Assembly process No.

Installation of pivot shaft (1/2)

A-3

Note) This work is required for disassembly to 32-t parts for transportation.

Fig. 1

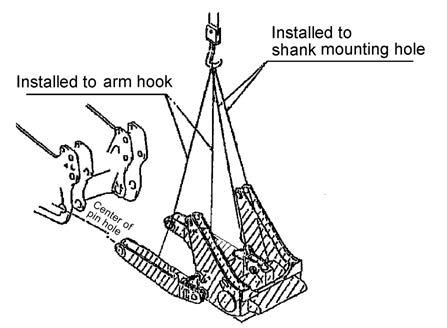

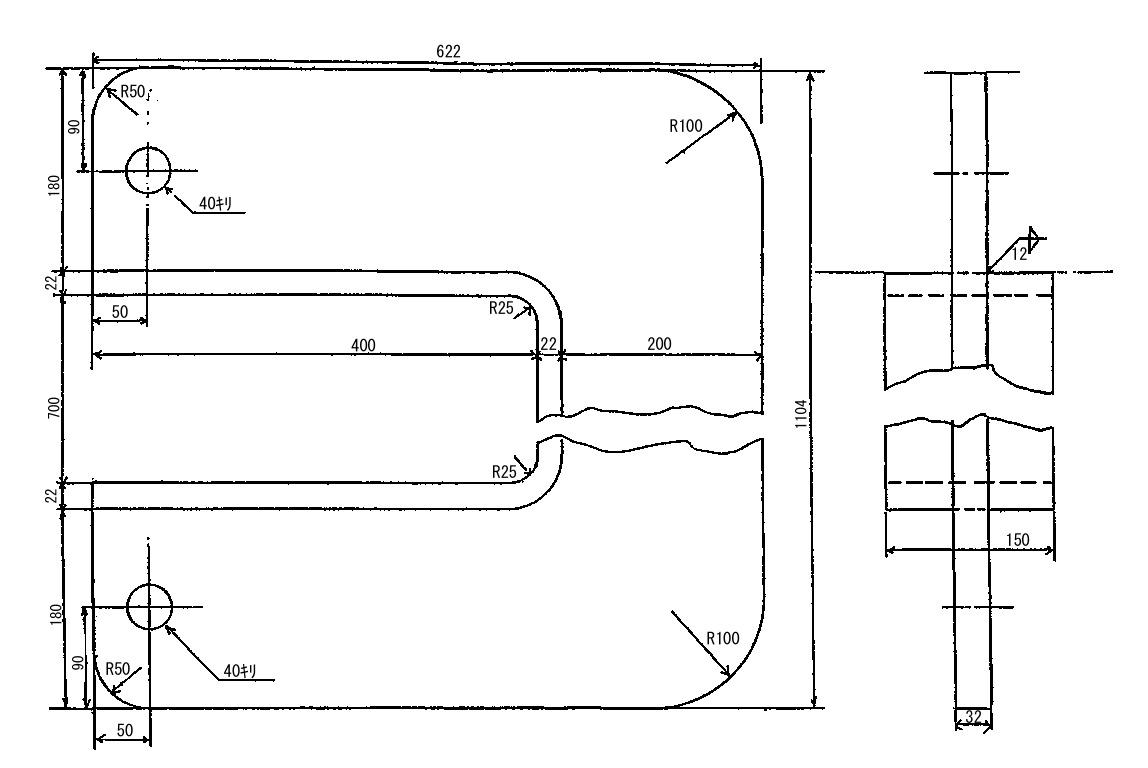

1) Slinging pivot shaft • To sling the pivot shaft, install the sling as shown in (Fig. 1). • A proper length of the sling wire is about 600 mm. Dimension (A) in (Fig. 1) • Install the sling wire to about 500 mm from the pivot shaft end. Dimension (B) in (Fig. 1) Part Nos. of pivot shafts Dual Single

Right shaft 195-50-42111 195-50-42111

Left shaft 195-50-42111 195-50-42210

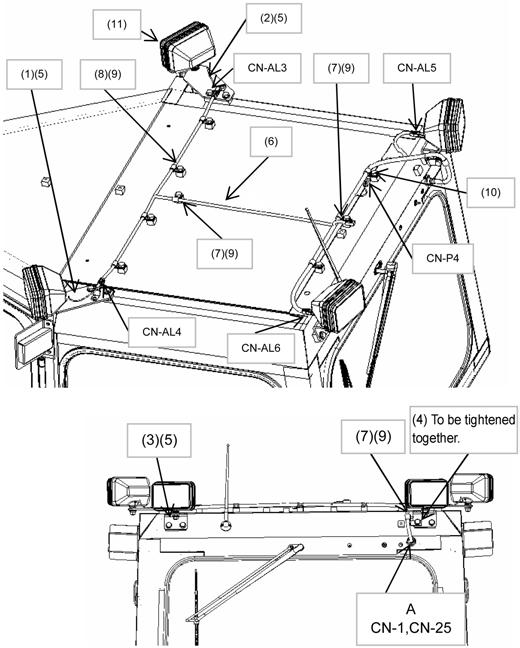

2) Setting position of pivot shaft * For details of installation, see the following page. • Set the pivot shaft to the machine with its flange directed as shown in (Fig. 2).

Fig. 2

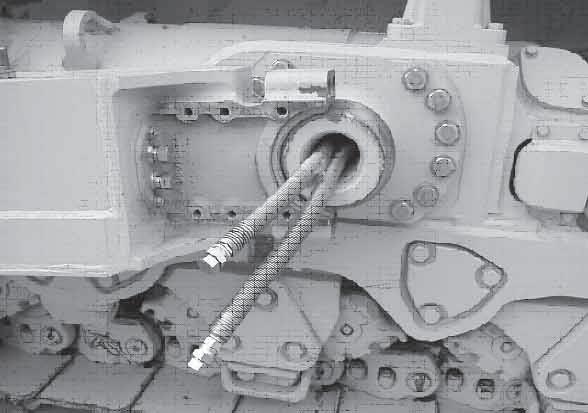

3) Bolting to machine • When installing the pivot shaft, tighten the bolts lightly and evenly in the diagonal order to press fit the spigot joint portion until the flange face is seated. • Use an impact wrench (– 306 kgm) and a socket shown in the following table. (See [Fig. 3]) • While turning the torsion seal cover properly, tighten the bolts. Note: After tightening, be sure to check the tightening torque. Part No. of bolt

01010-83000 (14 pieces each on right and left)

Part No. of washer

01643-33080 (14 pieces each on right and left)

Bolt specification

Fig. 3

M30 × 100 mm

Socket

46 mm 1,720 ± 196 Nm (175 ± 20 kgm)

Tightening torque

Tilt hose 4) Installation of cork plug After tightening the above bolts, drive the cork plugs into the screw bolt holes in which the bolts of the pivot shaft flange will not be installed. Part name Plug

Part No.

Q’ty

07049-03038

2 pieces each on right and left

32