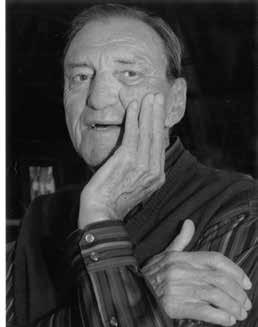

September 23, 1936 to October 6, 2017

As many of you are aware, in 1978 at the age of 42, my Dad started “Flynn and Associates Ltd.” With one green half ton truck and a handful of hard-working employees, Dad’s vision was on the way to becoming a reality. He took many risks that accompany starting a business from scratch, but he truly believed in people and that with hard work, the right kind of leadership and a good plan, there was nothing that couldn’t be accomplished. He was right.

Although he retired in 1991, the values and guiding principles that he instilled in so many of us who he coached and mentored through the years are still with the company to this day. They have formed the pillars of our culture that we call “The Flynn Way” - behaviours such as trust, doing the right thing, caring for each other, and being honest. These have been key to our success.

Whenever I hear someone in the company say “The truth will do”, I think of my father. Those who had a personal connection with my Dad were aware that being honest and forthright were very important personal attributes to him, and defined the way he lived his life.

Dad made the transition from quarterback, to coach and then happily on to our biggest cheerleader and lit a fire in so many people - a small flickering pilot light, which is now a burning inferno in the bellies of so many people across North America. He loved this company and will be missed.

Dad will remain with us all in spirit; his legacy is alive and well. I know this because I see it as I travel across the company. The way we value our customers and our people is part of our roots that will, like Dad, never be forgotten.

Doug FlynnIn this issue, we feature Dave Flint, British Columbia Regional Manager.

Read the full story on page 57

“The first time I met Dave was in Victoria and…Dave is kind of a special guy because he has spent a lot of time involved in the community. His children grew up there, his son played Lacrosse and he was a coach for many years, and always had a coaching mentality with the kids who lived in the city. I walked into Tim Hortons with him and I joked and said he was like Norm from Cheers with the bartender who always had a beer waiting for him. Everyone in there knew him.

A lot of people came to Flynn through his community relationships. He likes to give people opportunities.

Dave is a successful mentor because he’s honest, he has tremendous people skills, is always willing to help and will always put some time aside for you. He has an open door policy – anyone can come tell him anything. He is a pleasure to work with; somebody you know will always make the right decision and if he’s bouncing something off of you, it’s out of respect. He’s the type of person that can say “follow me” and when you turn around, there are actually going to be people there.”

“I began working with Dave in the summer when I was in grade 11 and then again in the summer of grade 12. When I finished grade 12, I came back after graduation and started working with him full time in 1991. I was doing metal roofing and really enjoyed the work. At the time, my father had passed away and Dave became someone to look up to. We worked well together and he helped me out in a lot of ways. He helped me become a man.

It feels like family at the branch and it always will.

Dave is a great listener, a great speaker, friendly –just a great guy.”

Submitted by Melissa Richardson

Cofferdam is the new construction of a 512 square Data Center. It required the maximum rating for wind protection which is 185 wind uplift pressure, which lead us to use a Sika Sarnifil approved roof system. Materials used included 75 mil Feltback EnergySmart membrane installed using low rise foam adhesive over a vapor barrier on a concrete deck. The General Contractor was JE Dunn Construction out of Kansas City, Missouri. It took a total of 20 crew members and consecutive weekend hours to meet the tight scheduling demands.

Submitted by Melissa Richardson

Work on the MAC Parking Maintenance Building and Revenue Control project in St Paul, Minneapolis began on May 1, 2017 and wrapped up on August 8, 2017. The scope included 17,000-sq. ft. of anodized aluminum plate panels, and 5,000-sq. ft. of Centria hidden fastener panels.

The new two-storey parking maintenance building will office all airport parking facility employees. The new revenue control system will provide shelter to visitors as they pay on their way out of airport parking.

The project had a particularly tight schedule on the Revenue Control Canopy and Flynn was able to meet it by utilizing a crew of up to 10 employees. Roofers and sheet metal workers came together to create the super crew! The project was a large undertaking for our branch with over 4,500 total hours on the job.

Employees with 100+ hours on the project included Brennon Scharffbillig, Bryan Cox, Colton Wallace, Cory Weinhold, Dave Larsen, Don Cox, Jess Pesola, John Meier, Justin Phillips, Mac Pribyl and Nick Lauterbach. The General Contractor was Knutson Construction.

Submitted by Corey Meyer

Flynn Midwest Minneapolis began working on the Ameriprise tower in April, 2017. Crews tore off the existing roof down to the deck and replaced it with 60 mil reinforced EPDM fully adhered to isocyanurate insulation – 71,800-sq.ft. in total.

All material handling and debris removal had to take place using a freight elevator on the inside of the building. There were 12 different areas roofed with multiple elevations, the highest being 17 storeys. There were two crews working in two different areas at all times, including weekend work for a third level area where a crane was required to be parked in the street blocking a lane of traffic. Coordination of weather and events happening in the downtown area provided some challenges to requesting lane closure permits.

Branch Manager Dan Lewis and Foreman Corey Meyer were praised for their outstanding communication and cooperation in a letter of appreciation sent to Doug Flynn by Richard Grobovsky, Principal Consultant for the Ameriprise Project and owner of AMBE Ltd.

Corey said the main method of communication was via email. “At the beginning of the project, we set up a group email that included members of the consultant company and members of Ameriprise. Each morning when we arrived on site, I sent an email out stating we were on site and then at the end of the day we sent one out that we were off site. Then, each week I sent out an email with a schedule of what we were going to do the next week. In addition to the emails, there was an engineer at the building that I communicated with each day.” Great job

Submitted by James

Spann

Atchison, Kansas was the birthplace and home to Amelia Earhart! It’s also the place where our Flynn Midwest Kansas City metals crews recently did a much-needed remodel (and addition of a new gym) at the Atchison Family YMCA. In conjunction with JE Dunn Construction Co., our KC crews began the project in May 2017 and completed work in September. Their scope was architectural metals including the use of 3,355-sq. ft. of Centira MetalWrap (Insulated Backup Panels), 355-sq. ft. of Centria Versawall (Insulated Metal Wall Panels) 3,400-sq. ft. of CentriaProfile Series – IW10A and IW20A, and 688-sq. ft. of Custom Fabricated and Post Painted Aluminum Plate panels by Flynn in-house. Within the wall panels systems, two custom colors were utilized. For Flynn Midwest, the Insulated back-up system with Centria was a vertical system. This was their first install for a vertical back-up system; they have only ever installed horizontal on past projects. For a town with a lot of old history and the age of Atchison and the YMCA, this was a big and exciting upgrade for the town.

Submitted by

Matt PierceThe 869 square Grandview Middle School roof replacement began in May 2017 and finished up in October. The crew did a complete tear off down to the gyp and tectum decks, installed nailed base to the tectum deck and adhered 2.5 ISO and 3/8 Securock in Low Rise Foam throughout.

A 2 Ply Mod Bit roof system was installed consisting of Derbigum’s Debibase Ultra and a Derbicolor P cap sheet both in cold adhesive with adhered 2 Ply flashings to all wall and curbs set in flashing cement. The gypsium deck areas were unique as they had raised hexagons built within the flat areas which made the installation more difficult and slower, and the tectum deck was steep enough that all field membrane had to be fastened to keep it from sliding.

Submitted by Archie MacDonald, Kirby Struttmann, Nick Markley and Terry Ard

Submitted by Archie MacDonald, Kirby Struttmann, Nick Markley and Terry Ard

The University of Kansas Hospital Cambridge Tower North is a 12-storey patient tower addition for the hospital. This project utilized architectural metals, glass and roofing. Work began in October 2016 and is expected to be completed in November, 2018. The General Contractor is JE Dunn Construction.

For the metals scope, crews are using rain screen metal wall panel systems consisting of approximately 60,500-sq. ft. of a QC Facades/Hunter Douglas QC-300 aluminum panel system over 3 ½” layer of Roxul insulation and extruded aluminum hardware system. These panels were imported from the Netherlands, which proved to be a challenge when dealing with varied panel releases, overseas transportation and project scheduling. The non typical trapezoidal shaped QC-300 panels on the soffit of the serpentine shaped bridge were shop fabricated in the Netherlands based from scan data provided by Flynn and every panel fit exactly as planned.

The level four “belt-line” and level 12 penthouse walls consisted of 23,300-sq. ft. of perforated aluminum ATAS Metafor panels installed to span over top and conceal the mechanical intake louvers also installed along those floors by Flynn’s architectural metal crew. The perforated panels provided the right amount of free air for the intake louvers while still shielding the louvers from view, and at non-louver locations the perforated panels were backed by shop fabricated black flat-lock panels to provide a monolithic appearance throughout.

For the roofing scope, there are nine roof locations spread out over fourteen floors totalling 80,200-sq. ft. Included in this is two bridge locations, one of which was built while maintaining an open street below. Some of the challenges within the project were the interior wall vapor barrier mixed with insulated wall sheathing while maintaining continuity with the air barrier on the exterior walls. Another challenge was getting a kettle to the thirteenth floor for the roofing applications taking place on the upper decks. Products used included Overall Firestone UltraPly TPO XR 115 Mil Fleece Back Membrane (Gray), Firestone UltraPly TPO 60 Mil Smooth (Gray)flashing materials fully adhered, and Firestone TPO Walkway (Gray), Firestone V-Force for the Vapor Barrier, Firestone Tapered Polyiso insulation, and flat stock material.

For glazing, the exterior scope includes a 12-storey all glass patient tower. Levels 1 to 3 are approximately 18,300-sq. ft. of Wausau 4250/7250/8250 SuperWall stick-built curtain wall utilized in punched openings. Levels 5 to 12 are approximately 100,000-sq. ft. (1,176 Unitized Panels) of Flynn Wall Custom 6450 Fully-Unitized Curtain Wall. The North elevation includes a “bump out” for possible future building expansion with approximately 1,500-sq. ft. of Wausau Unitized Curtain Wall. On the South elevation, there is a 40-foot-tall Pedestrian Bridge connecting the new Cambridge Tower to the existing KU Heart Hospital -approximately

Metals Crew:

Front Row, left to right: Aaron Hobbs, Derrick Rew, Todd Phillips, Dominic Castro, Ethan White, Jason Harrison and Keith Baker

Back Row, left to right: Jack Ketterman, Joe Wolfgeher Jr., Brett Rouchka, Rodney Krewson, Mike Wolf, Fred Boyer and Justin Barnes.

18,420-sq. ft. (150 Unitized Panels) of Flynn Wall Custom 6450 Fully-Unitized Curtain Wall. The Unitized curtain wall was supplied and furnished by Flynn Manufacturing Toronto and installed by Flynn Midwest (KC). The glass systems were glazed with 1 inch overall thick VNE1-63 Solarblue Vision, Fritted and Spandrel glass units insulated by Viracon. Backpans were provided with the unitized curtain wall at areas required to conceal the interior wall terminations.

The interior scope included three decorative art glass types: Fry Reglet system with Rudy Art Glass (Pennsylvania, PA), Vividgraphics Glass (Chicago, IL) and Skyline Design Art Glass (Phoenix, AZ.). It also included over 300 Vistamatic Between Glass Blinds, Inc. (Coral Springs, Florida) and 2,500-sq. ft. of Technical Glass Products X-Ray Leaded Glass.

The radius configuration of the project on the exterior skin created some challenges in regards to layout and overall scanning of the project. The jobsite was very tight and the bridge had to be installed over an active road to the existing hospital which created some challenges in scheduling which were overcome.

Submitted by Ryan Tollefson

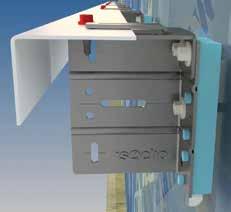

The Kansas City crew are working on a giant sunshade at one of the Twin Cities largest General Contractors; Kraus Anderson – a great Flynn customer. The sunshade covers a fifth-floor walkout patio outside the executive office level and projects 15 feet off the building, which is massive for any sunshade. The team worked with supplier Industrial Louvers to offer a system that looked great and was easy to install. Crews utilized their own crane and two scissor lifts for installing the sunshade. The team was made up of both roofers and sheet metal workers, and they did a fantastic job.

From left to right: Tom Cavanaugh, Nick Wittstock, Justin Phillips, Mac Pribyl Missing: Nick Lauterbach, Dave Larsen, Rodney Halsten, Brian Jensen, Jess Millner, Mark Fischer and Zach Egge.

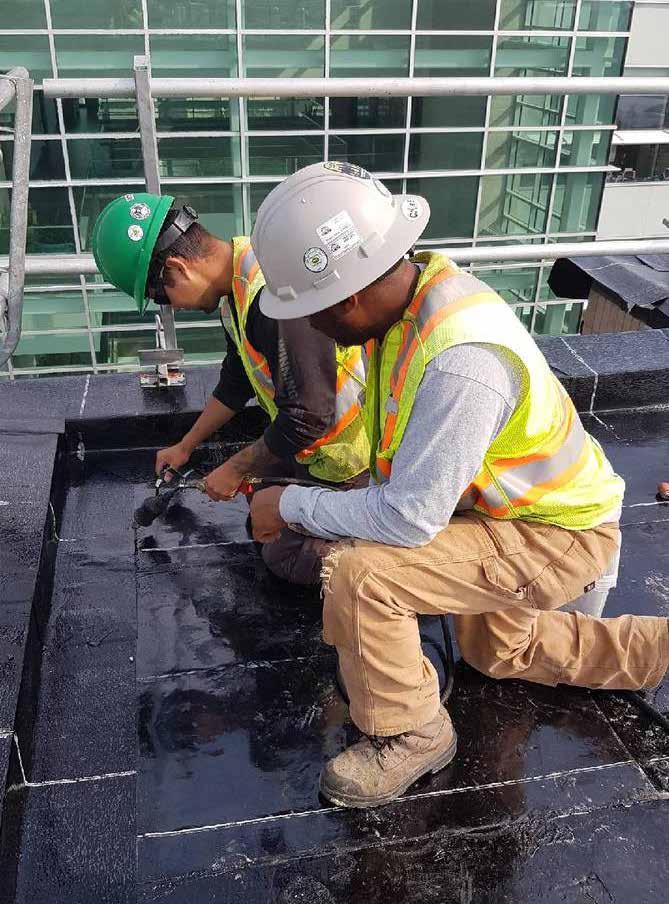

The Denver Service Department has been busy this summer. Despite a spring hail storm and heavy rains the past few months, our technicians have successfully completed several tenant finishes, preventative maintenance jobs, and small re-roof projects in between leak investigations/repairs. Pictured is our Foreman Luis Cardiel, right and his helper Salvador Garcia. Salvador came to us from the H2B program and the service department was fortunate enough to have him work with them during his time here. The service department is so thankful for all of Salvador’s hard work this summer and he will be greatly missed when he returns to his home in Mexico this November!

Submitted by Megan Rebol

Denver’s production crew was working against Mother Nature when they completed the Franklin Elementary School project. The project had to be completed during summer break so that the work didn’t affect the students schedule. The crew had to complete an overlay on a 500-square modified roof system. They began the project by power washing the entire roof surface 24 hours before the installation. After the roof was power washed and dried, they installed 5/8” dens deck over the existing roof and then installed a fully adhered Carlisle 60 mil KEE PVC roof system. Several rainy days and last minute changes to the details made this project difficult, but Irineo Garza and crew successfully finished the project in time for the students to return to school.

Submitted

by Megan RebolDenver’s production crew was busy this summer completing another school re-roof. This is one of six successful school re-roofs that our branch completed during the summer of 2017. The crew had to vacuum existing river rock ballast before removing the 60 mil EPDM existing roof system. They had to mechanically fasten 3.5” ISO and set ½” JM retro-fit cover board in hot asphalt before installing a Johns Manville 4 Ply BUR with gravel surfaced system. A Flynn sheet metal crew helped the production crew by installing all new 24-gauge pre-finished sheet metal flashings associated with the new roof system. After the roof was completed, the production crew replaced 16 kalwall 7’ X 7’ skylights. The crews faced the challenge of the school being in the mountains with early afternoon showers which affected the production and work schedule. Despite the challenges, Bacilio Marrufo and crew successfully completed the project ahead of schedule and under budget. Great job!

The Phoenix branch held an open house and employee appreciation event on August 12th to celebrate their new office location in Scottsdale, Arizona. They enjoyed a barbecue, a bouncy castle for the kids, and delicious desserts including Rice Krispies treats in the shape of orange safety cones. They hired several promising new field employees who came to check them out at the event too. Everyone is now happily settled into their space!

Submitted by Lisa Brownfield

Our Phoenix and Flagstaff branches worked together, under the guidance of Frank Kraus, OPEX Technical Training Specialist, to complete the Northern Arizona University (NAU) Science and Health Center. They removed and reapplied a fully adhered 50 mil KEE FiberTite Roofing Membrane System. The project was scheduled to take 30 days, but fell in the middle of monsoon season, which made it challenging for the Flynn crew and GC, Mortenson Construction. After it rained for 23 out of 30 days, the guys were very excited to have sunny days to complete the project. The sunny days saw weather hitting 100+°F! Thanks to everyone involved helping make this project a success.

Submitted by Trisha Dykstra

The Phoenix branch would like to take the opportunity to thank Shop Manager, Raul Romo, for all his hard-working efforts.

“We consider him our unsung hero. Not only does he manage our shop, make all of our pickups, deliveries, and keep our vehicles safe and maintained, he also packed up and moved the entire contents of our office and shop in extreme summer temperatures during our recent move across town. We really appreciate all he does for us every day,” said Branch Administrator, Trisha Dykstra.

The Dallas-Fort Worth branch has secured the bid on a Facebook data center, with a scope of 320,000-sq. ft. of mod bit roofing. The successful bid was due to hard work of the Dallas Fort-Worth branch as a team. But another huge factor was the support of the Kansas City branch, which had worked with Facebook in the past on similar jobs.

Reising,“In Kansas City we have done a lot of these jobs, we did two exactly like it, and another three jobs for Facebook in Iowa. So we made some calls on behalf of Ed [Reising], and acted as an advisor during the bidding process, just to lend what support we could”, said Mike Pierce, Senior Advisor - OPEX, Kansas City. “Hopefully this helped, but I really give all the credit to Ed and his group. The attention to detail in the bid was phenomenal, we didn’t see anything missed. I don’t even believe that we were the lowest bid, I just think Ed did a great job selling Flynn.”

“The data center traction here in North Texas has gotten very large, and this is presenting a great opportunity for us. Not only has Flynn done work with Facebook in the past, but Facebook was very pleased with the results,” said Ed Reising, Roofing & Estimating Manager, DallasFort Worth. “I have no doubt that Kansas City helped us win the final bid, and that their support will help us moving forward.”

It’s great to see the Flynn branches working together and lending a hand when needed. Congratulations to Ed and his team!

The Harbor Chase of the Park Cities, an assisted living facility in Dallas, Texas had a unique scope. Flynn Southwest Dallas- Fort Worth was awarded the contract for 7,700-sq. ft. of asphalt shingles, 4,500-sq. ft. of TPO, 3,800-sq. ft. of metal Standing Seam roof, and 5,200-sq. ft. of metal wall panels.

This project with The Beck Group as the General Contractor began in April 2017, and was completed in September.

Special mention goes to Estimator, Brian Rhoades; Project Manager, Jake Miller; Roofing Foreman, Oswaldo Zatarain and Sheet Metal Foreman, Jesus Pineda.

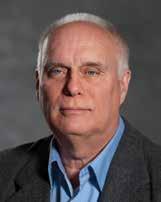

In the Spring 2017 Flash, the incorrect photo for Ed Reising, Roofing & Estimating Manager of the Dallas-Fort Worth branch was published. The correct photo can be seen to the left.

Josh Douthitt lived his whole life in Kansas City, Missouri and began his career in drafting at A2MG (now Flynn Midwest Kansas City) 13 years ago, upon completion of his schooling. “I was just some guy at a small vocational school for AutoCAD drafting and they gave me a chance right out of the program – they gave me that opportunity to get started and that meant a lot to me,” he said about joining the company over a decade ago. Over the years of coming up with designs and working through different and challenging projects, Josh said his coworkers became like family members to him and he looked forward to seeing them every day. Outside of his work though, Josh had been making a 500-mile commute between Kansas City and Dallas-Fort Worth multiple times per year to visit his actual family members living there.

When Josh and his wife Cayla had their first of two children, Trevor now 8 years old, and Jillian, 4, they had always contemplated the idea of moving to be closer to their family. It wasn’t until Cayla received a good job offer in the DallasFort Worth area last year that it became a “now or never” situation, Josh recalled. “If we were going to make the move that job offer was the open door to do it,” he said, and so it was time to let his coworkers know his plans. “Being around a group of really great people all working toward the same goal was amazing – that’s why it was so incredibly tough to make the decision to leave.” While most people give their two weeks’ notice, Josh gave six weeks’ notice, which included sleeping on a friend’s couch for three weeks while his family settled into their new home. “I felt and still do feel deep loyalty to my coworkers and the company – I said ‘whatever I can do to help them transition, I’ll do it’.”

Once Josh joined his family in Dallas-Fort Worth, he opened a small drafting service out of his house that was running for about six months when he got a call from Bob Livingston, Kansas City Branch Manager, telling him they recently acquired a business in the Dallas-Fort Worth area. “If you know the Dallas area –it’s huge! From where I live to the middle of Dallas, it’s about a two-hour drive. The new branch was 20 minutes North of where I live. For it to be pretty much right by my house – it was crazy!” he said. He went to talk to Branch Manager, Mike Beeter and the rest is history. “It was a very, very difficult decision to leave – but a really interesting, more stable opportunity presented itself, and I’m happy to be back with the company I looked forward to working at every day in Kansas City. I’ve seen Jerry Schaefer (President, US Operations) and I thought I heard Mike Pierce’s (Senior OPEX, Kansas City) voice in the hall one day and sure enough it was him – I didn’t even know he was coming down – you miss people from home. There’s a new set of challenges now and a new group of good people to work with and so far, the transition has been a good experience.”

Upon reconnecting with Josh in Dallas-Fort Worth as pictured above, Jerry Schaefer said, “Seeing Josh and listening to him express the circle of opportunity that Flynn presented is exactly why our culture is so different than many other companies. The key to this happening though was that Josh, due to his work ethic and dedication, actually created this opportunity for himself without even knowing it. Everyone should take note of that! Congratulations Josh and we are proud to have you and your family back with us!”

Submitted by Shane Stephenson

Flynn Southwest Dallas-Fort Worth and Flynn Southwest Flagstaff joined forces to complete work on Thompson Road Middle School for the Keller Independent School District. Work included 1065 squares of PVC – Johns Manville 60 mil FleeceBack PVC and 200 squares of Standing Seam Metal Roof Panels.

Submitted by Nicole Ewing and Manuel Alicea

This multi-scope, new construction project may have started on April Fool’s day, but it was no joke! In conjunction with Mullan Contracting, it included 206 squares of Kemper fluid applied roofing – a very difficult system to apply in the hot summer months. If a drop of sweat gets in the system during the application process, it causes a bubble in the roofing membrane which needs to patched and repaired! Crews also did 2000-sq. ft. of ACM panels. Work was completed in October.

Submitted by Manuel Alicea

Production on this 670-Square new construction Carlisle Fleeback TPO roof with General Contractor Tutor Perini began in June, 2017. With small space for material handling, and many trades on the same site – maintaining a safe environment for the crew, and everyone around them, was both challenging and rewarding.

Submitted by Manuel Alicea

Work on this project for the Caroline County Public School District began on June 24, 2017 and was completed on August 31, 2017. It was an 854-square roof replacement that involved the installation of a hot applied, 2 Ply modified roofing system with Energy Star coating over coverboard and polyisocyranurate insulation. All layers were

It also included a 67-square new metal wall panel system over the existing wall and new ice

shield. When it comes

schools, work must be complete in a very specific time frame but the crews got the job done on schedule!

Submitted by Evan Bartram

Halifax’s Roofing division were brought in to do a re-roofing job at the Walmart in Greenwood, Nova Scotia. The 71,200-sq. ft. roof was originally a mechanically fastened EPDM and is being replaced with a TPO RhinoBond system. Work commenced on July 10th, and the team wrapped up in early September. With Lewis Gale being a more veteran Foreman, they thought it would be a great opportunity to film an OPEX training video involving the RhinoBond process. Frank Kraus and Joe Neiva were more than happy to make an appearance on site and review some best work practices involved with the RhinoBond process.

Submitted by Evan Bartram

The Sackville Superstore is one of three Superstores that the Flynn Halifax roofing division has been awarded a re-roof on this year. The 20,200-sq. ft. 4 Ply BUR roof is being replaced with a Mod Bit system. The crew have been able to execute accordingly despite the on-going obstacles that come with working on an operating building. Work on site began late July and finished at the beginning of September on schedule.

Congratulations to the graduates of Flynn University for Frontline Leaders (FUFL) Number 22 held in Minneapolis in July! FUFL is our accelerated two-day leadership program designed specifically for the leaders, and future leaders, of Flynn.

Congratulations to our Flynn University for Training the Trainer (FUTT) Session 2 program participants! FUTT is a practical, hands-on program that is grounded in the real world, not academic theory. This program focuses on what happens before, during, and after one delivers training. FUTT is for Subject Matter Experts that develop and facilitate training at Flynn and it concentrates on the following areas: workshop design, participant engagement, expert facilitation, and the applicable tools and techniques to design and deliver engaging and interactive training. Way to go!

Our sixth session of Flynn University for Frontline Coaches (FUFC) took place in July. Congratulations to all in attendance. FUFC is a training session for our Roofing Production team members who want to become Flynn Coaches. They learn tools they can use to guide, assist and support rookies beginning their careers in Roofing Production.

Thirty plus Flynn safety team members from across North America met in early August to attend Flynn University for Safety Professionals. It was three days of interactive workshops, along with team building activities, and fun. They had a heavy schedule that included presentations from senior leaders, as well as hands-on training that will be incorporated in Flynn’s future training sessions to enhance the learning experience on all levels. Group presentations allowed everyone to both learn from and teach one another.

Submitted by Danielle

McCallumOur Flynn University for the Next Generation Flynn Way Task Force has started a program offering site visits/tours for people who usually don’t have a chance to do so. Senior Marketing Specialist Brian Brett (leader), Financial Analyst Brandon Patrick; Learning and Development Specialist Latoya Francis and Group Equipment Coordinator Scott Watt-Harrison from our Toronto Branch, were accompanied by Health and Safety Specialist Danielle McCallum for their recent site tour. They visited a 513 square re-roof project at a No Frills grocery store. When they arrived on site, the crew had already removed the ballast and existing EPDM from the work area and were working on replacing the wet insulation before installing the new protective mat and EPDM. The crew was working in the area on the roof that contained the chillers for the store’s freezers, and the visitors got to see just how sensitive and difficult the roofing process can be to ensure the work is completed and the store below remains operational. Foreman Mark Martins talked about the work and took the visitors to the trailer to showcase all of the components that are required for a site to be operational, as well as safe. He also provided some insight as to just how important it is for every job to be completed through a ‘team’ approach to ensure that the work gets done safely, on time, and that all of the customers are happy!

Submitted by Kyle Kennedy

Submitted by Kyle Kennedy

Gisele Hebert from our Moncton Branch has been at Flynn for six years and up until this point, she hasn’t had the opportunity to visit a job site and see what the site crews do day to day. Britany Tye has been an Estimator at Flynn Moncton for almost two years and although she has been to multiple tender site visits, she never had the opportunity to see the crews actually install the product that she estimates daily. In August, the roofing department at the Moncton branch invited Gisele and Britany to come see the action first hand. The site was new construction project where Flynn was awarded 8900-sq. ft. of Mod Bit roof assembly. When they arrived on site, the field crew was in the process of laying down a tapered insulation package and were happy to show the installation process. It was a great first site tour experience and the Moncton branch looks forward to being able to get out to more projects in the future!

Submitted by Ian Barrett

Since completing a successful 5,300-sq. ft. re-roof project for Schlumberger in 2016, Flynn St. John’s branch has been working closely with Schlumberger Facility Managers as their service provider for roof maintenance. The St. John’s service team has been engaged by Schlumberger to remove snow from roof tops during the winter, complete leak investigations and repairs and more recently, to conduct roof maintenance audits at two local Schlumberger locations. These audits have resulted in preventative maintenance work orders to prepare roofs for the upcoming winter season. The service crews of Brian Hendry (Foreman) and his crew member Tony Codney, and Mark McDonald (Foreman), and his crew member Brandon Ward, were on this project and look forward to a continued relationship with Schlumberger as their number one service provider!

Submitted by Anthony Upwards

From left to right: Tommy Breen, Rob Kennedy, William Kennedy (Superintendent) and James Frizzell are putting the finishing touches on the Dominion and preparing to move ahead into a busy Fall. The scope includes 2 Ply Mod Bit and roof coating.

Submitted by Anthony Upwards

Foreman Mike Parrott and crew have started work on the Wedgewood Medical Clinic. When searching for a contractor to perform this work, Flynn was the best contractor of choice. The scope included removing the existing BUR and supplying and installing new 2 Ply Mod Bit.

There’s a new and improved way to get your hands on exciting merchandise. Visit our newly designed awards website at https://flynn. mybrightsites.com/

Your newly designed website now has a wider range of product selection. It enables ease of registration including setting your account to a personal email, points that never expire, the ability to add points to existing accounts, and the option to use your personal credit card for purchases too.

If you have any questions with regards to carrying over points from the previous platform, contact awards-estore@flynncompanies.com

Detailed instructions outlining how to use the site can be viewed at www.flynncrew.com – locate the “Win With Flynn” tab on Flynn Central, and select “My Awards Website” from the drop-down menu.

Submitted by Kyle Kennedy

Jean-Noel and crew are pictured gearing up for a job on Prince Edward Island. Flynn often does work on “the Island” as it’s known, via the Moncton, New Brunswick branch. The crew is currently working on re-roofing a 12,000-sq. ft. grocery store. The project consists of three different roofing scopes: A Mod-Bit re-roof, Mod-Bit re-cap and asphalt shingles.

Submitted by Kyle Kennedy

Roger LeBlanc’s crew were “surgical” in how efficiently they roofed in the multiple roof areas on the George Dumont’s Hospital’s new Precision Medical Centre. The project consisted of six different roof levels for a total of 8,900-sq. ft. The GC was very pleased with Flynn’s work and how quickly they were able to mobilize and complete these roof areas.

Submitted by Kyle Kennedy

Flynn’s crew in Fredericton is no stranger to performing roof work at the Canadian Forces Base in Gagetown. This particular project involved 45,800-sq. ft. of roofing for the bases new Explosive Ordinance Disposal Building. Flynn installed a mod-bit roof for Maxim Construction who was the General Contractor on this project. At the end of July, all the cap sheet was installed and with August came the finishing touches for another CFB Gagetown project for Flynn!

Submitted by Kyle Kennedy

Marcel LeBlanc’s Crew were moving quickly with their new Inverta Press Machine while installing a fully adhered mod-bit roofing system at the Holland College Waterfront Campus in Summerside, PEI. The 25,000sq. ft. re-roof was completed on time and on budget. The crew was too busy to pause for a group photo but there was a chance that had something to do with the golf course attached to the hotel they were staying at.

Submitted by Bo Sung Han

The 10 Schilling Road project consists of supplying unitized curtain wall frames to an existing building where the old concrete structure is retained. The total scope of the project consists of 1,233 unitized curtain wall frames on a seven storey building, covering over 85,822-sq. ft. The project is located in Cockeysville, Maryland, and is the global headquarters for McCormick & Co. Inc. Although this project is smaller in terms of scale and time frame compared to some other projects, it came with its own set of challenges. Through working together, Flynn Manufacturing/Northern Facades Ltd., our USA customer TSI and the General Contractor (Gilbane) were able to overcome the challenges and meet the construction schedule.

This year, the Pointe-à-Callière museum in Montreal renewed its facade and modernized its interior installation for the 375th Anniversary.

Many features distinguished this project from the others. Mirropane glass (one way mirror) was used for the security office and laminated glass was used for the shaft of the elevator, but the most impressive feature was the sealed units of the curtain wall. They were made of a laminated ½” ultra-clear tempered glass with an SGP and a ¼” ultra-clear heat strengthened glass with an Energy Advantage Low-E, a 5/8” spacer with argon and another laminated 3/8” ultra-clear tempered glass with a SGP and a 3/8” ultra-clear heat strengthened glass for a total thickness of 2-5/16”.

Some of the glass measured up to 52” x 142” for a total weight of 1000 lbs.

This was a challenge that was successfully met by the whole team. The Project Manager was Sergyi Kholodov, the Assistant Project Manager was Simon Brisebois, and the Foreman was Steve Sirois.

Submitted by Francis Labonté

Éric Dufour and his team are renovating the windows of this suburban school in Montreal. Replacing old windows with stick curtain wall will make the learning process much more comfortable for the students.

Submitted by Francis Labonté

Here is the new Alfa Romeo dealership situated in the west-island in Montreal. Stick curtain walls and partitions were the main materials installed by a team of four glaziers. Congrats to Foremen Steve Sirois and Guillaume English and to their hardworking crews for making this job a success.

Submitted by Antoine Levasseur

Yannick Vallée (Foreman) and his team, along with Antoine Levasseur (Project Manager) are currently completing multiple curtain wall works at Baril School, on the island of Montreal. They had to remove and reinstall the curtain walls that were previously installed by another contractor.

Submitted by Francis Labonté

Submitted by Francis Labonté

Flynn Facades in partnership with Flynn Montreal (Vitreco) are working on the renovation of the Montreal Olympic Stadium. The stadium’s tower is being renovated to accommodate the offices of Les Caisses Populaires Desjardins. 840 unitized curtain wall modules, assembled by Alumicoin Montreal and Flynn Manufacturing in Mississauga, are being installed by a team of 18 experienced glaziers on the inclined and inverted sloped faces on the tower. The actual height of the tower is 165 meters and the modules are being installed by the highest tower crane in Canada which is visible at a distance of 20 km! The work is moving along quickly, and it’s looking to be finished by the end of the year. This is an iconic and prestigious project for Flynn Montreal (Vitreco) and Flynn Facades to be part of, and it’s great to see the team tackle it together! Flynn Montreal (Vitreco’s) Project Manager is Osama A. Ghani, the lead Foreman is Francis Labonté, the Foreman is Donald St-Pierre and the General Contractor is Pomerleau.

Submitted by Michael Roche

Submitted by Michael Roche

Congratulations to our Toronto Flynn Facades team on securing Flynn’s largest façade contract to date! Leading Property Developer Oxford Properties have awarded a Design Build contract to Flynn Facades for the 380,000-sq. ft. recladding and re-glazing of the iconic Bay Adelaide towers 120 and 130 at Adelaide St. West Toronto. The towers are 26 and 33-storeys, 120 Adelaide built in the mid-sixties and 130 Adelaide in 1979. For our Director of Engineering, John Spadaro, this is full circle having cut his teeth in this industry on the original construction of 130 Adelaide and now leading the design of the custom systems required for this major refurbishment.

Both buildings will be fully operational and fully occupied and our work consists of the removal of all glazing and panels, mainly at night on both towers, and replacement with 23,145 new custom designed glazing and spandrel glazed cassettes completely manufactured off site at our Flynn Manufacturing plant in Mississauga, Ontario. It was this unique custom cassette approach combined with our logistic and safety proposal that separated Flynn from our competitors all thanks to the creativity and expertise of our Business Development, Estimation, Design/Engineering and Construction teams. Adelaide, among other major re-clad projects such as Toronto’s 401 Bay Tower, Montreal’s Olympic Tower and others in Canada and the USA, ranks Flynn a top contender for major façade renovation and retrofit in North America.

Submitted by Tony Gyuro

Flynn has contributed to the latest high-tech Hospital in Burlington. Joseph Brant Hospital opened mid-August and is impressive in every way. Flynn was the main building envelope contractor that EllisDon hired to enclose this state-of-theart hospital. Crews installed 1400 Unitized Curtain Wall Frames, multiple doors and exterior metal panels. There were many challenges, but the outcome is spectacular. Great job to all who contributed. We are planning to have this project as a feature Flynn Flash article in the next edition, stay tuned!

Submitted by Tony Gyuro

The Hudson Bay Company (HBC) tower is a 32-storey building made of concrete and glass, and HBC wants to upgrade the look of the tower to bring it a more modern feel. The Flynn team is installing unitized curtain wall framing on the tower portion and installing frames at the podium level (lower portion of the building in the photo). The glazing team has been met with challenges concerning the steel skelton structure and there have been issues where the steel is in relation to the anchor of Flynn’s frames. On other projects of similar scope it would be best to have one sub-trade coordinate this, but Flynn is equipped to deal and outsource the steel scope, allowing one point of contact while working on the steel structure right up to finish. In spite of this challenge, the team remains optimistic. There should be an update to the project in the next issue of the Flash.

Submitted by Matthew Bielawski

Mark Martin’s crew at the Toronto Pearson Airport are pictured working on the GTAA Gate 193 Expansion for PCL. The job scope consisted of grey TPO that was mechanically fastened.

Submitted by Aimee Eden

Work on this project, in conjunction with Daniels as the General Contractor and Architect Rafael Bigauskas, began in September, 2017. The scope of work includes Axiom Aluminum Plate Panel (1200-sq.ft. and 4th floor Soffit), Porcelain Panels by Hycomb (3.5mm Porcelain “Laminam Bianco White Colour” on 19mm Honeycomb Aluminum Sheet, George Brown Entrance, 2nd Floor Canopy and Terrace – 9,200sq. ft.), and Tradition 150 Metal Roof Panels (3,500-sq. ft., 4th floor roof and 2nd floor canopy.) The Project Manager is Will Vongsasanoubane and the Site Superintendent is Brian Decker. More exciting information to come in the next Flynn Flash!

Submitted by Joseph Raposo and Dan Castonguay

GE Power is a new building in Welland, Ontario. Pedro Costa and his crew are tackling this 425,500-sq. ft. project with an extremely tight schedule in place. The roof consists of ¼” Dens Deck Mechanically fastened to Metal Deck, SA V.R. with 2 layers 2.6” ISI & Tapered ISO Insulation with a ¼” Dens Deck Overlay. It’s a 1 Ply 60 mil Carlisle TPO RhinoBond Roof System. Pedro and crew not only have kept up to the PCL schedule; they have caught upon several occasions to the deck installation. Well done Pedro and crew!

Submitted by Craig van de Merwe

The Hamilton team is currently working on the Go Transit Control Centre in Oakville. The project consists of 200,000-sq. ft., using the systems

PVC RhinoBond and PVC Fully Adhered.

Submitted by Joseph Raposo and Dan Castonguay

This Project is the City of Hamilton Provincial Offences Administration Building completed with Eastern Construction as the Project Managers. It consisted of a complete roof replacement. 26,400-sq. ft. of the existing roof areas were replaced with a new Soprema 2 Ply Mod Bit Roof System. Intricate and very tight site conditions required close coordination between Eastern Construction and all the subcontractors.

Lucille Lahaie, mother of Daniel Bisson from our Flynn Ottawa branch, sent a thank you letter to Flynn for allowing Daniel to borrow Flynn’s water pump to help her during a terrible flood that left her with 15 inches of water around her house plus two feet of water in the basement. Daniel and his brother Francois handled 50-pound sand bags resting them over the basement windows and doors all around the house. Daniel made light of a stressful situation by jokingly saying, “Mom, when you sell your house, you’ll get more money because it’s now water-front!" We are glad to hear everyone is safe and wish everyone involved all the best as they work hard to get their lives back to normal.

Kristopher Laframboise, Wayne Harris, Dan Asselin, JP Lussier (Foreman), Yvon Ladoucer, Roch Legendre and Alex Liberty completed this 23,900-sq.ft. Mod Bit roof replacement.

Submitted by Ron Flanagan

Nearing the end of summer, our Ottawa Service Crew lent a helping hand to our Roofing Production Department to complete a new roof replacement at St. Marguerite D’Youville Catholic School.

Submitted by Michael Quesnel

Jake Coppaway, Mathieu Boisvert (Foreman), Al Trepanier, Rick Meace and Alex Milette finished up work at St. Philip School, a 14,300-sq. ft. 2 ply Mod Bit roof system.

Submitted by Michael Lumley

Nevon Green, Kyle Duquette, Jarrod Lafond, Chris Fortin, Craig Lumley, Grant Perreault (Foreman), and Roger Fortin are keeping busy re-roofing the Northern Youth Services Building.

Submitted by Michael Lumley

The Sudbury Branch had their Safety Day which included a game of Safety Jeopardy as one of their activities. The winners are shown wearing their prizes!

Back Row: Chris Fortin, Andre Jutras, Denis Perrin, Tim Sanders, Don Marcotte, Evan Lowe, Ron Levesque and Maverick Bolger

Middle Row: Paul Lalonde and Steph Dufour

Front Row: Andre Dionne, Lee Leduc, Brian Oram, and Mario Napora

Submitted by Michael Lumley

The roofing crew of Andre Dionne, Elijah Parker, Zack Peppin, Mario Napora, Jeff Croke and Foreman Lee Leduc are hard at work on the reroof of the Sudbury Public Library Main Branch.

Submitted by Rob McMillan

The Sudbury Service Crew of Eric Gagnon, Chad Stevens, Mike Hill and Brad Nolan were busy installing a 2 Ply Modified Bitumen cold applied roof system. They completed the project in the warm summer months while in full face respirators to access the roof. While on the roof, they were allowed to remove the respirators but stayed in cool looking overalls! Good job, boys!

The Cambridge Service crew of Krzysztof Koc and Colton McAleney reported to site to investigate a soft spot in the walk out terrace roof. What they found was the cavity between the concrete deck and roof membrane was completely saturated with 3-1/2” water. After some serious pumping, consultation with the owners, and patching, they were able to resolve the situation to everyone’s satisfaction.

Submitted by Alex Boterman

The Cambridge Service crew of Greg Philip (left) and Milton (Milly) Soza, started using a new piece of spray equipment to apply a Tremco roof coating at the St. Kateri Tekakwitha Elementary School. After getting the hang of the equipment, production doubled. Way to go guys!

EFAP offers financial experts and online programs to help you take control of your financial future. You and your eligible family members can receive support through online programs or telephone consultations on a variety of topics, including:

• Debt & Credit

• Retirement

• Divorce

• Estate

• Termination

• Mortgages

• Bankruptcy

• Taxes

Call for confidential and immediate support:

Canada: 1.844.880.9142 and workhealthlife.com

US: 1.800.272.2727 and workhealthlife.com/us

(PAID THROUGH PAYROLL AND SUBJECT TO TAXES & DEDUCTIONS)

THE NEW HIRE MUST INCLUDE THE NAME AND EMPLOYEE NUMBER OF THE PERSON WHO REFERRED THEM ON THEIR NEW HIRE PAPERWORK *Please

THE NEW HIRE MUST BE WORKING FOR A MINIMUM OF 6 MONTHS AND STILL BE EMPLOYED AT THE TIME OF PAYOUT

In conjunction with EllisDon, the team is busy working on Campus Building B at the Fanshawe College in downtown London – a building with multiple roof systems such as a Soprema modified Hydrotech roof membrane combined with a green roof component. The scope of work includes a vapor barrier, fully tapered ISO, Sopra smart board and torch cap sheet. With very restricted work space, laydown area, and adjacent roofs being re-roofed as part of the contract, the crew expects to have this project wrapped up in December. Once completed, this will be the new home of the Tourism and Hospitality School and Programs for the school of Information Technology.

Submitted by Craig

DoyleJames MacDonald has successfully immigrated to Canada from London, England to come and work for Flynn. James arrived in Canada at the beginning of July and has undergone intense training in Toronto and Calgary before going to London, Ontario. He is a welcomed addition to the London Service Department. He says he is excited to be here in Canada and is looking forward to succeeding in his new role as Superintendent. Welcome, James!

Submitted by Craig

DoyleLondon’s Service Department has been busy all throughout the summer completing HVAC upgrades and small replacements for the local school board. The London crew who completed the recent Kensal Park School re-roof is from left to right: Jeremy Rowan, Matt Regier, Darryl Cushman and Foreman John Dadson. They finished just in time before school started up again.

As part of the Enterprise Ireland trade mission to Canada led by Irish Minister and Teachta Dala (TD) for the Galway East Constituency Sean Canney, Flynn Group of Companies hosted a visit to help promote and strengthen trade ties with Irish based supply partners. Flynn has a long standing relationship with supply partners APA Systems and Carey Glass among others. This meeting recognized the success of the relationships and will help develop them in the future.

“The Flynn Group of Companies are proud to host the members of the official Irish trade mission to Canada at our North American HQ here in Toronto,” said Noel Cunningham, Glazing Operations Manager. “From small beginnings back in 2014, our engagements with our Irish based supply partners are now significant, with several of our projects featuring Irish designed and manufactured components. We look forward to continuing, and growing these partnerships in the years ahead.”

Submitted by Drew Halliday

The Brandon Roofing crew took an opportunity to check out Niagara Falls while on a down day. They have been helping out the London Branch for the last couple months before heading to Hamilton to lend a hand there.

Submitted by Drew Halliday

The Brandon Metals Crew (Dave Schwarz, Alpheus Sinclair and Mike Genaille) posed for a picture while working on the Westoba Credit Union, a small Cladding project where the crew removed and reinstalled 350 feet of cladding. They will be installing new AD-300 cladding, with new vapor barrier and sheeting around the perimeter of the building.

Submitted by Natasha Farren

The Brandon Service Department completed a small re-roof on Ethelbert Canada Post Office. This 1,200-sq. ft. roof required slope and the installation of scuppers to allow for positive water drainage. The system installed was mechanically fastened Soprasmart Board sanded with a HRGR capsheet. While on site, the Foreman noticed that the canopy was rotted out on one of the beams. Safety was an issue as it required removal and reinforcing. The crew repaired this area to ensure there was a safe working environment for all.

Submitted by Chris Cunnane

Flynn Winnipeg is currently working on the Wilkes Reservoir north cell renovation with Graham Construction and Dillion Engineering for the City of Winnipeg. The project consists of 264,000-sq. ft. of EPDM roofing cover by Kingspan insulated roof panels along with 21,400sq. ft. of insulated wall panel.

Submitted by Breanne Van Linge and Jordy

JohnsonThe Boeing Project is a complete re-roof of 76,300-sq. ft. down to the steel deck replacing it with a Modified Bitumen Roof System. A talented crew of seven, plus a full-time onsite Project Manager, have been tirelessly working to ensure that this project runs smoothly without incident while meeting the strict work deadlines set out by Boeing.

Submitted by Chris Cunnane

Winnipeg’s Metal Division are currently replacing the roof on the Kenora Courthouse. This heritage building originally built in 1910 is having a 2,000-sq. ft. copper roof replaced with the crew working evenings and weekends so that order

court

be maintained.

Submitted

by Craig KucherForeman Ray Blahey, Janice Bonyai, Ross Edwards, and Harley Olson are busy at this

replacement that includes 4mm Accumet 2000.

Submitted by Sean Thompson

Morguard Investments Inc. specifically requested Kevin Anaka and crew to complete this roofing project for them as they have been very successful on past projects with this client on the mall. Well done guys! Thanks for showing them the Flynn Way! The crew ripped the existing roof down to the steel deck and used Sopravap’r VB, ProtectRSS ModulR Panel Insulation w/ Duotack, Sopralene

Flam 180 Torch Applied, Sopralene

1900-sq. ft.

Flam 250 GR Cap Torch Applied. This was their first time working with ProtectRSS Panel and the crew is really enjoying the installation method of this product. There are various expansion joint details to construct. Working over Sportchek and the Food Court, there has been complications with mechanical and interior protection that the guys are successfully working through. With regards to staging and safety, it is immaculate with a well constructed wooden walkway on 2 inch insulation to travel with debris over 500 feet.

Submitted by Craig Kucher

Our Saskatoon crew is hard at work on the Saskatchewan North Battle Hospital. The scope of the job is made up of 113,000sq. ft. of cladding, and 19,000-sq. ft. of HardieBoard over 4000 lineal feet of 1" z-bars. Good job, team!

Submitted by Devin Kardynal

This is one of six schools being built in the Saskatoon area under the P3 model by BirdWright. Flynn is roofing three of them. Once completed, this will house both Public and Catholic schools. This project was 1030 squares of Soprafix base finished with Soprastar Flam HD white granular cap sheet.

Foreman Bryan Hiltz and his crew started in midFebruary and worked through a harsher than normal spring which caused weather delays. The thawing ground and spring rains made for a muddy site –sometimes making it very difficult to get materials there. The hot summer temperatures made torching white cap sheet challenging but Bryan and the crew kept pushing on and completed it. The guys have forged a good relationship with the GC on site and kept them happy.

H&M

Submitted by Troy Csada

This is a multi-scope job that has the Regina Metals Department doing roof flashings, and a pedway to install 5 squares of HF-12 soffit and 12 squares of aluminum panels. This job is for PCL and the pedway is over one of the busiest back alleys

Regina, making this a very safety sensitive job.

Submitted by Troy Csada

This multi-scope project included the removal of old roof deck and the installation of 9 squares of new 22ga roof deck, reroofing the metal roof (2 squares of new Standing Seam Roof) and miles of flashing, all at 13 storeys in the air!

EFAP offers expert, confidential information about how the law applies to specific situations. You and your eligible family members can receive support by telephone or in person consultations on a variety of topics, including:

• Child Support

• Civil Litigation

• Criminal Law

• Landlord-Tenant

• Property Law

• Real Estate

• Separation & Divorce

• Will & Estates

Call for confidential and immediate support: Canada: 1.844.880.9142 and workhealthlife.com US: 1.800.272.2727 and workhealthlife.com/us

Flynn University for Frontline Coaches (FUFC) launched in February this year, and since then has run six sessions and trained 94 roofing production coaches. These coaches have returned to their crews and are providing training to rookies while creating a better onboarding experience. The feedback from our coaches and rookies has been very encouraging, and that is why FUFC aims to provide a coach for all of our roofing crews in the near future.

“The coaching course gives you the knowledge and support to be confident in leading a crew to success. I was really impressed at how well the content at FUFC was kept interesting. One thing I really enjoyed, was how hands on it was teaching teamwork and how to lead by example,” said David McGregor, Brandon Coach. “I enjoy coaching my rookies. Helping them go from the start of their career, to becoming successful is very fulfilling. Great ideas can come from anyone on the crew, you never know who is going to have the next great idea. If you put the time and patience into them, and make them feel like they are part of the crew, you will be surprised at what they can teach you.”

“I just joined David’s crew recently, and I think having a coaching program is a great thing for the rookies,” said Zach Sinclaire, Rookie. “We are working with Tremco, and this was all new to me, but David (my coach) has been teaching me how to do my angle cuts, working on the curbs, and how to run the sprayer. I could have done it without him, but with his help it was much easier, and I got better at it quicker.”

“Personally I focus more on the mental side of coaching, such as teaching people how they should approach their job. Having the right attitude is an important thing to learn when you are starting your career,” said Jesse Faulkner, Kansas City Coach. “Learning to be accountable for your actions, having a positive attitude, and knowing you can ask questions if you don’t understand something. Building the right team attitude from the start lets us all know that we all want to get the job done, and everyone on the crew is needed to do that.”

“I just started working at Flynn two months ago, and not only have I learned from my coach, but it helps me feel part of the team.” said Jacob Carver, Rookie. “I’ve learned better and quicker ways of measuring and cutting materials, and it’s good to know you have someone you can go to who can teach you this stuff.”

With nearly 100 Flynn coaches in the field, we are well on our way to providing a coach to all of our roofing crews. Flynn University for Frontline Coaches has already had a visible impact on our coaches, and that benefit is carrying over into the field to our rookies.

If you are interested in learning more about Flynn University for Frontline Coaches or attending, visit www.FlynnCrew.com

Submitted by Greg Rudd

Holy Rosary Church in Regina, Saskatchewan’s Cathedral area required new copper flashings and trough. There were also various roof repairs to be done. Our service crew has done an excellent job and the customer is happy with the workmanship. This project and repair had many challenges along the way and our crew showed their expertise and ability in completing this difficult job.

Submitted by Greg McCulloch and Blaine Braun

Submitted by Greg McCulloch and Blaine Braun

The College West Residence Revitalization is a high profile 38,700-sq. ft. project at the College West Building on the campus of the University of Regina. As the original roof system was inverted, crews are removing insulation and ballast to the original membrane on concrete and installing the new IKO HD system complete with new insulation and slope package. The site is clean and organized, and there are multiple levels of roof areas to get to. Michael James and crew are doing a great job and look forward to completing another successful project at the University.

Flynn Industrial Limited (FIL) is currently leading a multiscope Pilot Project for Lakeland College in both Vermilion and Lloydminster, Alberta. The project involves workers from FIL, Edmonton Service Roofing and Mid-West Glazing (MWG). The work scopes for FIL and service roofing are confined only to Lakeland College Vermilion but MWG have work on both the Vermilion and the Lloydminster facilities. Crews mobilized to site at the beginning of July finished by the end of September 2017. The Vermilion project work includes the removal of both an existing metal roof, an existing skylight, the installation of a new metal roof system and a new glazed skylight system with some roofing and membrane tie-ins being completed by service roofing. The Lloydminster work includes repairs and re-work to existing glazed entrance ways. So far, this project has been without incident and the college recognized that the Flynn approach to safety is above and beyond what had been expected. Congratulations to all involved and here’s to finishing safely and exceeding client expectations!

Flynn Industrial is currently at the late stage of construction of Unit 40 Gasifier Buildings for PCL Industrial in Redwater, Alberta. The project involves the installation of Kingspan Insulated Wall Panels (3” foam and 6” Fire Rated), 4” Kingspan Insulated Roof Panels, 4” Kingspan Interior Ceiling Panels, gutter and downspouts, snow/ice rakes, pedestrian doors and door canopies, rollup doors and roof hatches. The crew started work on December 2016 and will complete it in November 2017. They’ve overcome many challenges throughout the project and are determined to deliver good results to our client PCL and are confident in doing so. Ryan Goddard and his dedicated site crew are working with a mix of materials but the quality of the workmanship and finishing is of a very high standard.

Submitted by Colin Swirles

This is a very unique project being installed by the Calgary Glazing Team with PCL as the General Contractor. There is 18,600-sq. ft. of aluminum curtain wall using Kawneer system 1 for the pavilions and 1,600 ss ladder system for the bridges. The project began in late March, 2017 with a grand opening slated for November. Most of the bridge work had to be done at night as it spans across the very busy McLeod Trail. Start time was 9 p.m. and the crews had to be off the road by 5 a.m. and the site had no room so organization was paramount. The guys worked one stretch of 12 nights in a row, and they did a fantastic job. The pavilions are very complex as you can see in the photos. Bob Jones, Foreman, looked after the night work and then Scott Tanner, Foreman, has taken over for the pavilions. This is, and will be, an architectural showpiece for the City of Calgary and Cadillac Fairview.

Submitted by Ryan Admussen

Flynn is working with PCL to complete this project which involves removing and replacing a large percentage of the exterior finishes on the building due to hail damage. The scopes for this project include 9000-sq. ft. of AdekaZinc Tiles, 15,000-sq. ft. of corrugated cladding, 1300-sq. ft. of hidden fastener cladding, 75,000-sq. ft. of SBS base and cap sheet and 6000 lineal ft. of flashings. The main challenge on this project was a tight schedule and a lack of available manpower in the architectural division. This was solved by the glazing division generously lending three men to the project which helped bring it in on schedule and under budget. Great work to all involved!

Submitted

by Julie FosterFour members of the Calgary Service team are enjoying their summer in the beautiful Rocky Mountains working with Canadian Pacific Railway at the Mount MacDonald Fan House. The 14.7 km long Mount MacDonald tunnel in Rogers Pass was built to reduce grades and increase capacity on the single track main line through treacherous terrain. The ventilation concept for long diesel rail tunnels requires a cooling cycle as the train progresses through the tunnel followed by a purge cycle to clear smoke and diesel pollutants before another train enters the tunnel. The project is to recoat the exterior walls of the building, using a swing stage. This job is the first of its kind for Calgary Service and the team has been enjoying every moment of it!

Submitted by Bob Stadnyk

The Edmonton Mechanized River Valley Access (MRVA) is a high-profile project for the city of Edmonton with Graham Construction as the GC. The project consists of a funicular (cable car) that starts at the southwest corner of the Hotel MacDonald in the centre of Edmonton, travelling down the river valley 72 feet. Here, you would exit the car and take the walkway across Grierson Hill Road ending up overlooking the North Saskatchewan River. From here, you can take the elevator or stairs down to the river itself. Flynn has supplied and installed the glass for the upper and lower funicular entrances, and the glass stair guardrail from the upper and lower funicular entrances which is approximately 200 feet long. There are also three lookout glass guard rails. Flynn used a Novum Structures glazing system on the elevator shaft which is 52 feet tall and located almost directly at the river’s edge. This shaft is made up of very large heavy sealed units held to the structure by a point supported system. Our Foreman for this project was Piotr Slowinski. Peter’s dedication to precise measurements was the key to having all the glass fit to the exact millimeter. Good job to all involved!

Submitted by Bob Stadynk

Supreme Steel’s new office building was a very complex project consisting of a combination of standard triple glazed curtainwall framing, veneer triple glazed SSG curtainwall framing, and inverted veneer triple glazed SSG Kawneer toggle glazed system. Since this is a steel fabrication company, they wanted to have as much exposed steel as possible so the architect chose this style of framing. The toggle glazed portion took a lot of precise measurements with many inside and outside corners along with a sloped roof line. This system was also attached directly to the steel structure causing quite the challenge in keeping the framing true and straight. Even the ceiling of the canopy above the main entrance was the toggle system glazed upside down. The architect wanted to keep the same look throughout, so on the interior there is also a considerable amount of floor to ceiling glass office walls with 12mm butt jointed glass and the vestibule is made almost entirely of glass tying directly into the exterior glazing system. Our Foreman on this project was Zsolt Miklos, he and his crew did an amazing job. Flynn metals also did a complete three inch spray foam insulation, accumet aluminum wall panels, accusteel metal roof on the atrium and garage. The multi-color layout gives the project a unique and appealing appearance.

Submitted by Patrick Connell

Foreman Jamie Massan and his crew are working on a low rise industrial building in the south end of Edmonton. Jamie is a new Foreman. He is not new to Flynn as he has been working with this crew for 10 years. He recently stepped up to the Foreman role and is using his experience and F.U.F.C. training to get the job done! The picture was not taken with a vintage camera...the yellow hue is actually smoke from the B.C. wildfires!

Submitted by Jordy

RyhorchukOur Edmonton metals crews were hard at work on the American biopharmaceutical giant Gilead Sciences API Process Tower alongside GC Graham Construction and Engineering. The tower will host new spray drying technology to allow pharmaceutical ingredients to absorb better. Work began in March 2017 with completion forecast for October 2017. Our team supplied and installed 36,000-sq. ft. of Kingspan 4” PIR Microrib Horizontal (1,287 panels), 15,300-sq. ft. of Kingspan 8” MF Microrib Horizontal Fire-Rated panels (378 panels) and punch windows with Flynn Midwest Glazing. This was the third phase of working with Gilead Sciences (owner) and Graham Construction to compete the building envelope on their phased construction of expansion. This project was challenging from the start as crews only had approximately 10 feet of room around the perimeter of the building for access and laydown. This meant utilizing tower crane/pickers with Clad Boy vacuum panel lifters to install the panels off of swing-stages. The crews worked through a very congested site with other trades/contractors, installing the insulated metal panels and experienced all of the Edmonton elements through this phase; cold, snow, ice, rain, heat, winds, etc. One interesting fact is that the civil work was done first so it was a clean site working off asphalt –this helped the congested area with laydown and helped keep the site clean.

With the cold weather imminent in most of our branches, it’s a good time to share some reminders about cold weather roofing best practices. Here are 10 tips and reminders that will help our work continue to run smoothly throughout winter.

1. Keep your production area for the next day dry from overnight dew and frost by using weighted tarps, EPDM, etc.

2. Be aware of slippery surfaces (TPO, PVC, and glazed asphalt areas).

3. Keep materials warm: Use Pail/barrel heating bands/wraps (bands work on propane bottles too), and hot boxes for pallets. Keep foam adhesives warm by using heated hoses for pumps and heated storage.

4. Keep in mind the temperature limitation of various products, and be sure to use winter grade self-adhering membranes, primers, adhesives, and mastics.

5. When handling old BUR (Built-up Roof) night seal preparation, exercise caution when scraping, as old felts can split or shatter when they get very cold.

6. Mix bonding adhesives and primers as they will separate more in cold conditions.

7. Properly maintain your equipment by keeping charged booster packs available, filling fuel tanks for overnight storage and covering motors and fuel tanks.

8. Hot asphalt: Use proper insulating for asphalt pipes and luggers. Keep mop strokes short. Cut modified rolls into shorter lengths when mopping depending on your geographical location and temperature.

9. Be sure to complete all detailing, BUR roof gravel, and Mod. Bit. cap sheet on a daily basis.

10. Degranulate cap sheet flashing areas when field cap goes down. Degranulation is faster while the roll is still warm, seals the edge at upstands, and dries much faster for future flashing/stripping work.

The OPEX team recently completed a time study that examined the speed and efficiency of the Ramset T3 single shot gun while installing the ISO clips into a concrete slab (we used both Tapcon and the Ramset). With the Tapcon installation method the install took 3:06 to install three ISO brackets, compared to the 1:20 with the Ramset T3 single shot gun. These results suggest that the Ramset method is nearly three times faster. Please confirm with your local Management group for the right application methods for your particular application.

If you would like to view the video or learn more about the Ramset, please visit www.flynncrew.com/videos

1

2

Always be the first to arrive on the job site

- Discuss the day’s production plans with owner’s representative or GC site superintendent so they understand where we’re working and any precautions that may need to be arranged.

- Have paperwork done prior to crew arrival

Involve your lead hand in discussions and safety

- Show you value his/her opinion, as well as another perspective on the job

When crew arrives, clearly state plans and goals for that day

3

- Ensures that they have an understanding of the work to be done by the end of the day

- Encourage everyone’s involvement in maintaining a safe worksite as work progresses when doing FLRA

- Ask for feedback on day’s plans and goals - they may have suggestions

Plan out coffee and lunch breaks for optimum efficiency for the system you are working with

4

- Designate one person to go for coffee to ensure that coffee is there for break

- Encourage crew to bring their lunch to site, if people need lunch, make sure they discuss who needs lunch and have only one person leave the job site if needed

Engagement between foreman and super

- Regular discussions on managing labor hours and dollars, size of crew for project

5

- Project schedule – plans for week, next week, overall project, manpower needs

- Is your superintendent providing all of the information you need?

- Are you both having open discussions with the client?

- Are you getting the material that’s needed on time?

Engaging all workers, in all aspects of work

6

- Putting senior workers with younger/new workers

- Giving all workers learning opportunities, and a chance for all tasks 7

Spend time with all workers

- Get to know each member of your crew and what motivates them 8

9

Make sure all machinery is ready to go for the next day

- Bring all empty containers to your truck so you can fill them up at the end of the day

- Send down all damaged and broken tools down at the end of the day

- Water jugs to be sent down to be filled at the end of the day

Take time for yourself to physically check materials inventory on site

- How much is left at the end of the day, how much was used today?

- Crew needs to tell you before running out of material

End of the day check list

- All materials, equipment secured per safety requirements

- No loose garbage left around

- What materials do we need for the next day? 10

- Night seal done properly and double checked

- All unnecessary caution tape and pylons removed if impeding client

This edition of Mentorship Matters recognizes Dave Flint who began his career with Flynn as a Branch Manger after selling his former company Armour Sheet Metal in 2003. He went on to become a shareholder in 2004, a Regional Manager in 2013, and says he has been fortunate enough to have a been a mentor throughout the entire process.

“I just finished taking part in our office stretch. We have been doing it for a few months now. Someone leads it each time, chooses their music, and we stretch while getting to catch up and see how everyone is doing,” said Dave Flint. As it turns out, Dave has had a deep interest in seeing how people are doing, both personally and professionally, by coaching, teaching and mentoring throughout the course of his career.

“ I get my energy from people,” he said. “Connecting with a mentor gives people access to experience they can trust. And when there is trust and security in being able to share and exchange information between a mentor and a mentee and both parties feel better for it, that’s a win-win situation.” With that exchange of information comes an opportunity for the mentor to learn valuable information as well – a benefit of mentorship that Dave says is often overlooked. “One important thing I have learned is that advice is really criticism wrapped up. I don’t give advice; I put ideas out there. If you give information to people in a manner that gives them the choice to do what they want instead of telling them what to do, chances are they will do the right thing.”

It’s clear Dave’s ideas have positively impacted many people’s lives in the community and company. “When people achieve success that I’ve been fortunate enough to be part of…that’s really cool,” he said. He thinks being named the next mentor in our Mentorship Matters series is pretty cool too. “I was telling my mom and dad that I am very proud of this because this isn’t something I’m necessarily being recognized for due to performance. I’m being recognized due to helping others which has been the most satisfying part of my whole career.”

“Dave was the driving force that brought me to Flynn and he assisted me in the beginning of my apprenticeship. I often look back and think where would I be today if it wasn’t for Dave approaching me and asking, “What the hell are you doing with your life?” Ever since that day I truly haven’t looked back.

He has been a persistent figure of guidance and mentorship that I attribute a lot of my successes to. He has always made time to assist my development leading to the excellent career path I have today.

One of Dave’s best qualities is his ability to manage and mentor people. He takes great pride in sharing his knowledge, developing talent and assisting in the development of his employee’s future growth.

“Dave has helped me grow into the role I currently hold with Flynn. I started as a temp seven years ago and he provided guidance and knowledge to help me gain the skills needed to be successful and grow my role into a career.

Dave has supported my interest in the Women in Construction network group where I have been able to benefit form guest speakers, site tours and networking opportunities.

Two years ago I experienced a personal family tragedy with the suicide of my brother. Dave not only provided me with support at work but supported me as a friend and was a great confidant during that time.”

Dave wanted to make sure I succeeded when I relocated to Victoria from Saskatoon in 2013. He had everything planned - who I should meet, contacts I would be connecting with, introducing me to people in the area, etc.

He’s well respected here, amongst his competitors, people in the construction industry, and within the community. He goes to schools to promote construction and encourage kids to go to the trades in high school. He’s involved with aboriginal communities - telling them about Flynn and the roofing industry and promoting and encouraging people to start a career in roofing and sheet metal.

He is always reminding us and checking to see how the young guys are doing in their apprenticeship program – he doesn’t ever give up on that. He likes to see people succeed.

~ Marnie Pullman Branch Administrator, Victoria

Dave has an exceptional ability to relate and connect with teams and individuals. He picks up quickly on personalities and dynamics and is able to advise and relate with a true understanding.

Dave excels as a mentor because he projects a deep sense of caring for each individual in our Flynn team. He is driven to help everyone from the field on up grow, develop, and succeed.

Dave gives genuine and realistic feedback that aids professional and personal development. He really takes the time to listen to what you have to say and doesn’t rush you. He also likes for you to have a plan.

He gave me an opportunity I don’t think many people would have. He thought I might be a good estimator and wanted to see where I could go with it. But he didn’t just want to see where I’d go with it – he ensured I had the confidence and training to succeed. That was a really neat thing for him to do.

I’ve always really enjoyed working with Dave – he’s been accessible and open and willing to discuss ideas. He’s supportive and somebody you can talk to and work through problems with.