1 minute read

Monthly ......................................................................... 5

crawler anchor pins

breaker electric motor

breaker reducer Monthly

Lubricate grease fittings on both left and right side crawler anchor pins with Spec. 100-3 (Fig. 51). Pump grease into the fittings until new grease can be observed coming out of the pins.

Fig. 51: Crawler anchor pin lubrication

Crawler anchor pin (s) (grease fitting located inside crawler frame)

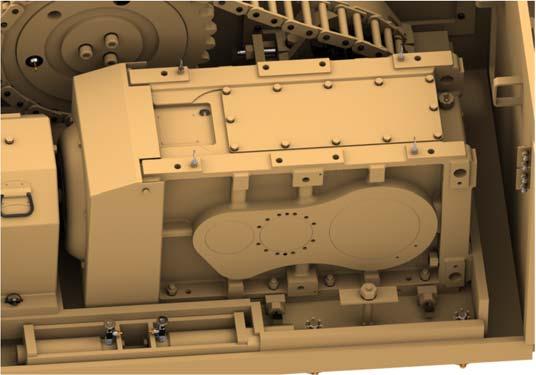

Lubricate the breaker power unit electric motor with Spec. 100-14 or Spec. 100.16 high temperature grease through the two (2) grease fittings located on the lubrication manifold (Fig. 52) on the right side of the machine. Pump only one or two pumps of grease into each fitting.

NOTICE! Incorrect grease or over greasing may cause serious damage to the electric motor.

Lubricate the breaker reducer with Spec. 100-3 through the two (2) grease fittings located on the remote grease block (Fig. 52). Pump only one or two pumps of grease into each fitting using a hand grease gun.

IMPORTANT! Rapid greasing with a power grease gun can force grease inward past the seals, causing seal leaks.

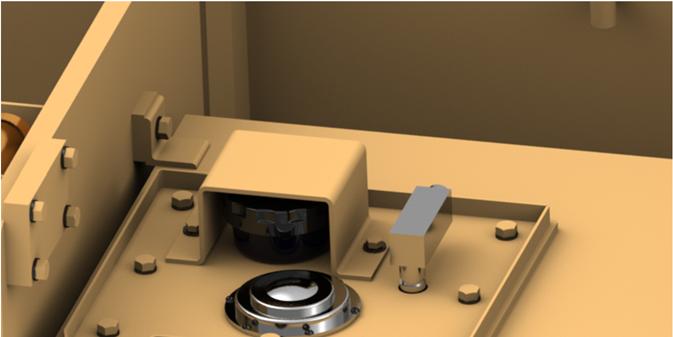

Fig. 52: Breaker reducer lubrication

Breaker reducer grease fitting (2)

Electric motor grease fitting (2)

Check the breather vent element on the hydraulic oil tank (Fig. 53) and change as required.

hydraulic oil tank breather vent

Fig. 53: Hydraulic oil tank breather vent

Breather vent