2 minute read

Special Torques

from Case L-Series Loader Backhoe Transmission Update Kits Installation Instructions Manual 7-54022 - PDF

DISASSEMBLY OF THE TRANSMISSION HOUSING

NOTE: Parts can be replaced individually for the transmission in which Kit 256888A3 has already been installed.

NOTE: If the transmission has already been updated (U3 stamped on the plate) and is to be overhauled for general service, the references to the update kit in the procedures should be ignored.

NOTE: There has been different revisions to these overhaul kits. Early revisions have only two O-rings (item 20 or 66), four copper washers (item 51 or 97), and no roll pins (item 60 or 124). If you have an early overhaul kit, reuse the existing parts as necessary.

STEP 1

Remove the transmission and torque converter from the tractor as a unit. Once the transmission has been removed from the tractor, carefully remove the torque converter from the transmission charge pump. Examine the drive hub of the torque converter. If any damage is apparent to the drive tangs or the diameter of the hub, the torque converter should be replaced and the charge pump should be disassembled and inspected carefully (see steps 311 through 344).

Examine the guide button on the crankshaft end of the torque converter. If the button shows any evidence of being bent, distorted, or worn on one side, the torque converter was not properly aligned with the crankshaft before being bolted to the flexplate-starter ring support (flywheel). Discard and replace the torque converter if any of these conditions are apparent. Also check the guide hole in the end of the crankshaft for damage from this condition. May be repaired with an abrasive cloth or a file if damage is miner. Replace if damage is excessive.

STEP 2 STEP 3

BP95F007 Remove the drain plug and drain the oil from the transmission, if this was not done prior to removal.

NOTE: The four-wheel drive transmission is shown. On two-wheel drive transmissions, the drain plug is at the rear of the transmission.

STEP 4

Examine the drain plug closely. If excessive iron and steel particles are present, it is possible the transmission charge pump is failing. If excessive bronze particles are apparent in the oil, the synchronizers my be worn. If the magnet is loose or missing, replace the drain plug.

STEP 5

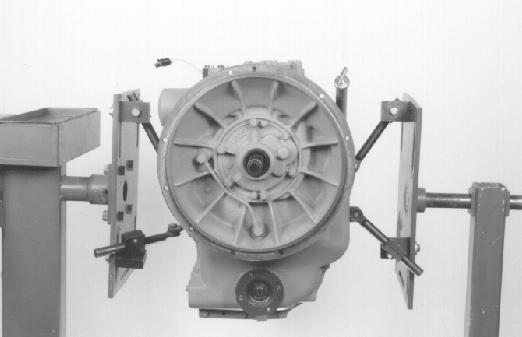

BP95F004 Fasten the rear housing to acceptable support equipment. It is recommended that you use equipment that will let you rotate the transmission. BP95F013 Remove the cap screws which fasten the transmission control valve to the front housing.