinspectionismadeundernormallyavailablelightingconditionssuchasdaylight,hangar lighting, flashlight or drop-light and may require removal or opening of access panels or doors. Stands, ladders or platforms may be required to have safe access to the area being checked.

Detailed Check item, installation or assembly to detect damage, failure or irregularity. This examination may require the use of specialized inspection techniques and/or equipments. Surface cleaning and elaborate access may also be required.

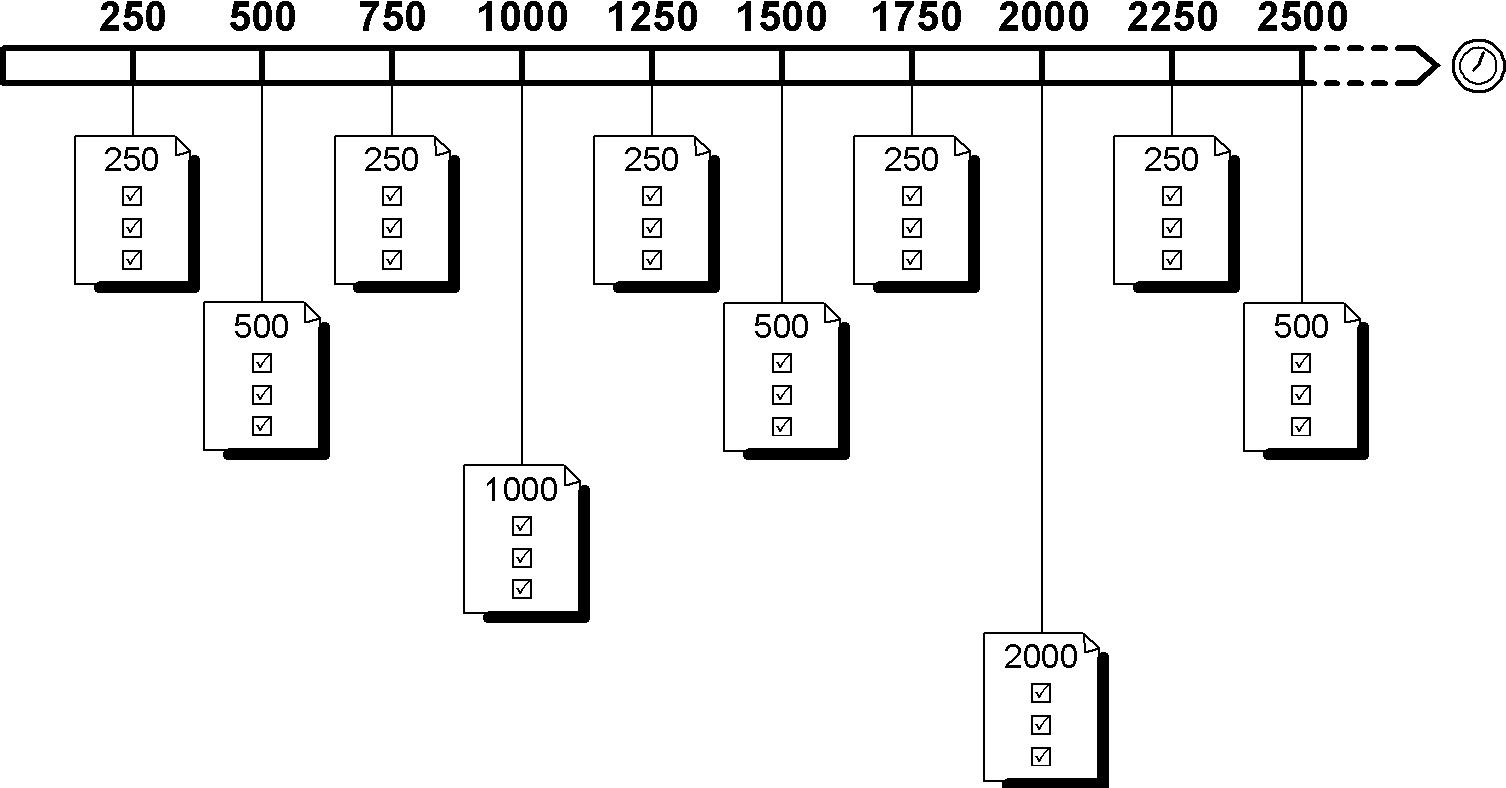

5.19.2How

To Use The Maintenance Chart

The following maintenance chart is split in 5 individual check lists:

Intervals:

00 hours, 7000 hours, ... 00 hours, 8000 hours, ...

Examples:

At 750 hours you must follow the 250 hours maintenance chart.

At 2500hours you must follow the 500 hours maintenance chart.

At 3000 hours, you must follow the 1000 hours maintenance chart.

At 6000 hours, you must follow the 2000 hours maintenance chart.

Serial Number: Fleet Number: SMU HOURS: Travel Hours:

5.19.3Daily Maintenance Schedule - P 9250 E

Completed by:

Work To Be Performed Daily

Check for first and only interval or Check for repeat interval

GENERAL HYDRAULIC SYSTEM

Doavisualcheckofall hoses,pipesandfittings foranyexternaldamage or leakage

Do a visual check of the hydraulic components for leaks and/or damages

Doa visual check of thehydraulic cylinder rods forleaks and good condition

General Fastening

General hydraulic: Do a visual check for missing, broken or loosen mounting screws of all hoses, pipes, fittings and clamps, tighten if necessary

Attachment: Do a visual check for missing, broken or loosen mounting screws of the handrails, pin covers fastening and greases connections, tighten if necessary

Uppercarriage:Doavisualcheckformissing,brokenorloosenmounting screws of the counterweight, tanks, Powerpack, control valve console, cab, cab elevation, high and low voltage boxes, catwalks, handrails, grease box, ladder, tighten if necessary

Swing gear: Do a visual check for missing, broken or loosen mounting bolts of the swing gear and hydraulic motors, tighten if necessary

ATTACHMENT

Do a visual check of the bucket teeth and wear kit for wear

Do a visual check of the grease supply at each lube point

Do a visual check of cable harness and sensors for damage

UPPERCARRIAGE

Do a visual check of the service trap for leaks or damage

Do a visual check of oil or grease for leaks

SWING GEAR

Do a visual check of the swing gears for leaks and oil level in expansion tanks

Centralized Lubrication System

Perform a complete daily maintenancegivenintheSKF /LincolnOperating Instructions

Work To Be Performed Daily

Check for first and only interval or Check for repeat interval

Do a check of the grease tank level

Electric Motor And Splitterbox

Check voltage / load gauges and lights into the cabin

Check oil level in the splitterbox

Check oil level in hydraulic tank

Hydraulic System

Clean magnetic rods of the leak oil filter (daily during the first 250 hours)

Clean magnetic rods of bypass filter (daily during the first 250 hours)

Electrical System

Presstoopendustdischargevalveonaerationdevicesforcabinandelectrical boxes

Fire Fighting System

Doavisualcheckofthefirefightingsystemcondition(refertothefirefighting system documentation)

- If any issue contact fire fighting local dealer

Follow the inspection intervals recommended by the specific Health and Safety rules existing in country and/or on mine site

START THE MOTOR TO CHECK THE FOLLOWING ACTIONS

General: Maintenance work must include the check of the correct functions of hydraulic and electric systems before starting operation

Attachment:Checkfunctionoftheworkingattachmentlubricationsystem during operation

Attachment: Check if the damping system on equipment is working correctly

Uppercarriage: Check position of the hydraulic shut-off valve

Swing Gear: Check function and operation of the swing brake

SwingRing: Check functionoftheswing ringbearinglubrication system during operation

Swing Ring: Check function of the swing ring teeth lubrication system during operation

Electricalsystem:CleanandcheckLCDscreenofthedisplayforproper function when starting

Electricalsystem:Checkindicatorlightsandgaugesonthecontrolpanel when starting

Work To Be Performed Daily

Check for first and only interval or Check for repeat interval

Electrical system: Check for warning and fault messages on display (monitoring,grease,airconditioning,...).Ifnecessaryrefertochapter4in the Operating Manual to identify and rectify faults and errors.

Cabin: Check if the safety lever is working properly

Cabin: Check the horn

Cabin:Checkforgreenflashlightoncontrolmoduleiffirefightingsystem is installed

Weekly Check These Steps In Addition To The Daily Requirements

UPPERCARRIAGE

Check level in reservoir for windshield washer, refill if necessary

CENTRALIZED LUBRICATION SYSTEM

PerformthecompleteweeklymaintenancegivenintheSKF / LincolnOperating Instructions

ELECTRIC MOTOR AND SPLITTERBOX

Doa visual check of the air flow, clean the inlets from thecooling system if necessary

HYDRAULIC SYSTEM

Cleanmagnetic rodsofallreturnfilters(weeklyduringthefirst250hours)

Do a visual check of the hydraulic tank air filter, clean if necessary

ELECTRICAL SYSTEM

Doavisualcheckoftheheadandfloodlight,cleanandadjustifnecessary

Do a visual check of the wiring system for damage

Check the emergency stop on the power station

Check the emergency stops on the excavator

HIGH / LOW VOLTAGE SYSTEM

DoavisualcheckoftheinsideboxesS1andS2fordustandcomponents condition

ForPersonalProtectiveEquipmentinspection,refertothePPEdocumentation

Work To Be Performed Daily

Check for first and only interval or Check for repeat interval

CheckInitials

CABIN, CABIN ELEVATION AND HEATER AIR/CONDITIONER

Operate air conditioner every week for 10 minutes

Visual check condenser unit and evaporator filter

Check refrigerant level, if necessary refill circuit

Do a detailed check of the V-belt tension for air conditioner

Comments

Work To Be Performed Daily

Check for first and only interval or Check for repeat interval CheckInitials

General comments:

Serial Number: Fleet Number: SMUHOURS: Travel Hours:

5.19.4 250 Hours Maintenance Schedule - P 9250 E

Completed by: Dateand Signature:

WORK TO BE PERFORMED AT 250, 750, 1250 HOURS, ...

Check for first and only interval or Check for repeat interval

GENERAL HYDRAULIC SYSTEM

Doavisualcheckofallhoses,pipesandfittingsforanyexternaldamageorleakage

Do a detailed check for good condition of pipes, hoses, clamps and fittings for damage and leakage

Do a visual check of the hydraulic components for leaks and/or damages

Do a visual check of the hydraulic cylinderrods for leaks and good condition

GENERAL FASTENING

General hydraulic: Do a visual check for missing, broken or loosen mounting screws of all hoses, pipes, fittings and clamps, tighten if necessary

Attachment: Do a visual check for missing, broken or loosen mounting screws of thehandrails, pin covers fastening andgreases connections,tightenif necessary

Uppercarriage: Do a visual check for missing, broken or loosen mounting screwsof thecounterweight,tanks,Powerpack,controlvalve console,cab, cab elevation, high and low voltage boxes, catwalks, handrails, grease box, ladder, tighten if necessary

Swing gear: Do a visual check for missing, broken or loosen mounting bolts of the swing gear and hydraulic motors, tighten if necessary

ATTACHMENT

Do a visual check of the bucket teeth and wear kit for wear

Do a visual check of the grease supply at each lube point

Do a visual check of cable harness and sensors for damage

Do a visual check of all parts for damages and cracks

Ifnecessaryfilloutthe"StructuralInspection"forminServiceManual-Chapter4

Do a visual check of the fastening of pin covers

Do a visual check of the non-slip surfaces for wear and damage

UPPERCARRIAGE

Do a visual check of the service trap for leaks or damage

Do a visual check of oil, or grease for leaks

Do a visual check of the non-slip surfaces for wear and damage

CheckInitials

Comments

WORK TO BE PERFORMED AT 250, 750, 1250 HOURS, ...

Check for first and only interval or Check for repeat interval CheckInitials

SWING GEAR

Do a visual check of the swing gears for leaks and oil level in expansion tanks

CENTRALIZED LUBRICATION SYSTEM

Perform a complete daily maintenance given in the SKF / Lincoln Operating Instructions

Do a check of the grease tank level

ELECTRIC MOTOR AND SPLITTERBOX

Check voltage / load gauges and lights into the cabin

Check oil level in the splitterbox

Change oil in splitterbox

Check oil level in hydraulic tank

HYDRAULIC SYSTEM

Sampleandanalysehydraulicoilandchangeoilifnecessary(iffilledwithHEES biodegradable oil)

Clean magnetic rods of the leak oil filter

Clean magnetic rods of bypass filter

Clean magnetic rods of all return filters

ELECTRICAL SYSTEM

Press to open dust discharge valve on aeration devices for cabin and electrical boxes

Do a visual check of the head and floodlights, clean and adjust if necessary

Do a visual check of electric harness, sensors for damage and/or rubbing zone

Do a detailed check of fuses and circuit breakers

CABIN

Do a detailed check of the V-belt tension for air conditioner

Do a visual check of the cabin for oil/fluids leaks

FIRE FIGHTING SYSTEM

Doavisual checkofthefirefightingsystem condition(optional equipment,refer to the fire fighting system documentation)

- If any issue contact fire fighting local dealer

Follow the inspection intervals recommended by the specific Health and Safety rules existing in country and/or on mine site

WORK TO BE PERFORMED AT 250, 750, 1250 HOURS, ...

Check for first and only interval or Check for repeat interval

Start The Motor To Check The Following Actions

General: Maintenance work must include the check of the correct functions of hydraulic and electric systems before starting operation

Attachment: Check function of the working attachment lubrication system during operation

Attachment: Check if the damping system on equipment is working correctly

Uppercarriage: Check position of the hydraulic shut-off valve

Swing Gear: Check function and operation of the swing brake

SwingRing:Checkfunctionoftheswingring bearinglubricationsystemduring operation

SwingRing:Checkfunctionoftheswingringteethlubricationsystemduringoperation

Electrical system: Clean and check LCD screen of the display for proper function when starting

Electricalsystem:Checkindicatorlightsandgaugesonthecontrolpanelwhen starting

Electrical system: Check for warning and fault messages on display (monitoring,grease,airconditioning,...).Ifnecessary refertochapter 4intheOperating Manual to identify and rectify faults and errors.

Cabin: Check if the safety lever is working properly

Cabin: Check the horn

Cabin: Check for green flash light on control module if fire fighting system is installed

WORK TO BE PERFORMED AT 250, 750, 1250 HOURS, ...

Check for first and only interval or Check for repeat interval

General comments:

Serial Number: Fleet Number: SMUHOURS: Travel Hours:

5.19.5 500 Hours Maintenance Schedule - P 9250 E

Completed by: Dateand Signature:

WORK TO BE PERFORMED AT 500, 1500, 2500 HOURS, ...

Check for first and only interval or Check for repeat interval

GENERAL HYDRAULIC SYSTEM

Doavisualcheckofallhoses,pipesandfittingsforanyexternaldamageorleakage

Do a detailed check for good condition of pipes, hoses, clamps and fittings for damage and leakage

Do a visual check of the hydraulic components for leaks and/or damages

Do a visual check of the hydraulic cylinderrods for leaks and good condition

GENERAL FASTENING

General hydraulic: Do a visual check for missing, broken or loosen mounting screws of all hoses, pipes, fittings and clamps, tighten if necessary

Attachment: Do a visual check for missing, broken or loosen mounting screws of the handrails, pin covers fastening and greases connections, tighten if necessary

Uppercarriage: Do a visual check for missing, broken or loosen mounting screws of the counterweight, tanks, Powerpack, control valve console, cab, cab elevation, high and low voltage boxes, catwalks, handrails, grease box, ladder, tighten if necessary

Swing gear: Do a visual check for missing, broken or loosen mounting bolts of the swing gear and hydraulic motors, tighten if necessary

Hydraulic: Do a detailed check for missing, broken or loosen mounting screws of pumps, motors, clamps, ..., tighten the screws

ATTACHMENT

Do a visual check of the bucket teeth and wear kit for wear

Do a visual check of the grease supply at each lube point

Do a visual check of cable harness and sensors for damage

Do a visual check of all parts for damages and cracks

Ifnecessaryfilloutthe"StructuralInspection"forminServiceManual-Chapter4

Do a visual check of the fastening of pin covers

Do a visual check of the non-slip surfaces for wear and damage

UPPERCARRIAGE

Do a visual check of the service trap for leaks or damage

Do a visual check of oil or grease for leaks

CheckInitials

Comments

WORK TO BE PERFORMED AT 500, 1500, 2500 HOURS, ...

Check for first and only interval or Check for repeat interval

Do a detailed check of all structural parts for damages and cracks

Ifnecessaryfilloutthe"StructuralInspection"forminServiceManual-Chapter4

Do a visual check if the fan guards are in place and secured

Do a visual check of the non-slip surfaces for wear and damage

SWING GEAR

Do a visual check of the swing gears for leaks and oil level in expansion tanks

Sample and analyse gear oil, change oil if necessary

Change gear oil (if filled with COB-1 gear oil)

Change gear oil (if filled with COB-2, COB-3 or COB-4 gear oil)

SWING RING

Doadetailedcheckofthegreasesupply(outletofnewgreasearoundtheswing ring)

Centralized Lubrication System

Perform a complete daily maintenance given in the SKF / Lincoln Operating Instructions

Do a check of the grease tank level

Every 7500 hours, perform a complete 7500 hours Maintenance Echelon given in the SKF / Lincoln Operating Instructions

Electric Motor And Splitterbox

Check voltage / load gauges and lights into the cabin

Check oil level in the splitterbox

Sample and analyse splitterbox oil

Do a visual check of the splitterbox breather for clogging, replace if necessary

HYDRAULIC SYSTEM

Drain water sediment from hydraulic tank

Check oil level in hydraulic tank

Sample and analyse hydraulic oil and change oil if necessary

Clean magnetic rods of the leak oil filter

Clean magnetic rods of bypass filter

Clean magnetic rods of all return filters

Replace filter element of the return filters

Replace filter element of the leak oil filter

Replace control oil filter element

WORK TO BE PERFORMED AT 500, 1500, 2500 HOURS, ...

Check for first and only interval or Check for repeat interval

Replace swing pumps replenishing oil filter elements

Doavisualcheckoftheoilcoolerprotectionfilters,cleanorreplaceifnecessary (optional equipment)

Replace filter elements of bypass filter

Electrical System

Press to open dust discharge valve on aeration devices for cabin and electrical boxes

Replacemainelementonaerationdevicesforcabinandelectricalboxes(atleast once a year)

Replacesafetyelementonaerationdevices for cabin and electrical boxes,after 3 services of main element

Do a visual check of the head and floodlights, clean and adjust if necessary

Do a visual check of electric harness, sensors for damage and/or rubbing zone

Do a detailed check of fuses and circuit breakers

Do a visual check of wiring system damage

Check battery electrolyte level (refill if necessary) and clean battery terminals

Clean up the electric rotary connection

Check the carbon brushes of electric rotary connection, replace if necessary

Lubricate the contact bow of the slip ring

Grease the bearings of the slip ring

Do a detailed check of the V-belt tension for air conditioner

Do a visual check of the cabin for oil/fluids leaks

Operate air conditioner every week for 10 minutes

Do a visual check of the condenser unit and evaporator filter

Do a visual check of the refrigerant level, if necessary refill circuit

Replace if necessary the air conditioner filter/dryer (at least once a year)

Yearly check condition of the refrigerant receiver, if necessary replace it

Lubricate all doors seals with silicone or talc (before cold season)

Do a visual check of the AC for leaks or rubbing hoses or pipes

Fire Fighting System

Doavisual check ofthefirefighting systemcondition(optional equipment,refer to the fire fighting system documentation)

- If any issue contact fire fighting local dealer

WORK TO BE PERFORMED AT 500, 1500, 2500 HOURS, ...

Check for first and only interval or Check for repeat interval

Follow the inspection intervals recommended by the specific Health and Safety rules existing in country and/or on mine site

Start The Motor To Check The Following Actions

General: Maintenance work must include the check of the correct functions of hydraulic and electric systems before starting operation

Attachment:Checkfunctionoftheworkingattachmentlubricationsystemduring operation

Attachment: Check if the damping system on equipment is working correctly

Uppercarriage: Check position of the hydraulic shut-off valve

Swing Gear: Check function and operation of the swing brake

SwingRing:Checkfunctionof theswingringbearinglubricationsystem during operation

SwingRing:Checkfunctionoftheswingringteethlubricationsystemduringoperation

Electrical system: Clean and check LCD screen of the display forproper function when starting

Electricalsystem:Checkindicatorlightsandgaugesonthecontrolpanelwhen starting

Electrical system: Check for warning and fault messages on display (monitoring, grease,air conditioning, ...).Ifnecessary refer tochapter 4inthe Operating Manual to identify and rectify faults and errors.

Cabin: Check if the safety lever is working properly

Cabin: Check the horn

Cabin: Check for green flash light on control module if fire fighting system is installed

WORK TO BE PERFORMED AT 500, 1500, 2500 HOURS, ...

Check for first and only interval or Check for repeat interval

General comments:

Serial Number: Fleet Number: SMU HOURS: Travel Hours:

5.19.6 1000 Hours

Maintenance Schedule - P 9250 E

Completed by: Date and Signature:

WORK TO BE PERFORMED AT 1000, 3000, 5000 HOURS, ...

Check for first and only interval or Check for repeat interval CheckInitials

GENERAL HYDRAULIC SYSTEM

Doavisualcheckofallhoses,pipesandfittingsforanyexternaldamageorleakage

Do a detailed check for good condition of pipes, hoses, clamps and fittings for damage and leakage

Do a visual check of the hydraulic components for leaks and/or damages

Do a visual check of the hydraulic cylinder rods for leaks and good condition

GENERAL FASTENING

General hydraulic: Do a visual check for missing, broken or loosen mounting screws of all hoses, pipes, fittings and clamps, tighten if necessary

Attachment: Do a visual check for missing, broken or loosen mounting screws of the handrails, pin covers fastening and greases connections, tighten if necessary

Uppercarriage: Do a visual check for missing, broken or loosen mounting screws of the counterweight, tanks, Powerpack,control valveconsole, cab, cab elevation, high and low voltage boxes, catwalks, handrails, grease box, ladder, tighten if necessary

Swing gear: Do a visual check for missing, broken or loosen mounting bolts of the swing gear and hydraulic motors, tighten if necessary

Swingring:Doadetailedcheckformissing,brokenorloosenmountingscrews and protective nuts of swing ring, tighten the bolts

Hydraulic: Do a detailed check for missing, broken or loosen mounting screws of pumps, motors, clamps, ..., tighten the screws

Attachment

Do a visual check of the bucket teeth and wear kit for wear

Do a visual check of the grease supply at each lube point

Do a visual check of cable harness and sensors for damage

Do a visual check of all parts for cracks

-Ifnecessaryfilloutthe"StructuralInspection"forminServiceManual-Chapter 4

Do a visual check of the fastening of pin covers

Do a visual check of the non-slip surfaces for wear and damage

Comments

WORK TO BE PERFORMED AT 1000, 3000, 5000 HOURS, ...

Check for first and only interval or Check for repeat interval

Uppercarriage

Do a visual check of the service trap for leaks or damage

Do a visual check of oil or grease for leaks

Do a detailed check of all structural parts for cracks

-Ifnecessaryfilloutthe"StructuralInspection"forminServiceManual-Chapter 4

Doadetailed checkandlubricatethecovers,doors hinges,locks as well as service trap cylinders bushings and swivel pins

Do a visual check if the fan guards are in place and secured

Do a visual check of the non-slip surfaces for wear and damage

SWING GEAR

Do a visual check of the swing gears for leaks and oil level in expansion tanks

Sample and analyse gear oil, change oil if necessary

Change gear oil (if filled with COB-2, COB-3 or COB-4 gear oil)

SWING RING

Doadetailedcheckofthegreasesupply(outletofnewgreasearoundtheswing ring)

Centralized Lubrication System

Perform a complete daily maintenance given in the SKF / Lincoln Operating Instructions

Do a check of the grease tank level

Every 1000 hours, perform a complete 1000 hours Maintenance Echelon given in the SKF / Lincoln Operating Instructions

Electric Motor And Splitterbox

Check voltage / load gauges and lights into the cabin

Check oil level in the splitterbox

Sample and analyse splitterbox oil

Do a visual check of the splitterbox breather for clogging, replace if necessary

Replace filter in splitterbox breather

Drain water sediment from hydraulic tank

Check oil level in hydraulic tank

HYDRAULIC SYSTEM

Sample and analyse hydraulic oil and change oil if necessary

CheckInitials

Comments

WORK TO BE PERFORMED AT 1000, 3000, 5000 HOURS, ...

Check for first and only interval or Check for repeat interval

Clean magnetic rods of the leak oil filter

Clean magnetic rods of bypass filter

Clean magnetic rods of all return filters

Replace filter element of the return filters

Replace filter element of the leak oil filter

Replace the hydraulic tank air filter

Replace control oil filter element

Replace swing pumps replenishing oil filter elements

Doavisualcheckoftheoilcoolerprotectionfilters,cleanorreplaceifnecessary (optional equipment)

Replace filter elements of bypass filter

Check and adjust primary and secondary pressure relief valves

Electrical System

Press to open dust discharge valve on aeration devices for cabin and electrical boxes

Replacemainelementonaerationdevicesforcabinandelectricalboxes(atleast once a year)

Replace safetyelement onaerationdevicesfor cabinandelectrical boxes,after 3 services of main element

Do a visual check of the head and floodlights, clean and adjust if necessary

Do a visual check of electric harness, sensors for damage and/or rubbing zone

Do a detailed check of fuses and circuit breakers

Do a visual check of wiring system damage

Check battery electrolyte level (refill if necessary) and clean battery terminals

Checkthefunctionofanti-condensingheatersfromS2box(currentofcontinuity)

Clean up the electric rotary connection

Check the carbon brushes of electric rotary connection, replace if necessary

Lubricate the contact bow of the slip ring

Grease the bearings of the slip ring

Cabin

Do a detailed check of the V-belt tension for air conditioner

Do a visual check of the cabin for oil/fluids leaks

Operate air conditioner every week for 10 minutes

WORK TO BE PERFORMED AT 1000, 3000, 5000 HOURS, ...

Check for first and only interval or Check for repeat interval CheckInitials

Do a visual check of the condenser unit and evaporator filter

Do a visual check of the refrigerant level, if necessary refill circuit

Replace if necessary the air conditioner filter/dryer (at least once a year)

Yearly check condition of the refrigerant receiver, if necessary replace it

Lubricate all doors seals with silicone or talc (before cold season)

Do a visual check of the AC for leaks or rubbing hoses or pipes

Doavisualcheckofthelocksandhingesondoorsandwindows(lubricateifnecessary)

Do a detailed check of the cabin rubber mounts

Fire Fighting System

Doavisual check ofthefirefighting systemcondition(optional equipment,refer to the fire fighting system documentation)

- If any issue contact fire fighting local dealer

Follow the inspection intervals recommended by the specific Health and Safety rules existing in country and/or on mine site

Start The Motor To Check The Following Actions

General: Maintenance work must include the check of the correct functions of hydraulic and electric systems before starting operation

Attachment:Checkfunctionoftheworkingattachmentlubricationsystemduring operation

Attachment: Check if the damping system on equipment is working correctly

Uppercarriage: Check position of the hydraulic shut-off valve

Swing Gear: Check function and operation of the swing brake

SwingRing:Check functionoftheswingringbearinglubricationsystemduring operation

SwingRing:Checkfunctionoftheswingringteethlubricationsystemduringoperation

Electrical system: Clean and check LCD screen of the display for proper function when starting

Electricalsystem:Checkindicatorlightsandgaugesonthecontrolpanelwhen starting

Comments

WORK TO BE PERFORMED AT 1000, 3000, 5000 HOURS, ...

Check for first and only interval or Check for repeat interval

Electrical system: Check for warning and fault messages on display (monitoring, grease,air conditioning, ...).Ifnecessary refer tochapter 4inthe Operating Manual to identify and rectify faults and errors.

Cabin: Check if the safety lever is working properly

Cabin: Check the horn

Cabin: Check for green flash light on control module if fire fighting system is installed

WORK TO BE PERFORMED AT 1000, 3000, 5000 HOURS, ...

Check for first and only interval or Check for repeat interval

General comments:

Serial Number: Fleet Number: SMU HOURS: Travel Hours:

5.19.72000 Hours MaintenanceSchedule - P 9250 E

Completed by: Date and Signature:

WORK TO BE PERFORMED AT 2000, 4000, 6000 HOURS, ...

Check for first and only interval or Check for repeat interval CheckInitials

GENERAL HYDRAULIC SYSTEM

Doavisualcheckofallhoses,pipesandfittingsforanyexternaldamageorleakage

Do a detailed check for good condition of pipes, hoses, clamps and fittings for damage and leakage

Do a visual check of the hydraulic components for leaks and/or damages

Do a visual check of the hydraulic cylinder rods for leaks and good condition

GENERAL FASTENING

General hydraulic: Do a visual check for missing, broken or loosen mounting screws of all hoses, pipes, fittings and clamps, tighten if necessary

Attachment: Do a visual check for missing, broken or loosen mounting screws of the handrails, pin covers fastening and greases connections, tighten if necessary

Attachment:Doadetailedcheckformissing,brokenorloosenmountingscrews of the handrails, pin covers fastening and greases connections, tighten the screws

Uppercarriage: Do a visual check for missing, broken or loosen mounting screws of the counterweight, tanks, Powerpack,control valveconsole, cab, cab elevation, high and low voltage boxes, catwalks, handrails, grease box, ladder, tighten if necessary

Uppercarriage: Do a detailed check for missing, broken or loosen mounting screws of the counterweight, tanks, Powerpack,control valveconsole, cab, cab elevation, high and low voltage boxes, catwalks, handrails, grease box, ladder, tighten the screws

Swing gear: Do a visual check for missing, broken or loosen mounting bolts of the swing gear and hydraulic motors, tighten if necessary

Swinggear:Doadetailedcheckformissing,brokenorloosenmountingboltsof the swing gear and hydraulic motors, tighten the bolts

Swingring:Doadetailedcheckformissing,brokenorloosenmountingscrews and protective nuts of swing ring, tighten the bolts

Electric motor: Do a detailed check for missing, broken or loosen mounting screws of the splitterbox, tighten the screws

Electricmotor:Every2000hours(ortwiceayear),doadetailedcheckformissing, broken or loosen mounting screws of parts subject to vibration and various elements securing the electric motor, tighten the screws

Comments

WORK TO BE PERFORMED AT 2000, 4000, 6000 HOURS, ...

Check for first and only interval or Check for repeat interval

Hydraulic: Do a detailed check for missing, broken or loosen mounting screws of pumps, motors, clamps, ..., tighten the screws

Attachment

Do a visual check of the bucket teeth and wear kit for wear

Do a visual check of the grease supply at each lube point

Do a visual check of cable harness and sensors for damage

Do a visual check of all parts for cracks

-Ifnecessaryfilloutthe«StructuralInspection»forminServiceManual-Chapter

4

Do a visual check of the fastening of pin covers

Do a visual check of the non-slip surfaces for wear and damage

Do a detailed check of all the anchor points and the tightening of the handrails mounting screws, only by authorized specialist personnel (at least once a year)

UPPERCARRIAGE

Do a visual check of the service trap for leaks or damage

Do a visual check of oil or grease for leaks

Do a detailed check of all structural parts for cracks

-Ifnecessaryfilloutthe«StructuralInspection»forminServiceManual-Chapter

4

Doadetailed checkandlubricatethecovers,doors hinges,locks as well as service trap cylinders bushings and swivel pins

Do a visual check if the fan guards are in place and secured

Do a check of the global view around machine (including mirrors)

Do a visual check of the non-slip surfaces for wear and damage

Do a detailed check of all the anchor points and the tightening of the handrails mounting screws, only by authorized specialist personnel (at least once a year)

SWING GEAR

Do a visual check of the swing gears for leaks and oil level in expansion tanks

Sample and analyse gear oil, change oil if necessary

Change gear oil (if filled with COB-1 gear oil)

Change gear oil (if filled with COB-2, COB-3 or COB-4 gear oil)

Measure the axial play of the output shaft bearing, replace if necessary

SWING RING

Doadetailedcheckofthegreasesupply(outletofnewgreasearoundtheswing ring)

CheckInitials

Comments

WORK TO BE PERFORMED AT 2000, 4000, 6000 HOURS, ...

Check for first and only interval or Check for repeat interval

Do a detailed check of the meshing of the swing gears with the swing ring

Do a detailed check of the swing ring teeth for damage

Do a detailed check of the swing ring axial play

Centralized Lubrication System

Perform a complete daily maintenance given in the SKF / Lincoln Operating Instructions

Do a check of the grease tank level

Every 1000 hours, perform a complete 1000 hours Maintenance Echelon given in the SKF / Lincoln Operating Instructions

Electric Motor And Splitterbox

Check voltage / load gauges and lights into the cabin

Check oil level in the splitterbox

Sample and analyse splitterbox oil

Change oil in splitterbox

Do a visual check of the splitterbox breather for clogging, replace if necessary

Replace filter in splitterbox breather

Greasethemotorbearing.RefertotheManualofsafety,installationandmaintenance of the electric motormanufacturer.

Clean the cooling tubes

Every 4000 hours (or at least twice a year), perform a general inspection of the electric motor given in the Manual of safety, installation and maintenance of the electric motor manufacturer

Every8000hours,performadetailedinspectionoftheelectricmotorgiveninthe Manualofsafety,installationandmaintenanceoftheelectricmotormanufacturer

Every 40000 hours (or at least every 5years), perform a complete inspection of the electric motor given inthe Manual of safety, installationand maintenance of the electric motor manufacturer

Hydraulic System

Drain water sediment from hydraulic tank

Check oil level in hydraulic tank

Sample and analyse hydraulic oil and change oil if necessary

Change hydraulic oil

Clean magnetic rods of the leak oil filter

Clean magnetic rods of bypass filter

Clean magnetic rods of all return filters

WORK TO BE PERFORMED AT 2000, 4000, 6000 HOURS, ...

Check for first and only interval or Check for repeat interval

Replace filter element of the return filters

Replace filter element of the leak oil filter

Replace the hydraulic tank air filter

Replace control oil filter element

Replace swing pumps replenishing oil filter elements

Replacethecontrolvalveshighpressurefilters,replacefilterelementsaftereach replacement or repair of a working pump and check the internal surface of the filter housing

Doavisualcheckoftheoilcoolerprotectionfilters,cleanorreplaceifnecessary (optional equipment)

Replace filter elements of bypass filter

Do a detailed check of the oil coolers, clean if necessary

Do a visual check of the coolingfan blades, replace if necessary

Check and adjust primary and secondary pressure relief valves

Do a detailed check of mounting of components (pumps, motors, ...)

Every4000hours(oratleastonceayear),allhydraulicpumpsmustbechecked and adjusted by trained and qualified Liebherr personnel

Every 4000 hours (or at least once a year), check the pressure of the hydraulic accumulatorsandfillifnecessary:usethespecialtoolwhichisdedicatedforthis purpose

Every 8000 hours, replace following high pressure (HP) hoses:

CheckInitials

Comments ive circuit, including HP pilot hoses.

Electrical System

Press to open dust discharge valve on aeration devices for cabin and electrical boxes

Replacemainelementonaerationdevicesforcabinandelectricalboxes(atleast once a year)

Replacesafetyelementonaerationdevices for cabin and electrical boxes,after 3 services of main element

Do a visual check of the head and floodlights, clean and adjust if necessary

Do a visual check of electric harness, sensors for damage and/or rubbing zone

Do a detailed check of fuses and circuit breakers

WORK TO BE PERFORMED AT 2000, 4000, 6000 HOURS, ...

Check for first and only interval or Check for repeat interval

Do a visual check of wiring system damage

Check battery electrolyte level (refill if necessary) and clean battery terminals

Do a test of all emergency stops (with electric motor stopped only)

Make sure that the display goes off after each test

Checkthefunctionofanti-condensingheatersfromS2box(currentofcontinuity)

Clean up the electric boxes S1 and S2 and check the air filter, replace if necessary

Clean up the electric rotary connection

Check the carbon brushes of electric rotary connection, replace if necessary

Lubricate the contact bow of the slip ring

Grease the bearings of the slip ring

Check the high voltage cable fixing and sheath

Doadetailedcheckformissing,brokenorloosenmountingscrewsoftheelectric rotary connection, tighten the screws

CABIN

Do a detailed check of the V-belt tension for air conditioner

Do a visual check of the cabin for oil/fluids leaks

Operate air conditioner every week for 10 minutes

Do a visual check of the condenser unit and evaporator filter

Do a visual check of the refrigerant level, if necessary refill circuit

Replace if necessary the air conditioner filter/dryer (at least once a year)

Yearly check condition of the refrigerant receiver, if necessary replace it

Lubricate all doors seals with silicone or talc (before cold season)

Do a visual check of the AC for leaks or rubbing hoses or pipes

Doavisualcheckofthelocksandhingesondoorsandwindows(lubricateifnecessary)

Do a detailed check of the cabin rubber mounts

Do a detailed check of the heater exchanger and filter for leaks

Fire Fighting System

Doavisual checkofthefirefightingsystemcondition (optional equipment, refer to the fire fighting system documentation)

- If any issue contact fire fighting local dealer

Follow the inspection intervals recommended by the specific Health and Safety rules existing in country and/or on mine site

WORK TO BE PERFORMED AT 2000, 4000, 6000 HOURS, ...

Check for first and only interval or Check for repeat interval

Start The Motor To Check The Following Actions

General: Maintenance work must include the check of the correct functions of hydraulic and electric systems before starting operation

Attachment:Checkfunctionoftheworkingattachmentlubricationsystemduring operation

Attachment: Check if the damping system on equipment is working correctly

Uppercarriage: Check position of the hydraulic shut-off valve

Swing Gear: Check function and operation of the swing brake

SwingRing:Check functionoftheswingringbearinglubricationsystemduring operation

SwingRing:Checkfunctionoftheswingringteethlubricationsystemduringoperation

Electrical system: Clean and check LCD screen of the display for proper function when starting

Electricalsystem:Checkindicatorlightsandgaugesonthecontrolpanelwhen starting

Electrical system: Check for warning and fault messages on display (monitoring, grease,air conditioning, ...).Ifnecessaryrefer to chapter 4intheOperating Manual to identify and rectify faults and errors.

Cabin: Check if the safety lever is working properly

Cabin: Check the horn

Cabin: Check for green flash light on control module if fire fighting system is installed

WORK TO BE PERFORMED AT 2000, 4000, 6000 HOURS, ...

Check for first and only interval or Check for repeat interval

General comments:

6.1Visual check of the hydraulic hoses

6.1.1Preface

Thissectiondescribestheprocedureforthevisualcheckofthehydraulichoses escapes from a pinhole and it can go through the skin and contaminate the blood. edical treatmentis necessary immediately. available safety protection. vice Manual.

Note!

These instructions have been written for the maintenance personnel of the machine.

Theactivitiesdescribed in this section may onlybe carried out by speciallytrained personnel.

Theinstructionsaretobereadandusedcarefullybyallpersonswhocarryout work with or on the machine before putting the machine into service for the first time and later, at regular intervals.

Theinstructionsmustbecompletedbyinformationoncurrentnationalregulationsfor accident prevention and protection. In addition, authorized specialist rules for safe and correct working procedures are also to be observed.

However, should you require any further explanations or information, LIEBHERR technical documentation, sales school and customer service departments are available for your convenience.

Danger!

Fluid injection injuries have to be treated immediately!

Visual check of the hydraulic hoses

6.1.2General information

Components description

1 Rubber cover

2 Reinforcement layer

3 Inside rubber tube

4 Crimp fitting

5 Nipple

6 Nipple wire trap area

7 Sealing zone

8 Damping zone

For this document, the terms that follow are available: hose is a hydraulic tube. It is made by: hoseassemblyisahosewithfittingsattachedatthetwoends.Thefittingsare made by: 4 5

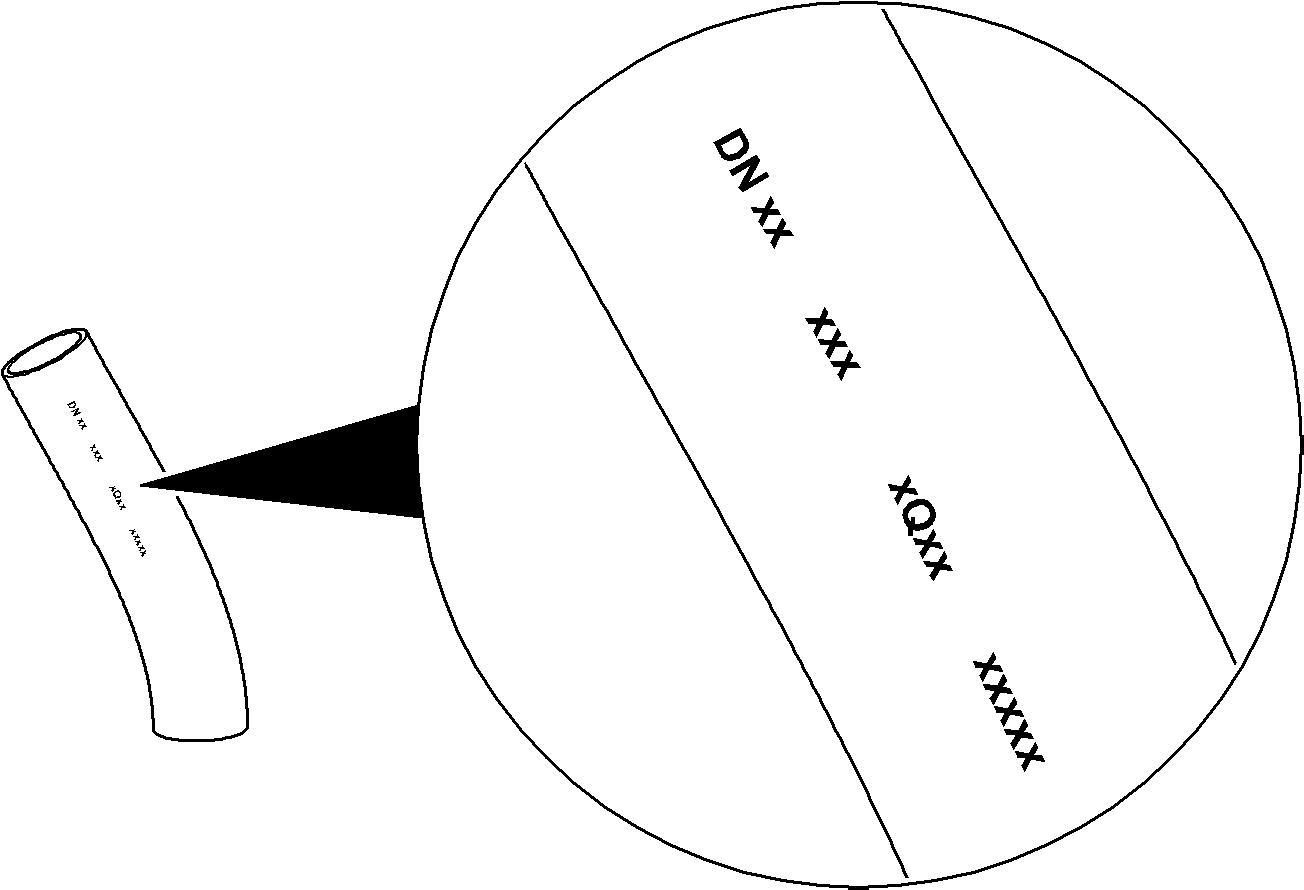

Marking of the components

The hose and the hose assembly are marked with the general data given below.

Hose marking

The hose is marked on the rubber cover with: se (i.e. 2Q13 = second quarter of 2013)

Hose assembly marking

The hose assembly is marked on the fittings with:

Visual check of the hydraulic hoses

Normal conditions of use

Danger!

Itisnecessarytoreplacethehydraulichosesatspecifiedintervalstomaintaintheir maximum operating performance and to reduce the risk of personal injury and/or machine damage.

Obey the replacement intervals given below.

Natural ageing

Hydraulic hoses and hose assemblies undergo a process of natural ageing. Thus, their service life has a limit: stobeytherequirementsgiveninthesection "Replacement of the hydraulic hoses" of this manual.

When you check a hose assembly or you install a new one, refer to the date of assembly marked on the hose assembly fittings.

Operating stress

Thehydraulichosesmustalsoberegularlyreplacedbecauseoftheoperatingstress. Forthereplacementintervalsgiveninworkinghoursofthehydraulichoses,refer to the section "Control and maintenance chart" of this manual.

Mounting instructions

Refer to the Operating Manual.

6.1.3Components functions

This section gives the function of the different main components of a hydraulic hose assembly.

Insiderubber tube

The inside rubber tube keeps the conveyed fluid in the hose. It is resistant against thefluidandthetemperatureofthefluid.Internaldamagestothistubecanbecaused by contamination of the hydraulic circuit.

The inside rubber seals the hose but it has no pressure stability.

Reinforcement layer

Thereinforcementlayer,madeupofsomesteellayerswithrubberinbetween,holds the internal pressure.

The reinforcement layer is theonly componentof the hose whichgives thehose the pressure stability. The hose has a minimum burst pressure (static) and a maximum operating pressure (dynamic). The maximum operating pressure is usually at least four times lower than the minimum burst pressure because dynamic pressures fatigue the reinforcement layer more quickly than static pressures.

The value of the burst pressure and the operating pressure will be lower if the reinforcement layer has one of the damages that follow:

The inside rubber can also be damaged if the reinforcement layer moves.

Rubber cover

The rubber cover protects the reinforcement layer from the ambient conditions (UV, ozone, different liquids) and from mechanical effects (scrubbing, corrosion).

Anyrub,cutorribintherubbercovermeansthattheprotectionisnolongersatisfactory and the reinforcement layer is subject to a potential destruction.

Nipple

Thenippleisnecessaryto connecta hydraulichoseto anothercomponent. Thenipple is resistant to all the mechanical forces and bending stress caused by the pressurepulsationsinthehose.Thus,itisimportanttohaveagoodcontactbetweenthe nipple and the hose.

Cracks on the nipple cause its fast failure.

Crimp fitting

To make sure that the assembly is correctly sealed, the crimp fitting presses the inside rubber tube onto the nipple. In addition, if the hose has a wire trap area, the crimp fitting clamps the reinforcement layer in between the nipple and the crimp fitting.

Ifthe hoseassemblystarts to leak at the end of the crimp fitting, the causes that follow are possible:

6.1.4Recommendations for hose assembly maintenance

Severity levels

Hose assembly damages can be divided into three severity levels: For each severity level, there are special actions to do at specific intervals.

Checks and recommendations

The sections that follow give: makeanestimateofthedamageseverity level

Visual check of the hydraulic hoses

Minordamage

If you find a minor damage:

Daily

Examine the hose assembly. Monitor if the deterioration increases. In case of rubbing, move the hose assembly to make sure there is no more contact.

Check all necessary conditions forthe possible replacement of the defective part(s)(e.g. part in stock, time of delivery).

Rubber cover is rubbed -Reinforcement layer is not corroded or not rubbed - No sign of oil

Rubber cover has a cut or a crack - Reinforcement layer is not corroded or not cut - No sign of oil

Hose is visually wet near the crimp fitting - Oil does not propagate There is a small surface of remaining oil which is visually wet but does not result in the formation of drop.

Dry dust collection which does not propagate

Immediately

Seriousdamage

If you find a serious damage:

Inform formally the responsible Maintenance Manager about the condition of the hose assembly.

Make sure that you have the correct replacement part in stock.

Examine the hose assembly. Monitor if the deterioration increases.

Daily

One of the next services, but not later than 250 hours

Ifthedeteriorationofthehoseassemblyincreasesinasmall numberofdays, refer to next section "Major damage" for the actions to do.

Replace the hose assembly.

Rubber cover has many cuts or cracks - Reinforcement layer is not corroded or not cut - No sign of oil

Rubber cover is rubbed - Reinforcement layer is uncovered but not corroded - No sign of oil

Hoses and fittings are visually wet - Oil propagates There is a surface of remaining oil which is visually wet and results in the formation of non-falling or falling drop.

Visual check of the hydraulic hoses

Majordamage

If you find a major damage:

Danger!

Inthiscase,thehoseassemblymustbereplacedimmediatelybecauseitcanburst at any time.

Obey all safety instructions given in the Operating Manual to avoid accidents and fires.

Stop the machine immediately (no exception).

Immediately

InformformallytheresponsibleMaintenanceManager,orhissuperior,thatthe machine is stopped and about the condition of the hose assembly.

Before restart the machine Replace the hose assembly.

Oil leakage

The frequency of the drops makes a measurable flow.

6.2Centralized lubrication system

1.MainScreensandControlButtons

Menu:UsedtoEnterintoMenuListandreturntoPreviousMenu.

Up:UsedtomoveupcursorintheMenuListsandtoincreaseaValue.

Down:UsedtomovedowncursorintheMenuListsandtodecreaseaValue.

Themainmenuisaccessedthroughthe"Menu"button;allthemenusaredisplayedontherightdisplay.

InagivenMenulist,youcanpressthe"Up"and"Down"buttonstoscrollthroughmenus.Pressingthe buttonwillthenscrollthroughmenusfromtopofscreentothelastmenuonscreen;butifthe buttonis pressed,selectionwillscrollfromtoptobottomofmenuslist.

Theactivelineis"inversevideo"(whitetext,blackhighlighted),usethe"Menu"keytogetinsidetheselected submenu.

Thelastlineofamenulistisalwaysdefinedas"Back",itisusedtomovetothepreviousmenubypressingthe "Menu"buttonwhenhighlighted.

WithinagivenMenuwherethevaluecanbechanged,thechangecanbemadebyusingthe"Up"buttonto increasethevalueandusingthe"Down"buttontodecreasethevalue.Changesareimmediatelyregisteredin controller.Pressingthe"Menu"buttonreturnsyoutothepreviousmenu.

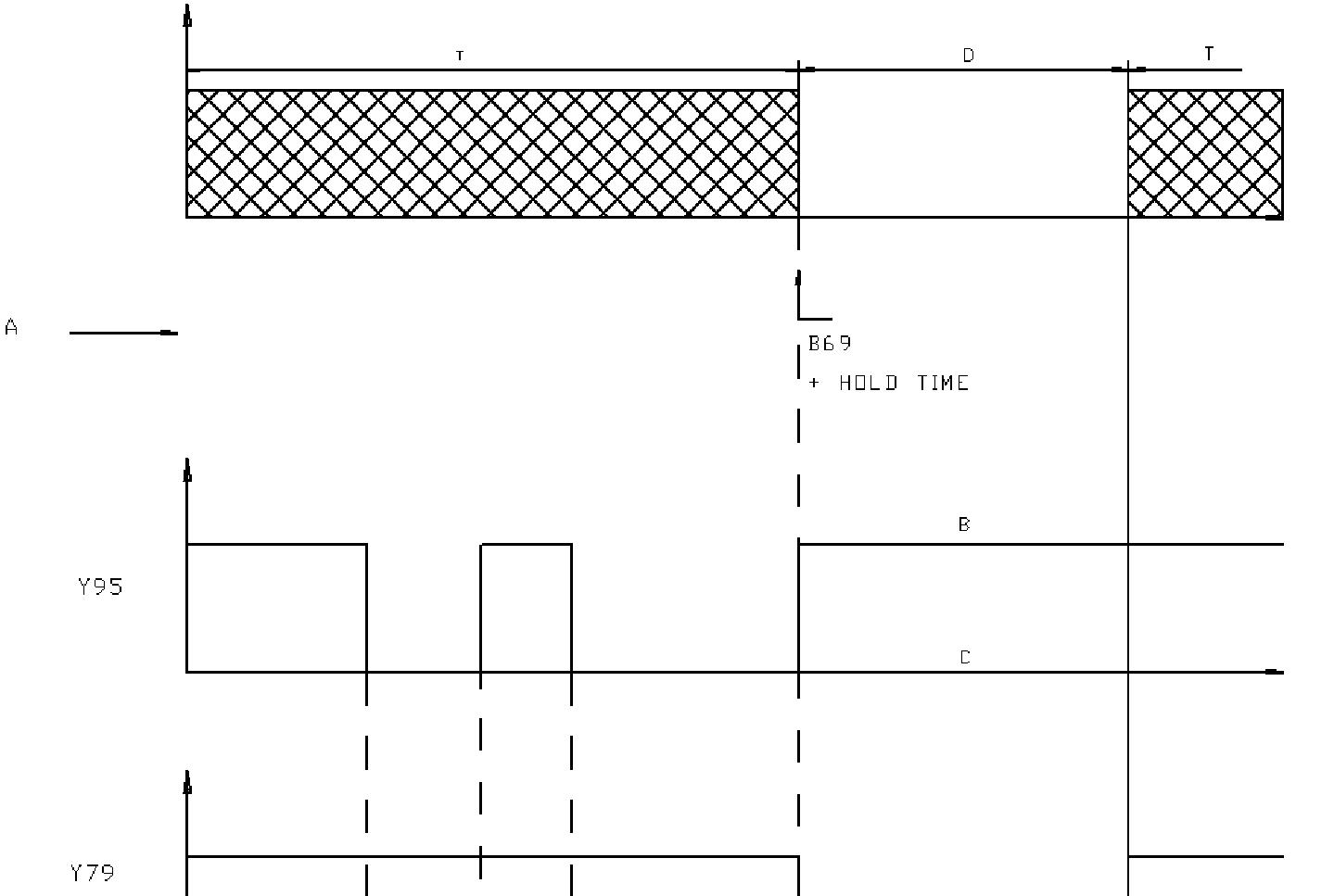

StartCycle

Thethreekeys"StartCyclePX"canbeusedtostartanewlubricationcycleatthecorrespondingpump.Pushing thisbuttonsactslikesimulatinganEnablingsignalcomingtothegreasingcontroller, foreachpump independently.ThechosenpumpwillstartifthePilotpressureissufficient.

IfpumpPXisinsafetymode,athreesecondsactivationofthebutton makesthepumpPXreturnto thenormalmode.

Description of the software menus

2.StartScreens

LeftStartScreen: Grease Controller Startin g

RightStartScreen:

3.MainScreens

LeftMainScreen:

P1OFF

123bar 4 5 6 sec

P2ONSafet y bar0sec

P3ON 1 p ulse200sec

RightMainScreen:

LevelP1100%

P395%

PilotP 4 2bar

B150 12 p ulse

B150 21 p ulse

P2Safet y serv

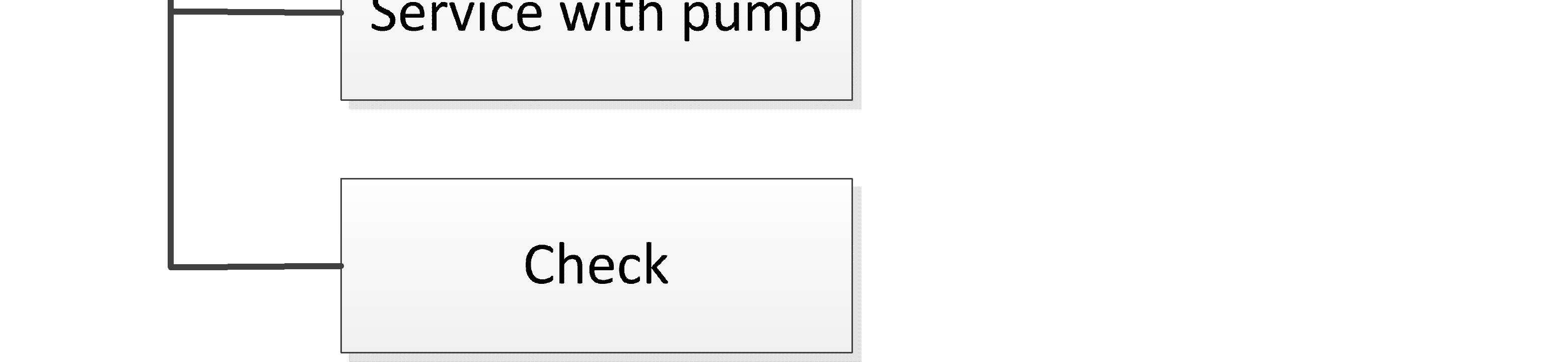

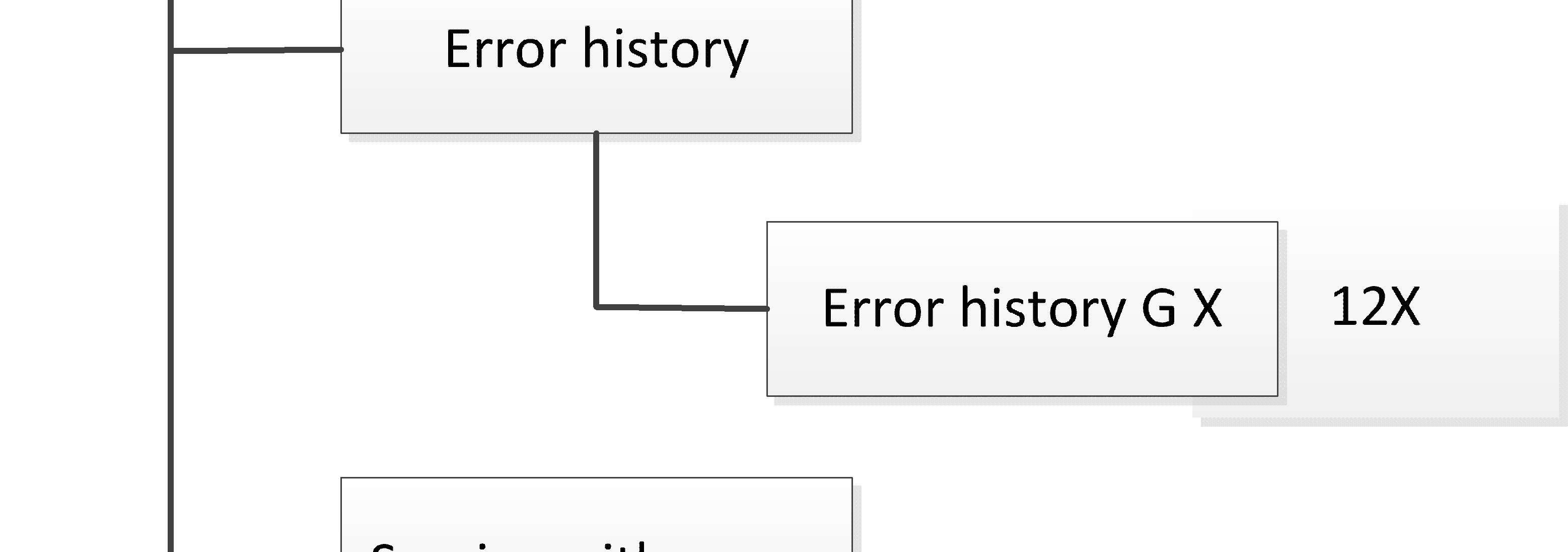

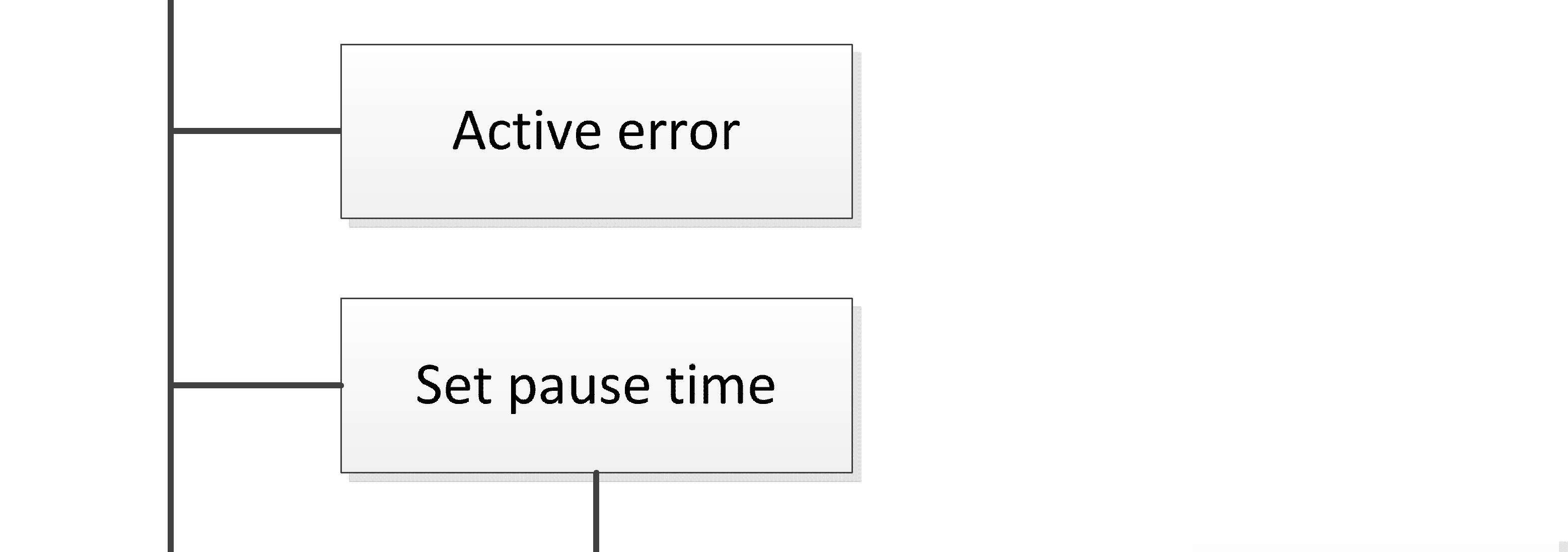

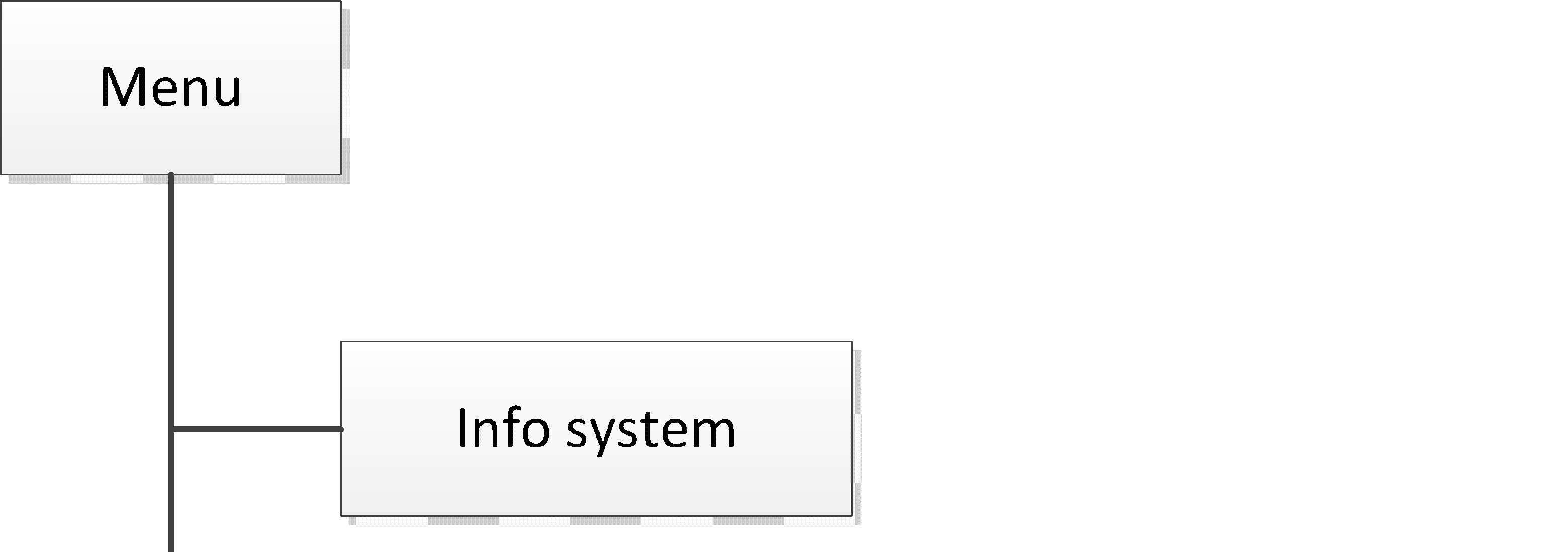

4. ArchitectureofMenus

5. Menu

Infos y stem

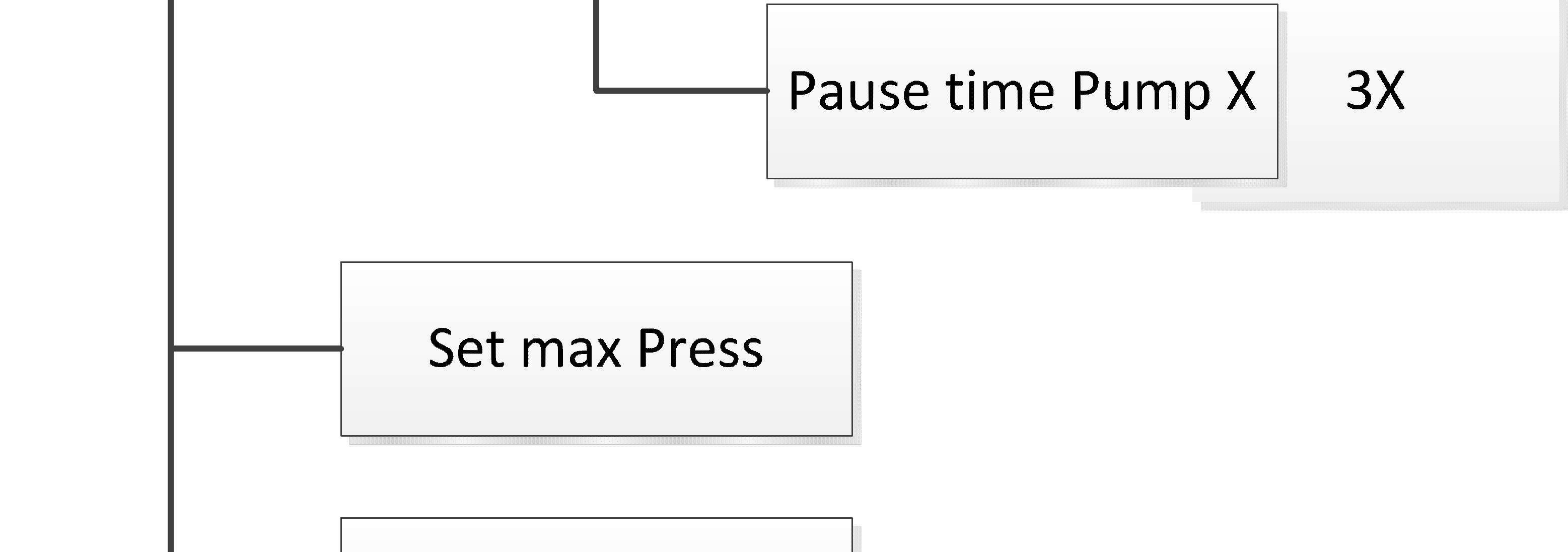

Activeerrors

SetPausetime

Setmax p ress

Errorhistor y

Psafet y serv

SetPausetime

Setmax p ress

Errorhistor y

Psafet y serv

Check Back

Check:

UponenteringtheCheckmenu,thestatusesoftheanaloguesensorsareshown.

B 6 9OK

B71OK

B1 8 4 OK

B5 0 1OK

B5 0 2E R R

TorepresentSensorvaluesinmA,pressandholdboth"Up"and"Down"arrowbuttonsformorethanthree seconds.Thiswillonlyapplywhenaserviceorinspectordongleisplugged.

B6912mAB713 4mA

B18 4 1

6mAB5112mA

B5 0 _121mA A

B5 0 _219m

B15 0 19mA

B15 0 29mA

6.Appendix

ErrorList:

Operating Manual

Centralized Lubrication Systems

R9250

Productidentification

Manufacturer: SKF Lubrication SystemsGermany GmbH

Type: R9250, R9250E

Type no.: R9250: 437 and 1357, R9250E:1129

Address

Heinrich-Hertz-Str. 2-8

69190 Walldorf - Germany

1 Guidelines

As you read theseinstructions, you will notice a number of depictions and symbols which are to facilitate the navigation and understandingof these instructions.

For reasons of better legibility, in these instructions we mainly use the male form for general references.Of course, the femaleformis alsoalways intended.

Please read these instructions thoroughly and heed the warning and safety notes. Please observethewarning and safety notesand exerciseparticular caution in these cases.

Informalso other usersaccordingly.

Text representations

Bold print

Meaning

Highlighting ofparticularly important words or passages

List 1 Marks lists o List 2 Marks lists

(parenthesis)

Instructions

Itemnumbers

Instructions to personnel. These always appear in chronological order.

Explanation of symbols and signs

Activities which generate actual hazards (to life and limb or possible damage to the material) aremarked by warnings. Definitely observe the instructions given in the warnings. Youwillfindthesesymbols,whichwarnofspecificdangerstopersons,materialassets,orthe environment, next to all safetyinstructions intheseoperating instructions.

Please read these instructions thoroughly and heed the warning and safety notes. Please observethewarning and safety notesand exerciseparticular caution in these cases.

Informalso other usersaccordingly.

Thefollowing warningsare possible.

Symbol Meaning

Generalwarning

Activities which generateactual hazards (to life and limb or possible damage to thematerial)

Warning of suspended load

Risk ofexplosion

Carry out work on electricalparts only ifthe atmosphereis not potentially explosive. Workhas to be carried out by aspecialistfor maintenanceand repairs inpotentially explosive atmospheres.

Electrical component hazard, electrical shock hazard

Make sure to disconnect the system or component from the power supply before carrying out works on electrical parts.

Do not use steam jet or high pressure cleaners for cleaning. Otherwise electrical components may be damaged. Do not touch cables or electrical components with wet or damphands.

Cleaning work on energized components may be carried out by electrical specialists only.

Risk offire

Risk of fireand explosion when using inflammablecleaning agents.

Health hazard

Hazarddue to spouting lubricant / pressureinjection due to a leakage (defectivefitting, too high systempressure orother damages).

Crushing hazard

Slipping hazard

Hot surfaces

Symbol Meaning

Disposal

Environmentally sound disposal and recycling

Disposal

Environmentally sound disposal of waste electricaland electronic equipment

Illustrations

The illustrations used refer to a specific product. In the case of other products or product versions they may have a schematic character only. The basic function, however, does not change.

Abbreviations

The followingabbreviations may beused within these instructions:. max. maximum min. minimum min minutes s seconds etc. and so on poss. possibly e.g. for example ml millilitre ccm cubic cm mm millimetre

°C degrees Celsius

°F degrees Fahrenheit

K Kelvin inch inch etc. et cetera kg kilogram l litre mbar millibar no. Number

Nm Newtonmeter incl. including i.e. this means rh relativehumidity approx.approximately

Ø diameter

® registered trademark

© Copyright

TM Trademark

% per cent dB (A) sound pressure level

> greater than < less than ± plus minus

SW width across flats

ESD Electrostatic Discharge

N/A not applicable

Manufacturer and Service addresses

Manufacturer

SKF Lubrication Systems Germany

GmbH

Heinrich-Hertz-Str. 2-8

DE - 69190 Walldorf

Customer Service

SKF Lubrication Systems Germany GmbH

Heinrich Hertz Straße 2-8

DE - 69183 Walldorf

+49 (0)6227-330

SKF Lubrication Systems Germany GmbH

2. Industriestraße 4

DE - 68766 Hockenheim

+49 (0)620527101

SKF Lubrication Systems Germany GmbH

Motzener Straße 35-37

DE - 12277 Berlin

+49 (0)30-720020

Warranty

Theinstallationinstructionsdonotcontainanyinformationonthewarranty.Thiscanbefound in our general terms and conditions.

Copyright

© Copyright SKF Lubrication Systems Germany GmbH. These installation instructions are copyright-protected. All rights reserved.

The integration of the content into the manufacturer's installation instructions of the machine, into which the pump shall be integrated, is expressly allowed.

Thisalsoincludesthecreationoftrainingmaterial for internal,non-commercial purposes.Any other use without the written consent of the copyright holder - of whatever kind - is prohibited and is regarded as aviolation of copyright.

2 Safetyinformation

Safety information is to be read and observed by any persons entrusted with works on the centralized lubrication system or by those persons who supervise or instruct the beforementioned group of persons.

It is prohibited to commission or operate the machine, the centralized lubrication system or single components prior to reading the installation instructions. The installation instructions must be keptat an accessible location for further use.

Disclaimer

Observation of these installation instructions is the prerequisite for safe operation and the achievement of productcharacteristics and performance levels.

The manufacturer shallnot be held responsible for damages causedby: o nonappropriateuse,faultyassembly,operation,setting,maintenance,repairoraccidents o improper or late response tomalfunctions o unauthorized modifications of the product o intent or negligence o Use of non-original SKF spareparts.

Liability for loss or damage resulting from the use of our products is limited to the maximum purchase price. Liability for consequential damages ofwhateverkind is excluded.

Emergency stopping of the centralized lubrication system

Incase of anemergencystop thecentralized lubrication systemby: switching off the machine, system or vehicle, into which the SKF centralized lubrication system or its componentshavebeenintegrated. separating the supply of power, compressed airor hydraulic pressure (dependingon the system) to thecentralized lubrication system or the corresponding components. actuatingthe emergency-offswitch, if any, of the machine, system or vehicle.

Intended use

ATTENTION

Allproductsmay be used onlyfor theirintendedpurposeand inaccordancewith the instructions.

Intendeduseistheuseoftheproducts to lubricatebearings andfrictionpointswith lubricants within the physical limits that can be found in the relevant product documentation, e. g. operating instructions and product descriptions, e. g. technical drawings and catalogues.

Operation of the lubrication system or single components of it

Operation ispermitted only, if in compliance with:

Allinformation given inthese installation instructions or stated in the referenced documents.

All laws andregulationsto be complied with by the user.

Properly andappropriately conducted installationof the system.

Foreseeable misuse

Any other use and purpose of the centralized lubrication system or its components than the ones described before arestrictly prohibited.

Use isexpresslyforbidden:

in a potentially explosive atmosphere, unless the centralized lubrication system or its components are expressly suitable for itand have been approved accordingly.

in a working environment or condition that corresponds to the required protection types IP (International Protection) and Nema (National Electrical Manufacturers Association) only inparts or not at all.

to use the CLS to feed, forward, or store hazardous substances and mixtures in accordance with annex I part 2-5 of the CLP regulation (EC1272/2008).

Forthesupply,transport,stockpilingofgases,liquefiedgases,dissolvedgases,vapours, andfluidswhosevapourpressureexceedsnormalatmosphericpressure(1013 mbar)by more than 0.5 bar at the maximumadmissible operating temperature. to use the CLSto feed, forward, or store glycol- or polyglycol based oils and greases. to use inadmissible components or components expressly not suitable for the purpose.

Unauthorised activities

The following activities may be carried out by SKF manufacturer specialists or authorized persons only due to potential sources of faults that may not be visible for the user, or due to legal regulations:

Removal, replacement or changes to the centralized lubrication system or components integrated or connected to it.

Changes to the control printed circuit board or the power supply board exceeding the adjustment of lubrication and pause times or thereplacement in caseof defects.

Dismantling of individualcomponents of the centralized lubrication system. Changesto the power supply or to the admissibleinput voltage.

Changes to the admissible or specifically required operating pressure for the supplied centralized lubrication system.

Conversions or modifications

Unauthorizedconversionsormodificationsmayresultinunforeseeableimpactsonsafetyand functionality. Therefore, any unauthorized reconstructions or changes are expressly prohibited.

Inspections

Thefollowing inspections were carried out prior to delivery: Electrical inspections following EN 60204-1 (depending on the type of component supplied) Tests made in accordance with ATEX (depending on the type of component supplied)

Safety and functional tests (depending on the type of component supplied)

Warning labels on the centralized lubrication pump or system

Hand injurywarning

During operation of the centralized lubrication system,particularly of the pump, never remove the lid or the barrel andreach into the reservoiror the barrel. Risk of trapping or shearingoff hands and fingers!

Electric shock

Connection of 24 V DCcomponents mustbe provided by a safe galvanic isolation PELV (ProtectiveExtraLow Voltage) or SELV (Safety Extra LowVoltage) always.

Other applicable documents

Inaddition tothese installation instructions,the following documents mustbe observed by the respective target group:

Operational instructions andreleaseprovisions by theoperator.