2 minute read

A-19 Check track tension

Assembly process No.

A-19 Check track tension (1/2)

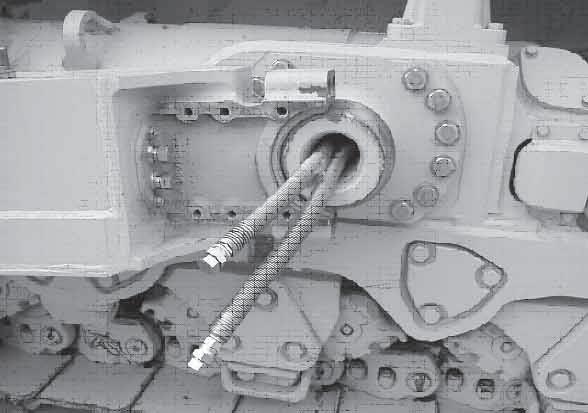

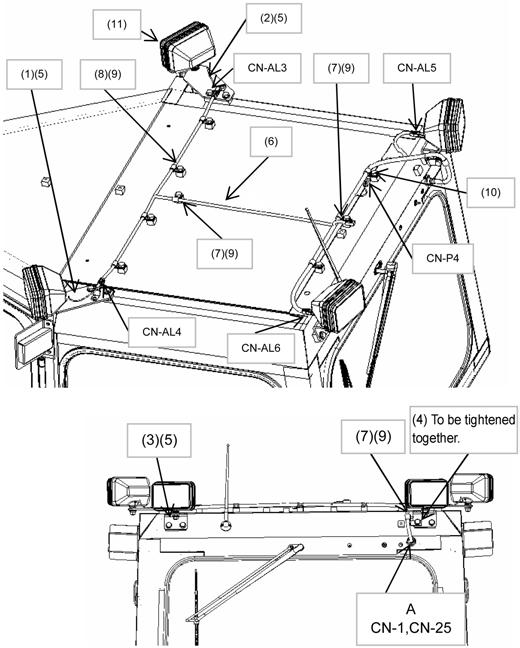

Adjusting ï When increasing tension 1.First remove the bolts (1) and then remove the cover (2). (Fig. 1) 2.Pump in grease through the grease fitting (3) with a grease pump. (Fig. 3) 3.To check that the correct tension has been achieved, move the machine backwards and forwards. 4.Check the track tension again, and if the tension is not correct, adjust it again.

5. Continue to pump in grease until S becomes 720mm (28.4 in).

If the tension is still loose, the pin and bushing are excessively worn, so they must be either turned or replaced.

Please contact your Komatsu distributor. (Fig.2)

ï When loosening tension 1.Remove both bolts (1), then remove cover (2). (Fig. 1) 2.Loosen plug (4) gradually to release the grease. (Fig. 3) 3.Turn plug (4) a maximum of one turn. 4.If the grease does not come out smoothly, move the machine backwards and forwards a short distance. 5.Tighten plug (4). 6.To check that the correct tension has been achieved, move the machine backwards and forwards. 7.Check the track tension again, and if the tension is not correct, adjust it again. Fig. 1 Fig. 2 Fig. 3

Precautions Necessary tools Necessary equipment ïThere is danger of plug (4) flying out under the high Name Q'ty Name Q'ty internal pressure of the grease. Never loosen plug (4) more than 1 turn.

Never loosen any part other than plug (4). Never put your face in the mounting direction of plug (4).

If the track tension cannot be loosened with the procedure given here, please contact your Komatsu distributor. ïWhen removing cover (2), be careful not to let any dirt get inside. ïThere is a safety label stuck to the back of cover (2). Other remarks

Be careful not to damage the safety label.

Assembly process No.

A-19 Check track tension (2/2)

Inspection

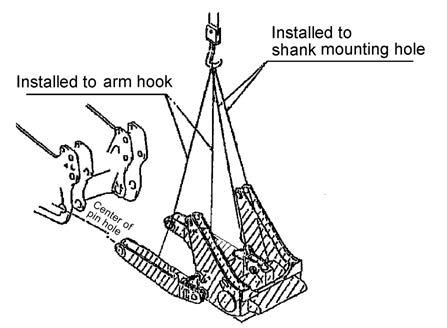

Stop the machine on level ground (stop with the transmission in FORWARD without applying the brake). Then place a straight bar on the track shoes between the carrier roller and the idler as shown in the figure, and measure the clearance between the bar and the grouser at the midpoint. If the clearance is 20 to 30 mm (0.79 to 1.18 in), the tension is standard. If the track tension is not at the standard value, adjust it in the following manner. (Fig. 4) Fig. 4

Precautions Necessary tools Necessary equipment

Name Q'ty Name Q'ty

Other remarks