SPANTEC: MAKING BUILDING EASY FOR OVER 30 YEARS SPANTEC IS A LEADING INNOVATOR OF LIGHT STRUCTURAL STEEL BEAMS AND STEEL FLOORING SYSTEMS. SINCE THE COMPANY WAS ESTABLISHED IN 1991, IT HAS HAD MANY FIRSTS; SPANTEC PIONEERED STEEL FLOORING SYSTEMS IN AUSTRALIA, AS WELL AS THE USE OF ADJUSTABLE STEEL PIERS UNDER SUB-FLOORS, AND WAS THE FIRST COMPANY TO LAUNCH A LIGHT STRUCTURAL STEEL BEAM IN THE HOME IMPROVEMENT MARKET.

According to Grant Irvine (General Manager, Spantec), "The company was started by Roy Beaumont back in 1991 in Sydney. Roy saw the need for a timber alternative to assist the DIY and owner-builder market. Roy wanted to create a system that homeowners could put together themselves—a system that was durable and simple to install. When Spantec was first established, we focused predominantly on our flooring, which is lightweight, termite resistant, and easy to use on all types of sites." Spantec's foundation product was Boxspan®. A rollformed beam manufactured from two C-shaped sections of Z450 high tensile, zinc coated steel, Boxspan® mechanically locks together with a patented process. The result is a 40% to 60% lighter beam with the strength of steel and the versatility of timber. This unique system provides the benefits of a full protective zinc coating on the inside and outside of the beam. Boxspan® beams can substitute timber in many structural

Engineering specification of wall studs for Sydney Metro.

applications, such as sub-floors, decks and roof frames, without the concern of termites. "Since the early 1990s, Spantec has become the leading innovator in lightweight structural beams and steel flooring systems, through automation and innovative design that constantly improves our products," said Irvine. "In 1996, to support our Boxspan® system, we launched EzipierTM. The range of pier heads suit specific bearer arrangements and locations in a floor to make installation as seamless as possible. The result is a pier system that is easy to assemble, can be adjusted with just a spanner, and helps people to get their floors absolutely level. EzipierTM works in conjunction with Boxspan®, but also supports timber, purlins and the like—it's a universal product." "Out of that came EzibraceTM—our high capacity sub-floor bracing system. We set out to simplify our sub-floor

bracing because the alternative bracing components we'd used over the years were slow to install and expensive to buy." "In 2006, we developed a second beam—Colorbeam®—and evolved the riveting process so that the galvanized beam could be powder coated in any colour and used in architectural applications," said Irvine. "Within the factory, we've always looked at innovation and automation to improve the floor system, boost efficiencies, reduce costs and make the products more economical for people to use." "With the lack of timber in the market and skilled labour shortages, builders are looking for innovative products that can reduce time, labour and waste on site. Builders are looking for a point of difference for their clients, as well as flame, flood and termite resistant building materials. Our products offer all these advantages," said Irvine.

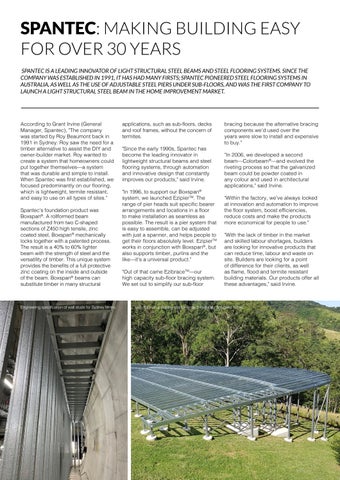

Sub-floor on a sloping site for an architecturally designed home.

Molycop's SAG robot.