1 minute read

Adapting the hydraulics

Swather with operating terminal

1

Swather with ISOBUS Terminal

1 2

2 5

6 6.2.3 Adapting the hydraulics

Attention!

Because tractors have different hydraulic systems, it is essential to consult the tractor's operating manual. This is the only way to prevent damage to the tractor's hydraulic system. Do not allow the tractor hydraulics to overheat. Observe any warning signals installed on the tractor. – Adapt the swather's hydraulic system to the tractor hydraulics. – Do not exceed the max. permitted oil quantity –see Specifications, page20. – The machine's pressure relief valve must be set to a higher value (+20bar) than the tractor's relief valve.

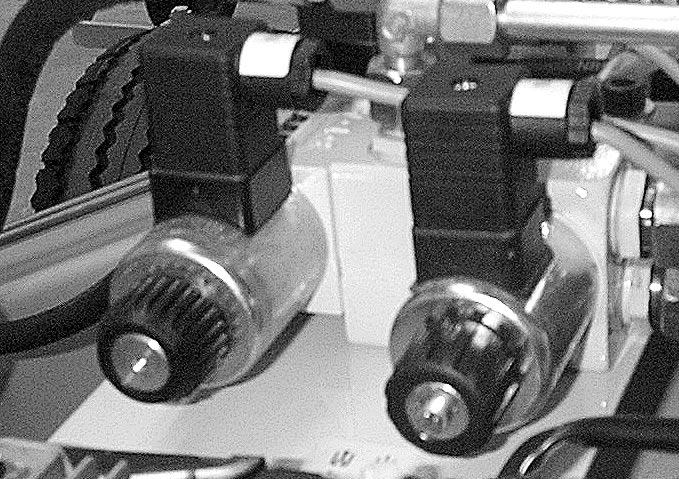

The swather's hydraulic system must be adjusted to match the tractor hydraulics. The adjustment is made at the hydraulic valve block(1). The factory setting on the rotary swather is for tractors with an open hydraulic system (standard system). (Fig.5,6)

Constant flow pump

Tractor with constant flow pump = open hydraulic system (standard system): • Turn the adjusting screw(2) on hydraulic valve block(1) outwards. (Fig.5,6)

Constant pressure pump

Tractor with constant pressure pump = closed hydraulic system (e.g. John Deere, Case Maxxum, Case Magnum, Ford Series 40): • Screw in adjusting screw (2) on hydraulic valve block(1) completely. (Fig.5,6)

3

2 7 Load sensing of hydraulic coupling

(swather withISOBUS Terminal) The rotary swather has a load-sensing connection(3). If the tractor is fitted with a load-sensing hydraulic system, the control line of the rotary swather can be attached to it. Connect the control line to the tractor at the bulkhead coupling(3) (size L10). (Fig.7)

Turn the adjusting screw(2) on the hydraulic valve block fully inwards. (Fig.8)