Table of tools for field assembly No. Tool name Specification 1 Air compressor Min. 0.69 MPa – 15 m³/min 2 Pneumatic hose and cou- Hose length: 30 m pler (for pneumatic tools) Coupler must fit impact wrench and oil feed pump. 3 Crane truck Lifting load: 50 ton Lifting load: 25 ton 4 Welder 5

8 9

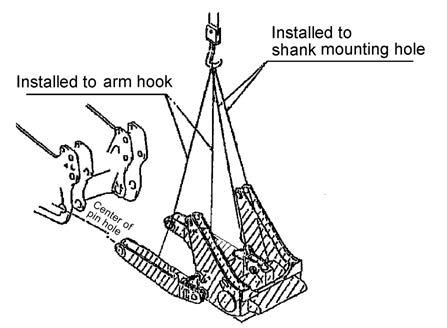

Rated load 1.5 ton Rated load 3.2 ton Rated load 6.3 ton Wire rope sling ø 36 × 6 m ø 20 × 5 m ø 12 × 2 m Belt sling 25 mm wide × 3 m (made of synthetic fibers) 50 mm wide × 3 m Hydraulic wrench Min 5,890 Nm {600 kgm} Hydraulic wrench socket Width across flats: 46

10 11 12

Extension bar Air impact wrench Socket for impact wrench

13

Torque wrench

6

7

Chain lever hoist (Chain block)

14

Soket for torque wrench

15

Eyebolt

16

17 18 19

20 21 22 23 24 25 26

T 38.1 × L300 See No. 41 Width across flats: 19, 22, 24, 27, 30, 32, 36, 41, 46, 50 Tightening capacity 588 Nm {60 kgm} Tightening capacity 1,370 Nm {140 kgm} Tightening capacity 2,060 Nm {210 kgm} Width across flats: 32, 36, 41, 46

M12, Using load: 220 kg M16, Using load: 450 kg Shackle SD22 BC36 SB44(T) Sledge hammer Double-headed: 4.5 kg (10 lbs) Pinch bar (Lever) ø 25 × 900 mm Thread repair tap M33 × Pitch 2 M30 × Pitch 3 M24 × Pitch 3 Jack Screw type, Using load: 15 ton Single ended wrench Nominal width across flats (mm) 17, 19, 22, 24, 27, 30, 32, 36, 41, 46, 50 Lubricating oil and grease See assembly procedures A-3 and A-18. Anti-seize compound Molybdenum disulphide grease (LM-P) Cleaning oil For removing preservative Paint remover For removing phthalate resin coating Paint for repair See coating material list

11

Q'ty 1 1 set 2 1 2 1 1 1 4 2 4 2 1 1 1 unit each 1 1 unit each 1

Remarks For air compressor

For welding blade spill guard (If equipped) JIS B8819 or equivalent

Specification: JIS B8817 or equivalent

Specification: JIS B8818 or equivalent Mainly for master link bolt For master link bolt

Must fit impact wrench No. 41. Impact wrench socket may be used if it fits.

1 1 1 unit each 4 2 4 2 2 1 1 1 1 1 2 2 units each

For blade center link Specification symbols are quoted from JIS B2801

JCMAS P018 or equivalent, Note 1) For master link

For assembling track frame For tightening hydraulic hose mouthpiece nut

— 200 g 40 l 5l 3 units each

See coating material list.