2 minute read

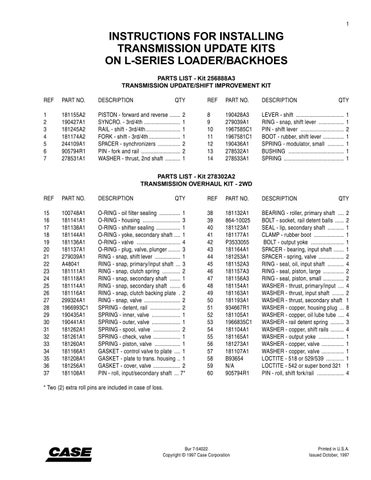

Inspection of the Input Shaft

from Case L-Series Loader Backhoe Transmission Update Kits Installation Instructions Manual 7-54022 - PDF

STEP 142

Check the piston return springs for broken or cracking coils. Compare the height of both springs. If they are not the same height, or show evidence of damage, replace both springs. The springs should be approximately 63 mm (2.48 inches) long.

STEP 146

STEP 143

Check the teeth on the gears for wear and damage. If a tooth is badly damaged, be sure to inspect the gear or spline that is in mesh with the damaged gear.

STEP 144

Check the splines on the input shaft for wear and damage. Check the passages in the input shaft to be sure that the passages are open and free of foreign material. Inspect the input shaft housing piston bores for evidence of irregular wear patterns, rough finish, grooving, or scratches that might cause leakage or cause the piston to bind in the bore when reassembled. Also check the slots in the side of the housing for grooves or notching from the tangs on the OD of the separator plates. If any of these conditions are apparent, replace the input shaft housing.

STEP 145 1

BP95F130

2

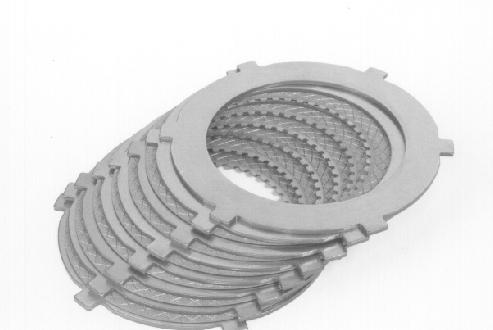

BP95F129 If the clutch discs are to be used again, keep the clutch packs separate and record which clutch pack goes with each clutch. See photo above for correct number and arrangement of clutch discs. BP95F131 Use a straight edge to check each steel disc (1) and each friction disc (2) to be sure each part is flat. If a steel disc (1) or a friction disc (2) is not flat, a new part must be installed during assembly. If the friction discs (2) are smooth or almost smooth (some or all of the grooves are no longer distingushable) or the friction material is chipped, flaking or appears burned, use new parts during assembly. Inspect the steel discs (1) for pitting, scoring, or other damage. If there is any damage, use new parts during assembly. Also, check the splines for wear. Inspect the bore and the shaft in the clutch housing for damage that will cause leakage when the clutch is assembled. Use new parts as required during assembly. If you will be using new friction discs, soak the friction discs in clean transmission oil for at least an hour before assembly. If you are using the old friction discs, make sure that the friction surfaces are coated with transmission oil before assembly.

STEP 147

Check the ball bearings and the needle bearings for flat areas, pitting, and other damage. Replace as necessary.