3 minute read

Assembly of the Oil Pump

from Case L-Series Loader Backhoe Transmission Update Kits Installation Instructions Manual 7-54022 - PDF

NOTE: Other than reassembling an “A4” pump found in good condition, DO NOT attempt to rebuild the pump as part of the transmission update rebuild. Any pump found in questionable condition should be replaced with a new 181199A4 pump from NAPO (must be ordered separately).

STEP 331 STEP 333

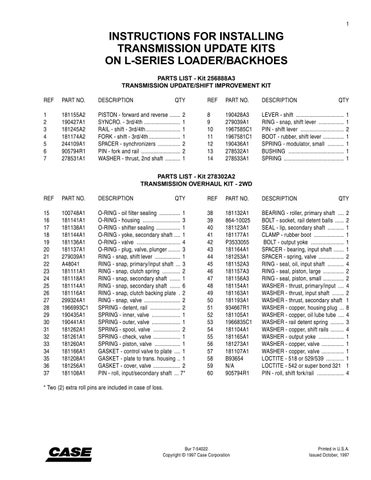

Install the plunger for the oil pump relief valve.

STEP 332

BP95F603

BP95F602 Install the pin for the oil pump relief valve. The machined end of the pin must be toward the plunger. Make sure that the pin goes into the bore of the plunger. Install the spring.

STEP 334

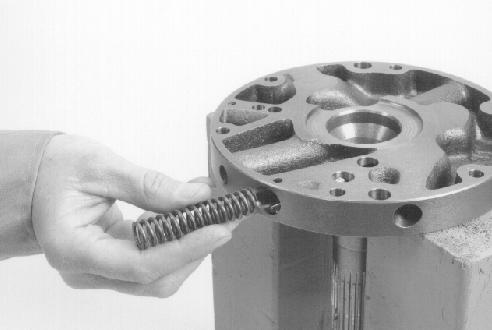

Install the plug.

STEP 335

BP95F601

BP95F600

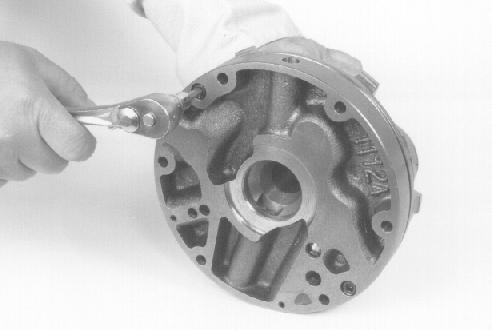

BP95F269 This step will be difficult because the spring will be under heavy tension. Push the plug in until the plug is to the inside of the hole for the roll pin. Install the roll pin. It helps to use an appropriate size punch, inserted from the bottom to hold the plug in place, while the roll pin is driven in from the top.

BP95F268 Install the ball, the spring, and the plug for the torque converter relief valve. Make sure that the hole in the plug is aligned with the hole for the roll pin.

STEP 337

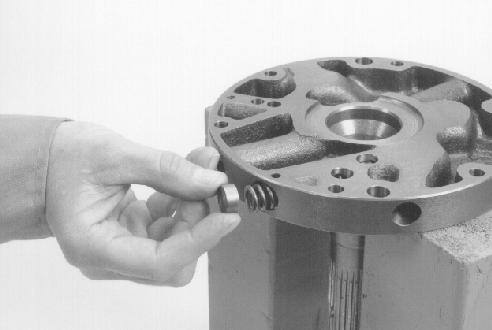

BP95F255 Use clean transmission oil to lubricate the small bore in the housing, the small gear, and the needle bearing. Install the small gear on the shaft in the pump housing.

STEP 340

BP95F271 Install the roll pin through the holes in the pump support and the hole in the plug.

STEP 338

BP95F254 Use clean transmission oil to lubricate the large gear, the bushing in the large gear, and the bore in the pump housing. Install the large gear so that the side with the lugs is down.

STEP 341

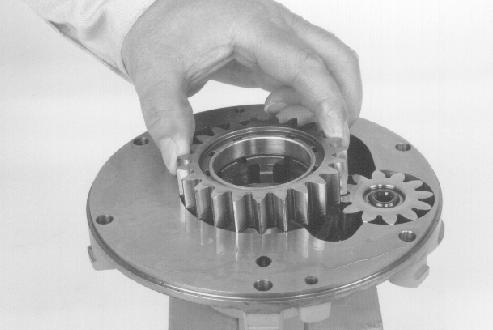

BP95F259 If the seal was damaged or worn but the rest of the pump was found to be in acceptable condition, replace the seal with a new seal from NAPO on 181199A4 pumps only. Use an acceptable driver or a press to install a new seal in the end of the pump housing. BP95F253 Install the pump support on the pump housing. Make sure that all the bolt holes are aligned.

BP95F252 Install the two Allen head screws to fasten the pump support to the pump housing. Tighten the Allen head screws snug.

STEP 343

Install a large worm gear clamp (radiator hose clamp) around the outside of the pump housing and support. Position the clamp so that it covers the seam between the two parts and contacts both. Tighten the clamp.

Tap the housing with a soft hammer. Retighten the clamp.

Tap the housing again with a soft hammer. Retighten the clamp.

Tighten the Allen head screws to 10 mm (89 pound-inches). Remove the clamp and set the pump on a clean work surface with the housing facing up. Insert a small screw driver or punch through the torque converter hub hole and rotate the large gear by pushing against one of the drive tangs. The gear should rotate freely. If it does not, loosen the Allen head screws and repeat the above steps.

If the large gear rotates freely, fill the pump full of clean transmission oil and rotate the large gear three revolutions before installing the pump on the transmission. BP95F251 Reinstall the O-ring, if still in usable condition. Install a new O-ring if available.