2 minute read

REAR AXLE - TROUBLESHOOTING 3. TROUBLESHOOTING

SYMPTOM CAUSE SOLUTION

Impossible to disengage differential lock Poorly lubricated or damaged differential lock related links

Check differential lock pedal link, differential lock fork pin and differential lock shifter for abnormal condition or missing.

Creaking noise from tires while driving

No driving force for rear wheels when differential lock is deactivated (however, driving force exists in rear wheels when differential lock is activated)

Noise in rear axle

Leaked rear axle oil

Loose wheel nut/bolt or wheel disc mounting bolt

Damaged side gear or differential pinion in differential system

Damaged axle or related gear

Damaged 9 gear shaft, 56 gear

Damaged O-ring of brake cam lever

Damaged oil seal of rear axle

Check and tighten wheel bolts and nuts to specified torque

Check and replace any abnormal part

Replace

Replace

Replace

4. INSPECTION AND ADJUSTMENT

4.1 BACKLASH FOR DIFFERENTIAL PINION AND SIDE GEAR

4.2 PRELOAD OF TAPER ROLLER BEARING IN DIFF.

1. Measure the backlash of the differential side gear and the differential pinion.

• Standard: 0.15 ~ 0.30 mm (0.001 - 0.012 in)

Important

• Replace the differential washer with another type when adjusting the backlash.

• The both differential washers should be equal in thickness.

• (factory setting: 1.5 mm)]

2. Bind one end of the wiring to the pin of the differential shift and the other end to the push pull gauge.

3. Wind the wiring around the pin of the differential shift by turning the differential gear assembly 1~2 rounds.

4. Set the push pull gauge to the "Pull" position and pull the wiring to measure the rotating force.

Load of push pull gauge (only when using differential shift):

12 ~ 19 kgf (26 ~ 42 lb)

Standard turning torque .............

4.3 BACKLASH FOR SPIRAL BEVEL PINION AND RING GEAR

CALCULATION FOR LOAD OF PUSH PULL GAUGE

F = T kgf-m/R = 0.4 ~ 0.65 kgf-m / 0.034m = 11.76 kgf ~ 19.12 kgf (26 ~ 42 lb)

Therefore, F = Load of push pull gauge

T = Value for differential gear assembly turning torque by regulation

R = Radius of differential lock shift

5. Adjust the shim (2) in the differential bearing case (1) if necessary.

Size of adjusting shim:....... 0.1, 0.2, 0.4 mm

(Factory setting: L/H - 0.55 mm

R/H - 0.5 mm)

6. If the turning torque is over the specified value, increase the amount of the shims. If it is below the specified value, decreased the amount of the shims.

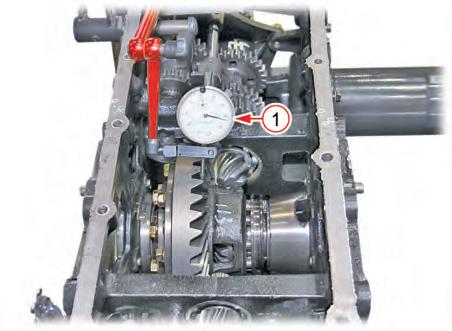

1. Set the lever type dial gauge (1) as shown in the figure.

2. Measure the backlash by shaking the gear with the pinion secured.

3. Standard backlash: 0.2 ~ 0.3 mm (0.0079 ~ 0.118 in)

4. If the backlash is below the specified value, move the shim for the bevel gear (1) heading the differential lock shift (2) at a proper amount. If the backlash is over the specified value, move the shim to the opposite direction.

Caution

• The number of both shims (1.05 mm) should be same in when adjusting the bearing preload.