Roofing Industry Alliance MVP Award Page 4

Flynn University for Frontline Coaches Begins

Page 18

20th Anniversary of Peerless Joining Flynn

Page 27

Roofing Industry Alliance MVP Award Page 4

Flynn University for Frontline Coaches Begins

Page 18

20th Anniversary of Peerless Joining Flynn

Page 27

A 176 bed facility for all general pediatrics, heart, cancer, psychiatry, and speech and hearing treatments.

Page 39

Hello everyone,

At a recent senior leadership meeting we discussed, among other things, the importance of culture to our success. A big part of our culture, which we call “The Flynn Way”, is the right kind of leadership, and how leaders act every day.

When it comes to Leadership, actions speak a lot louder than words, and the action we decided to take was to participate in a workshop to capture positive leadership behaviours that we have observed and experienced throughout the years. The effective leadership behaviours we discussed help build teams by motivating, inspiring and driving our people in the right direction. We took what we discussed and summarized it, and we found that there were six common themes.

These common themes were then captured to create “The Flynn Leadership Promise”.

The Flynn Leadership Promise is six actions or behaviours that all senior Flynn leaders are committed to following. That is why each member of our senior leadership team will be signing their own copy of the Flynn Leadership Promise and displaying it in their office. This will create a physical reminder of our commitment to maintaining our great culture. Pictured here you can see my own signed Flynn Leadership Promise.

I am sharing what we learned in the workshop because these leadership behaviours are not only reserved for our senior leaders. These leadership behaviours should cascade throughout our entire organization, right to the crew level! I would like to explain the Flynn Leadership Promise in more detail here, but it’s difficult to share the purpose and meaning in text alone, that is why we have created a short video that you can find on our YouTube channel here: http://bit.ly/2p9BBJM and also on our Portal, Facebook and FlynnCrew.com

I invite you to take a few minutes and watch the video, it will offer a more in-depth look at how important leadership behaviours are to our great culture.

I welcome feedback on the Leadership Behaviours contained in the Leadership Promise particularly where leaders are demonstrating the right behaviours and are good examples of the “Flynn Way” from a leadership perspective.

Until next time stay safe!

In this issue we feature José (Joe) Neiva, Roofing Foreman of Toronto, for Mentorship Matters. Read the full story on page 43.

“Joe Neiva has been a mentor for me for my entire roofing career in Canada. When I started as a roofer I knew very little about roofing. Joe was patient and professional and taught me the work and safety skills that made me the foreman that I am today.

Joe is very proud of the quality of his crew’s work, telling everyone to make sure to “let them know that we did it,” meaning that if we were not on the jobsite, people would still know that it was Joe Neiva’s crew that had completed the job, just by looking at the quality of the workmanship.

Joe was always there for me as a mentor and a friend. He is the brother that I did not have during the times I needed one the most.”

~ Martinho Ondas, Roofing Foreman

Justin Cooper, Service Foreman from the Flynn Denver branch has received the MVP Award from the Roofing Industry Alliance for Progress in collaboration with the National Roofing Contractors Association. This award is presented annually to a select few individuals who are role models, and have made a significant contribution to safety performance, teamwork, community service and overall outstanding performance in the roofing field.

“Justin is the technician that customers call to specifically request and they will wait until he is available even when he is on vacation. Customers rave about him and always request to have him back after their first experience with him,” said Megan McReynolds, Service Manager. “Justin works hard every day to be a strong example and a positive representative of the company. His contributions to his family and his work life are both outstanding examples of the type of employee Flynn is proud to employ.”

“Justin has been outstanding to work with at both the Arvada Fire Protection and Southwest Mechanical. He can always be counted on to let me know what the problem is, follow up with the repair, and communicate with me through the whole process,” said Ken Rubenking, Building Maintenance for Arvada Fire Department. “The communication part is what I struggle with most of my vendors on and Justin is always keeping me up to date.

Congratulations to Justin for receiving this well-deserved honour. His commitment, positive attitude and open communication with his customers are great examples of what we strive for at Flynn.

“I am really excited to receive the MVP recognition. Happy to see that Flynn and my customers really appreciate my hard work”, said Justin. “The key to my success is being nice while communicating to my customers, paying close attention when it comes to detail and putting in the hard work. At the end of the day people notice when you are willing to go that extra mile.”

MVPs are role models who demonstrate work-related and personal goals to which others aspire. Through the MVP program, you can nominate your employee for an award to formally recognize his or her outstanding contributions.Justin Cooper and wife Emily Shoop

One of the best things about working with such talented people is also being able to witness the special projects they take on to improve the look and feel of our work space. Brian Anderson and Ralph King, our Architectural Shop Fabrication Masters, along with Cristobal Rosalez, one of our very dedicated Architectural Superintendents, designed and installed this beautiful entrance to our Architectural Fabrication shop. Brian, pictured here, explained that their vision was to create a display piece that was not only functional but also artistically pleasing. This new entrance displays the various materials and installation options for our customers. In addition to their incredible talent and vision, our fabrication team takes pride in everything they do. They strive to bring together design and function so that our customers can create a home or business that is unique and memorable.

The trim and toe kick featured is composed of Berridge Antique Copper-Cote. The other materials consist of Western States

Weathered Metallic, Rheinzinc, Clear Coated 16oz. Copper, Freedom Grey

16oz. Copper, Scheffield AZP

Raw, Eggshell

Stainless, and Natural Age Copper.

We are proud to have this addition to our branch and welcome visitors anytime!

Submitted by Megan McReynolds

Submitted by Megan McReynolds

Denver decided to add a new award to our holiday party this past December 2016. In addition to the foreman, safety, and project awards, we added the H.E.A.R.T. award to the mix. This award recognizes a special employee who performs his/her job duties with pride while also being...

All office staff and field employees had an opportunity to nominate the individual which best met the criteria listed above. Everardo Fernandez Alvarez, pictured here, a longtime employee, was our first annual recipient of this award. He is a true example of how to put HEART into everything to improve the lives of others in the company. Thank you Everardo, for your contagious smile and positivity. Thank you for inspiring us to do the right thing every day, to take pride in what we do no matter the task, and to motivate others to be the best version of themselves.

Flynn Group of Companies is once again extremely proud to be recognized as a Platinum Member of Canada’s Best Managed Companies. Thank you to our dedicated staff from coast to coast, for your efforts toward achieving this award for the 18th consecutive year. It is through your hard work that we continue to be the trade contractor of choice, in all our markets, for all of our clients.

Submitted by Megan McReynolds

Flynn had a big night of recognition this year at the 2017 Colorado Roofing Association (CRA) Awards Dinner held February 16th, 2017. The Flynn Denver branch was proud to stand strong among the best of the best in award submissions for roofing projects amongst fellow competitors across Colorado. It is a great night to celebrate the achievements and professionalism of its members and highlight the many ways Colorado is striving to help positively improve the roofing industry. Members of the CRA can nominate a job based on the following categories, depending on the size of the contract.

Division I: Under $150,000

Division II: $150,001 - $450,000

Division III: $450,001 - $850,000

Division IV: Over $850,000

Flynn was proud to celebrate and take home the following wins for outstanding workmanship on the following projects!

Division III:

1st Place: Safeway - Freezer A Reroof Project

2nd Place: Denver Scottish Rite Consistory

Division IV:

1st Place: University of Denver – Ritchie School of Engineering & Computer Science

Submitted by Trisha Dykstra

Flagstaff and Phoenix teams collaborated on Flagstaff’s Indian Garden project at the Grand Canyon. The crew hiked 4.5 miles down the Canyon to re-roof the pump houses at Indian Garden, which is the halfway resting point for hikers going all the way down into the Canyon. Roofing materials were flown in by helicopter and the crew camped out for the week. Sore from the hike in, the crew worked hard to get the job done and then had to hike out after stormy weather and a hard week’s work. Great job team!

The Colorado Roofing Association’s goal is to help homeowners, commercial building owners and managers make informed decisions about replacing and maintaining their roof systems.From left to right: Dustin Johnson, Jim Quick and Ernie Velasco hiking down Bright Angel Trail at the Grand Canyon

The Phoenix branch would like to thank Stan Maciboric for mentoring our branch for the last six months. We have greatly appreciated his business acumen and extensive roofing knowledge. Now that Stan is returning to Canada to work on other projects, we would like him to know he will be missed here in Phoenix and that we hope to see him again soon. Stan, you are welcome back anytime!

Submitted by Kevin O’Dir

The Flagstaff metal crew is in the process of completing the Mountain Trails project. The three story, 160 unit luxury apartment community in West Flagstaff has a standing seam metal roof and walls.

Submitted by Trisha Dykstra

Ernie Velasco, Jim Quick, Rob Loera Jr and Luis Martinez Delafuente are working on Carlisle waterproofing at Arizona State University’s Student Pavilions for JE Dunn. The customer was so pleased with the performance on the TPO scope of 30,000 sq. ft. that they added 3,000 sq. ft. of waterproofing for an amenities deck. This project was particularly challenging due to constant student foot traffic.

Submitted by Trisha Dykstra

This is Flynn Phoenix’s fourth project with Balfour Beatty Construction. The project includes 16,600 sq. ft. standing seam metal roofing and flush wall siding and 6.7 million sq. ft. of 60 mil JM TPO. Balfour Beatty is particularly strict on their safety requirements and the Phoenix branch has been recognized by Balfour on safety standards.

Submitted by Trisha Dykstra

Drury Inn in Chandler was Phoenix’s first EPDM project. It was 19,000 sq. ft. of fleecedback EPDM over lightweight insulating concrete done for Drury Development Corporation.

Submitted by Gabe Duff

The team is currently working at the Kansas State University, Seaton Hall project in Manhattan, KS. The work started in January, and the team hopes to finish up in mid-May. The weather and site conditions have proven tough. The weather has been extremely rainy as of late, so the team took advantage of a duct tape canoe someone fashioned together to show that they are going all out to get this project done, a little bit of rain won’t stop them.

Submitted by Amanda Schaefer

Blaine Williams (Sheet Metal Superintendent –KC Branch) was driving home one night and the driver in front of him veered off the road and drove in to a ditch (she thinks she fell asleep). Blaine was a little surprised by what happened and pulled over to assist her. Blaine used his First Aid training to try and identify what was hurting her before moving her out of the car. She was a little dazed and confused but she was able to get out of the car with the assistance of Blaine. Blaine called 911 and assisted her in stopping her forehead from bleeding. He waited with her until the EMT & Fire department showed up and took over.

Great job Blaine in keeping calm and using your First Aid/ CPR training.

Our ten years of service award guys were accidentally left out during our Kansas City safety day, so we are taking a moment to recognize them, congrats guys!

Back row: Dave Case, Jacob Gately, Brian Jackson, Branch Manager Bob Livingston

Front row: Mark Nelson, Virgil Hilburn, Dave Newman, Chuck Lammers

Submitted by Ryan Tollefson

The team in Minneapolis were doing panel work on the City Hall building. Since they are using heavy concrete panels they needed to take extra safety precautions. Additionally Project Superintendent Jeremy Broking was able to inform the supplier of their deficiencies in crating their materials and offered suggestions on ways to improve their crates. The final result benefited everyone.

Submitted by Rebecca Welsh

The Springfield team Brad Bowen, Keith Barret and Foreman Michael Dillon are working on the Cox Hospital re-roof, things are going smoothly with no complications.

Submitted by Rebecca Welsh

The Springfield branch has completed some glazing work for the New Reeds Springs Middle School. The scope included 250 feet of skylight over the main hallway, interior storefront systems, EFCO curtainwall, punched openings, and Nanawall systems. It has received a Merit award from the local AIA Chapter.

Flynn is excited to announce that we have signed a Letter of Intent with BRI Commercial Roofing (BRI) in Dallas, Ft. Worth. BRI has earned an outstanding reputation in the industry based on their strong values and commitment to safety, customer loyalty, and most importantly their people. With BRI, Flynn will now have 10 operations in the US, with two locations in Texas, including our branch in Lubbock.

BRI is led by Mike Beeter, President/CEO and Ed Reising, Vice President, Mike will stay on as Branch Manager and Kevin Kloiber will become Roofing Operations Manager. Mike and Ed started BRI 15 years ago based on a business philosophy and the primary principle of “doing what’s right to take care of their team”. Both Mike and Ed will become shareholders in Flynn, and they will continue in primary leadership roles as Flynn grows its business.

“The Dallas Ft. Worth market has over 7 million people, which is comparable to the market in the Greater Toronto area, where our operation generates over $100M in Roofing Services and Building envelope contracting. Given the strong leadership of Mike, Ed, and their team, we are excited to add BRI as our launching point to building a similar business in this growing market over time,” stated Doug Flynn, CEO of Flynn.

The team just recently finished tearing off a roof and replacing it with a 2 ply, cold applied, modified roof system along with flood coat and gravel. Afterwards they installed formed metal wall panels on existing brick walls. The budget was tight, and the cold winter weather made progression difficult, but the team pushed through.

Submitted by Jacob Tantlinger

The crew were furnishing and installing wall panels on newly constructed luxury condos and a parking garage in Washington, DC. The cold weather made it slightly difficult to work with the zinc panels, but the crew persisted, because the final product with zinc panels will be worth it. Plus the cold weather is on its way out, so hopefully the team will get a break from it soon.

Submitted by Jacob Tantlinger

The Flynn’s service team preformed patching and flashing for the newly installed roof top units. This meant working closely with the carpenters and mechanical contractors to ensure everything was properly aligned.

Flynn has sponsored Tim Si’s (Winnipeg Branch) daughter Chloe who is six years old. Chloe practices Taekwondo at Kyung’s St. Vital Taekwondo - Martial Arts School. Always happy to encourage youth involvement in sports.

Craig MacRitchie’s (Vancouver Estimator) 8 year old son of the Langley Snipers went on their first hockey road trip in February. Flynn was happy to sponsor the young hockey team.

Gilles Lavoie and daughter Karianne

Dufour Lavoie of the Rockets of Gatineau want to thank Flynn for their sponsorship. They got nice vests with the Flynn logo on it. The girls are really proud of their season right now with 16 games played and no losses.

Flynn sponsored Kevin Anaka, Site Supervisor’s son hockey team the Saskatoon Wild Bantam A Outlaws

The National Roofing Contractors Association accepts nominations for US Branch MVP’s, so Flynn America submitted nominations and began Flynn US Branch MVP’s, and added categories to include all scopes – roofing, sheet metal, glazing, and service. Nominees are judged on the following criteria:

• Outstanding on-the-job performance

• On-the-job safety performance

• Contributions to a team effort

• Community service and volunteerism

• Other noteworthy contributions and activities

Winners receive a customized Flynn MVP jacket, paid vacation day, name displayed on a plaque in their branch office.

Also a special mention for last year’s winners:

Baltimore – Antonio Miranda (Roof)

Minneapolis – Esbey Rios-Mojica (Roof)

Kansas City – Mike Mauck (Roof), Jack Ketterman (Metal), Chad Vermillion (Glass)

Springfield – Floyd Hall (Roof), John Schaaf (Metal), Scott Meyer (Glass)

Phoenix – Josh Rygg (Roof)

Flagstaff – Chris Chavez (Roof)

Submitted by Frank Kraus

The Halifax team took a picture to commemorate their last day on the IKEA project and a job well done. This will be the first IKEA in the Atlantic region and it had a very tight construction schedule, which Flynn was able to match. The team installed 97,800 sq. ft. of Kingspan Insulated wall panels and 230,000 sq. ft. of Sika PVC roof. Great work guys.

Submitted by Neil Culligan

It was a feel good day on site as the guys dropped in the last two Flynn unitized curtain wall frames to complete a job well done for Flynn. The site team would like to thank everybody that worked on the Nova Centre Project from Halifax to Mississauga. It took our combined efforts to make this job a success.

Eric Veniot presented the Nova Centre site team with a picture of the Nova Centre to commemorate a job well done.

right: Tim Bazinet, Eric Veniot, Blair Cormier, and Neil Culligan

From left

The Roy Condo is Halifax’s newest premiere luxury Condo that is currently being built in the downtown core of the city. The building has 22 floors, and Flynn has been awarded glazing metals and roofing. The glazing team is headed up by Sr. Project Manager Blair Cormier, Site Superintendent Darrin Dunwoodie, Foreman Tim Bazinet and Project Coordinator Kevin Turlo. Both metals and roofing are being facilitated through the glazing PM team in an effort to maintain the most effective communication channels for the customer.

Glazing is being done by Flynn Facades out of the Toronto Branch utilizing labour from the Halifax glazing union hall. Flynn is using our newly developed curtain wall system and window system. The design includes the TB50 Curtain Wall system, the ST145 Window Wall system as well as custom punched windows, storefronts, and a 12,500 SF Rain Screen system.

“This is an exciting project in a city that is seeing a huge revitalization of the downtown core. The Roy is a landmark project for Flynn in the region which requires cooperation and coordination across multiple branches and divisions,” said Blair Cormier, Sr. Project Manager, Flynn Facades.

Flynn metals out of Halifax will be working with the glazing division with the installation of a combination of Aluminum Composite Panel and 2mm Aluminum pre-finished plate. Halifax Roofing will be doing two main roof areas. The level 7 amenity terrace will be getting a hot rubberized asphalt roofing system by Hydrotech that will tie in directly with the rooftop landscaping system that Flynn is also looking at bidding on for this project.

“Our local Atlantic management team is ready to support the field staff in this demanding downtown project. With previous total envelope jobs under our belt in this region, Halifax is looking forward to working with the glazing team to make this job a success,” said Neil Culligan, Sr. Project Coordinator, Flynn Halifax.

Submitted by Evan Bartram

Flynn Halifax’s roofing division was brought in to install 58,200 sq. ft. of Rhinobond TPO at the Tatamagouche P-12 School. Roofing during the winter presented various challenges, but the biggest challenge was the heavy storm conditions. The Halifax branch coordinated with the Moncton branch to bring in an additional crew to bolster the crew size to assist with these winter conditions and execute accordingly. Great to see the branches working together to get the job done.

Flynn University for Frontline Coaches (FUFC) held its first two classes in February and March and trained 40 Coaches who work in roofing production. These Coaches will now return to their crews, and help provide a better onboarding experience to our Flynn Rookies. Flynn University for Frontline Leaders (FUFL) recently passed a milestone of 20 graduating classes, with over 400 students within six years. Imagine the progress FUFC could make in six years. Within two years all of our crews could have a coach laying the ground work for the next generation in the trades.

If you are interested in attending FUFC please visit flynnuniversity.com or contact Latoya Francis, 1.905.671.3971 ext. 1146.

Pictured above: Paul Jones, Brian McCaghren, Ali Hammoud, Kory Robins, Pedro Parra, Hugo Gonzalez, Justin Bomas, Siggy Morin Duarte, Adam George, Evan Benoit, Josenny Almonte, Mark Martins, Eddie Lima, Nuno Silva, Emanuel Freitas, Mauro Videla, Bryan Perrin, Johnathen Wright, Rasey Dumayas, Phuong (Dustin) Nguyen, Paul Gravito, Carlos Ribeiro and Brody Cochlan

Pictured above: Alain Trepanier, Chad Keating, Chris Moos, Dave McGregor, Drew Halliday, Elkin Vergara, Eric Smirnjak, Jamie Massan, Jesse Pesola, Jordan Cooke, Justin Vandale, Maxime Lallement, Rick Meace, Sam Husam Hussain, Stephane Beland, Tomasz Zotara, and Wieslaw Lazar

Submitted by Francis Labonté

From left to right are David St- Amour, Daniel Tanguay, Patrick Mayer and Foreman André De Sousa, who are glaziers working on Place Bell project in a Montreal suburb. They are installing stick curtain walls and aluminum doors in this project that will become home of the Montreal Canadiens affiliate team of the America hockey league.

Submitted by Francis Labonté

Submitted by Francis Labonté

The Project Director of Green Cross bio-therapeutics is Pascal Norris and the project has been under way for one year now and the end is within sight. The project includes Kawneer unitized curtain walls, stick curtain wall, a variety of coloured aluminium panels and many glass partitions inside.

Submitted by Francis

LabontéThe team are working on high-end luxury home extensions in one of the most select districts in Montréal. Most of the glaziers form the service team (Jocelyn Larocque, Michael Larocque, Daniel Morin, Pierre Therrien, Danny Sasseville, Nicolas Forest and Hugo Côté) along with Antoine Levasseur (Project Manager) worked to complete the project in multiple phases. Products installed were four sided silicone curtain wall, digitally printed fritted glass units, fritted decorative glass, aluminum panel soffit, 12’ x 10’ patio door and aluminum parapet flashing.

Donald St-Pierre, Guillaume English and their team have now completed this 40 storey condominium complex and one of several towers going up around the Bell Centre home of the Montreal Canadiens. This project consists of unitized curtain wall system which is fabricated and assembled by Northern Facades, situated in Mississauga, Ontario, part of Flynn Group of Companies. The stick system for the balconies was fabricated by Vitreco, part of Flynn Group of Companies.

Submitted by Craig Van De Merwe

Our team in Hamilton is working on the University of Waterloo with our guys from the Cambridge branch. They are applying 12,500 sq. ft. of a 3 ply Tremco system. Just took a quick pictures while the guys were taking a break.

Submitted by Mark Davis

Our service team in Hamilton were working on the Ontario Power Generation screen house in Niagara on the Lake. The project includes removing the bases of Hydro One line posts/braces, installation of a cold applied modified bitumen membrane and sheet metal flashings. The screen house is beside the Niagara reservoir overlooking the Niagara gorge.

Submitted by Giacomo Zanabria

The Blair Station project consists of an installation of 650 ACM panels covering an area of 12,500 sq. ft. The roof panels are 90% of the way there, the team is currently doing fascias around the skylights. In addition another team at Blair Station is working on the installation of STX Rainscreen Porcelain

for 7,000

Submitted by Mathieu Guay

Our Ottawa glazing crew is starting to wrap up the exterior curtain wall portion for our project at the 1000 Islands Border Crossing Redevelopment. This contract includes interior frames, glazing, glass balustrades, and exterior/interior curtain wall both with an interesting glass combination. We are looking forward to seeing the completed project in Sept. 2017.

Submitted by Giacomo Zanabria

The Cryville Station project includes an installation of 300 panels of 4 mm FR Composite Panels which will cover 9,000 sq. ft. The Installation includes all components such as air/vapour barrier, sub framing, flashings and miscellaneous items. The roof panels are nearly complete, the team is moving on to doing soffit at platform levels.

Finishing up 17,300 sq. ft. of TPO and 7,400 sq. ft. of modified bitumen, things are going smoothly.

Submitted by Richard Martel

The Learning Centre is to be a state of the art teaching space meant to encourage collaborative learning. This project for Flynn Ottawa Glazing includes an extensive exterior curtain wall system with an equally impressive, beautifully laid out interior package. The package includes balustrades and floor to ceiling glazing in a five level atrium which will be sure to catch the eye. We are currently working on the exterior and expect to begin the interior layout within the next couple of weeks.

Submitted by Camilo Varela

Submitted by Camilo Varela

Hotel X has been under construction since 2015, and is now nearing completion. The project is being overseen by Project Manager Camilo Varela, Superintendent Brian Decker, Foreman Luis Soares, Manuel Bandeira, Kevin Lacey, Pedro Almeida, Alex Coutino and Miles Weiss.

Once finished the hotel is a focal point on the waterfront, as it is a unique property that will service innumerable venues and events in Toronto. The key feature of the building is the unobstructed 360 degree view. This fantastic view caused a few hurdles that Flynn needed to overcome. The tower is located on Lakeshore and has no adjacent buildings taller than a couple of stories. This meant the installation of the upper soffits and walls from swing stages were a challenge due to the constant high winds and exposure on all elevations. But the Flynn team pushed through, and the results were clearly worth it.

Submitted by Mark Agius

Flynn has been chosen as the 2016 “Best of Best” Trade Contractor through the Toronto Construction Association (TCA). The TCA is Canada’s oldest and largest ICI association. It was established in 1867 and now consists of over 2000 member companies across the Greater Toronto Area (GTA). This prestigious award not only recognizes projects successfully built by Flynn, it reflects the accomplishment of all of the talented people we have from the field to the office. Toronto is a world class city and we have been fortunate to collaborate with the best industry partners to complete some of most interesting architecturally complex buildings in the GTA.

Submitted by Camilo Varela

The Toronto team recently wrapped up work on the Park Towns job. The scope of the work included supplying and installing Wood Grain Urban Accent Pre-finished Metal Interlocking Panels throughout the building and penthouses, as well as accent fins on the main elevation in White Accumet Composite Panel System. Scope gaps and a changing building plan hindered progress but the final delivered product exceeded the expectations of the client.

Great work Project Manager Camilo Varela, Foreman Paul Furtado, Bruce Paquete, Adrian Crossfield, Taiwo Balogun, and Tim Manley.

Submitted by Camilo Varela

The Madison project involved supplying and installing Axiom Plate Panel system, Aluminum Louvres and pre-finished siding. The location of the building provided logistical obstacles since it sits on the busy Eglinton St. West. This artery street had concurrent construction of the new subway line. As with every condominium with a commercial podium, it had a demanding schedule with little flexibility regardless of the hurdles encountered. The moderately intricate architectural design made for an interesting façade that presented some design challenges that were resolved by our drafting team with the help of our TSC surveying team and engineers.

Twenty years ago Flynn Group of Companies made a pivotal decision that set it down the path of becoming North America's leading building envelope trade contractor. The acquisition of Peerless Enterprises allowed Flynn to more than double its work force, and relocate its headquarters to Toronto, where it still is today. To celebrate the 20th anniversary we held a BBQ lunch with all of the Peerless employees, many of whom still work with Flynn. It was a great opportunity to remember how far we have come, and look forward to where Flynn will be twenty years from now.

For the past few months Flynn University for Service Excellence 2 (FUSE 2) has been touring North America and visiting our branches. With 17 total sessions held, all of our service teams had the opportunity to attend. FUSE 2 is a one-day program designed for our service teams. It’s a fun and engaging way to really improve service excellence skills and ensure our teams all operate at top notch. Thank you to everyone who took the time to attend..

Submitted by Michael Lumley

Metals crew members Andre Jutras and Paul Hebert are installing Kalzip cladding at the AMRIC project in Sudbury. The building will be a 14,000 sq. ft., state-of-the-art research centre and is expected to be completed in 2017.

Submitted by Michael Lumley

The team were installing liner sheets at the Dynamic Earth project in Sudbury. Dynamic Earth is an interactive science museum in Greater Sudbury, Ontario.

Submitted by Kimberley Golberg

With a winter storm approaching some of the Sudbury roofers used an alternate means of travel to attend Tremco training.

Submitted by Alex Boterman

To complete a large Heating, Ventilation and Air Conditioning (HVAC) roof alteration at the University of Waterloo, a large tarp tent was constructed on the roof. This will make the work go smoother. The University of Waterloo is also being worked on by our Hamilton crew.

Submitted by Alex Boterman

Service Roofing and Sheet Metal are working together to complete the reworking of an expansion joint between two metal roof structures. George Murray has been added to the service department locally to bolster the sheet metal work in the Service Department.

Submitted by Camilo Varela

This small project in London had strict schedule restrictions resulting from delicate testing equipment and chambers inside the building. The triangular design of the stairs incorporated random finishes with an intricate asymmetric mosaic configuration. Great work to the team team working on it, Camilo Varela, Daniel Griffiths, Lawrence Bond, Todd Lion, Desi King and Rui Gomes.

Submitted by Carlos Medeiros

Jim Furtado and his crew have been really busy at Masonville Mall for Cadillac Fairview for the last year. Flynn was awarded the contract through EllisDon in November, 2016 and started the project on December 7, 2016. The roofing project consists of removing the existing roof to the steel deck. Adhere one ply Sopravap’r vapor barrier and torch Soprelene Flam 180 base sheet over the base sheet.

The snow storms and high winds proved to be a challenge, but the team battled through and completed the project this month. Great job guys, hopefully the spring weather is on its way.

Submitted by Craig

DoyleDuring a major rain storm a large section of shingles blew off of a senior centre, which resulted in numerous leaks. The London Service team was called in, and Charlie Thomas and Jeremy Rowan were on site until 11 PM installing tarps to stop the water from entering. Good to see the team going the extra mile to make sure everyone could stay dry for the night.

Submitted by Craig Doyle

While fixing a roof on a recent service call, the Flynn London team went above and beyond by performing landscaping to ensure the roof was protected from falling branches.

Submitted by Jason McKay

The London branch received an email from No Frills requesting roof repairs as soon as possible. There was leak dripping water into a room with a variety of electronic equipment. The team was quick to respond, and the customer sent this email in the next day.

“First of all, thank you so much for getting us fixed up, it was/is greatly appreciated! Also the two gentlemen that came out to do the work, I must say were top notch, very polite, kind, helpful and informative, kudos to your business for having such great employees.” - Tracy Mantel

Always good to see more examples of the high standards of service we hold.

by

Bo Sung HanThe team at Flynn was tasked with suppling the curtain walls to recreate the look of the Prescott House Hotel in the heart of NYC with a more modern appearance. The building was first built in 1910 but reduced to a two-storey building in 1935. In 2013, the decision was made to recreate a new building with original 1910 building design concepts. The finished product has been praised by many with one Landmarks Preservation commissioner calling it “as exciting a building as I’ve seen [in my time] on the committee” and another deemed it “a brilliant piece of architecture.” The defining features of the frames were the terra cotta rain screen that twist and dematerialize to give the building modern curtain walls. Flynn Manufacturing’s scope for the project was to supply approximately 500 Unitized curtain wall frames and Cornice panels which were designed with the Flynn Systems.

A thank you to all Design/Engineering/Drafting/Production/QC/Project management teams and project manager Dayakar Jillela, everyone contributed to successful completion of project.

Submitted by Lorenzo

DAlessandroThe 1133 Yonge St. project is comprised of re-cladding a unitized curtain wall. The outside corners of the building were designed and manufactured with curved glass and extrusions supplied by Europe. Ensuring curved extrusions accuracy required many brain storming sessions within Flynn. The schedule was extremely tight and required a joint effort from the drafting side. Despite needing outsourced materials, a variety of technical challenges, and very tight schedule, the project was completed on time. Fantastic work team, the final project looks great.

The Complete UCW drafting and engineering group were Sam Garnace, Jerry Bondame, Ace Benavides, Charles Lenzo, Chris Medeiros, Anthony Roti, Paul Harris and the management team, Noel Cunningham and Lorenzo D’Alessandro.

This February saw the 20th FUFL group graduate from Flynn University for Frontline Leaders. FUFL is an accelerated 2-day leadership program designed specifically for the leaders (and future leaders) of Flynn. The program launched in May 2011, and as of today has trained 400 Frontline Leaders. FUFL is going strong, with more sessions planned for this year. Congrats to Group 20, our most recent graduates of FUFL!

Submitted by Ryley Koch

The Manitoba Clinic’s scope consists of 2,700,000, sq. ft. of metal cladding – at the penthouse and soffit areas. Plus the team is working on the glazing work for the curtain wall. The contractor for the job is PCL, who Flynn has a long history with. The work is going smoothly, and the team looks forward to finishing.

Jesse Schmidt, Michael Cummings, Igor Grom, Maciej Forusinski, Viktor Huk, Aleksandrs Springis, Lukasz Krol, John Vilayvanh, Anton Galliamov, Richard Forbes, Ric Slipchuk, Glazing Foreman Darren Weigel, Shawn Traverse, Metals Foreman Robert Hogue, Mitch Bonneteau, Dale Kulbacki, Jeff Kulbacki, Frank Lanouette, Jordan Wishnowski, and Steven Nobiss.

Submitted by Tyler Tomlinson

We would like to announce the addition of two new staff members in the Winnipeg office. Adam Baxter has joined the firm as our Stores Coordinator and Rod Sass has joined the firm as our Fabrication Coordinator assisting Adam Hodgins in Mid-West Fabrication.

EFAP offers expert, confidential information about how the law applies to specific situations. You and your eligible family members can receive support by telephone or in person consultations on a variety of topics, including:

• Child Support

• Civil Litigation

• Criminal Law

• Landlord-Tenant

• Property Law

• Real Estate

• Separation & Divorce

• Will & Estates

Call for confidential and immediate support: Canada: 1.844.880.9142 and workhealthlife.com US: 1.800.272.2727 and workhealthlife.com/us

The Saskatoon Flynn Branch has teamed with Graham Construction in Saskatoon to build a state-of-the-art facility for Neonatal, Pediatric and Emergency Care Services for the province. Opening in 2019, the hospital will provide a 176 bed facility for all general pediatrics, heart, cancer, psychiatry, and speech and hearing treatments for the children of Saskatchewan.

The four floor facility is designed for the treatment and comfort of the little ones and includes added budget costs for specialty wall finishes, planters, playground and even a small cinema. The exterior finishes that Flynn are providing includes: waterproofing, roofing, plenum bases, green roof, steel deck, custom cladding finishes, custom aluminum shingle finishes and composite panel column covers. All products that the Flynn team excels at.

The local branch started the project by teaming with all levels within Flynn to tap into resources not normally utilized in their day to day operations. The process started late in 2015 with estimating and had Matthew Bielawski and Kevin Tuah of Shared Services working together with Saskatoon Branch Manager, Vernon Hunt, Construction Manager, Benjamin Smith and Saskatoon Roofing Manager, Sean Thompson in closing the tender and finalizing the sale of the project to the client.

Project management was resourced from the Vancouver branch along with drafting services. Kimiko Nakano and Ramon Labayo handled the drafting for the project’s metal finishes and roofing layouts. Alan Chui and Don Delaney of Toronto followed up with all engineering services for the project.

Fabrication of the custom aluminum shingles and composite panels to be installed on the project are being manufactured in Winnipeg by Adam Hodgins and his shop team. Long distance product shipping from the suppliers and manufacturers is being coached by David Ramdawar of Toronto.

Site safety planning occurred from the Saskatoon branch with Mark Novecosky and Laurie Rozak reviewing the plans and providing expertise to the trades and foremen.

On-site production started early in 2016 with foundation waterproofing performed by the Saskatoon Service Department. The work continued off and on until the fall with Jamie Birtley overseeing the crew assignments so nothing was lost in translation.

In October of 2016 the on-site production started with wall and roof vapour barrier installations for the client. Bart Kucher was assigned as the site based Superintendent and Allan Barnhill was hired as the Project Coordinator. The scope of work involves several areas of expertise that are rarely utilized by the local branch. Those include working from swing-stages and heat

It is a team effort that indicates the pride and true strength within Flynn. A company trait and process that occurs on more projects than we recognize. From estimate to installation – we are doing it the right way; the Flynn way.

applied wall membrane. As such the crews were trained for lifts, swing-stages and torch applied membranes before starting work on site. The majority of the work involves hot work permits for both roofing and wall systems. Due to this the roofing crew, led by Sly Baron and two lead hands, Justin Bomas and Matthew Fiddler, started all of the torch applied wall membrane.

The cladding crew is headed by Foreman Frank Bond and Lead Hand, Travis Redlich. Working alongside these tradesmen are a cast of characters that create the core of the metals group for the site production.

During the early phase of the roofing an addition was made to the team. Adam Gero joined Flynn as a Roofing Project Manager allowing for additional input on all roofing scopes as well as an extensive daily quality assurance review for the overall project. Further to the quality assurance program on the site, the team is also looking at growth and education for each and every member on site. This has led to requests of both Rick Lacey and Frank Kraus of OPEX being involved by sharing best practices, tips and tricks that can be useful for the project. The experience to date has netted steady growth in site team confidence and the ability of the site team to resolve construction issues.

Through resourcing the project team has attained the temporary services of metals crews from both Calgary and St. John’s. The crews and their leaders, Heinrich Ternes and Claude Slade, are road warriors for Flynn. Both crews bring with them extensive metal expertise and leadership.

Every project has individuals that work tirelessly behind the scenes towards keeping a project going and this is no exception as the Saskatoon branch support starts with the branch manager, Vernon Hunt, department managers, Rocky Luciw, Benjamin Smith and Sean Thompson. Then there are the people keeping everyone in check, the branch administration group headed by Marie Kirkwood and includes both Ashley Daniels and Nikki Padfield.

The Children’s Hospital of Saskatchewan is currently twenty percent complete and the number of individuals that have been working on the project continue to grow. The actual number of people that have had direct involvement, or have been involved in consultation, or that have had actual hands on work at site truly makes this a “Flynn team effort”. Now we understand that this phrase often seems overused. However, the realization that input from coast to coast has gone into this project, it is a team effort

that indicates the pride and true strength within Flynn. A company trait and process that occurs on more projects than we recognize. From estimate to installation – we are doing it the right way; the Flynn way.

Sales – Vernon Hunt, Sean Thompson, Matthew Bielawski and Kevin Tuah

Drafting, Design & Engineering – Don Delaney, Alan Chui, John Ngo, Kimiko Nakano and Ramon Labayo

Consultation – Mark Novecoski, Jim Karahalios, Benjamin Smith, Sean Thompson, Rocky Luciw, David Ramdawar, Devin Kardynal, Marceh Materi, Kevin Bereza, Craig Kucher, Jeff Small, Rick Lacey and Frank Kraus

Administration – Marie Kirkwood, Ashley Daniels and Nikki Padfield

Site Team – Sly Baron, Frank Bond, Justin Bomas, Travis Redlich, Matthew Fiddler, James Lathlin, Ross Edwards, Brad Turner, Albert Kubiak, Valeriy Ayvazyan, Colton Dubrule, Cordelia McKenzie, John O’Neil, Ricardo Mitchell, John Graf, Tomasz Debski, Konstantyn Melnyk, Janusz Kubiak, Georden Wilson, Josh Weiland, Kirtis Rogers, Dylan Ritzand, Chiril Dubceac, Bryce Friesen, Jeff Prosak and Shawn Chaboyer

Calgary – Heinrich Ternes, Shawn Ellis, Nick Acierno and Jordan Prendergast

St. John’s – Claude Slade, Sheldon Fitzgerald, Joshua Slade, Rodney Butt

Project Management – Laurie Rozak, Bart Kucher, Adam Gero, Allan Barnhill and Blake Merrick

Submitted by Drew Halliday

From March 5th to 7th a record breaking snow storm hit Southwestern Manitoba, with heavy winds 90km/hr, and temperatures that reached around -38 C with wind chill, and a large amount of snow and ice. This stranded over 60 motorists on the #1 Highway overnight and into the next day just outside Brandon near Alexander, Manitoba. Brandon Branch Foreman Dave McGregor, who lives in Alexander decided to jump into action. He strapped on his snow shoes, packed a bag with water, snack bars and other supplies. Then he headed out 5km to where the vehicles were stranded, handing out supplies to everyone that was in need.

After running out of goods he then returned to town, where the community of Alexander had started to gather essential supplies and setting up at the local school to receive the men, women and children who were stranded. Everyone from the Brandon Branch and Flynn would like to give a big shout out to Dave and his family for stepping up to the plate and helping people in a time of need!

Submitted by Drew Halliday

The team taking some time to do some carlisle training.

Submitted by Drew Halliday

From left to right: Jordan McGregor, Jon Neapew, Roman Kurowski (Soprema trainer), Dave McGregor, Randy Monkman, Larry Neapew, Marlow Deaffie, Dan McLean, Scott Lavallee, Johny Quevedo, Drew Halliday and Joaquin Salazar

Submitted by Greg McCulloch

The Cornwall Village Seniors complex is a 12-storey building in the heart of Regina. Kalman Redwood and crew will have their challenges on this 7,000 sq. ft. job with multiple roof sections, some with steep structural slopes, multiple roof systems, multiple decks, and of course, Regina’s famous prairie winds. The project calls for all existing systems to be removed to deck and replaced with a new Firestone EPDM system.

From left to right: Joe Crane, Andy Maxie (behind), Kalman Redwood, Erwin Woodward, Moses Cappo, Val Ntabindi, Ron Kragh, and Rick Peters

For Mentorship Matters we are continuing to recognize our mentors in the field. Of course our mentors in the field are more appropriately called coaches, because they focus more on skill transfer. This edition’s Mentorship Matters recognizes Joe Neiva, who has been a Foreman with the Toronto branch for 20 years. We sat down and interviewed Joe and many of the people he has influenced and guided throughout his career. It soon became very clear that Joe’s patience and coaching had helped shape the next generation of coaches at the branch.

I have been with Flynn since they bought Peerless in 1997, so 20 years now. Before that I was with Peerless since 1981, so I have been at this for near 40 years. I’ve had a lot of guys on my crew, and I’ve tried to be a coach to them. Some guys just need a hand, so you take the time to show them the ropes. They are going to screw up sometimes, but when that happens, you talk to them, and hope they don’t screw up again, or if they do screw up, it won’t be as bad next time.

I’ve found during my time here that some guys really have the DNA for this job, they have it in them to succeed. These guys want to learn, they want to do something. So you need to take the time to build a relationship with them, talk to them, get to know them, get them comfortable being part of the crew. If you give them a hard time they are just going to leave the crew or quit.

The number one thing to remember when bringing on new guys is patience. Things are not always going to succeed, people are going to screw up, and jobs are going to have problems. Be patient. Things will get better.

Patience is my key to success with training the new guys. Which leads to the reason why I have been successful, having a good crew. You are only as good as the people around you. I attribute my success to my crew.

Getting with Peerless in 1997 was a crossroads time for Flynn in our history. This was a BIG DEAL for us, as Peerless was about a third bigger than Flynn at that time! It was an exciting, yet scary point in time; we didn’t have much room to stumble or any wiggle room at all. Things had to work, and they had to work fast.

The day I met Joe Neiva, not long after closing, was the day all fear was removed from the equation for me. I had full confidence that we were going to be just fine.

Anyone who knows Joe will talk about his patience and his calm demeanour. In addition to that, I saw as natural a leader as I had ever seen. Joe leads by example, and just does the right thing. Whether for a new employee, his crew mates or the customer. Joe is consistent, authentic, and leaves everyone with a confidence that this man knows what the heck he is doing!

He is also low ego, and is more likely to give credit than take it.

Joe has been a wonderful mentor to many in this company for a long period of time, and is most deserving of this recognition.

Thanks Joe! For all you do.

~ Doug Flynn, President and CEO“The first time I met Joe was when he was still with Peerless, I met him on a job at Queen’s University, and the crew that was in place was not keeping up with the schedule. The management team at the time brought Joe and his team in to take over. The job went from an ok job, to a highly productive job. You can tell a job has been done by Joe’s crew just by looking at it.

We couldn’t have a better foreman, always calm, collected, and understanding, he knows how to talk to people, and he knows how to manage people. First guy in, last guy out. There is no job that was too tough for him. He is up for every single challenge, he never says no, and his team follows his lead. When I first started at Flynn about 20 years ago, he really helped me out. He helped make sure my mistakes were minimized. He told me what I had to do, and he taught me a lot. Guys like Joe showed me what it takes to make it in this business, and that you do what it takes to get the job done.

Joe always holds to his commitments. He is a leader, and he sets a high bar for the foreman at this company.”

~ Paul Manchisi, Vice President Operations“From a coaching perspective Joe is a person who listens, he looks at your capabilities and will help you out in the areas that he thinks you are the weakest in. He never goes off the deep end and gets upset at anyone, he is a very calm individual.

When I first met Joe on the roof, I didn’t know him, and he didn’t know me, but by the time I left I felt comfortable with Joe. He was willing to show you that it does not matter, field or office, we were both from the same company working towards the same goal.”

~ Marcel Perri, Vice President Business Development“Joe has been around for a long time, and has a lot of experience, in particular he has a lot of experience dealing with different personalities. He’s pretty patient, which is a good quality to have when training the new guys. He is fair, and the guys respect him, so they listen to him. They take what he teaches them, and they run with it.

There is no yelling and screaming on Joe’s jobsite, everyone knows what they are doing. A lot of sites there are people screaming back and forth, but on Joe’s site it’s pretty calm.”

~ Stefano Panarisi, Construction Manager“Joe is my brother, we have worked together for many years, since the 80’s. He is a good guy to work with. He spends a lot of time with the new guys that he brings in, because he knows that they need help learning the trade. He is far more patient than I am, and you need to be patient when you are training the new guys. He must be doing the right thing, because Joe’s crew has produced a lot of foreman for Flynn.”

~ Arlindo, Roofing ForemanJoe exemplifies “The Flynn Way” in all aspects. I have had the pleasure of working with Joe on various projects over the past 20 years and I can truly say that Joe has been not only a mentor to my career development, but also too many of our foreman and office personal employed today. Joe has always demonstrated true leadership qualities over the years. There hasn’t been a project that I can remember where Joe was not ready for a challenge and when called upon Joe gets the job done. Joe’s ability to inspire those around, his demeanor and tenacious work ethic are second to none. I can truly say that the most inspiring leaders are the ones who walk the talk and Joe does just that! On behalf of the Flynn Group of Companies I am proud to say that Mentorship does Matter and Joe deserves accolades for his many contributions to this company. Well done Joe!

~ Mark Agius, Branch Manager - Toronto“

Joe is a coach to a lot of the guys who come on, he will teach anyone, and will help you as much as he can. He makes a great coach because he is always calm, he is the calmest man you will ever meet. He never shows he is under pressure, as a foreman, I try and be like him, he is a role model.”

~ Filipe Cunha, Roofing ForemanThe crew involved on the project were: Gary Potter, Keith Hepditch, Chris Chapman, Fernando Giardino, Jason Pollock, Mykal Chapman, Avery Green, William Butt, Chris Hunter, Rocky Domingo, Urmo Pani, Dylan Potter and Jesse Gillard.

Submitted by Ian Alvarado

The Suncor Fort Hills Surge & Conveyor Crushing Plant 1 & 2 project has just been recently completed. The scope of work involved supplying and installing fire bricks, seal penetrations, ice rakes, gutters and downspouts. With the original scope being ahead of schedule and on budget, Flynn Industrial was awarded with additional scope. Upon the completion of the original scope, Flynn Industrial was awarded with a major roof repair of the Surge Building.

Submitted by Mark Pearson

Flynn has partnered with Truman Development Corporation to provide the full building envelope on the Kensington Legion project which has made national news due to the unique arrangement Truman has made with the Kensington Legion. Truman will receive the land that the existing Legion sits on for future development in exchange for the new building currently under construction on the same property.

The entire Flynn team is hard at work to finish the project on time and on budget, while keeping safety and quality as top priorities, by achieving these goals there is a very good chance we will be awarded the next project on this site.

*Missing Paul Jones and crew (Roofing) & Scott Tanner and crew (Glazing)

Submitted by Mark Pearson

Flynn Canada is the prime contractor on the job for a tower retro fit. There are 29 floors of aluminum hidden fastener panels and composite metal panel on the job. Flynn Canada performed asbestos abatement work to prep structural base plate locations for structural frames which are installed by our structural steel subcontractor. All four sides of the building have been fitted with mast climbers and custom profiled platforms to accept the zig zag contour of the building. We have hired a full time safety representative to ensure all safety precautions and measures are followed by both Flynn Canada and Flynn Canada subcontractors on site.

Submitted by Jordy Ryhorchuk

Flynn Canada Edmonton Metals Division is currently working on a design/build contract for the Stanton Territorial Hospital Renewal Project for the Owner, Stanton Territorial Health Authority in Yellowknife, NWT.

This is a two phase project for 2016/2017 that is extensively planned out with continual coverage of 21/7 shifts for the men. Phase 2 for 2017 is to fabricate, supply and install approximately 80,000 sq. ft. Accumet System 2000 Panels, 20,000 sq. ft. Face Fastened ACM Assembly and 6,000 sq. ft. of Longboard Woodgrain Panels.

Best of luck on the project team, look forward to seeing it complete!

Submitted by Kerri Zacharias

The team in Edmonton were working on the Capital Paper Recycling building. The scope of the project included 2,800 sq. ft. of multi coloured composite aluminum panels including wing walls and wing wall caps, plus 22,200 sq. ft. foam panels.

Not seen in the photo but who put in a lot of hours to get this project completed: Adam Buttery, Bryan Collier, Charles Washburn, Cory Steinburg, Daniel Wasikiewicz, Darryl Saindon, Dmitry Karpov, Larry Rolinger, Lynn Schmuland, Maksym Kononenko, Mark Barkley, Rock Langevin, Sage Coburn, Sylvester Mensah, Tomasz Kurzeja, Vladimir Semenkov, and Zach Bunzenmeyer

Submitted by Kerri Zacharias

Our crew recently completed panel work for the local fire station. The scope of the work included 1,900 sq. ft. of Composite Aluminum Panels (custom white) and 2,600 sq. ft. of Extruded Terra Cotta Clay Tiles (red). The titles were brought in from Germany and give the final product a striking look.

Submitted by Kerri Zacharias

The crew in Edmonton is currently working on a recreation centre. The project involves 4,600 sq. ft. of of exposed fastener Trespa Phenolic panels, which are blue lagoon and amber in colour.

Submitted

by Michael Petch

by Michael Petch

Each day on the job site brings about a variety of working conditions – varying temperatures, humidity levels, wind speed, material thickness, and substrates that we’re working on. On thermoplastic roofs (TPO, PVC), the seams are critical details that make or break the long term performance of the roof system. Properly done, the seams are the strongest part of the roof system.

EFAP health coaches are Registered Nurses and Occupational Health Nurses who offer practical, personalized support for physical health issues. You and your eligible family members can receive support through online resources or telephone consultations on a variety of topics, including:

• Nutrition

• Naturopathic

• Smoking

Cessation

• Health

Coaching

• Stress

Call for confidential and immediate support:

Canada: 1.844.880.9142 and workhealthlife.com

US: 1.800.272.2727 and workhealthlife.com/us

Because of the varying site conditions, equipment age and condition, and the importance of seam performance, test welds need to be completed at least twice a day. Complete your first round of test welds with your robotic welder just before you begin welding field seams for the day. Frank Kraus demonstrates how, in an OPEX best practices video posted flynncrew.com

Remember to perform another round of test welds after lunch break, or when weather conditions change. As always, probe all seams and install cut edge sealant at all non-factory edges on a daily basis. Each day, save the optimal weld test patch in your toolbox so consultants or manufacturers can see them if requested at a later date.

Submitted by Kim Gaskill

Flynn Kelowna is now working on the second side of this building. The first half was awarded to us in December, and it went very smoothly. Upon successful completion of the first phase, we were awarded the second half of the roof. Pepsi has been a fantastic customer and very easy to work with. It is the first opportunity in quite some time for our team to install a 60 mil reinforced EPDM roofing system that is mechanically fastened. An elaborate engineered gutter system is also being installed. The crew, to the consultants’ and the Pepsi representatives surprise, completed half of the roofing in just one day!

Submitted by Kim Gaskill

This project was awarded to us in the winter and the crew battled inclement weather conditions to accommodate the customer’s tight deadline for completion. Ultimately, they did meet their deadline and were able to finish on time. Due to the extremely tight schedule, this project was all hands on deck and several members of our production team pitched in to help. Service Foreman Sean MacInnis, successfully led our team and worked hard to ensure that the customer received consistent service and a quality finished product. The roofing system was a combination board and base ply mechanically fastened with SBS cap ply complete with adhesive and gravel coating.

Submitted by Kim Gaskill

The most unusual part of this project is the system that we are using. It will be the first hot-applied Tremco project that our crew has completed in the past three years. Another interesting item is that there are 13 different roof levels ranging 3,000 sq. ft. to 100 sq. ft. each. Access and public security are huge factors on this site. This will be the first project that we are completing for the City of Vernon and it is located right in the center of town so it will be quite a high profile. Coordinating the security for this project took a lot of effort from our team up front, but we are mobilizing quickly and looking forward to a successful completion.

Submitted by Jonathan

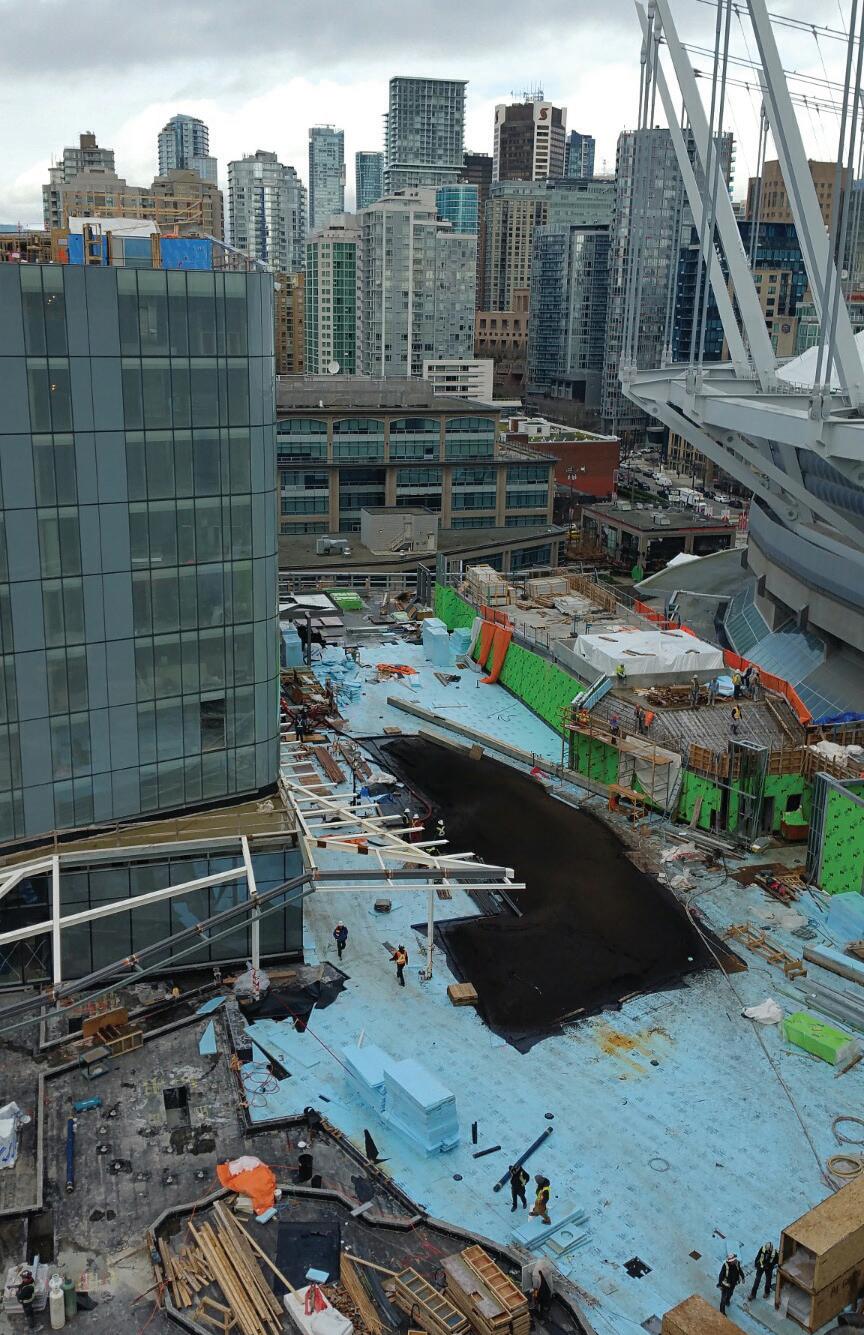

SimpsonThis project was a whole envelope design assist with EllisDon as the general contractor, it consisted of glazing, metal panels and roofing all by Flynn. The Vancouver roofing department installed over 80,000 sq. ft. of Carlisle TPO membrane. Roch and his crew worked over one of the worst Vancouver winters in living memory, and pulled it off on schedule. Several other crews and office coordinators helped make this project a success.

EFAP offers financial experts and online programs to help you take control of your financial future. You and your eligible family members can receive support through online programs or telephone consultations on a variety of topics, including:

• Debt & Credit

• Retirement

• Divorce

• Estate

• Termination

• Mortgages

• Bankruptcy

• Taxes

Call for confidential and immediate support: Canada: 1.844.880.9142 and workhealthlife.com

US: 1.800.272.2727 and workhealthlife.com/us

Submitted by John Ngo

Submitted by John Ngo

Flynn Vancouver is happy to announce the completion of the Evergreen Rapid Transit Line which was a two year project with 13 separate buildings that spanned across three cities connecting the Tri-Cities to the rest of Greater Vancouver. Flynn was responsible for the total envelope which included all types of glazing, composite panels, metal, TPO roofing, latchways fall protection, and snow guards.

Flynn was also tasked with installing and reinforcing various pieces of artwork within the stations which included two canoes, bicycle spheres, etched stained glass and a native wood sign. Special thanks to the massive team that help put this project together: John Ngo (Project Manager), Denise Francisco (Project Coordinator), JP Schmidt (Glazing Super), Rick Conniff (Metals Super), Brett Templeman (Glazing Foreman), Bryce Young (Metals Foreman), Chi Nguyen & Billy Yorke (Service – Roofing), Leopold Dallo (Estimator), Yanhua Sun (Senior Drafter), Rav Sandhu (Metals shop) and Justin Edmiston (Shipping/ Receiving) and Denise Francisco, Benjamin Hayes (Project Coordinator).

Submitted by Jonathan Simpson

Submitted by Jonathan Simpson

The Parq Resort and Casino is the largest private construction project in BC and scheduled to open in the fall. It is going to contain two boutique hotels and a casino with over 30,000 sq. ft. of public outdoor space on the level six podium. It consists of over 180,000 sq. ft. of SBS roofing, most of it is an inverted system.

With other trades doing the other envelope components, communication has been critical with the GC to ensure correct sequencing is adhered to. Several other crews have helped along the way and we hope to be completed ahead of schedule.

Submitted by Gary Stride

Flynn Canada was awarded a multi-scope work package (roofing, panels and siding) on this project several years ago. Shawn Mason led our Victoria team on the original construction phase. Now JJ Boudreault and his service crew have returned to this project to carry out some tenant improvements to meet the facility’s ongoing and changing needs. Team members must undergo security screening prior to accessing this site.

The 443 Maritime Helicopter Squadron is a division of the Royal Canadian Air Force. The fleet of six CH-124 Sea King Helicopters are deployed throughout the North Pacific, South Pacific and Indian Ocean. Operational requirements will at times dispatch the helicopters to other parts of the world as well. These deployments are in concert with the Royal Canadian Navy and are assigned to the Pacific Naval Group’s Maritime Coastal Defense Vessels.

Submitted by Gary Stride

Nothing defines a Canadian as much as back bacon, the RCMP, the Maple Leaf, the Toque and a good ol’ game of pond hockey. A lunchtime game broke out beside the Victoria BC office when an infrequent episode of artic air invaded and plunged the temperature low enough to create a playing surface. Given the obvious lack of PPE, they were lucky to come out of it unscathed.

From left to right: Metals Foreman

Shawn Mason, Jason O’Hanley, Dylan

Solecki, Roofing Foreman Wahib

Othman, Glazing Foreman Shane Blyth, John Glassey and Rob Newell.

*Missing: Ryan Van Bree and Glazing

Estimator Cody Daku

The Empress Hotel is a world famous iconic architectural landmark that is prominently located in downtown Victoria, BC. This 464 room hotel is once again being renovated and Flynn is tasked with the finishing of a new construction “Porte Cochère” at the front entrance of the building. Our main scope of work is glazing with some associated architectural metals and roofing. At the time of writing, our crew has not, or may be reluctant to report any encounters of ghosts within the Empress.

In 1989, a massive renovation was carried out on the hotel as well an addition to the north end. It was the single largest renovation project in Canada’s history at the time. Several ghosts are said to inhabit the hotel. Hotel staff and guests claim that they have seen the ghost of Francis Rattenbury in the archives located in the basement of The Empress and on some of the upper floors.

The Roofing (torch-on built in gutters) is assigned to Wahib Othman (Roofing Foreman) and Dylan Solecki; Metals (standing seam roof and longboard soffits) are looked after by Shawn Mason (Metals Foreman), Jason O’Hanley and Ryan Van Bree. Glazing work is being carried out by Shane Blyth (Glazing Foreman), Rob Newell, Cody Daku and John Glasser.

JOIN 1500+ ACTIVE USERS

CONTESTS BRANCH NEWS

CAREERS BENEFITS

ANNOUNCEMENTS