At Gencor®, we’ve led the industry with the most fuel-efficient, environmentally clean and lowest-maintenance design available to the hot mix industry. Gencor Industries remains focused on proactively serving and satisfying its customers from all aspects.

Through improved cost-effectiveness, and quality of its products and services, Gencor’s personnel are dedicated to the principle of providing the highest quality to the industry to maintain a sustainable competitive advantage for Gencor®

Your Trusted Choice! INDUSTRIES INC.

Call 407-290-6000 or visit www.gencor.com

The main objective of WSNs is to stay ahead of time-consuming and costly repairs through effective forecasting.

McMillen Corp. squeezes more value from its $6 million fleet leveraging insights from Tenna and Viewpoint Spectrum to support construction equipment life-cycles.

PO Box 3605, Northbrook, Illinois 600653605. Printed in the U.S.A. SUBSCRIPTION POLICY: Individual subscriptions are available without charge only in the USA. The Publisher reserves the right to reject nonqualifying subscribers. One-year subscription to nonqualifying individuals: U.S. $45.00, Canada & Mexico $65.00, and $95.00 all other countries (payable in U.S. funds, drawn on U.S. bank). Single copies available (prepaid only) $10.00 each (U.S., Canada & Mexico), $15.00 each (International).

The partnership between Robotic Maintenance Vehicles and SealMaster produced one of the most innovative new technologies in the world of road maintenance. It’s potential has only scratched the surface!

The state of Florida challenged a 30 year rule kept by the EPA that disallows phosphogypsum, a radioactive byproduct of the fertilizer industry, as a material for road pavement mixes.

Read more at: https://asph. link/6anaaq

Bill Klehm, CEO of e-mobility company “ebliss”, talks about the realities driving changes in the market, this history of consumer demand and why it’s better to be forward thinking.

Read more at: https://asph. link/5r6unq

Conventional dark pavements contribute to urban heat islands as they absorb 80–95% of sunlight and warm the local air. Cool pavements are made with different materials to increase albedo, thereby reducing heat transfer to the surface.

Read more at: https://asph. link/cgm5lk

A new report released by TRIP, a national transportation research non-profit, focused on traffic conditions and their impacts on the Maryland cities of Baltimore and the surrounding D.C. area, revealed an unexpected connection to labor shortfalls.

Read more at: https://asph.link/ r5j39d

As a decades-long leader for asphalt plant innovation, Astec has introduced numerous products contributing to sustainability. From the Double Barrel® dryer/mixer introduced in 1988 to the debut of the high RAP Double Barrel XHR in 2016. In addition to these industry-changing products, Astec also leads in sustainability with our warm mix system, the V-PAC stack temperature control system, low emission burners, and blue smoke systems. Astec is well-equipped to carry our culture of innovation into the future. Our dedication to sustainability includes new product development teams and an on-staff product manager for sustainability.

Reach out to learn more about how we can help you meet your asphalt plant sustainability goals.

Sustainable Innovation

Sustainable Innovation

Brandon Noel, Editor bNoel@ACBusinessMedia.com

234-600-8983

The challenging thing about the technology sector is no one can predict what new advancement, tool, or invention will truly have staying power. Classically, it doesn't really have a lot to do with what is "best," as everyone is familiar with the 1980s format wars between VHS and BetaMax cassettes. That's only one example, from one industry, of how the higher quality technology didn't win the market. That's because it depends on so many other market factors, and the most difficult market factor is the least predictable: consumers.

Literally, billions of dollars are spent on marketing in order to grab the attention and sway the purchasing dollars of consumers. Despite all of that, it still takes time to see what will last. At CONEXPO thousands of new products were launched. In last month's issue of AC we even highlighted our annual Top 30! There's no shortage of new bells and whistles from each and every company, but, unlike the consumer electronics industry, there is one factor that they can control: usefulness.

Simple as it may sound, this takes a lot of effort and research, because what might seem useful in the lab, doesn't always translate to the "real" world application of on the job use by contractors, foremen, and operators. That's the key, though, it ultimately has to be useful. For new hardware that can be determined in fairly straightforward ways.

Take the new excavator out on the job, and put it through its paces. Were the controls actually easier? Drive that new roller over the asphalt. Did it take fewer passes and achieve the same result? To put it in even simpler terms, if you have a nut and a bolt that needs loosened, a ratchet is better than a crescent, and a pneumatic ratchet is even better. Even then, however, there can still be times when the original tool comes in handy.

You don't see that sort of thing happen in the world of computers, and, even less so, in

terms of software. As new versions of operating systems, digital tools, or guidance systems are released, old ones are made obsolete. You don't see a lot of people still rocking MS-DOS (some readers may not even get this reference), and there's good reasons for this, but the world of software can be somewhat more impenetrable, or at the very least unapproachable, for users. When something works and the user is familiar with it, the idea of adopting something new can be intimidating or even downright unpleasant.

With this in mind, we decided to build a new industry-centered roundtable discussion that is all about technology, which will be available for a free download through our home website ForConstructionPros.com!

The all-new concept is called the "Big Tech Roundtable" and places several leading companies into conversation with each other. The goal is for readers to narrow down what needs there really are within your operations, logistics, and business structure, and then assist in partnering those needs with the best type of tech-product that addresses them. My hope is that you might be able to save yourself some time and headaches, by finding answers to the kinds of questions contractors ask, as well as, some questions about where things are going too. That way you can feel more confident in what direction you choose to take.

Alongside that, this month's issue is jammed packed with articles and information about cutting-edge technology. We even decided to talk to an artificial intelligence program, and get some of its advice on the work that asphalt contractors and business owners do. Then we sent its answers out to actual human experts to review and comment on just how well the AI did. I think it's safe to say that all our jobs are still safe...for now. See you on the road!

EDITORIAL

Editor Brandon Noel bnoel@acbusinessmedia.com

Contributing Editor Sarah Webb Swebb@acbusinessmedia.com

Managing Editor Gigi Wood gwood@acbusinessmedia.com

Senior Editor, Construction Technology, IRONPROS .................................. Charles Rathmann crathmann@acbusinessmedia.com

Senior Editor, Equipment & Workwear, IRONPROS Michael Cheng mcheng@acbusinessmedia.com

AUDIENCE

Audience Development Manager Angela Franks

PRODUCTION

Senior Production Manger Cindy Rusch crusch@acbusinessmedia.com

Art Director April Van Etten

ADVERTISING/SALES

Brand Director Amy Schwandt aschwandt@acbusinessmedia.com

Sales Representative Sean Dunphy sdunphy@acbusinessmedia.com

Sales Representative Kris Flitcroft kflitcroft@acbusinessmedia.com

Sales Representative Tadashi Soma tsoma@acbusinessmedia.com

AC BUSINESS MEDIA

Chief Executive Officer Ron Spink

Chief Financial Officer JoAnn Breuchel

Chief Revenue Officer Amy Schwandt

Brand Director, Supply Chain & Green Industry ..Jason DeSarle

Brand Director, Construction ..................................Sean Dunphy

VP, Audience Development ................................... Ronda Hughes

VP, Operations & IT Nick Raether

Content Director Marina Mayer

Director, Online & Marketing Services Bethany Chambers

Content Director, Marketing Services Jess Lombardo

Director, Demand Generation & Education Jim Bagan

CIRCULATION & SUBSCRIPTIONS

P.O. Box 3605, Northbrook, IL 60065-3605 (877) 201-3915 | Fax: (847)-291-4816 circ.pavement@omeda.com

LIST RENTAL

Sr. Account Manager Bart Piccirillo | Data Axle (518) 339 4511 | bart.piccirillo@infogroup.com

REPRINT SERVICES

Tadashi Soma (800) 538-5544 ext. 1267 | tsoma@ACBusinessMedia.com

Published and copyrighted 2022 by AC Business Media. All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopy, recording, or any information storage or retrieval system, without written permission from the publisher.

@ASPHALT-CONTRACTOR-MAGAZINE

Topcon Positioning Systems has introduced Digital Layout, a building construction software to help contractors adopt a digital layout workflow for their projects. Designed to help both first-time and experienced users of digital layout technology, this building construction field software works in combination with a 3D laser — the Topcon LN — or a Topcon GT robotic total station, providing a step-by-step guide to support routines and workflows. Additionally, the software can be used with the Point Manager plug-in for Autodesk Revit or AutoCAD to create point files in the office and transfer as-built data back to a contractor’s design software.

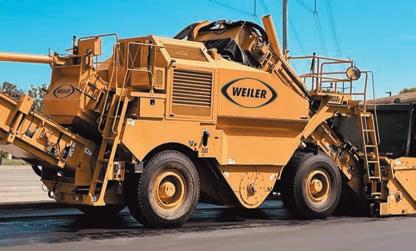

The new Caterpillar RM600 and RM800 reclaimer/ stabilizers compete at the high end of the reclaimer/ stabilizer size class with an all-new adjustable height design capable of cross-slope cutting. Their turbocharged Cat C18 engine gives the RM600 up to 17% more power than the RM500B. The RM800 delivers up to 42% more power than the RM500B and up to 23% more power than the RM600. These reclaimer/stabilizer models adopt rotor system components from Cat cold planers for cutting and mixing. Featuring a belt driven rotor drive system, the machine is capable of flush-cutting on the right side. The new System K rotor uses the same cold planer fastener-free, dual-taper toolholder and base block components to deliver material quality on a range of projects.

MB Crusher has released three new padding buckets for material processing on construction sites: MB-HDS307, MB-HDS312 and MB-HDS412. Two of the new padding buckets were designed for compact line equipment, while the third is for heavy equipment. All three were made to facilitate tasks that need to aerate packed soil – for example when a green area or a garden or flower bed need to be sorted. The attachments are also designed to reclaim demolition debris, stones or roots; or to screen backfill material to cover pipes or create the trench bedding. The three padding bucket models include:

• The MB-HDS307 padding bucket weighs 375 lbs. made for excavators from 5,600 lbs. to 11,200 lbs.

• The MB-HDS312 padding bucket weighs 1,587 lbs. made for excavators from 15,700 lbs. to 24,600 lbs.

• The MB-HDS412 padding bucket weighs 2,688 lbs. made for excavators from 22,400 lbs. to 31,400 lbs.

PlanRadar has announced updates to its suite of digital management tools with a new document management function. The Document Management feature has been specifically designed in response to calls from existing PlanRadar subscribers for a way to collate and manage data between in-field and back-office teams. It answers the call by offering a way to track, plan and document approvals and sign-offs for maintaining a tamperproof audit trail and clear picture of all sign-offs during a project. This new feature helps minimize rework while maintaining documentation for claims protection.

Hitachi has introduced the ZW-7 generation wheel loaders are equipped with large cabs with panoramic visibility to support operators on the jobsite. A standard, fully adjustable heated air ride seat incorporates a seat-mounted armrest with electrichydraulic controls and switches. The armrest and controls adjust 3.5 in. (8.9 cm) forward or reverse to accommodate operators of all sizes. ZW-7 generation wheel loaders will range in size from 3 cu. yd. to 5.5 cu. yd. (2.3 m3 to 3.8 m3). Most models offer either a standard-lift or high-lift configuration to meet the demands of a variety of applications.

WORLD TESTED. CONTRACTOR APPROVED: As the global leader in paving technology, we‘ve seen just about everything there is to see. In every climate, every condition, every twist, turn and terrain. And we put that world of experience in your hands, so you can experience exceptional performance and results at every phase of the paving process.

www.wirtgen.com

Telematics can help boost productivity on construction sites. According to Trimble, a company specializing in construction telematics, connected construction can help businesses increase productivity by 30 percent. So how exactly

does a business use data to increase productivity in their operations?

The first step in leveraging datadriven insights is collecting information from connected machines and tools on the jobsite. This can range from large excavators and material handling equipment to cordless hand tools and wearables. There are many types of data available on construction sites, capable of providing the feedback and information you need to minimize risks when making operational decisions.

Vehicles: Engine Overspeed

Monitoring an engine’s overspeed rates through remote diagnostics can help equipment managers predict when construction vehicles are due for maintenance, as well as gain a thorough

understanding of the challenges of the jobsite. Critical overspeed settings vary depending on the vehicle or motor type. Generally, engines hitting overspeed conditions are prone to reduced lifespan and engine failure, which influences maintenance, budget and rebuild strategies. Overspeed can also cause the engine to generate unwanted heat, resulting in higher operating temperatures associated with damage. Engine overspeed could serve as a warning for dangerous working conditions on the jobsite and should not be taken lightly.

“When we see engine overspeed, the first thing we take into account is the type of machine reporting out the data. Let’s use an articulated truck as an example. Is it happening on one part of the job? Is it happening all over the job? It is critical to know not just the frequency of triggering engine overspeed, but also where it is happening

Data points are like puzzle pieces that when connected properly, form a fresh perspective that can change the way you operate your fleet and your business.Monitoring fuel use is one of many ways data collection can be used on the jobsite. @Kzenon - adobe.stock.com

on the jobsite,” said Jason Threewitts, performance services manager at Carter Machinery.

With more than 90 years of experience in the construction sector, Cater Machinery sells and supports Caterpillar equipment for construction projects. The company has an expansive network consisting of more than 30 locations across the United States.

“This information will tell you a couple of things. If it is happening across the worksite, then it is probably an operator thing. If it is happening on one specific part of the job, it is probably less of an operator issue. Instead, it could be an indication that this part of the job is dangerous. Maybe I need to go out there and check the area to prevent an unsafe situation,” said Threewitts.

Equipment managers monitor overspeed on construction sites using remote diagnostics. Remote diagnostics refers to real-time monitoring of the vehicle’s status (in this case, overspeed). Upon detecting overspeed conditions, a fault code associated with the condition is triggered and a signal is transmitted to a management platform via a telematics device. These days, newer machines

come with factory equipped telematics devices that can be used to capture engine overspeed data. A timestamp, vehicle identification and location data may come with the fault code during transmission.

Engine overspeed data can be combined with other types of information on construction sites for in-depth jobsite analysis.

“It is never just one thing. When analyzing the full situation, how can I continue connecting the dots all the way through? So then, I would start looking for related things. Am I getting an overheat reading at the same time while getting an engine overspeed condition? Am I getting filter plugging issues at the same time? Do I have engine or transmission oil samples coming out of the machine that is telling me something else? When you start adding all of that up together, if you have correlating data sets based on either other fault codes or sources, like an oil sample, then you have some powerful information to determine if you have a machine issue, how rebuild life is being affected or if you need to talk to the operator about how they are using the machine,” explained Threewitts.

When it comes to safety, fall detection is a critical piece of data to monitor in worksites. Falls, slips and trips are very common in the construction sector.

“The construction industry accounted for 46.1% of all fatal falls, slips and trips in 2020,” according to a report from the U.S. Bureau of Labor Statistics. Falls are tracked using gyroscope and accelerometer sensors on smart watches, tablets or safety devices. Some devices can detect both a normal fall and a hard fall. These wearable devices generate loud auditory alerts and issue emergency notifications to specified contacts or project management platforms in the event of fall without a response, increasing the possibility for workers to receive immediate medical attention.

In addition to monitoring individual falls and slips, there are several benefits to tracking the rates at which they occur. Tracking the frequency of falls over a period of time can expose gaps in safety protocols. To make tracking fall detection rates effective, a timestamp and location data should be recorded with the emergency notification for a complete assessment. This information

Road Maintenance Products & Equipment with Proven Performance

ROAD SEALANTS

CRACKMASTER HOT-APPLIED CRACK SEALANTS

CRACK PRO

MELTER/APPLICATORS

CRACK PRO

MASTIC MACHINES

can help ensure proper safety standards and fall protection measures were implemented prior to the fall. Falls that occur frequently around a specific machine, such as telehandler or forklift, or a specific location on a jobsite, such as fueling stations or stairways, can prompt managers to update work safety practices.

“Employers must set up the work place to prevent employees from falling off of overhead platforms, elevated work stations or into holes in the floor and walls. The Occupational Safety and Health Administration (OSHA) requires that fall protection be provided at elevations of 4 feet in general industry workplaces, 5 feet in shipyards, 6 feet in the construction industry and 8 feet in longshoring operations. In addition, OSHA requires that fall protection be provided when working over dangerous

equipment and machinery, regardless of the fall distance,” according to an OSHA overview about fall protection.

Fuel keeps construction vehicles and machines, such as generators and tools, operating, yet is a major cost in the budget of construction projects, usually second to labor. Monitoring fuel consumption is traditionally carried out at the fuel pump. Newer machines come with features that carefully monitor fuel consumption or fuel burn automatically without needing to manually log the information.

“When you start thinking about fuel consumption, the first thing people think about is component life. This is because there is a point in time a maximum number of gallons of fuel goes

through a particular asset before you start thinking end of life. This would cause you to consider if it is time to rebuild the machine or take it down,” said Threewitts.

“I also like to think of it another way. When you start thinking about productivity, when you start thinking about how the machine is being leveraged, how much tonnage you’re moving or the load factor of that machine – that’s when fuel consumption can also be something you take a peek at and wonder how hard you are working your asset,” explained Threewitts.

Threewitts highlighted a situation wherein an operator was light-loading a wheel loader vehicle on the jobsite. The operator was not fully loading the vehicle’s bucket during each pass. As a result, the operator needed to make two to three additional passes. The operator’s thought process was that he was able to work faster without fully loading the loader bucket. Threewitts utilized fuel consumption data to show the customer that not fully loading the bucket of the wheel loader and making additional passes burned 20% more fuel, compared to maximizing the load capacity of the machine and reducing the number of passes.

“Once you start correlating fuel savings or fuel efficiency and you’re also still able to get the production and payload out of the fleet that you need; that is solid gold for a production or equipment manager. Being able to correlate those two data points together or three data points is huge,” said Threewitts.

Monitoring the location and utilization of hand tools and equipment on jobsites is an effective way to streamline productivity, inventory, security and asset management for businesses. This information seems straightforward, though in application there are many ways to use this data to support operations on construction sites. From a hardware perspective, this involves installing small identification tags on equipment and using wireless Bluetooth technology to transmit the data.

Cloud-based management platforms allow managers to view the status of equipment, as well as historical usage data, where they can assess how tools are used on the worksite.

"Our research shows that each jobsite loses on average one day per month of productivity due to workers searching for tools. In addition, the contractors end up spending up to 90 hours per month tracking tools: in essence, productivity

loss for both workers and contractors due to lack of an effective asset/tool management platform,” said Michael McGowan, region head and CEO of Hilti North America.

The types of data associated with tracking tool usage are numerous. Monitoring the location of equipment minimizes the risk of theft and improper use of tools by individuals without adequate

“The construction industry accounted for of all fatal falls.”

46.1%

training for the equipment. The ability to address theft and missing equipment directly by tracking location reduces the need to replace tools, preserving the company’s budget over the long term. Preventing equipment theft also helps reduce unforeseen delays and ensures jobs are completed in a timely manner.

Next, knowing when tools are idle or in use by operators can help with allocation, as well as keep billing accurate (for rental equipment). Tracking equipment uptime is also used in predictive analytics, enabling businesses to know when equipment is needing repair or replacement. Tools that do not meet expected uptime performance can prompt individuals to bring the equipment in for inspection or maintenance. This information can also help businesses stay ahead of costs related to replacing tools by anticipating the equipment’s end of life based on accrued uptime.

“Tracking small tools — whether in repair status, on location or with employees and the associated costs — is one of the most ineffective parts of accounting and internal controls in a construction company,” said Maria Lumke, CFO of Waterline Industries, a New Hampshire-based civil general contractor.

Equipment utilization data of specific tools enables managers to track the completion of various aspects of a project. For example, a business that uses three chipping hammers for light demolition work when removing concrete for site preparation averages 10 hours of tool utilization per project. With this information, managers would know that when the three chipping hammers are at eight hours of utilization, the demolition work is nearing completion and the next phase of the project is approaching. This ability to forecast various stages of a construction project allows managers to stay one step ahead of schedule.

For businesses juggling multiple projects, the combination of location and tool utilization data for equipment is useful. Tapping into such data would enable equipment managers to allocate tools efficiently across different ongoing projects, minimizing idle time while increasing productivity.

A major takeaway from these examples is that in most cases, it is not the amount of data collected from machines that determines one’s ability to raise productivity. After all, there is no shortage in the amount of data you can collect from sensors and loggers found on connected machines or vehicles. Instead, it is how you analyze the data you have at hand, combine or match data sets together and assemble information that allows you to form new strategies that can enhance operations or uncover new perspectives. Ensure that the data you are collecting on the jobsite is accurate and relevant to your business goals.

Having a deep understanding of the types of data your equipment generates is a vital part of analysis on construction sites. This requires businesses to tap into readily available information generated every day by machines and equipment.

For more information visit https://asph.link/9ywso6

Donnie & T.J. Reed, Madison Asphalt

Donnie & T.J. Reed, Madison Asphalt

With ADM’s standard components, the choice is yours. We can customize any plant we make to your specific production needs.

“ADM helped with everything we needed to get the right plant for our business. From zoning ordinance restrictions to environmental testing, ADM was with us every step of the way.”

The rise of “A.I.” to the level of household name means everyone has an opinion, but true expertise is harder to come by. What can these algorithms do for the likes of our industry?

Can they help you answer your asphalt or business questions?

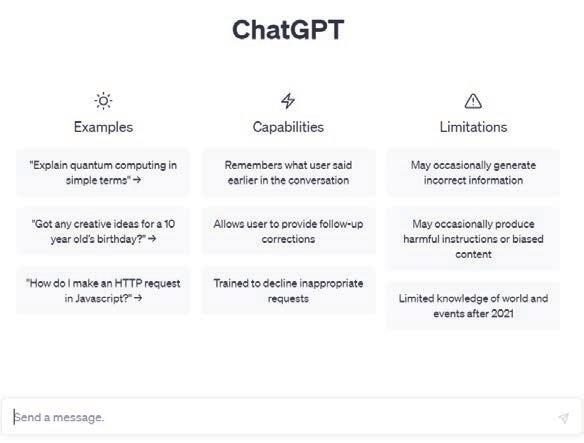

Since the June/July issue of the magazine is dedicated to technology, it would be a mistake to ignore the biggest technology story of the last year: ChatGPT. Every corner of our culture from entertainment, marketing, and product development, in far

ranging and different industries is now forced to reconcile with the rise of "artificial intelligence" (AI) as a platform. For contractors, it doesn't seem obvious at first how algorithms like ChatGPT, as well as the myriad of others springing up every day, could be useful. A chatbot AI can't produce asphalt or go out and pave a road...yet. However, could it potentially act as a tool for contractors? Could it be useful as a source of information? How accurate or reliable would it be if you asked it questions related to mix design or compaction? The best way to find the answers to these questions would be to conduct an experiment and report the results.

Firstly, it is vitally important to mention that there are several important caveats. The most important might come as a shock to you, when you consider how

most of the media, news, or other internet outlets discuss artificial intelligence. Calling these platforms AI is a lot like calling the popular two-wheeled motion scooters my daughters love "hoverboards" when they are firmly connected to the ground at all times, or another example might be that of “crypto currency.” The current AIs are similar in that the disparity between their names and what they actually are is vast and often misunderstood by the general public, and that misunderstanding is sometimes taken advantage of by others.

In a recent article on the subject for America Magazine, Jim McDermott wrote:

"These programs generate complete and seemingly original works in an instant. They can also communicate with a person in a way that resembles actual conversation. But in fact, for the time being anyway, these programs are

not sentient but just a very complex form of the kind of predictive text bot you find using Gmail or Google docs. ChatGPT-3, for instance, was trained on and is informed by 500 billion “tokens”—words or phrases culled from books, articles and the internet through which it interprets and responds to the prompts given to it.

In calling these programs ‘artificial intelligence’ we grant them a claim to authorship that is simply untrue. Each of those tokens used by programs like ChatGPT—the ‘language’ in their ‘large language model’—represents a tiny, tiny piece of material that someone else created. And those authors are not credited for it, paid for it or asked permission for its use. In a sense, these machine-learning bots are actually the most advanced form of a chop shop: They steal material from creators (that is, they use it without permission), cut that material into parts so small that no one can trace them and then repurpose them to form new products."

When we talk about ChatGPT and AI it should be noted that it isn't artificial intelligence in any way that you might expect. It isn't thinking, or even approximating thinking. It is "scraping". It uses complex algorithms to aggregate data and information already created by human knowledge and documentation. It can mimic, it can reproduce, and it can predict based on previously established data, but it doesn't invent something novel. Which, in a way, makes it ideal as a potential tool for this experiment. We aren't interested in its ability to generate something new, but whether or not it could be used as a way of conversationally accessing established fact.

Before diving into any of the questions or final analysis, it shuold be noted the platform is interesting enough to at least play around with yourself, should you be curious to do so. It is fascinating to interact with, even more so when you know it isn't actually intelligently thinking. However, near the end of the

experiment, I began to distinguish its constraints more obviously the longer that I carried on the conversation.

If you are interested in indulging your curiosity, the first thing you will need to do is head to Chat.OpenAI.com and create a user account just like you would for any website. After you answer some basic questions about usage, and data sharing, you can start up a new conversation with ChatGPT in about five minutes. Once you complete these steps, you can start asking it some basic questions in minutes.

The questions I chose were based in my own curiosity, and from the gaps in my personal knowledge. So, if you find the questions strange, I actually think it plays an important function in the experiment which I will explain near the end. For the moment, however, bear with my naïve or seemingly strange line of questions.

mix grade used for residential streets is a dense-graded hot mix asphalt (HMA) with a nominal maximum aggregate size (NMAS) of 12.5mm (1/2 inch) or 9.5mm (3/8 inch). This type of mix is designed to provide a smooth, long-lasting surface that can withstand moderate traffic volumes.

However, if the residential street experiences heavy traffic, such as buses or trucks, a higher-grade mix may be required, such as a Superpave mix or a stone matrix asphalt (SMA) mix. These mixes are designed to withstand higher traffic volumes and provide increased durability and skid resistance.

Noel: What asphalt mix grade is the most versatile while also being the most sustainable and environmentally friendly?

Noel:

ChatGPT: The best asphalt mix grade for paving residential streets depends on several factors, including traffic volume, climate, and budget.

In general, residential streets typically require a mix that is durable enough to withstand regular vehicle traffic but also cost-effective. A common asphalt

ChatGPT: One type of asphalt mix that is often considered to be sustainable and versatile is porous asphalt. Porous asphalt is designed to allow water to drain through the pavement and into the ground, which can help reduce stormwater runoff, improve water quality, and reduce the risk of flooding. This mix can be used for a wide range of applications, including parking lots, residential streets, and low-speed roads.

Porous asphalt can also be mixed with recycled materials such as

reclaimed asphalt pavement (RAP) and recycled concrete aggregates (RCA) to reduce the demand for virgin materials and lower greenhouse gas emissions associated with asphalt production. Furthermore, the use of porous asphalt can help reduce the urban heat island effect, which can help mitigate the impacts of climate change.

However, it's important to note that porous asphalt may not be suitable for high-traffic applications, and the maintenance requirements for this type of pavement can be higher than for traditional asphalt.

With my first question, something became immediately apparent: I was using ChatGPT like Google search. Decades of internet experience had taught me that this is how you type questions into a search bar. Thankfully, a more experienced ChatGPT user was assisting me with the experiment, and was able to offer some advice. They explained that I didn't need to think of each question as a standalone event, but rather, an ongoing conversation on a topic. It would remember and reintegrate previous portions of the interaction, allowing my questions, as well as its answers, to become increasingly complex.

I started a new line of questions with one I knew the answer to, and then decided to probe ever more specifically

the limits of its answers: Noel: What are the best practices for the milling and repaving of a section of interstate road?

ChatGPT:

• Conduct a thorough inspection: Before milling and repaving, conduct a thorough inspection of the existing pavement to identify any structural or surface defects, drainage issues, or other problems that need to be addressed before repaving.

• Plan the project: Develop a comprehensive project plan that outlines the scope of the work, project timelines, traffic control plans, and equipment needs.

• Milling: The milling depth should be based on the condition of the existing pavement and the desired final pavement thickness. Careful control of the milling depth is essential to prevent damage to the underlying layers of the pavement.

• Prepare the base: Once the existing pavement surface has been milled, the base should be inspected and any defects, such as soft spots or inadequate drainage, should be repaired. The base should then be leveled and compacted to provide a stable foundation for the new pavement.

• Mix design: The selection of an appropriate mix design is crucial to ensure that the new pavement meets the required specifications for performance and durability. Factors to consider include the type of pavement, traffic volume, climate, and materials availability.

• Placement: The new pavement should be placed and compacted using the appropriate equipment and techniques to ensure proper density and surface smoothness. Adequate compaction is critical to the longterm performance and durability of the pavement.

• Quality control: Conduct regular quality control checks throughout the project to ensure that the work meets the required specifications and standards.

• Maintenance: Once the new pavement has been placed, it's essential to conduct regular maintenance, such as crack sealing, to prevent water infiltration and extend the pavement's lifespan.

At this point, I noticed two things from its answer. The first was that it is very good at mimicking the style of best practice articles, which wasn't a surprise when you consider that it could draw upon the internet's vast wealth of previously published work. The second thing I recognized was that it implemented a certain vagueness with some points that stuck out to me like when a high school kid is trying to "pad" out their literature essay with generalizations that aren't technically false, but aren't specific enough to really be of any real value, or show that the author actually did the reading, for that matter.

It felt concentrated in ChatGPT's answers in regards to mix design and placement, so, I pressed the matter and utilized my home state of Ohio as a basis for specificity.

Noel: What are best practices for the milling and repaving of a section of interstate road according to Ohio's mix design requirements?

This question only yielded a set of identical answers to my previous question, except it added the qualifier

What does that mean? It means that we are determined to support you in your journey towards greater profitability, safety and environmental stewardship. It means that we will help you forge new paths, shape key trends and offer new solutions to support you on that journey. And it means we will be with you for every step of that journey through application consultancy, personalized trainings; across numerous geographic territories and around the clock.

Tell us where you’re going and we will help you get there.

"Ohio" when referencing the required specifications. However, what if you didn't know the required specs for Ohio, as was the case with me? Depending on the next question I decided to ask, I felt I might be close to hitting a dead end, but I was rewarded, instead, with some progress.

Noel: What is the proper asphalt mix design spec for Ohio interstate paving?

ChatGPT: The Ohio Department of Transportation (ODOT) has specific asphalt mix design specifications for interstate paving projects. The ODOT 2018 Construction and Material Specifications (CMS) manual outlines the required specifications for asphalt mix designs. Here are some key specifications for asphalt mix design for Ohio interstate paving:

• Aggregate gradation: The aggregate gradation must conform to the ODOT 2018 CMS manual's requirements for specific asphalt mix types.

• Asphalt binder: The asphalt binder must meet the requirements of ODOT specifications for the specific mix type. The binder grade is determined by the expected high and low temperatures during the pavement's service life.

• Asphalt content: The asphalt content is determined based on the aggregate gradation, asphalt binder properties, and expected traffic loading. The total asphalt content should be within the specified range for the particular mix type.

• Compaction: The asphalt mix must be designed to achieve a minimum compaction of 92% of maximum theoretical density.

• Performance testing: The mix design must be tested for properties such as air voids, voids in mineral aggregate, and Marshall stability to ensure that it meets the specified requirements for performance and durability.

This was the first mention of the ODOT 2018 CMS manual, and while that was interesting, it acknowledged

a separate source that could provide detailed answers, and it didn't provide the specs in detail in its own answer. I decided to pull out all the stops at this point, and ask a wildly specific question.

Noel: According to the ODOT 2018 CMS manual, what would be the proper mix design for a 2 mile stretch of highway on I-77 south near Cleveland, Ohio?

ChatGPT: To determine the proper mix design for a 2-mile stretch of highway on I-77 south near Cleveland, Ohio, additional information is needed such as the expected traffic volume, pavement thickness, and climate conditions. The specific mix design requirements will depend on these factors.

It was the very next thing it said in its answer that provided the first real instance of this experiment surprising me.

ChatGPT: However, I can provide a general overview of the mix design specifications for a Superpave HMA 19.0 surface course, which is commonly used for interstate highways in Ohio.

According to the ODOT 2018 CMS manual, the required specifications for a Superpave HMA 19.0 surface course are as follows:

• Aggregate gradation: The aggregate gradation must conform to the

ODOT 2018 CMS manual's requirements for Superpave HMA 19.0 mix.

• Asphalt binder: The asphalt binder must meet the requirements of ODOT specifications for the specific mix type. For a Superpave HMA 19.0 mix, the required asphalt binder grade is PG 76-22.

• Asphalt content: The asphalt content for a Superpave HMA 19.0 mix should be within the range of 4.8 to 5.8 percent by weight of total mix.

• Compaction: The Superpave HMA 19.0 mix must be designed to achieve a minimum compaction of 92.0% of maximum theoretical density.

• Performance testing: The mix design must be tested for properties such as air voids, voids in mineral aggregate, and Marshall stability to ensure that it meets the specified requirements for performance and durability. After about an hour of conversing with the language model, this was the first time it felt like it was "talking" back to me. It detected a gap of needed information in my question. I wasn't aware of the Superpave HMA 19.0 specification, and thus didn't include it in my question, and ChatGPT offered it as as example of a "commonly" utilized standard, and then provided a specific list of details about it. Although

it took awhile, eventually, the algorithm handed me some information that was genuinely new to me.

I didn't list every question I asked ChatGPT about asphalt and the industry, instead, focusing in on one thread of that conversation that resulted in something interesting. Other questions did lead to dead ends, and I spent a lot of time analyzing it's answers to find out why I struggled to gain new insight from the platform which had access to much more information that I did.

Therein lies the first caution related to using this as a tool in our industry, it's going to leave things out, because you didn't ask -- not that any serious contractor was likely considering using ChatGPT for jobsite questions, but that doesn't mean a next-generation, young upstart contractor wouldn't. This reveals it's second weakness, which is that even when it does offer correct information, it doesn't yet have the ability to cite sources like we do in the industry. If we make a claim, we provide the expert, engineer, OEM, or research that backs up that claim. ChatGPT style language models have been

for contractors and business owners. If you trained the platform on your company's previous jobsite, scheduling, resource, and accounting data, you would be able to ask it questions like "based on the last year, what would be the most efficient employee schedule to reduce call-off?" or "Based on the last six month of material costs and upcoming projects, what future projects should be prioritized to maximize margins?" and it should be able to give you something useful. The task right now is how to

The platforms that emerge to simplify the training of such an AI on your company's data will likely find a lot of demand for that functionality. In the meantime, I offer the final question I asked ChatGPT for this article, and it's full reply.

Noel: If you were an asphalt contractor, would you trust an AI language model enough to implement its guidance?

ChatGPT: As an AI language model, I can provide accurate and reliable information based on my training and the available data. However, it is ultimately up to the asphalt contractor to decide whether or not to trust and implement my guidance.

The answer is that ChatGPT and the generation of language models like it, are only capable of one level of reflective analysis. That means it is only pulling in data related to your exact question, and if you don't know exactly what you don't know, then it can't really help you. Not like real people can.

For example, it was only able to help me with those specifics when I realized there was a term I was unfamiliar with (Superpave HMA 19.0), and could include it in my question by name. When you are talking with a human being who has real experiences and expertise to draw upon, they are able to grasp what you aren't saying, and offer information you didn't know to ask about.

known to completely fabric sources and remix information, much to the chagrin of students looking for an easy path to essay writing.

By the end of my nearly three-hour session with ChatGPT, it became apparent that it was most effective at mimicking conversational intelligence when I treated it like characters on Star Trek do the ship's computer. A google search that fulfills the original promise of AskJeeves (if you don't know what that is, then I am currently turning to dust).

It's weaknesses, though, outline what it could truly become useful in doing

While I can provide useful insights and suggestions, I am not a substitute for the knowledge, experience, and expertise of a professional asphalt contractor. My responses are based on the data and information available to me, and may not take into account all of the variables and nuances that a contractor may encounter in the field.

Therefore, it is important for contractors to use their own judgment and expertise when making decisions about their operations. However, I can be a valuable tool for contractors to use in conjunction with their own knowledge and experience to make informed decisions and improve their operations.

For more information visit https://asph.link/9ywso6

On the road towards automation, manufacturers and consumers will bridge the gap with parallel technology like operator augmentation or “assist”

Straight, plumb, level, square and true will apply more than ever as we transition into the technology-augmented workforce of the future, allowing the industry and workers to do more with less.

It's in the news everywhere. The construction industry is heading for a glut of open positions and a labor shortage of historic proportions. Project budgets and schedules are already constrained by the need for speed, and

this requires the best of the best in labor which comes now at an increasing premium. The dichotomy of labor as the seasoned veterans phase out of their careers and the next generation of techno-infused Tik Tok aspirationals

are less inclined to join a seemingly anachronistic field of work has a generational worker decline crisis algorithm running at full speed. Before too long, there will not be enough workers to get the projects built for the still expanding

populations of the world, and the cost and time to construct will only continue to rise.

However, what if I told you this is a fallacy or a hysteria similar to the reactions to technology taking jobs as a net negative as in the Luddite fallacy. What if I told you that slowly in the background, new professional methods and technologies have been slowly iterating in the fields and offices of construction projects across the world and that this is not a systemic problem that will come crashing down on us suddenly?

look upon their creations with pride. There will just be less sweat equity as we continue to transition away from the back-breaking work of our fathers and take up the mantle of “work smarter, not harder!”

It takes creativity to craft anything, and it takes brilliant and creative folks to work together in the chaotic symphony of construction. From those first days of paper plans, I worked my way into learning surveying and began my fascination with construction technology. Once I learned about lasers,

tandem with the VDC department in the exploration of advanced and emerging technologies for construction. This sent me on the path to where I work now, at one of the leading construction risk automation companies in the world. I state this to begin to circle back to my comment about the labor shortage being a catastrophe or a point of great worry. I speak from the experience of learning construction the old way, the hard way. I speak from years of exploring how we can improve across many workflows and processes and from the standpoint of someone who believes they understand where this is leading and is experienced in construction technology and innovation.

I know from firsthand experience, having seen the shifts and changes underway in the construction industry over the course of the last 18 years. I started in 2005 in the Seattle carpenters’ apprenticeship, learning the “old way” as one of the last of the carpenter apprentice classes before the new technologies really began settling in. Pre iPhone, it was paper drawings and traditional building methods. Straight, plumb, level, square, and most importantly, true. Those were the carpenters' mantras and indicative of the pride and craftsmanship which was imbued upon the apprentice in this field of knowledge passed down from generation to generation. That last part was to be true to your craft, true to your intentions, and to the pride in your work; this will never leave the trades and will not be augmented. There will always be those creative, hard-working men and women who will take up construction tools and, through hard, hands-on work, will

cartesian coordinates and geo-location it unlocked terrific opportunities for me. I returned to college after attaining the journeyman carpenters’ status and learned about CAD and more importantly 3D modeling. At that time, 3D modeling was taking hold of the industry, and it was perfect timing. I was able to take my hands-on background in construction and apply that to construction management and suffuse it with the increasing technological advancements of virtual design and construction.

In what feels like a very short period of time relative to the construction industry, 3D modeling and virtual design and construction took root in the larger contractors' offices and laid the groundwork for the following decade of rapid advancement in construction technology.

This led me to create a construction technology R&D department at one of the most forward-looking large GCs in the Seattle area, which worked in

I’ve seen technologies being developed in every sector of the construction industry and see these advancements being refined and purpose-built, not to replace labor but to augment the labor force we have. These technologies will support the newer generations of builders, and this is important to attract them to one of the oldest and most rewarding industries available to them. This will create newer, yet unknown, opportunities similar to how the advancements in ride-sharing and task-based applications on the heels of the smartphone explosion gave rise to the gig economy.

Technologies that seemed futuristic just a few years ago and definitely scifi almost 20 years ago when I started are already in use on construction sites today:

• Digitization is the most basic and widely proliferating technology, and the network effects of this digital transformation which has taken place over the last 20+ years. This really got a boost as digital technologies became more accessible in tablets and smartphones, and their impact cannot be overlooked.

• Robotics can print the project designs onto the floor, lasers which can project the plans onto the walls and ceilings, both with fantastic accuracy exist, saving the knees and backs of those who would traditionally have to laboriously bend and reach all day to

transcribe design onto the real world. I have been there and would gladly give some of the workloads to a robot.

• Laser scanning and 360 photos, along with photogrammetry and reality reconstructing technologies as captured by drones in the sky and ground-based robots are scanning and documenting projects and capturing realistic and photographic representations or reality capture of the projects at a given moment in time. That documentation is being uploaded into web-based environments saving countless human resources in the capture and then even more in providing visibility to projects like never experienced.

• Telepresence and teleoperation will become more feasible in the coming years as technology increases and safety concerns and trust are built. The early jobsite robots are paving the way for more and many different kinds of robotics in the near future which will address the labor shortage. I’m not saying fully autonomous robotics immediately but think teleoperated or collaborative robots which augment the existing workforce by taking over repetitive tasks and significantly improve worker productivity and safety. Many examples are already making their way into the field for everything from drywall finishing, welding and concrete drilling.

• Advancements in the cloud and virtual access and virtual oversight of construction projects have proliferated as mobile and edge computing technologies have taken root. This augments personnel to cover more ground for reviewing work in place and reduces the safety risk of unnecessary on-site personnel by bringing the job site safety to them offsite.

• Artificial intelligence is already underlying in many of the widely used applications for document and project data, while newer and more cutting-edge techniques for analyzing and reporting on the job

sites' progress are beginning to take root now. This is being enabled by the advancements in documentation and reality capture technologies This is saving countless human hours in analyzing progress and finding deviations from design intent so that contractors can spend time-solving problems, not finding them. This is augmenting the workforce by honing in on the areas which need the most attention and preventing the unnecessary resource drain of rework, which saddles projects with added costs and delays

• Digital twins of construction projects are being built from the project's data and a single source of truth as delivered by digitization and technology proliferation are changing the paradigm of what it means to build and what it is in fact which is being built. No longer is the project just analog physical structures but they are digitally infused and data rich constructions meant to inform not just the construction project but to be the basis for the future of and the entire lifecycle of the building

• Advancements in AR/VR/XR technologies to share and experience the construction project are already here and just awaiting the iPhone moment with the right combination of timing, software and hardware to proliferate. This will fuel the ability to enable remote collaboration which the industry has never had before allowing untold future labor to be tapped as remote access to projects is safely and easily accessible as playing a video game. The Fortnite generation may just get excited about that!

• The advancements in virtual design and construction are leading to more prefabrication of components and in the case of cross-laminated timber projects nearly entire buildings eliminating waste and maximizing human capital.

• 3D printing and on-site customization is evolving rapidly and major concrete formwork companies are experimenting with delivering

the future of building foundation construction to enable faster, less wasteful and more digitally-controlled construction which in turn will require less human effort.

These are a few of the new and emerging technologies which will affect every aspect of the construction workflow. They are being tested or used daily as we work towards a technology-mediated augmented workforce. The wide breadth and range of the technologies are creating new roles which the newer generation of builders will be adept at and engaged with. The technologies themselves will augment and optimize the existing workforce and elongate their working capacity by offloading repetitive, dangerous and automatable tasks. This will free up the human workforce to engage with the creative aspects of the trades and help continue to hasten the advancements. This will allow the construction industry and professionals to turn a better profit well into the future. After experiencing the rapid pace of change over the last few decades and watching now the even faster advancements in large language models and generative AI, I think that we will see an increase in the speed and proliferation of construction solutions.

We just have to remember that no matter what the technology is that is disrupting the industry and the foundations of the trades, the basics will not change. We will need to build new buildings and repurpose the ones we already have, it will be just a matter of how and if we can maximize profit, while being good stewards to the resources of the earth, reusing what we can while optimizing and protecting the precious human resources which we rely on. Straight, plumb, level, square and true will apply more than ever as we transition into the technology-augmented workforce of the future, allowing the industry and workers to do more with less.

by Adam Cisler, senior solutions engineer at Avvir.For more information visit https://asph.link/9ywso6

The main objective of WSNs is to stay ahead of time-consuming and costly repairs through effective forecasting.

Wireless Sensor Network (WSN) technology is widely used across a myriad of industries to monitor large structures or complex environments. This monitoring solution has made its way to the asphalt sector, enabling organizations and roadway operators to remotely monitor asphalt structures from a safe distance, stay ahead of demanding maintenance schedules and avoid pavement failure through predictive analysis using data collected by sensors along the network.

A WSN is designed to monitor different types of conditions, occurrences

and properties in specific areas of the asphalt structure. For instance, wireless sensors can be embedded into the asphalt pavement to monitor the temperature of the asphalt as it cools down after being laid. This information can be used to ensure that the asphalt is being laid at the optimal temperature, which can help in preventing premature failure of the pavement due to thermal cracking.

Wireless sensors can also be used to monitor strain on the asphalt pavement caused by road traffic. This information can be used to identify areas where

the pavement is experiencing excessive stress, which can help in identifying potential areas of failure and informing maintenance and repair decisions in a timely manner.

The main objective of WSNs is to stay ahead of time-consuming and costly repairs through effective forecasting and analysis by implementing passive, non-destructive monitoring methods. In most cases, small changes in the asphalt’s structure occurs before major damage or notable decline in performance. Such micro changes in the structure typically go unnoticed

This summer, Asphalt Contractor is highlighting jobsites and the hardworking crews across the U.S. utilizing Vögele pavers. Submit your action shots for a chance to be featured by Asphalt Contractor and your crew could win lunch from Vögele!

Three winning crews will receive:

Restaurant gift card to location of choice*

Vögele swag

Shareworthy recognition on our social media pages

Entering is easy: Snap a jobsite picture of your Vögele paver in action Go to PaverSnapshot.com

Upload your photo and submit your information for a chance to win lunch!

Submit your photos TODAY!

through manual observation practices and requires sensitive instruments to detect, measure and monitor.

WSNs have numerous working components, ranging from individual sensors and power supplies to modems for data transmission and software platforms for analysis. Because of this, deploying a WSN for asphalt monitoring tends to be very tedious. The presence of several working components increases points of failure within the system and is a considerable challenge in managing WSNs for asphalt monitoring.

A point of failure refers to a single point in a system that can cause the system to break down or become inoperable. In the case of a WSN, you could be using the latest and most reliable software for data analysis, but if the sensors gathering data in the asphalt are faulty and returns inaccurate data then the entire monitoring system is compromised.

Monitoring along the roadway is facilitated by small sensor nodes. The sensors are buried in the pavement, either by drilling into the surface or incorporated in the structure during construction. The latter method is less invasive and requires careful planning before construction.

Sensor nodes can take on a wide range of packaging styles, determined by the power supply, operating principle and application of the sensor. For example, a sensor used for monitoring structural health with an acoustic attenuation operating principle may feature cylindrical packaging. Sensors used for monitoring traffic and environmental conditions with a magnetic or vibration operating principle may have a box case packaging style. The area of installation along the asphalt structure is also a major factor in packaging style. Sensors can be installed at the top, middle or bottom asphalt layer. The area of installation is determined by the conditions the sensor is designed to measure or monitor.

For large WSNs, relay nodes must be installed to extend the network's coverage area and increase its connectivity.

Relay nodes typically act as intermediaries between sensor nodes and the base station or other nodes in the network. These nodes can help to overcome obstacles such as physical barriers, radio signal interference and transmission range limitations by relaying data packets between sensor nodes and the base station or other nodes that are out of direct communication range.

Coordinator nodes are used to serve as the central point of control for the network. The coordinator node is usually a powerful node that has additional functionalities and responsibilities compared to the other nodes in the WSN.

Remote monitoring is facilitated by sink nodes, also known as a base station or gateway node. These components contain antennas for data transmission

seasonal changes in weather. The data generated by the sensors should also be accurate so that it can be used to generate actionable reports, serving as the foundation of predictive analysis.

“WSNs must be packaged with a material that is compatible with that of the pavement and can protect the internal circuits from thermal and mechanical damage without compromising on their performance capabilities. For example, the strain gauges of WSNs are often packaged with epoxy resin, as it is associated with a high-energy harvesting efficiency and can simultaneously protect the internal circuits of the WSN from high pressure and potential harm from aggregates within the pavement,” highlighted Benedette Cuffari, researcher and scientific writer at AZoNetwork.

to an external network. The sink node is usually a fixed, stationary node that is located at a central location in the network. It may have more processing power, larger storage capacity and better connectivity than the other nodes in the network.

A WSN installation is considered successful if it can support 24/7 uptime with minimal onsite maintenance. This requires the hardware and system components to be extremely durable, capable of withstanding extended periods of vibration imposed by vehicles and fluctuating temperatures due to

A challenging aspect of planning a WSN installation is deciding on a node layout along the asphalt structure. A WSN layout should use the least amount of sensor nodes possible, while maintaining quality data collection and transmission. By minimizing the number of sensors nodes in the network, the WSN would be less costly to install and maintain.

Wireless sensor nodes have limited detection and connectivity ranges; therefore, it is important to incorporate

•CAPACITY: 40,000 lbs.

•20 Ton Air Brakes

•Trailer Weight: 8,380 lbs.

•Overall Width:102", Length: 31'4"

•Deck Length: 21’ Flat (model shown)

•6’ Beavertail

•Deck Height: 34"

•Tires: Eight 215/75R17.5 (H)

•Brakes: Air (Full ABS System)

•Ramps: 72" Long x 22” Wide Range: 102" Max. 29" Min.

•Lighting:100% Sealed Wiring harness and L.E.D. Lights

ONE PIECE CAST LUNETTE EYE

Tested @ 275,000# and wrap around nose plate. Standard on all trailers.

HIGH TENSILE MAIN RAIL

One piece and cold formed. CROSS MEMBERS pierced through Main Beam for lowest possible deck height and more unitized frame.

APITONG/COMPOSITE DECK

Durable Composite Decking is fastened to the crossmembers with bolts and deck washers making it easier to replace decking when required.

Eager Beaver WIDE TRACK AXLES: 98” Some Competition - 92”

ALL WHEEL ABS with Spring Brakes on all axles. Standard on all air brake trailers.

SUMITOMO BRAND TIRES

National Dealer Supported. HUB PILOTED WHEELS

Outboard brake drums for easier maintenance.

1946-2022

th 76 6

•8 Degree Loading Angle Low Profile ANNIVERSARY

a layout that addresses such limitations. Another factor in choosing a node layout is data transmission. Sensor nodes pass around and forward data to the sink node. Not all sensor nodes transmit data to the sink node. From a practical perspective, it wouldn’t make sense for a sensor node located very far away to directly send data to a sink node on the other end of the network.

Sensor nodes are usually installed in clusters, serving a specific part of the roadway or structure. Additionally, their coverage area can overlap. Multiple sink nodes can be present in a WSN, serving individual clusters of sensor nodes. There are several options for the configuration of node installations on roads. Nodes can be installed on the outer lanes of wide roads with alternating spacing, forming a triangular cluster (when installed on both sides of the outer lanes). On the other hand, narrow roads can easily be covered with a single line of sensor nodes.

“The challenge in designing the WSN lies in finding the minimum number of sensors that allows to maintain good data quality. An optimization problem therefore arises in which a limited number of elements must be associated with an infinite number of possible positions. Optimization can take place on the basis of certain parameters such as data quality, the maximum sensing coverage, the fault tolerance, the network connectivity and so on,” explained Alessandro Di Graziano, researcher from Department of Civil Engineering and Architecture, University of Catania.

The “heart” of a WSN is the power supply; without reliable power the WSN would not function. A compromised power supply could cause the critical components to go down or in some cases the entire WSN. Nodes are low-power components that require small amounts of energy during application. The challenge in powering nodes is utilizing a power source that

is maintenance-free and reliable for extended periods.

A leading solution for powering sensor nodes within a WSN is energy harvesting. This process involves converting vibrations from vehicles to electrical energy. A key component in energy harvesting is lead zirconate titanate (PZT). The material can generate electricity in response to mechanical stress, such as vibration or deformation.

In an asphalt pavement, PZT-based sensors can be embedded to convert the mechanical energy generated by the passing vehicles into electrical energy, which can then be used to power the WSN deployed in the structure. PZTbased sensors are installed in the middle or top layer of the asphalt pavement, where they can detect the vibrations caused by the vehicles passing over the pavement. The vibrations cause the PZT material to deform and generate an electric charge, which can be captured and stored in a capacitor or a rechargeable battery.

Sensor nodes used for asphalt cannot rely solely on batteries for power. This is because the sensors are buried in asphalt, making access difficult and costly for battery maintenance or changes. Batteries inside commercial sensors (that rely solely on batteries) must be replaced every four months or 1-2 years, depending on the type of battery. Using PZT technology enables the batteries to remain in a charged state for consistent power, resulting in a “selfpowered” solution. The problem with using solar panels or wind energy to charge batteries powering nodes within the asphalt is underground deployment, which requires long and buried wiring connections. PZT does not have this requirement.

Not all components within a WSN are fit for energy harvesting via PZT. Solar energy can be used to power modems and other network components near nodes for remote data transmission. A battery stores solar energy for use at night or during low-light conditions. These components are located on

the sides of roads and are protected by heavy-duty cabinets, such as stainless steel enclosures to withstand rugged elements.

Using different types of power supplies makes WSNs increasingly complex and adds to its long list of potential points of failures. This is because power supplies have different lifespans and are prone to degrading performance over a long period of time. Managing power supplies for WSN components requires monitoring healthy charge states and energy harvesting performance.

With so many hurdles and challenges associated with deploying a WSN, why would roadway builders and operators consider implementing such daunting projects? WSNs can help increase the uptime of roadways and reduce maintenance costs through preventive measures. According to research, it is 6-10 times more costly to perform corrective or emergency maintenance on asphalt pavement, compared to implementing preventive maintenance.

Reducing corrective or emergency maintenance also has positive effects on cities and residents. Local businesses are usually caught off-guard and when road construction hits their area. In most cases, their only option to wait for the project to finish. Road repair projects can take months to years, depending on the size of the project.

“Public works projects can seriously disrupt business activity and construction mitigation is designed to help businesses through what is often a very difficult period,” said Bo McCready of the University of Wisconsin's Robert M. La Follette School of Public Affairs. By supporting preventive maintenance efforts, WSNs can help keep roadways open ensuring access to business establishments and public locations.

For more information visit https://asph.link/9ywso6

This unique event will help contractors and business owners propel their business and expertise forward with live equipment demonstrations, an in-depth educational program and deeper connection opportunities on an expansive trade show floor.

JANUARY 30 - FEBRUARY 1, 2024

Henry B. Gonzalez Convention Center - San Antonio, TX

FOR MORE INFORMATION, VISIT: PAVEXSHOW.COM

McMillen Corp. squeezes more value form its $6 million fleet by leveraging insights from Tenna and Viewpoint Spectrum to support construction equipment life-cycle extensions.

While the construction industry is sometimes at odds with the environment, and must take care to prevent impacts to water resources through the use of everything from wetlands delineations to silt fences to spraying anionic polyacrylamide on dirt piles, design-build teams of engineers and construction professionals at Boise, Idaho-based McMillen Corp. face the additional challenge of working on projects directly in waterways— renewable power, dams, spillways, fish ladders, in-stream habitat improvements, reservoir outlets and more.

The company is involved in early stages of environmental studies, permitting, civil engineering and project design. But they also self-perform many construction tasks, which means they rely on a $6 million fleet of construction equipment and other vehicles ranging from a hydrocrawler, six boats, barges, boom trucks, a half dozen excavators, dozers, telehandlers and skid steers.

“We don’t have that large of a fleet,” McMillen Equipment Manager Christopher Schauer said. “Last year was about getting started doing full-frame rebuilds on our existing machines, but this coming year we will be growing the fleet.”

While McMillen may be buying more new equipment soon, since joining the company in August of 2021 and implementing GPS-enabled asset management software from Tenna in February of 2022, Schauer’s team has focused

on getting more value out of the existing fleet, leaning on maintenance and operations history from Tenna to inform the process. The company had evaluated HCSS Equipment360, but Schauer was also intrigued by CAT’s Visionlink and the United Rentals API. Their decision, he said, was ultimately based on the software to meet their needs across a mixed fleet with robust telematics and computerized maintenance management systems (CMMS) capabilities.

When we caught up with Schauer in January, he was at a McMillen facility where his team was rebuilding a Caterpillar 289 skid steer.

“This is a D series model—which was the last generation,” Schauer said. “They are now moved on to the D3s. But when I look at our machines, they are sitting at about half life. How I generally look at a piece of equipment is to take stock of where in its life cycle, and about 4,800 hours of operations is

You move fast. You need flexibility from job to job. You need maneuverability in every job. And of course, there is performance. Introducing the new line of Cat® Compact Asphalt Pavers. These 8-foot class pavers deliver on it all, while remaining simple to operate. Designed for applications from narrow city streets to straight-line rural applications, it’s just another reason to trust the paving industry leader to be with you every step of the way.

Learn more at Cat.com/Pavers.

halfway through its useful life. If I talk to a salesperson, they will tell me to get a new one.”

But having come to McMillen from a stint as equipment manager for Kiewit, Schauer was accustomed to taking equipment into higher hours and sweating the assets.

“At Kiewitt, we took a longer and in depth look at where the repairs are in terms of the returns on investing more in a piece of equipment,” Schauer said. “So I know, personally speaking, these skid steers can go 10,000 hours. Hardly anybody does that, but I know you can do it.”

While some companies may not have the staffing to complete the necessary rebuilds, which may include everything from line boring to bushings and bearings, Schauer said the work itself could be outsourced. The challenge is the visibility to balance productivity with cost for parts, materials and staffing.

“If you are a smaller company, you may dump these skid steers at 4,000 to 5,000 hours, before they have issues,” Schauer said. “Maintenance will start to creep up in cost. But many times they are spending so much money paying the creditors and the banks for these new units they are not actually coming out ahead. We want to get everything we profitably can out of equipment.”

A full asset life-cycle approach to equipment maintenance is, in even many large and complex companies with much more tied up in capital assets, an aspirational idea. Between a reactive maintenance culture and a lack of enterprise systems that can support financial decision making about

equipment, a full life-cycle approach to any type of asset is rare.

“It is something people talk about idly,” Schauer said. “Like, it would be so nice to do. But to do it and stay on top of it takes some dedication to making this program work.”

Success in full asset life-cycle management is less about the size of a team or company and more about structure and data visibility.

“You need to have a centralized equipment structure,” Schauer said. “If you are relying on the project managers themselves to handle maintenance on equipment used on their project, it just won’t happen. It has to be centralized in order to have one person responsible for the fleet. Otherwise, the numbers do not get to the same point. Five people will never cross-compare numbers together to know what they need to do with a machine. Centralization verses decentralized equipment management is one step. Even if you are a landscaping company—and I use that as an example because they are picked on for being small and unsophisticated—can do this if they have someone who is knowledgeable. They don’t need a full-time staff member doing it doing the overhauls and the work—that can be outsourced. You just need someone who is aware of it and has equipment as their responsibility. There is more emphasis put on it in the larger organizations because the numbers get larger faster.”

One challenge in achieving an asset lifecycle approach is the fact that it requires visibility not just into the equipment itself, including a full maintenance history, but the project activity through which each piece of equipment drives value. This means that utilization data from telematics units installed on equipment is crucial. This data must not only be harvested from the piece of equipment, but also exposed in an application that supports financial decision making by placing it in context with other factors.

“Utilization is key—and telematics is the only avenue into that realm to really track it,” Schauer said. “It doesn’t make sense to own a 349 excavator if it only runs 5% of its life. It is a huge waste of capital. If a skid steer is used 75-95 percent of time, you can justify the capital investment and also justify investing more in keeping it operational.”

Decisions about the equipment then cascade into other parts of the business, including spares and repairs parts ordering and staffing levels for maintenance technicians.