ON EVERY ROAD AND HIGHWAY, THERE ARE THOSE THAT FOLLOW AND THOSE WHO LEAD.

At Gencor, we’ve led the industry with the most fuel-efficient, environmentally clean and lowest-maintenance design available to the hot mix industry. From the award winning Ultraplant® to the Green Machine, our record is unrivaled in innovative design. That’s the kind of leadership you’ve come to expect from Gencor.

THE LEADER IN PERFORMANCE AND EFFICIENCY

Call 407-290-6000 or visit www.gencor.com

12 How A Kentucky Contractor Punches Their E-Ticket to Success

Eliminating trucks waiting at the paver or at the plant, by sending those trucks to another project, allows contractors to lay more asphalt with fewer trucks.

16 What Is Road Base?

Going back to basics, this article details the importance of the correct road base in the durability and life of roads.

This guide offers training and education opportunities for contractors, a schedule of both in-person and remote sessions to expand employee skills and grow their value to your clients and your company.

McMillen Corp. squeezes more value form its $6 million fleet by leveraging insights from Tenna and Viewpoint Spectrum to support construction equipment life-cycle extensions.

One-year subscription to nonqualifying individuals: U.S. $45.00, Canada & Mexico $65.00, and $95.00 all other countries (payable in U.S. funds, drawn on U.S. bank). Single copies available (prepaid only) $10.00 each (U.S., Canada & Mexico), $15.00 each (International).

2024 DATES

• Week 1: January 22-25

• Week 2: January 29-February 1

• Week 3: February 5-8

• Week 4: February 12-15

REGISTRATION

CLASS SIZE IS LIMITED !

To secure your seat, please register before December 15, 2023

The Blaw-Knox University, now in its 58th season, is dedicated to training paver operators and foreman on proper Paver Operation and Maintenance and applied Best Paving Practices through classroom-style and hands-on application courses.

DETAILS

Details can be found at www.blawknox. com/training or call us at 407-290-6000 ext. 342.

For over a half a decade Blaw-Knox has earned its reputation as the go to source of training and instruction on hot mix paving. Blaw-Knox provides improved technical and problem solving skills on a variety of paver operations and maintenance topics. Course instructors share decades of field and teaching experience with attendees, including training on the latest DOT requirements.

Blaw-Knox offers multiple dates to satisfy the demand for its popular courses.

Electric and hybrid equipment needs to meet the same rugged and reliable standards of their diesel peers. The concept equipment unveiled here shows how John Deere is going to make that happen. Watch the video at: https://asph.link/jl8nc9

In a press release by the EEOC, Balfour Beatty was named the defendant in a lawsuit after a female employee was allegedly subjected to an environment of long-term, repeated sexual harassment, and was ignored despite reporting the incidents.

Read more at: https://asph.link/ iaam5k

The FHWA announced the immediate availability of the emergency relief funds, to help offset the costs related to infrastructure repairs and management services on the island.

Read more at: https://asph. link/galayr

The construction industry accounts for a large number of yearly work-related fatalities. There are ways to prevent this by following protocol and knowing the heavy equipment you are working with.

Read more at: https://asph. link/159b6i

While the government’s promotion of electric vehicles on the premise of combating climate change supports EV sales and battery manufacturing, the true reasons behind the switch are more complex.

Read more at: https://asph.link/ ft5tzz

Get social with us! Share pictures of what you’re working with over 29,000 other asphalt contractors on our Facebook page: Facebook.com/Asphalt.Contractor

As a decades-long leader for asphalt plant innovation, Astec has introduced numerous products contributing to sustainability. From the Double Barrel® dryer/mixer introduced in 1988 to the debut of the high RAP Double Barrel XHR in 2016. In addition to these industry-changing products, Astec also leads in sustainability with our warm mix system, the V-PAC stack temperature control system, low emission burners, and blue smoke systems. Astec is well-equipped to carry our culture of innovation into the future. Our dedication to sustainability includes new product development teams and an on-staff product manager for sustainability.

Reach out to learn more about how we can help you meet your asphalt plant sustainability goals.

Sustainable Innovation

Brandon Noel, Editor bNoel@ACBusinessMedia.com

Sustainable Innovation

Brandon Noel, Editor bNoel@ACBusinessMedia.com

234-600-8983

It’s not that uncommon for the flow of work to be interrupted during the day, but those long delays can now impact

y dream was to be in the film industry, to make blockbuster movies, and spend my days writing screenplays. I spent some time on a few film sets, working as a production assistant, and one of the truisms that I learned from that short stint was about how things worked on set. “Hurry up and wait,” was how another PA put it to me. Our job was to get there before the director, the actors, or anyone else in the movie, and hustle everything together and be ready for “action,” but it never failed to result in a lot of just waiting around.

The asphalt industry shares this element with the film industry. Crews can get everything ready to pave, and then just be stuck waiting for a truck to arrive with the material. It’s this unpredictable beast at the center of the jobsite, and sometimes it just goes wrong. On the other side of that, there are times you’ve got a line of trucks ready and rearing to go, but they’re stuck waiting due to unforeseen issues on the paving end. These types of delays on both side are not uncommon.

However, in this month’s issue, under the “Last Exit” article, I cover new rule changes made by the National Labor Relations Bureau, that significantly alter the rules regarding “prevailing wage rates” and what is considered a “work zone.” This is the October issue, and by the time you’re reading this, the rules are already in effect. If this is just coming as news to you, definitely check out that article, and perhaps, do some extra research about how it may impact your projects.

Last year was the first ever IGNITE Construction Summit, and it was a huge success. During the wintery days of December, experienced business owners/ operators, and representatives from the asphalt-pavement industry’s leading manufacturers came together to share growth strategies, as well as some of the knowledge they’ve gained from years of real-world experience.

Many of the sessions were open format (and will be again this year), panel-like discussions, where the best and most valuable information came from unplanned interactions with attendees. If you’re a business owner looking for an enriching off-season experience and for insights on how to go to the next-level. Don’t miss this. The conference runs Dec. 6-8!

The registration for IGNITE includes all education (opening keynote from Adam Smith and closing keynote from Ramon Ray) PLUS the five awesome panel discussions, ALL meals, and multiple cocktail receptions

It’s an incredible deal for a great conference experience you won’t want to miss.

I will be there, and I am really looking forward to getting to further my own knowledge, but, also, the social time we get to spend with everyone is incredibly valuable. All of the contractors that I connected with last December were people that I spent more time with and called on for help during 2023.

I can’t wait to see who I meet this year, and what connections we make. See ya’ll on the road!

EDITORIAL Editor Brandon Noel bnoel@acbusinessmedia.com

Contributing Editor ............................................. Jessica Lombardo jlombardo@acbusinessmedia.com

Managing Editor ............................................................... Gigi Wood gwood@acbusinessmedia.com

Senior Editor, Construction Technology, IRONPROS Charles Rathmann crathmann@acbusinessmedia.com

Senior Editor, Equipment & Workwear, IRONPROS Michael Cheng mcheng@acbusinessmedia.com

AUDIENCE

Audience Development Manager Angela Franks

PRODUCTION

Senior Production Manger Cindy Rusch crusch@acbusinessmedia.com

Art Director April Van Etten

ADVERTISING/SALES

Brand Director Amy Schwandt aschwandt@acbusinessmedia.com

Sales Representative Sean Dunphy sdunphy@acbusinessmedia.com

Sales Representative Kris Flitcroft kflitcroft@acbusinessmedia.com

Sales Representative Tadashi Soma tsoma@acbusinessmedia.com

AC BUSINESS MEDIA

Chief Executive Officer Ron Spink

Chief Financial Officer JoAnn Breuchel

Chief Revenue Officer Amy Schwandt

Brand Director, Supply Chain & Green Industry Jason DeSarle

Brand Director, Construction Sean Dunphy

VP, Audience Development Ronda Hughes

VP, Operations & IT Nick Raether

Content Director Marina Mayer

Director, Online & Marketing Services Bethany Chambers

Director, Demand Generation & Education Jim Bagan

Content Director, Marketing Services Jess Lombardo

CIRCULATION & SUBSCRIPTIONS

P.O. Box 3605, Northbrook, IL 60065-3605 (877) 201-3915 | Fax: (847)-291-4816 circ.pavement@omeda.com

LIST RENTAL

Sr. Account Manager Bart Piccirillo | Data Axle (518) 339 4511 | bart.piccirillo@infogroup.com

REPRINT SERVICES

Tadashi Soma (800) 538-5544 ext. 1267 | tsoma@ACBusinessMedia.com

Published and copyrighted 2023 by AC Business Media.

All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopy, recording, or any information storage or retrieval system, without written permission from the publisher.

@ASPHALT-CONTRACTOR-MAGAZINE

workers’ wages.

We’ve built our business and reputation through our unparalleled focus on equipment durability, attention to detail, and the ability to customize our products for each customer. We apply these foundations to our complete range of asphalt mixing plants and asphalt plant equipment designed for producers of all sizes.

The MB-R800 Drum Cutter enables precision cutting, as well as grinding compact materials, on construction sites. The MB-R800 can be used for railway, airport, underwater work, tunnels, pipelines and road work. This attachment features a 40-in. cut width and a pick force of 25,003 ft. lbs. Designed for heavy machinery equipment, the MB-R800 offers an output torque of 10,000 Nm. Available accessories include a spare parts kit, fixed coupling, low set drum kit, full set drum kit, dust suppression kit, high oil temperature reducing device, as well as rock and asphalt pick kits.

Coming in at 51-metric tons, the 510 P-Tier is a replacement of the current 470 P-Tier model. Including a variable undercarriage and the ability to handle buckets 5 yards and above, this new model will continue to deliver exceptional performance and capability in its class, while specifically targeting customer enhancements in operating costs and reliability. By using a more efficient powertrain, including the integration of E-fans, this new model provides customers up to 25% lower maintenance costs, 15% lower repair costs and 20% lower fuel consumption. This machine is designed to deliver exceptional performance to customers in mass excavation or deep underground applications while providing significant improvement in the cost of ownership.

The LiuGong 936F Crawler Excavator is designed for heavy digging and excavation. This 314-hp machine is powered by a 6-cyl., EPA Tier 4 Final L9 Cummins engine and features an operating weight of 85,538 lbs. Three accessible power modes, auto-idle and auto-shutdown help manage fuel consumption during use. Equipped with heavyduty tracks, the 936F offers a maximum digging depth of 24 ft., 1 in. This combination allows the excavator to work near and above trenching areas, while maximizing reach. A large bucket capacity enables moving heavy loads.

The DEVELON DL320-7 wheel loader is part of the next-generation -7 Series lineup, featuring upgrades such as increased bucket capacity, redesigned cab with first-class comfort features and fuel-saving technologies. The DL320-7 offers a 7% larger capacity bucket (4.5 yds.³) and axle upgrades. The increased capacity has been designed to provide faster, easier loading in fewer cycles. Standard features include powershift 4-speed transmission, multiple power modes, Z-bar lift arm, return to dig and limited slip differentials. The machine comes with a 271 hp engine, has an operating weight of 43,506 lbs., a bucket capacity of 4.5 yds.³, and a static tipping load of 30,461 lbs.

Kleemann MOBIBELT mobile stackers are used for logistics processes on worksites, helping move different types of material for processing, site clearing and more. The machines flexibly extend the action radius of crushing and screening plants, making large stockpiles and logistics possible. Nowadays modern crushing and screening plants regulate material streams within the plant to a large extent automatically. Machine operators still have an influence on the final product and daily output. They control the input with their excavators and wheel loaders or the loading of stone or recycling material.

The Kleemann MOBIREX MR 130i PRO Mobile Impact Crusher is used as a primary and secondary crusher and combines output and sustainability. The new impact crusher covers a wide range of applications: from soft to medium-hard natural stone to recycling applications, such as the processing of concrete, rubble and asphalt. This machine generates an hourly output of up to 661 U.S. t/h. With its heavy rotor and powerful electric 335 hp drive together with prescreening capabilities, the crushing unit provides high and stable throughput. Thanks to the Continuous Feed System (CFS), continuous crusher utilization is provided. The all-electric drive concept E-DRIVE with the option of an external power supply enables the MR 130i PRO to be operated onsite free of emissions.

2024 DATES

• Week 1: January 22 - 25

• Week 2: January 29 - February 1

• Week 3: February 5 - 8

• Week 4: February 12 - 15 (SOLD OUT)

REGISTRATION

CLASS SIZE IS LIMITED ! To secure your seat, please register before December 15, 2023

DETAILS

Details can be found at www.gencor.com/ training or call us at 407-290-6000 ext. 342.

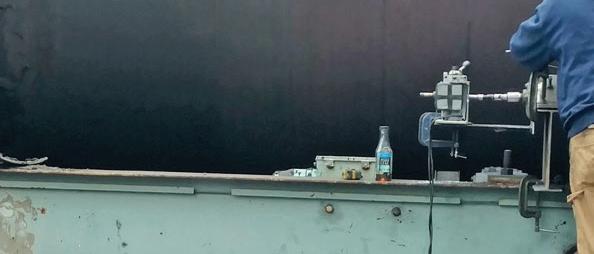

Improving overall plant production and efficiency are all common concerns for plant owners and operators. Having a well-trained technical crew is vital to maintaining plant performance and efficiency.

Gencor and its training staff represent the biggest concentration of knowledge and expertise in all the sciences and technologies involved in the production of asphalt plants. Customers who attend these seminars benefit by having the support and focused attention of the best specialists in the asphalt industry.

Using Gencor’s state-of-the-art control simulators and actual equipment, our experts take you stepby-step through a comprehensive & intensive concentrated hands-on training program providing the latest techniques on optimizing production efficiency.

5201 N. Orange Blossom Trail Orlando Florida 32810

Some days running a business can feel like you’re treading water just to stay afloat. But on good days business leaders will have just enough bandwidth to manage their current day while planning for tomorrow. On days like this Walker Construction’s Scales/ Truck Supervising Manager Kevin Howard is happy that his company has the telematic tools to prepare themselves to excel in tomorrow’s business climate.

Headquartered in Mount Sterling, Ky., Walker Construction operates two rock quarries and two blacktop plants. With 20 dump trucks and two pavers, the Walker Construction team performs paving projects across Menifee, Mt. Sterling, Clark, Bourbon, and Montgomery counties.

“We do a few driveways and the occasional parking lot job, but most of the work we do is state and county work,” said Howard of the workload.

When dealing with the Department of Transportation (DOT), Howard’s found that partnering with Earthwave’s telematics saves Walker Construction time and operating headaches.

“Most of the state guys want a ticket summary every evening. If, for instance, you haul 50 loads to a state job–we just take that job number and then send our contact that day’s tickets via email in one PDF… It just saves everybody some trouble.”

E-ticketing also means no more keeping track of paper tickets for all parties.

“Our state contacts used to come to us all the time and ask for a specific ticket, sometimes weeks after the job. Now we can just go back to that date and send them over again. It’s a huge timesaver.”

While not all DOT jobs in Kentucky currently require e-ticketing, Howard sees a future where that could be a possibility. “There’s not a lot of jobs that require e-ticketing yet. From what I understand, the DOT jobs are probably going to require it more and more as time goes on,” Howard explained. If and when that eventual future comes, Walker Construction will be prepared for an easy transition.

Walker Construction’s digital paper trail goes beyond just ticketing. The

two pavers in their fleet, as well as their fourteen company-owned dump trucks, use FleetWatcher’s GPS capabilities to help increase their efficiency across multiple fronts. The company trucks, plus their six third-party trucks, haul blacktop, asphalt, and aggregate. While they’re working, FleetWatcher allows Walker Construction employees to see in real-time where the trucks are and if there are any opportunities to move assets to other jobs.

“If it looks like trucks are bunching up at one place or the other, we may pull the truck off and send it somewhere else…If you have more than a couple trucks starting to do that, then you’ll take a look at it and see if you need to maybe send them somewhere else or if you need more trucks,” Howard said.

Eliminating trucks waiting at the paver or at the plant, by sending those trucks to another project, allows contractors to lay more asphalt with fewer trucks.

Beyond truck location, Howard and his coworkers can also track their materials management from their plants. “If it’s a decent-sized job, we’ll set it up as a shift in FleetWatcher, which shows you all the trucks that are in rotation to

and from the plant. This also shows you the tonnage moved and target tonnage,” said Howard. This allows the team at Walker Construction to see at a glance how many materials went to what job and whether they are on track or not to finish in time.

GPS tracking also helps Walker Construction manage DOT jobs after the project wraps up. If a specific job has a trouble spot, Howard and his team can reverse engineer where the pavement came from and identify where other trouble spots may appear.

“It helps the scale house personnel see how long it’s going to be before the truck gets back…Just gives everyone a better timeframe.”

This also works the other way around too however as presumably it eliminates drivers from showing up and waiting for someone to accept the load - and increases sales because they can get more cycles in per shift. Relaying accurate information to the customer is always a good thing regardless!

GPS based fleet tracking software helps customers better utilize their paving and construction equipment fleet through real-time tracking and status information. However, some utilizing material management solutions developed specifically for asphalt contractors can provide timely and accurate information on key performance indicators like Tons-perhour by crew or by truck, Feet-perminute, Cycle Time, Trucking Cost per Ton (TCpT), and more. This information empowers companies to make informed and data driven decisions to effectively manage their equipment and employees.

re-route them to different plants, and improve cycle times which can lead to streamlined productivity and profitability. Accurate information and analysis can also be used to bid future projects and potentially win more business.

Additionally, customized data reports with hundreds of filtering options can be set up to be automatically delivered at frequent intervals throughout the day to give owners and operators fleet information at their fingertips. Customized GPS technology lets users always know where equipment is located, with location reports available online and downloadable. Track multiple data points including cycle times, productivity and down times, equipment utilization, project status, budgets, shop costs, trends, and behaviors. Fleet level data enables paving contractors to have better asset management through greater productivity and efficiency.

Armed with data, Kevin Howard and the Walker Construction team are saving time and resources operating today while continually preparing their business for what’s next.

Evan Triggs is the vice president of Earthwave Technologies.

Using FleetWatcher.

Walker Construction

Walker Construction

“You have a GPS marker where a load was actually put on the road from a paver. …If there’s a bad spot on the road, they’ll know what batch that spot came from. It also has the temperature attached to it when it was put on the truck,” Howard said of his telematics tracking capabilities.

This breadth and depth of analytics makes Walker Construction easy to work with, and be a valued partner to the DOT in quickly addressing and solving problems if they arise.

This same GPS technology also logistically helps Walker Construction manage their materials management. Howard has a GPS marker on a thirdparty truck that exclusively hauls out of Menifee’s quarry.

Software like Fleetwatch integrates with easy-to-install hardware that connects all equipment to an online platform accessible via a desktop or mobile app. The Executive Scoreboard functionality features color coding which shows at-a-glance what metrics need corrective action, as KPIs are automatically measured against estimated benchmarks. Metrics shaded in green are meeting their targets, yellow shading indicates those to monitor, and red shading shows underperformance. Total tons loaded is automatically compared to shift times to show users if they are ahead of schedule or behind with both a bar chart showing progress and a numerical indicator of percentage. Metrics can be graphed to quickly show performance over time. Users can select the KPIs to display and change them as desired.

This instant visibility into performance allows managers to add trucks,

For more information visit https://asph.link/9ywso6

Road base is typically introduced after the subgrade has been prepared and compacted to a stable and level surface.

Jeremy Merchant & Canva ProGoing back to basics, this article details the importance of the correct road base in the durability and life of roads.

Road infrastructure is an essential component of any society, connecting people and facilitating the movement of goods and services. However, constructing a road requires much more than laying asphalt or concrete.

One critical component of road construction is the road base, which provides the necessary support and stability for the road to withstand heavy traffic and diverse weather conditions. Road base is a layer of material placed on the subgrade. It typically consists of crushed rock or gravel. This layer serves as a foundation for the pavement, helping to distribute the weight of vehicles evenly and prevent cracking or deformation.

This article explores the different road base materials, the factors that influence their selection and the process of constructing a road base. Whether you are a construction professional or just interested in the inner workings

of road infrastructure, this article will provide valuable insights into the critical role of road bases in ensuring safe and durable roadways.

Road base refers to the material used when constructing roads, driveways, parking areas, paving substrates or anything paved. These materials are compacted tightly together to form a hard surface. Despite the material selected, it is essential that it provides strength and optimal drainage. Below are the most common road base types:

• Gravel: Very fine and has a smooth texture

• Crushed stone: More jagged appearance with different shapes and sizes

• Recycled materials: Made from recycled subgrade base materials like concrete, asphalt and dirt

Road base is a crucial component of the road construction process that serves several functions and benefits. One of the primary functions of road base is to provide strong structural support for the

road surface, enabling it to withstand heavy traffic and weather conditions.

This layer of material helps distribute the weight of vehicles evenly, preventing cracking or deformation of the road surface. In addition to load distribution and stability, road base also provides better drainage for the road. By allowing water to drain away from the road surface, road base helps prevent erosion and damage caused by standing water. Adequate drainage is most important in areas with heavy rainfall, snow or tropical storms.

Road base also provides a stable platform for the pavement, reducing the risk of settlement and heaving. This stability is essential in areas with unstable soils or soft subgrades, where the road surface is more susceptible to shifting and deformation. In addition, stability affects road maintenance. Having the proper road base in place requires less maintenance.

Road base is typically introduced after the subgrade has been prepared and compacted to a stable and level surface. The subgrade, the natural soil that lies beneath the road surface, serves as the

foundation for the road base layer. Once the subgrade has been prepared, road base materials can be used.

When installing road base, it must be spread over the subgrade to the required thickness. Then, the materials are compacted using a special machine, such as a roller or compactor. This helps the materials achieve the desired density and stability. This step is essential because it ensures that the road base is compact and provides a solid foundation that is ready for the pavement layer.

in upstate New York, for example, as road base in Austin is subjected to high heat and lighter rain compared to a New York highway that will see much lower average temperatures and are subjected to higher rainfall totals, winter weather conditions, and road treatment such as salting and heating to deal with the winter weather. So if the area is typically exposed to rain, snow or heavy storms, a road base that has great drainage properties should be selected. Gravel or crushed stone are great options as each allows water to pass through easily.

safety of the road network, as well as minimize the costs associated with frequent maintenance and repairs.

After the road base has been installed, it must undergo testing to ensure that it meets the required standards and specifications. Testing typically involves measuring the density, strength, and permeability of the road base material to ensure that it is suitable for the intended use. Testing may be conducted on samples taken from the road base layer or using nondestructive testing methods, such as ground penetrating radar.

When selecting a road base, several factors must be considered to ensure the road’s durability and longevity. These include:

• Local climate —The local weather that the road base will be frequently exposed to is extremely important to consider. A typical Austin, Texas, road base would likely not fare well

• Cost —Different materials used for road base have different prices that should be considered when choosing a road base. Typically, gravel and crushed rock are the least expensive road base materials, while engineered base materials like asphalt, concrete or even glass can be more costly. While cost is a crucial factor to consider when selecting road base materials, it is also essential to consider the long-term costs associated with maintenance and repairs. Low-cost road base materials may save money upfront, but they may require more frequent maintenance and repairs, leading to higher long-term costs.

• Materials available —Depending on the location, road base options may be limited.

• Traffic —For roads or paved areas being constructed in locations with high traffic, it is essential to choose a base that can withstand a heavy flow of traffic. If the wrong base is chosen, the road may need frequent maintenance which can be quite costly due to material and labor. For this reason, it is crucial to consider traffic volume, axle loads, and environmental conditions when selecting road base materials. Thicker and more durable road-base materials may be required for high-volume highways and roads with heavy truck traffic, while roads with lower traffic volumes may be able to use thinner and less expensive road-base materials. Choosing the appropriate road base materials can significantly impact the longevity and

Advancements in road base materials are focused on improving sustainability, durability, and cost-effectiveness. One such advancement is the use of recycled materials as road bases. Recycled materials such as recycled concrete and asphalt can be used as base materials, reducing waste and lowering costs while maintaining the same structural integrity as traditional materials.

Another advancement in road base technology is the use of plantbased materials. Plant-derived road base materials are made from organic materials such as wood chips or coconut fibers. These materials can be mixed with traditional materials like gravel or sand to create a more sustainable and cost-effective road base.

Geosynthetic materials are another advancement in road base technology. Geosynthetics such as geotextiles and geogrids can be used to reinforce or stabilize road base materials. These materials can improve the strength and durability of the road base and help prevent damage from heavy traffic or harsh environmental conditions.

The road base materials selected affect the durability and longevity of roads. The decision depends on factors such as local climate, cost, materials available and traffic volume/type.

Recycled materials, plant-based materials, and geosynthetic materials are among the advancements in road base technology that offer promising alternatives to traditional materials, providing cost-effective and sustainable solutions for road construction and maintenance.

Despitethe material selected, road base must provide strength and optimal drainage. Jeremy Merchant & Canva Pro

adobestock/anzebizjan

This guide offers training and education opportunities for contractors and operators, a schedule of both in-person and remote sessions to expand employee skills and grow their value to your clients and your company.

The labor shortages and the competitive market for skilled workers means that training is more important now than at any time in the previous twenty years. These educational investments can mean the difference between your business and its success in the coming year. Statistics show that thirty percent of all new construction hires don’t have prior experience with heavy machinery, and the overall construction labor shortfall in 2023 exceeded 500,000 workers. The best solution for success is proper training, which will not only ensure hires are more productive for you on the jobsite, but that they have an increased chance at sticking with the job, reducing turnover for you. Here’s the training opportunities available for the asphalt industry in fall of 2023 and spring 2024: *These dates and schedules were accurate as of press time but are subject to change. Please contact each company directly for up-to-date information.

Website: https://www.astecindustries. com/service/training

Phone: 423.827.1899

Through Astec University, students can receive hands-on training at our factories or utilize our online resources at their own pace. Our experts have hundreds of years of combined technical and application experience and we look forward to sharing it with you.

Paving Professionals Workshop (PPW) is the industry standard in asphalt paving education. Attendees receive detailed education from the industry’s most experienced and knowledgeable paving professionals. PPW is a comprehensive, in depth two-day training that includes ample time for questions and one-onone access to paving pros.

Jan. 10 - 11, 2024

Jan. 15 - 16, 2024

Jan. 17 - 18, 2024

This four-day training school offers valuable experience to increase skills and machine uptime through classroom and hands-on instruction delivered by experienced factory specialists. Topics covered include safe operation, maintenance and service, troubleshooting, electrical systems and hydraulic systems of road-building paver equipment. Additionally, students will learn grade control and screed adjustment.

Jan. 23 - 26, 2024

Jan. 30 - Feb. 2, 2024

Feb. 13 - 16, 2024

Feb. 20 - 23, 2024

Asphalt Plant Customer Schools:

Registration opens: Tuesday, Oct. 3, 2023

Week 1: Jan. 8 – Jan. 11

Week 2: Jan. 15 – Jan. 18

Week 3: Jan. 22 – Jan. 25

Week 4: Jan. 29 – Feb. 1

Week 5: Feb. 12 – Feb. 15

Week 6: Feb. 19 – Feb. 22

Week 7: Feb. 26 – Feb. 29

Cost per attendee: $2,100

Website: https://www.bomag.com/ us-en/services/support-and-training/ training/

Registration open for online school

Email: marketing.ba@bomag.com

BOMAG offers you the chance to learn from the experts! BOMAG provides technical and product training on their website for free!

BOMAG application training is notable for the wide range of topics covered. The specially designed courses are targeted equally at members of construction

crews, site managers, and owners of construction companies. The application trainings cover a wide range of topics from actual construction site situations. In addition to content relating to the possible applications and operation, relevant regulatory requirements are also addressed.

Asphalt Paving:

The course gives an overview of the paving of asphalt and shows factors of influence during the paving process.

Working time: 45 minutes

The Basics of Compaction:

The importance of compaction, materials for compaction, definitions from the areas of compaction technology and fields of application.

Working time: 25 minutes

ASPHALT MANAGER:

In this eLearning, ASPHALT MANAGER 2 is presented as the all-rounder for asphalt compaction

Working time: 15 minutes

Drum Knowledge Compact:

In this eLearning module we are going to show the different drum types for BOMAG Single Drum Rollers. We also take a short foray into exciter systems and the measurement systems

ECONOMIZER and TERRAMETER.

Working time: 25 minutes

BOMAP Connect:

BOMAP runs on all standard Android tablets and smartphones, and is compatible with rollers from all manufacturers.

Working time: 30 minutes

Phone: 763.315.5510

Email: cat_mpls_training@cat.com

Web: https://www.cat.com/en_US/ by-industry/paving/real-world-trainingsolution.html

Caterpillar offers both operator and technician training on Cat asphalt pavers and cold planers. The full

2023-2024 training schedule will be announced soon. For Caterpillar paving training information go to cat. com>Industries>Paving>Training or email cat_mpls_training@cat.com.

Courses:

• Paving Operations TrainingThis course is designed for paving supervisors and paving crew members with one or more years of experience with the lay down of hot mix asphalt. Training is taught using Cat Asphalt Pavers with Cat Grade and Slope systems. The daily curriculum includes classroom and hands-on training.

Course Fee: $3900

• Large Asphalt Pavers Service Training – This four-day course provides theory and hands-on training. Upon completion, students will be able to trace the flow of oil through hydraulic systems, test and adjust hydraulic pressures, troubleshoot hydraulic and electrical systems, and explain ECM functions and calibration steps for the Cat AP1000, AP1055, AP600, and AP655 asphalt pavers.

Course Fee: $1840

• Milling Operations Training – This 2-day course provides theory and hands-on training for operation of the Cat PM300, PM600 and PM800 series cold planers. Upon conclusion of this course, attendees will be able to put the machine to work.

Course fee: $1,560

• PM600 Series and PM800 Series Cold Planer Service Training – This three-day course provides theory and hands-on training. Upon completion of the course, students will be able to trace the flow of oil through hydraulic systems, test and adjust hydraulic pressures, troubleshoot hydraulic and electrical systems, explain Electronic Control Module

(ECM) functions and calibration steps, and set up automatic grade and slope control.

Course fee: $1380

• PM300 Series Cold Planer Service Training – This three-day course provides theory and hands-on training. Upon completion of the course, students will be able to trace the flow of oil through hydraulic systems, test and adjust hydraulic pressures, troubleshoot hydraulic and electrical systems, explain ECM functions and calibration steps, and set up automatic grade and slope control.

Course fee: $1,380

Website: https://commandalkon.com/ trainingdays/

Email: avines@commandalkon.com

TRAININGDAYS are brought to regional settings each year to allow system users and administrators to master application skills, stay up to date on new software features, and learn best practices from application experts and industry peers. Sessions benefit both new users as well as veteran users.

TRAININGDAYS offers dedicated time away from the office or plant to focus on learning, allowing system users to take their knowledge and skills to the next level. Whether you are a new user or needing to freshen up your skills and best practices, TRAININGDAYS provides an in-depth, in-person classroom experience where you can stay up-to-date on our product features, collaborate with other users, and ensure you have the best possible foundational knowledge to help your operations be successful.

San Diego, Calif., Nov. 13 – 16

Attend classes from a single product line or mix and match half-day sessions across product lines to meet your specific training needs.

Donnie & T.J. Reed, Madison Asphalt

Donnie & T.J. Reed, Madison Asphalt

With

Nov 13th & 14th

• COMMANDbatch

• COMMANDseries

• Apex

• Integra - Nov 14 only

• Nov 15th & 16th

• COMMANDbatch

• COMMANDqc

• Trackit

Location: Sheraton Mission Valley San Diego

Registration ends Oct. 30th

Email: Smendez@Gencor.com

2024 TRAINING SCHOOL

Expert instructors provide step-bystep comprehensive and concentrated training on our state-of-the-art control simulation and plant equipment. Benefit from our advanced knowledge and expertise in the science and technology of hot mix asphalt production. Then get ready to conquer any challenge! Gencor also offers custom training; contact for more information.

Gencor Trainings are designed specifically for hot mix asphalt producers that own and operate HMA Facilities and are not open to industry vendors, or suppliers.

Space is limited, please register early. Registration opened Sept. 1, 2023.

• Week 1: Jan. 22 - 25, 2024

• Week 2: Jan. 29 - Feb. 1, 2024

• Week 3: Feb. 5 - 8, 2024

The Blaw-Knox University is dedicated to training paver operators and foreman on proper paver operation and maintenance, paver hydraulic and electrical systems and applied best paving practices through several classroom-style and hands-on application courses. For over half a decade Blaw-Knox has earned its reputation as the go to source for training and instruction on hot mix paving.

Who: Any individual interested in, or responsible for the laydown of HMA, WMA, SMA, or Thinlays.

Duration: 4 days

Location: 5201 N. Orange Blossom

Trail, Orlando, FL 32810

Topics:

• Paving Safety on the Job Site

• Material Quality

• Paving Principles

• Paver Preparation

• Paver and Screed Operation

• Hands-on Paver Set-up and Operation

• Joint Construction

• Screed Operation and Setup

• Troubleshooting Mat Defects

• Automatic Grade & Slope Operation with Blaw-Kontrol, Topcon or Moba

• Daily Maintenance

Course Dates:

Week 1: Jan. 16 – 19, 2024

Week 2: Jan. 23 – 26, 2024

Week 3: Jan. 30 – Feb. 2, 2024

Week 4: Feb. 6 – 9, 2024

Contact: Lauren Hill

Phone: 1.713.270.4000

E-mail: lauren.hill@hcss.com

Website: ugm.hcss.com

NEXT LEVEL: User Group Meeting

Taking place Feb. 13-15 in the heart of Houston. Events and classes will be split between two hotels, the Marriott Marquis Houston Downtown and Hilton AmericasHouston. Events and classes will be split between two hotels, the Marriott Marquis Houston Downtown (operations and fleet) and Hilton Americas-Houston (estimating). HCSS offers 250+ classes during 14 sessions across the three days of meetings.

Website: https://secure.touchnet. net/C20021_ustores/web/store_cat. jsp?STOREID=6&CATID=15

Email: slh0037@auburn.edu

Performance Graded Binder Technician Course

Dates: Oct. 14 -18, 2024

Cost per attendee: $1,250 - $1,375

Asphalt Engineers Workshop

This one-week workshop is taught at NCAT in Auburn, AL for agency engineers. The course provides a clear and up to date understanding of asphalt technology and best practices to provide the public with a cost-effective and sustainable roadway system. Engineers involved with materials, construction, design, preservation, and rehabilitation of asphalt pavements will benefit from the workshop.

Dates: Feb. 5 - 9, 2024

Advanced Mix Design Course (WMA, RAP, and RAS)

Dates: Jan. 30 - Feb. 1, 2024

Cost per attendee: $1,200

Asphalt Mix Design (Superpave) Course

Dates: April 1 -5, 2024

Cost per attendee: $1,200 - $1,400

Asphalt Technology Course

Dates: Feb. 26 - March 1, 2024

Cost per attendee: $1,100 - $1,350

Balanced Mix Design Course

Dates: March 12 -14, 2024

Cost per attendee: $850 - $900

Phone: 1-877-TROXLER (1.877.876.9537) | 1.919.549.8661

Email: training@troxlerlabs.com

Website: www.troxlerlabs.com

Free Online Training Site: www. troxlerlearningcenter.com

Nuclear Gauge User Training - 3400 Series

Online training course on the proper use of Troxler’s 3400 series nuclear density gauges.

Radiation Safety Officer Certification Course

All attendees must first complete a Nuclear Gauge Operator Safety and Hazmat Course. A certification of successful completion can be printed and/ or saved to your computer.

What does that mean? It means that we are determined to support you in your journey towards greater profitability, safety and environmental stewardship. It means that we will help you forge new paths, shape key trends and offer new solutions to support you on that journey. And it means we will be with you for every step of that journey through application consultancy, personalized trainings; across numerous geographic territories and around the clock.

Tell us where you’re going and we will help you get there.

Topics covered include:

• Review of radiological fundamentals

• Radiological protection regulatory requirements

• Gauge storage

• Transportation regulations

• Personnel monitoring

• Record keeping

• Leak testing

• Accident response

• Gauge maintenance

Nuclear Gauge Operator Safety Training Course with Hazmat

This course is for nuclear moisture density gauge operators. This course provides the certification required to operate and transport nuclear moisture density gauges. A quiz will be given at the end and a certificate issued with a passing score.

Topics covered include:

• Radiation safety fundamentals and principles

• Regulatory requirements

• Portable gauge theory, design and operation

• Gauge maintenance and troubleshooting

• Operating, emergency, maintenance and transportation procedures

• Leak testing

• Storing, packaging and transporting gauges

Hazmat Certification / Recertification Course

This course is for Hazmat transportation certification/ recertification. It can be taken to renew your Hazmat certification (every 3 years) or for individuals who may need to transport nuclear gauges, but not operate them.

This course satisfies US DOT training requirements of 49 CFR 172, subpart H (Hazmat) for individuals shipping or transporting hazardous materials. Recurrent training is required every three years.

Radiation Safety Refresher Course for the Nuclear Gauge Operator

This course is designed as an annual safety refresher for nuclear gauge operators who are in a state where an annual safety recertification is required by the licensing agency. This should not be taken by new nuclear gauge operators. The Nuclear Gauge Safety Training Course with Hazmat is the initial course for new operators.

Topics covered include:

• Radiation safety refresher

• New regulatory requirements

• Operating, emergency, maintenance, and transportation procedures

Compaction and Density Testing Course

This course is designed to teach you the basic principles of compaction and density testing methods, with emphasis on nuclear testing methods.

Since 1917, BITCO has provided customized insurance programs and services to support the backbone of the American economy. We’ve been protecting contractors like you who help maintain America’s critical infrastructure through the ups and downs of the economy for years. Looking for a partner who values long-term relationships, understands your business, and affords you the benefits of being insured by a carrier that provides the financial strength and stability of being a part of one of America’s 50 largest shareholder-owned insurance businesses? Look no further.

We are committed to you and are here for the long run. Visit BITCO.com to learn more and find a specialist agent near you.

BITCO.com | 1-800-475-4477

Topics covered include:

• Why we compact asphalt, soil, sand, aggregate, etc.

• Factors to consider when compacting

• Terms related to density testing of soil and asphalt

• Overview of the various methods used for measuring compaction

• Theory behind nuclear gauge measurements of moisture and density

• Proper methods of nuclear gauge operation

Phone: 1.615.501.0600

Website: https://www.wirtgen-group. com/america/en-us/customer-support/ know-how/training-program

Location: Nashville, TN

The 40,000+ sq. ft. state-of-theart facility in Antioch, TN houses eleven classrooms as well as four bays dedicated exclusively to training so hands on training can take place regardless of weather. The CTT includes a five-acre test track for equipment demonstrations and hands-on application training for the WIRTGEN GROUP products, as well as a gourmet cafeteria for meals and snacks during your sessions.

WIRTGEN - Intro to Leica Machine Control on Wirtgen Group Machines: Paving and Milling Basic

This course is an introduction to using the Leica machine control on WIRTGEN milling machines and VÖGELE asphalt pavers. Dates: March 4-6, 2024 | March

6-8, 2024

Cost: $800

Upon completion of this course, you will be able to:

• Follow safe work practices on and around WIRTGEN milling machines and VÖGELE asphalt pavers.

• Locate and identify machine/Leica components.

• Navigate the Leica machine control on WIRTGEN milling machines and VÖGELE asphalt pavers.

• Setup basic machine control jobsite/ machine calibration.

• Perform basic data modeling.

WIRTGEN - W 100 CFi / W 130 XFi Cold Milling Operation

This course prepares you to safely and effectively operate W 100 CFi - W 130 XFi cold milling machines (Series: 1810). Participants learn about Wirtgen cutting technology & operation/application best practices. Machine operator controls, Level Pro Plus, & daily/routine maintenance are covered in detail.

Dates: 8/31/23 - 11/01/23

Cost: $800

WIRTGEN - W 100 Fi Series Cold Milling Operation

This course prepares you to safely and effectively operate W 100-130 Fi cold milling machines (Series: 2710). Participants learn about Wirtgen cutting technology & operation/application best practices. Machine operator controls, Level Pro Active, & daily/routine maintenance are covered in detail.

Dates: 11/02/23 - 11/03/23 | 11/13/23 - 11/14/23 | 11/27/23 - 11/28/23

Cost: $800

WIRTGEN - W 100 Fi Series Technical Service for Customers

This course prepares you to troubleshoot & diagnose symptoms of W 100-130 Fi milling machines (Series: 2710). You learn to reference factory-recommended procedures for electrical, hydraulic, & mechanical service repairs.

Dates: 11/15/23 - 11/16/23

Cost: $800

Upon completion of this course, participants will be able to:

• Diagnose & clear machine operating state messages.

• Reference & know what to do when an engine code occurs.

• Interpret & navigate WIRTGEN schematics to locate devices & trace circuitry & hydraulic lines.

• Recall the various CAN Buses & with which systems each communicates.

• Replace control panel buttons, switches, levers, & hydraulic components, & identify which can be swapped.

• Troubleshoot & diagnose machine operational malfunctions to determine the root cause.

WIRTGEN - W 200 Fi Series Cold Milling Operation

Dates: 11/02/23 - 11/03/23 | 11/15/2311/16/23 | 11/29/23 - 11/30/23

Cost: $800

WIRTGEN - WR 200 i Series Cold Recyclers Technical Service

Dates: 11/06/23 - 11/08/23

Cost: $1,200

WIRTGEN - WR 200 i Series Cold Recycling Operation

Dates: 11/09/23 - 11/10/23

Cost: $800

KLEEMANN - MSC EVO Series Mobiscreen Classifier OperationsMaintenance - Technical Service

This course prepares you for daily operation of the Kleemann MSC EVO Series Mobiscreen classifier screening systems. You will learn factory recommended best practices for machine operation and maintenance. You will learn about the electrical and hydraulic systems that control functions of the MSC EVO Series Mobiscreen classifier screening systems (Series: K083, K103, K084, K104, K085, K105, K086, & K106).

Dates: 11/06/23 - 11/08/23 | 12/13/2312/14/23

Cost: $1,200

Upon completion of this course, you will be able to:

• Follow safe working practices while working on or around MSC EVO Series Mobiscreen classfier screening machines.

• Operate Kleemann MSC EVO Series Mobiscreen classifier screening systems in a safe & efficient manner.

• Reference the operator’s manual to identify machine controls/ components, as well as machine operation and maintenance information.

• Perform basic setup to prepare machine for work.

• Perform basic machine setup in accordance with manufacturer’s recommendations to prepare machine for work.

• Reference & perform maintenance on jaw crushers.

• Interpret Kleemann-specific electrical and hydraulic schematics and symbols.

• Troubleshoot, calibrate, and setup components/systems.

KLEEMANN - MSS EVO Series Mobiscreen Scalper Operations - Maintenance - Technical Service

This course prepares you for daily operation of the Kleemann MSS EVO Series Mobiscreen scalper screening systems. You will learn factory recommended best practices for machine operation and maintenance. You will learn about the electrical and hydraulic systems that control functions of the MSS EVO Series Mobiscreen scalper screening systems (Series: K082, K102, K067, & K066).

Dates: 11/08/23 - 11/10/23

Cost: $1,000

KLEEMANN - MC 110 EVO2 Jaw Crusher Operations & Maintenance

Dates: 11/13/23 - 11/14/23 Cost: $800

VÖGELE - FIU Paver: Machine Operation and Quality

Purpose of this Course: Provides equipment owners, operators, user-fixers, paving crews and technicians with efficient, effective, and safe methods for getting the most out of paving equipment: i.e, what to do before paving, what to do while paving, and what to do when done paving. Day 3 consists of a course review and final exam (70% required to pass). Dates: 11/07/23 - 11/09/23 |

12/12/23 - 12/14/23 Cost: $1,000

Upon completion of this course, you will be able to:

• Identify the advantages & preferred applications of the various road pavers & screeds.

• Explain the five forces on a free-floating screed and how each affects paving quality.

• Recognize the various components & functions of both pavers & screeds, some best practices for working with them, and how each affects paving quality.

• Plan a successful paving job:

• Ask the appropriate questions to help you determine material amount & paving speed.

• Identify proper setup procedures as well as ideal sensors & other paving tools needed.

• Perform the necessary checks & procedures prior to, during, & after paving.

VÖGELE - 8ft SUPER 3i Technical Service

Dates: 11/13/23 - 11/16/23 Cost: $1,600

VÖGELE - Paver Operations & Application

Dates: 11/27/23 - 11/28/23 | 11/29/23 - 11/30/23

Cost: $800

By Brandon Noel, Editor

By Brandon Noel, Editor

If you have the right the tool for the job, it goes a long way to getting the job you’re doing, done correctly. What do you do if there are multiple “right” tools? How do you decide which one to use? When it comes to the type of screed on your paver, as an operator, you might not get a choice. You have to work with what you’ve got, but that doesn’t mean there isn’t value in understanding how the different types of screeds work in various conditions. While they might all be capable of completing the job, the way each operates can mean subtle differences in the end result. Knowing what makes them different could make you reconsider previously held assumptions about screed technology.

A screed is the very backbone of the paving process. It largely determines the quality of mat smoothness, as well as initial compaction. The three most common types of asphalt screeds are widely implemented in models across the United States, however, there’s a fourth variety of screed that is very

popular in the global market that only sees limited, or specialized usage in North America. We’ll discuss that one down below, but let’s first cover the two that most contractors and operators are most familiar with.

Front and rear mounted extension screeds, by far, dominate the domestic U.S. market. On the front-mount screeds, the extensions are out ahead of the main screed, whereas on the rear-mounts it’s the opposite. The main screed sits ahead of the extensions.

“These two can do the exact same scope of work,” said Tom Travers, Director of Technical Sales at Astec Industries. With forty-five years in the paver market, and more than half of those years working on the back of a paver, Travers speaks from a place of solid experience. “The value of the frontmount is that, when you extend and retract your extensions to accommodate the footprint you’re trying to cover, you do it with less force on the screed. This is because the head of material stays out in front of the product.”

Traver’s isn’t the only one evangelizing the ways of the front-mount screeds, Bill Laing, Director of Engineering, Blaw-Knox Corporation, also speaks to the benefits of their design. “With front

mounted extensions, you can keep the head-of-material confined and in front of the screed. By and large, they do that easier than a rear extendable screed.”

For jobs where you might be frequently making adjustments to the width of the paving foot-print, these offer the benefit of reduced force, but that, also can translate into less wear, less frequent maintenance, and a slight reduction in fuel consumption. Additionally, when retracting the width, front mounted screeds can bring the material back into the center without fear of “pinching” it.

However, rear-mounted screeds aren’t without their benefits. “A rear-mount screed extension plate has the same depth as the main plate,” said Laing. Say a main screed is twenty inches deep, then extension is also 20 inches inches deep. This results in a very consistent mat quality. “Depending on the model of front mounted screed, the dimensional depth of the extension to the main plate can be the same, just like the rear mounted screeds. Both can get the same uniform texture and consistency. ”

Front mounted screeds have unequal extension depth vs the main screed depth. To overcome this difference front mounted screeds require an additional

adjustment, the individual angle of attack for the extension. For example, if the main screed is twenty-four inches deep, the extension could be set to ten inches. In order to have uniformity of texture, you nose the extension up higher, forcing more material under it in order to match the texture a deeper plate naturally provides. Despite this small extra step, Laing doesn’t think impact the decision between the two types of screeds.

“Both products will perform just as well in the same environment,” Laing said. So, the questions is: what is the main driver behind which type of paver is selected, between front and rear mounts?

“A lot of what determines whether a company runs a front-mounted or a rear-mounted screed, is what they know,” said Travers.” People are reluctant towards what they don’t know, and asphalt workers even more so, are creatures of habit. It’s a bit of a challenge to get a front-mounted operator to go to a rear-mount or the opposite, and, at the end of the day it has nothing to do what’s best for the job.”

This can be even more true when it comes to the third most common type of screed here in the United States.

The beauty of a wedge-lock, or a fixedwidth, screed, if you’re on a job that can utilize it, is volume it can lay down and the integrity of the mat quality. You build up the width of the screed for the day’s scope of work, usually in two-foot bolt-on sections, and then you aren’t concerned with the sorts of variables that extendable screeds are. This can be a great solutions for airports and long stretches of roadway, however, a lot of America’s highways aren’t necessarily built to suit that type of use.

“We’re talking thirty-to-forty-yearold technology here, but it has its place,” Travers insisted. “If you can maintain width for the whole day, then that’s probably the product that works best. It’s kind of a bullet proof product, and it requires a lot of finesse from a crew. When you go from a wedge lock to a power extendable screed, it takes a little bit more concentration from the crew.”

While wedge-lock screeds can produce a highly consistent mat quality, and reduce segregation, it comes at a price. It’s very time consuming. The end of the screed might be twelve or sixteen feet from the hopper, and, in order to achieve proper ride quality, it is usually required that auger segments be built out from the tractor no less than twelve inches from the end.

“It’s at a great cost to the contractor,” admitted Travers. “It’s time, labor, and you have to have the iron there to do it. And although it should be done, some don’t do it.”

To get it done correctly, it takes a trained mechanic, and since usually the components are heavy, it can often require a support truck and/or a crane to build it up. When a contractor opts not to do it, and cut corners in the application, it is a risk they are taking. According to the experts, if the contractor thoroughly believes in best practices and best material placement, they should uphold the auger requirement, maintaining proper and consistent material flow in front of the screed.

Wirtgen Group. “European style paving is deep, wide, and slow. Here in the U.S. we pave, thin and narrow and fast So, tamper screeds don’t get a lot work in our environment, because it is a different type of paving that requires slower paving speed.”

The Euro-paving style is driven by precompaction technology. The tamper bar kneads the material before it passes under the screed. At it’s most basic, the tamper is a bar ahead of the screed that goes up and down in rapid cycles, like a piston. However, the technology is combined with vibration (on the screed), also, in addition to the tamper bar, two pressure bars (after the screed) can be added to even further improve levels of compaction.

The U.S. market is focuses on vibration, and picks up compaction through rolling. European paving picks up a larger percentage of their compaction as they lay the material.

As an example, if there were twelve inches of asphalt going down, in Europe, they would spend more time getting the base as flat as possible, and then lay a single layer ten inches deep, using a tamper bar screed, and then finish with a wear layer of two inches. Whereas, here at home, we would build up the road in three inch lifts, gradually smoothing out the surface, layer-by-layer.

In Europe and most other countries, they utilize a type of screed that only sees extremely limited, specific uses here in the United States. This is the case despite some clear benefits that they offer, and it brings back to mind the words of Mr. Travers earlier, that people pave what they know. However, when it comes to tamper-bar style screeds, it’s goes beyond just habit. The whole methodology of European paving is different from how asphalt is laid in North America.

There’s, there’s a big difference in screeds in North America versus the rest of the world,” said Kevin Comer, North American Vogele Product Director at

“The tamper bar allows you to pave deeper lifts with improved compaction, therefore allowing pavers to pave larger lifts and excellent smoothness.,” said Comer. “It’s just a different way of building the roads, and there’s a place for it in the American market, it’s just not the most common.”

It mostly sees use on specialized raceways, bridges, and other structures where extremely heavy compaction equipment is not a suitable or desirable option. However, it doesn’t mean it couldn’t see wider adoption as labor shortages and the cost of that labor increase. These types of screeds can reduce the overall compaction train, reducing the number of trained roller operators on a given site.

For more information visit https://asph.link/orqb8o

McMillen Corp. squeezes more value from its $6 million fleet by leveraging insights for construction equipment life-cycle extensions.

While the construction industry is sometimes at odds with the environment, and must take care to prevent impacts to water resources through the use of everything from wetlands delineations to silt fences to spraying anionic polyacrylamide on dirt piles, design-build teams of engineers and construction professionals at Boise, Idaho-based McMillen Corp. face the additional challenge of working on projects directly in waterways— renewable power, dams, spillways, fish ladders, in-stream habitat improvements, reservoir outlets and more.

The company is involved in early stages of environmental studies, permitting, civil engineering and project design. But they also self-perform many construction tasks, which means they rely on a $6 million fleet of construction equipment and other vehicles ranging from a hydrocrawler, six boats, barges, boom trucks, a half dozen excavators, dozers, telehandlers and skid steers.

“We don’t have that large of a fleet,” McMillen Equipment Manager Christopher Schauer said. “Last year was about getting started doing full-frame rebuilds on our existing machines, but this coming year we will be growing the fleet.”

While McMillen may be buying more new equipment soon, since joining the company in August of 2021 and implementing GPS-enabled asset management software from Tenna in February of 2022, Schauer’s team has focused on getting more value out of the existing fleet, leaning on maintenance and operations history from Tenna to inform the process. The company had evaluated HCSS Equipment360, but Schauer was also intrigued by CAT’s Visionlink and the United Rentals API. Their decision, he said, was ultimately based on the software to meet their needs across a mixed fleet with robust telematics and computerized maintenance management systems (CMMS) capabilities.

When ForConstructionPros caught up with Schauer in January, he was at a McMillen facility where his team was rebuilding a Caterpillar 289 skid steer.

“This is a D series model—which is last generation,” Schauer said. “They are

now moved on to the D3s. But when I look at our machines, they are sitting at about half life. How I generally look at a piece of equipment is to take stock of where in its life cycle, and about 4,800 hours of operations is halfway through its useful life. If I talk to our CAT salesperson, they will tell me to get a new one.”

But having come to McMillen from a stint as equipment manager for Kiewit, Schauer was accustomed to taking equipment into higher hours and sweating the assets.

“At Kiewitt, we took a longer and in depth look at where the repairs are in terms of the returns on investing more in a piece of equipment,” Schauer said. “So I know, personally speaking, these skid steers can go 10,000 hours. Hardly anybody does that, but I know you can do it.”

While some companies may not have the staffing to complete the necessary rebuilds, which may include everything

•CAPACITY: 40,000 lbs.

•20 Ton Air Brakes

•Trailer Weight: 8,380 lbs.

•Overall Width:102", Length: 31'4"

•Deck Length: 21’ Flat (model shown)

•6’ Beaver tail

•Deck Height: 34"

•Tires: Eight 215/75R17.5 (H)

•Brakes: Air (Full ABS System)

•Ramps: 72" Long x 22” Wide Range: 102" Max. 29" Min.

•Lighting: 100% Sealed Wiring harness and L.E.D. Lights

ONE PIECE CAST LUNETTE EYE

Tested @ 275,000# and wrap around nose plate. Standard on all trailers.

HIGH TENSILE MAIN RAIL

One piece and cold formed. CROSS MEMBERS pierced through Main Beam for lowest possible deck height and more unitized frame.

APITONG/COMPOSITE DECK

Durable Composite Decking is fastened to the crossmembers with bolts and deck washers making it easier to replace decking when required.

Eager Beaver WIDE TRACK AXLES: 98”

ALL WHEEL ABS with Spring Brakes on all axles. Standard on all air brake trailers.

SUMITOMO BRAND TIRES

National Dealer Supported. HUB PILOTED WHEELS

Outboard brake drums for easier maintenance.

1946-2022

th 76 6

•8 Degree Loading Angle Low Profile ANNIVERSARY

from line boring to bushings and bearings, Schauer said the work itself could be outsourced. The challenge is the visibility to balance productivity with cost for parts, materials and staffing.

“If you are a smaller company, you may dump these skid steers at 4,000 to 5,000 hours, before they have issues,” Schauer said. “Maintenance will start to creep up in cost. But many times they are spending so much money paying the creditors and the banks for these new units they are not actually coming out ahead. We want to get everything we profitably can out of equipment.”

A full asset life-cycle approach to equipment maintenance is, in even many large and complex companies with much more tied up in capital assets, an aspirational idea. Between a reactive maintenance culture and a lack of enterprise systems that can support financial decision making about equipment, a full life-cycle approach to any

type of asset is rare.

“It is something people talk about idly,” Schauer said. “Like, it would be so nice to do. But to do it and stay on top of it takes some dedication to making this program work.”

Success in full asset life-cycle management is about structure and data.

“If you are relying on the project managers themselves to handle maintenance on equipment used on their project, it just won’t happen,” Schauer said. “It has to be centralized in order to have one person responsible for the fleet. Otherwise, the numbers do not get to the same point. Five people will never crosscompare numbers together to know what they need to do with a machine. Centralization verses decentralized equipment management is one step.”

One challenge in achieving an asset lifecycle approach is the fact that it requires

visibility not just into the equipment itself, including a full maintenance history, but the project activity through which each piece of equipment drives value. This means that utilization data from telematics units installed on equipment is crucial. This data must not only be harvested from the piece of equipment, but also exposed in an application that supports financial decision making by placing it in context with other factors.

“Utilization is key—and telematics is the only avenue into that realm to really track it,” Schauer said. “It doesn’t make sense to own a 349 excavator if it only runs 5% of its life. It is a huge waste of capital. If a skid steer is used 75-95 percent of time, you can justify the capital investment and also justify investing more in keeping it operational.”

Decisions about the equipment then cascade into other parts of the business, including spares and repairs parts

DESIGNED FOR PAVING & PAVEMENT

MAINTENANCE INDUSTRY PROFESSIONALS

★ Business owners and high-level executives will have the opportunity to identify areas within their company that need immediate change and obtain the tools they need to succeed.

December 6-8, 2023

LOCATED AT THE SANDPEARL RESORT IN CLEARWATER BEACH, FL

From the producers of:

ordering and staffing levels for maintenance technicians.

“It absolutely drives how many mechanics we assign to projects,” Schauer said. “We rely on maintenance manhours factors to determine how many maintenance hours we expend per hour of operation. We then use those numbers to figure out the number of mechanics, how many tracks we are going to have available, up to and including hose connections to service the scraper fleet. With Tenna we are not just shooting from the hip and guessing.”

Apart from insight into the equipment, which comes from utilization and other data collected from telematics at the tip of the spear, McMillen and Schauer have access to hard cost data from their back-office accounting application, Trimble Viewpoint Spectrum. This comes thanks to a recently expanded

integration, created by integration platform as a service (iPaaS) vendor Ryvit, which in January of 2023 was acquired by Trimble.

A work order, which contains information on maintenance activities and parts and materials consumed against equipment, and associated mechanic labor is created in Tenna. This new unidirectional integration with Viewpoint Vista then passes that information on to the ERP when created in Tenna, automatically creating a record of the work order in that application to record the costs associated with the parts, labor and consumables from the work order in Tenna, enabling full asset life-cycle management cost for construction equipment. Tenna sends an update to Vista when the work order is completed, updating final total notes accordingly.

“We already integrated with Viewpoint Vista, (hosted or within Viewpoint One) and Spectrum,” Tenna Cofounder and Vice President of Product

Jose Cueva told ForConstructionPros at the time of the expanded integration launch. “We also integrate with other ERP and accounting software products, including Sage 100 Contractor and Sage 300 Construction and Real Estate, Coins, Foundation and Fleet Cost & Care. These integrations focus on equipment location, usage and mileage. This new and deeper integration with Viewpoint Vista though is the first that exposes our maintenance work order functionality to an ERP product.”

While Schauer said his was one of the first teams using the integration, and implementation involved some back and forth with Tenna,

Now that the integration is up and running, estimating its value to McMillen would be difficult, according to Schauer.

“It is priceless,” Schauer said. “To put a dollar value on it, it would be in the realm of every rebuild I do being directly attributed to that integration. Doubling the life of any unit can be attributed to that integration, Before I joined and we implemented Tenna, everything was handled by the recommendation of the dealership. They did not perform rebuilds. It would just be a tradeoff and a sale. A lot of value was lost.”

“This integration, like Tenna and Trimble-Viewpoint’s greater partnership, solves a multi-million-dollar business need for contractors, making it easier for them to see where they are bleeding capital and helps them get better control over how they leverage their current resources to ultimately benefit the books,” Tenna Chief Business Development Officer Russ Young said. “Knowing more by seeing data clearly within the integrated systems and being able to better account for equipment costs and investments allows contractors to take strategic actions to own less, rent less, better maintain and optimize what they have, and deliver work more with less downtime, which leads to increased project margins and higher revenue.”

For more information visit https://asph.link/9ywso6

DESIGNED FOR

MINIMAL

TO

On March 18, 2022, the Department of Labor (DOL) announced a Notice of Proposed Rulemaking, which set in motion a year-and-a-half long process to modernize the Davis-Bacon and Related Acts (DBRA). Comments came in from all corners of the construction industry, including labor groups, workers, and all manner of industry stakeholders.

The updates announced on Aug. 8, 2023, go into effect 60 days from that date and are the most comprehensive in nearly four decades. The final ruling issues major changes to the administration and enforcement of labor standards applicable to federally subsidized construction projects. This includes federally funded highway projects that fall under the jurisdiction of the DBRA.

“Modernizing the Davis-Bacon and Related Acts is key to making sure that the jobs being created under the BidenHarris administration’s Investing in America agenda are good jobs, and that workers get the fair wages and benefits they deserve on federally funded constructions projects,” said Acting Secretary of Labor Julie Su.

The new DBRA rules alter how the “prevailing wage rate” is determined, complied with, and enforced. As it concerns the asphalt and road building industry, there are three areas of focus which impact it the most: the newly expanded, codified, and clarified rules for “site of work” flaggers, material suppliers, and truck drivers.

In the past, there was some gray area about material suppliers. Do they pay the prevailing wage rates to the truck drivers carrying the material in? If the truck driver was going in, and he was just dropping off material, and maybe he was doing something else on the jobsite that was de minimis, then

prevailing wage rates did not take effect.

The new regulations establish clear lines of when you have to pay truck drivers the prevailing wage rate. For instance, if a truck driver hauling material is only dropping off and picking up, you don’t have to pay prevailing wage rates. If they’re doing literally anything else, it falls under the DBRA.

The DOL generally did not count short periods of a few minutes onsite just to drop off materials as de minimis However, the total amount of time a driver spends on the site of work during a day or workweek—not just the amount of time that each delivery takes—is considered in determining whether the driver’s onsite time was de minimis.

Likewise, flaggers might be a mile down the road from the main work site, which previously meant you didn’t have to pay prevailing wage rates. The new ruling defines such a space as “virtually adjacent,” because they’re tied to the project directly.

If a majority of wage rates in a classification are the same, that is the prevailing wage, but if there is no majority, then the wage rate earned by the greatest number of workers, provided that at least 30% earn that rate, is the prevailing wage. The DBRA requirements apply to an estimated billions of dollars in federal and federally assisted construction spending each year and provide minimum wage rates for thousands of U.S. construction workers.

From the perspective of laborers and labor groups (both union

and non-union), these regulatory adjustments result in real quality of life improvements for workers. However, with wages likely to increase, a larger pool of job seekers may potentially come to fill the many open positions.

The final rule’s regulatory changes improve the department’s ability to administer and enforce DBRA labor standards more effectively and efficiently. These changes include the following:

• Creating new efficiencies in the prevailing wage update system and making sure prevailing wage rates keep up with actual wages which, over time, would mean higher wages for workers

• Periodically updating prevailing wage rates to address out-of-date wage determinations.

• Providing broader authority to adopt state or local wage determinations when certain criteria are met

• Issuing supplemental rates for key job classifications when no survey data exists.

• Updating the regulatory language to better reflect modern construction practices.

• Strengthening worker protections and enforcement, including debarment and anti-retaliation provisions. For more information and answers to FAQ on the Davis-Bacon Rulemaking, visit https://www.dol.gov/agencies/whd/ government-contracts/construction/ rulemaking-davis-bacon/faqs</a>