1 minute read

ASSEMBLY INSTRUCTIONS (Continued)

Level Base

Place a level on the top of the traverse base and check the unit for level side to side. Adjust the leveling feet as necessary until the machine is level. See FIG. 3 .

Now place the level across the traverse base from front to rear. Adjust the leveling feet as necessary until the machine is level. See FIG. 3 .

When both front to back and side to side leveling procedures have been completed, thread the hex jam nuts up against the nut that is welded to the bottom of the machine. Be careful not to move the leveling feet when tightening the jam nut. See FIG. 3. Make certain that all four leveling feet are firmly contacting the floor.

Recheck that the machine is level after locking the four feet into position.

Remove the carton and remove the contents from the carton onto a workbench. The carton includes:

LOOSEN JAM NUT TO ADJUST FOOT

LEVELING FEET LOCATED AT CORNERS OF MAHCINE

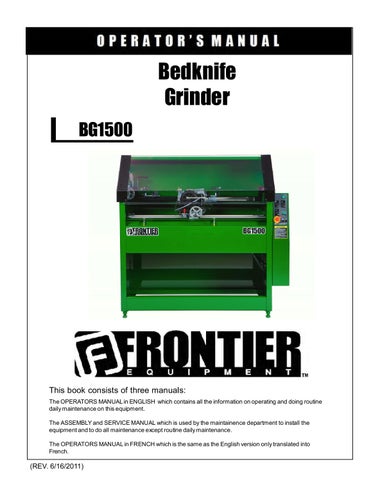

Product Packet Assembly (Operators & Service Manuals)

Coolant Concentrate (Pint)

Grinding Wheel Wrench

Assemble The Flood Coolant System

1. The flood coolant system has been fully assembled at the factory. The only requirement is to fill the coolant tank.

2. Mix the coolant concentrate at a ratio of 50 parts water to 1 part concentrate. Refer also to the label on the coolant container. If the coolant tray is empty, this will take about 6.5 gallons of water and one pint of concentrate [24.6liters of water, and 0.5 liter of concentrate].

USE OF COOLANT OTHER THAN FACTORY SUPPLIED COOLANT CONCENTRATE IS NOT RECOMMENDED. ALTERNATIVE COOLANT CONCENTRATES MAY CAUSE CORROSION, GUMMING, OR GRINDING PROBLEMS.

3. After the mixed coolant has been added, your coolant system is ready to operate. When you start the coolant pump for the first time you must adjust the coolant flow using the valve on the grinding head. See FIG 4.