The 8680 Asphalt Paver delivers high production capacity while maintaining a compact and maneuverable footprint meeting the needs of heavy commercial and main-line contractors alike.

210 hp (157 kW) Kubota Tier 4 Final Diesel Engine

Weight: 33,600 lbs. with LB5 Screed; 36,000 lbs. with LB7 Screed

Paving Widths Variable Up To 15’ 6”

High Speed Smooth Rubber Tracks

Actuator Driven Hood Lift to Aid in Maintenance

Bryce Harem and Central Paving in Ellensburg, WA, have made it their mission to do things differently and they’re seeing the results! Discover how cultural shifts are changing what it means to be an effective leader in the asphalt industry.

Digital innovation is revolutionizing the sweeping industry. GPS tools, telematics, and data-driven platforms are helping operators cut costs, reduce pollution, and improve compliance.

A contractor’s cautionary tale shows why planning, budgeting, and market evaluation should come before buying that next shiny new piece of equipment.

In

A new report shows 78% of contractors are already using or testing AI tools, signaling a major shift in how firms tackle labor shortages, rising competition and complex project demands.

Formoreinformationvisit

https://pavemg.com/5eyife2n

As OSHA advances its long-awaited heat safety standard, ARTBA has provided detailed feedback representing the transportation construction industry.

Formoreinformationvisit

https://pavemg.com/jktunvv8

Pavewise

Seed funding will accelerate go-to-market strategy for realtime project management platform.

Formoreinformationvisit

https://pavemg.com/luhz02vm

Vol. 39, No. 8, December 2025

ADVISORY BOARD

Agua Trucks Inc

Wickenburg, AZ, Scott Duscher

Asphalt Contractors Inc., Union Grove, WI Robert Kordus

Published and copyrighted 2025 by IRONMARKETS. All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopy, recording or any information storage or retrieval system, without written permission from the publisher.

Subscription policy: Individual subscriptions are available without charge in the U.S. only to pavement maintenance contractors, producers and government employees involved in paving or pavement maintenance; dealers, and distributors of pavement maintenance equipment or materials; and others with similar business activities. Complete the subscription form at www.forconstructionpros.com or use your company letterhead giving all the information requested. Publisher reserves the right to reject nonqualified subscribers. One year subscriptions for nonqualified individuals: $35.00 U.S.A., $60.00 Canada and Mexico, and $85.00 all other countries (payable in U.S. funds, drawn on U.S. bank). Single copies available (prepaid only) $10.00 each (U.S., Canada & Mexico), $15.00 each (International). Pavement Maintenance & Reconstruction (ISSN 1098-5875), is published eight times per year: January, February, March, April/May, June/July, August/September, October/ November, December by IRONMARKETS, 201 N. Main St. Ste 350, Fort Atkinson, WI 53538. Periodicals postage paid at Fort Atkinson, WI and additional entry offices.

POSTMASTER: Please send change of address to Pavement, 201 N. Main St. Ste. 350, Fort Atkinson, WI 53538. Printed in the USA.

PAVEMENT MAINTENANCE & RECONSTRUCTION is proudly supported by these associations:

Asphalt Restoration Technology Systems, Orlando, FL Connie Lorenz

Brahney Paving, Hillsborough, NJ Steven Brahney

Eosso Brothers Paving; Hazlet, NJ Tom Eosso

Maul Paving/Concrete/Sealcoating, PLainfield, IL

Parking Lot Maintenance, Lake St. Louis, MO

Petra Paving, Hampstead, NH

Pioneer Paving, Albuquerque, NM

Chris Maul

Todd Bruening

Chris Tammany

Don Rooney

Roberts Traffic, Hollywood, FL ....................................................................... Lisa Birchfield

Show Striping Inc. (SSI), Wisconsin Dells, WI ...................................... Amber Showalter

T&N Asphalt Services, Salt Lake City, UT ........................................................ Nick Howell

Young Sealcoating Inc, Lynchburg, VA Steve Young

The Paving Lady Mauro Comuzzi

JMP Excelsior Services Jim Panzenhagen

Sweeping Industry Veteran Gabe Vitale

Flat Nickel Management

Wis-Coat Asphalt Maintenance

Clear Choice Sealing

Jacketta Sweeping Services

Michael Nawa

Marvin Joles

Warren Johnson

Debbie Jacketta

Royal Pavement Solutions Kenneth Roy III

ASSOCIATION REPRESENTATIVES:

Pavement Coatings Technology Council Brian Riggs, Executive Director

While there’s been a lot of change during 2025, it’s an almost certainty that next year is going to be a challenge for our industry.

We are heading into the soon-to-be offseason for many in the industry, and when things kick back up again in the spring, it’s going to be a different place. There have been lots of signs during the second half of 2025 that the economy is weakening, and, according to some economists, those indicators which have been lagging are going to likely catch up with us.

Brandon Noel, Editor-In-Chief bNoel@iron.markets 234-600-8983

Now, I will be the first person to celebrate me being wrong if, in fact, I turn out to be wrong here. That would be great news! But there have been some other troubling things this year that could also start to make a noticeable difference in 2026 for those in the asphalt business. But there’s some good news!

While the IIJA expires next September, there’s a good chance that a new infrastructure bill can be passed before that happens. The Transportation and Infrastructure Committee have already been at work on the language and priorities of the bill since session began earlier this year.

All that being said, I’ve talked to a lot of large firms that are playing things safe for the time being, and I imagine that might continue to be the case until the new funding is set in stone by congress. The responses I’ve received from experts and other professionals within the asphalt industry are cautious at best, and, at worst, bleak in their outlook.

Exactly how different it will be and how far ranging won’t be known until we get into things, however, there seems to be a confluence of factors pointing towards at least some form of a downturn from the trajectory the industry has been on the last few years. Even the 2025 Top Contractor data back in June seemed to indicate the possibility of this direction.

It’s not fun being a huge downer. Nobody wants to say this or for this to happen. However, it feels like my responsibility to at least send up the signal-flare if I think I see some bad weather coming our way. And, sadly, I do believe there’s good reason to think some rougher seas lay ahead of us. However, this isn’t a cause for despair.

In previous times of economic uncertainty, the blacktop industry has continued to remain at an arguably healthy level. That doesn’t mean it won’t require some belt-tightening, and it will almost certainly require a change in approach to prospecting and sales. Clients are going to be stingier with their dollars, they’re going to be looking to stretch not only their budgets, but, also, their current assets.

This could look like fewer resurfacing jobs, and more sealcoat opportunities. This could look like more pothole patching rather than milling up a whole parking lot. Be open, be creative, and look for ways to proactively bring these deals and savings to your customers. Pitch them on longevity, on pavement extensions, and show them that you’re in their corner.

We got this — See you on the road! ■

EDITORIAL

Editor-In-Chief Brandon Noel bnoel@iron.markets

Content Director, Marketing Services Jessica Lombardo jlombardo@iron.markets

Managing Editor Allyson Sherrier asherrier@iron.markets

AUDIENCE

Audience Development Director Angela Franks

PRODUCTION

Senior Production Manager Cindy Rusch crusch@iron.markets

Art Director April Van Etten

ADVERTISING/SALES

Brand Director Amy Schwandt aschwandt@iron.markets

Brand Manager Megan Perleberg mperleberg@iron.markets

Sales Representative Sean Dunphy sdunphy@iron.markets

Sales Representative ..................................................... Kris Flitcroft kflitcroft@iron.markets

IRONMARKETS

Chief Executive Officer Ron Spink

Chief Revenue Officer Amy Schwandt VP, Finance Greta Teter VP, Operations & IT Nick Raether VP, Demand Generation & Education Jim Bagan

Brand Director, Construction, OEM & IRONPROS Sean Dunphy Content Director Marina Mayer Director, Online & Marketing Services Bethany Chambers Director, Event Content & Programming Jess Lombardo

CIRCULATION & SUBSCRIPTIONS

201 N. Main St. Ste. 350, Fort Atkinson, WI 53538 afranks@iron.markets

LIST RENTAL

Sr. Account Manager Bart Piccirillo | Data Axle (518) 339 4511 | bart.piccirillo@infogroup.com

REPRINT SERVICES

Brand Manager Megan Perleberg mperleberg@iron.markets | (800) 538-5544

Published and copyrighted 2025 by IRONMARKETS. All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopy, recording, or any information storage or retrieval system, without written permission from the publisher.

@PAVEMENTMAGAZINE

@PAVEMENTMAGAZINE

@PAVEMENTMAGAZINE

@PAVEMENTMAINTENANCE

WWW.FORCONSTRUCTIONPROS.COM/PAVEMENT Published by IRONMARKETS

201 N. Main St. Ste 350, Fort Atkinson, WI 53538 (800) 538-5544 • IRON.MARKETS.COM

Crafco offers durability where other repair methods fail. Combine that with versatility, easy installation, and quick reopening to traffic. Mastic One® is the smart solution for pavement repairs that last. Learn more at crafco.com.

The U.S. Department of Labor has awarded more than $86 million in Industry-Driven Skills Training Fund grants to 14 states to support workforce development and strengthen domestic manufacturing and shipbuilding.

Administered by the department’s Employment and Training Administration, the grants will provide outcome-based reimbursements to employers that offer training for new and existing workers in high-demand and emerging industries. The funding is intended to advance national goals for innovation, domestic production and workforce readiness.

More than $20 million of the total investment will go toward revitalizing the shipbuilding industry, with a focus on training workers in welding, marine electrical systems, manufacturing and related trades.

“By investing more than $86 million in workforce development initiatives across the country, we are preparing American workers to fill the high-paying jobs being created in manufacturing, shipbuilding, energy and other key sectors,” said Secretary of Labor Lori Chavez-DeRemer.

Each state’s workforce agency will direct the funding toward industryspecific training programs.

The Labor Department announced the availability of funding in August and said additional grant rounds may be offered depending on future appropriations.

Effective Jan. 1, 2026, Todd Stucke will become president of Kubota North America and general manager of Agri Solutions Headquarters in Japan. In these roles, he will oversee Kubota’s technology and business growth initiatives across North America. Stucke succeeds Nobuyuki Ishii, who is retiring from the company.

Stucke, a former chairman of the Association of Equipment Manufacturers (AEM), will continue serving on AEM’s board of directors.

Brian Arnold has been appointed general manager of the North America Manufacturing Unit, reporting to Kubota Corporation. Arnold will continue as president of Kubota Manufacturing of America Corporation, based in Georgia, and will lead efforts to enhance the company’s manufacturing operations across the region.

Kubota North America Corporation announced several leadership changes following a recent Kubota Corporation Board of Directors meeting in Osaka, Japan.

Arnold, a 30-year Kubota veteran, was the first American to serve as president of Kubota Manufacturing of America since its founding in 1988.

In Japan, Shingo Hanada will succeed Yuichi Kitao as president and CEO of Kubota Corporation. Kitao will remain as chairman and representative director.

Hitachi Construction Machinery has announced that in April 2027 it will officially change its corporate name and brand to LANDCROS. This change will introduce updated equipment and parts branding, while maintaining the same manufacturing excellence and dealer support customers have always trusted. This brand transition represents the company’s next stage of accelerating innovation.

“Hitachi Construction Machinery started as a part of Hitachi Ltd. in 1950. In 1970, they incorporated as a corporation and has since built a strong legacy of earning customer trust and contributing to society with the Hitachi Brand.” Says Hidehiko Matsui, CEO and chairman of Hitachi Construction Machinery Americas.

Beginning in April 2027, the LANDCROS brand will debut with new machine decals and company logo. All other core aspects like company structure, equipment manufacturing, product offerings, and warranty policies will remain the same. Customers can trust that the dealers they have built strong relationships with will continue to support them. The industry leading engineering they depend on will also remain, only with new decal stickers.

LANDCROS is a symbolic word that represents the guiding ideals the company will follow as they look towards the future. The new brand name combines the word”LAND”, representing their respect for the company’s history and their vision for the future, with”Customer,” “Reliable,” “Open,” and”Solutions,” to express how they plan to provide innovative solutions to their customers.

Brandon Noel, Editor-in-Chief

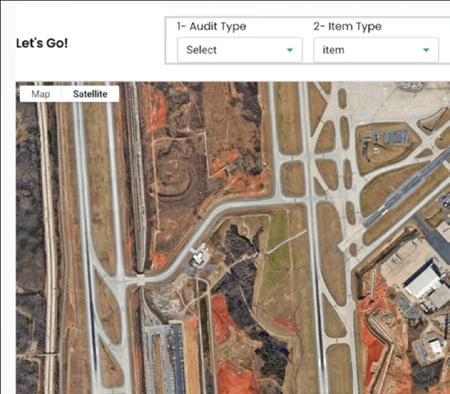

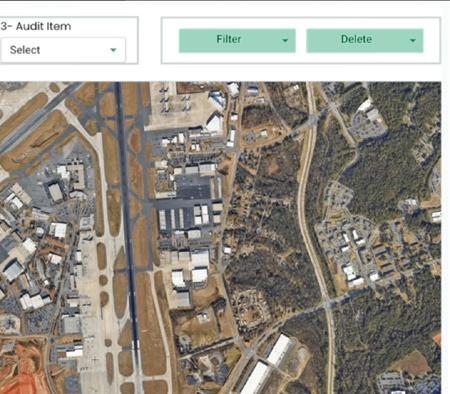

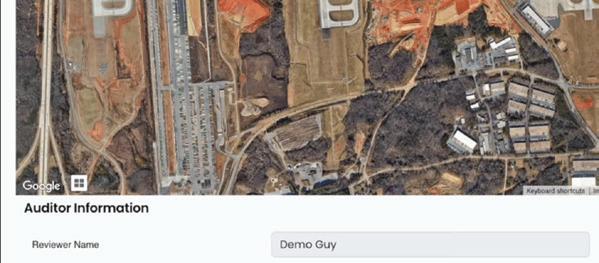

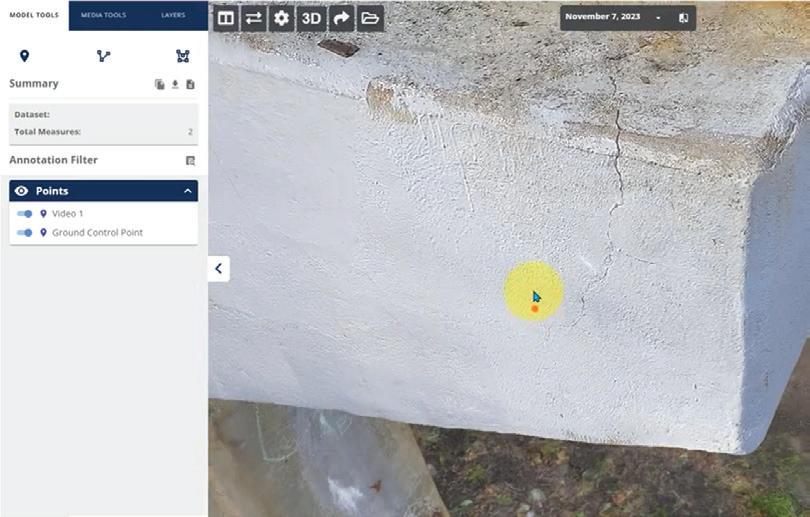

How a lifelong paving contractor turned frustration into innovation with a new field-driven asset management tool.

When Jason Ciavarro describes himself, he doesn’t lead with “founder” or “developer,” no, he prefers to start with asphalt.

“I’ve been in the business for almost forty years now. I sleep, eat, and drink asphalt and concrete. I’m just an asphalt nerd, born and raised on blacktop, and now [I’m] sitting in a damn office,” Ciavarro said with a laugh.

That hands-on start, and the decades of experiences that came with the traditional process pipeline of field work

to documentation, are what ultimately led Ciavarro to create SiteVision Pro, a cloud-based inspection and communication tool designed specifically for pavement contractors, property managers, and maintenance professionals. However, two decades before SiteVision Pro existed as an app, it lived in a spreadsheet.

“I created this app, probably on an Excel workbook, about 25 years ago,” Ciavarro said. “Engineers didn’t allow me to bid on projects… so I built this thing called a component inventory.”

That early “component inventory” offered something the industry didn’t yet have: asset condition visibility and tracking of pavement asset data. However, its big key was that Ciavarro wasn’t just cataloging data, he was sharing it with the potential clients. The concept ruffled feathers.

“I was democratizing the information and making it available to people,” he

explained. “I was giving it away, and I’m all about full transparency. If an association owns the property, they should own their own data.”

This was a foundational and guiding concept behind the eventual platform Ciavarro would go on to build.

As a contractor first, one of the reasons Ciavarro developed the software was to keep contractors and property managers from losing their records every time personnel changed or relationships shifted. The platform centralized jobsite data, including: photos, videos, maps, and notes. This meant that everyone involved, from estimator to superintendent to client, was working from the same record.

“It aligns your salespeople to your estimating and then to your ops team like the guys performing the work or to

your project managers,” Ciavarro said. “It can even be shared with subcontractors. [But] I want to put this app in a property manager’s hand.”

When a property manager uploads a video or photo from the field, it instantly appears on the contractor’s dashboard. From there, the pavement maintenance company contracted to maintain said property can be made instantly aware of any changes or repairs that are required on the site, as well as the severity and/or priority of said project. This brings everyone involved, all parties, as well as the data, under the same roof.

Unlike software designed for municipalities or engineers, SiteVision Pro was built to make sense to working contractors. Within the interface, users can drop pins, draw lines and areas directly on maps, and document site conditions with precise measurements.

“It’s all exact measurement tools,” Ciavarro demonstrated to me over a video call how it easy the interface was. Each annotation included space for photos, videos, and notes, while keeping two separate settings for what’s visible on the client-side from what stays internal to your team.

But all this isn’t just about data capture, it’s also about protecting the company. Ciavarro explained a situation where it was an active life-saver.

“I had a $300,000 job,” Ciavarro recalled. “The owner said, ‘You broke my fence. I want it replaced.’ I went back to my pre-con video and photos. The fence was broken before we touched it. Saved us ten grand.”

For contractors who’ve ever been blamed for damage they didn’t cause, or who’ve had to defend project quality months after completion, the documentation alone could justify having something like this.

“Having more documentation can save you hundreds of thousands of dollars in legal fees and insurance,” Ciavarro said.

Despite obvious advantages, getting buy-in hasn’t been easy, but that’s not exclusive to just his experiences it’s something OEMs, manufacturers, and other software companies have all experienced, as well. The blacktop industry is notoriously slow to change, and, perhaps most notably, the industry is deeply fragmented. Asphalt contractors are not a monolithic bunch, meaning no two companies look, act, or function fully the same way.

This industry fragmentation is what can make it look like change is slow to come, but it’s sometimes just a reflection of how products can be incredibly user-specific. No single platform could meet everyone’s needs universally, but Ciavarro wants to try and make something that, at the very least, works for most people out there doing the work he’s known so well.

“The hurdle is you’ve got a bunch of guys like me at fifty-five years old that are successful with their business,” Ciavarro admitted. “At the end of the year, I’ve got money in my account, so why do I need to change?”

SiteVision Pro is now two years into field testing, with about 2,000 completed audits and roughly 30 active users providing real-world feedback. For Ciavarro, it is as much an educational platform as a piece of software. Inside

the app, users can access an educational library.

“[We’ve] made ninety-four videos— little things to help people become better site assessors,” he said. “I want to educate people. I don’t want to just sell an app.”

Those short clips cover everything from proper slope checks on sports courts to managing drainage or reading asphalt joints. Many are bilingual.

“You need to be able to communicate to your Spanish project managers how to use this,” Ciavarro said.

What separates SiteVision Pro from other asset-management platforms is its origin story. It didn’t come from a venture-funded startup or a top-down engineering firm. It came from a contractor with a shovel, a spreadsheet, and a desire to solve his own daily headaches.

“I was two men in a truck with a five hundred dollar loan from my father,” Ciavarro said. “I constantly look at, how do I make a contractor’s life easier? How do I buy them back time? How do I make them differentiate?”

In an era where technology often feels imposed on the trades rather than built for them, SiteVision Pro stands out as something rare: a tool forged in the field, by someone who still thinks like a contractor. ■

By Brandon Noel, Editor-in-Chief

The year’s new and improved pavement maintenance tools to help contractor’s do their best work.

Bergkamp Inc

With the SP5E Pothole Patcher from Bergkamp, each repair takes just a few minutes, where traditional hot-mix patchers require much more time to complete a patch.

• Utilizing Bergkamp’s exclusive SPECS, units are equipped with a joystick and touchscreen display that provide full operator control

• The SP5E is truck-mounted, operated safely from inside the cab by just one operator -- freeing up the crew to work on other tasks

• Asphalt repairs are handled from the front of the machine; traffic stays safely behind the patcher

• SPECS monitors the front boom position, to help keep it in the safe operating zone

• An automatic latching system allows the operator to secure the boom for safe travel without leaving the cab

• Lights, arrow boards, and camera options (basic or 360-degree) provide additional safety measures

The updated Multi-Tank Trailer (MTT) fuel and service platform now allows users to legally haul up to 920 gal. of diesel without a CDL or HAZMAT endorsement (Title 49 (CFR49).

• Electric manifold automatically shuts off tank valves after fueling

• Redesigned front end enables customization and quality improvements such as an improved door hinge design and stronger DEF container shelf

• Re-engineered tank design for increased strength and durability

An underground utility detection system designed to identify buried infrastructure with improved depth and clarity. Capable of detecting underground assets up to 60% deeper than traditional methods, the system aims to enhance safety and efficiency in subsurface mapping.

The DS4000 integrates Equalised Scrambling Technology (EsT), developed by IDS GeoRadar, which enhances the visibility of both shallow and deeply buried utilities. It also increases the chances of detecting smaller or more elusive items like fiber optic cables, which are often missed by older systems.

With urban environments growing increasingly dense, the need for accurate underground utility mapping is becoming more urgent. The DS4000 is intended to help reduce the risk of damaging critical infrastructure during excavation or construction.

FAE USA Inc.

The FAE RPM/SSL road planer attachment is designed for road surface preparation before adding a new layer of asphalt or concrete and excavation operations. Compatible with skid steers from 75 to 135 hp, the attachment can shred up to 10 in. deep at a width of 24 in. Self-leveling skids and tilt enables operation on uneven surfaces. The hydraulic drive system, as well as practical depth and cutting indicators, promote accuracy during use. This attachment also features a working pressure control gauge, anti-shock block valve with relief and anti-cavtation valves. The line is completed with teeth specifically designed for asphalt and concrete road surfaces.

This version of the PQI is fully equipped with a touch screen and a user friendly graphical user interface. The PQI 380+ uses Microsoft Windows 10 for smooth operation, easy software upgrades and enhanced user support. IOS, Android application for data transfer and cloud storage, instantly send measurement data from the gauge to the cloud with just a QR code scan.

• Non-Nuclear technology

• Asphalt density readings in 3 seconds

• 800 x 480 LCD with projected capacitive touchscreen with antiscratch surface

• IOS, Android application for data transfer and cloud storage to the TransTech Connect App

A solution for contractors for everyday challenges with both internal and external management.

PROcru provides:

• Customer relationship management system that tracked client the way you want or should

• Estimating/proposal building and could provide auto bidding

• Custom client insights for every proposal and job performed

• Scheduling system for increased production and client communication and confidence

• Provided phone app for labor time keeping and pushed production schedule to employees daily work load

• Provides you with the direct costing tools using technology interfaces, phones/tablets

Graco Inc.

Powered by a lithium battery and provides quiet, fume-free striping that is safe to use indoors while having the power and performance for outdoor jobs.

• Provides 10 times more charges, 36-lbs. light and 50% more runtime than previous battery

• Onboard 120V inverter/charger, simple plug-in charging

• SmartControl 2.5 which eliminates pressure fluctuation

• The FastFlush system cleans the pump 4X faster with only half the water

Raise your limits by taking advantage of modern technology to make employees more productive and finally be able to see your business in one place.Build a collection of estimate items with reusable components for faster proposal creation. Manage proposals & documents from anywhere on any device. Always backed up for peace of mind. Send professional proposals before even leaving the job site. Automatically organize your proposals and never lose track of a sale again. Improved visibility, status tracking, and simple organization. View proposal wins/losses, performance insights and analytics. Manage your workload, reduce downtime, forecast accurately and keep crews running efficiently.

Dynapac North America LLC

SEISMIC Asphalt technology automatically detects the natural resonance frequency of the asphalt, works together with it, and applies the correct amount of energy exactly when required. While conventional vibratory compactors deliver a rapid succession of impacts to the soil surface at a frequency that is either pre-set at a high or low amplitude or at a frequency that is adjusted manually, Dynapac SEISMIC Asphalt does it differently. The CC2200 VI weighs 7.6 tons and features a 59-in. drum, which is ideal for finish rolling on a variety of job sites. It includes a Tier 4 Final diesel engine with a high torque setting, efficient patented eccentric weights, and an ECO Mode for fuel efficiency.

The camera system supports visibility on the front right tire and front right corner of the sweeper in addition to the right-side broom. The new DualEyes will first be available on the Elgin RegenX – a mid-dump, regenerative air sweeper that is both reliable and durable. The DualEyes system is for use when there is no right-hand steering available, so operating the sweeper from the left-hand position is possible. DualEyes can be used in bright sunlight or in darkness without any lighting. A clear color picture is available at night due to the use of Starlight Technology. The camera integrates rear-view and pickup head cameras on RegenX sweepers utilizing a 10-in. dash-mounted screen, so operators only have one central location they need to look.

A patented unique latch and slide assembly comes in at only 16 lbs. and is the brightest, lightest and strongest on the market at the 300 Watt classification. It’s one push to rapidly deploy and another to de-latch the balloon has made it the simplest to set up. The top and bottom assemblies are anodized billet aluminum to ensure the strength. This design was made to withstand the rigors of heavy construction and outdoor elements. Easy to fabricate mounts for different applications with no set screws to fail. Portable Lighting Solutions is one of the only balloon light manufacturers to offer a screw in, consumer replaceable LED bulb.

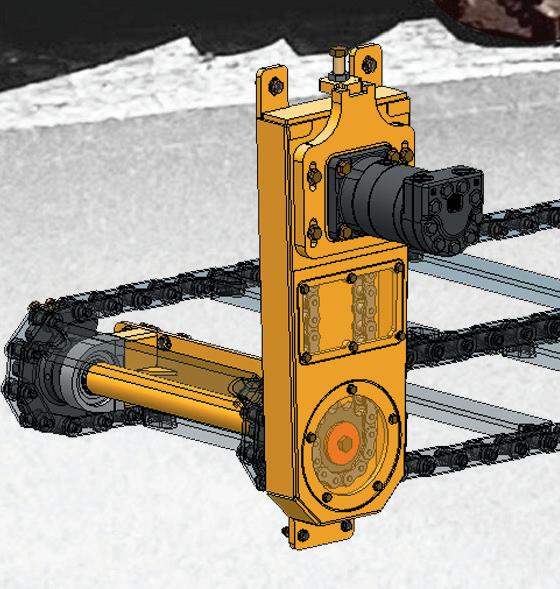

Etnyre

Hydraulically adjustable width ranging from 8 to 14 feet via a wireless remote control, the Broom Box ensures precise coverage tailored to your needs. Its quick-release broom heads facilitate easy replacement, while the high-lift attachment enables self-loading onto trailers, minimizing downtime. Equipped with a box that contains emulsion, it eliminates run-off against curbs or road edges, reducing mess and ensuring environmental compliance. Its hinged design automatically flexes on crowned roads, while the firm attachment to the distributor prevents drifting on sloped surfaces.

This product is designed for versatile applications like narrow paving projects, utility trenches, and paving asphalt between rail tracks. Its efficient design includes a universal skid steer attachment quick connection, ensuring easy setup and operation. The purposeplaced material minimizes wastage, eliminating the need for hand work, and it requires only a standard flow skid steer, making it accessible to a wide range of users.

• Wireless remote-control system.

• Easily transported to jobsites.

• Equipped with two built-in cameras for better monitoring.

• Hopper capacity of 88 ft3 allows for efficient material handling.

• The paver can take material from conventional-size trucks.

Caterpillar will introduce the nextgeneration Cat 140 LVR Motor Grader in early 2026, upgrading the long-running 140 model with enhanced cab design, expanded technology, and improved operator comfort. The 140 LVR continues the series’ reputation for versatility in roadbuilding, snow clearance, ditching, and municipal projects. Caterpillar reports more than 40,000 testing hours on machines worldwide. The machine maintains a favorable power-to-weight ratio and fuel efficiency while offering simplified maintenance through centralized access checkpoints. Expanded technology options range from blade stability features to fully calibrated 3D systems.

E-Z Grader

Introducing the new E-Z Grader skid-steer attachment which boasts a built-in roller compactor, retractable ripper shanks, and deployable wings for superior performance. The attachment is designed for seamless compatibility with all top skidsteer brands. The E-Z Grader is a multifaceted attachment designed to deliver precise grading across a wide range of projects with the ability to grade in both 2D and 3D. This tool is perfect for various applications, including warehouses, parking lots, and athletic fields.

BOMAG Americas Inc.

A light electric tandem roller for compaction and repair work in earthwork and asphalt construction.

• 5,732 lbs. | Width of 47.2 in.

• Lower noise emissions.

• For work on sites and in sensitive areas like schools and hospitals.

• The e-tandem roller’s articulated joint is easily accessible.

• Energy can be recovered when braking, mechanical energy is converted back into battery.

• Equipped with two electric motors: one for the travel system and steering and one for vibration.

Wirtgen Group, a John Deere Co.

the Wirtgen large milling machine W 210 XF is the ideal choice, no matter whether for milling work on freeways, state highways, airports, or other major construction projects. Its MILL ASSIST machine control system ensures absolute efficiency on every construction site. In automatic mode, it always ensures the most favorable working balance between performance and costs. It also allows the selection of three different working strategies that optimize the process with respect to cost, performance, or quality. The combination of the powerful engine and the DUAL SHIFT two-speed powershift transmission enables a large range of milling drum speeds. The lower range of milling drum speeds enables significant reductions of fuel consumption, pick wear, and noise.

X-Broom

The extremely rugged street sweepers are built to last. The American dream, creating and defining a product that supports a consumers wants and needs to their full extent. This is what Nescon has done over the past 9 years with the XBroom. Efficiency & productivity are the primary objectives in any industry, this couldn’t be more true with roadwork. Extreme efficiency& super productivity of the XBroom allows virtual single pass sweeping cleanup& considerably more sweeping time before dumping than other street sweepers on the market. More sweeping, less downtime& easy operating equate to larger profit margins.

HOPPER

• TYPE -HIGH LIFT/ RIGHT SIDE DUMP

• DUMP HEIGHT -VARIABLE FROM FRAME OF TRUCK TO 150” MAX

A new version of the mobile LiDAR scanner — the RD-M2 — is introduced. The scanner is part of the longstanding SmoothRide solution, which is designed to minimize road closures, shorten planning times and optimize processes when evaluating road surfaces while keeping crews safe. Topcon also introduces the new MC-Max Paving aftermarket solution to control screed height, width and steering for integrated pavers. Now expanded to a brand-generic aftermarket solution to control screed height on all major asphalt paver brands.

The POWERSTATE Brushless Motor hits harder and travel faster for maximum productivity without sacrificing compaction performance. The rammer provides no gas headaches with push button start and no engine to maintain, reducing downtime and allowing you to get jobs done faster. No gas engine means fewer wearable parts, less noise and vibration, and zero emissions mean a safer workplace indoors and in trenches. For greater control and easier maneuverability, the centralized user interface provides simple start/stop and fast/slow travel.

BR48 Asphalt Roller:

• 43.5 hp Yanmar@ 3000 RPM

• 47.2- inch steel asphalt drum

• Centrifugal force of 6,800 lbf

• Vibration frequency of 4,200 vpm

• Water tank capacity of 52.8 gallons

BR36 Asphalt Roller:

• 20.8 hp Honda GX630@3600 RPM

• 35.5- inch steel asphalt drum

• Centrifugal force of 3,825 lbf

• Vibration frequency of 4,000 vpm

• Water tank capacity of 31.7 gallons

SR48 Soil Roller:

• 47 hp Yanmar@ 3000 RPM

• 47.2- inch steel asphalt drum

• Maximum centrifugal force of 19,109 lbf

• Vibration frequency of 2,460 vpm

• Optional dozer blade

• Optional padfoot drum shell

BASIC Equipment

Our Model 240V features a Pressurized Water System, 3000 VPM Vibrating System, up to 7 mph forward and reverse and a 24.8HP T4F water-cooled 4 cylinder Kubota diesel engine. What makes this roller so special is that it doesn’t require a lowboy or trailer to transport it. It can be towed behind a truck all by itself.

• Pressurized water system

• 3600 VPM Vibrating system

• Up to 7 mph forward and reverse

• 24.8 hp T4F water-cooled 4 cylinder Kubota diesel engine

• Folding ROPS

Wacker Neuson’s RTD-SC4 Trench Roller was designed to serve the needs of the rental industry and contractors. This new model meets several critical goals: superior durability and serviceability, minimal maintenance, a best-in-class operator experience, and productivity with safety at the forefront. When Wacker introduced the first articulated trench roller over 30 years ago, it took the industry by storm. The increased stability and compaction performance over rigid-framed trench rollers quickly launched the roller into the market leader position.

Over the years, Wacker Neuson has built on this platform, incorporating features like dual width drums, COMPATEC compaction control, improved drive and remote control systems. Inspired by proven designs of articulated agricultural tractors, the asymmetric design of the RTD-SC4 significantly reduces the number of parts, hoses and connections by more than 30%. This simplified hose routing improves serviceability. This translates into lower downtime and total cost of ownership. The new model also features a 1,000-hour service interval on the transmission and exciter system. Additionally, drum width can be adjusted from 23.6 to 32 inches, to fit the application/trench. Powered by the proven 19.8 hp Kohler KDW1003 series diesel engine, the RTD-SC4 will run within its optimized powerband for improved fuel efficiency and noise reduction. The design of the electrical system on the RTD-SC4 allows for functionality of Wacker Neuson’s optional COMPATEC compaction controls, as well as EquipCare telematics that deliver pinpoint location and a host of performance and maintenance data.

Astec Industries Inc.

Astec surprised the industry with a late season drop of a brand new, redesigned, reengineered super screed. Created with contractor feedback, the EZR3 is engineered for balance, both in design and operation. Its rear-mount configuration enhances tractor stability and reduces the need for constant adjustments, keeping paving operations smooth and consistent across wider widths. The company touts it as a”new standard” in paving performance.

With advanced hydraulics and a strong loader arm, it delivers excellent lift capacity and breakout force. The 74-horsepower JCB EcoMAX engine provides high torque at low rpm, maximizing fuel savings without compromising performance. The six-speed AutoSHIFT transmission ensures smooth and efficient operation, reducing operator fatigue and increasing productivity. Updates across the line include four-wheel drive and an automatic torque lock, improving traction and reducing fuel consumption when roading. High-flow hydraulics system allows operators to run powered attachments efficiently, expanding its versatility across different applications.

Steel Diverter to control direction

Steel Diverter to control direction of material flow

pugmill

12

Brandon Noel, Editor-in-Chief

Discover how cultural shifts are changing what it means to be an effective leader in the asphalt industry.

For decades, much of the construction trades, and especially the asphalt industry, have been built on a specific type of hierarchy. The boss gives orders, the field gets it done, and the office handles the paperwork.

These business leadership structures familiar to most people today, were largely built and reinforced during the post-war era by those who’d served under similar structures. When they returned home, they brought those

structures and leadership styles back with them. For a long time they worked.

But talk to the next generation of leaders, and you start to hear something different.

Bryce Harem, general manager at Central Paving in Ellensburg, Washington, represents that change. I met with him outside of his home, surrounded by open pasture and the soft hum of a valley town, Harem reflected on how his views on leadership and company culture have evolved over time, and how that shift has reshaped both his team and his outlook.

“This is the spot,” he said, looking across a vast field of quiet farmland. “This is what I want, and [some version of this] is what we all need. Coming out here, it’s perfect.”

For someone who spends his days managing complex municipal projects, negotiating contracts, and coordinating field operations, the ability to disconnect and recharge matters.

“I like space,” he said. “We moved out here for space and slow, and now the asphalt industry is anything but slow. But I come out here and I get to be slow.”

Harem’s perspective on leadership is grounded in experience across both sides of the construction divide: office and field, white collar and blue collar. He’s quick to acknowledge the tension that sometimes exists between the two worlds—and the need to bridge it.

“There’s definitely, not just in the asphalt industry, but in construction

as a whole, a divide between the hard working, work-with-your-hands, dirtyhands, clean-money guy and what they consider white collar, which is me,” he said. “To a lot of people, I’m considered white collar because I went to college and because I didn’t come through the ranks of the ditch and the shovel.”

But he said something that kind of made something click in my mind.

“Everybody has a role in the blue collar industry,” he said. There’s a certain clarity to that I understand, as a former steel worker myself, but when he said it our conversation came into full view. On the blacktop, everyone knows the job and their purpose in getting that job done.

That’s an idea many asphalt contractors can get behind, it makes sense and the next generation of leaders are starting to full embrace it and other newer ideas as they step into management roles. The best teams today understand that operational success depends on mutual respect and shared purpose, not just titles or degrees.

Like many in his generation, Harem admits he once equated leadership with authority. “For more than a decade, I chased the title. I wanted to be the boss,” he said. “I was the young project manager and estimator for various companies, always youngest, and you didn’t get to be included in anything.”

That drive paid off when he joined Central Paving. “Within two years, I was offered the GM position,” he said. But the first year didn’t go as planned. “The problem is I failed terribly. The great thing about Central Paving is that everybody on the team will say we failed, because we did. But I put a lot of it on myself, and a big part of it was I was focused on me, on my position, where I wanted to be.”

He traced that early misstep back to how project managers were often trained. “As a PM, I was taught that

I was the boss, which is entirely incorrect,” he said. “I wasn’t the boss. You’re a role player.”

That realization changed everything about how he manages today. “My job in the field is to make sure all the lights are green.”

That clarity of purpose had ripple effects far beyond the office. It’s changed how Harem thinks about trust, both within the company and with clients. He regularly reminds his team that sales don’t stop once the contract is signed. The salesman or saleswoman, the account manager, they will sell opportunity one. What goes down in the field, sells opportunity two.

In other words, every paving crew member is part of the sales team. The way they conduct themselves on a jobsite, the way they talk to city officials, residents, or property managers, can define the company’s reputation and impact future opportunities.

“There’s people who will say that in the private side, commercial, residential, you don’t need to be low bid,” Harem explained. “And it’s very true. You build off relationships. You don’t necessarily have to be low bid if you take care of the customer.”

Even in the public or municipal market, he said, relationships matter. “It’s competitive. They don’t have to take low bid, but most commonly do, unless you’re a sub they know is going to show up, be dependable, and be the one they can count on to take care of their headache. And if you can solve their problems, oftentimes you don’t have to be the low bid.”

Perspective is a recurring theme in Harem’s story. It shows up in how he balances his family life, in how he sees the relationship between management and labor, and in how he defines success.

“The only reason I consider myself

slightly successful, is because of the perspective change,” he said. “You know, the office member who gets the entitlement that they are better than somebody in the field is asking for it.”

That humility came from seeing failure, not as defeat, but as information.

“I had to learn that leadership isn’t about being the smartest guy in the room, it’s about creating the space for everyone else to succeed,” Harem said.

In an industry where equipment costs, bid margins, and supply prices dominate most business conversations, culture might sound soft. But for Harem, culture is Central Paving’s competitive edge.

“It’s about how we treat each other, how we handle mistakes, and how we grow together,” he said. “We play a critical role in the office, but the field those guys are the heartbeat. If you lose that connection, you lose the company.”

That mindset is contagious. It shapes hiring decisions, retention, and the daily atmosphere on the job. Younger employees entering the workforce often prioritize work-life balance, respect, and a sense of purpose over just pay. Leaders who can provide that will find

themselves with a more engaged, loyal, and productive workforce.

Ellensburg itself has a way of reinforcing these lessons. It’s a place where the horizon is wide, the air is clear, and priorities feel simpler. Growth is coming. There are new developments, more people moving from the coast, but for Harem, that mix of expansion and

tradition mirrors the balance he tries to strike at work.

“You will have people that say this town is going to hell, only because it’s growing,” he said. “But if this is hell, then sign me up.”

That balance between ambition and contentment, growth and gratitude is perhaps the clearest reflection of

where modern leadership in the asphalt industry is heading.

A few lessons stood out to me from Bryce’s story that I think could be useful to other contractor’s in his shoes:

• Leadership is service, not status. Managers exist to clear the road for their teams, not to direct traffic from the sidelines.

• Culture compounds. A healthy workplace multiplies productivity, safety, and retention. A toxic one drains all three.

• Perspective changes everything. Failure, when viewed correctly, is feedback. It builds resilience and empathy.

• Trust is the new bid advantage. In a world where every penny counts, relationships still win the job. ■

There are more benefits in using a drone than getting a bird’s eye view - let’s talk about it.

hen first introduced, drones or unmanned aerial vehicles (UAVs) were mostly used for capturing photos and video. Today, they have become increasingly popular for everything from surveillance and disaster management to crop monitoring and building inspections.

They can also provide valuable insights for concrete and asphalt applications for commercial and residential jobsites, road work and bridge construction — and improve efficiency.

Drones offer contractors the advantage of cost and time savings compared to manually performing duties involved with concrete and asphalt jobs, such as data capture for prepping and pouring or laying, along with monitoring progress. They can also provide a competitive advantage when it comes to bidding on projects since contractors can complete work faster with the assistance of drones. Manually collecting data could take days to complete, while it can be done in hours with a drone. This technology is also more accurate, since it eliminates human error associated with capturing data, interpreting it and writing field reports.

For contractors new to drones or those who may be reluctant to purchase one, rental solutions providers can assist. Rental allows contractors to try out the latest technology through a business operating expense as

opposed to a capital investment. It also places the responsibility of service and maintenance, along with drone registration and compliance, on the rental provider. The rental provider can assist in training concrete and asphalt contractors on proper and safe drone usage and provide guidance and training resources to complete FAA Part 107 Certification Exam. This certification verifies that the contractor understands basic flight operations and has a clear understanding of airspace regulations and emergency procedures.

For concrete and asphalt applications, drones provide real-time data throughout the process that can also be shared with other stakeholders on the project. Drones equipped for LiDAR (or Light Detection and Ranging) or photogrammetry

can accurately collect raw data related to ground conditions during pre-work inspections and surveying, identifying various ground levels, elevations, vegetation and potential worksite hazards. Using data processing software, concrete and asphalt contractors can transform raw data into valuable and actionable tools such as orthomosaics, 3D models and elevation maps. Combined, this information provides the basis for accurate ground preparation. These insights help contractors identify and correct any mistakes prior to pouring the concrete or laying asphalt, ensuring high-quality results and saving them time and money by avoiding rework later. It also saves labor by minimizing the number of team members required on a jobsite. Once the correct groundwork has been verified, contractors can rely on

Since its introduction, the Weiler P385 has set the standard for commercial pavers. The P385C raises that standard.

Variable speed and reversible conveyors and augers and a 25% increase in tunnel height provide optimal material output.

Increase to 120 hp with the Cat® C3.6 Tier 4F/Stage V engine.

Modular conveyor drive and sealed chain case increase feeder system reliability and life.

Enhanced heat system performance with direct-drive hydraulic generator and elimination of GFCI breakers.

drones for pre-pour or pre-lay inspections. Drones can provide survey grade accuracy for measurement and can identify the correct placement of rebar, forms and sleeves prior to concrete pouring. Some data processing software has concrete-specific AI that can identify placement discrepancies prior to pours, providing contractors with detailed reports

that allow them to make informed decisions to rectify any problems.

Along with site work and monitoring, contractors can use drones for inventory management, tracking stockpiles to determine the materials available. This can be done with LiDAR or photogrammetry to gather the data, then the contractor can process that to create

Inspection footage from a 3D digital twin.

volumetrics reports to calculate square footage and cost and track changes over time. Consistent and accurate reporting reduces errors from manual estimations and leads to better financial reporting and material tracking.

While drones offer the advantage of time and cost savings, they also play a vital role in helping create a safe job site. They can provide remote access to potentially hazardous areas so that contractors and their teams can assess and monitor them virtually and minimize the need to work at heights.

Drones can also help maintain a secure jobsite by monitoring activity

MID-SIZE SRV-2 DELIVERS FULL-SIZE

The new StarJet™ SRV-2 offers superior pavement marking and rubber removal with small-job maneuverability. Its mid-size design features a frontmounted SpinJet® arm for efficient cleaning, excellent cab visibility, and a 40,000 psi NLB pump with HydraFlex™ closed loop hydrostatic drive — providing dry shut-off with less heat and noise. Typical run time is two hours, thanks to high-capacity water and debris tanks. Call us today to learn more!

during off-work hours. Some contractors have begun using drones that are housed and charged on a dock. With the proper waivers, they can remotely fly the drones or the drone can autonomously fly the jobsite. Some drones have unauthorized person detection capabilities that can identify individuals who should not be on the site, which minimizes or even eliminates the need for security personnel to monitor the site. Contractors must obtain a beyondvisual line of sight (BVLOS) waiver to execute these flights, which can be scheduled to fly preprogrammed flight patterns.

Drones are just one tool within the construction process; however, there is significant value that can be gained from them. Understanding and defining the outcomes that the contractors

want is the most important way to be successful with this technology. The data obtained from drones can help concrete and asphalt contractors refine project planning in ways that are beneficial to bidding and executing new jobs by applying learnings from previous ones. They have the data and reports to reference digitally to identify where mistakes have been made and to look at the best practices they implemented.

To ensure efficiency when using drones for current and future projects, it is imperative that communication between all parties involved is clear and consistent. The data that a drone captures can be used to inform decision making throughout the project — but only if it is visible to everyone. ■

A contractor shares how systemizing the business increased efficiency by more than 50%. These five essential tools can help any construction company do the same.

Systemizing our business increased efficiency by more than 50%.

And, that’s a real number. We had the data. We tracked our progress. We saw the results. Systemizing your business does not just mean implementing technology, but choosing the right technology is a big part.

TOP 5 TECH TOOLS TO STREAMLINE THE BACK OFFICE:

➊ CRM – Customer Relationship Management Tool. You need some form of a CRM system in your business. Whether this is built into your project management system, or a separate tool you use that integrates with your other systems, a CRM is critical for staying on top of your sales process, maintaining relationships with your customers, and keeping your sales team organized. Your CRM should manage customer

information, tasks, projects, and deal flow. Choose a system that integrates with your other tools and one that automates as much of your sales process as possible. Some CRMs have marketing built in, which can reduce your need for more tools

➋ Project Management System – In the construction industry, it’s critical to have a project management system to track your projects. A good project management system should provide you with estimating, job-costing, and scheduling tools. Find one that has a dashboard that gives you a high-level overview of your business at any given time. Choose a system that is easy for your team to use. One of the biggest challenges of project management systems is proper use. If your team isn’t using it, because it’s difficult to manage, then you’re not only going to lose the benefits of having a project management system, but you’ll likely have a big mess on your hands. Make sure there is an app so that the team in the field can have easy access. Require all team members use it.

➌ Accounting System – Many project management or construction management systems have built-in accounting tools. However, most are not built for that and can cause you more pain than relief. If you’ve been trying to make your business work with the accounting tool that was an afterthought built into your project management tool, you may want to consider implementing a standalone accounting system that integrates with your project management and CRM tools instead. With today’s automation tools, even without native integrations you can connect systems in order to get the best workflows for your business, while

also getting the most accurate and relevant financial data.

➍ Document Storage – While you may not think of this as a tech tool as much as a filing system, the way you store your electronic data is critical to your efficiency. Determine how and where you’re going to store electronic data so that your team can easily find what they need, when they need it. Determine which files get attached to CRM or project management records. Figure out how to consistently name your documents so that when you’re looking for a contract, you know how to find a contract. Create a folder structure that organizes your data and provides team members with an easy roadmap to know where to find things.

➎ Communication Suite – Email, chat, texting. Determine the primary communication system you’re going to use for your team. While you can use a combination of communication tools, be consistent in how you use each. Don’t send the weekly schedule out via email most weeks, but then switch it up to the chat channel in your project management system one week. Consistency is the key with communication. Set policies for retention and use. With every system you implement in your business, the most important step you need to take is to make sure you set it up correctly. Invest the time up front to strategically think about how you will use each system. Be methodical in your setup. Create integrations that streamline your operations. If you don’t take the time to set your systems up correctly in the beginning, you will be dealing with a big mess down the road! ■

Our combi-versions feature four rear rubber tires in place of a traditional drum. Each pair is independently powered by separate drive motors, significantly reducing the risk of surface damage —especially during tight turns on freshly laid asphalt. The rubber tires also help achieve a denser, smoother finish, meeting the demands of high-spec paving jobs.

BY NICK HOWELL

A few minutes considering “alternate routes” for on-the-job “turbulence” can pay off in productivity, profit and more workdays.

nyone who knows me or reads these pieces knows I’m an “AVGEEK” – an aviation enthusiast -- through and through. I enjoy the commercial aviation industry, airports, planes and of course air travel. I fly whenever I can – and I mean seriously, whenever I can. In fact, I’ve been known to connect through several cities rather than fly direct just so I can enjoy the experience! But what does

commercial aviation have to do with asphalt?

In aviation, having an alternate plan – a Plan B -- isn’t optional, it’s critical. Every flight plan includes an alternate airport in case weather or mechanical issues prevent a landing. Many aircraft systems even have triple redundancy : Plans A, B, and C.

So, here’s the question: What’s your alternate plan when things don’t go

as expected on the job? Because you know when you bid the job and when you get awarded the job that there’s a good chance the job isn’t going to go as planned (or as bid).

The first factor that can change your job that comes to mind: weather.

NR-201 is a one-part, selfleveling, moisture-curing, isocyanate free sealant based on a unique hybrid STPU (Silyl Terminated Polyurethane) designed for use as a traffic loop sealant and applications requiring jet fuel resistance.

300SL is a self-leveling onepart, ultra low modulus elastomer designed for sealing joints in roadways.

301NS

301NS is a non-sag, one-part, ultra low modulus product designed for sealing joints in concrete or asphalt.

Pecora 322FC is a two-part, coldapplied, self-leveling, fast-curing, ultra-low modulus 100% silicone material designed for the sealing of concrete pavement joints that experience thermal movement.

Like it or not, Mother Nature runs the asphalt business. Whether you pave, seal, or stripe, weather can shut you down in an instant. And even if you factor weather disruptions into your bid and schedule there’s a good chance the weather will create some job “turbulence.” Maybe it rains for a week instead of a day. Maybe an early-winter snow refuses to melt. Maybe you want to jump start your spring, but the pavement is just too damp and cold.

But it’s not just storms that wreck your schedule. What about showing up to find a dumpster or storage container still in the work zone? Or pulling up to find cars parked in an area you’re ready to seal (despite multiple notices)? How about the sprinkler system that kicked in overnight – or worse yet turns on after you’ve already applied a bunch of sealer? Or key team members calling in sick on a big job day?

When those things happen, what’s your Plan B?

Just like in aviation, the show must go on. The flight needs to land safely; the job needs to get done.

Staying on schedule is critical— especially late in the season when every workday counts. We figure we have

about 100 workable days in our season. Every one we can salvage counts.

Over the years, I’ve learned that spending just a few minutes developing alternate plans saves hours of frustration and thousands of dollars. Here are a few of our “alternate routes”:

When bad weather is likely, we don’t gamble—we plan…I should say we’ve already planned! If you wait until the problem arises you’ve already lost time (and potentially profit).

Even with all the apps and radar tools out there, forecasting weather is still part science, part art. I personally read the NOAA (National Oceanic and Atmospheric Administration) forecast discussions—the same technical reports meteorologists use to create their local forecasts. They’re issued twice daily and packed with the real data behind the TV forecast. We build “buffer days” into

the schedule so we can pivot quickly if the skies turn. It always amazes me how many contractors run blind, get caught by rain, and lose whole days. But if you think ahead – if you have a Plan B -rainy days don’t have to be wasted days.

Sure, you can’t do the work as scheduled and you have to rework your schedule and loop-in the client. But if planned for, rainy days can be productive days. Use them for:

• Equipment maintenance

• Yard cleanup

• Prep work or non-weather-critical tasks on other jobs

• Office paperwork

By utilizing those rainy downtime days we’re able to do work that otherwise would be bumped to after hours or after the season. And in the case of equipment maintenance, we might be preventing a breakdown in the field that could cost us even more time.

Cars still on the lot -- Here’s another classic: you arrive at a sealcoat job and there are cars parked where we’re supposed to sealcoat. Never happened to you, right?

Too many crews pack up and reschedule. We don’t.

We’re proactive long before the job starts. We’ve planned for this problem. Our pre-construction communication includes clear notices that cars left behind may be towed—and we confirm

the owner is on board. That’s our Plan B.

So, if we show up to 25 cars that weren’t moved, we call our towing company and we start on another section or do other work (if possible) while they’re being towed. No lost time. No wasted day. All because we had a Plan B.

Key people are no-shows -- Your key people are in those key positions because they are reliable and because you can count on them. But nobody’s perfect and things happen so occasionally one or more key people don’t make it in.

You can’t wait for it to happen to develop a Plan B. We prepare for this possibility by regularly training crew members for multiple positions so that, when needed, they can step up. It’s also a great way to see who’s next in line for a promotion. Interestingly, these days often go even better—everyone’s focused, motivated, and trying to shine.

It sounds simple—and it is—but most crews don’t do it. We’re all working so hard to get the sale, to get the job started and finished so we can get on to the next one and the next one. Admirable and necessary for sure, but the old saying holds true: “If you fail to plan, you are planning to fail.”

So, take a few extra minutes to think through your “alternate routes” on every project – in advance of the project. And this offseason take some time to examine your entire operation to see where you can plan for the “turbulence” that comes with running a contracting business. That small effort can translate into major gains—whether in productivity, profit, or simply not losing the day.

So, I’ll ask again—what’s your Plan B? ■

Some investments deliver lasting returns.

Nancy Terry, Executive Director

Amembership in the North American Power Sweeping Association (NAPSA) is one of them—your gateway to industry connections, professional credibility, and valuable opportunities that strengthen both your business and your bottom line.

Networking: Your Strongest Advantage. The sweeping industry runs on relationships. Through NAPSA, you join a nationwide community of professionals who share ideas, solve problems, and open doors.

• Connect year-round with peers in the Power Sweeping Pros Facebook group.

• Build relationships at Pave/X with exclusive networking events and member training.

• Enjoy free admission to Sweepers Night Out, a highlight of the year that blends fun, friendship, and professional connection. NAPSA’s network isn’t just about who you know—it’s about who helps you grow.

Certification: A Mark of Excellence. With NAPSA’s leadership in developing the ANSI standard for power sweeping, certification proves your commitment to best practices and professionalism. It strengthens client trust and provides a clear edge in the marketplace. Members receive significant tuition discounts, making advancement even more attainable.

Be Found, Get Hired. NAPSA connects property owners and municipalities with trusted, certified sweeping contractors. When prospects search for qualified professionals, members stand out in the results.

Marketing and Visibility

NAPSA membership helps you project

professionalism and credibility. Members have access to NAPSA logos and marketing materials, plus discounted digital services through Visual App for website design, SEO, and online marketing.

Exclusive Discounts. From Pave/X education savings (a $500+ value) or Sweeper Summit registration discounts to member-only supplier discounts on leading industry equipment.

Invest in your success. Joining NAPSA means joining a community of professionals committed to raising the standards of the power sweeping industry. ■

The North American Power Sweeping Association (NAPSA) is a nonprofit association made up of 200+ contract sweepers, service providers and sweeping equipment dealers, manufacturers and suppliers. NAPSA is dedicated to providing beneficial support to the membership and enhancing services to the sweeping industry. NAPSA is committed to promoting and educating the power sweeping community while enhancing the environment. For more information on NAPSA membership, please visit www.powersweeping.org or call (888) 757-0130.

Ranger Kidwell-Ross, Executive Director

Technology is transforming the sweeping industry in substantial ways, enhancing the efficiency, accountability, and environmental impact of both street and parking lot power sweeping operations. Advanced sweeper designs, digital tools, and datadriven management platforms are fundamentally changing how municipalities and contractors approach routine cleaning tasks, optimize resources, and document compliance with increasingly stringent regulatory requirements.

GPS and Telematics Tools. Modern sweepers are commonly equipped with GPS tracking and routing systems, allowing for real-time management of fleets and routes. Operators and managers can verify coverage, optimize driving paths to reduce fuel usage, prevent

missed areas or redundant passes, and document service for contract compliance. GPS-enabled logs aid in timekeeping and billing, decrease disputes over whether specific sites were cleaned, and can integrate with accounting and maintenance systems.

Smart Sensors and Data. Sensors, cameras, and advanced telematics may now be used to collect detailed information about sweeper performance and pavement conditions. These enable sweeping programs to dynamically adjust schedules based on debris accumulation, weather conditions, and operational delays due to parked vehicles or obstructions.

Equipment Innovations. Technological advancements in sweeper design are boosting cleaning efficiency, especially with the growth of regenerative air and vacuum sweepers for fine particle removal.

Software for Management. Dedicated software platforms now manage jobs, assets, and workflows for sweeping

contractors and public works departments. These systems handle scheduling, dispatch, record-keeping, invoicing, public notifications, citizen engagement, and even regulatory reporting, consolidating previously manual processes into efficient, auditable operations.

Overall, the sweeping industry’s adoption of modern technology is driving higher standards in cleanliness, accountability, and sustainability, benefitting municipalities, contractors, and communities alike. ■

WSA contributor Ranger Kidwell-Ross has been providing information to the power sweeping industry since 1988. He is editor of WorldSweeper.com, an information resource for power sweeping, as well as founder and executive director of the World Sweeping Association. For more information about WSA visit www.WorldSweepingPros.org or contact Kidwell-Ross at director@worldsweepingpros.org.

Cam Roberts, President of Laser Pavement Solutions, shares how innovation, relationships, and a “gut instinct” approach helped him grow a thriving pavement maintenance business.

One morning in 2018, Cam Roberts rolled up to a shopping mall parking lot with his new line striper, some paint, and a borrowed minivan – but he had no idea what he was doing, or where that day would lead him.

“I remember unloading the machine, standing by myself in an empty parking lot, and saying out loud, ‘this had better work,’” Roberts recalls. What began as an experiment — just to “try out the new machine for an hour or two” — turned into a six-hour job and a new calling.

At the time, Roberts had been working for a glass company, convinced that it was his long-term career path. But the need for another pavement service provider in his small town sparked an idea he couldn’t ignore. With a combination of curiosity and determination, he took a risk that would ultimately change his path completely.

What started with simple line striping has grown into a full-service pavement maintenance company. Today, Laser Pavement Solutions handles everything from crack sealing and seal coating to infrared repair and patching projects. In winter, the company runs a strong commercial snow removal program, ensuring that customers’ properties remain

safe and functional year-round. Roberts says the company’s growth stems from an intentional focus on quality and long-term value. “We do anything that maximizes the value or aesthetics of our customers’ pavement,” he explains. “It’s about being proactive and helping them protect their investment.”

That proactive mindset isn’t just applied to customers — it’s built into the company’s internal culture as well.

The Secret Sauce: Relationships and Alignment

When asked what sets Laser Pavement Solutions apart, Roberts’ answer comes down to people. “The secret sauce of our company has always been a proactive, relationship-based approach.”

Rather than trying to win every job, Roberts prioritizes working with clients who share the company’s passion for maximizing value, safety, and aesthetics. “We realize that not every customer might be a good fit for what we do,” he adds. “We’re interested in partnering with people who align with our values.”

That same philosophy applies to hiring. The company often brings in team members who are new to the industry but deeply aligned with its mission. Roberts believes it’s easier to teach technical skills than to teach commitment and culture. “We’ve been able to hire

people who buy into what we believe and produce great results, despite having no previous experience,” he says.

For Roberts, one of the proudest accomplishments of the past year has been watching his team unite around a shared purpose. “We’ve worked hard to make sure everyone understands what the company is trying to build, no matter their position,” he says.

By being transparent and vocal about the company’s goals — both internally and within the community — Laser Pavement Solutions has attracted exceptional talent. “It’s been amazing to see unique individuals and talents come together around a common vision,” Roberts notes.

That focus on vision has also shaped how the company addresses its biggest challenge: managing growth.

As Laser Pavement Solutions scaled, the company formalized systems and processes that once operated on instinct. “The biggest challenge we’ve faced has been internal structure to facilitate growth,” Roberts says.

To meet that challenge, Roberts and his leadership team leaned into process development and training. They’ve built training documents and videos directly into their project management software, giving technicians instant access to information while they’re in the field.

Laser Pavement Solutions runs off five core values, and at the top of those values is one word: innovation. Since day one, he’s looked for ways to use technology to improve quality, efficiency, and profitability.

“There are a lot of options out there, but we’ve been adamant about finding the right technologies that work together harmoniously and provide a true return on investment,” he says.

That mindset has led the company to adopt tools such as job-logging and computerized layout systems for line striping, which have improved accuracy and project margins. The result: better performance on jobs and more resources to reinvest back into the business.

After six years of growing Laser Pavement Solutions from the back of a van to a respected regional business, Roberts says his biggest personal takeaway has been the importance of mentorship and self-education.

“The single most important thing for me has been investing in the knowledge and wisdom from people who have already accomplished the things I’m trying to accomplish.”

Advice to his younger self? That’s something Roberts answers without hesitation: “Make the call faster.” While his company grew quickly, he often delayed decisions he knew were right — whether it involved a vendor, employee, or partner. “Sometimes you need to trust your gut, so the entire organization benefits from quicker decision-making.” ■

A cautionary tale before buying that next shiny new piece of equipment.

For most contractors, I would sound like “Captain Obvious” if I told you to plan before. Yet, this is exactly what I found with a client just a short time ago. Wanting to enter another specialty service for their customers, they had been discussing for a few years on whether they should purchase a special piece of equipment. On again, off again, it went for almost three years of talking about adding the new service. Then, last year, they suddenly found out that another contractor, who had ordered this same piece of equipment, was backing out of the purchase. The equipment vendor called and let the owner know that this piece of equipment was theirs to purchase.

When I arrived at their office recently, the owner escorted me about the yard. I had to stop to ask the owner about the “shiny” new piece of metal that looked like it hadn’t made its maiden voyage. The owner simply confessed that he had purchased the equipment a year earlier. When I asked him about how they were going to use the equipment he admitted, “Well, we don’t even have anyone who can run the equipment right now, and we don’t have the crew to support the effort.”

This was a very good contractor who was growing, performed quality and profitable work, and wanted some help. So how did a contractor, who is experiencing success, fall for

the shiny new piece of equipment just waiting to be purchased?

Let’s look at a safe, and proven, strategy when purchasing equipment, especially equipment that may not be simply replacement equipment, but equipment that will allow you to be better equipped to enter a new service for customers.

• When you are considering a new service to add, always determine if there is a need for the service. For example, if you are looking at adding curb and gutter work, involving concrete, and your market area is overrun with contractors who perform curb and gutter, you may weigh the benefits of subbing out to one of the existing contractors or by entering the same service yourself. Additionally, do you have any current workers with any concrete and curb and gutter experience?

• When a new service market is under consideration, always consider what equipment will be needed. Your workers need the appropriate equipment, and tools, to perform the work productively and safely. However, the needed equipment should be strictly screened as the cost to purchase or to lease has grown more expensive. Look for your best options that fits your budget and plans.

• Before purchasing any equipment, develop the strategy of how you are going to enter the market that you are purchasing the equipment to support. Are you going to reach out to your current client base and update them on the new service you are considering? Go back to those customers who have encouraged you to enter this new service and confirm, “Are

you going to give me the work?” Develop a rough estimate of what the potential revenue might be for first few years of work.

• Consider who is going to operate the new piece of equipment as well as the support crew. Do you have those individuals today? If not, are you committed to hire the needed expertise and help? Do you have existing workers who you can move into this new service without harming the existing crew they may be leaving? Tough questions such as these can give you more confidence about entering a new service division.

• Finally, have you considered a budget to open the new service effort. Most contractors are getting better at creating a yearly budget for operations and cash flow purposes but creating a budget for the new service effort could be very helpful. You want to keep your eyes on the costs, especially the early months of the new service, to monitor how we are actually doing.

I love seeing contractors who test their boundaries, including that of expanding their company to include other services, BUT, only after a good dive into the specifics of service needs, costs, resources, including equipment, and the clients who will purchase such services.

There is absolutely nothing wrong with acquiring new equipment, but purchasing any new equipment just because it is suddenly available is usually not a wise decision. Just be sure that what you buy has been thoroughly vetted and you have a plan on execution. ■

Featuring a robust educational program that is unlike any other learning experience in the market. The educational program will feature 60+ hours of education covering business management, paving, sealcoating, preservation, sweeping, striping and more.

Over the three-day event, there will be an incredible amount of opportunities for nextlevel networking that will create and strengthen the relationships that are vital to the success of business owners working to grow.