4 minute read

Chain elongation measurement ........................... 5

Measure Chain for Elongation

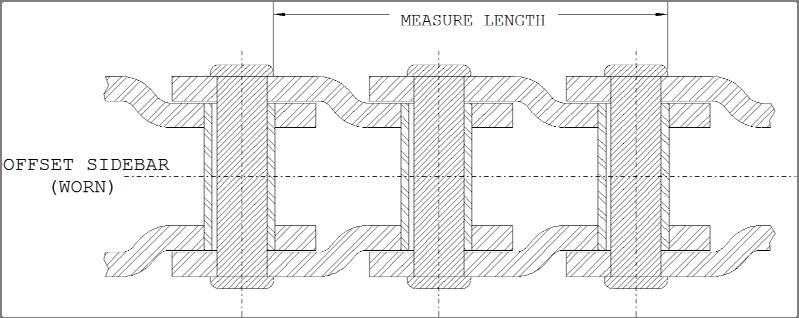

One of the most important areas in the evaluation of chain wear is the elongation of the chain. This is obtainable in the field and does not require chain disassembly or return to manufacturer for analysis.

To measure a chain for elongation:

The selected strand must be under some load to pull out internal clearances and must be supported, if necessary, to insure the chain lies in a straight line.

The selected strand should include as many pitches as possible, with a minimum of four pitches. Always use an even number of pitches for

straight sidebar chain.

Use any reasonably accurate measuring device (steel ruler, calipers, tape measure, etc.).

Determine the distance from a spot on the first pitch to the same spot on the last pitch. The edge of the pin head is usually a good spot to measure (see Fig. 73).

Fig. 73: Chain elongation measurement

The percent elongation is defined as:

% elongation = measured strand length – (nominal pitch x number of pitches measured) x 100 (nominal pitch x number of pitches measured)

Example 1: 20 pitches of 3.500 inch pitch chain were measured as 71 13/16inches, therefore

% elongation = 71 13/16 – (3.5 x 20) x 100 = 2.57% (3.5 x 20)

Example 2: 20 pitches of 3.750 inch pitch chain were measured as 76 15/16 inches, therefore

% elongation = 76 15/16 – (3.75 x 20) x 100 = 2.67% (3.75 x 20)

Replacement chain should be order at approximately 2.6% elongation and replaced at approximately 3% elongation. It is highly recommend-

ed that the headshaft sprockets be changed at the same time as a new chain is installed to obtain maximum chain life.

Table 4 lists chain order and replacement values.

Table 4: Chain elongation values

Chain Pitch Baseline Length (20 pitches)

Order Length (approximately 2.6%) (20 pitches)

Replacement Length (approximately 3%) (20 pitches)

3.500 70 inches 71 13/16 inches 72 1/8 inches 3.750 75 inches 76 15/16 inches 77 1/4 inches

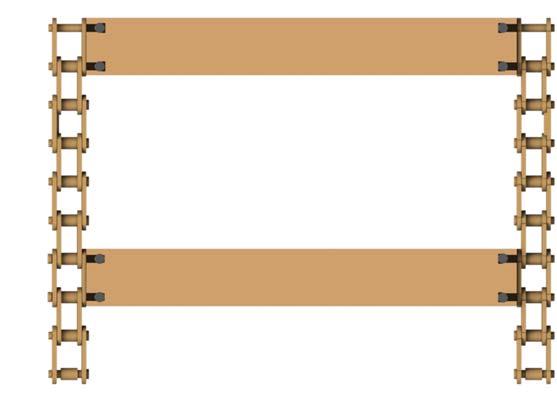

How to assemble the conveyor chain sections

To assemble the conveyor chain sections proceed as follows (Fig. 74):

1. Lay conveyor chain sections on a clean flat surface.

2. Insert connector pins through flight end and align holes in spiral pin with holes in flight bar.

3. Insert spiral pin.

4. Drive spiral pin in with a hammer and punch. Ensure that spiral pin is recessed on both sides of flight bar.

5. Repeat the previous assembly instructions until the complete chain has been assembled.

Fig: 74: Conveyor chain assembly

6 link chain section

Extended pin connecting link Spiral pin (4)

Block link assembly Flight bar

Side bar

How to remove the conveyor chain assembly

To remove the conveyor chain assembly proceed as follows: 1. Release tension on the conveyor chain. (See Conveyor chain adjustment in this chapter).

2. At the chain disassembly/assembly point, raise the chain a minimum of 3” high and block it under the flight.

Note: There are notches in the frame on both sides of the conveyor deck. The notches are to provide access to the conveyor chain during disassembly and assembly. This is the chain disassembly/assembly point.

3. Separate conveyor chain by removing spiral pins and connecting links in one section of the chain.

4. Connect a pulling device (e.g. winch or lifting tackle with adequate load limit), or the new conveyor chain, to either end of the old conveyor chain and slowly pull the old conveyor chain completely out of the machine.

WARNING! When using a pulling device (e.g. winch or lifting tackle with adequate load limit) for pulling the conveyor chain, the connection could fracture under the load. You could be seriously injured or killed by the recoiling chain or cable. Use only approved lifting equipment for connecting pulling devices to the conveyor chain.

How to install the conveyor chain assembly

To install the conveyor chain assembly proceed as follows:

1. Check to ensure that the conveyor tail shaft is completely retracted. If not retracted, see Conveyor chain adjustment in this chapter.

2. If the old conveyor chain was not used to install the new conveyor chain, then run a cable or pull rope with an adequate load limit through the bottom conveyor pan and connect to the conveyor chain.

3. Connect an additional pulling or lifting device (e.g. winch or lifting tackle with adequate load limit) to the other end of the cable or pull rope and slowly pull the new conveyor chain completely through the bottom conveyor pan.

IMPORTANT! If old conveyor chain is still on machine, installation can be facilitated by connecting the new conveyor chain to the old conveyor chain via the chain connectors and pulling it through the bottom conveyor pan.

4. Fold conveyor chain back over the tail shaft and drive shaft and slowly pull the chain along the conveyor ensuring that the chain is under the chain hold downs.

5. Ensure that the chain is properly meshed with the sprockets on the head and rollers on the tailshaft.

6. Connect conveyor chain (see How to assemble the conveyor chain sections in this chapter for proper connection).

7. Adjust tension on the conveyor chain (see Conveyor chain adjustment procedure in this chapter.

8. With machine running, visually inspect tail shaft to ensure that the conveyor chain is properly engaged with the tailshaft rollers.