A FOCUS ON FLYNN GROUP OF COMPANIES’ CREWS AND PROJECTS Don Flynn

As many of you are aware, we have undertaken some significant growth over the past couple of years as a North American company. We have continued to enjoy steady organic growth in Canada, along with significant geographical growth in the U.S. In fact, with the latest addition of D & D Roofing and D & D Monarch Sheet Metal in Denver, as well as our new office in Lubbock, Texas, we now have 675 employees in the U.S. where less than two years ago, we had none.

No doubt, that’s a lot of growth! But actually, I consider this controlled growth, mainly because in almost every case, high quality leadership has accompanied the growth.

Speaking of leadership, I can say with certainty that every company I have ever come across, in any business sector, is either successful or not successful based on the effectiveness of its leadership. And I am not just talking about leadership at the top – every company needs the right kind of leadership at every level of the organization to be successful.

With this in mind, I am pleased to report on two relatively new leadership development initiatives for both management and field leaders, both being managed under our “Flynn University” umbrella.

Flynn University for Next Generation (Management Focused): I recently attended our kick off conference for FUNG. It was attended by 75 management employees who are mostly millennials, who have been flagged as people who have significant future leadership potential. I was very pleased to learn that we had to cap the attendees to 75 due to the limitations of the venue, and that we actually have quite a few more who fit the criteria for attending FUNG. The next FUNG conference is planned for early 2017. The good news in all of this; we have the bench strength to support all of the amazing opportunities that continues to come our way.

Flynn University for Frontline Coaches (Field Focused):

Our next field based leadership development initiative is called FUFC and is expected to kick off mid-year. This module is, to some extent, an extension of “Flynn University for Frontline Leaders” which has been attended by over 300 of our Foremen, Superintendents and key field people across the organization. FUFC will focus on how to effectively coach inexperienced general labourers, which after all is where our future field leaders will come from! This training is all about building a quality workforce and reducing turnover. It will also be supported by a mobile application, to track progress and help our “coaches” remain organized.

On page 16 of this edition of Flynn Flash, you will find an update on all current and future Flynn University programs. As a company, we buy into the notion of investing in the leadership development of our people at every level. Make no mistake, there is a considerable monetary investment in the short term with all of these efforts, but we know that the long term benefits will be worth it. We know that the best investment we can make as a company is in YOU! After all, the business does not lead itself; it takes qualified, motivated and inspiring people at every level.

Keep an eye out for some of these leadership development opportunities, and if you would like to participate, ask your supervisor or local HR rep for some coaching.

Until next time,

Stay safe!

Doug Flynn

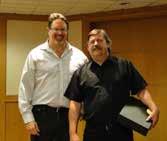

In January, Flynn Group of Companies merged with D&D Roofing and D&D Monarch Sheet Metal in Denver, Colorado. The company is now the third branch for Flynn Southwest, LP. D&D Roofing was established in 1977 and serves as one of Colorado’s top two largest roofing contractors. They provide roofing, architectural and sheet metal fabrication and installation all over the Rocky Mountain region. The company is headed by Rob McReynolds, Vice President of Denver Operations, and Ty Mattern, Vice President of Architectural.

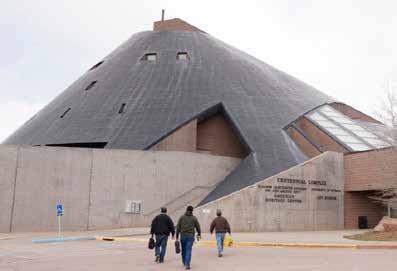

They boast many LEED certified and award-winning projects. They were awarded “National Project of the Year” in 2014 for the American Heritage Center at the University of Wyoming. Since 1998, they have also been ranked nationally among the top 45 roofing contractors in the US by RSI and Roofing Contractor.

We are proud to have such a quality company with the cultural fit to join us as we expand into this new and exciting marketplace!

Submitted by Megan McReynolds

Last year, Denver’s project for DPS Thomas Jefferson High School was awarded Gold by Asphalt Roofing Manufacturer’s Association (ARMA) at the fifth annual Quality Asphalt Roofing Case Study Awards. This 110,100 sq. ft. job consisted of a BUR system tear-off down to the steel deck and installing a Johns Manville Spec 4GIG BUR roof system.

Submitted by Josh Rygg

The scope to be completed on the Fairmont Princess Guestrooms is 180 squares of Fleeceback TPO over lightweight concrete. The Fleeceback will be installed directly to the lightweight using a spray rig with FAST 100 as the adhesive.

Submitted by Megan McReynolds

Last year, our newly acquired branch in Denver, Flynn D&D/Monarch, had won a national award from the National Roofing Construction Association (NRCA) for the American Heritage Center in the "Innovative Solutions" category. These innovative solutions included a scaffolding system that D&D designed to encapsulate the entire odd shaped structure. The system was designed to be adjustable in height to allow for the removal of old roof and the installation of a new roof, all the while continually carrying the load of all the new materials and maintaining a safe working platform for all of the employees. D&D fabricated all 15,000 metal panels in the shop and also installed all of the windows, flat roofs, and skylights.

Not pictured:

Submitted by Josh Rygg

The scope to be completed on the Victory Club is 20 squares of standing seam metal and 370 squares of both mechanically seamed flush mount wall panels and corrugated wall panels.

Flynn Southwest will also complete five squares of wall panels, four chimneys, and 250 squares of standing seam roof panels.

Submitted by Josh Rygg

For the roofing scope on Liberty Wildlife, the crew will use a Firestone torch applied system on 180 squares. The scope of work will include installing crickets with insulation, 1.5 inch insulation board with two layers of touch down over the top, installing three gutters and over 500 pipe penetrations for a solar power system on the roof. The metal shape is 30 squares of copper metal, a flush wall panel system, fascia metal, window and door trim.

From left to right: Raul Gonzalez and Walter Morris

Not pictured: Antonio Soto Bezarra, Saul Mireles, Ernesto Hernandez

Safety has been of utmost importance here as the dome shape of the roof requires crews to be tied off at all times. Special thanks to Rob Morehead for his assistance throughout this process. Great job, guys!

Flagstaff Foreman Jay Riot with his 5 1/2 month old son, Azariah, who was born in Denver while Jay was working there on a Flynn project. Congrats on such a cutie Jay!

Congratulations to Antero Furtado who retired from Flynn London on July 24, 2015. For the last 15 years of his career, Antero and his crew would be up at Bruce Power for six to eight months out of the year. Antero was a great guy to work with and knew what had to be done. He will truly be missed. Production Manager Carlos Medeiros says “Enjoy your retirement with your family and thank you.”

Congratulations to Jose Moniz who retired from Flynn on October 27, 2015. London Production Manager Carlos Medeiros says, “Jose has taught a large number of people how to roof over the years and was a great mentor to the young guys. Jose was one of the hardest workers at Flynn London, and will truly be missed. Enjoy your new found love in your gardens Joe!”

Submitted by Dale Burns

Flynn Southwest is currently working on Little America, a motel in Flagstaff. The job is a wood shake tear-off and replacement with a 30 yr dimensional shingle EPDM, single-ply on all flat areas, plus new rain gutters and fascia wrap.

Minneapolis architect DLR Group has created a design for the transformation of Jordan Middle School into a student-centered facility with a breathtaking, clean, transformative atmosphere, providing students with a unique educational, developmental, and social environment.

Flynn Minneapolis Project Managers were instrumental in the development of a roof design, which not only cut cost to reach budget, but enhanced the roof design and better served the customer. Totaling 196,223 sq. ft., an improved fully adhered 60 mil EPDM roof system was installed.

The real visual transformation of the project came as sheet metal installation began. The schools’ exterior was clad with 27,000 sq. ft. of an insulated, intricate tri-colored Firestone Una-Foam metal wall panel system. The crowning touch to the exterior was the CNC machine-cut letters identifying the school into the phenolic wall panels at the entrances. The enhancements only started on the outside, following the insulated metal panel soffits transitioning into the building.

The exterior upgrade was complimented with the installation of 9,000 sq. ft. of phenolic panels in the schools’ interior areas and clad everything from elevator enclosures, stairwells, wall and ceiling highlights - all to provide the perfect accents to create a place for educational tranquility.

We are happy to introduce our latest Flynn Midwest, LP family from MinneapolisFlynn Dalco Roofing & Sheet Metal. Flynn Group of Companies merged with Dalco in April 2015, becoming the third branch in our US Midwest region.

Dalco has been around since 1945 and provides roofing and sheet metal services throughout Minnesota, as well as Wisconsin, Iowa, North Dakota, South Dakota, and Nebraska. These services include all roofing types and architectural sheet metal fabrication and installation, and is exponential to our progress in the US commercial construction industry.

In the past year, Branch Manager Dan Lewis and crew, and the Flynn team have transformed Dalco into an essential part of our US operations. We’re glad to have you on our team!

Dan Lewis

Dan Lewis

90,000 sq. ft. Women’s and Children’s Center and Neuroscience Center added to existing medical center building that includes roofing, sheet metal, and glass by Flynn.

This was a tear-off and replacement of a ballasted EPDM roof over a high trafficked, occupied, Walgreen’s store.

Submitted by Mark Webb & Blaine Williams

One of Kansas City’s largest projects this year is providing the total building envelope to Cerner’s new Three Trails Campus. This is the third Cerner’s campus that the branch has been instrumental in building, which includes the Continuous Campus in 2013 and Cerner’s World Headquarters in 1999.

In nine cold, snowy days over Christmas and New Year’s Holidays, the roofing crews of Kansas City completed one of their biggest and most difficult jobs of the year. The Ford Motor Company closes down production at their Claycomo facility for one week this time of the year for the Holidays and building maintenance. During this time, 60 Flynn crew members volunteered to give up their Holidays to ensure that this project was completed to Flynn’s standards of quality and safety. It is notable that during this project, the crew sustained zero injuries - not even a pulled muscle!

Weather and time constraint were only part of the challenges of this project. First of all, the setup area was 1000 feet away from the work itself. The work included a tear-off of 600 squares of coal tar pitch roof with fiberglass insulation - known to be a brutal task for any roofer. Of those 600 squares, 300 of them contained two roofs, totaling seven inches thick. Afterward, the crew installed one layer of 1.5 ISO mechanically attached, one layer of half-inch wood fiber

in low-rise foam, and one-ply of Siplast Paradiene 20 in cold mastic with hot air welded laps.

Mike Pierce, Roofing Operations Manager, said he got a call from Ford on Thursday, December 17th, at 7:00 AM asking him, “Can you do an additional 300 squares over the paint line in the allotted time?” The paint line is not only a completely different area from the work, but is approximately 70 feet tall. Before Pierce could answer that question, he needed to talk to his roofers.

“We asked who would or could give up their Christmas to work in a pitch tear-off at Ford. We did not feel that it would work any other way than to ask for volunteers,” says Pierce. “The answer was that out of our 60 available workers at this time, we had 42 available to work Christmas. So our answer was ‘Yes’.”

Starting at 4:00 AM on Christmas morning, the first crew tore off 90 squares of roof totaling 54 tons. The second crew began at 7:00 AM installing the new roof system. With the weather looking to be a real problem (an ice storm had hit), the crews made good on their promise to Ford and completed the job at 5:30 PM on New Year’s Day.

On December 31st, Pierce and Jerry Schaefer, Regional Vice President, visited the site to greet the hardworking crew. “To our amazement, everyone was upbeat and still going strong, knowing that they were just about complete with this high-pressured project. They really did an excellent job,” said Schaefer.

Pierce contributes the success of this job to the Superintendents, Foremen, and their crews, as well as to the support staff, purchasing, trucking, crane operators, and maintenance. Doug Flynn would also like to commend everyone for their commitment and customer service. Amazing work, everyone!

Not pictured: Charlie Holloway, David Gee, Jeff Frazier, Mario Blankenship, Vince Gallegos, Jason Ross, Van Burk, Donald Allison, Daniel Riddle, Chris Zearley, Steve Engstrom, Brian Watters, Jerry Caldwell, Eddie Verhaalen, Zach Wisdom, Dwight McCubbin, Felipe Aguirre, Justin Clark, Trevor Howard, Ken Lamming, Mike Forrester, Aaron Alsup, Corey Ashburn, Billy Smith, Gregorio Alvarez, Martin Dehn, Sam Abbey, Gary Marckel, Jordan Dehn, Travis Stillwell, Matt Cain, Brian Cain, James Pruitt, Ronnie Pruitt, Jeff Tucker, Jason Zearley, Russell Hillburn, Mike Shannon, Steve Frogge, Ron Morris, Chris Ishmael, Jim Hultman, Mike Mauk, Doug Sutton, Mike Pierce

Submitted by Blaine Williams

ATK is the world’s leader in aerospace and defense technologies. Kansas City Metals Crew works on remodeling their 60 year old brick building in Independence with insulated metal panels and style rib panels.

Submitted by Andrew McCoy

Thanks to the entire Baltimore team, this project has progressed smoothly. The new academic building at Washington College is an adequately designed project. The roofing consists of synthetic slate, half round copper gutters, flat seam copper, white EPDM, and metal trim. The Whiting-Turner crew has been great to work with, along with all of the other subcontractors. Great team work!

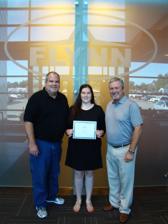

Congratulations to our eight scholarship recipients who each received $2,500 towards their post-secondary studies! Check with your local HR Representative to learn more about upcoming opportunities to apply for 2016 Scholarships!

right is Brian

(Winnipeg Branch Manager), Ilan Rubinchik (recipient), and Leonid Rubinchik (Glazing Apprentice). Ilan is attending the University of Manitoba

Victoria

Dave Flint (BC Regional Manager), and Braiden Cutforth (recipient). Braiden

Bachelor of Social Work.

Manager), Christina Mann (recipient), and Jerry Schaefer (Regional Vice President). Christina is attending Northwest Missouri State University where she will major in education with an emphasis on Special Education.

attending the University of Victoria with a focus on Engineering. Université du Québec en Outaouais where she is taking her Bachelor of Administration with a focus on Management and People Management.

The Flynn University series of programs are designed to accelerate the development of current and future leaders within The Flynn Group of Companies through the acquisition of critical business and life skills, which will benefit all participants and guarantee the long-term success of Flynn.

People are our most important asset. Our success is directly linked to our peoples’ knowledge, skills and motivation. Due to our rapid growth it is increasingly important that we continue to strengthen our culture, knowledge, and skills through the development of our leaders, at all levels.

All FU programs start with raising our participants level of self-awareness. Effective leaders improve themselves before trying to develop their followers. Developing context as to “where do I fit in”, is also critical in identifying what lessons need to be learned. This context comes from understanding ones role within a team and within the company which is influenced by the external environment.

There is just enough theory to set context and get started and then the focus is on collaborative learning which is hands-on and fun.

During FU 10 sessions, we invited four foremen to each group. It quickly became apparent that our Frontline Leaders were benefiting significantly from life skills training. It was going to take far too long training four foremen at a time to reach this key audience. FUFL was developed to accelerate Frontline Leaders’ exposure to key lessons contained in FU 10.

Flynn University for Frontline Leaders is an accelerated 2-day leadership program designed specifically for the leaders (and future leaders) of our field operations.

Status: On-going, wait list for FUFL18.

Flynn University for Service Excellence is a customized workshop which provides our Service Technicians with broader skills and expertise in client relations and the service management process. The workshop focuses on both administration and procedural issues as well as communication, customer service, problem solving and relationship building. A custom video has been made which will reinforce these key lessons. Half of the session will also be dedicated to the Service Mobile Application.

Status: Rollout 2016!

Flynn University for the Next Generation is a conference that will connect future leaders within Flynn and equip them with some of the tools necessary to facilitate their growth. This program is uniquely adapted to the needs of Generation Y and will explore topics of interest to this group such as strategy, culture, personal branding, self-development, teamwork and mentorship.

Status: Rollout January 2016!

Flynn University for Frontline Coaches builds on Flynn University for Frontline Leaders. This program focuses on how to effectively coach inexperienced general labourers to engage this group, reducing turnover and building a quality workforce. It is supported after training with a mobile application.

Status: Rollout 2016!

The first Flynn University for Next Generation or FUNG as it is now better known as took place in January at Kingbridge Conference Centre in King City, Ontario. The purpose of the conference is to connect future leaders within Flynn and equip them with the tools necessary to facilitate their growth, exploring topics such as strategy, culture, personal branding, selfdevelopment, teamwork and mentorship.

The following people were in attendance: Nicole Ewing, Natasha Farren, Bryan Fink, April Luscombe, Theresa Thomas, Dan Rayner, Trevor Murl, Sarah Woolverton, Craig van de Merwe, Jeff Roy, Megan McReynolds, Khalid Abou-Morad, Steven Clark, Patrick Olszak, David Van Happen, Steve Monteith, Griffin Beauregard, Will Pierce, Jason Nowell, Jason Vincent,

Craig Colgan, Carlos Dias, Matt Pierce, Mike Carter, James Spann, Ann Trave, David Blake, Stephanie Bartlett, Nathan Lee, Serge LeBlanc, Brendan Walsh, Kyle Kennedy, Philippe Thivierge, Antoine Levasseur, Michael Quesnel, Jennifer Rockburn, Ian Anderson, Bobby Baker, Jon Federko, Brittany Steptoe, Lena Hellyer, Sean Thompson, Brandon Grunow, Ian Barrett, Rob McMillan, Katie Dolan, Alan Zych, Brandon Patrick, Farhan Hafeez, Tavneet Sethi, Irene Neureuther, Latoya Francis, Matt Bielawski, Les Chan, Aimee Eden, Matt Jones, Mark Martins, Anthony Roti, Cassandra Toffolon, Paul Walker, Steven Ordonez, Chris Voogd, Phillip Ciantar, Alan Chiu, Sheela Murday, Farhan Aslam, Scott Watt-Harrison, Amita Aulakh, Hugo Huynh, Rou Golsheh, John Ngo, Derek Beingessner, Derek Matthews, Jeff Clarkson and Chad Keating

Check with your local HR Representative for more information about future Flynn U and FUNG programs.

Submitted by Anthony

UpwardsJohn Fleming (Foreman), Brandon Fry and Matthew Sheppard are pictured at Paradise School in Paradise, Newfoundland. This is a new construction project and work includes installing air vapour barrier, insulation, z-bars and composite panel/metal siding. Construction started last fall and will likely continue throughout the winter.

Submitted by Anthony Upwards

The crew is working on a re-roof at Pinetree Apartments located in Gander. The area is approximately 7000 sq. ft. that was damaged by a severe storm in January 2015. They are installing a 2-Ply modified bitumen roofing system adhered in hot asphalt. The owner and his representatives have been pleased with the completed work and as a result, we are now in the process of negotiating additional repairs/ roofing on this same complex. Great job to Mike and the crew!

Submitted by Jeff Spurrell

Halifax is growing again, this time with a new military building on the CFB Halifax site.

The facility will be a housing and training facility for Junior Ranks personnel at CFB Halifax. It is intended to be a LEED Silver project upon completion.

Flynn is undertaking two scopes on this building: glazing and metal cladding. The glazing scope entails punch windows and curtainwall, along with the exterior guardrails, glass canopy and glass stairs inside the main lobby. The cladding will be blue and grey profiles at high elevations and at the ground level.

The Halifax waterfront will provide challenges to our crews; winds are usually high in this area and this project will not be immune to their effects.

From left to right is: Brandon Rohde, Kyle Holmes (Glazing Foreman), Trevor Millet, Mark Ramey, Bryan Coudy, Patrick Rideout, Clarence Dominix, Peter Westhaver, Triston Pattison, Robert MacKinnon (Architectural Foreman) and Jamie Cox.

Submitted by Kyle Kennedy

Winter work is nothing new for the guys at Flynn’s Moncton branch! It’s a given to see cold temperatures and snow four to five months of the year in New Brunswick, and the crews are all well at home in it. Roger LeBlanc’s crew is shown installing an EPDM roof on an addition to a cold storage plant. The job wrapped up in January.

Submitted by Kyle Kennedy

Flynn was called into a tissue plant to clean up a roof full of tissue paper that had blown up onto the roof from their exhaust vents. The job expanded after the guys performed a roof audit and several test cuts. As a result of the audit Flynn made multiple repairs including the replacement of a section of rotten steel deck to ensure the roof was water tight for the winter. Irving tissue has since agreed to use Flynn exclusively for all their service related work going forward.

Submitted by Kyle Kennedy

Jean-Noels crew from the Moncton branch is always willing to lend a hand when needed. The crew was brought in to supplement manpower on a large Atlantic Superstore re-roof to help a maxed out Halifax crew (Foreman’s Jeff Haslet and Ryan Lunn) - A great example of Flynn’s ability to parachute crews where ever and whenever the need is.

Submitted by Jason Vincent

Submitted by Craig Colgan

Flynn was contracted by PCL to perform 1200 LF of perimeter repairs to an existing EPDM roof to extend its life. The crew battled through the snow and cold temperatures to bring the project in on schedule and budget. Great work guys!

Crews are wrapping up a 1200+ square EPDM recover, and 200+ shingle replacements. Ryan Lunn and crew, are missing from the photo as most of them are at Apprenticeship Level 2 for Roofing. After receiving 30+ cm of snow, the crew dug themselves out and managed to lay a section of roof in the afternoon. Way to go guys!

Vice President of the Atlantic Region, Eric Veniot, took a moment to reflect on the win. “It’s hard to have a personal feeling about it because it’s such a team award but it feels fantastic – it’s a huge achievement that we are very proud of. This award is a reward to all of our guys in the field - for their effort and accomplishments and commitment to our safety culture that has grown over the years.“

Eric knows a thing or two about how safety culture has grown both in the industry in general, and here at Flynn. Eric began his career in construction in the early 80’s. “I was a young fellow who moved to Calgary from the East Coast looking for a job and was hired as a glazier. I showed up on site with a uni-driver in my back pocket not having a clue what was going on. Twenty seven years later of field work, I grew through the safety culture and saw how due diligence became an important process. It was a slow process of acceptance, but once people started to see how important safety was, it slowly became number one and everyone started understanding why it had to be number one. Being part of that growth has helped me explain it and get the message across to our guys and anyone I discuss it with because I’ve grown and evolved with it,” he said. “The bottom line is that without a safe working environment for our crews –– success just isn’t possible. We need to make sure everyone gets home safe. We set the bar high, but it has to be that way.”

To celebrate their hard work and dedication to our safety culture, the branch decided to head to Tree Go – an “aerial adventure” as they call the series of obstacle courses and zip lining that takes place literally in the tree tops in the woods, with each “level” increasing in difficulty…. all while using a harness and safety cables of course. The safest branch in the country takes their safety seriously both on and off of the job site.

Later in the evening, everyone reconvened at the Old Triangle Irish Alehouse for steak and lobster dinner, oyster shucking, live entertainment and the official award presentation.

The Don Flynn Pioneer Safety Award found some comfort on its trip to the East Coast of Canada in 2014; it went from St. John’s, Newfoundland, to its new home for 2015 in Moncton, New Brunswick!

“Believe me when I say it’s a tough award to win. To win this award means everyone here takes safety very seriously and does the right thing every single day,” said Doug Flynn before the New Brunswick Flag was lifted to unveil the trophy they were waiting to see and feel.

Eric Veniot sees a strong similarity between the culture in the province of New Brunswick, and our safety culture at Flynn. “New Brunswick is a very diverse, harmonious, bilingual province with rich culture – we call it the Moncton branch, but we have a shop in Fredericton that is a very important part of our processes and success in Moncton. For our Moncton based crews – a large majority come from Bouctouche. In both these, areas and all throughout New Brunswick, everyone looks out for one another. It’s a good feeling – a real family feeling – to know that you are taking care of your brother and he is taking care of you.”

So what comes next after you reach number one? Eric says, “The next steps are to win it again as anyone would like to – but we’re going to focus on maintaining that standard, to not become complacent, to continue to be proactive – and to contribute at our branch and Flynn as a whole in any way that we can. We will lead by example – especially for any of our new branches coming on board. It shows how important safety is here and how we place the safety of our crews as number one. Without a doubt it has to be. That’s the message we would like to get across to everyone and keep strong.

Eric also said while a lot of people come in and out of Moncton for business, he’s looking forward to the annual video which captures the surrounding areas and the great things they have to offer. Stay tuned for the video that will be shown at your 2016 Annual Safety Meetings and will then be available on flynncrew.com once your meetings are complete!

Submitted by Francis

LabonteForeman André De Sousa and his crew of nine workers completed this project at the end of February after 15 months of hard work that consisted of the installation of curtain wall extrusions (10 inches deep) with triple glazing panels, structural silicone and decorative aluminium extrusions. One of the biggest challenges encountered by André’s team was the building’s different shapes - almost none of them were square. A lot of crane hours were required for the realization of this cool project with an incredible visual finished product!

The Project Director was Pascal Norris. André would like to thank the whole team for the hard work that they’ve put in over the last 15 months on this project. Great job to all involved!

Project Manager Ian

Aloysius and ForemanMartin Morin and his team have been working on this 40 storey condominium complex in the heart of downtown Montreal and one of several towers going up around the Bell Centre - home of the Montreal Canadiens. The general contractor for this project is the highly respected Pomerleau Construction. This project consists of unitized curtain wall system fabricated and assembled by Flynn Manufacturing, situated in Mississauga, Ontario and part of Flynn Group of Companies and a stick system for the balconies fabricated by Vitreco. Our installation is currently on the 38th floor and we expect to have this project complete by June 2016. Martin Morin has been involved in the construction of many multi-storey complexes in Montreal over the last couple of years. Congratulations!

Started by Foreman Phylippe Masson and successfully completed by Donald St-Pierre with a team of close to thirty glaziers, this condominium complex situated in the city of Lorraine in the greater Montreal, consists of bottom to top curtain wall with opening insertions, vents and heating exits and louvered panels. This project was completed even with some issues of tight deadlines, apartment owners moving in and some very restricted land to work on. The Project Manager was Pascal Vanasse. Congratulations to the whole team!

Submitted by Francis Labonte

Pictured is Vitreco/Flynn glaziers Gabriel Soucy, Daniel Tanguay, Sébastien Lewis Croteau, Jean-Pascal Guimont, Sylvain Duchesne, Phylippe Masson and Francis Labonte after their First Aid and CPR certification classes that occurred during the last weekend in January. More workers were certified on the week-end of March 12th and 13th. Great job!

Submitted by Richard Martel

Flynn Ottawa’s glazing division is currently acting as the general contractor on this interesting skylight replacement project at Portage 111 (in Gatineau, Quebec) for Brookfield GIS. A Quebec based subcontractor is installing the second skylight for the final phase. The skylight material was supplied by IBG Canada and Multiver. A large exterior enclosure and a four story interior structural scaffold made it possible for this project to meet its schedule during the winter months.

Submitted by Giacomo Zanabria

This $2.5 million project involves the installation of exterior wall assemblies at the new maintenance and storage facility and shed buildings.

The maintenance and storage facility is 11,000 sq. ft. of 3 mm Aluminum Axiom Plus Panels and the shed is 70,000 sq. ft. of Kingspan Insulated Metal wall panels and 3,000 sq. ft. of continuous blade louvers.

Installation includes all components including air/vapour barrier, insulation, sub framing, flashings and miscellaneous items.

The Ottawa Metals Crew is working hard at this $2 million dollar project covering the installation of exterior wall assemblies at the East and West building additions. Work includes: 25,500 sq. ft. of 8 mm Fibre Cement Panels, 8,700 sq. of 22Ga Urban Accent metal wall siding, 5,000 sq. ft. of Trespa Phenolic soffit panels, 1,200 sq. ft. of Alpolic composite aluminum panels and 2,200 sq. ft. of Tenplus roof screen louvers. Installation includes all components including air/vapour barrier, insulation, sub framing, thermo clips and flashings and miscellaneous items. Wall assemblies are in progress, peel and stick, insulation and thermo clips are 90% complete on the West addition, and siding is in progress. The East addition is still in the early stages.

The production crew is working on 52,900 sq. ft. of two ply modified bitumen and 14,400 sq. ft. of hydrotech green roof system. Challenges include doing 27 different additions to the Hospital! Great job to all involved!

Forman Pedro Costa and crew (Dominic Girard, Jun Palma, Armenio Raposo, Jesse Merritt, Kyle Culp, Paul Costa, Terrance Gilroy and Jason Oliveira) are busy working on Horizon Utilities in downtown Hamilton. This project includes removing and disposing of the existing roof and replacing it with approximately 373 squares of 3-ply Composite set in Tremco Burmastic. It is expected to be completed in April.

Submitted by Josh Bowman

Submitted by Josh Bowman

In conjunction with general contractor Firstcon Construction, Saucier + Perotte, ZAS Architects, this project consists of approximately 58000 sq. ft. of HF11 and HF12 steel siding walls and soffit, 1000 sq. ft. of Aluminum Plate Panels, and 3000 sq. ft. of zinc roofing, walls and soffits.

Challenges included meeting the architect’s vision of a high-end condominium in Toronto’s Entertainment District, with a steel siding product with a design build contract. This included adding alternating reveal joints, and bent custom corner panels. Also, there were some areas where the adjacent building was 12” from this project, and we were tasked with designing details to attach within these parameters and getting a wall panel as far into this space as possible. This project was also challenging due to the busy downtown Toronto construction site with logistical limitations, minimal storage for material and limited access to our work.

Submitted by Josh Bowman

Tableau Condos in Toronto included approximately 14,140 linear feet of Custom 7”x 8” aluminum extrusion deco grid installed on the height of the tower, 36,000 sq. ft. of aluminum composite panel on the podium and 5,000 sq. ft. of aluminum plate panels at the penthouse level of the tower.

The project, being completed with Walman Architects and General Contractor Tucker Hirise, is ongoing with an anticipated completion in March 2016.

Challenges included installing the newly developed 7”x 8” custom extrusion on the full height of the tower in a grid pattern and logistics, staging material and access to each area of work in downtown Toronto.

Dear Mr. (Doug) Flynn:

I write to you to express my sincere gratitude for the delivery of a successful roofing project at The Oaks Condominium in Jackson’s Point, Ontario.

Starting with the bidding process, followed by the project management by Mark Martins, the project effort and conclusion has exceeded the Board’s expectations. The quality of workmanship and roofing products has been superior from the beginning. For my part, the professionalism shown by your company and especially by Mark eliminated almost all of my anxiety and that of the Board and the owners. It has been a pleasure working with Flynn Canada Ltd. on the most expensive project that York Region Condominium Corporation No. 666 has ever undertaken.

David Sweeting President/Treasurer

York Region Condominium Corporation No. 666 (The Oaks)

What an honour! On December 3rd, 2015

Michael Roche and Tyler Koshurba proudly accepted “Façade of The Year 2015 – International Award for Façade Engineering Excellence” during the Society of Façade Engineering- Glass Supper event held at The Sky Garden in London, UK. The award was for the Ryerson Student Learning Centre located in downtown Toronto. There were many submissions – some as far away as Japan. We are incredibly honoured to have received this recognition in the company of so many other amazing projects! Great job to all involved.

FLYNN

The multi-award winning Ryerson Student Learning Centre is described as a “precious gem” in the heart of Toronto. This unique building is a dedicated space where students collaborate and share innovative ideas both inside and outside of the classroom.

“Innovation” is the best word to describe the contributions to this project from the team at Flynn Manufacturing – especially those of Clinton Wilkinson. We spoke with Clinton to learn more about how his ideas became a reality.

How long have you worked at Flynn Manufacturing and in what roles?

I first started with AGS (before Flynn came along) 10 years ago. I was working as a General Labourer on the shop floor. In 2008, I was put in charge of programming and operating the AXYZ machine that routes ACM Panels (Aluminum Composite Material) before becoming the Composite Foreman in 2010. At this point my responsibility was to program all the CNC machines that we had in the shop. Now I am currently Production Manager in charge of glazing.

Can you explain Flynn Manufacturing’s Involvement in the Ryerson Student Learning Centre Project?

Our involvement was to produce all the Dome Composite Ceiling Panels and the Unitized Curtain Wall.

Can you explain your specific contributions to this project?

My contribution for the Ryerson project started with the dome composite triangle panels and coming up with a solution to make this out of one piece of ACM panel that could be folded like origami. This made the panel look seamless. Also, I was responsible for making sure all the programs worked for the new Elumatec SBZ 151 machine that we used to fabricate all the complex mullions on the curtain wall frames.

What were some other solutions they were proposing? Why wouldn’t they work?

The first one I saw was a molded fiber glass that was very pricey. Next, was the two piece welded aluminum plate panel that would still need to be sent out for finishing. This was even more expensive. Then I came up with the composite one piece finished product and that was a no brainer. It had to be cheaper than any other solution.

How did you come up with this solution? Take us through that process. How were you certain it would work?

I was actually programming the aluminum plate option first and thought I could make it out of one piece in composite which would be a finished product straight from the CNC. I was never certain that it would work for everything….but any challenge that came up - we found a solution for it.

How did it feel to come up with the winning solution? How does it feel to see your work and see it winning awards and media attention?

I loved it. I went to the site probably 20 times – checking progress and fixing things when it was being built. Now, I am just happy with the way it turned out. It’s a monumental building in the heart of Toronto that turns heads. We have an awesome team at NFL and our work speaks for itself. We went outside the box.

Can you talk a little bit about thinking outside the box….is it important to you? How do you come up with ideas that other people may not necessarily “see” the same way as you do?

As the Programmer at the time, I was well versed in machine capabilities and even product capabilities. I like to problem solve. There were lots of ideas that went around, but I was given the chance to do what I knew would work and with a great team to take ideas and make them a reality. Everything came together quite nicely.

What are you working on now?

Right now, I am in charge of the Unitize Glazing Department and we are working frames for Nova Centre in Halifax, Nova Scotia; Joseph Brant Hospital in Burlington, Ontario and 529 Broadway in New York.

What do you like to do in your spare time?

I like golfing, and being with my wife Lisa Wilkinson and daughter Aylah Wilkinson. We also have a baby on the way!

In December, the US branches submitted a candidate for The Roofing Industry Alliance for Progress’s Most Valuable Player Award. These men were selected for excellence in their career, going beyond compliance in safety, and for being mentors to others in their field. The following received an MVP Award Certificate of Merit from Alliance: Josh Rygg (Phoenix), Mike Mauck (Kansas City), Esbey Rios-Mojica (Minneapolis), and Floyd Hall (Springfield).

Pictured is André Boucher (left) and Erich Schultz (Service Foreman) from Flynn Ottawa. They responded quickly to a situation, but little did they know, other people were watching and took note prompting the email below:

Today I saw a wonderful thing -- something that truly reflected one of your company’s stated goals:

“Flynn is committed to delivering quality and value with health and safety as a top priority.”

I was stopped at a light at Kilborn Ave. / and Bank St. when a Flynn truck stopped and two men in the truck jumped out and ran to the sidewalk and then bent down. I could not see what they were doing as the snow pile was very high...and a minute later an elderl stood up with them who had obviously fallen on the ice.

The two men stayed with him and one of them moved the truck off them, and I just wanted to add how impressed I was with their fast response and obvious patience and care.

I will be keeping your company’s name on file for when I need any roof repairs and will be passing on this story to friends.

-Paula ComeauAnother email came through shortly thereafter reading: Erich (Schultz),

A big thanks to you and the other fellow for helping the man who fell at the corner of Kilborn and Bank. I took him to his appointment at the medical building across the street and left him in their care. They were going to call his family as they thought he should not drive ... He was pretty shaken up.

Your kindness is appreciated by both myself and the gentleman. He asked that I pass along his thanks.

Robin Bourke, Owner Driving Miss Daisy - Ottawa SouthSubmitted by Ryan

TrotterFlynn is providing the complete building envelope for this project located directly next door to our Sudbury office. Working with Reasbeck Construction, there is a mix of Agway’s HF-12 metal cladding, Accumet and Axiom panels provided by Flynn Manufacturing, Tremco’s Thermastic BUR roof, and Alumicor’s curtainwall and entrances. Roofing was completed in December with glazing is to be completed in February, and panel installation set to begin toward the end of the month.

Submitted by Alex Boterman

Cambridge Service is retrofitting a BlackBerry manufacturing building in Waterloo into prime office space. The first phase has been to install twenty four 8’ by 8’ skylights.

Congratulations to Ernesto Moniz who retired from Flynn on September 3, 2015. Production Manager Carlos Medeiros says, “Ernesto was one hard worker and a big heart, always on time and knew what had to be done, rain, shine or snow Ernesto was there and will truly be missed. Enjoy this time in your life with the family.”

Rogers Place is a new arena, home to the Edmonton Oilers. It is the focal point of Edmonton’s revitalized downtown core, known as the Ice District, and has been designed to look like an oil drop from a birds eye view.

It will ultimately be used as a hockey arena but can also be configured as a venue for concerts and other events. Production began in March 2015 on this LEED Silver project, which incorporates 220,000 sq. ft. of metal work, 50,000 sq. ft. of roofing, and 44,000 sq. ft. of glazing.

This job is a Design-Assist project, which Flynn is working on with Architects HOK and Dialog. The entire exterior envelope is being handled by Flynn who has teamed up with Zahner out of Kansas City as a design-assist supply partner for the stainless steel building envelope. The building, being an intricate design of numerous curved facets on differing planes, required a bespoke system of aluminum ladder frames (ZEPPs) which were designed to create the required geometry.

The Schmuland Brothers (Kelly and Lynn) are the Foremen for the metals scope, as well as Rob Leitch who is in charge of assembling ZEPP frames prior to delivery to site. At up to 14 feet wide and 48 feet long, the logistics of delivering and installing such frames must be carefully coordinated. Once installed, the frames are clad in stainless steel skin panels with an angel hair finish. In total, we will require about 25,000 skin panels.

The unitized curtain wall, which was installed under the supervision of glazing Foreman Craig Butler, has been designed with a false diagonal mullion to compliment the orientation of the stainless shingles, each screen being shaped to suit the curved nature of the façade. To accommodate the visual effect of diagonal members and curvature of screen through Flynn’s systems, Flynn’s 6450 system 4 SSG was introduced with required complex miters on the transoms and diagonal caps (internally and externally) to reflect the architectural intent and served as structural wind guards to wide span glass. Senior Construction Projects Manager Tamer Rouby worked closely with Flynn Manufacturing to ensure fabrication and delivery of the seven separate curtain wall screens in a timely manner to meet the required schedule.

The roof is a combination of white and grey Sarnafil PVC with the work being overseen by Superintendent Darren Nakonechny and Foreman Peter Gutsche. Installation during winter months added to the challenges faced by the roofing team, but the main arena roof was completed as required to achieve water tight dates for the internal work to progress.

Being a very large scale project, a full time site team is employed to satisfy the extremely demanding needs of this project. Andrew Fish is the Multi Scope Project Manager bringing all of our trades together, Shanna Whately (Project Manager) is indispensable due to her abilities with 3D models, Bill Brown (Project Manager) has the important role of Site Logistics Manager being a single point of contact for all trades on site and Steven Clark (Project Coordinator) is controlling quality and material procurement.

On target to be complete ahead of the 2016-2017 hockey season, this outstanding facility will be the envy of the NHL and be fitting of the glory days that are just round the corner for the Edmonton Oilers. Let’s Go Oilers!

Camera feeds of the site are available at the following websites: http://www.rogersplace.com/live-view/ http://www.mcnishsteel.com/earthcam/

How long have you been with Flynn and in what role/roles?

I started in 2010, so it’s been six years with the company. Originally, I was brought in as Project Manager for glazing and I quickly went into the multi-scope aspect of project management. Then I became a Construction Manager in March of 2012 and a Shareholder in October 2013.

What is the most interesting aspect of your job? Interacting with people is really the most interesting aspect of my job. It’s really about balancing interpersonal dynamics and the unique traits of everyone on your team. It’s about getting a job done effectively while leveraging your team members’ individual skill sets and personalities to deliver the highest quality results under the schedule put in front of you.

Who has been a mentor to you in your career, and how has that relationship influenced how you mentor others?

I’ve had a lot of good mentors in the past. The way this company is structured is such that when you have a question to ask there is always an open door. I’ve never had someone close the door on a question yet. You have people with different personalities and skills everywhere in the company that can add value to your career and your life in general.

When you talk about “mentors” - I really see everyone in my life as a mentor. It doesn’t matter who I come into contact with…I can always learn something from just about everybody. Some of the biggest mentors in my life are people I didn’t expect to be a mentor.

As far as my personal mentors, I’d have to start with parents and grandparents. I’ve got a good friend who is a Pastor and he is a fantastic mentor. There’s also my wife who challenges me every day without a

ton of expectations – the only one being that I would do my best and be the man I was made to be. I think anybody can be a mentor when they challenge you and then support you. You need to be challenged and some of these people my wife, kids, parents, grandparents, family, and work colleagues offer a challenge followed by support.

You say someone can be a mentor when they offer a challenge that is followed by support – can you discuss what that “support” looks like in more detail?

You have to challenge someone to think outside the box and then encourage them to act on their thoughts. When I think of support, a few thoughts come to my mind. When you ride a bike for the first time, someone doesn’t roll you down the biggest hill and say “make it or break it.” They take the training wheels off and stand beside you. You will fall off…you’re not sure where or when but hopefully you don’t get hurt too badly. You need to set it up so they can fall and hurt themselves – not get killed in the

process. Let people scrape their knees and make mistakes - that’s how we learn. I remember when I was five years old and my grandfather gave me a jackknife. Other family members thought I was going to cut myself – and my grandfather would say, “Maybe it’s okay if he cuts himself, but I will be with him.” My grandfather never stifled my creativity or ability to grow. He let me poke myself with a fishing lure or poke myself with a jackknife, but he was always there to help me along if I needed it when I made a mistake - that’s how we learn. What values attract you to people and make you accept their mentoring?

Honesty is the first one. I look for someone to be honest, as long as there is a bit of compassion involved - that’s important. I look for someone who is going to challenge me to think and come up with the answers instead of giving them to me; someone who asks me more questions than firing off directions. Authenticity is another one. If you are not authentic with your intentions, people can

“I think anybody can be a mentor when they challenge you and then support you.”

- Jeff Ferrey

read through you pretty quickly. If you have an ulterior motive and are hiding it to get something out of them…they’ll know. Be accessible and honest, but ensure that honesty comes with a certain level of respect and compassion for people. These are obviously qualities people recognize in you.

That’s interesting…it’s thrilling that people thought this way of me. I thought a lot about mentors I’ve had…John Silva is someone who doesn’t micromanage me. I can walk into his office and talk to him when I need to and he’ll spend more time asking questions. He points out things gently and sends you on your way while watching from a distance. Gerard Montocchio has been a fantastic mentor and John Spadaro is another one - always there to pick up the phone no matter what time you phone them, and they get back to you every time which is important. You don’t feel like you are interrupting or bothering any of these people. I am not always good at that, but I strive toward improving upon it. Being a mentor sometimes means having difficult conversations/giving tough feedback. Can you talk about this?

We talk about a “feedback sandwich” which is a good theory (positive feedback, more critical feedback and positive feedback again). Every tough conversation has to start with honesty and can’t threaten people. You can’t call them names or pigeonhole them – you need to stick to the facts and base your conversation on being honest and compassionate at the same time. If you start out by backing someone in corner they will come out fighting –myself included. At some point, you need to listen to where they’re at and where their head is at. A tough conversation usually relates to performance or attitude and if those things are suffering it is usually related to something else in their life that is affecting them. Usually, if you get to the root of that, you can figure out where the problem exists and that’s where honesty comes in. You say it’s your personal life…you need to deal with it and we need to figure out how to get you back on track. You look for symptoms, and then get to the root of the cause.

We’ve been talking a lot about the Flynn Way. What connections do you see

between the whole philosophy of mentoring others and what we call the Flynn Way (our culture)?

I see Flynn as a unique company and when I take a look around at the leaders, I don’t see a lot of formally educated people. I see a lot of intelligent and motivated people that come from the ground up. Our culture provides opportunity to people who are perhaps not formally educated business graduates. It allows opportunity for intelligent people who have been encouraged to learn through culture and its mentorship. The culture in the company is such that it allows people who may have not otherwise been given the opportunity for reasons such as credentials or a degree on the wall - an opportunity to do great things with their lives. In other environments, they may not be accepted or able to do that.

What are some of the benefits of being a mentor as opposed to being mentored?

It’s seeing people grow and succeed –seeing someone come up with a great idea or plan and become really successful in life. Watching people grow and do great things is the reward.

There’s JP Schmidt, a Superintendent here in Vancouver…when he was 17 years old, he worked at a gas station I filled up at. I ended up hiring him to work for me when I owned my own company and look at where he is today! What a fantastic path he’s come along and it’s only the tip of iceberg. Watching that happen is great.

What potential did you see in him?

He stood out as someone who was different – the way he approached people, his attentiveness, his ethic and his attitude. Those are always the first things I notice. You took a chance on him when you recognized his potential and it paid off.

Yes. That’s the case with most people I think. You have to recognize potential. I’m spending a lot of time going back to my grandfather but he said…you take a look at a guy’s heart first. If a person has a good heart and they care, go with that first. If you take a look at the Supers here in Vancouver, every one of them has a great heart and really cares about people. That’s the theory: Hire for attitude and train for skills.

As a mentor, how do you make and keep meaningful connections with people?

You have to put yourself out there and invest in connecting with people – don’t hide in a corner and sit in the office. Get out there and actually connect with them one-on-one. Put yourself out there first and take some risks, otherwise you won’t have good relationships. It’s a lot of work, but it’s worth it.

One thing we started here about three or four years ago….I started putting birthday’s on my calendar – every time someone has a birthday, their name pops up on my calendar and I phone them and wish them happy birthday. It’s small, little things like that that can build connections with every field guy. Also, we do reviews every year. Every single person in the field gets a sit down with the managers to talk about their performance, where they want to be, and what their goals are. We do it through Halogen in the office –but field guys can get set aside or forgotten about I think at least with interpersonal connections. It’s a big investment of time, but we do it. Same thing goes for birthdays or whatever else it may be. It’s an investment in people and people are what really matter. If someone were to reflect on your time at Flynn – what would you like them to say about you?

Above all, Jeff cared about us and never compromised our well-being for his own interests. I don’t want to be known as someone who sold someone out to move myself ahead. I would want people to say he cared deeply about us and took a back seat. What does being nominated, and now chosen, mean to you?

When you take a look at the other people in this company who are incredibly effective leaders and mentors and now see I am cast into that category – it is absolutely humbling. I think there are so many other people much more deserving and who have been at the company much longer and have had greater accomplishments. I’m not going to say I’m not proud though. The first thing I did when I received the email from Doug was forward it off to my wife and parents. I’m incredibly proud to be nominated and selected. I don’t know what to say other than thank you – I have a new bounce in my step of added encouragement that I didn’t have yesterday.

Do you know a Flynn mentor you would like to see recognized in an upcoming edition of the Flash?

Submit your nomination to Doug Flynn at Doug.Flynn@flynncompanies.com

Submitted by Alex Boterman

Flynn Cambridge’s Service Crew of Shawn Hancott, Greg Philip, Lucas Nanasi (Foreman), Ankhang Nguyen and Rich Kelley installed a 900 sq. ft. roof curb at Septodont Novocol Pharmaceuticals - the largest curb this office has installed to date!

Submitted by Alex Boterman

The sheet metal crew of Andrew Pifer and Zach Culliton (Foreman) were repairing the siding at Yazaki. The work was being completed for Manulife Financial.

Submitted by Carlos Medeiros

With General Contractor Ellis

Don, the London crew of James Webster, Jimmy Furtado (Foreman) Rob Monk, Danny Camara, Dan Bush and Manuel DaPonte are working on 662 Squares of Modified Bitumen. The project started in November 2015 and is expected to wrap up in spring.

Submitted by Carlos Medeiros

Submitted by Carlos Medeiros

This project is 357 Squares of 2-ply Modbit in conjunction with General Contractor McKay-Cocker Construction.

Submitted by Ryan Trotter

Flynn sheet metal workers have been installing 30,000 sq. ft. of insulated metal wall cladding, 4,300 sq. ft. of Kingspan’s mineral fibre panels and steel roof deck on the new 10,000 sq. ft. emissions building. Delayed schedules have brought our crew into mid-winter installation and the challenges of Sudbury winter installations 80’ in the air at -30 Celsius. We had the retirement of longtime Foreman, Leo Franceour, in December and Ron Levesque has taken the reigns and we are on schedule for our completion date.

In September 2015, Flynn donated $50,000 to the Clinical Research and Chronic Disease Centre at St. Joseph’s Heath Care in London, Ontario. The 6,000 square foot state-of-the-art facility is a partnership with St. Joseph’s research arm Lawson Health Research institute. It is described by Dr. David Hill, Lawson’s Scientific Director and the Integrated VP of Research at St. Joseph’s and London Health Sciences Centre as a “unique juxtaposition of facilities that exist nowhere else in Canada.” The centre enables researchers to work together, ultimately aiming to transform care for people living with chronic disease, specifically in three areas of focus: cardiac rehabilitation, diabetes, and breast cancer.

The research side of Cardiac Rehabilitation and Secondary Prevention which will be located in the new centre, aims to expand studies in the management of cardiac disease and refine models for cardiac care with the goal of improving outcomes for patients and lowering the risk of secondary cardiac events.

As home to one of the three national clinical trials testing new ways to manage type 1 diabetes, current trials include the REMOVAL study which is testing if a drug for type 2 diabetes can reduce the risk of cardiac complications in adults with type 1 diabetes. Researchers are also trialing an insulin pump shut-off system in children with type 1 diabetes to prevent low blood sugars overnight. This has previously been studied amongst adults, but is their first trial in children. The new space enables the diabetes program to expand and enhance efforts to understand and treat it - with discoveries that have the potential to alter the course of diagnosis, treatment and education for people living with diabetes.

St. Joseph’s is also a regional referral center for breast care. The Breast Cancer Clinical Research and Tumour Biobank is an important resource for fast-tracking discoveries in breast cancer diagnosis, treatment and prevention. Every patient with suspected cancer will have an opportunity to donate tissue at the time of their biopsy. Newly-diagnosed breast cancer patients can also take part in pre-operative clinic trials that are not typically available. While the initial focus is on breast cancer, there is capacity to extend studies to prostate and ovarian cancer.

The $50,000 donation from Flynn resulted in the “The Flynn Group of Companies Assessment Room” within the Centre. It is a multi-function space for patient assessment used by clinicians and researchers across these disciplines during trials conducted here. These trials play a key role in translating research findings into clinic treatments to improve care for people living with these chronic diseases.

Because of St. Joseph’s... we are helping people live to their fullest through excellence in care, teaching and research.

Submitted by Blair Cormier with additions from Mike Arnott and Clinton Wilkinson

The Nova Center “Blue Box” is a twin-span unitized curtainwall system which serves as a main architectural feature on Nova Scotia’s new convention center in downtown Halifax. From the exterior, Viracon Solar-Blue glass creates a distinct mirrored “box” projecting out from the main structure. Inside, a 2-story tall floor to ceiling vision glass area provides an un-obstructed view of the downtown core for occupants of the main ballroom. A mechanical sun-shade with vertical roller track integrated within curtainwall system protects occupants from the suns glare. Customized Flynn Wall 6450 was used to facilitate the architects design.

Many of the 229 mm deep aluminum mullions had to be steel re-enforced due to high wind-loads. Seventy four, 7 ft. wide by 32 ft. tall pre-glazed units weighing up to 3,500 lbs each were made at Flynn Manufacturing. A special assembly line was used for the task and the units were then shipped lying flat on trailers to Halifax. A combination of tower and mobile cranes was used to set the curtainwall in place. Site conditions such as one side of the building being on a steep hill, road closures, night work and a Nova Scotia winter called for careful planning to facilitate a safe and efficient installation.

16,576 square feet of the largest unitized curtainwall modules ever produced by Flynn were fabricated and installed in little over three months, beating even the most optimistic schedule estimates by the customer and Construction Manager (Ellis Don).

Pictured is: Clinton Wilkinson, Mike Arnott, Andrew Nembhard, Sean Gordon, Anner Cruz, Constantino Cruz, Reinaldo Restrepo, Miguel O Bustamante, Dilan Warnapura, Soto Lander, Kevin Walker, Sivalingarajah Sivakumar, Vimal Thangavadivelu, Nallathamby Natkunanathan, Joseph Sebastian, Rakesh Patel, Saini Narinder, Sonny Bola, Saini Gurcharan, Whitley Fowler, Danroy Roach, Maurice Brown, Victor Cacanindin, Daniel Daum, Aaron Mortson, Ryan Gryschuk, Shineford Martin, Praveen Anto and Palvinder Grewal. Thanks to former Project Manager Syed “West Coast” Kazim.

Humber River Hospital is North America’s first fully digital hospital. Using the most modern technologies such as robots who administer medication and other supplies, Premiere Kathleen Wynne says it offers patients more efficient, safe, accurate and reliable care in the province of Ontario.

The 1.8 million square foot facility serving more than 850,000 people in the northwestern Greater Toronto Area opened its doors on October 18, 2015. It has 656 beds, 3,000 staff members, approximately 700 physicians and 400 volunteers.

The hospital was designed and built to adhere to Leadership in Energy and Environmental design (LEED) standards. LEED buildings focus on healthy indoor environments, reduced greenhouse gas emissions and efficient use of resources such as energy and water.

In conjunction with General Contractor PCL, The Flynn Group of Companies (Flynn Canada Ltd.) was subcontracted to provide Roofing, Green Roofing and Sheet Metal Cap Flashing.

At its peak, more than 1,300 workers were on site daily. Our crews completed 140,000 sq. feet of green roof spanning over 17 different levels. The green roof was compiled of 4 inch live roof tray systems and plating was designed by Terry McGlade and Kees Govers. Planting was comprised of sedums and perennials specifically shade orientated perennials such as Hostas, Bergenia for shade, and grasses and chives for sun areas intermixed with sedum varieties. Planting was designed as sustainable as possible to LEED Sites standards with no potable water to be used in future years. The total roof and plenum area that was

completed, including green roof, was 351,000 square feet.

At Flynn, safety is always our top priority. Crews were very proud to receive an award in recognition of their safety excellence. They achieved 5 million hours without lost time incident. During the third quarter of 2013, Flynn Foreman Joe Neiva’s crew won the Quarterly Safety Award. In addition to this, Flynn’s Dinis Meireis and Tim Speck were both awarded the Monthly Worker Safety Award presented by the Workers Trade Committee.

Drone footage of the whole area can be seen at: https://vimeo.com/140328166

Eduardo Camara passed away on September 25, 2015. He worked with Flynn for over 20 years and is dearly missed by his friends and colleagues at the Flynn London Branch.

Eduardo lived and worked for his family, never asking for much but making sure they had everything they needed. His immediate family is wife, Lucia and two children Sonia Michalczyk and Danny Camara.

As Eduardo and Lucia were raising their first born, Sonia, in Portugal, Eduardo was given an opportunity to go to Bermuda to earn a good living and provide a better life for his family. They made the move and Eduardo worked hard day and night for 10 years at multiple jobs before welcoming a second child, Danny. Soon after having their son, another opportunity came knocking and the family decided to relocate to Canada where he accepted a job as a roofer.

As time passed by, he became a grandfather to two beautiful boys, Marcus and Arius. He found great joy in spending time with them taking them for walks and teaching them how to be little men, and always found great joy in making sure everyone around him was happy and eating, drinking and dancing… and he sure loved to dance!

His family says:

“You will never be forgotten. You will never be alone on journey in Heaven. We are all with you and you are with us. You will live forever inside our heart in the hearts of your wife Lucia, your son Danny, your grandsons Marcus and Aruis, your sisters, your mother, brother, your nephews, your cousins, your friends and your new extended family. We did not say goodbye but instead say rest my darling rest…we will see you again.”

Submitted by Dave Philippe

On the original strip of Main Street in Moose Jaw sits a beautiful old brick building. This building houses the bank of Nova Scotia. Don’t let the outside fool you, this building was in dire need of a new roof system!

Flynn Regina’s Service Technicians helped breathe new life into the old building. The old roof was removed down to the deck. They installed 26 squares of new 10 year Platinum warranty cold applied SBS roofing. Our talented metals department installed new 24 gauge cladding to the high parapet interior along with the pre-finished flashings. The job is now 100% complete and it turned out beautifully! Way to go Regina Service Team!

You can trust your Employee and Family Assistance Program (EFAP) to help you and your family find solutions for a wide range of life’s challenges.

Caring professionals can help you access support related to:

• Fitness and physical health

• Mental health

• Relationships

• Nutrition and naturopathic Medicine

There are many ways to get help today - all completely confidential.

• Finances

• Elder care

• Legal

• And much more

You and your eligible family members can receive support over the telephone, in person, online, and through a variety of health and wellness resources. For each concern you are experiencing, you can receive a series of private sessions with an expert. You can also take advantage of online tools to help manage your and your family’s health. You’ll get practical and fast support in a way that is most suited to your preferences, learning preference and lifestyle.

LET US HELP YOU:

FOCUS ON YOUR WELL-BEING

• Identify conditions

• Prevent illness

• Manage symptoms

• Discover natural healing strategies

• Create an action plan for better health

MANAGE RELATIONSHIPS AND FAMILY

• Separation and divorce

• Elder care

• Relationship conflict

• Parenting

• Blended Family issues

GET FINANCIAL GUIDANCE

• Credit and debt management

• Budgeting

• Bankruptcy

• Financial emergencies

• Changing circumstances

TACKLE ADDICTIONS

• Alcohol

• Tobacco

• Drugs

• Gambling

• Other addictions

• Post-recovery support

FIND CHILD &ELDER CARE RESOURCES

• Maternity and parental leave

• Adoption

• Child care services

• Schooling

• Adult day programs

• Nursing and retirement homes

DEAL WITH WORKPLACE CHALLENGES

• Work-life balance

• Conflict

• Career planning

• Bullying and harassment

ACHIEVE WELL-BEING

• Stress

• Depression

• Anxiety

• Anger

• Crisis situations

• Life transitions

GET LEGAL ADVICE

• Separation and divorce

• Civil litigation

• Custody and child support

• Wills and estate planning

Call for confidential and immediate support with your work. Health and well-being 24/7/365.

From Canada: 1.844.880.9142 workhealthlife.com

From the US: 1.800.272.2727

workhealthlife.com/us

*Services are provided in English (and French in Canada). If service provision in another language is required, please request it at the time of intake.

Submitted by Chris

CunnaneThe Winnipeg metals crew of Doug McElroy, James Lewis, Eric Brass, James Parker, Jason Clarkson, Kris Shaw, Christian Bujiriri, Robert Hogue and Cory Tourand are working hard at the Keewatinohk project with Outland Camps. They completed remedial works to cladding to meet the Manitoba Hydro standards.

Submitted by Mark

NovecoskyAll production roofing and service team members in Winnipeg took part in training for pitch box sealing, night seals and scupper tricks and tips. Trainers included senior Superintendents and Foremen from both divisions…a real team effort! Those in attendance listened intently, providing feedback, asking questions and raising the bar in reducing call-backs for these common roofing leaks issues. The entire training session was videotaped by local safety for future reference.

Submitted

by Kirill ShvedThis crew recently finished a project called CWS Logistics. They cut, preassembled and shipped frames to the job site. Materials used were aluminum extrusion (as usually used for curtainwall framing.)

This project was a renovation of an existing building. The general contractor insisted on keeping the building secured, so after each brick wall section was demolished and sizes confirmed, they had 48 hours to supply the job site crew with prefabricated frame section 24’ x 20’.

Submitted

by Kyle KennedyFlynn Brandon landed the largest re-roofing project the city has seen in a while. Coming in at 147,000 sq. ft the Assiniboine Community College is the largest project and most complex of the general contractor’s (Graham Construction) package consisting of 10 government re-roofs. Being an occupied college with classes going all day the crew on site had to alter their start time to 4 AM, giving the guys some pretty scenic sunrises while roofing! Large tower lights were brought in to light up this large roof area in the mornings and it was often joked that it looked more like a ballfield than a roof. A project coordinator from the Moncton branch was brought in to assist the crew on site with the multiple outside parties involved in the project, showing that Flynn will parachute someone in from halfway across the country to help out the proper project.

Graham’s safety department had nothing but high praise for Flynn’s crew, going so far as to say Flynn’s project was the gold standard of safety and the benchmark for the other nine projects. Brandon Branch is looking to wrap this large project up next fall. Great job guys!

Marcin (Rzedzian) and Chris (Cunnane), I just wanted to send a note to express our appreciation for the quality and efficiency that both your teams demonstrated while on our site at the Manitoba Hydro Keewatinohk Project. Outland Camps was impressed with the project execution and final product delivered as promised. Your crews operated in a professional manner while working through some difficult weather and situations while still maintaining a high level of quality and productivity.

Please make sure that you pass on our appreciation and thank you to all involved in both the Roof and Drip Edge installation project.

Thank you again,

Tim Leitch, P. Eng. Resident Engineer/QA/QC Manager Outland | www.outlandcamps.caSubmitted by Darren McCallum

Flynn is the general contractor for this project that has crews replacing an existing roof with new SBS modified roof system (23,000 square feet). The project also involved fall arrest installation for the entire building.

Submitted by Darren McCallum

Seven people attended training on night and penetration seals in Brandon.

Staff on this project are: Dave McGregor, Chris Jolly, Derek George, Dwain Mason, Bruce Neapew, Mike Genaille, Jordan McGregor and Daniel McLain.

Flynn Brandon had some special visitors at the office. Luckily Mark Douglas and Dale Magee were there to corral their new friends and get them back to their rightful places.

Good afternoon Doug, I know we have not met in person however, I want to thank you and the Regina branch for their support, leadership and engagement as a trade partner on the last couple of projects with myself.

Your team lead by Eric Aschenbrener and Sean McGregor is flexible, knowledgeable and have a great team approach on our current projects. I sometimes find our team players never get enough credit. Your team here in Regina and Graham have had several very successful projects with the Ministry of Central Service and the RCMP. Each of these projects carried unique challenges that were overcome by utilizing a team approach, collaboration and pick up the phone & talk method.

Your team continues to demonstrate their knowledge, experience and leadership skills to overcome the challenges that may arise.

In closing, I wanted to let you know how much we appreciate the diligence that Eric and Sean bring to the table; towards completing these projects, trade partner on projects and our strong working relationship. Communication is key to success, and I believe we have that.

Thank you again for your support.

Dorian Fortier Project ManagerThe crew is working at Hyde Park View doing a 470 square project with different aspects (all of them SBS). They are currently doing a 2-ply IKO system (protection board, fast and stick 180 base and 180 cap sheet with no insulation). The general contractor is Qourex Construction.

One of the challenges faced every day is the weather. It’s a bit colder in Saskatchewan than other provinces, so most of the time they have been pushing to get things done in average temperatures of -20 Celsius. Something to mention is that the guys were on a coffee break about one month ago and a driver pulled over to deliver a heavy load of wood joists for the construction of the second phase of the bulging. As mentioned, conditions in Saskatoon are not the best and the ground was soft due to snow melting in the soil making her truck tilt to one side, so when she released the straps that were tying down her load, all the joists fell on top of her crushing her leg and trapping her under all that weight. Without hesitationGabriel Cameron, Chad Coben and Thomas Debski ran to help her and lifted the joists and dragged her to a safer place. They called 911 and assisted the lady until the first responders arrived. Great job!

Our service and glazing team joined forces to redo EPDM membrane stripping on the Galleria Building in Saskatoon. Removal of the existing pressure bars and tying in the new EPDM membrane was the only answer to stop their water infiltration. Several unforeseen issues had to be dealt with as we progressed (working on 5’ wide roof did not help) but with the team work of both divisions we successfully completed it!

Sears Canada experienced an emergency situation that had the Flynn team to the rescue. The roof that was completed just one week prior (by a competitor) had roughly 50 pieces of foam fly off the roof and land in the nearby area causing safety concerns. Some of the insulation from the roof was spotted as far as Preston Crossing –two to three kilometers away. After handling the situation, the following note was sent by Paul Nunes, VP National Service.

Jamie / Terry / Rocky, Thanks for the report and thank your team for their heroic handling of this emergency. Time and time again you and your team have proven to go well above and beyond the call of duty in dealing with these types of emergencies. Not often are we leaving our families during Holiday’s to secure insulation that’s blowing off a roof that is being re-roofed by our competitor. This truly shows your team’s commitment to safety and the safety of the public. Please rest assured that your extraordinary efforts are noted and appreciated. If you have not done so already, please extend a special note of thanks to your team for rising to the occasion.

Submitted by Troy Csada

From left to right is Derek Kuzek, John Krysak (Foreman) and Riley Williams, just finishing putting in a Prodema soffit at a Swiss Chalet.