SAFETY 1. Forklift, lift equipment and rigging have been inspected (each shift, month and year) and are in good, safe condition and properly installed.

Ü

DO NOT exceed the rated capacity of the telescopic handler as equipped for handling suspended loads. The weight of the rigging must be included as part of the load.

2. An operator's manual and applicable load charts are on the forklift.

Ü

During transport, the length of the rigging between the attachment and load should be as short as possible to reduce booms height and movement. DO NOT raise the load more than 305 mm (12 inches) above the ground, or raise the boom more than 45 degrees.

Ü

Only lift the load vertically – NEVER drag it horizontally.

Ü

Use multiple pickup points on the load when possible. Use taglines to restrain the load from swinging and rotating.

Ü

Start, travel, turn and stop SLOWLY to prevent the load from swinging. DO NOT exceed walking speed.

Ü

Inspect rigging before use. Rigging must be in good condition and in the U.S. comply with OSHA regulation §1910.184, “Slings,” or §1926.251, “Rigging equipment for material handling.”

Ü

Rigging equipment attached to the forks must be secured such that it cannot move either sideways or fore and aft. The load center must not exceed 610 mm (24 inches).

Ü

DO NOT lift the load with anyone on the load, rigging or lift equipment, and NEVER lift the load over personnel.

Ü

Beware of the wind, which can cause suspended loads to swing, even with taglines.

Ü

DO NOT attempt to use frame-leveling to compensate for load swing.

3. Work zone ground conditions can support the equipment and load. Any hazardous conditions in the work area have been identified, and the operator notified. 4. Equipment is being used within its rated capacity and in accordance with the manufacturer's instructions. 5. Operator and crew members have been trained in the safe use and operation of the equipment, including how to avoid electrocution. 6. During use, no part of the equipment, load line or load will be within the minimum clearance distance specified by OSHA [3.0 m (10 feet), and more for lines rated over 50 kV] of any energized power line, and any taglines used are non-conductive. 7. In addition, for lift equipment with a rated capacity greater than 907 kg (2000 lbs.), the employer must ensure that: a.) An accessible fire extinguisher is on the forklift; b.) Monthly and annual inspections are performed and documented, and records retained (three months for monthly, one year for annual); c.) Before November 10, 2014, operators must have had the additional training and qualification / certification required by OSHA regulations §1926.1427 and §1926.1430.

RS9-50 Tire Servicing Safety Reminder Ü

Note: Refer to the full text of the OSHA crane regulation (29 CFR Part 1926, Subpart CC) for a detailed description of the regulatory requirements.

PRINTED IN U.S.A.

21

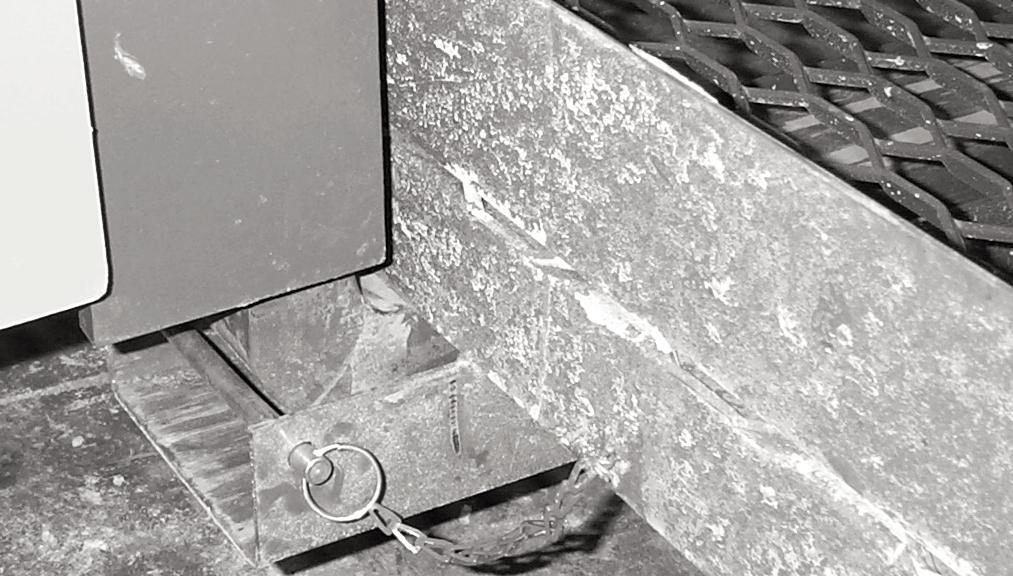

The RS9-50 telehandler requires foam filled or solid rubber tires for proper load capacity and stabilty. Never replace foam filled or solid rubber tires with pneumatic tires. Pneumatic tires will affect machine load capacity and stability.

50960200/A0521