• Week 1: January 12 - 15

• Week 2: January 19 - 22

• Week 3: January 26 - 29

• Week 4: February 2 - 5

Details can be found at www. gencor.com/training or call us at 407-290-6000 ext. 342.

CLASS SIZE IS LIMITED!

To secure your seat, please register before December 15, 2025

Improving overall plant production and efficiency are all common concerns for plant owners and operators. Having a well-trained technical crew is vital to maintaining plant performance and efficiency.

Gencor and its training staff represent the biggest concentration of knowledge and expertise in all the sciences and technologies involved in the production of asphalt plants. Customers who attend these seminars benefit by having the support and focused attention of the best specialists in the asphalt industry

Using Gencor’s state-of-the-art control simulators and actual equipment, our experts take you step-by-step through a comprehensive & intensive concentrated hands-on training program providing the latest techniques on optimizing production efficiency.

16 Breaking The Mold: How Cloud Tech Is Shaping The Future Of Asphalt Production

Is outdated scheduling and disconnected data holding back your asphalt operations? Discover how cloud-based, realtime systems streamline dispatch, enhance visibility, and deliver higher efficiency—transforming profitability and customer satisfaction.

20 Impacts Of CAIA On Asphalt’s Future

A new bipartisan bill could offer a new pathway to greener road building.

FACE OF THE INDUSTRY

40 A New Approach to Growth in the Asphalt Industry

With heart, hustle, and a vision for the future, Elite Paving’s Ali Williams is reimagining what success looks like in construction.

44 The New Playbook for Road Construction Efficiency

How contractors can use the latest John Deere and WIRTGEN GROUP machine data by tracking each machine’s performance on a road construction site..

PRESERVATION & SUSTAINABILITY

48 The Sanibel Causeway Reconstruction

The island community’s new bridge should be able to stand the test of time, as well as handle just about anything mother nature might throw at it..

Published and copyrighted 2025 by IRONMARKETS. All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopy, recording or any information storage or retrieval system, without written permission from the publisher.

Asphalt Contractor (ISSN 1055-9205, USPS 0020-688): is published ten times per year: January, February, March/April, May, June/July, August, September, October, November, December by IRONMARKETS, 201 N. Main St. Ste 350, Fort Atkinson, Wisconsin 53538. Periodicals postage paid at Fort Atkinson, Wisconsin and additional entry offices.

POSTMASTER: Please send change of address to ASPHALT CONTRACTOR, 201 N. Main St. Ste. 350, Fort Atkinson, WI 53538. Printed in the U.S.A.

SUBSCRIPTION POLICY: Individual subscriptions are available without charge only in the USA. The Publisher reserves the right to reject nonqualifying subscribers. One-year subscription to nonqualifying individuals: U.S. $45.00, Canada & Mexico $65.00, and $95.00 all other countries (payable in U.S.

0 2 6

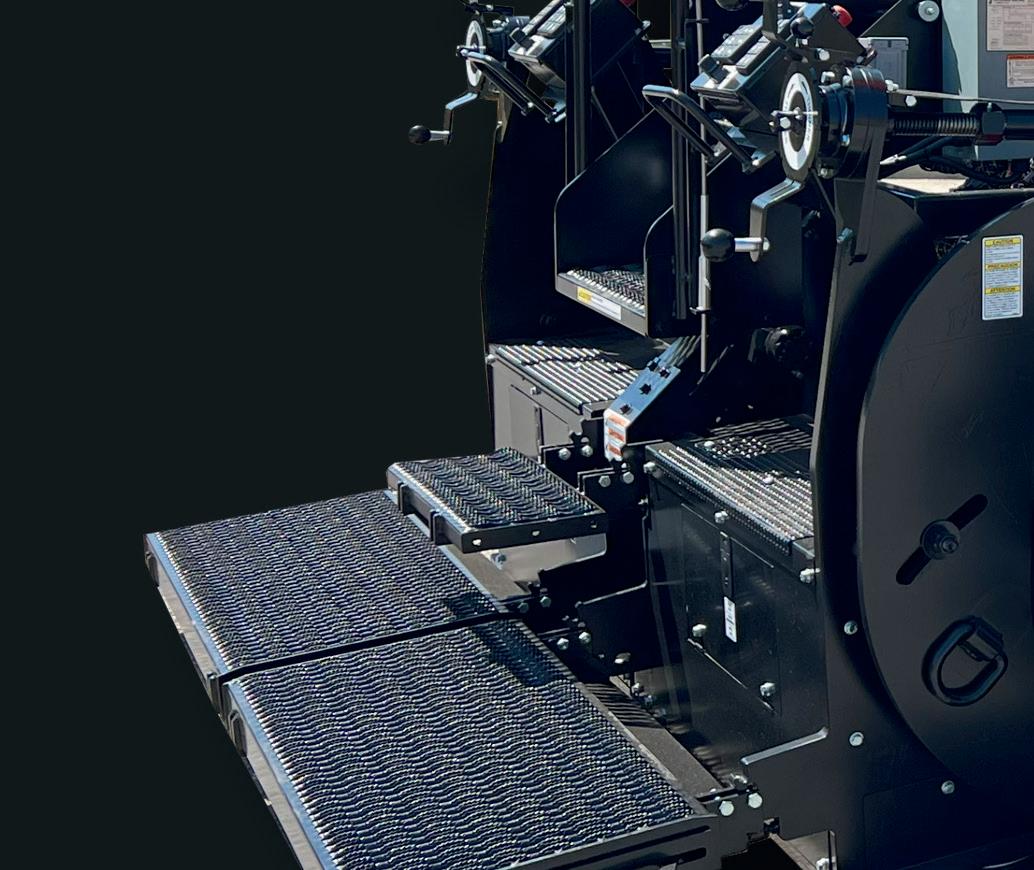

For over a half a decade Blaw-Knox has earned its reputation as the go to source of training and instruction on hot mix paving.

The Blaw-Knox University, is dedicated to training paver operators and foreman on proper Paver Operation and Maintenance and applied Best Paving Practices through classroom-style and handson application courses.

Blaw-Knox provides improved technical and problem-solving skills on a variety of paver operations and maintenance topics. Course instructors share decades of field and teaching experience with attendees, including training on the latest DOT requirements.

• January 12 - January 15

• January 19 - January 22

• January 26 - January 29

• February 2 - February 5 2026 DATES

All details can be found at www.blawknox.com/training or contact at (407) 290-6000 ext. 342 or training@blawknox.com

A quick, multiple-choice questionnaire built to collect contractor insight on this year’s challenges and changes. Your feedback drives our State of the Industry Report.

Scan to take the survey: https://asph.link/ survey2025

Pros’ PACER Award

This award recognizes construction pros on the jobsite and in the office for their accomplishments in shaping the construction industry. Applications close Oct. 10.

Read more at: https://asph.link/ hj58idpv

From moisture-wicking fabrics to cooling evaporative gear, temperature-regulating gear is quickly shifting from a comfort feature to a jobsite necessity.

Read more at: https://asph. link/vgip9hjy

Discover how AI-powered, OEM-agnostic platforms deliver accurate, predictive insights to optimize equipment acquisition, maintenance, insurance and ROI.

Read more at: https://asph.link/ kfjvpq40

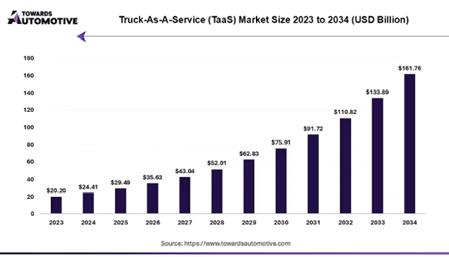

Truck-as-a-Service (TaaS) Market Poised for Major Growth Through 2034

The global Truck-as-a-Service (TaaS) market is projected to reach approximately USD 161.76 billion by 2034, increasing from USD 24.41 billion in 2024.

Read more at: https://asph. link/6fmzhzqm

Signup for the Roadbuilding Update, a free bi-monthly newsletter for the most up-to-date DOT, FHWA, asphalt, and other industry news

Astec paves the way for sustainable, innovative asphalt plants. The new IntelliPac Moisture System is a revolutionary solution that integrates seamlessly with Astec control systems. This provides unparalleled, real-time visibility into virgin aggregate moisture content. IntelliPac empowers operators to optimize mix design, minimize energy consumption, and reduce environmental impact. With Astec, you get superior asphalt production – better for the environment, better for your business.

Brandon Noel, Editor

bNoel@iron.markets

234-600-8983

Heat safety has become a buzzword to health and safety professionals, but what happens when state’s move to erode protections for workers?

Imagine if tomorrow you woke up to news that a few states had passed laws banning local governments from requiring work zone barriers like cones or flaggers. You’d fact-check immediately, because it sounds like something no one in authority would actually do.

But something just like this is quietly happening, and it’s putting our most vulnerable workers at risk. Several “sun belt” states passed laws forbidding their cities and counties from requiring extra breaks for workers exposed to extreme heat.

Extreme heat, already the deadliest weather hazard in the U.S., is responsible for roughly 2,000 deaths each year, more than hurricanes, floods, or tornadoes. And the number of extreme-heat days has been steadily on the rise. Rather than strengthen rules that protect workers, these new laws invite added risk to those we depend on to build and maintain critical infrastructure.

In 2023, Texas enacted House Bill 2127, eliminating local requirements for added water and shade breaks for construction workers. That year, Texas recorded 334 heat-related deaths, a 16% jump over 2022’s total. At least 42 workers died from environmental heat exposure in Texas between 2011 and 2021, before the hottest years on record.

Florida followed in 2024, barring counties and cities from passing similar protections. That same summer, Florida saw 84 heatrelated deaths, more than double the previous year. Georgia took its own preemption route in 2022, passing SB 331, which blocks any city or county from setting local rules on work hours, scheduling, or breaks, which effectively included heat protections.

While these states promote, “Work Zone Awareness Week,” their focus remains on

traffic safety alone. Meanwhile, other risks, like the kind created by extreme heat, continue to grow.

Climate data shows the average number of heat waves in major U.S. cities has tripled since the 1960s, and many of the biggest increases are in the South.

Austin, TX now sees about 47 more days above 100°F each year than it did in 1970. In 2023, the U.S. endured its hottest summer on record.

Younger and newer workers may be especially vulnerable. As Richard Juang, Senior Manager for Environmental Justice Policy at Ceres, told OSHA during a recent hearing: “Notably, and perhaps counterintuitively, it was younger workers under the age of 35 and workers new to their jobs who reported the highest rates of heat-related illness.”

And for those working on or near hot mix asphalt, the danger goes beyond the weather. Freshly laid asphalt exceeds 300°F, radiating heat that can make the “felt” temperature for crews 10–20°F higher than the air.

What’s the real on-the-ground effect of that? How do crews balance safety with the pressures of deadlines? And what might new federal OSHA rules mean for states that have rolled back protections?

EDITORIAL

Editor Brandon Noel bnoel@iron.markets

Content Director, Marketing Services Jessica Lombardo jlombardo@iron.markets

Managing Editor Allyson Sherrier asherrier@iron.markets

AUDIENCE

Audience Development Director Angela Franks

PRODUCTION

Senior Production Manager ...................................... Cindy Rusch crusch@iron.markets

ADVERTISING/SALES

I dig into all of that — including firsthand accounts from the field — in the full version of this story online. Read it now by scanning the QR code above or by visitng forconstructionpros.com/ heat-safety-rollbacks-asphalt-workers.

See you on the road!

Art Director ............................................................... April Van Etten

Brand Director Amy Schwandt aschwandt@iron.markets

Brand Manager Megan Perleberg mperleberg@iron.markets

Sales Representative Sean Dunphy sdunphy@iron.markets

Sales Representative ................................................... Kris Flitcroft kflitcroft@iron.markets

IRONMARKETS

Chief Executive Officer Ron Spink

Chief Revenue Officer ............................................ Amy Schwandt VP, Finance Greta Teter VP, Operations & IT Nick Raether VP, Demand Generation & Education ....................... Jim Bagan Brand Director, Construction, OEM & IRONPROS Sean Dunphy

Content Director Marina Mayer Director, Online & Marketing Services Bethany Chambers Director, Event Content & Programming Jess Lombardo

CIRCULATION & SUBSCRIPTIONS

201 N. Main St. Ste. 350, Fort Atkinson, WI 53538 afranks@iron.markets

LIST RENTAL

Sr. Account Manager Bart Piccirillo | Data Axle (518) 339 4511 | bart.piccirillo@infogroup.com

REPRINT SERVICES

Brand Manager Megan Perleberg mperleberg@iron.markets | (800) 538-5544

Published and copyrighted 2025 by IRONMARKETS. All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopy, recording, or any information storage or retrieval system, without written permission from the publisher. Scan for the

@ASPHALTCONTRACTOR

@ASPHALTCONTRCTR

@ASPHALTCONTRACTOR

@ASPHALT-CONTRACTOR-MAGAZINE

CLOSE TO OUR CUSTOMERS. The compactors are impressive thanks to their compact design, language-neutral operation and perfect visibility. The permanent all-wheel drive ensures outstanding gradeability, and the ECOMode reduces both fuel consumption and emissions. All of the models in this series are ready for the digital future – and that will impress drivers, rental companies and construction firms alike.

A tandem roller for typical asphalt layers in road and farm track construction, as well as applications on car parks and access roads, antifreeze agents, and light earthworks.

• 17,637 lbs. | Working width 66.1 in.

• ECONOMIZER and BOMAP help avoid unnecessary passes and document the compaction progress.

• Reach all maintenance points from the ground.

• Offers three vibration systems, with double vibration, TanGO, and ASPHALT MANAGER to choose from.

The Leica DS4000, an underground utility detection system designed to identify buried infrastructure with improved depth and clarity. Capable of detecting underground assets up to 60% deeper than traditional methods, the system aims to enhance safety and efficiency in subsurface mapping.

The DS4000 integrates Equalised Scrambling Technology (EsT), developed by IDS GeoRadar, which enhances the visibility of both shallow and deeply buried utilities. It also increases the chances of detecting smaller or more elusive items like fiber optic cables, which are often missed by older systems.

A new software solution aimed at helping contractors manage purchasing, inventory, and accounts payable in one centralized platform. The tool is designed to support better tracking of material costs and inventory levels across job sites, warehouses, and offices. The launch comes at a time when construction firms face increased pressure to control material costs amid ongoing supply chain uncertainty and pricing fluctuations. Trimble Materials connects field teams, warehouse staff, purchasing departments, and suppliers through both mobile and desktop applications, enabling streamlined communication and greater visibility into material usage and expenses.

A compact machine engineered for work in dense urban environments across North America and Europe. Designed for tight jobsites where maneuverability and size are critical, the ST230V targets applications that are unsuitable for larger, conventional equipment. Built to address challenges like limited space, land-use restrictions, and rising labor costs, the ST230V offers a compact solution while still delivering the power and durability needed for heavy-duty applications. The machine meets both CE and EPA Tier 4 Final emission standards, making it compliant for use across regulated markets.

The PQI 380+ uses Microsoft Windows 10 for smooth operation, easy software upgrades and enhanced user support. IOS, Android application for data transfer and cloud storage, instantly send measurement data from the gauge to the cloud with just a QR code scan.

• Asphalt density readings in 3 secs

• 800 x 480 LCD with projected capacitive touchscreen with antiscratch surface

• IOS, Android application for data transfer and cloud storage to the TransTech Connect App

• Instantly send measurement data

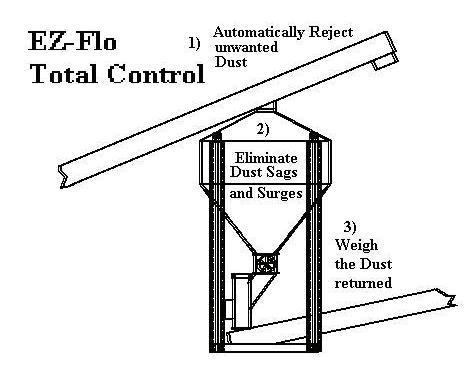

The EZ-Flo Dust Control System helps eliminate the sags and surges of dust delivery coming from the baghouse. When the aggregate contains too much dust, the system will deliver a required amount of dust to the mix and automatically reject the difference. The operator shall operate the system differently when rejecting dust. When rejecting dust, it is easier to operate the system when the Surge Bin is always full of dust and the Blend Controller just delivers the amount of dust required by the mix design. When using all the dust, the system takes out the sags and surges.

Our UL asphalt tanks have properly sized normal and emergency venting as standard.

All structural attachments are OSHA approved and are af xed to our tanks per code.

All tanks are tested to UL142 Section 42.2.1a 10th Edition.

All weld joints are per UL142 standards.

Your asphalt tanks will be properly labeled and registered with UL142.

Kleemann has announced updates to its SPECTIVE CONNECT system and new integrations in the John Deere Operations Center. These digital tools help equipment operators and site managers streamline machine operations, monitor performance in real time and improve overall worksite efficiency. The app allows operators to manage key machine functions directly from a smartphone. With this bi-directional control system, tasks such as adjusting the crusher gap or calibrating belt scales can be completed from the cab of an excavator, reducing time on foot and increasing safety. By moving controls closer to the operator, the system supports faster adjustments and improved comfort on the jobsite.

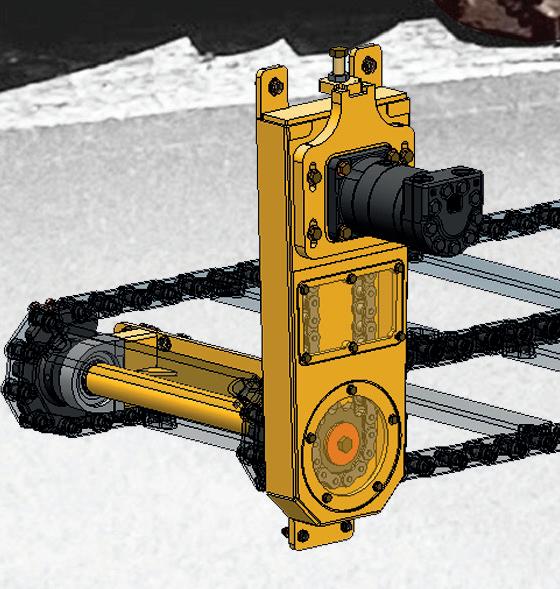

Designed to serve the needs of the rental industry and contractors. This new model meets several critical goals: superior durability and serviceability, minimal maintenance, a best-in-class operator experience, and productivity with safety at the forefront. The increased stability and compaction performance over rigidframed trench rollers quickly launched the roller into the market leader position. Features dual width drums, COMPATEC compaction control, improved drive and remote control systems.

A new field tool is changing the way contractors and inspectors measure compacted aggregate base depth — and it’s earning attention from state Departments of Transportation.

The Base Course Pro, developed by Base Course Solutions, offers an alternative to the traditional pickaxe method with a more efficient and less destructive alternative. What once took days of labor can now be done in minutes, with greater consistency and minimal damage to the finished grade.

Originally created out of necessity on one of the largest highway paving projects in New Mexico, the tool was born from firsthand field experience.

Bergkamp has entered the Cold Central Plant Recycling (CCPR) market with the launch of its Journeyman Mobile Mix Plant, expanding its presence beyond slurry and micro surfacing equipment. Designed with input from contractors and operators, the Journeyman focuses on ease of use, uptime and jobsite flexibility. It supports a wide range of material mixes — including 100% RAP, 100% virgin aggregate or any combination — while delivering consistent performance through integrated automation and metering controls.

Instead of adapting existing machinery, Bergkamp developed the Journeyman from the ground up, incorporating lessons from its EMCADS control system and real-world feedback. The result is a CCPR plant built for intuitive operation, reduced calibration time, and long-term reliability — bringing Bergkamp’s established standards into a new category of pavement preservation equipment.

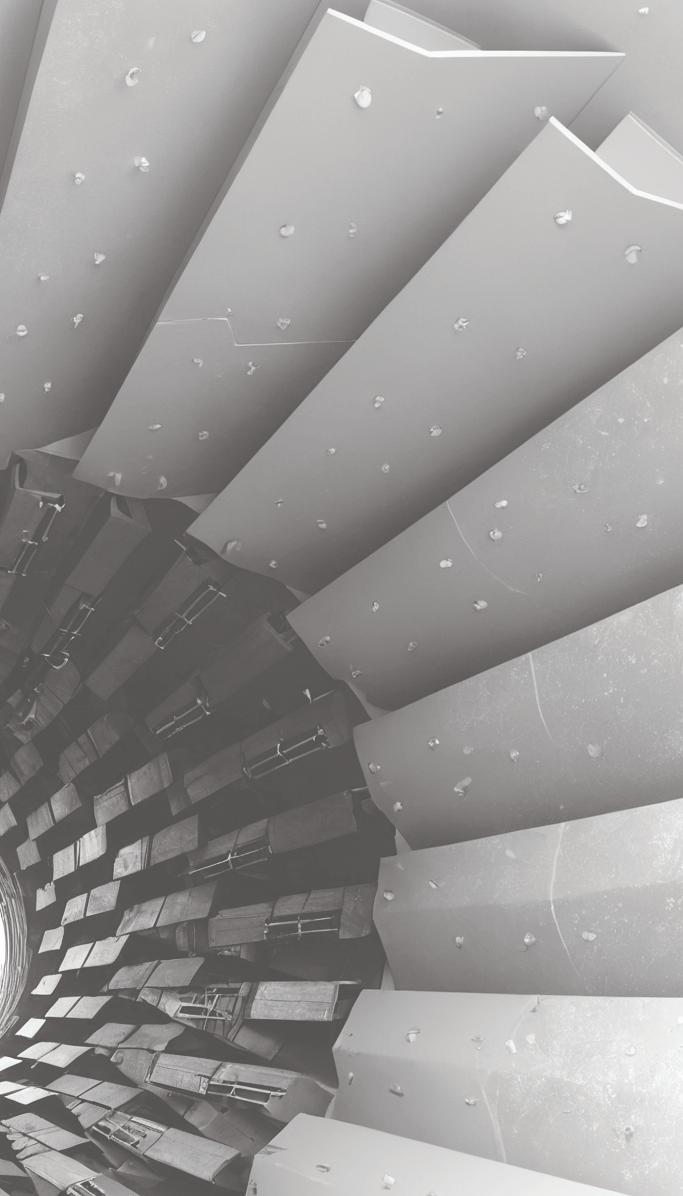

The ideal choice, no matter whether for milling work on freeways, state highways, airports, or other major construction projects.

Its MILL ASSIST machine control system ensures absolute efficiency on every construction site. In automatic mode, it always ensures the most favorable working balance between performance and costs. It also allows the selection of three different working strategies that optimize the process with respect to cost, performance, or quality.

Powered by a John Deere engine with a maximum rated power output of 580 kW, the W 210 XF delivers powerful and efficient milling performance in every situation.

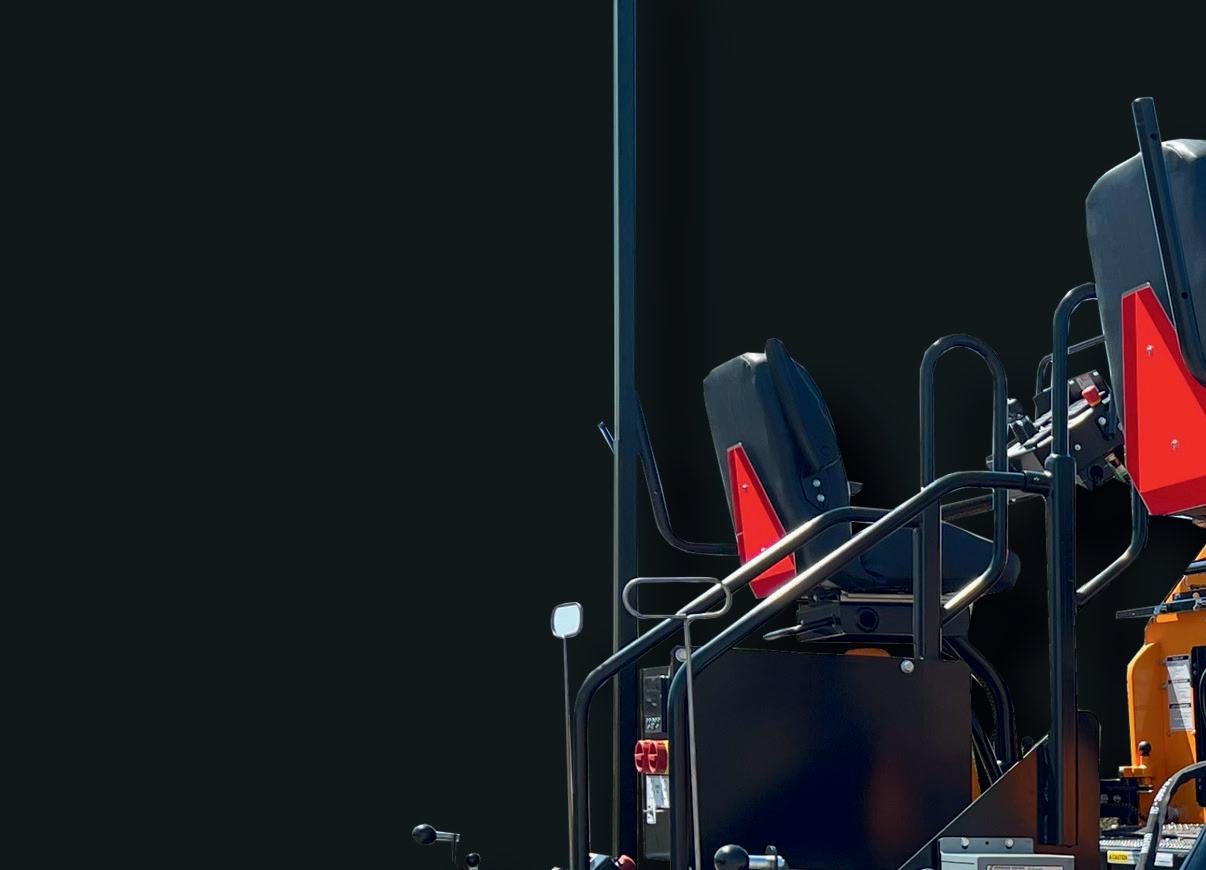

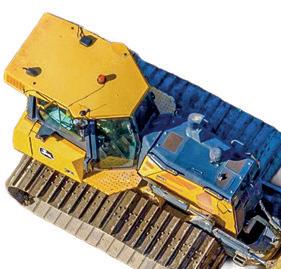

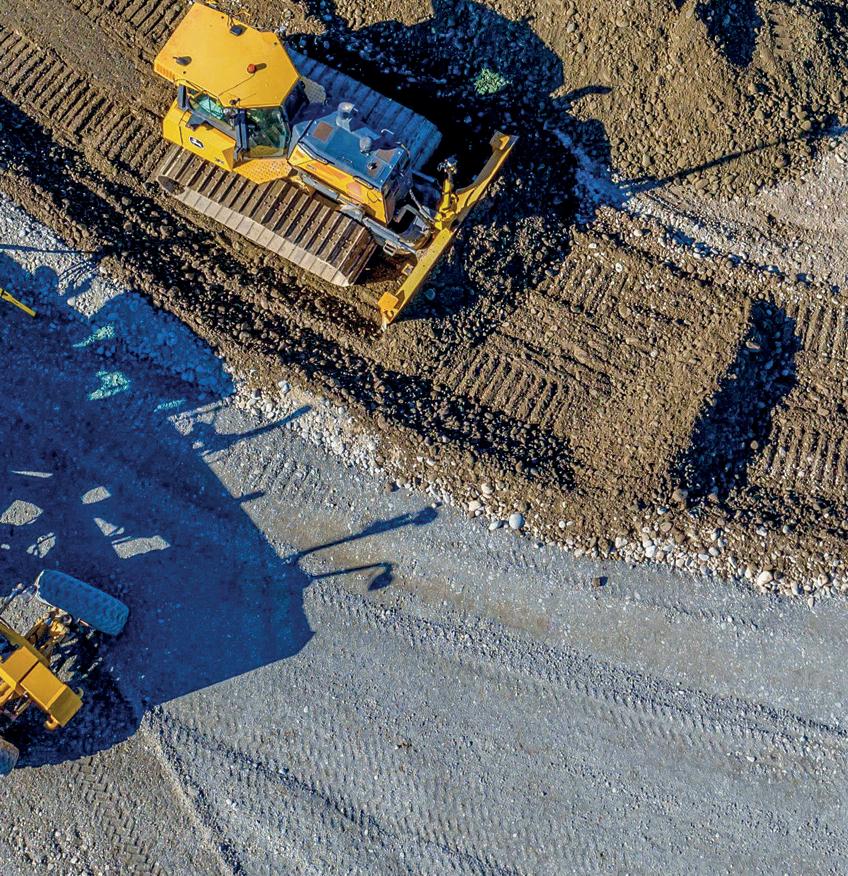

John Deere has introduced the 850 X-Tier Dozer, featuring dual-path electric drive for simplified power delivery and reduced machine complexity.

The new model builds on John Deere’s E-Drive legacy with improved torque, fuel efficiency and service access through a tilting cab. For added peace of mind, eligible 850 X-Tier machines come with up to 84 months/15,000 hours of E-Drive component coverage.

Operator comfort and visibility are also enhanced, with a redesigned cab offering 14% more glass, ergonomic controls and John Deere’s Advanced Vision System.

• All diesel power (both burner and engine) for maximum efficiency and performance.

• Industry’s fastest heat up time - less than 2.5 hours from cold start.

• Advanced plow-point agitation for faster heat-up and material discharge.

• Heated discharge chute for uninterupted material applicaton.

We’ve built our business and reputation through our unparalleled focus on equipment design, durability, and attention to detail. We apply these foundations to our complete range of asphalt plants and asphalt plant equipment. Let us customize to your request - big or small.

In the world of heavy construction materials, asphalt production is one of the most complex and demanding sectors. Yet for years, many asphalt producers have relied on outdated methods for scheduling, dispatching, and communication. This reliance has led to inefficiencies, disconnected data, and operational slowdowns that eat into profitability. Sound familiar? It’s a challenge many in the industry know all too well – but the good news is, the landscape is changing.

More asphalt producers are embracing cloud technology and real-time data systems to modernize their operations. From plant scheduling to ticketing and delivery tracking, the benefits of digital transformation are being realized across the board. The move may sound daunting, but the upside is clear: enhanced

visibility, improved accuracy, increased efficiency, and better decision-making, all in real time.

Running an asphalt operation with disconnected systems is like trying to lay down pavement with a crew working from different blueprints – while using walkie-talkies from the’90s. In conversations with customers, the same challenges keep coming up: key systems like plant control, dispatch, scale operations, customer communication, and billing often don’t talk to each other. This fragmentation creates bottlenecks that lead to rework, costly delays, and inconsistent information across the supply chain.

In many cases, dispatchers still rely on phone calls and spreadsheets to coordinate truck movements, while paper tickets remain the norm at many sites. These outdated practices not only slow things down – they also increase the risk of mistakes, limit visibility into

daily operations, and make it harder to adapt when things don’t go as planned. Timing is everything in asphalt. Plants must stay hot, trucks need to stay on schedule, and paving crews can’t afford to wait. Without real-time load tracking or live truck locations, operations teams are often left in the dark, reacting to issues only after they’ve caused a problem. Missed loads, material waste, and inefficient routing are common – and expensive.

Paper tickets make audits a headache and can be lost or misfiled, creating complications when it’s time to prove compliance with weight limits, environmental guidelines, or delivery requirements. With regulations getting stricter, traditional systems just can’t keep up. Meanwhile, the workforce is changing. Veteran team members are retiring, and younger workers expect mobile, intuitive tools that reflect how they live and work today. Digital transformation isn’t just about improving processes –it’s about attracting and retaining talent, too. And that starts with training and

change management strategies that help teams adapt and thrive.

Customer expectations are evolving just as fast. Thanks to apps like Amazon and DoorDash, real-time updates and self-service tracking are now expected. Your customers want to know when loads are on the way, how much material they’ve received, and whether everything’s running on time – without making a single call. If your business can’t deliver that visibility, they’ll find someone who can.

Cloud-based systems bring a new level of visibility to asphalt operations. Whether it’s plant operators, dispatchers, drivers, or managers, everyone has access to the same realtime information. Teams can track trucks in motion, monitor load statuses, and confirm deliveries the moment they happen. If traffic hits or a plant goes down, dispatchers can reroute trucks instantly, minimizing disruption.

This real-time insight streamlines processes across the board. Truck checkins and ticketing are faster. Alerts on idle trucks or missed loads help teams take immediate action. Managers can shift from reactive decisions based on yesterday’s reports to real-time decisionmaking that keeps operations running efficiently.

When you layer in technologies like IoT and edge computing, the benefits get even bigger. Sensors can monitor everything from temperature to load weights to tank levels, feeding that data into the cloud for instant visibility. Edge computing processes that data locally before pushing it to the cloud, reducing delays and improving responsiveness. This hybrid approach gives asphalt producers the best of both worlds –speed and insight.

Real-time data is powerful. But when it’s flowing between systems, it becomes transformational. Cloud platforms built with an API-first mindset make it easy

to integrate with your ERP, accounting tools, fleet tracking systems, and customer portals.

When your systems are connected, the silos between departments disappear. No more manual data entry across multiple platforms. Dispatch, production, billing, and logistics stay in sync, improving accuracy and reducing double-work. Schedule changes are reflected instantly across the board. Invoices match delivery tickets. Customer updates go out automatically. Everyone is on the same page.

Customers feel the difference, too. They get digital tickets, real-time delivery updates, and electronic invoices – all without chasing down your team. Integration improves internal efficiency while elevating the customer experience.

Migrating to the cloud isn’t just about efficiency – it’s also about security. Cloud environments allow producers to standardize and strengthen

security policies across all their sites and systems. From enforcing encryption and password protocols to monitoring access logs and alerts, cloud-based tools simplify security oversight.

Identity and Access Management (IAM) systems make it easy to assign and manage roles from a single dashboard. Single SignOn (SSO) and Multi-Factor Authentication (MFA) enhance both security and ease of use. Instead of juggling multiple logins and passwords, your team logs in once and gains access to all the tools they need.

Leading cloud providers also meet high industry standards, offering SOC2 certification, routine patching, intrusion detection, and more. Look for providers aligned with NIST cybersecurity frameworks to ensure you’re getting both flexibility and strong protection – critical when uptime, compliance, and customer trust are on the line.

Today’s platforms are designed with end users in mind. Easy-to-use interfaces and mobile functionality allow teams to work smarter from anywhere – whether that’s in the cab of a truck, at the plant, or in the field. Drivers can receive job assignments, capture signatures, upload load photos, and close out tickets all from their smartphones.

Dispatchers aren’t stuck at a desk either. Tablets and laptops let them manage workflows remotely, track activity in real time, and respond to issues on the fly. And with cloud access, everyone across your operation – including remote offices or satellite plants – can stay informed and aligned.

This kind of accessibility improves collaboration, reduces delays, and ensures that everyone has the most up-to-date information, no matter where they’re working.

The shift to cloud-based platforms isn’t just a trend – it’s a competitive advantage. Asphalt producers who make the leap are seeing measurable results: less IT overhead, improved efficiency, and greater operational agility.

Cloud platforms make it easier to scale, too. Need to add a new plant or location? No problem. Software updates are pushed automatically. No downtime, no disruption. And as the industry continues to evolve, cloud-based systems offer a launchpad for innovations like AI, machine learning, and smarter IoT applications.

By adopting cloud-based dispatch and ticketing solutions, asphalt producers are setting themselves up not just to meet today’s demands – but to lead the industry into the future. With realtime visibility, better data, integrated systems, and intuitive user experiences, cloud technology is paving the way for more efficient, more agile, and more profitable operations.

The future is here – and it’s in the cloud.

by Gary Bisel, Project Manager, Cloud Scale Ticketing and Dispatch at Command Alkon

Tom_AdobeStock

By Brandon Noel, Editor

A new bipartisan bill could offer a pathway to greener road building.

In March of 2025, Senators Chris Coons (D-DE) and Thom Tillis (R-NC) reintroduced the Concrete And Asphalt Innovation Act (CAIA) as a companion to House bill H.R. 1534, which passed with overwhelming bipartisan support to the tune of 35073. Currently, it awaits further action by the Senate Energy and Natural Resources committee before going to a possible vote on the floor.

The bill’s core aim is to reduce the carbon footprint of many vital construction materials utilized in state and federal infrastructure projects, as well as boosting American manufacturing and supply chain competitiveness. To get there, the bill sets up Federal Highway Administration (FHWA) grants that reward state Departments of Transportation (DOTs) for specifying and sourcing lower-emission mixes, essentially paying contractors a premium to bid using greener materials and suppliers.

POLICY DOUBLE-TAKE

Reading that, some of you might be experiencing the faintest amounts of deja vu. If you paid attention during the formation and passage of the Inflation Reduction Act, then you already know that the bill appropriated roughly $4.5 billion for a wide-range of cleaner construction materials as part of the larger Federal Buy Clean Initiative. The goal of which was to jump-start demand for green concrete and asphalt, as well as other essential building materials, by subsidizing projects that use them and settings new standard

for federal purchasing.

Ironically, the recently passed One Big Beautiful Bill Act (BBB) that was passed earlier this month (July 2025), clawed back billions in unspent IRA funds, practically defunding the bill’s low-carbon materials grants for roads. Over $1.8 billion meant for cleaner concrete and asphalt infrastructure was rescinded before it could be used. The CAIA’s funding in this regard is extremely modest by comparison, equalling only $15 million (only 0.9% of rescinded funds) spanning 2025-2027 for the FWHA low-carbon incentives pilot.

The new bill is more about setting up frameworks (it creates program authorities and pilot funding), which Congress could expand in the future (possibly in the next Highway Bill which the National Asphalt Association is currently help craft). So, the new legislation is less a giant spending package and more a policy foundation for sustained support. It adds tools (contracts, research initiatives, task force) that IRA didn’t have, but it doesn’t currently match IRA’s scale of investment.

What’s interesting to note, however, isn’t so much the differences between the two pieces of, arguably, greenlegislation, but how similar they are in spirit, aim, and desired outcomes. The CAIA, in some ways, reads more like a second-draft of the IRA’s sustainability ambitions. Rather than a complete change of course or direction, it wants to take a different route to get to the same destination.

Imagine the IRA as a single major highway, made with one hundred lanes for

traffic, between two states on opposite ends of the country. It has no exits, no additional on-ramps, and no rest stops (this is fictional, remember). While it might be a fast way to get from state”A” to state”B” it ultimately is not that practical or functional. It’s a bottleneck with only one place to get on, forcing everyone to the same entrance point.

Now, the CAIA might look like that one gigantic highway, just scaled down to four traffic lanes, but it has plenty of connections, exits, and ways for people to utilize it from wherever they are along the way. It might take a little longer, but, from a long-term perspective, it’s building a functional foundation that might better withstand the shifting political winds of Washington.

For asphalt producers, the CAIA seemingly means more ways to plug into federal funding over time, rather than racing to qualify for a single round of short-lived grants.

While the objectives between the two bills aligns, the most significant addition created by the CAIA are long-term market commitments in the form of advance purchase authorizations. This is one of those metaphorical and literal on-ramps. Rather than the one-time cash infusion of the IRA, the CAIA sets up a system for ongoing, multi-year procurement contracts for low-carbon materials.

By giving suppliers a more predictable roadmap for future demand, it directly responds to a gap noted by experts during the post-IRA period, which were, perhaps, too short-term to convince asphalt and cement producers to invest in deep decarbonization. With CAIA’s multi-year contracts to lower

Since its introduction, the Weiler P385 has set the standard for commercial pavers. The P385C raises that standard.

Variable speed and reversible conveyors and augers and a 25% increase in tunnel height provide optimal material output.

Increase to 120 hp with the Cat® C3.6 Tier 4F/Stage V engine.

Modular conveyor drive and sealed chain case increase feeder system reliability and life.

Enhanced heat system performance with direct-drive hydraulic generator and elimination of GFCI breakers.

the financial risk for such investments, producers have the stability to innovate knowing that states will buy their product over a period of years.

Another big difference here is a focus on future needs and impacts, not just the issues in the extreme present. The IRA’s provisions largely focused on immediate deployment. Shovel-ready projects and the procurement of existing low-carbon materials were primed to take immediate advantage of the glut of funding.

and clear whatever regulatory hurdles might arise jointly.

How this might benefit contractors is through the alignment of military and civilian standards and pooling federal and state purchasing power through a more coordinated Buy Clean effort than what was present in the IRA.

This new bipartisan bill explicitly aims at reducing greenhouse gas emissions (GHG). It is a green bill by any other name, and as we’ve detailed here, it includes much of the same language, if not similar architecture, to its legislative predecessor. And it has large bi-partisan support, as well as support from the broader industry.

diverge the most is in its messaging and constraints. The IRA’s low-carbon material grants were attached to strict climate safeguards, for instance: The low-carbon materials grants could not be utilized for projects that were intended for road or lane expansions which have shown to increase overall local emissions through things like induced demand.

The CAIA does not have such explicit prohibitions attached to its’ funding, it doesn’t matter how the roads are built or expanded, because it’s focus is solely on that of the emissions related to the materials themselves.

andrew_shots_AdobeStock

By contrast, the CAIA heavily emphasizes new research and development methodologies, pipelines of innovation, time for proper testing of new materials, and scaling-up demand along with production. To accomplish this it requires the creation of a Department of Energy (DOE) led research program covering everything from new forms of carbon capture to novel mix designs.

Additionally, it calls for the creation of not one, but two manufacturing institutes devoted solely to low-emission concrete and asphalt. This is intended to ensure the industry doesn’t settle for current techniques and products, but is future-focused on new technologies.

While the IRA did inject hefty funds into various government agencies (DOT, EPA, GSA, etc) to use lowcarbon materials, it did not explicitly outline a unified strategy on how to go about doing that.

Nile Elam, VP of Government Affairs for NAPA, who worked on the CAIA’s parent bill (IMPACT Act) from its origination said:

[It’s] a great example of industry and policy stakeholders coming together to identify and execute an idea that strives for environmental stewardship without sacrificing the great work asphalt producers have prioritized, and continue to prioritize, regarding low-carbon pavements and innovative technology deployments. We will continue to work on the IMPACT Act in the Senate and work with our friends in Congress on more pragmatic bills to achieve our industry’s sustainability goals.

Brad Townsend, VP of Policy and Outreach at the Center for Climate and Energy Solutions (C2ES), spoke regarding the bills tools to help the industry decarbonize:

The bill is framed in a bipartisan manner to emphasize its job creation, industrial strengthening, and, for lack of a better term, American production exceptionalism by-way-of improved production efficiencies.

If these terms were on a recipe card and I was cooking dinner, you might think I was cooking up climate change goals for supper. That’s because while the substance of the bill aligns with familiar, and much needed, climate goals, the messaging is implicitly targeting more economically-driven language, compared to the IRA’s specifically climate-focused messaging.

A concerning problem that both the IRA and the CAIA share is a practical one: verification. How do these low-carbon materials get classified and confirmed as such? Who decides these thresholds?

The “how” was largely left up to each standalone entity. The CAIA changes that by bringing the agencies together (Energy, Transportation, Defense, GSA, NIST) to share data, construct a set of common goals, set clear plans in place,

The Concrete and Asphalt Innovation Act provides critical tools needed to decarbonize concrete, cement, and asphalt while ensuring continued U.S. leadership in the production of materials that are vital to the buildings and infrastructure that supports our economy. Importantly, the legislation recognizes the role that the federal and state governments play in unlocking innovation and addressing regulatory barriers to low-carbon materials as the largest buyers of concrete, cement, and asphalt.

While both legislative efforts aim to cut emissions, where they, perhaps,

Without a doubt, The IRA set the template for using federal spending to drive a “buy clean” paradigm shift, and the CAIA follows closely in its footsteps. The changes mostly involve changes to strategy and longevity, hopefully creating a more sustainable framework that will outlast both pieces of legislation.

In effect, the”buy clean” initiative has undergone a reboot, shifting away from heavy investment toward a more phased, business-friendly approach. Whether or not this accelerates the type of technological innovation and climate progress the CAIA was written for remains to be seen.

With so many options available, purchasing a new piece of equipment that meets your needs is not an easy decision. If you’re in the market for a tandem roller, however, this is your best resource. Here, we’ve complied the industry’s only Tandem Roller Spec Guide, featuring equipment specifications for nearly 180 models. For an even easier way to compare, visit the exclusive, interactive and customizable version of this spec guide at http://www.forconstructionpros.com/ specguide/roller to sort and compare models based on your requirements.

The Hyundai HR series tandem-drum rollers offer hydrostatic vibration system at both drums and automatic vibration mode (double / single vibration) – combined with front and rear scrapers to keep the drums free of material buildup.

SAKAI specializes in asphalt rollers, soil compactors, and light compaction. The storied 100-year-old Japanese manufacturer is known for reliability, durability, and operating simplicity of its machines. Long-life drum isolators, high-capacity reliable water system and gear-driven oscillatory drums limit down time. SAKAI also offers the Guardman auto brake assist system which detects personnel or equipment in the path of the roller and automatically stops if needed. All SAKAI equipment is built in Japan and USA.

HAMM compaction technology boosts paving contractor productivity and profitability. The new HD+ 120i V-VIO and HD+ 120i VIO-2-HF rollers come with the new VIO compaction system which combines vibration and oscillation all into one system – allowing the operator to switch easily between the two while in motion.

*specs are for front vibratory drums only. See additional oscillation drum specs on website for more detail

Continued on page 26

BOMAG offers a diverse range of tandem asphalt rollers, designed with a focus on durability, productivity, and efficiency. The heavy tandem range offers three choices in vibration: standard, TanGO oscillation, and Asphalt Manager. The Asphalt Manager system integrates fully automated amplitude control to achieve density faster while preventing over-compaction, and also features an oscillation-only mode. BOMAG has a solution to fit your needs.

Our combi-versions feature four rear rubber tires in place of a traditional drum. Each pair is independently powered by separate drive motors, significantly reducing the risk of surface damage —especially during tight turns on freshly laid asphalt. The rubber tires also help achieve a denser, smoother finish, meeting the demands of high-spec paving jobs.

Caterpillar has a wide range of compaction products designed to make customers more successful. An extensive Cat dealer network gives customers amazing lifetime value from their equipment allowing them to focus on getting the job done. CAT builds the machines that build a better world. For more information visit CAT.com.

Wacker Neuson’s Pro-roller family includes the RD45 which offers a variety of operator-friendly features including an ergonomic work platform designed for low vibration and comfortable operation, excellent line of sight to the drums and work site, intuitive operator’s display with all functions clearly labeled and activated with the push of a button, and dual operator control lever for right or left hand operation of drive and activation of vibration/oscillation energy.

Dynapac tandem asphalt rollers are built for consistent uniform compaction on the job and consistently achieving required density. The operators station is safe, comfortable and have all needed controls easy to access and use. SEISMIC Asphalt for the heavy tandem roller segment is a game changer with automatic adjustable vibration frequency to insure optimal compaction, fuel savings and operator comfort with quieter operation.

Double-drum asphalt compactors from Volvo Construction Equipment offer features that support productivity, accuracy and sustainability. Many models have optional 8-amplitude settings for added precision. The DD25 Electric is an emissions-free machine with performance greater than or equal to its conventional equivalent. Compact Assist, the Volvo Intelligent Compaction System, provides real-time density calculations as well as pass and temperature mapping. ActiveCare Direct, Volvo’s advanced telematics program, focuses on simple case alerts rather than complex fault codes.

* Oscillating drum; ** Oscillation force

When static compaction is required, the Weiler C310A and C307A perform in a wide range of applications with a split front drum that enables the outer half of the drum to rotate faster than the inner half resulting in quick work on corners and curves, without mat tearing.

Miss the

TOP 3 REASONS TO ATTEND IGNITE

➊ A TWIST ON TYPICAL NETWORKING - Engage in Conversations with your peers, while participating in daily networking receptions, and our annual golf outing. This event includes corn hole, golf, signature drinks and more!

➋ A STAY AT AN AWARD-WINNING PROPERTY - Staying at the OPAL SOL in Clearwater Beach, Florida will allow the perfect mix of relaxation, fun, and education!

➌ EDUCATION LASER-FOCUSED FOR THE FUTUREGain access to information and tactics that you can put to use as soon as you get back to the office. Hear from industry experts and receive the resources you need to succeed.

The BR36 + BR48 Asphalt Rollers were designed for smaller paving and pavement maintenance projects, the SR48 Soil Roller for your soil compaction needs and the BR48R is built to handle the toughest compaction jobs. Trust the LeeBoy rollers to deliver superior compaction results, setting a new standard in asphalt technology.

Permanent pavement maintenance solutions at the lowest operating costs available in the industry.

Pothole Patching Crack Sealing Asphalt Pavement Emulsion Storage

A permanent pavement repair in four steps: Clean, Tack, Fill, Coat and ready for traffic.

Seal and protect your pavement asset with the safest and most efficient

Prevent premature asphalt joint failures before you pave with the MA4 melter ap-

Reduce material and transport costs while boosting productivity with a heated crack sealer. tank.

P5™ One-Person Patcher

Spray Injection Patcher

300 Gallon emulsion capacity

Covered five yard aggregate hopper

Unique, 3-section boom is easily maneuvered

Store up to 10,000 gallons of Emulsion Fast 15 GPM pump keeps operations efficient

Digital controller allows tank agitation to be set by both time and day of week

CASE E Series vibratory rollers feature a completely redesigned operator interface for intuitive operation and improved ergonomics. New control features include an electronic travel lever with an extended range of functions right at the operator’s fingertips, including RPM settings, drive settings, sprinkler system controls, parking brake and more.

By Allyson Sherrier, Managing Editor

With heart, hustle, and a vision for the future, Elite Paving’s Ali Williams is reimagining what success looks like in construction.

In an industry known for grit, legacy, and tradition, Ali Williams brings something different to the table: perspective. As Business Development Manager for Elite Paving, she doesn’t just help grow the company’s client base — she’s helping to reshape how the asphalt industry presents itself.

Williams is part of a new generation of construction professionals who didn’t come up through the trades but found their way in through other strengths — strategy, storytelling and a drive to build something that lasts. While her role at Elite technically centers on business development, her actual scope goes much further.

“I’m the problem solver, the organizer and the person the team comes to when something needs to get done,” she said.

Her daily work blends external relationship building with internal brand development — identifying growth opportunities, reconnecting with past clients and creating content that keeps Elite top of mind in a competitive paving market.

“I’m always looking for opportunities to elevate our presence and stay competitive,” she said. “And I take pride in making sure our team stays sharp, responsive and visible.”

While asphalt may be one of the most established trades in infrastructure, it’s

not immune to disruption. Contractors across the country are navigating labor shortages, aging workforces, tighter bid margins and growing demand for project transparency. At the same time, customers expect a higher level of professionalism and digital savvy.

Williams sees all of that not as a challenge, but an opening.

“I see myself as someone who helps shift the perception of what this industry can look like,” she said.

That includes how asphalt contractors communicate, market themselves and engage new audiences. And it’s not just about flashy branding — it’s about connection, clarity and consistency.

Her approach is shaped by what she didn’t see when she first entered the field: women, young professionals, and creative thinkers who saw value beyond the jobsite. She’s making it part of her mission to change that.

“If I can help create pathways for others to see themselves here, especially women and youth, then I know I’m doing something meaningful,” she said.

Williams entered the asphalt world less than two years ago, and she’ll be the first to tell you it wasn’t a career she planned for. Introduced to the trades through a professional connection, she was drawn in by the culture, the work ethic, the people and a sense of purpose.

“What surprised me right away was the sense of belonging I felt,” she said. “The people were real, hardworking and passionate about what they do.”

Her background brought a fresh lens to a field that often favors technical experience over communication skills. But Williams saw untapped potential in areas like client outreach, storytelling

and strategic branding — tools that could help asphalt companies build lasting trust with both customers and communities.

She also quickly realized the learning curve that came with the job. While she was confident in her business acumen, she knew she had to earn credibility in an industry built on experience. That meant asking questions, staying curious and respecting the knowledge that others brought to the table.

While she acknowledges the unique challenges of being a young woman in a male-dominated field, Williams sees her own leadership style as a strength.

“We process things, communicate, and lead differently than our male counterparts,” she said. “That might’ve been seen as a weakness, but I see it as the future.”

She’s also quick to point out that success in the asphalt industry doesn’t have to follow a single blueprint. Whether you’re on a crew, in the office, or working on brand development, there’s room for many kinds of contribution.

From navigating complex client expectations to helping Elite Paving modernize how it shows up online, Williams is proving that the future of the asphalt industry isn’t just about equipment or material — it’s about people. And it’s personal.

“If you’re considering it, and you’re willing to take a chance on yourself, this industry can give you more than a job. It can give you a place to grow, contribute and be part of something bigger than yourself.”

At Dimensions 2025, connection is magnetic.

Plug into a powerful network of industry experts, unlock hidden potential within your Trimble solutions, and master the latest techniques driving the future of your work. Discover innovative workflows and solutions, and solve your toughest challenges alongside peers, partners and Trimble professionals.

November 10–12, 2025 | The Venetian Resort Las Vegas Trimble.com/Dimensions Register now to reserve your spot at Trimble Dimensions

How contractors can use the latest John Deere and WIRTGEN GROUP machine data by tracking each machine’s performance on a road construction site.

No matter the sport, grabbing a seat to experience it live in an arena, stadium or ballpark etches a deeper appreciation and understanding of the game. Watching our favorite team, we discover more nuances of their plays — a quarterback reduces their time to throw, or a defensive back notices a slight cue from the offensive line to stop a play in motion. Similarly, contractors and equipment or project managers regularly visit their jobsites to monitor their progress. We in the industry know jobsite visits are one of the best ways to keep projects on track. But when contractors integrate a centralized fleet management system (FMS) for their entire project, machine monitoring and automated data collection essentially multiplies contractors’ seat view from one to several vantage points. While teams usually wear the same color on the field, many contractors’ jobsites have machines in different colors — and from different manufacturers — to get the job done.

Like the coaches who partner with assistant coaches, managers and a facility’s videographers, an FMS developed from an open system concept helps contractors to record their jobsite plays and save these important datasets. When equipment or project managers segment these datasets for specialized teams to review at a later date — like a chief estimator looking at a paver’s idle time reports within the Operations Center — they are considering the project not only from the end zone, but also from the

50-yard line. From a road construction site, let’s review how machine monitoring software, datasets and GPS tracking can increase machine efficiency without the increased risk of downtime.

Contractors partnering with Department of Transportation (DOT) officials find that sharing machine performance data is like adding stadium seats to the jobsite — offering a higher vantage point and a clearer view of what’s really happening on the ground. With their preferred machine monitoring technology and an open-platform fleet management system, teams can capture detailed road conditions and surrounding context through point cloud data. This elevated perspective enables smarter modeling, more accurate cost forecasting, and real-time decision-making.

Some road construction sites are expected to offer DOT officials and other

stakeholders machine data and project modeling in the near future. This way, the jobsite team and their customers can periodically view the construction game play as it progresses. While these real-time views for VIP ticket holders are only available for a small fraction of road builders, many other stakeholders already view machines’ performance data to adjust for better efficiency.

Certain machines play pivotal roles on the jobsite, much like a tight end in football. In road rehabilitation, the milling machine is that versatile player, critical to setting the pace and progress of the project. This is why tracking the mill’s GPS location, idle times and quantities milled (removed) can offer valuable information.

“Tracking certain mill machine data points like idling times and quantities removed not only enables precise documentation of the actual performance

but also offers valuable benefits in terms of efficient jobsite management,” said Daniel Robertson, machine control expert with nearly 20 years of experience at RDO.

Cold milling machines are specialized machines for removing the road’s base layer, typically asphalt or concrete. The milled material can be recycled at a very high rate. In the United States, about 93% of Reclaimed Asphalt Pavement (RAP) is reused in new asphalt layers.

Operators can access real-time performance data like fuel usage, working speed, the material being milled and its GPS location from a mill’s control unit screen. Team members not currently behind the wheel can access this info from the Operations Center and view automated PDF or Excel reports of total milled area, material volume processed, and the mill’s distance covered over a specific period.

Robertson shared that an Arizonan contractor used some of these capabilities to enable quick, simple and transparent billing for their milling projects. .

Cody Wagner, RDO paving technology product manager who spent years as a quality control official in Minnesota and Colorado, shares how Topcon Positioning Systems’ latest RD-M2 Road Surface Scanner can be used to quickly create a digital survey of the mill’s progress.

“The mill’s effectiveness depends heavily on the density of the material being removed,” Wagner said. “Contractors who use a road scanner that operates at highway speeds, like the RD-M2, can track the quantities being removed and then the ‘millings’, the material created from the milling process.”

Wagner said that this material data tracking on milling machines can not only provide valuable insight into a road resurfacing project this summer, but also for future projects, as materials with similar densities could require similar fuel or replacement parts or create nearly the same number of recyclable materials.

With this data, contractors can coach their crews more effectively and collaborate with stakeholders to estimate the effort, cost and time required to mill a road base layer,” Wagner said.

More than five years ago, Minnesota’s DOT adopted an eTicketing system to track asphalt loads, time to deliver, and tonnage. Before 2020, plant-mixed asphalt was tracked by paper tickets that listed the asphalt’s weight and its confirmation of payment from the contractor. The paper ticket, along with its important data points, could easily be misplaced, proving costly to the project.

“Minnesota DOT’s implementation of the eTicketing allows asphalt transportation machines to be digitally weighed and tracked from the plant to its delivery location,” Wagner said. “Using GPS and machine monitoring, operators were able to share vital asphalt ticketing information with stakeholders through the use of geofences without delaying the project.”

Besides the labor and time savings, jobsites using the eTicketing systems were able to tap into some pavers’ open systems to keep their mix full and decrease the likelihood of grade changes.

“When a paver’s load is low, it begins to cool down and decrease its compaction force,” Wagner said. “Machine monitoring solutions like VÖGELE’s WITOS Paving and Smart Pave systems record and automate the tracking of a paver’s GPS location and its asphalt material consumption.”

Robertson and Wagner explain VÖGELE pavers are equipped with independent feeder controls and digital displays. DOT’s eTicketing system and machine monitoring technology work together to track data points to get operators in their peak paving zone. Here’s how it can work:

• A paver’s monitoring system like WITOS Paving will receive info like mix type, quantity, time at loading and Truck ID after a truck operator scans an eTicket’s QR code.

• Once in the WITOS system, a paver logs GPS location and timestamps it.

• As the truck is in transport, a paver’s sensors on conveyor belts and augers measure the flow of asphalt mix in the hopper and send data to the machine’s control unit.

• If the mix drops below a certain threshold, a warning pops up on the paver control unit screen and the operator can notify the truck driver or project foreman. These systems working together allow consistent material mix flow as each operator, the paver and truck operators know their real-time locations so they can proactively coordinate deliveries. Other pavers from different manufacturers can still work with John Deere Operations Center and DOT’s eTicketing through a StarFire RTK and Smart Pave system, a custom API or a semi-automated workflow. A trusted equipment technology dealer like RDO should be able to discuss specific options with contractors depending on their machine and FMS.

This summer, contractors are looking to expand their FMS and geofence system to track more vehicles — other than the trucks delivering asphalt — to check if machines travel the most efficient route and adjust as the road is completed and traffic changes.

With the amount of data collected through automated machine monitoring and open system FMS, contractors and operators can review a project’s game film to understand machine performance. We all know a smooth road is safer and requires less maintenance during the time a contractor is responsible for upkeep. During less busy times of the year, a team could come together to review machine performance and previous environmental conditions like weather to understand reasons why changes in slopes or densities occurred. Teams that win the World Series or the Super Bowl do so in part because they’ve reviewed the game’s film endlessly. Applying the same concept to road building, machine data or control solutions can reveal trick plays that enable contractors to stand at the project’s finish line with a trophyworthy road.

By Dennis Howard, Vice President, RDO Equipment

By Brandon Noel, Editor

The island community’s new bridge should be able to stand the test of time, as well as handle just about anything mother nature might throw at it.

Three years ago I sat at my desk and saw the photos and videos posted online in the aftermath of hurricane Ian. I felt a catch in my throat as I saw what happened to the small community just off the coast of Fort Myers, Florida. You see, I grew up in the state of Florida, just a few hours north in Ocala, and my family spent several years vacationing there. More recently, even though I live in Ohio now, I’ve taken my own family back there, and my children have made memories on the same beaches I did when I was their age.

We all cried over the devastation to our home-away-from-home. It was hard enough thinking about the loss from a distance, but we also thought of the losses for the people who live in that community whom we’d grown to love and appreciate, as well as, the harm brought to the habitat and the animals who live there too.

In the immediate wake of the storm, one of the biggest dangers centered on the loss of the Sanibel Causeway, built

six decades ago in 1963, which is the only way on-or-off the island. Regaining access was essential to the recovery efforts and emergency relief getting to where it was most needed. Amazingly, in less than thirty days, a temporary bridge was built to get things moving again.

In June of 2025, Superior Construction announced that the full causeway rebuild was complete, along with many enhanced design and engineering features to increase the bridge’s ability to withstand severe weather events like hurricanes and storm surges in the future.

“Hurricane Ian’s timing was particularly devastating,” noted Toby Mazzoni, Area Manager at Superior Construction, the primary contractor responsible for reconstruction. “Because it destroyed not only the original infrastructure but also obliterated nearly $9 million worth of active improvements that were about 30% complete when the storm hit.”

These enhancements, which began in September 2021, included:

• New public parking areas

• Restroom facilities

• Erosion control measures

• Native landscaping

• Bear noursihment

• Additional tourist amenities

The extent of Ian’s damage was catastrophic. The hurricane washed out all mechanically stabilized earth (MSE) walls, breached the islands themselves, and undermined bridge approaches at

all three locations. More than 280,000 cubic yards of earthwork, 8,500 cubic yards of concrete, 750,000 square feet of sheet piling, 30,000 tons of asphalt, and over 215,000 tons of coastal armoring were required to rebuild. These quantities barely give you an idea of the sheer scale of the damages.

However, within the destruction lay an opportunity to innovate and build the causeway back, better than it had ever been before.

“We incorporated major changes designed to create resilience against future hurricanes,” explained Mazzoni. Among these upgrades, the causeway road was elevated two feet higher, seawalls increased from five to eight feet, and vulnerable MSE walls were replaced entirely by cantilevered steel sheet pile walls installed as deep as 70 feet.

These sheet pile walls were placed along the entire length of the roadway on both sides of the chain islands, and were reinforced with”King Pile” technology at critical locations, aimed at increased wave resistance. King piles provide significant load-bearing capacity and resistance to bending.

The reconstruction team also took lessons from Ian’s devastation to heart, implementing 25,225 square yards of Gabion marine mattress technology to protect against scour, an innovative closed-loop underdrain system to alleviate hydrostatic pressures, and significantly upgraded coastal armoring. It required almost a quarter million tons of various aggregates, consisting of 128,000 tons of granite armor stone,

larger and more robust than traditional riprap; paired with 87,000 tons of riprap stone.

According to Mazzoni, “These changes reflected nearly 60 years of advancement in coastal engineering, including modern hurricane modeling capabilities and climate projections that weren’t available when the original causeway was designed.”

In terms of materials, the roadway underwent substantial design changes to withstand tidal conditions and the corrosive coastal environment. Superior Construction explained that traditional Florida Department of Transportation (FDOT) roadway structures, which typically involve stabilized earth layers, were significantly modified to remove vulnerable earth elements altogether. Instead, they employed a robust design featuring shell base, limerock/stone layers, and thicker asphalt courses. This adaptation was described as shifting from earth, stone, and asphalt, to a resilient structure of stone, asphalt, and more asphalt.

Beyond asphalt, concrete specifications were tailored meticulously to the aggressive coastal environment. The reconstruction utilized sophisticated concrete mixtures incorporating highly reactive pozzolans to enhance resistance to saltwater intrusion. Most of the concrete used (8,500 cubic yards) had a strength of 5,500 psi, with fiber-reinforced polymer (FRP) reinforcement strategically placed in the most vulnerable areas, providing superior corrosion resistance compared to traditional steel reinforcement.

Advanced technology and novel materials played critical roles.

“Glass fiber polymer reinforcement was used extensively to extend infrastructure lifespan to 75 years,” stated Superior Construction. Moreover, GPSguided installations enabled precise placement of granite armor stone, critical for optimal performance.

The breakdown included:

• 1,300 cubic yards of Class II, 3,400 psi concrete with highly reactive pozzolan using standard Grade 60 carbon steel reinforcement for concrete fascia (requiring 41,800 lbs of standard reinforcement).

• 700 cubic yards of Class II (Bridge Deck), 4,500 psi concrete with standard reinforcement for concrete bridge approach slabs and transition slabs (requiring 100,600 lbs of standard reinforcement).

• 3,950 cubic yards of Class IV, 5,500 psi concrete with Fiber Reinforced Polymer (FRP) reinforcement for concrete bulkheads, concrete caps, and slope pavement on top of sheet pile walls (requiring 340,000 linear feet of FRP reinforcement).

• 2,500 cubic yards of Class IV, 5,500 psi concrete with highly reactive pozzolan using standard reinforcement for various concrete barrier walls (requiring 241,600 lbs of reinforcement).

Additionally, 1,400 square yards of concrete slope pavement required approximately 250 cubic yards of concrete, and 7,000 linear feet of various concrete barrier walls contributed about 2,500 cubic yards to the total.

Superior Construction partnered with The de Moya Group, who provided marine operations expertise, and the design efforts were led by Kisinger Campo& Associates with Hardesty& Hanover as a structural design subconsultant. Such large-scale collaboration required sophisticated, multi-layered communication strategies.

“During the emergency phase covering the first 15 days, the team conducted hourly coordination meetings for real-time problem-solving,” Mazzoni noted. When typical communication channels weren’t working optimally, teams relied on whiteboards and face-toface collaboration.

The reconstruction revealed that phased design-build delivery was critical for emergency response under uncertain conditions, allowing the team to begin emergency repairs immediately while concurrently designing permanent reconstruction.

The task-order-based structure prevented the design-builder from having to price unknown conditions in the immediate aftermath of a catastrophic hurricane, while collaborative cost development proved more effective than traditional fixed-price approaches.

Locals and visitors return to restored Sanibel Causeway island beaches, rebuilt with new sand after Hurricane Ian.

Superior Construction

A New Day for the Sanibel Causeway: An aerial view of the engineering excellence and environmental integration of the reconstructed Sanibel Causeway in Lee County, Florida.

Kisinger Campo& Associates

Technology integration lessons showed that advanced coastal modeling was essential for resilient design decisions, real-time collaboration was more important than rigid specifications, and colocation of teams was essential for rapid decision-making.

Risk management strategies validated a balanced approach through task-based work orders, with weather risks during emergency repairs primarily borne by the owner, construction methodology risks allocated to the designbuilder, and regulatory/permitting risks shared between parties.

In such a unique and difficult environment, leveraging new and innovative technological assets was essential. The reconstruction leveraged cutting-edge technology throughout all project phases:

• Drone technology played a crucial role, with Propeller drone mapping providing precise quantity surveying and 3D modeling capabilities, realtime streaming capabilities enabling remote progress monitoring, and initial damage assessment when physical access was impossible immediately after Hurricane Ian.

Steel sheet pile wall systems replace more vulnerable MSE walls. Superior Construction

drastically. As Superior Construction explained, analysis of the storm highlighted the inadequacies of previous coastal protection measures, driving a comprehensive overhaul of seawalls, armoring, and embedment techniques.

Hurricane Ian’s damage — and more importantly, its human toll — were catastrophic. Many helped to rebuild.

Superior Construction

The team learned that traditional procurement methods were inadequate for emergency conditions, and that collaborative approaches enabled rapid adaptation to challenges, including permit expirations that threatened marine operations, supply chain barriers overcome through extraordinary partnerships, and the successful reconfiguration of construction sequencing when marine permit limitations required switching from”outside-in” to”inside-out” construction approaches.

The integration of advanced materials like FRP reinforcement and sophisticated concrete mix designs under emergency timelines demonstrated that high-performance construction is achievable even under accelerated schedules when the team structure supports rapid decision-making and collaborative problem-solving.

• Communication technology included Starlink satellite communications to maintain reliable connectivity when traditional telecommunications infrastructure was compromised.

• Precision installation utilized GPSguided installation technology for critical coastal protection elements, particularly for the precise placement of the 128,000 tons of granite armor stone, and Global Navigation Satellite System (GNSS) with Automated Machine Control (AMC) for precise layout and installation.

• Assessment technology incorporated reality capture technologies for underwater bridge foundation assessments and remote-operated submersible vehicles for detailed subsurface damage documentation that would have been difficult to assess through traditional diving operations.

• Advanced modeling included Building Information Modeling (BIM) for complex coordination of utilities, drainage, and structural elements within the limited causeway footprint, along with sophisticated ADCIRC and SWAN coastal engineering modeling that enabled the team to simulate Hurricane Ian’s impacts and make critical, datadriven design decisions for permanent reconstruction.

Key lessons from Hurricane Ian reshaped shoreline protection strategies

This new approach proved its worth during the 2024 hurricane season when the rebuilt sections of the causeway withstood hurricanes Debby, Helene, and Milton with minimal damage. While everyone else might have been holding their breath during those storms, for the contractors, this was real-world validation of their resilience strategies.

Maintenance and lifecycle considerations also factored heavily into design decisions. According to Superior Construction, the causeway’s new infrastructure anticipates temporary inundation during storms but ensures rapid restoration of functionality once waters recede. The design, backed by advanced modeling and precise materials selection, significantly reduces long-term maintenance requirements.

The project’s innovative practices and successful management under intense emergency conditions have established the Superior-de Moya Joint Venture as leaders in coastal infrastructure resilience.

“We’ve received awards and recognition from multiple industry organizations,” Mazzoni shared, reinforcing the impact and effectiveness of their efforts.

For road builders and asphalt producers nationwide, the Sanibel Causeway reconstruction offers an essential blueprint for building resilience into infrastructure. It demonstrates not only how to respond quickly to disasters but how to emerge stronger, better prepared, and ready to withstand the forces of nature—whatever comes next.

Here’s what you need to know to keep your company compliant and protected.

California is well-known for having some of the most rigorous labor requirements in the United States, especially concerning employee meal and rest breaks. These regulations have been in place for over two decades, but recent legislative changes raise the stakes for non-compliance. As of July 1, 2024, California reformed its Private Attorneys General Act (PAGA), increasing the urgency for businesses to record and manage these breaks accurately.

Here’s what you need to know to keep your company compliant and protected.

Understanding California’s Meal and Rest Break Laws

California labor laws set specific meal and rest breaks requirements that employers must rigorously adhere to. These regulations include detailed guidelines about the timing, length, and documentation of breaks.

Meal breaks: Employees working more than five hours must receive a 30-minute unpaid meal break, which must be uninterrupted and off-duty. If the workday exceeds ten hours, a second meal break is required.

Rest breaks: For every four hours worked, employees must receive a 10-minute paid rest break. Unlike meal breaks, rest breaks do not require employers to record the exact start and stop times.

In addition to break requirements, California mandates premium overtime pay:

• 1.5 times the regular pay rate after working more than eight hours in a workday or over 40 hours in a workweek.

• Double the regular pay rate after exceeding 12 hours in a single workday.

Employers must accurately document employees’ hours, including shift start and end times and meal breaks, to fully comply with these regulations.

The Stakes Are Higher with PAGA

The recent reform of California’s PAGA has escalated the importance of compliance. Under PAGA, employees can file lawsuits against employers for labor code violations. Penalties can quickly multiply, making thorough compliance critical for your company’s financial health.

How Your Company Can Protect Itself

To safeguard your business, following California’s guidelines is essential. This means maintaining payroll and timekeeping records for at least four years. Here are some key practices your business should adopt immediately if you haven’t done so already.

Time-keeping policy: Implement a policy that educates your employees and managers on the proper clock-in and clock-out procedures for the start of a work day, rest breaks, and meal breaks. Accurate time tracking: Precisely document all hours worked, including daily shift start and stop times and meal break periods.

Compliance checks: Implement regular audits of time records to verify accuracy and compliance.

Process for reporting payroll issues: Ensure employees have been

trained and have easy access to channels to report missing hours or other inaccuracies.

HCSS Solutions to Assist Your Compliance and Protection

Navigating California’s complex regulations can be challenging, particularly in construction, where managing varied schedules and remote crews complicates compliance efforts. HCSS provides timekeeping applications designed for the construction industry that track hours worked and meal and break times effectively.

These applications also allow crew members to perform inspections and record the cost codes they worked on that day.

Comprehensive time card system: Our advanced time card system accurately records all required employee data, with down-to-the-minute clock-in times and employee signature options.

Efficient crew management: Align hours worked to scheduled hours and distribute them accurately across cost codes to reduce errors and discrepancies.

Detailed auditing and reporting: Tools like the Employee Detail Report inside HeavyJob provide a comprehensive audit trail of all employee hours, clearly documenting meal and rest breaks. The Time Card History report offers full transparency into any adjustments or changes made to the time card, further strengthening your defense against potential disputes.

BIO-BASED Trick Shot® Sustainable Products Asphalt SOLVENT AND CLEANER® is a high-performance product that dissolves bitumen, tar, oil, and tack from paving machinery, equipment, and tools. USDA Certified Biobased – Tested at 96% bio-based No Petroleum Distillates, Near Zero VOC’s (EPA 24) Safely Remove Asphalt from Skin – Non-irritating formula High Flash Point – Non-flammable in liquid form

Foodsafe (NSF-H1 Reg), Non-toxic (OECD 201, 202, 203), Biodegradable (OECD 301B, ASTM D5864), VGA/EAL CA Prop 65 Competitive Bulk Pricing Recyclable Containers

Customized attestation questions: HCSS lets your company include tailored questions for your employees in timecards when they are filled out. Employees can verify critical compliance details, such as confirming they took required breaks, verifying accurate hours worked, and reporting workplace injuries.

Secure, long-term record keeping: HCSS safeguards timekeeping data, ensuring that historical records are protected and accessible should future inquiries arise.

The evolving regulatory landscape in California, particularly after recent PAGA reforms, demands proactive compliance measures from employers. HCSS provides industry-specific tools designed to accurately track, manage, and audit employee hours so your company can confidently navigate California’s labor laws.

by Andrew Fowler, Senior Product Manager, HCSS

DESIGNED TO HONOR CONSTRUCTION PROFESSIONALS FOR THEIR ACCOMPLISHMENTS IN SHAPING THE INDUSTRY

Construction professionals - working in the heavy equipment, asphalt, pavement and reconstruction, concrete, and rental segments - can be nominated for any of the following categories: