Largest hotel currently under construction in the US

Largest hotel currently under construction in the US

Many of you may be unaware that 2018 is our 40th year in business. These last 40 years have seen our company go from a small startup in Winnipeg with less than 10 employees, to the market leader that we are today with over 5000 employees and 35 offices across North America.

When I think about any company’s growth cycle, it occurs to me that it is kind of like a person; there is birth; learning to crawl, then walk; adolescence; young adulthood; maturity; sometimes complacency – followed by renewal, and so on.

In my mind (and my heart) we are still at the young adult stage of growth. We have tons of energy, have lots to learn, are passionate and committed, and look forward to the challenges and opportunities of each and every day with gusto!

But, when I stop to think about how far we have come, I do wonder: How did this happen? And when I think about some of the possible answers to that question, I am reminded of what separates us from our competition.

There are all kinds of reasons behind our success over the past 40 years, far too many to share in this short message, but I will try! I think the following factors have been critical contributors to our success:

• Everything we do is grounded on a PEOPLE FIRST foundation. We learned a long time ago that if we take care of our people, the profits will follow.

• We are COMPELLED TO GROW. Ever since I can remember, we have been alert to opportunities for growth. We are not afraid to take the calculated risks to grow the company, with long-term thinking and opportunity for our people in mind.

• We have always believed that REINVESTING in the business is what we had to do if we were going to be a successful growth company. Whether it’s the best safety gear, new equipment to make the job easier, leadership development programs like Flynn University, or growth into new geographic regions, we’ve come to learn that investing back into the business is good for everyone that relies on Flynn for their livelihood. Growth and reinvestment enable us to continuously supply opportunities back to our people.

• When it comes to our people, we always try to PROMOTE FROM WITHIN first. We invest time and energy in “readiness” – or, making sure our people are set-up for success before taking on new challenges and opportunities.

• We DELIVER ON OUR PROMISES. We understand that every job we do has a repeat customer behind the scenes. And a satisfied client means we get the next job too.

• And finally, we value CULTURE, which we, of course, refer to as “The Flynn Way.” We learned long ago that for people to be productive, they need to be happy. And the road to inspired and motivated employees is paved with a great culture, where people are happy to be here and enjoy what they do each day.

I could go on and on, but these are a few answers to the question how did this happen?

This is, however, just my viewpoint. I would love to hear from you on why you think we have stood the test of time as a company, for 40 years and counting?

Write to me at Doug.Flynn@flynncompanies.com, and I would be happy to learn from, and share your feedback.

So it’s true…we have had a wonderful 40 years so far; and as long as we all remember how and why we have got to where we are, then we will be successful in the next 40 years. It’s the same winning recipe.

40 years is a pretty cool milestone that a lot of companies do not get to celebrate, and I look forward to celebrating this with you all at this year’s round of safety meetings.

Until then, stay safe!

Doug FlynnIn this issue, we feature Mike Rodrigues, Foreman at Flynn Hamilton, Ontario. Read the full story on page 59.

Check out our big award wins on pages 9, 14, 24, and 54.

Check out the benefits of starting your day with a stretch. Pages 10, 43 and 55.

From left to right is Jared Nelson, Jose Reyes, Jesse Millner and Scott Chapin. They have been busy at the Boy Scouts of America Leadership Center in Fort Snelling, Minneapolis. This new construction project in conjunction with Mortenson Company consists of 231 squares of EPDM. The job started in December 2017 and finished in January.

Submitted by Tess Puta

Super Bowl LII took place in Minneapolis in February, and even though the Vikings didn’t make it through, this crew was still happy to show their support for their team and city!

We are excited to announce that Flynn Group of Companies and Cobra BEC, Inc., have entered into a Letter of Intent to combine their operations. With offices in Spokane, Seattle, Portland, Boise and Dallas, Cobra has over 250 dedicated employees. Cobra has earned an outstanding reputation in the industry based on their strong values, award-winning safety culture and offering customers the most talented project teams in the market.

Cobra is led by brothers Travis and Eric Dix, who after completing succession in their family business, have aggressively grown the business in the region over the past decade. Travis and Eric’s strategic leadership will be key to Flynn’s growth in the Pacific Northwest and beyond, as they will continue to oversee operations throughout the Northwest.

“We are very excited to arrive in the Pacific Northwest. Even more importantly, we are thrilled to welcome the youthful, high energy talents of Travis and Eric to our group of senior leaders. They also bring with them a group of high-quality leaders and employees at all levels,” stated Doug Flynn, CEO.

“We think that by combining our teams of people, we are perfectly positioned to take advantage of growth opportunities in the region. Providing advancement for our people is particularly important to us; teaming up with Flynn offers our employees opportunity we could not otherwise provide,” added Travis Dix.

“We started a conversation with Flynn as a potential growth partner and discovered that both companies’ philosophies were closely aligned. We think the same way when it comes to people and strategy, and share the same level of passion for this business. Travis and I are excited to continue leading our team in this next phase of growth. We know this is good for Cobra AND Flynn,” continued Eric Dix.

“Teaming up with Cobra is a great opportunity for Flynn,” said John McManus, COO. “Not only does this accelerate our development in the vibrant Pacific Northwest, but we are adding significant leadership and delivery capacity overall.”

Based out of Toronto, Flynn Group of Companies now has 35 locations throughout Canada and the United States and although not in a race, is always on the lookout for culturally and strategically aligned potential growth partners. With Cobra, Flynn will now have upwards of 5500 employees and continues to be the industry leader in North America when it comes to the Total Building Envelope.

The scope of this project was 3,200 sq. ft. of rubber roofing (Carlisle 60 mil EPDM), and 3,000 sq. ft. of corrugated wall panels (Firestone Metal Products Omega Panels).

In conjunction with the GC MP Johnson, this project began on January 1st and wrapped up on February 18th. The crews did an excellent job!

Crew Members included: Roofing: Brandon Kaczor, Gordie Smith, Hilario Martinez and Rodney Halsten.

Metals: Dave Larsen, Justin Phillips, and Mac Pribyl

The KUP3 project with Clark Construction and McCownGordon Construction started in August 2016 and was completed in February. It consisted of four facilities in one project: An Integrated Sciences building, new Student Union, a Central Utilities Plant and a four-storey Parking Garage. For the metals scope, our work included the installation of two different back ventilated rainscreen panel systems - approximately 39,000 sq. ft. of Kalzip TF37/800r perforated and non-perforated panels and around 35,000 sq. ft. of 4mm Reynobond ACM panels.

Flynn utilized TSC scanning services early in the project to help identify out of tolerance substrate conditions which helped spearhead a change in the way the framing subcontractor approached quality through the balance of the project. Additionally, this was the first time that the Kansas City branch worked with TSC to use our scan data to provide ACM panel cards that could be imported straight into the Panel Builder program. The panels fit like a glove.

For the glazing scope, we were contracted to install 58,037 sq. ft. of Tubelite 400 Series Stick-built Curtain Wall. The curtain wall was glazed with 1” O.A. Clear Low-E (Solarban 70XL) insulated glass units. The curtain wall framing was finished in a custom warm gray finish with random 10” Curtain Wall extended covers in a pewter finish to create a random shadow box effect.

Submitted by Amanda Schaefer

National Training & Coaches Development Center for Sporting KC soccer club is a multiscope project including roofing, metals, and glazing. The new building consists of 52,000 sq. ft. of Sika Sarnifil PVC roof, 8,600 sq. ft. of Prodema wood panels and 7,000 sq. ft. of Wasco Lumiwall translucent wall system, with 7,200 sq. ft. of Centria panel system finishing out the metal scope. There were multiple manufacturers used in the diverse glazing scope including 6,200 sq. ft. of Oldcastle curtain wall, 1,340 sq. ft. of storefronts, over 25 doors with Stanley automatic sliding entry doors, CRL pass thru windows, Skyline Design decorative glass, Viracon glazing, and various miscellaneous interior glazing. The structure, dreamed up by Populous architects and ran by Turner, is currently wrapping up.

Flynn Midwest was awarded the challenging scope of restoring the elaborate copper cornice work on this historic building in downtown Kansas City. The majority of this cornice had been in place since the late 1800s, and the support structure was badly deteriorated. Jason Rodriguez and his crew removed the sections piece by piece and transported them to our shop for the lengthy restoration process. The existing copper was in a state of disarray. Some of the sections were damaged beyond repair and had to be replaced.

Now after several months of painstaking attention to detail, the project is nearing completion. The contractor, design team, and owner are all extremely impressed with Flynn’s quality and craftsmanship.

Rumor has it that this old building is not only historic but also haunted. Jason was able to capture the image to the right in a reflection from the glass in the original entry doors on one of our first days on site. The image is more impressive in person than in print! Judging from the look on this supposed aberration’s face, I’d say the spirits are slightly less pleased with the renovation.

In conjunction with General Contractor JE Dunn Construction, this was a hospital vertical expansion, so there was a lot of concern with keeping the existing building watertight and working around a facility that doesn’t close. Western Fireproofing was our subcontractor for the lightweight concrete portions of the cooling tower expansion. We installed a 2 Ply in hot asphalt for the vapor barrier, followed by tapered Polyiso insulation, DensDeck Prime, and Firestone TPO UltraPly XR 115 mil membrane all set in ribbons of foamable adhesive. The wall flashings and walkway were all set in TPO Bonding Adhesive. The total size of the project was 26,600 sq. ft.

The 2018 Capstone Real Estate Awards recognizing Kansas City’s best real estate and development projects were recently named, and Flynn worked on a whopping 8 projects awarded!

Cerner Innovations Campus: Total building envelope 483,270 sq. ft. + 21,200 sq. ft. interior.

Fishtech

Total building envelope 13,500 sq. ft.

University

Center Health Education Building: Total building envelope 253,276 sq. ft.

77,100 sq. ft.

Submitted by Aaron Beisly

Our Kansas City Service Roofing Crew has been leading the way for stretching every morning in our shop prior to starting the work day. One of our goals for 2018 is promoting stretching prior to work, after breaks and prior to picking up anything heavy or awkward.

See more about starting the day with stretching on page 43 and 55.

Submitted by Josh Rygg

This was a new construction project with General Contractor Manhattan Construction – a high school football stadium that will seat 12,000 people and feature a 55-foot wide HD video screen (reportedly bigger than screens in some NFL stadiums).

Our crew from Phoenix went over to Dallas for a few weeks in January to help complete installation. The area that needed to be roofed was 544 squares of JM TPO. This system was mopped and fully adhered to the cover board, curbs, and walls with bonding adhesive. We checked in daily with the foreman onsite and quite frequently with the Dallas team to ensure there were no issues throughout our time there. The Dallas team did a great job managing this project.

Submitted by Josh Rygg

Eastwood High School is a new construction project that the metals division has recently started located in El Paso, Texas. The metal scopes includes 60 squares of Standing Seam metal roofing, 631 squares of insulated wall panels and 88 squares of modular metal wall panels.

The General Contractor for this project is Buford-Thompson Company.

Project Manager Blake Merrick from Vancouver is working in this project with our project coordinator who will manage it from start to finish. This project will be manned and run by the Phoenix team and will continue throughout 2018.

EFAP offers expert, confidential information about how the law applies to specific situations. You and your eligible family members can receive support by telephone or in person consultations on a variety of topics, including:

• Child Support

• Civil Litigation

• Criminal Law

• Landlord-Tenant

• Property Law

• Real Estate

• Separation & Divorce

• Will & Estates

Call for confidential and immediate support:

Canada: 1.844.880.9142 and workhealthlife.com

US: 1.800.272.2727 and workhealthlife.com/us

With General Contractor APS, this project was a full tear-off and re-roof of a fully adhered Tremco system over a metal deck totaling 30 squares. All of the parapet walls and curbs were the Tremco TPA set with the Tremco Sheathing Bond Adhesive. All transitions from TPA to cap sheet were three coursed in with Rock-It adhesive and Permafab reinforcement membrane. Once all of the parapet flashing was installed, we installed new parapet cap.

The challenge with this project was that it was pushed off to start from October to December, so the weather was much different than originally intended. The adhesives being used needed to be heated continuously due to the cold weather. The cure times took longer with the cold weather conditions too. This power plant was located in Joseph City, which was about four hours away from the shop and there were no stores for any miscellaneous items near the jobsite. Also, this

wear FR clothing throughout the install. This is the third job

Submitted

by Josh RyggThis was a new construction project: a new home custom-built from the ground up located at the top of Camelback Mountain. This project started in the middle of July and went through January - not straight through as there were a number of mobilizations.

The customer for this project was Plus Minus Studios LLC. The roof area was about 70 squares where we mechanically attached Carlisle fleece-back membrane to a plywood deck. After the membrane was installed, we spread ¾” to 3” river rock across the roof. For our metals work we installed fascia using the s-lock pattern and drip edge using a gravel stop profile around the entire building. We tied the drip edge into the TPO using pressure sensitive tape.

It was residential and there were multiple punch lists throughout the project. The access to the roof was difficult because of the narrow roads leading to the house, and there were multiple trades and the extra activities going on throughout the duration of the project. There were quite a few challenges along the way, but we pushed through them.

being a power plant, the crew was required to

APS has given to us due to our safety and quality.From left to right: Manny Valle (Foreman), Pablo Lopez, Cole Pope, Ray Martinez, and Miguel Hernandez.

With an abundance of work to complete within a certain time frame over the last few months, Flynn Dallas-Fort Worth asked for and received help in our roofing department from crews from Baltimore, MD and Phoenix, AZ.

One of the benefits of Flynn’s geography and resources is the ability to put a call for help out to our branches to solve production problems. Flynn DFW is appreciative of Baltimore Branch Manager Nicole Ewing and Phoenix Branch Manager Monty Hill, and of course the crews, for providing the much-needed help in DFW.

“It is great to see the collaborative effort from our other branches in the sharing of manpower. This is one of the benefits of being with Flynn and one of the reasons we decided to become a partner with a company like Flynn in 2017”, said Mike Beeter, branch Manager Flynn DFW.

Foreman Jorge Garcia, Jose Garcia, Agustin Mejia, Juan Cabrera and DeQuan Davis from Baltimore lent a helping hand for the re-roofing, new roofing, and architectural panels work at the ICR Discovery Center in Dallas for customer HCBeck, Ltd.

Tyus Eltsosie, Pablo Lopez, Jordan Castaneda, Gorge Rivera, Deshawn Jordan, and Manny Valle from Phoenix helped with the new roofing, and architectural panels work at the University of North Texas College of Visual Arts and Design in Denton, Texas for customer AECOM Hunt.

Flynn received the Gold Award in the Director’s Trade category for our work on the Coast Capital Savings (CCS) Building in Vancouver. The award was presented at the Vancouver Regional Construction Association Awards of Excellence. Congratulations to everyone who took part in this monumental project and win!

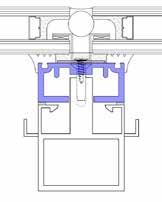

In collaboration with General Contractor Ledcor, Coast Capital Savings was a design-assist project that included roofing, glazing and metals. The complexity of this project required innovative thinking from the start. With both positive and negative slopes, vents were designed to work both with and against gravity. With opposing slopes coming together at 90-degree angles, sealed glazing units had to be reversed depending on the slope direction.

Custom glass units with hidden mechanical fasteners were made to suit the design which featured structural silicone joints with no pressure plates or cover caps. Custom designs are essentially everywhere, in fact, 62 new custom extrusions were created to accommodate the shape of the building, and a two-storey corner mock-up was produced to test fit and performance.

On our road to success, we encountered many challenges along the way. We identified a major leak in the curtain wall system which was not caught in the design and mock-up process. We immediately notified Ledcor and the building owner and made every resource available to deliver the high-performing curtain wall system as promised. Our commitment to doing the right thing, one of our collective values and beliefs that make up our culture “The Flynn Way,” has strengthened our relationship with Ledcor and the building owner, and is a point of pride for everyone involved.

In addition to an aggressive schedule, another major challenge during installation was the lack of physical space to work in. The site’s small construction footprint was bordered by a light rail line and one of the city’s busiest roads meaning both material handling and installation had to be creatively managed to ensure safe and timely work. The assembly, packaging, and shipping of each of the glazing modules had to be carefully planned to follow a pre-established installation pattern. Each spandrel panel was made of one piece of glass with three different frit colours. Adding further to the intricacy of sequencing was the fact that some panels were single glazed or laminated depending on the building elevation.

Another challenge involved access. The one of a kind glazing system was pre-glazed, and the finished work had to be completed from the exterior of the building. We solved the problem with specially designed swing stages, while some areas remained accessible by bosun chairs only.

We are proud to share that Flynn’s crews experienced no lost time incidents on the project! Way to go!

Submitted by Manuel

AliceaIn conjunction with the Board of Education of Baltimore County, Flynn’s scope of work includes removing and disposing of the existing metal flashing and roof system and replacing it with 500 squares of 4 Ply Delta Membrane (Garland) adhered in hot asphalt and installing White Star cold flood coat and number 7 Texas gravel.

One of the biggest challenges was the fact that once school started, we had to change the hours of operation from the AM to the PM meaning we had to change our operation and safety plans to be able to work more efficiently.

Submitted by Manuel

AliceaWorking with General Contractor Tutor Perini, crews are currently installing three different types of panels: Corrugated, Dri-Design and Composite Face Panels. We have the help of James Spann from Kansas City as Project Manager, OPEX team members Gord Wiggins and Rick Lacey, and also Diran Assadourian and Terry Skyba from TSC. Some of the challenges we are facing with this job are the time, the winter weather and the fact that it is new construction which comes with many different companies working together, so planning and safety are key.

Submitted by Evan Bartram

Brownlow Avenue is a 380-square re-roof which originally consisted of a ballasted 4 Ply BUR system being replaced with a 2 Ply modified bitumen system. Since our Halifax crews were all tied up with ongoing projects, Moncton was more than happy to send Marcel LeBlanc and his crew over to take care of this project for 20 VIC Management and IRC. Work began in November and was finalized in February.

Submitted by Evan Bartram

Flynn Halifax was awarded the flat roofing portion of the Dartmouth Sportsplex (DSP). DSP is an indoor sports arena and community centre undergoing a significant renovation which includes new construction. The scope consists of three modified bitumen roofs; a 238-square existing building re-roof, 121-square new gym addition, and a 14-square canopy roof totaling 373 squares. Work commenced in September and was completed in March. The crew has been working diligently despite the setbacks that go hand-in-hand with working in winter.

Submitted by Jodine Baker

In conjunction with General Contractor PCL, our metals crew has been busy installing vapour barrier, metal siding, and composite panels on the shops and administration buildings of the NSCC COVE (Nova Scotia Community College Centre for Ocean Ventures & Entrepreneurship). The COVE is receiving a full makeover, and our crew has been working diligently to complete our work on time.

Both buildings at NSCC COVE are located next to a busy train track, which makes scheduling deliveries and install quite complicated at times. We are very thankful for the great crew that we have working here and appreciate everyone’s hard work! Thanks, guys!

Congratulations to our participants of Flynn University for Frontline Leaders Group 23 held at The Briars! FUFL is our two-day program for leaders and future leaders of Flynn.

Our Flynn University for Frontline Coaches Group 7 participants are pictured during their training session at The Briars. FUFC is for roofing production team members who want to become Flynn coaches. They learn tools they can use to guide, assist and support rookies beginning their careers in roofing production.

Did you know that since the workshop began in February 2017, there are now more than 100 trained coaches in the field? Way to go!

Flynn University for Project Management is our custom workshop has been developed and is facilitated by several of Flynn’s Subject Matter Experts and the OPEX team. Topics covered included scheduling, Project Information Lifecycle (PIL) and hand-off meetings, risk management, dimensional inspection services, project finance, safety, and review of the Labour Loading Spreadsheet tool and change order template.

Flynn University for Service Excellence 2 was held in Dallas and in Regina with participants from our Dallas-Fort Worth, Kansas City, Lubbock, Minneapolis, Baltimore, Denver and Regina branches in attendance.

Flynn University for Service Excellence is our internal, engaging workshop aimed at improving service excellence skills. This training ensures our service teams are knowledgeable and up-to-date on best practices to operate as consistently and effectively as possible.

With representation from Halifax to Vancouver to Dallas Fort Worth and many places in between, Flynn University for Management Excellence 2 was held at The Briars and was enjoyed by all who attended.

FUME is a workshop specifically designed for senior leaders and covers topics including change management, building trust, strategy, emotional intelligence, mentoring and communication.

Branch Manager’s Breakfast is the brainchild of FUNG (Flynn University for Next Generation) graduates in the “Flynn Way Task Force.” The idea is to give staff an opportunity to chat with branch managers in a more relaxed setting. The conversation has touched on everything from ongoing projects and safety to culture and the Leadership Promise. These events have been held in Edmonton, Toronto, and Winnipeg, with more on the way.

The task force continues to run their program organizing site tours for office staff who have not had an opportunity to get out and see our crews in action. Site tours took place at the Scotia Tower in Edmonton, the Seton Recreation facility in Calgary and the Yello on Yates in Victoria. Congratulations to everyone who made this safe, fun and educational experience possible!

Submitted by Dennis Butt

The Bell Island Manufacturing & Galvanizing Plant re-roofing project was awarded to us as result of the March 2017 windstorm. Portions of the existing roof had blown off during the storm and Flynn forces were called to site to carry out temporary repairs. Just a few months later, we were awarded the contract to carry out the permanent repairs which consisted of 19,200 sq. ft. of new 2 Ply mod bit roofing.

Submitted by Dennis Butt

With harsh winter conditions upon us and an average of one decent working day per week, we’ve decided a couple of our crews should team-up to capitalize on production for this 30,000-sq. ft. 2 Ply mod bit re-roof.

Submitted by Kyle Kennedy

The crew on this warehouse project in Fredericton, NB have been hard at work in snowy winter conditions they’ve come to expect in the Maritimes. The project consists of re-roofing 430 squares of mod bit roofing. The crew is no stranger to what seems like weekly snowstorms this time of year, and regardless of the weather pushing towards us, this has been another successful project!

This past year has been a busy time for Flynn at the 5th Canadian Division Support Base in Gagetown, New Brunswick. Our crews have worked on three projects there in 2017 - the L33 Building is the latest and largest. This re-roof project consists of 1,478 squares of mod bit roofing. With a roof this size, the crews are using all the equipment advantages Flynn can offer including two full-time 53 ft. trailers with the ability to support two full-time crews, an InvertaPress used to install two-part adhesive from 189-litre barrels, the MINI MACADEN and ride on’s. The cold weather and snow build-up in the winter months have been challenging for the crews, but they have been on top of every obstacle and well on the way to delivering another successful project to Defense Construction Canada!

EFAP health coaches are Registered Nurses and Occupational Health Nurses who offer practical, personalized support for physical health issues. You and your eligible family members can receive support through online resources or telephone consultations on a variety of topics, including:

• Nutrition

• Naturopathic

• Smoking

Cessation

• Health

Coaching

• Stress

Call for confidential and immediate support:

Canada: 1.844.880.9142 and workhealthlife.com

US: 1.800.272.2727 and workhealthlife.com/us

Submitted by Kyle Kennedy

This Moncton crew has been busy re-roofing an area of a power generating station that had several inches of ponding water. The roof area was very restricted, and the crews did a great job of managing material on this site and providing the customer with a new roof that will last them years to come (without the swamp they had before.)

Submitted by Kyle Kennedy

The crew kicked off the New Year finishing another project in Fredericton, NB. This job consisted of 6,400-sq. ft. of mod bit roofing. The crew dealt with multiple snow storms throughout the project but still completed it well within the client’s construction schedule.

EFAP offers financial experts and online programs to help you take control of your financial future. You and your eligible family members can receive support through online programs or telephone consultations on a variety of topics, including:

• Debt & Credit

• Retirement

• Divorce

• Estate

• Termination

• Mortgages

• Bankruptcy

• Taxes

Call for confidential and immediate support: Canada: 1.844.880.9142 and workhealthlife.com US: 1.800.272.2727 and workhealthlife.com/us

Congratulations to our 2017 scholarship recipients who each received $2,500 toward their post-secondary studies. Did you know children of Flynn employees entering or currently enrolled in post-secondary studies are eligible to receive this scholarship? For more information about the 2018 application process, connect with your local Human Resources representative and be sure to check our employee website www.flynncrew.com for updates.

We are proud to share that Flynn Southwest Denver won the NRCA’s Gold Circle Award for Innovative Solutions: New Construction; and honorable mention for Outstanding Workmanship: Steep Slope for our work on the University of Denver’s Daniel Felix Ritchie School of Engineering and Computer Science!

Our scope of work included designing the diamond-like shingles for the dome, standing-seam copper roof panels, and copper diamond and flat-seam wall panels.

Flynn was presented with the challenge of designing the diamond-like shingles for the dome, including the complicated task of calculating the shingles to fall within the tolerances left behind by all other trades who had already completed the framing stages. Each row of the diamond-like shingles needed to be carefully calculated in order to maintain the flowing lines and appearance. Flynn overcame the inconsistencies by designing the shingles with an interlocking system in which each shingle could be adjusted in order to maintain the concentric lines which give the dome its signature look.

The award was presented during the NRCA’s 131st Annual Convention and the 2018 International Roofing Expo in New Orleans from Feb. 6-8. Congratulations to everyone involved with special mention to Project Manager Ty Mattern; Superindent Jeremy Jones; Foreman Cristobal Rosalez; GC, GH Phipps Construction and Architect: AndersonMasonDale Architects, PC.

The installation of pre-glazed curtain wall units on the east and west facades of the building was completed at the end of November. For the last module of the section, a GoPro was attached to the crane to follow its journey to the top. You can see the footage at www.flynncrew.com

The group took a quick break for the photo below before moving on to the south side where over 100 pre-glazed curtain wall modules will be installed on top of the stadium’s roof on a downward facing angle. All modules were assembled by Flynn Manufacturing. Way to go, team!

Submitted by Francis Labonté

Andre De Sousa and his team are installing stick curtain wall on the first five floors of this condo tower named “Tour des Canadiens 2” situated next to the Bell Centre: Home of the Montreal Canadiens. This project also includes sliding doors, garden doors and an eight-storey curtain wall connected to the condo tower. The major issues encountered on this project are the lack of space all around the building for storage and deliveries and the short deadline. Great job guys!

Submitted by Francis Labonté

This project included the installation of glass curtain wall. The conventional aluminum mullions were replaced by glass fins, and the thermos are held by aluminum clips on each corner. The weight of the glass plus the absence of horizontal mullions made the project quite challenging. Great job to all!

This commercial building is being rejuvenated by Project Manager Patrick Thibodeau and team. The old glass façade was removed to make way for a new curtain wall system on the four faces of this six-storey building. Situated on the renowned St-Catherine street in Montreal, the limited access and the materials handling were very restrained and presented a nice challenge for the whole team. Keep up the good work!

Our team is currently working on the Etobicoke General Hospital doing both sheet metal and roofing work. The scope consists of 83,000 sq. ft. over 24 separate roofs (47,150 sq. ft. of inverted mod bit roof system, 29,475 sq. ft. of conventional mod bit roof system and 6,675 sq. ft. of inverted mod bit canopies.)

As the project’s schedule has pushed into the winter months, it has become more difficult to install the roof system. While battling the elements, the crew had to put more emphasis on the changing safe work procedure due to the constant change in the weather forecast from morning to afternoon. That said, it is nothing the team hasn’t faced before and things are progressing well.

Located in the open fields of Halton Hills, Ontario stands an outlet mall with a parking structure that gets more praise on its look than the mall itself. In the Summer of 2017, the Toronto Architectural Metals Division started an aggressive six-month schedule.

With the help of TSC – eight stair towers, a link bridge and a landing tower were scanned and the ACM panels (25,000 sq. ft.) were built to precision by Flynn Manufacturing which resulted in less than 1 percent of panel remakes or site modifications. With Flynn Manufacturing exclusively building ACM panels for this project and to stay on schedule, we outsourced the perforated panels (7,000 sq. ft.) which had a custom pattern designed by the architect. The perforated panels are supported by custom aluminum truss framing designed in-house by our Engineers Kai Wang and Don Delaney and fabricated by our trusted vendor, RV Metalware. The stretched aluminum panels (7,000 sq. ft.) were something we do not do often, but for this project we picture frame supported the panels with 3 mm thick aluminum J-trims and tubes.

In addition to our base scope, we were awarded cladding for the new Starbucks and the stainlesssteel escalator cladding. This project was completed on-time and on-budget through strong leadership and teamwork – a prime example of what we can accomplish at Flynn. Thank you to everyone involved from estimating/sales, drafting/design, manufacturing and our field staff!

Front row from left to right: Sergiy Shcherbakan, Dan Alexander (Foreman), Aumid Zaman and Nick Valencia (Project Manager –Architectural).

Missing

In January 2017 Flynn’s Director of Engineering, John Spadaro, felt like it was the right time to put his retirement plans into motion. What would happen next was something you would expect to see in the movies. Shortly following his decision to retire, Oxford Properties made the decision to award Flynn Facades with their largest contract to date: The re-cladding and re-glazing of the iconic 120/130 Bay Adelaide Towers in downtown Toronto. The last project John would work on as he prepared to leave, also happens to be the very first project that started his career 40 years earlier.

“It was the strangest thing,” said John. “I took out my binder from 1978 of 130 Adelaide - the first project I ever started on, thirty-nine years later I would be going into interviews describing a similar process to the same people – Oxford Properties and WZMH Architects. I knew the building inside out. It was exciting. I couldn’t help but think about it being a coincidence and then couldn’t help but think...was it coincidence or was it all part of the plan?”

John studied architecture in high school, and after coming to a conclusion it wasn’t as promising of a prospect as he imagined it to be, he ventured into Civil Engineering. When he began looking for a job in 1978, he was hired as part of the design group at Kawneer Company Canada Limited as they were known at the time. “Kawneer wasn’t engineering per say; it was more architectural products specializing in curtain wall. I soon acquired a little department called Research and Development and started to experiment, and that really interested me. That’s where my career started: Doing investigations,” he said.

For John’s first job, he was sent out to 130 Adelaide called “Continental Bank” then, and Y&R Properties (on the pictured sketch) was purchased by Oxford Properties while the tower was going up! He was sent there to learn the installation process. He observed and documented what was happening, making sure the crews were doing what the drawing said to do. “It was all Lead Foreman on the job site, and I was learning from the best. I gained a lot of experience from those individuals,” he said.

“In 1978, we weren’t using fully unitized curtain wall – it was semi-unitized. We supplied all the engineering and frame assembly for the curtain wall and another company, in this case, Pilkington, would take the contract to go in and do the glazing from a swing stage. We produced the frames on the floor as opposed to a shop and they were hung over the side. Installations took a lot longer with no computers and no email,” he said. “Back then things were really just growing in the city too. It wasn’t like it is today,” he continued.

“Today, we are staging the whole building with mast climbers. During the day we are removing the opaque spandrel panels. Everything needs to be watertight by the evening. During the evening, we remove the vision lights and replace them with a factory-glazed cassette consisting of a sealed unit and aluminum frame around it,” he said. “In the original, the spandrels were all aluminum panels; the new look will be all glass. Back then they used the sealants of the time which were butyl sealants. Today we use silicone. There were compatibility issues we had to contend with. Overall it’s simple with regards to the components. The hardest part is connecting all components together and making it watertight – making it watertight is Flynn’s biggest risk,” he said.

On a 380,000 sq. ft. retrofit in the heart of the downtown core while businesses remain fully operational, there are other obvious risks as well. In addition to our unique custom cassette approach, John noted that it was our logistics and safety plan that set us apart from our competitors - a joint effort by the design, engineering, business development, estimation, construction and safety teams.

“If I have ever looked good, it’s only because I have good people on my team, and all around me, who have all of the talents that I don’t have,“ he said with a smile.

John worked for Kawneer for 30 years before joining Flynn for the final 10 years of his career. “My work became more administrative, and at some point I said to myself: That’s not who I am. I knew John Silva was starting up the glazing business with Flynn and connected with him and I eventually went from Director of Engineering at Kawneer to Director of Engineering at Flynn.”

While John has learned the in’s and out’s of the technical side of the industry, he’s also learned a lot about people along the way, another driving force behind his decision to join, and stay, with Flynn.

“I really wanted to come to Flynn to mentor people and share my knowledge – that was one of my main goals: to share my experience and knowledge with people who wanted to listen so we don’t have to reinvent everything each time we set out to do it,” he said. “I was given the opportunity to do that at Flynn with people like Tyler Koshurba and Phil Ciantar. Tyler is a very special individual with regards to his talents. I can look at a drawing and do sketching, but true design and functionality come from people like Tyler. And Phil – he absorbs everything. He’s very talented. He’s in technical services which is the right spot for him to be in. When you see and truly understand talents, you can make sure people are using them to their full advantage.”

John says he tells everyone who has ever worked for him that the best thing you can do is get your hands on the tools and work with the designs. “When there are opportunities to go and experience other curtain wall installations, test mock-ups, things happening in our own plant just next-door…I encourage everyone to get out and have those experiences. Those are the memorable things you can recall easier than looking at a drawing – those are the things that become imprinted in your memory much better than just looking at a piece of paper ever will,” he said.

“I would also share that this is a long-term career and the learning portion really never stops. You need to give it time. It can’t be done overnight. It’s truly a career. I thought when I came to Flynn that I had seen and done everything after 30 years. It took me some time figuring out things I hadn’t seen before. Be patient, passionate and don’t give up.”

Glazing Operations Manager Noel Cunningham said, “John has been at the forefront of Flynn’s push into the commercial glazing market. In more recent years, he has been instrumental in the growth and development of Flynn Facades in Toronto. John will be missed at Flynn but will leave behind a strong legacy of responsibility, knowledge, caring, and technical excellence that will continue his work in months and years ahead.”

Doug Flynn says, “When we decided to get into the glazing business in 2006 we initially thought, How hard can it be? We learned very quickly that without technical expertise from guys like John, we could not have been successful. John is a true servant leader. Through his support and mentorship, he has built a technical team of people all around him and leaves a legacy of excellence behind him. Enjoy your retirement, John! You truly deserve it. You will be missed, and we know who to call if we are ever really in a jam.”

Submitted by Joseph

RaposoThe Hamilton branch recruited Craig Crawford and his crew from Toronto to complete this new RhinoBond TPO roof for Modatek Systems in Milton. The 52,600 sq. ft. project started on December 18th; just as Mother Nature sent us into an early round of frigid temperatures!

Weather conditions made the project extremely difficult and to make matters worse, the client’s delivery dates were in jeopardy if roofing was not completed in time to permit interior fit up.

Craig and his crew did an excellent job in these treacherous conditions. Special thanks as well to Chad O’Hara and his crew as well as Peter Bendyk and his crew who also helped expedite roof installations to get the client back on schedule. With our backs to the wall, the boys figured out a way and “Got er Done.”

Submitted by Jordy Johnson

Winnipeg and Toronto crew: Back row from left to right: Tino Ferreira, Manuel Neiva, Jose Vitorino, Waldemar Hetze, Regique Babulal, Wayne Maki, Oleh Paulyna, Kyle Layne and Luis Martins.

Front Row: Glenn Depaulo, Pedro Soares, Kenith Thompson, Mark Martins, Dave Maltez, Walter Plandin and Javier Mercado.

Flynn was the General Contractor for the Toys R Us Project in Hamilton. With the Hamilton branch being very busy, a Winnipeg crew began the work on January 2nd with a Toronto crew lending a helping hand on January 18th. This was 472-square overlay job where we vacuumed the gravel and installed 1" ISO and mechanically installed new PVC membrane. We battled the ever-changing weather and high winds but needed to have the work completed by the end of January.

(Crews typically work 21 days on and seven days off, but our Winnipeg crew volunteered to stay an extra week to make it 28 days on site to help complete this project in the given time frame.)

Infrastructure Ontario is working with the City of Ottawa to design, build, finance and maintain the Ottawa Light Rail Transit System. It includes a 12.5-kilometer line along the existing Bus Route System corridor, a tunnel through the downtown core, and 13 stations, including three underground stations.

The Ottawa team has completed Blair, Cyrville and Tremblay stations. They are currently working on Bayview, Hurdman, Pimisi and University of Ottawa stations. The project scope includes the installation of 4,500 STX Rainscreen Porcelain Panels at approximately 82,000 sq. ft. and the installation of 2,750 Accumet Rainscreen panels approximately 95,000 sq. ft. This will also include air/vapor barrier, sub framing, flashing, etc. We are happy to share things are running smoothly. Crew pictures can be seen below.

Top row from left to right: Roger Fortin, Joe Poulsen, Mike Lazowik, Rob du Carufel and Al Chevrier.

Middle row from left to right: Zack Pepin, Craig Lumley, Al Desormeaux, Grant Perreault, Kirk Trayner, Brian Marsolais, Paul Hebert, Steph Dufour, Kevin McLaughlin, Luc Gagnon and Andre Jutras.

Front row from left to right: Jeff Croke, Kyle Savard, Don Marcotte and Grant Anderson.

Submitted by Michael Lumley

The Sudbury sheeters, roofers and glazers are working on the complete envelope for the Cliff Fielding Research, Innovation and Engineering Building at Laurentian University in Sudbury.

The project consists of aluminum curtainwall, windows, entrances and hardware, interior glazing, composite wood panels, prefinished metal panels, and metal, mod-bit and inverted membrane roofing.

The crew on site consists of seven roofers, nine sheeters and four glaziers.

Submitted by Michael Lumley

The Sudbury crew is putting the finishing touches on their work at the Joe Mavrinac Aquatic Facility in Kirkland Lake, Ontario. The scope of work includes the exterior curtainwall, automatic sliding entrances, door operators, interior framing and glazing.

Submitted by Alex Boterman

Our Service Department is keeping busy this winter keeping up with our customer needs. Our service crew of, left to right, Eric Hodgin, Alex Salzman (Foreman), and Ryan Groen took a quick break to pose for this picture in the parking lot of the Frederick Mall where they completed roof alterations to accommodate mechanical upgrades.

Submitted by Alex Boterman

The Cambridge Service department has added a Sheet Metal crew to meet the needs of our market. Foreman George Murray brings 20 years of experience, and Nick McQuiggen is the branch’s youngest apprentice. The crew recently completed a small sloped sheet metal roof installation at the Google building in Kitchener.

EFAP offers financial experts and online programs to help you take control of your financial future. You and your eligible family members can receive support through online programs or telephone consultations on a variety of topics, including:

• Debt & Credit

• Retirement

• Divorce

• Estate

• Termination

• Mortgages

• Bankruptcy

• Taxes

Call for confidential and immediate support: Canada: 1.844.880.9142 and workhealthlife.com US: 1.800.272.2727 and workhealthlife.com/us

Submitted by Carlos Medeiros

441 University is a project in Windsor, Ontario which will be a new federal building for 300 Canada Revenue Agency employees. Flynn’s work for General Contractor Fortis Group Construction Inc. was completed in mid-February. Roofing work included installing DensDeck board and torched vapor barrier. After the vapor barrier was completed, the NVS roof system was installed over the vapor barrier by our Hamilton branch. After the NVS concrete cured, Flynn London went back to install the vented base sheet and cap sheet. The roof area was 26,900 sq. ft. and challenges included an extreme cold spell and heavy snow in December and the beginning of January.

Submitted by Carlos Medeiros and Bill Mcfall

The three crews of Jason McKay, Rui Medeiros, and Jim Furtado are wrapping up work their work at Starlim North America Corporation which has been on and off since January 2017. Their work consists of replacing 937 squares of 2 ply mod bit roofing system.

Submitted by Drew Halliday

The Assiniboine Community College Trades Building is a 310 square re-roof project being done in the middle of the “beautiful” Manitoba winter. Crews are ripping off a mod bit system with four layers of full mopped fiberboard and then installing a new mod bit system.

Submitted by Drew Halliday

Our Brandon branch recently held their annual training days while prepping for another run at the Don Flynn Safety Award. Fall protection, WHMIS, asbestos awareness, fire extinguisher training, log book training and more were all reviewed. With the great team spirit and buy in from all staff, this should put Brandon in the running once again!

Submitted by Joshua Pereira

Winnipeg metals crew are currently completing the installation of Kingspan Insulated panels at 390 On the River. This 24-storey condominium project is located at 390 Assiniboine Ave. on the banks of the Assiniboine River in Winnipeg, Manitoba. Working with Bockstael Construction Limited, Flynn’s scope of work consisted of 148 squares of insulated metal panels at various locations throughout the building and seven squares of aluminum composite panels at the entrance canopy. Flynn’s five-man crew led by Foreman Jason Walsh received much praise from the GC for the quality of workmanship and Flynn’s continuing dedication to safety. 390 On The River is scheduled for completion summer/fall of 2018.

Submitted by Dave

RobinsonOur Winnipeg glazing crew battled with this monster of a triple pane sealed unit weighing 700 lbs. by using a Spider Crane to tuck the unit under the overhanging floor above. This heritage building on the corner of Selkirk Ave. and Andrews St. received a complete restoration as well as a three-storey addition to revitalize the community and provide shared housing for students in need.

The scope of this project included this 55’ x 10’ frame consisting of Alumicor’s 2600 series and three pairs of doors bringing loads of light to this creative addition. On the other side of the building, the heritage side, nine custom painted frames of the same series were installed.

The site was small and congested with little room to work. Limited space and tight time constraints on this build had all trades involved working around each other.

Submitted by Greg Ruud

Regina Service tackled roughly 300 linear feet of EPDM trough repair on the Farm Credit Canada Tower downtown, one of the highest buildings downtown subject to very high winds as a result. Despite poor weather conditions for this project, Lionel McNab and his crew were able to get it done on time. This job required a major focus on safety at all times, and we are proud of the crew’s commitment and efforts to be safe on this site.

Pictured from left to right: Phil Mercado, Ryan Huck, Lionel McNab, Troung Lea and Dale Nagy (Safety).

Missing from photo: Scott Bright.

Submitted by Greg Ruud

Dustin Geib and Riley Williams (pictured to the left) completed a 250 linear feet metal band on the NCO Building in downtown Regina. Although the concrete columns were way out of line due to shifting, the crew made adjustments with the design and made this look great. Their professionalism and safety on site was top notch, and the customer is happy with the final product.

Submitted by Troy Csada

This was a re-roofing and cladding project at the Regina Provincial Correctional Centre with two squares of cladding and 2,000 linear feet of cap flashing. The guys thought I was there to get them out, but I told them not until our job is complete.

From left to right: Dustin Geib (Foreman), Adam

Submitted by Troy Csada

On January 17th we had James Hardie training in our shop. The trainers were Mark Neufeld and Ryan Ralph. Once the PowerPoint was over the fun began! New tools had us feeling like a bunch of kids in a candy store. Everyone got a chance to do some installation of the HardiePlank and HardieShingle.

Back row left to right: Adam Kuntz (Foreman), John Krysak (Foreman), Riley Williams, Dustin Geib (Foreman), Ryan McAfee and Mike Punshon (Foreman).

Middle Row: Mark Neufeld of James Hardie.

Front row left to right: Noel Mercardo, Troy Csada and Tyler Robinson.

Missing due to leak call: Lionel McNab and Ryan Huck.

Submitted by Troy Csada

From left to right is Riley Williams, John Krysak (Foreman) and Ryan McAfee on this multiscope project which include re-roofing and new metal cladding. This project was safety sensitive because the arena was in operation and there was a pre-school within this arena. The project started in early winter and we have had weather ranging from +2 to -40 degrees Celsius, including freezing rain – but we made it through all adversities.

EFAP offers expert, confidential information about how the law applies to specific situations. You and your eligible family members can receive support by telephone or in person consultations on a variety of topics, including:

• Child Support

• Civil Litigation

• Criminal Law

• Landlord-Tenant

• Property Law

• Real Estate

• Separation & Divorce

• Will & Estates

Call for confidential and immediate support: Canada: 1.844.880.9142 and workhealthlife.com US: 1.800.272.2727 and workhealthlife.com/us

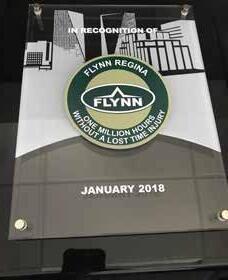

Regina:

January 4th, 2018 was a good day in Regina. Branch Manager Sean McGregor ran a report showing they had officially reached 1 million man hours of no lost time injuries. It has taken five years to reach this milestone - Dave Sterling, Vice President Prairies Region says is a real team effort, but first and foremost - it comes down to our frontline workers. “If a frontline worker is hurt, it’s their desire to stay at work, in combination with our management support providing meaningful work to the individual that makes our modified work program so successful. It’s not as if we don’t have any injuries – unfortunately they happen occasionally, especially when you are dealing outside environments such as slippery winter conditions where an injury can happen simply walking from the shack to your work area. It’s how we manage the injury together which takes buy-in at all levels. From a management perspective, you can say and do what you want, but if the person affected or injured isn’t into it – they’re not into it unless they see the value of participating in modified duties. Congratulations to everyone who participated in reaching this milestone together,” he said.

Regional Health and Safety Manager - Prairies Region, Mark Novecosky, agreed and shared some best practices that have helped them achieve their success.

“September 2011 was our last lost time injury. One of our foremen had a back injury and luckily came back to work pretty quickly after it happened. We initiated a connection with a physiotherapy clinic in town and started sending him and a few other people there for back strengthening exercises. Fast forward to 2018 and morning stretching is a normal process. In addition to stretching, our meetings all start with a Safety Share - an open dialogue where we discuss moments where safety has positively and negatively affected us in our personal or professional settings. Open communication is really important to us here,” he said.

That’s one reason why they have monthly general meetings with all staff in the branch recapping everything that happened that month and setting the bar that one notch higher. “It makes a big difference in our journey of continuous improvement to have the opportunity to share ideas and support for one another. It is the only time all of our crews in roofing, service, metals, and shops see each other,” he said.

Mark noted it’s not all about stretching and meetings, though. “When we talk about safety culture, it truly comes down to how we interact with and treat each other. It’s about promoting and encouraging people to be open, frank and share both their problems and their ideas, so we can all care for and help each other” he said. “After all, we’re all one big family!”

As the only two-time winners of the coveted Don Flynn Safety Award, and now surpassing 1 million hours of no lost time injury, Mark said the branch should be proud of achieving this success together. “It is not any one person who did this – it’s everyone in the Regina Flynn Family, and it took a lot of effort from every level. Congratulations Team!”

From January 1, 2015, to December 15, 2017, Calgary branch had in excess of 1.3 million man hours without lost time injury.

Darryl MacDonald, Safety and Fleet Manager said, “This is a tremendous accomplishment that demonstrates both the field and our local leadership’s commitment to world-class safety. It’s all about the workers and their dedication to keeping themselves, and others, safe,” he said. “We also started having quarterly injury review meetings with all our foremen. This kept injury prevention at the forefront of everyone’s mind throughout the entire year.”

Calgary Health and Safety Specialist Kevin Boone used to work as a Safety Consultant for Flynn approximately five years ago. He said that since starting with Flynn fulltime in 2017, he has seen an improvement in our safety culture. “Flynn’s safety culture is definitely one of our competitive advantages. Lots of companies out there say safety is their priority, but it’s a priority that shifts when it comes to productivity and quality. You can really tell that safety at Flynn is one of our core values. We don’t just say it – we mean it, and our actions prove that we mean it each and every day.”

Dan Sims, Vice President – Alberta says, “Flynn Family Winning Together is our logo that came from last year’s annual safety meetings, and that’s really what it takes to reach this impressive milestone. We look after ourselves to make sure that we go home safe, and have a shared responsibility and want to look out for each other to make sure everyone else gets home safe too,” he said. “One of the ways we foster our winning safety culture is through open communication lines between the field and the office. We encourage feedback to learn and improve our practices,” he said. “We provide ongoing training and have rolled out new programs and initiatives, such as Lead Hands and Project Managers participating in internal leadership safety training, conducting site safety evaluations, launching a glove policy for all employees on site and conducting incident review meetings that I am involved in,” he said.

“I would also like to make a special mention to the Calgary Service department as they have gone three years without a medical aid/recordable. We care which has, most importantly, resulted in buy-in at all levels and all positions at the branch. We are all committed to protecting our workers, preventing injuries and minimizing risks. These attitudes, beliefs and actions have been key to our successful safety culture.”

Late last year, very high winds blew through much of the Prairies. Winds in Saskatoon reached 113 km/h! Some buildings in the area had their roofs partially or fully blow off. Between the Saskatoon Service and Production departments, we responded to four emergency calls in the city and two about an hour outside of the city. Our forces were able to temporarily seal the roofs for these clients which made them very happy. Flynn ended up with three contracts thanks to our quick response time. We were also able to secure a fourth re-roof contract due to another roof blow off that had gone out for tender. Thanks to everyone involved for their efforts!

Gaylord Rockies™ Resort and Convention Center in Aurora, Colorado is currently the largest hotel under construction in the country! The opening is scheduled for December 2018. Some of its many impressive features include: 1,501 guest rooms, 114 suites, over 485,000 square feet of meeting and convention space, an outdoor pool that has the capacity for 1200 people at one time, a lazy river, retail shops and the sweeping views of the Colorado Rocky Mountains.

Flynn Southwest Denver began working on this joint venture with General Contractors M.A Mortenson Construction & Welbro Building Corporation in February 2017, and expect to finish in July 2018. Flynn’s scope of work includes 543,000 sq. ft. of PVC mechanically attached and fully adhered low slope roof systems, 311,800 sq. ft. of standing seam metal Roof, 7,000 sq. ft. of exposed fastened mechanical screen wall and 5,700 sq. ft. of flush seam soffit.

With a project of this magnitude, Denver Project Engineer Mahmood Alomar, Project Manager, Jeff Cary, and Superintendents Cristobal Rosalez, Terry Shulaw, Calvin Chester, and John Bigwater have their crews working hard to stay on track despite the number of challenges they have encountered and overcome. Kansas City crews led by Gabe Duff assisted with the critical path of steep slope roof dry-in and will soon return to help with the standing seam roof install.

One constant challenge is the weather. Crews have experienced extreme conditions with winds over 40 mph at times, along with snow, ice, and the cold temperatures. In these frosty conditions, the roofs become extremely slippery, so slips, trips, and falls are a major concern. Flynn’s Foremen and site Safety Specialist, Troy Norris, perform rigorous daily site safety inspections, mitigating hazards and ensuring a safe work environment.

In addition to slippery roofs, there are also numerous and varying steep roof slopes making loading and stocking materials very challenging, especially with other trades in close proximity. In fact, there are in excess of 1,500 workers on-site daily which creates heavy traffic issues and controlled access zone necessities!

Our crews continue to push through the challenges together, remaining optimistic along the road to completion. Their goals are to avoid repetition of problems encountered at the early stages of this project. They have established methods of continuous improvement of culture across the organization, implemented

a firm process by mastering the schedule, optimized construction sequence, and capitalized best practices.

“I am very proud of the Denver Team managing this Project,” said Branch Manager Joe Spezia. “Led by Jeff Cary, the team endures many obstacles on a daily basis. Whether it’s a schedule delay, managing other trades, inclement weather, safety stand down, etc. the team pushes through and incorporates backup plans to continue to be productive. Due to the magnitude of this project, it can easily become a stand-alone job which in turn, can create a divide between the branch and the project. The branch and the Gaylord team have done a great job bridging that gap, communicating resource needs and staying connected. I couldn’t be more proud of everyone involved.”

Project Engineer, Mahmood Alomar; Superintendent, Cristobal Rosalez; Health and Safety Specialist, Troy Norris; Project Manager, Jeff Cary; Metals Foreman, John Bigwater; Roofing Superintendent, Terry Shulaw, and Metals Foreman, Calvin Chester (kneeling).

Submitted by James Sheehan

Flynn Industrial Limited is currently working on a new power station project just outside of Swift Current, Saskatchewan with General Contractor PCL. FILSK mobilized to site on November 28, 2017, with the project expected to run through to May 2018. We are still in the early days of this project, but our crews have already had to battle strong winds and biting cold conditions while maintaining our high safety standards and meeting schedule. There’s no doubt winter in Saskatchewan still has some challenges to throw our way, but we are confident that our crew is more than ready to take them on and will end up with a successful project and a happy client!

Submitted by Ian Wang

Flynn Industrial was approached by Graham Construction to complete four buildings on the Suncor Fort Hills site located north of Fort McMurray. The initial scope was to apply EMSEAL and Emshield to the expansion joints in the concrete floors. After seeing how well our crews performed in terms of our safety and productivity, Graham asked for our help installing insulated wall panels and sealing numerous wall penetrations.

Even though the initial duration was 20 days, the overall project escalated to over eight months. Keith Hepditch and his crew’s dedication to safety, quality and productivity has been duly recognized and further strengthened our working relationship with Graham.

The contract amount increased tenfold with all of the change orders added at the end!

This project at 439 5th Avenue consisted of approximately 1,800 sq. ft. of SBS roof replacement over two main roof areas, plus four additional small roofs on a 15-storey building near downtown Saskatoon. The rain gutters around the perimeter of the building had to be repaired as well, which required the use of a man basket pictured. The entire rooftop mechanical system also had to be replaced as part of the contract, which required a lot of coordination with our mechanical subcontractor. Due to the height of the building, winds played a huge factor in determining if the guys could work or not. There were many down days because it was simply too windy to roof. Logistics including where to store materials and how to remove the garbage also complicated matters. Fred Wisminity and crew rose to the challenge and completed the roofing work safely, and with the high quality that Flynn is best known for. Greg Macaulay and his flashing team provided the finishing touches to bring the project to a close. Grant Greba is our go-to guy here in Saskatoon when it comes to man basket work and he helped us out big time by performing the gutter repairs. Dave Daigneault also performed some gutter repair work when Grant was unavailable. Thanks guys and good job!

Flynn Calgary is proud to be working on the new Strathmore K-9 school. This is a new school with a 500 student Kindergarten to Grade 9 capacity. This will help with the 150 students who are being taught in leased spaces in Strathmore. John Greenwood and his crew are tackling this 72,867sq. ft. project and installing a fully adhered SBS system.

Submitted by Joe da Costa

Our work on the Foothills Medical Parkade started in November 2017 and is looking to be completed by early 2018. Working with General Contractor CANA, we are doing 13 individual roofs totaling 6,000-sq. ft. torch on SBS (Soprema’s Colvent System), 3 layers of 1.8” ISO and taper package. Challenges for this project include managing project mobilizations and labour costs. With 13 small individual roofs to complete, the coordination and time management of the job will play a key role in the success of the project.

The Calgary Service Department received a request regarding loose metal displaced at the old Molson Brewery in the neighbourhood of Inglewood. A large panel came loose at the top, and more panels had fallen off the building during recent record windstorms. Even though the site is slated to be torn down in the spring of 2018, we needed to jump on this repair quickly!

Service Foreman Chris Fecteau and Service Technician Allan Miller attended the repair and took all precautions and followed safety measures regarding the lift. The ground was uneven and getting the lift in the small area between the brewery and chimney required precision maneuvering to get it safely in place. Chris and Allan had to make sure that the lift was positioned far away from the crumbling brick stack for both their safety and for heritage preservation.

By day’s end, the panel and cap flashing were resecured and the corner flashings, as well as a piece of louver flashing, were installed. A large piece of metal that was hanging off a sign was also removed and brought to the ground. Chris and Allan did a fantastic job. The customer was happy and appreciative, and the area is now safe to the public once again.

Joe da Costa is the Roofing Manager for the Flynn Calgary branch, but his career path moved him through several branches before he landed there. Starting as a Sheet Metal Foreman in 2006 at the Toronto branch, he quickly moved into a role as a Roofing Superintendent. When news came in that the Vancouver branch needed support, Joe volunteered to transfer branches.

“I volunteered to move to Vancouver and to help the branch out. I knew it would be a great opportunity to learn and grow at Flynn,” said Joe, “John Silva and Richard Gryz were there at the time, and they taught me a lot. It was a challenging time in my career, but soon things were running smoothly again in Vancouver, and I really appreciate what I learned from the experience.”

After a few years in Vancouver, Joe was offered the position of Roofing Manager at the Calgary branch. Ready to continue developing his career at Flynn, he accepted the role.

“I really feel everyone at Flynn has the opportunity to grow, you just need to be willing to go after it. I’ve been in Calgary for nearly three years now, and am enjoying it a lot. Moving from Toronto, to Vancouver, to Calgary has taught me a lot, and I wouldn’t be who I am today without it.”

Flynn has been hired to replace 38,000 sq. ft. of 24 gauge Standing Seam metal roof between a total of 11 buildings in two busy complexes in downtown Edmonton located across the street from each other. The roof sheets were run on site with our own JSM machine.

Our contract included installing a new liquid applied, two coat elastomeric roof coating system (Tremco –AlphaGuard) over existing hidden gutter membranes (both SBS and EPDM gutters were present).

As we progressed with the cleaning of the gutters prior to the AlphaGuard system being installed, we discovered that a few of the building gutter substrates were ridden with rot, so we proceeded with rebuilding sections of the gutter as required. Unfortunately, the product is weather sensitive for applying and curing and we ran out of good weather. For the hidden gutters we ran out of time with, we installed new EPDM gutters in place. Thanks to the roofing and serivce departments for their help. This project started in August 2017 and was completed in February.

Submitted by

Jordy RyhorchukWith Ledcor Construction as the General Contractor, Rampart Industrial Building #4 is a multi-scope project that consists of 47,000 sq. ft. Of Kingspan 3” Shadowline and Microrib Panels in three different color sequences for the walls, and 121,000 sq. ft. of membrane roofing system consisting of 10 mil Poly, two layers of 4.67” EPS Insulation and 60 mil EPDM. The metals panel crew faced some challenges of working during the winter cold snap in Edmonton (-30°C) and still maintained an excellent production schedule. They have to hustle to complete the panels so our roofing crew can complete the roofing system as their parapets tie into the panels to button up the building envelope. Once complete, Ledcor Construction will commence the interior finishes.

Submitted by Bob Stadnyk

Flynn Edmonton supplied three different types of material on the NAIT PIC (Northern Alberta Institute of Technology Productivity and Innovation Centre): ACM panels for soffits, 45,000 sq. ft. of AR-38 aluminum Standing Seam (roofing) as siding, and 31,000 sq. ft. of TAKTL fibre cement reinforced panel.

The project started in June 2017 with completion slated for the end of March 2018. Being a provincial institute of technology, the materials specified were very complex and had quite long lead times. Many of the TAKTL panels were 400+ pounds and needed to be craned 80 to 90 feet off the ground. In Aug 2017, we were also awarded the interior ACM aluminum panels along with the four-storey radius staircase that we will clad into the stainless ACM panels.

A few unique features of the project are the two different surface finishes of the TAKTL material, one being a ripple effect like waves on water and the other two with very smooth finishes. Also, the precision of the 12 mm reveal joints for these panels was quite critical to the architect.

On a Friday afternoon, when Edmonton’s Safety Specialist Anthony Feltham received a call from Jamie Hall from the Workers Compensation Board of Alberta (WCB), his first thought was “oh no.” She said she wanted to talk to him about something that happened earlier that day, but the mood quickly shifted as the conversation continued.

Jamie told Anthony that her colleague, Kara Fuhr, noticed a “strange” sight outside of her living room window while she was getting ready for work that day. Directly across the street, on the grounds of a school undergoing renovations, a group of men were standing in a perfect circle doing a series of purposeful stretches, talking among themselves unaware they were being watched. It was Foreman Rob Albert and his crew doing a reroof at St. Mark’s Junior High School!

When Kara arrived at work, she told Jamie she couldn’t believe what she was seeing. “Now, the sight of a group of workers stretching may not evoke such excitement with most people, but when you work at the Workers Compensation Board, you tend to look at life through a different lens,” said Jamie, a corporate writer for the company. “Kara is a colleague, and we are both part of the back pain team, whose mandate is to encourage Albertans - particularly working Albertans - to remain active through back pain. Back sprains and strains are unfortunately all too common, so maintaining good back health is critical. We know people in health and safety work hard to drive home the message of back health, especially when it comes to the importance of warming up and stretching cold muscles before the start of a work day - to see that in action was a welcome sight,” she said. She asked Anthony for an interview and published the article on www.backactive.ca which can be viewed now.

“It was really good to get that kind of call,” said Anthony. “Stretching before we start our day is something we implemented here in 2013/2014. A large number of injuries we were seeing were strains and sprains, so we got together with a back expert and had her come in and observe what our workers were doing – bending, kneeling, heavy lifting. She spoke to all our workforce about proper stretching and lifting techniques. While it was a little bit of a struggle to get the new habit going at first, as I started receiving pictures and videos and it started to catch on, we saw improvements,” he said. “Now our crews out in the field and in the shop do it here as well. We all get together in the morning and go do the stretches together,” he said.

Great job!

Submitted

by Brian BrettIt’s a happy coincidence that Flynn Group of Companies helped give WSP Place in Edmonton a new lease on life just as both celebrate their 40th years.

A lot has changed since 1978. When it comes to modernizing a decades-old building envelope to LEED ® Gold, we were aiming for a higher standard than “good as new.” Flynn’s design-assist team was involved at an early stage to advise on materials selection and design. Because however sleek the aesthetic, performance is the underlying beauty of any modern façade system.

Flynn supplied and installed curtain wall glazing, punched windows, wall panel, and a new membrane roof, all while the building was fully occupied. The insulated wall panel assembly uses ISO clip to help bring the building’s thermal performance into the 21st century. Here’s to the next 40 years!

Submitted by Patrick

ConnellWe are renovating Vincent J. Maloney Middle School in St. Albert for Alberta Infrastructure. The 412 square re-roof includes the removal of the inverted roof replacing it with a new, modified bitumen system. The main challenges on the site include doing a full school rehab project while the school remains occupied and operational. We are working with the contractor to very carefuly move our work areas around these occupied classrooms.

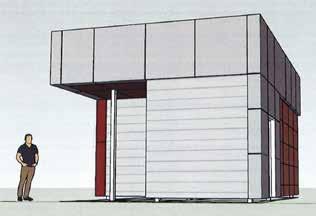

Flynn Group of Companies will soon have its very own architectural training facility, which will help provide best practice training to our architectural metals crews. The training facility is currently under construction at the Toronto branch and will be completed soon. Once the facility is complete we will be launching the Flynn University for Frontline Coaches –Metals Production program.

“We are going to invite selected experienced architectural metals journeyman to Toronto to further hone their skills and share their personal experience with each other. Part of this training will involve some practical hands-on training, and other parts will focus how to be an effective coach. This will empower our new coaches to return to their crews and share what they have learned with their teams.” said Gord Wiggins, Architectural Operations Specialist. “Expanding the Coaching Program to include metals will allow us to better share best practices and maintain consistent standards Flynn wide, and the training facility will give us the perfect place to make it happen.”

Watch for more information in the Spring Flynn Flash.

OPEX is a group of internal specialists that was put together to identify and implement best practices across all of our scopes, while at the same time look for continuous improvement. Part of this mission is documenting and then communicating these best practices company-wide. That is why the OPEX team is creating an OPEX video library that everyone can access on either www.FlynnCrew.com or on the Portal (Flynn Wiki). Here you will find a collection of best practices, tutorials and time studies.

We are always looking to expand this collection of videos. If you have an idea for a video or a question, feel free to reach out to Chris.Haddlesey@flynncompanies.com

Best Practice:

• Loading & Unloading Flashing Crate

• Ginsu Blade - Cutting Insulation with No Mess

• The Dangers of Torching - Invisible Flame

• Insulfast - Installing Insulation Pins